Exploring Design Optimization of Self-Compacting Mortars with Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

3. Results

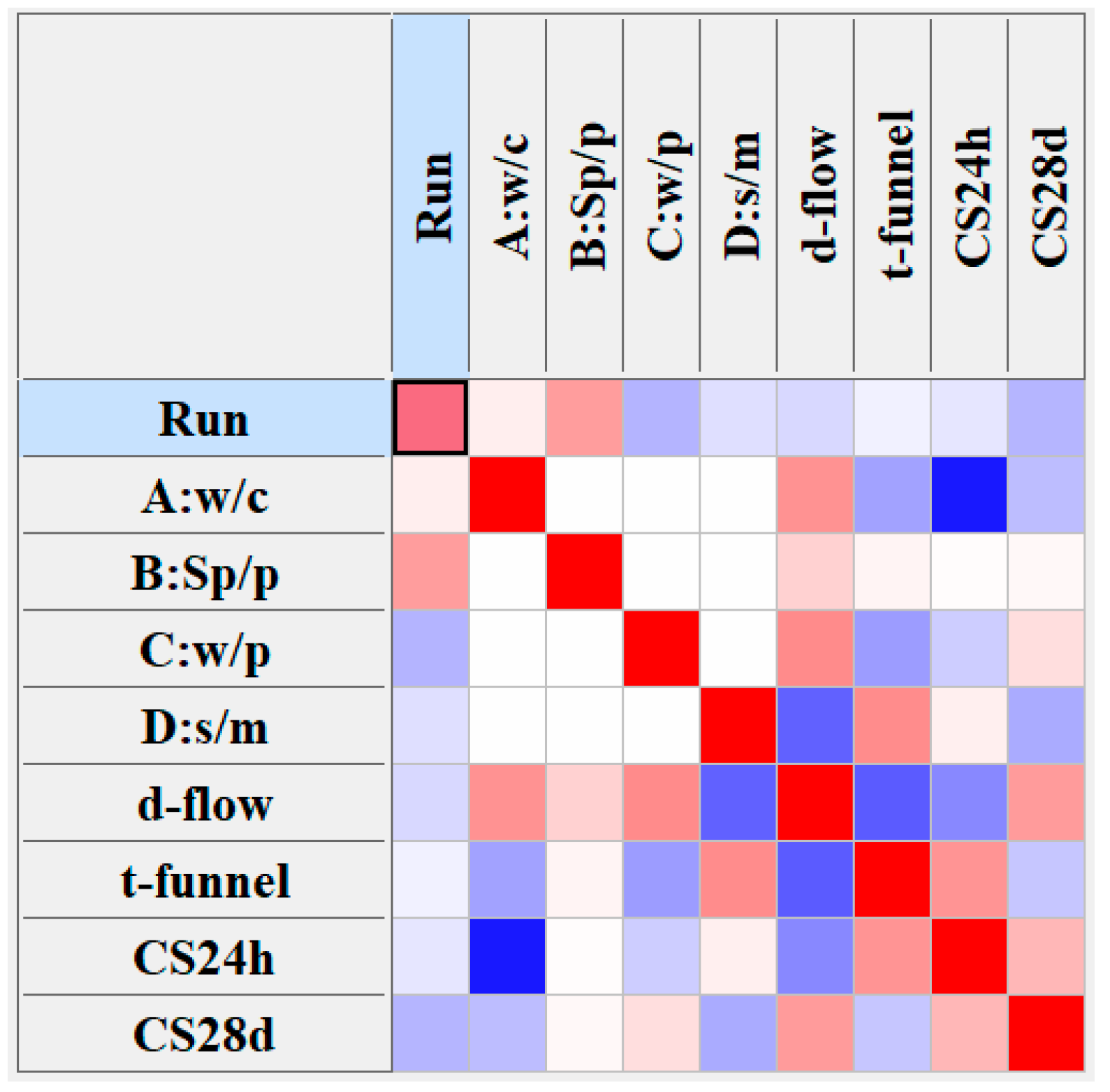

3.1. Preliminary Data Analysis

3.2. Fresh Properties of Self-Compacting Mortars

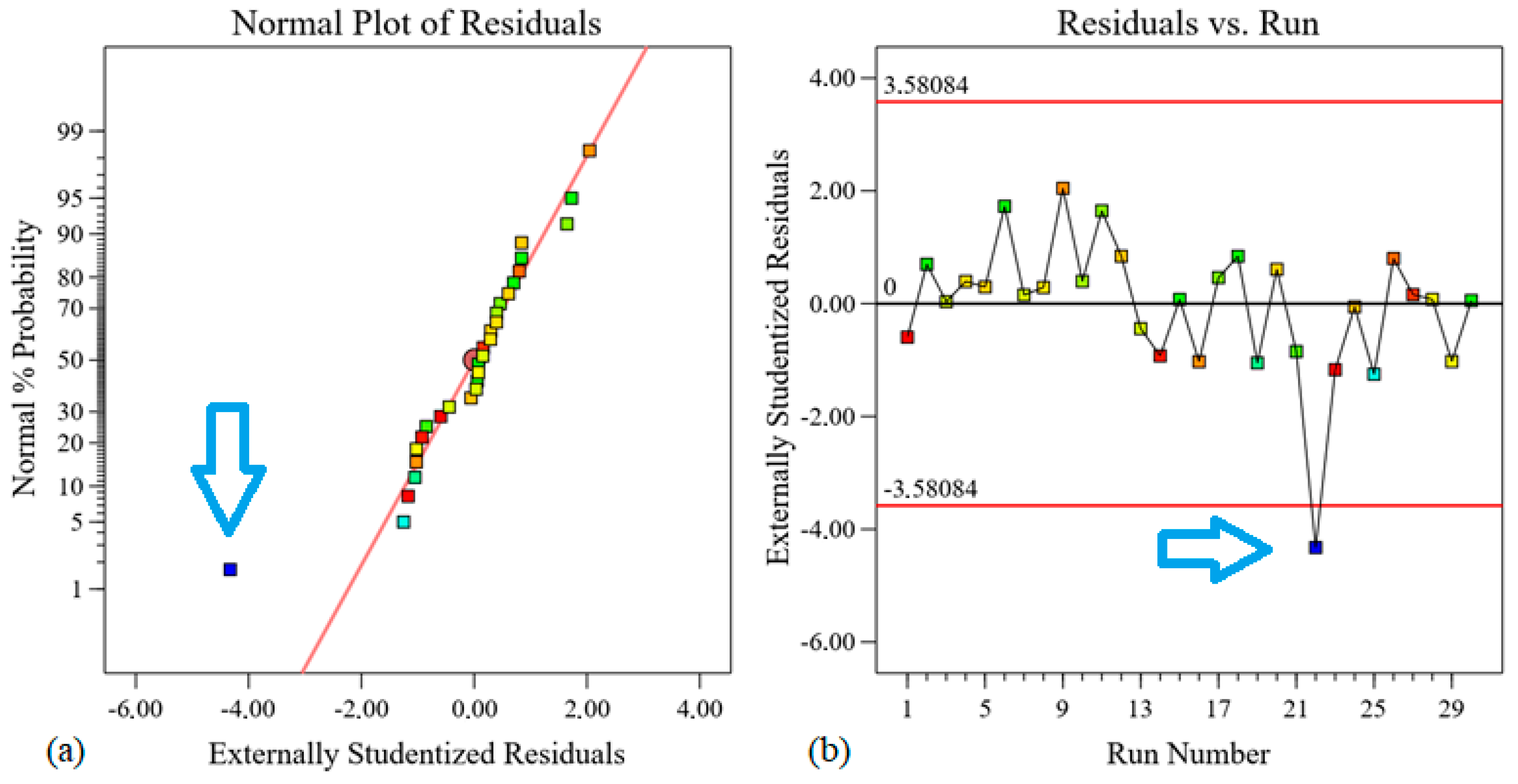

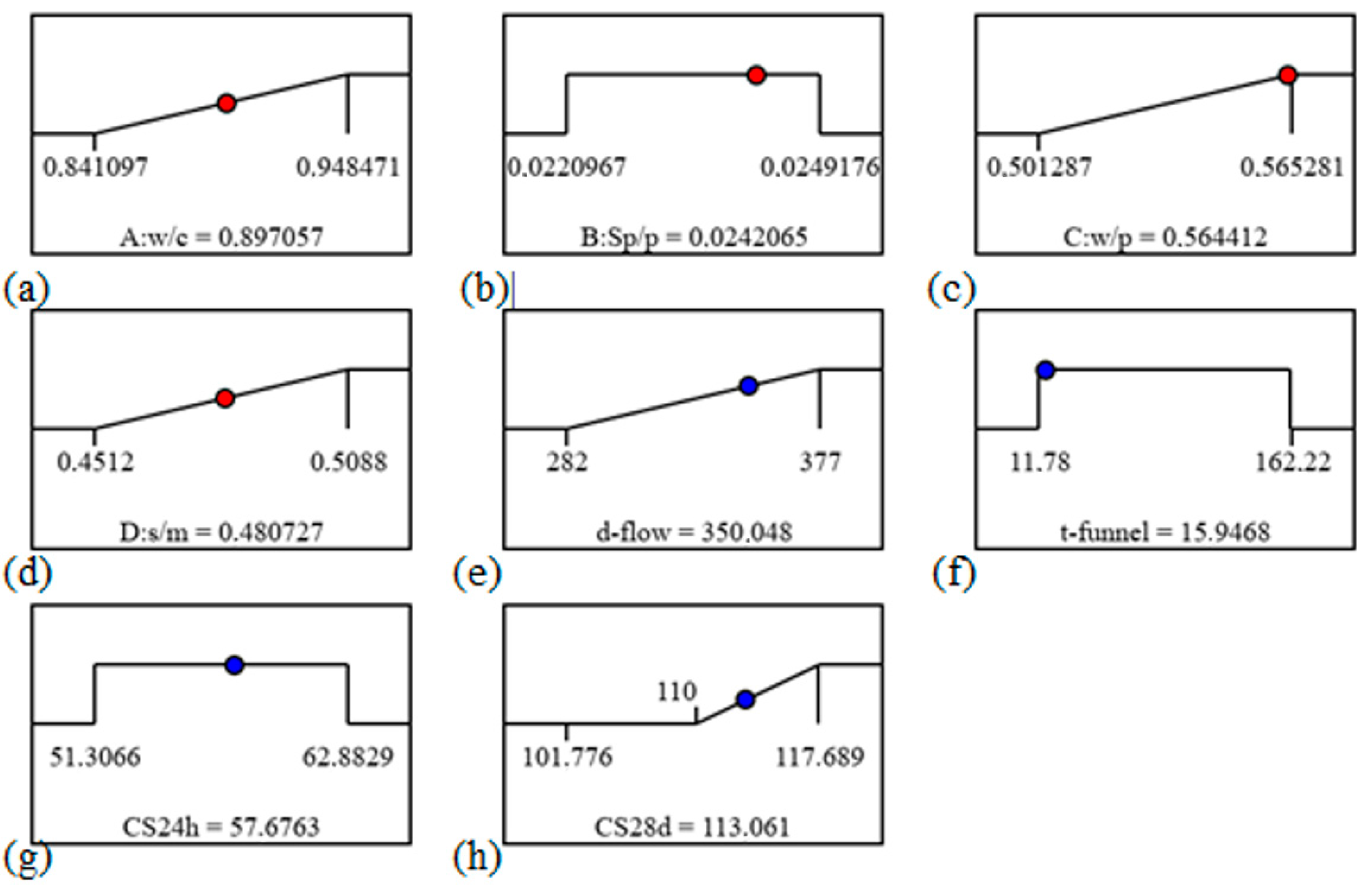

Regression Model for D-Flow

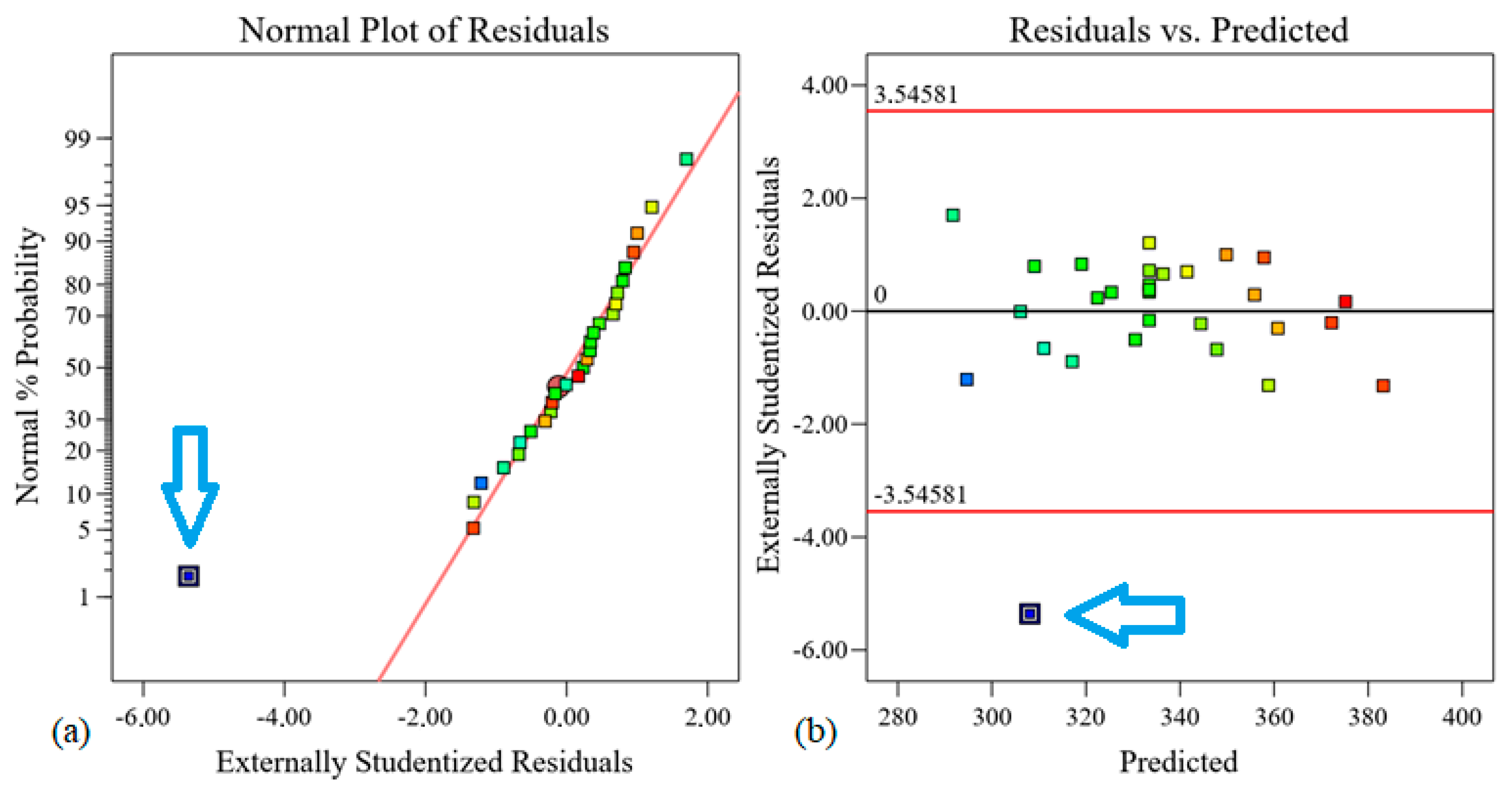

3.3. Regression Model for T-Funnel

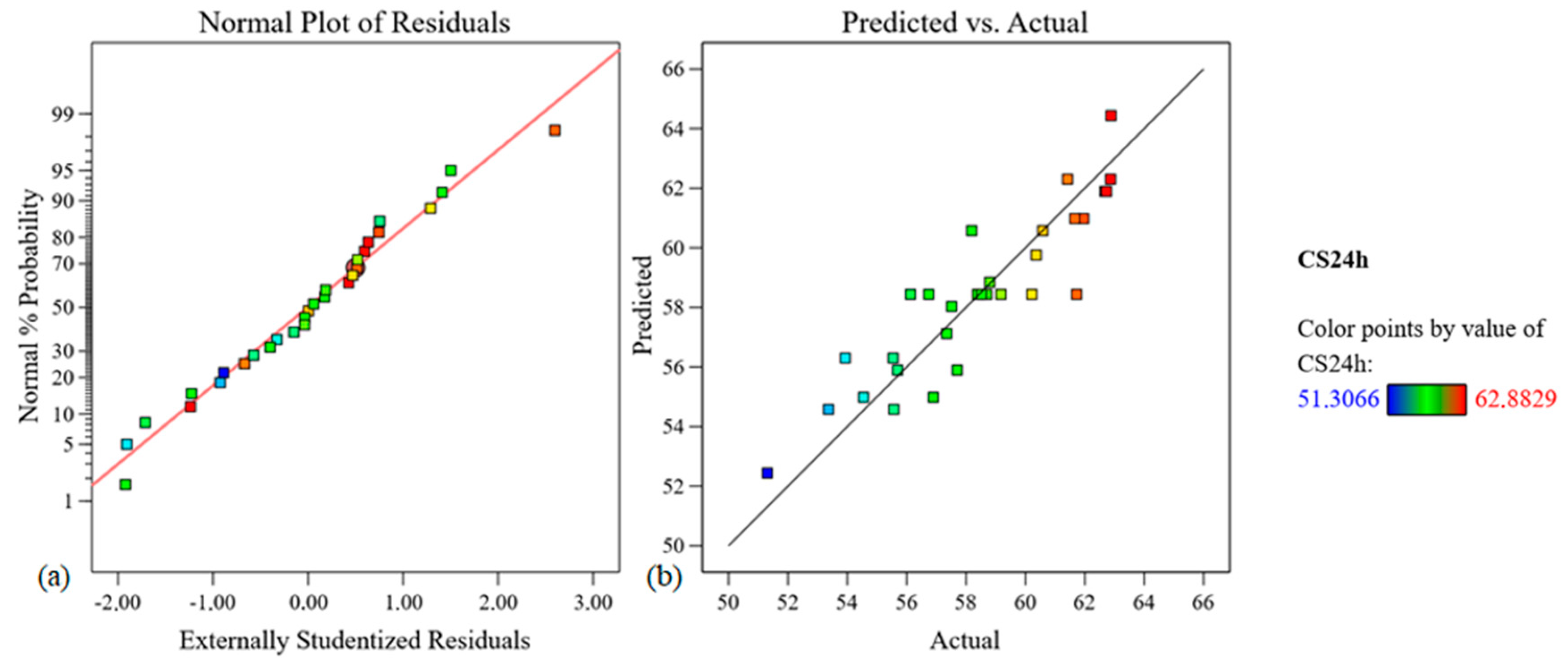

