Temporal Resolution of Acoustic Process Emissions for Monitoring Joint Gap Formation in Laser Beam Butt Welding

Abstract

:1. Introduction

2. Materials and Methods

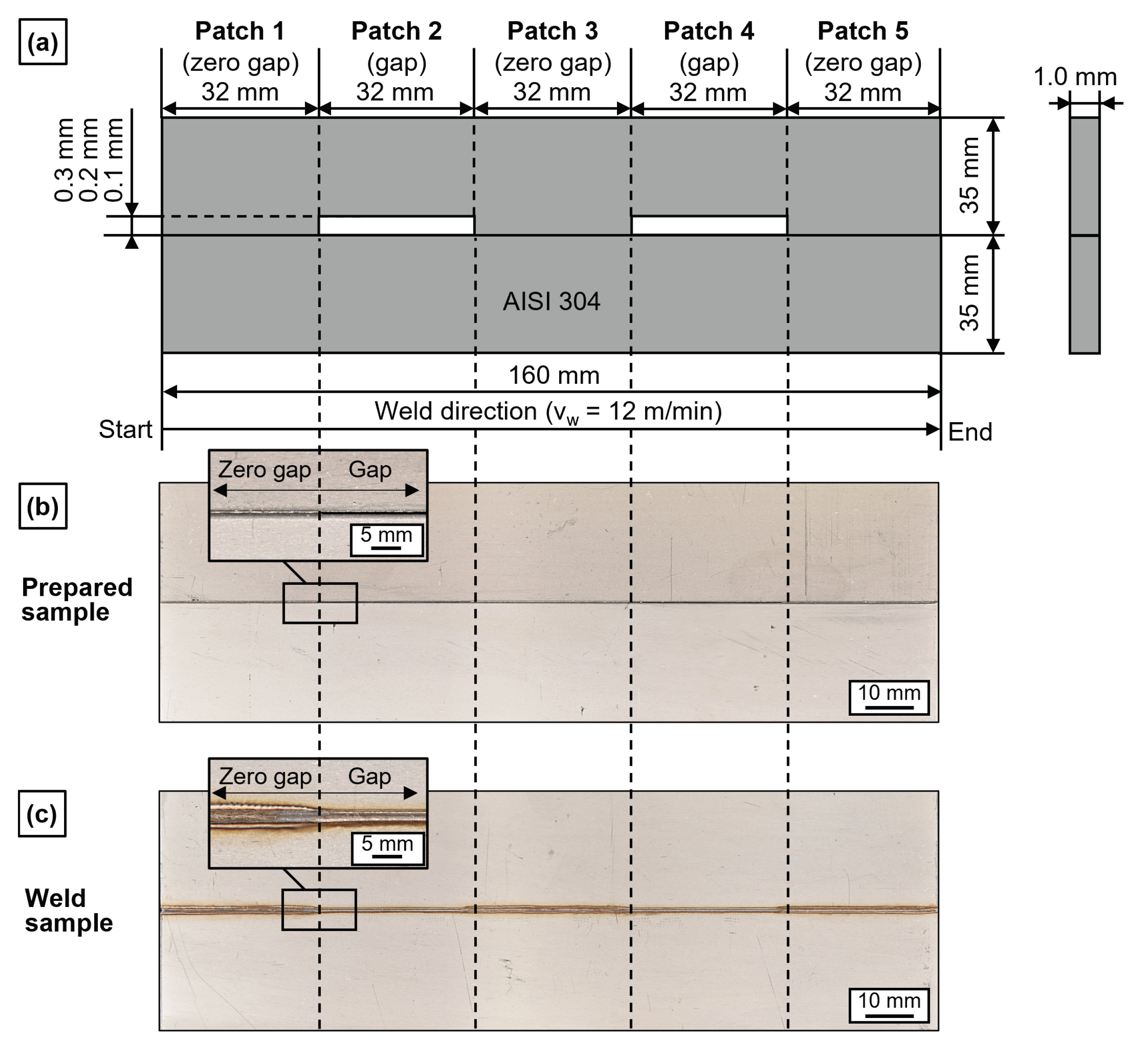

2.1. Specimen Configuration

2.2. Weld and Measurement Setup

3. Dataset and Cluster Analysis

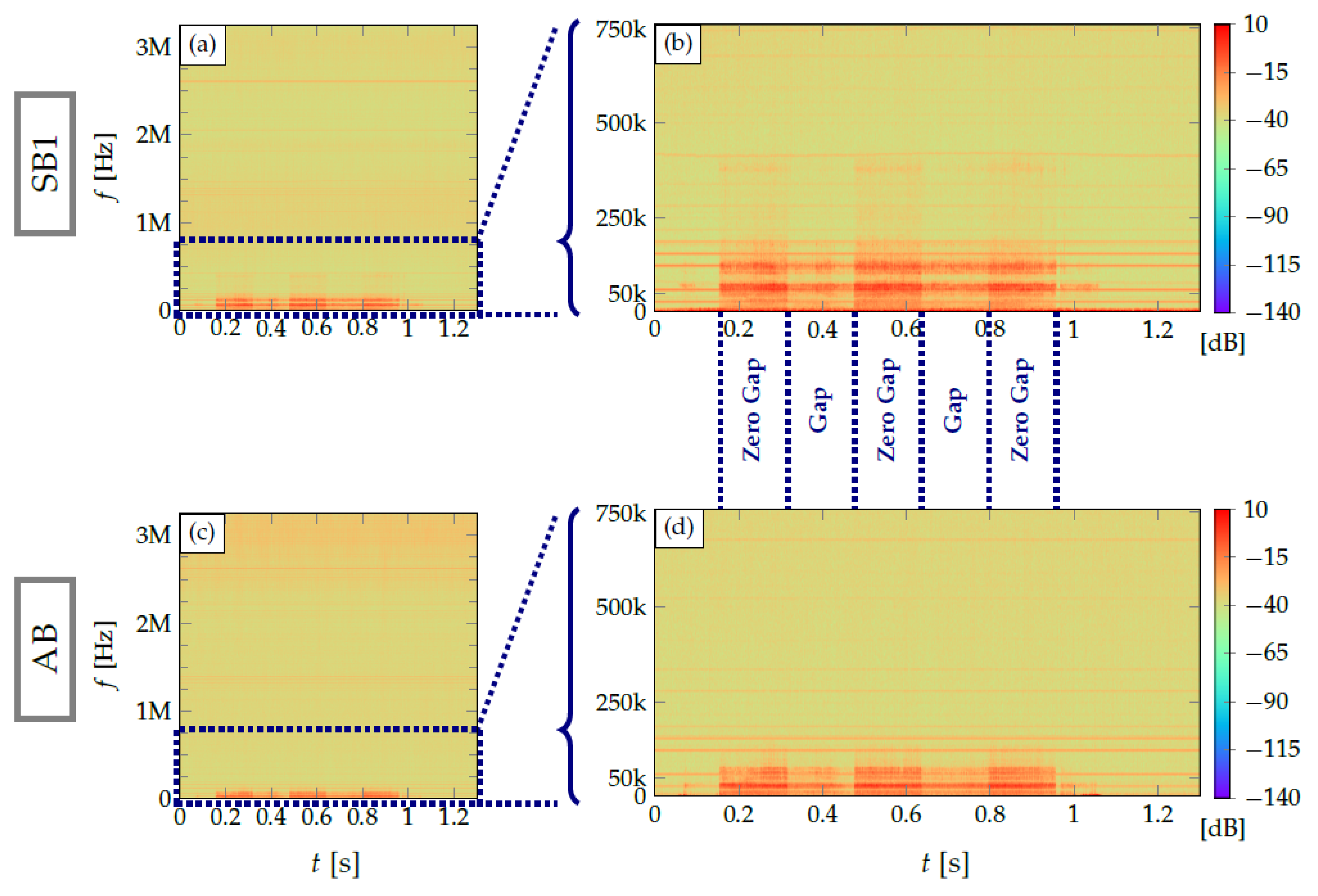

3.1. Signal Analysis

3.2. Dataset Preparation

3.3. Clustering Technique

4. Results and Discussions

4.1. Validation Setup and Parameters

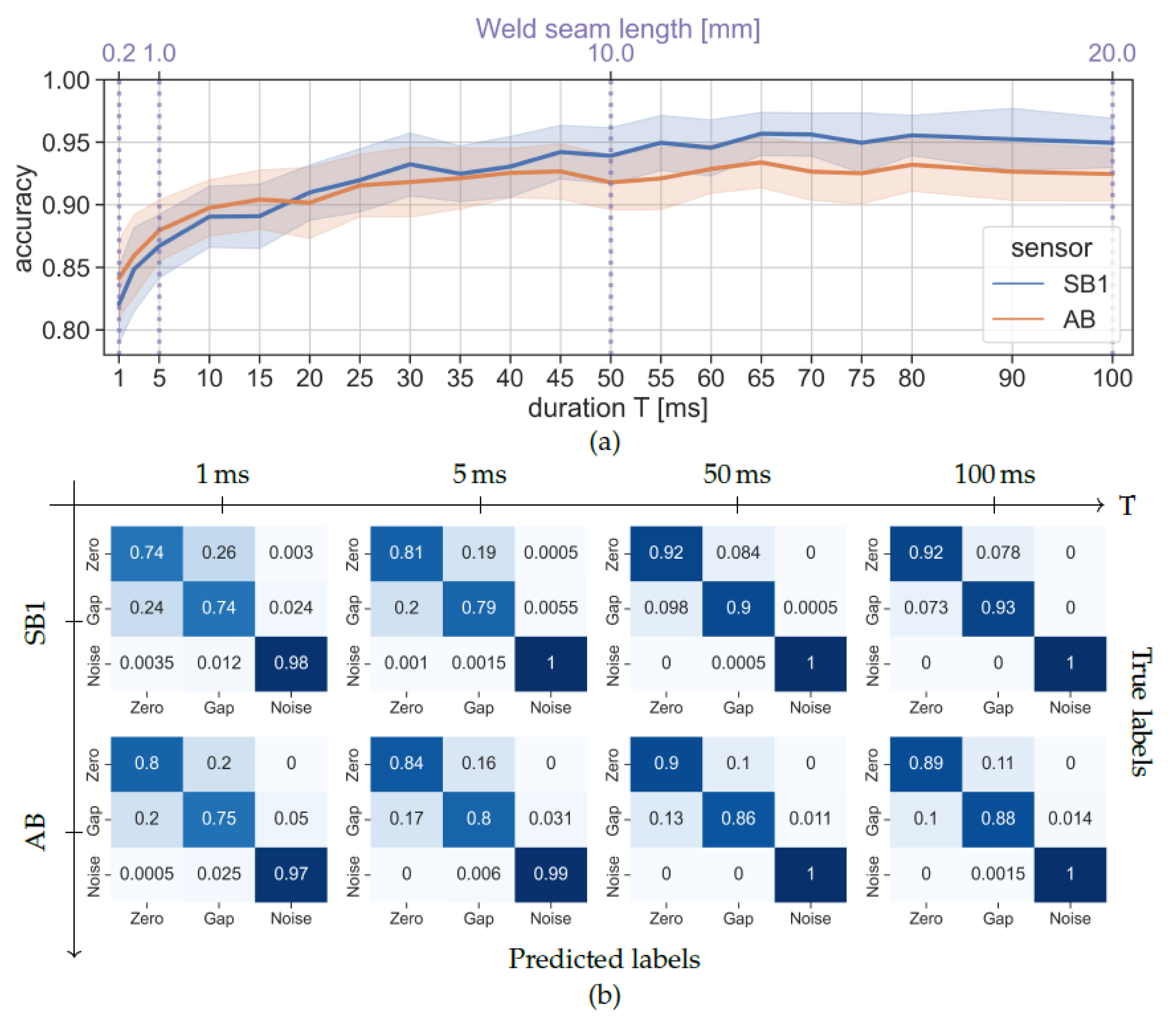

4.2. Scenario I: Gap Detection