3.4. Regression Model for 24-Hour Compressive Strength

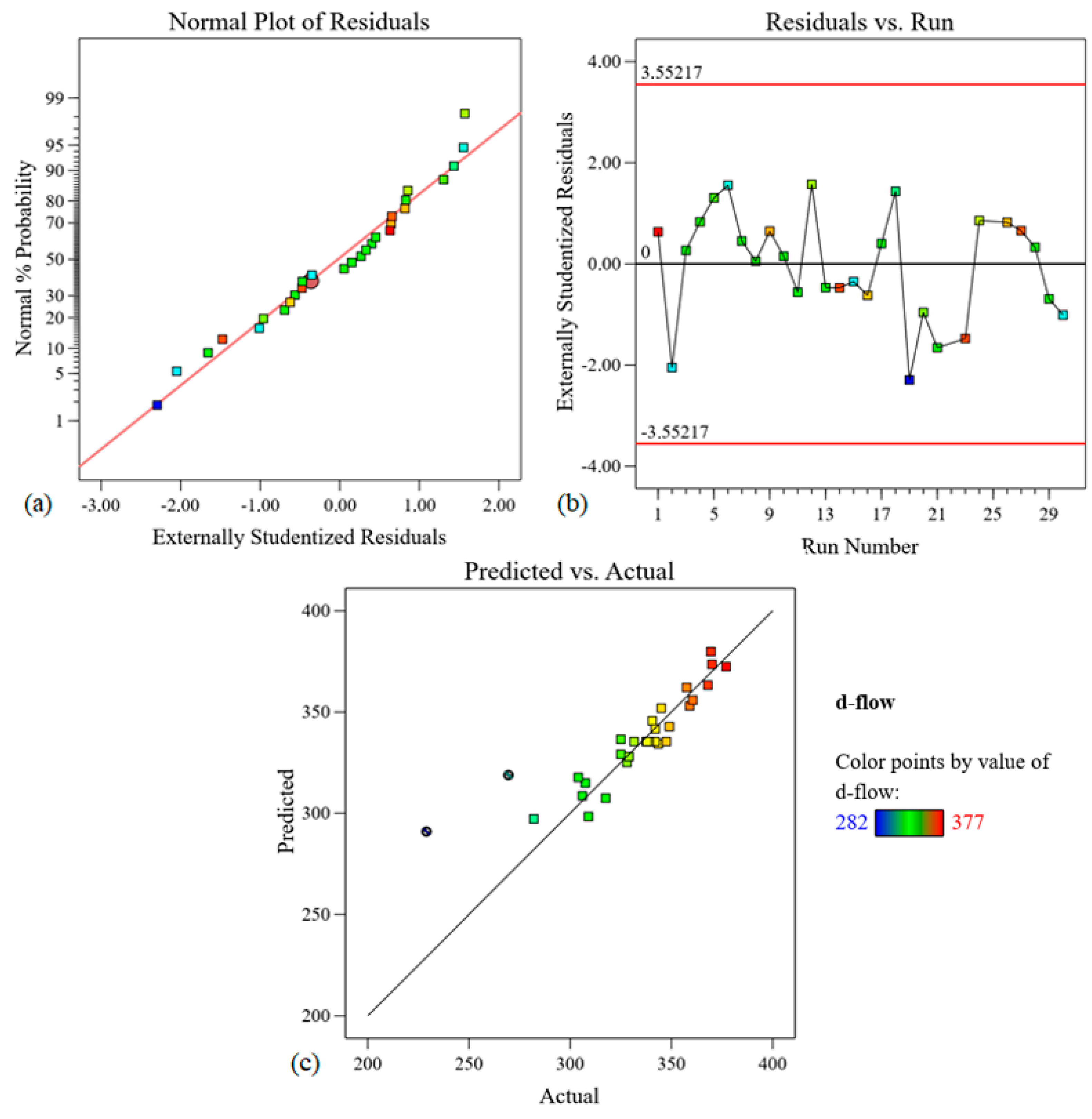

3.5. Regression Model for 28-Day Compressive Strength

4. Discussion

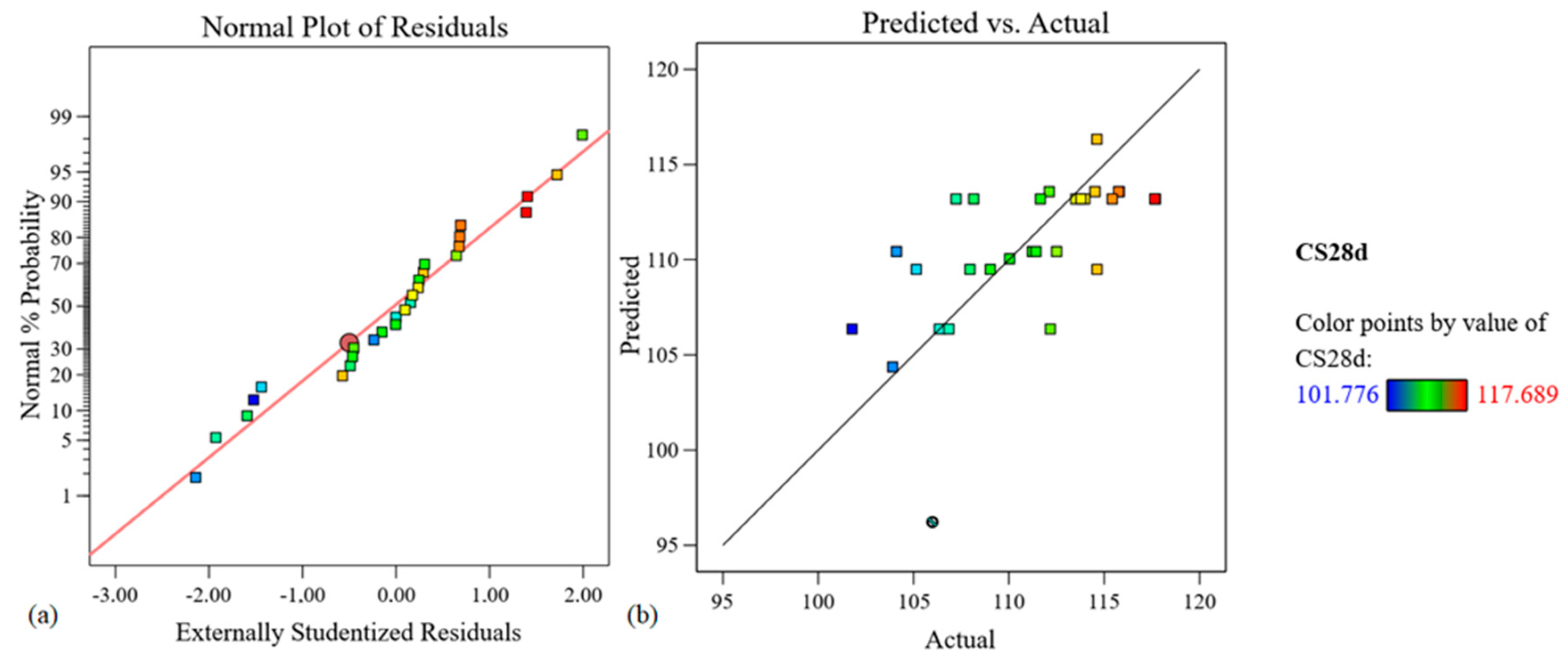

4.1. Model Optimization

4.2. Optimization of Self-Compacting Mortars Using Response Surface Methodology

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, M.; Kumar, A.; Yvaz, A.; Salah, B. Central composite design application in the optimization of the effect of pumice stone on lightweight concrete properties using RSM. Case Stud. Constr. Mater. 2023, 18, e01958. [Google Scholar] [CrossRef]

- Rashid, K.; Farooq, S.; Mahmood, A.; Iftikhar, S.; Ahmad, A. Moving towards resource conservation by automated prioritization of concrete mix design. Constr. Build. Mater. 2020, 236, 117586. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-compacting high performance concrete. Prog. Struct. Eng. Mater. 1998, 1, 378–383. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Lv, K.; Wu, L. A review on mixture design methods for self-compacting concrete. Constr. Build. Mater. 2015, 84, 387–398. [Google Scholar] [CrossRef]

- De Schutter, G.; Bartos, P.J.; Domone, P.; Gibbs, J. Self-Compacting Concrete (Vol. 288); Whittles Publishing: Caithness, The Netherlands, 2018; Available online: http://hdl.handle.net/1854/LU-689512 (accessed on 20 July 2023).

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Aitcin, P.C. Concreto de Alto Desempenho, 1st ed.; Pini: São Paulo, Brazil, 2000. [Google Scholar]

- Beersaerts, G.; Ascensão, G.; Pontikes, Y. Modifying the pore size distribution in Fe-rich inorganic polymer mortars: An effective shrinkage mitigation strategy. Cem. Concr. Res. 2021, 141, 106330. [Google Scholar] [CrossRef]

- Petrou, A.K.M.F.; Ioannou, I. Durability performance of self-compacting concrete. Constr. Build. Mater. 2012, 37, 320–325. [Google Scholar]

- Nuruzzaman; Ahmad, T.; Sarker, P.K.; Shaikh, F.U.A. Rheological behaviour, hydration, and microstructure of self-compacting concrete incorporating ground ferronickel slag as partial cement replacement. J. Build. Eng. 2023, 68, 106127. [Google Scholar] [CrossRef]

- Zerbino, R.; Barragán, B.; Garcia, T.; Agulló, L.; Gettu, R. Workability tests and rheological parameters in self-compacting con-crete. Mater. Struct. Constr. 2009, 42, 947–960. [Google Scholar] [CrossRef]

- Ascensão, G.; Marchi, M.; Segata, M.; Faleschini, F.; Pontikes, Y. Reaction kinetics and structural analysis of alkali activated Fe–Si–Ca rich materials. J. Clean. Prod. 2020, 246, 119065. [Google Scholar] [CrossRef]