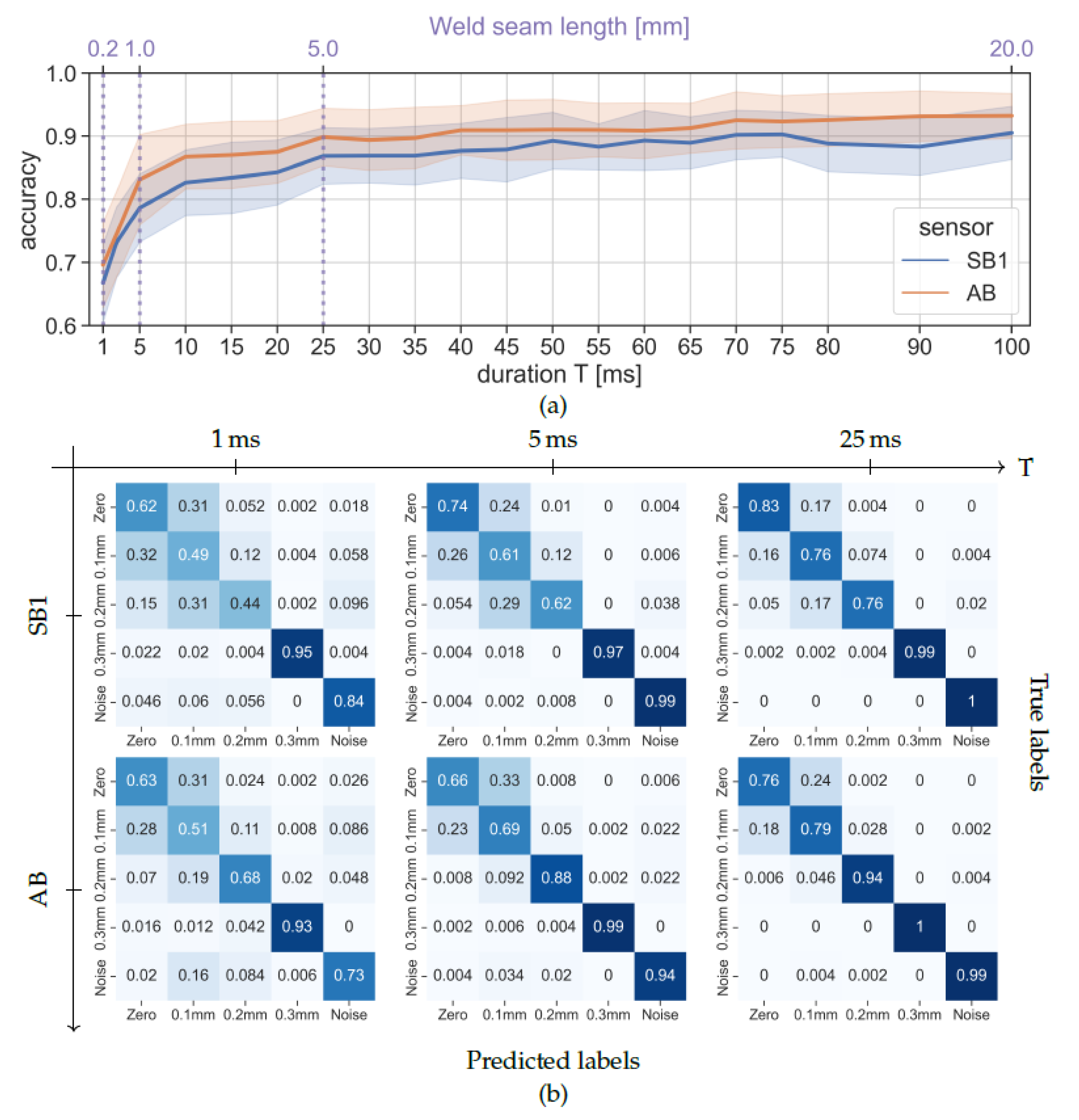

4.3. Scenario II: Identification of Gap Size

4.3.1. Classification Accuracy

4.3.2. Separability Analysis Using Relative Recall

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| kNN | k-nearest neighbors algorithm |

| NCA | Neighborhood components analysis |

| RLT | Repeated learning-testing validation |

| T | Duration of signal segments |

References

- Katayama, S.; Tsukamoto, S.; Fabbro, R. Handbook of Laser Welding Technologies; Woodhead Publishing Series; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Fabbro, R. Melt pool and keyhole behaviour analysis for deep penetration laser welding. J. Phys. D Appl. Phys. 2010, 43, 445501. [Google Scholar] [CrossRef]

- Fabbro, R.; Slimani, S.; Coste, F.; Briand, F. Analysis of the various melt pool hydrodynamic regimes observed during cw Nd-YAG deep penetration laser welding. In International Congress on Applications of Lasers & Electro-Optics; Laser Institute of America: Orlando, FL, USA, 2007; Volume 2007. [Google Scholar] [CrossRef]

- Sudnik, W.; Radaj, D.; Erofeew, W. Computerized simulation of laser beam weld formation comprising joint gaps. J. Phys. D Appl. Phys. 1998, 31, 3475. [Google Scholar] [CrossRef]

- Seang, C.; David, A.; Ragneau, E. Nd:YAG Laser Welding of Sheet Metal Assembly: Transformation Induced Volume Strain Affect on Elastoplastic Model. Phys. Procedia 2013, 41, 448–459. [Google Scholar] [CrossRef]

- Hsu, R.; Engler, A.; Heinemann, S. The gap bridging capability in laser tailored blank welding. In International Congress on Applications of Lasers & Electro-Optics; Laser Institute of America: Orlando, FL, USA, 1998; pp. F224–F231. [Google Scholar]