- Upasani, R.S.; Banga, A.K. Response Surface Methodology to Investigate the Iontophoretic Delivery of Tacrine Hydrochloride. Pharm. Res. 2004, 21, 2293–2299. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Box, K.B.; Wilson, G.E.P. On the experimental attainment of optimum conditions. J. R. Stat. Soc. 1951, 1–38. [Google Scholar] [CrossRef]

- Box, J.S.; Hunter, G.E.P.; Hunter, W.G. Statistics for Experimenters: An Introduction to Design, Data Analysis and Model Building; Wiley: New York, NY, USA, 1978. [Google Scholar]

- Awolusi, T.; Oke, O.; Akinkurolere, O.; Sojobi, A. Application of response surface methodology: Predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Constr. Mater. 2019, 10, e00212. [Google Scholar] [CrossRef]

- Ali, M.; Khan, M.I.; Masood, F.; Alsulami, B.T.; Bouallegue, B.; Nawaz, R.; Fediuk, R. Central composite design application in the optimization of the effect of waste foundry sand on concrete properties using RSM. Structures 2022, 46, 1581–1594. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Bin Napiah, M.; Khan, K.; Rafiq, W. Design optimization and statistical modeling of cementitious grout containing irradiated plastic waste and silica fume using response surface methodology. Constr. Build. Mater. 2021, 271, 121504. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. RSM-based model to predict the performance of self-compacting UHPC reinforced with hybrid steel micro-fibers. Constr. Build. Mater. 2014, 66, 375–383. [Google Scholar] [CrossRef]

- Dahish, H.A.; Almutairi, A.D. Effect of elevated temperatures on the compressive strength of nano-silica and nano-clay modified concretes using response surface methodology. Case Stud. Constr. Mater. 2023, 18, e02032. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Fang, O.C.; Hossain, K.M.A.; Lachemi, M. Mix proportioning of concrete containing paper mill residuals using response surface methodology. Constr. Build. Mater. 2012, 35, 63–68. [Google Scholar] [CrossRef]

- Nunes, S.; Matos, A.M.; Duarte, T.; Figueiras, H.; Sousa-Coutinho, J. Mixture design of self-compacting glass mortar. Cem. Concr. Compos. 2013, 43, 1–11. [Google Scholar] [CrossRef]

- Keleştemur, O.; Yildiz, S.; Gökçer, B.; Arici, E. Statistical analysis for freeze–thaw resistance of cement mortars containing marble dust and glass fiber. Mater. Des. 2014, 60, 548–555. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar] [CrossRef]

- Mermerdaş, K.; Algın, Z.; Oleiwi, S.M.; Nassani, D.E. Optimization of lightweight GGBFS and FA geopolymer mortars by response surface method. Constr. Build. Mater. 2017, 139, 159–171. [Google Scholar] [CrossRef]

- Zahid, M.; Shafiq, N.; Isa, M.H.; Gil, L. Statistical modeling and mix design optimization of fly ash based engineered geopolymer composite using response surface methodology. J. Clean. Prod. 2018, 194, 483–498. [Google Scholar] [CrossRef]

- Matos, A.M.; Maia, L.; Nunes, S.; Milheiro-Oliveira, P. Design of self-compacting high-performance concrete: Study of mortar phase. Constr. Build. Mater. 2018, 167, 617–630. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Zahid, M.; Usman, A. Optimization of Cementitious Grouts for Semi-Flexible Pavement Surfaces Using Response Surface Methodology. IOP Conf. Ser. Earth Environ. Sci. 2020, 498, 012004. [Google Scholar] [CrossRef]

- Al Salaheen, M.; Alaloul, W.S.; Malkawi, A.B.; de Brito, J.; Alzubi, K.M.; Al-Sabaeei, A.M.; Alnarabiji, M.S. Modelling and Optimization for Mortar Compressive Strength Incorporating Heat-Treated Fly Oil Shale Ash as an Effective Supplementary Cementitious Material Using Response Surface Methodology. Materials 2022, 15, 6538. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, C.; Wang, X.; Zhang, T.; Wang, Q. Response surface methodology for multi-objective optimization of fly ash-GGBS based geopolymer mortar. Constr. Build. Mater. 2022, 315, 125644. [Google Scholar] [CrossRef]

- Anurag; Singh, S. Estimation of the impacts of adding recycled demolition waste and steel fibers on different mechanical properties of self-compacting concrete. Mater. Today Proc. 2022, 48, 1723–1730. [Google Scholar] [CrossRef]

- Waqar, A.; Bheel, N.; Almujibah, H.R.; Benjeddou, O.; Alwetaishi, M.; Ahmad, M.; Sabri, M.M.S. Effect of Coir Fibre Ash (CFA) on the strengths, modulus of elasticity and embodied carbon of concrete using response surface methodology (RSM) and optimization. Results Eng. 2023, 17, 100883. [Google Scholar] [CrossRef]