- Walther, D.; Schmidt, L.; Schricker, K.; Junger, C.; Bergmann, J.P.; Notni, G.; Mäder, P. Automatic detection and prediction of discontinuities in laser beam butt welding utilizing deep learning. J. Adv. Join. Process. 2022, 6, 100119. [Google Scholar] [CrossRef]

- Schricker, K.; Schmidt, L.; Friedmann, H.; Bergmann, J.P. Gap and Force Adjustment during Laser Beam Welding by Means of a Closed-Loop Control Utilizing Fixture-Integrated Sensors and Actuators. Appl. Sci. 2023, 13, 2744. [Google Scholar] [CrossRef]

- Huang, W.; Kovacevic, R. Feasibility study of using acoustic signals for online monitoring of the depth of weld in the laser welding of high-strength steels. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 343–361. [Google Scholar] [CrossRef]

- Authier, N.; Touzet, E.; Lücking, F.; Sommerhuber, R.; Bruyère, V.; Namy, P. Coupled membrane free optical microphone and optical coherence tomography keyhole measurements to setup welding laser parameters. In High-Power Laser Materials Processing: Applications, Diagnostics, and Systems IX; Kaierle, S., Heinemann, S.W., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2020; Volume 11273, p. 1127308. [Google Scholar] [CrossRef]

- Li, L. A comparative study of ultrasound emission characteristics in laser processing. Appl. Surf. Sci. 2002, 186, 604–610. [Google Scholar] [CrossRef]

- Le-Quang, T.; Shevchik, S.; Meylan, B.; Vakili-Farahani, F.; Olbinado, M.; Rack, A.; Wasmer, K. Why is in situ quality control of laser keyhole welding a real challenge? Procedia CIRP 2018, 74, 649–653. [Google Scholar] [CrossRef]

- Schmidt, L.; Römer, F.; Böttger, D.; Leinenbach, F.; Straß, B.; Wolter, B.; Schricker, K.; Seibold, M.; Bergmann, J.P.; Del Galdo, G. Acoustic process monitoring in laser beam welding. Procedia CIRP 2020, 94, 763–768. [Google Scholar] [CrossRef]

- Gourishetti, S.; Schmidt, L.; Römer, F.; Schricker, K.; Kodera, S.; Böttger, D.; Krüger, T.; Kátai, A.; Straß, B.; Wolter, B.; et al. Monitoring of joint gap formation in laser beam butt welding by neural network-based AE analysis. Crystals 2023. [CrossRef]

- Huang, W.; Kovacevic, R. A neural network and multiple regression method for the characterization of the depth of weld penetration in laser welding based on acoustic signatures. J. Intell. Manuf. 2011, 22, 131–143. [Google Scholar] [CrossRef]

- Bastuck, M. In-Situ-Überwachung von Laserschweißprozessen Mittels höherfrequenter Schallemissionen. Ph.D. Thesis, Universität des Saarlandes, Saarbrücken, Germany, 2016. [Google Scholar]

- Yusof, M.; Ishak, M.; Ghazali, M. Weld depth estimation during pulse mode laser welding process by the analysis of the acquired sound using feature extraction analysis and artificial neural network. J. Manuf. Process. 2021, 63, 163–178. [Google Scholar] [CrossRef]

- Yusof, M.; Ishak, M.; Ghazali, M. Classification of weld penetration condition through synchrosqueezed-wavelet analysis of sound signal acquired from pulse mode laser welding process. J. Mater. Process. Technol. 2020, 279, 116559. [Google Scholar] [CrossRef]

- Sun, A.S.; Kannatey-Asibu, A., Jr.; Williams, W.J.; Gartner, M. Time-frequency analysis of laser weld signature. In Advanced Signal Processing Algorithms; Luk, F.T., Ed.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2001; Volume 4474, pp. 103–114. [Google Scholar] [CrossRef]

- Wasmer, K.; Le-Quang, T.; Meylan, B.; Vakili-Farahani, F.; Olbinado, M.; Rack, A.; Shevchik, S. Laser processing quality monitoring by combining acoustic emission and machine learning: A high-speed X-ray imaging approach. Procedia CIRP 2018, 74, 654–658. [Google Scholar] [CrossRef]

- Pandiyan, V.; Drissi-Daoudi, R.; Shevchik, S.; Masinelli, G.; Le-Quang, T.; Logé, R.; Wasmer, K. Semi-supervised Monitoring of Laser powder bed fusion process based on acoustic emissions. Virtual Phys. Prototyp. 2021, 16, 481–497. [Google Scholar] [CrossRef]

- Luo, Z.; Wu, D.; Zhang, P.; Ye, X.; Shi, H.; Cai, X.; Tian, Y. Laser Welding Penetration Monitoring Based on Time-Frequency Characterization of Acoustic Emission and CNN-LSTM Hybrid Network. Materials 2023, 16, 1614. [Google Scholar] [CrossRef]

- Blackman, R.B.; Tukey, J.W. The Measurement of Power Spectra from the Point of View of Communications Engineering — Part I. Bell Syst. Tech. J. 1958, 37, 185–282. [Google Scholar] [CrossRef]

- Bellet, A.; Habrard, A.; Sebban, M. A Survey on Metric Learning for Feature Vectors and Structured Data. arXiv 2014, arXiv:cs.LG/1306.6709. [Google Scholar]

- Cover, T.; Hart, P. Nearest neighbor pattern classification. IEEE Trans. Inf. Theory 1967, 13, 21–27. [Google Scholar] [CrossRef]

- Goldberger, J.; Hinton, G.E.; Roweis, S.; Salakhutdinov, R.R. Neighbourhood Components Analysis. In Advances in Neural Information Processing Systems; Saul, L., Weiss, Y., Bottou, L., Eds.; MIT Press: Cambridge, MA, USA, 2004; Volume 17. [Google Scholar]

- Breiman, L.; Friedman, J.; Stone, C.J.; Olshen, R. Classification and Regression Trees; Chapman and Hall/CRC: Boca Raton, FL, USA, 1984. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

| Name | Type | Specifications | Distance |

|---|---|---|---|

| IZFP RI-MA71RC | Airborne | Center frequency: 520 | |

| (AB) | ultrasound | Transducer diameter: 23 | = 297 |

| sensor | Focal point: 50 | ||

| QASS QWT sensors | Structure borne | ||

| (SB1: at the start, | ultrasound | Max frequency: 100 | = 114 |

| SB2: at the end) | sensor |

| File Type | File Count |

|---|---|

| Gap 0.1 + Zero Gap + Noise | 15 |

| Gap 0.2 + Zero Gap + Noise | 22 |

| Gap 0.3 + Zero Gap + Noise | 23 |

| Operation | Parameter | Value |

|---|---|---|

| RLT validation | Number of iterations | 50 |

| Segment durations | 1… 100 | |

| Scenario I | 120 segments per class | |

| Scenario II | 30 segments per class | |

| Data split ratio | 67% training | |

| 33% test | ||

| STFT | Sampling frequency | 6 |

| Frequency bins | 2048 | |

| Time window | 2048 samples (≈ ) | |

| Window type | Hanning window | |

| Overlap | 50% | |

| NCA | Initialization | linear discriminant analysis |

| Input size | 2048 | |

| Output size | ||

| kNN | k | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kodera, S.; Schmidt, L.; Römer, F.; Schricker, K.; Gourishetti, S.; Böttger, D.; Krüger, T.; Kátai, A.; Straß, B.; Wolter, B.; et al. Temporal Resolution of Acoustic Process Emissions for Monitoring Joint Gap Formation in Laser Beam Butt Welding. Appl. Sci. 2023, 13, 10548. https://doi.org/10.3390/app131810548

Kodera S, Schmidt L, Römer F, Schricker K, Gourishetti S, Böttger D, Krüger T, Kátai A, Straß B, Wolter B, et al. Temporal Resolution of Acoustic Process Emissions for Monitoring Joint Gap Formation in Laser Beam Butt Welding. Applied Sciences. 2023; 13(18):10548. https://doi.org/10.3390/app131810548

Chicago/Turabian StyleKodera, Sayako, Leander Schmidt, Florian Römer, Klaus Schricker, Saichand Gourishetti, David Böttger, Tanja Krüger, András Kátai, Benjamin Straß, Bernd Wolter, and et al. 2023. "Temporal Resolution of Acoustic Process Emissions for Monitoring Joint Gap Formation in Laser Beam Butt Welding" Applied Sciences 13, no. 18: 10548. https://doi.org/10.3390/app131810548

APA StyleKodera, S., Schmidt, L., Römer, F., Schricker, K., Gourishetti, S., Böttger, D., Krüger, T., Kátai, A., Straß, B., Wolter, B., & Bergmann, J. P. (2023). Temporal Resolution of Acoustic Process Emissions for Monitoring Joint Gap Formation in Laser Beam Butt Welding. Applied Sciences, 13(18), 10548. https://doi.org/10.3390/app131810548