- Khavari, B.C.; Shekarriz, M.; Aminnejad, B.; Lork, A.; Vahdani, S. Laboratory evaluation and optimization of mechanical properties of sulfur concrete reinforced with micro and macro steel fibers via response surface methodology. Constr. Build. Mater. 2023, 384, 131434. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.A.; Tayeh, B.; Yahaya, F.B.M.; Abu Aisheh, Y.I. Optimising concrete containing palm oil clinker and palm oil fuel ash using response surface method. Ain Shams Eng. J. 2023, 14, 102150. [Google Scholar] [CrossRef]

- Mita, A.F.; Ray, S.; Haque, M.; Saikat, H. Prediction and optimization of properties of concrete containing crushed stone dust and nylon fiber using response surface methodology. Heliyon 2023, 9, e14436. [Google Scholar] [CrossRef]

- Sinkhonde, D. Generating response surface models for optimisation of CO2 emission and properties of concrete modified with waste materials. Clean. Mater. 2022, 6, 100146. [Google Scholar] [CrossRef]

- Adamu, M.; Trabanpruek, P.; Jongvivatsakul, P.; Likitlersuang, S.; Iwanami, M. Mechanical performance and optimization of high-volume fly ash concrete containing plastic wastes and graphene nanoplatelets using response surface methodology. Constr. Build. Mater. 2021, 308, 125085. [Google Scholar] [CrossRef]

- Li, L.; Wan, Y.; Chen, S.; Tian, W.; Long, W.; Song, J. Prediction of optimal ranges of mix ratio of self-compacting mortars (SCMs) based on response surface method (RSM). Constr. Build. Mater. 2022, 319, 126043. [Google Scholar] [CrossRef]

- Safhi, A.e.M.; Benzerzour, M.; Rivard, P.; Abriak, N.-E.; Ennahal, I. Development of self-compacting mortars based on treated marine sediments. J. Build. Eng. 2019, 22, 252–261. [Google Scholar] [CrossRef]

- Maia, L. Experimental dataset from a central composite design with two qualitative independent variables to develop high strength mortars with self-compacting properties. Data Brief 2021, 40, 107738. [Google Scholar] [CrossRef] [PubMed]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology, 3rd ed.; Wiley: New York, NY, USA, 2009. [Google Scholar]

| Levels | A: w/c | B: Sp/p | C: w/p | D: s/m |

|---|---|---|---|---|

| −2 | 0.78741 | 0.02069 | 0.46929 | 0.42240 |

| −1 | 0.84110 | 0.02210 | 0.50129 | 0.45120 |

| 0 | 0.89478 | 0.02351 | 0.53328 | 0.48000 |

| +1 | 0.94847 | 0.02492 | 0.56528 | 0.50880 |

| +2 | 1.00216 | 0.02633 | 0.59728 | 0.53760 |

| Std | Run | Coded Values | Results | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | Y1 | Y2 | Y3 | Y4 | ||

| 1 | 11 | −1 | −1 | −1 | −1 | 325 | 22 | 62.7 | 115.8 |

| 2 | 29 | 1 | −1 | −1 | −1 | 341 | 18 | 55.7 | 108.0 |

| 3 | 21 | −1 | 1 | −1 | −1 | 325 | 21 | 62.7 | 112.1 |

| 4 | 26 | 1 | 1 | −1 | −1 | 359 | 15 | 57.7 | 114.6 |

| 5 | 9 | −1 | −1 | 1 | −1 | 361 | 16 | 60.6 | 114.5 |

| 6 | 1 | 1 | −1 | 1 | −1 | 377 | 12 | 53.4 | 109.0 |

| 7 | 27 | −1 | 1 | 1 | −1 | 368 | 13 | 58.2 | 115.8 |

| 8 | 23 | 1 | 1 | 1 | −1 | 370 | 13 | 55.6 | 105.1 |

| 9 | 22 | −1 | −1 | −1 | 1 | 229 | 108 | 61.4 | 104.1 |

| 10 | 18 | 1 | −1 | −1 | 1 | 318 | 31 | 55.5 | 106.4 |

| 11 | 6 | −1 | 1 | −1 | 1 | 309 | 162 | 62.9 | 111.2 |

| 12 | 30 | 1 | 1 | −1 | 1 | 308 | 30 | 53.9 | 101.8 |

| 13 | 2 | −1 | −1 | 1 | 1 | 304 | 29 | 62.0 | 112.5 |

| 14 | 5 | 1 | −1 | 1 | 1 | 344 | 19 | 54.6 | 106.9 |

| 15 | 17 | −1 | 1 | 1 | 1 | 328 | 24 | 61.7 | 111.4 |

| 16 | 8 | 1 | 1 | 1 | 1 | 342 | 18 | 56.9 | 112.2 |

| 17 | 25 | −2 | 0 | 0 | 0 | 270 | 45 | 62.9 | 103.9 |

| 18 | 20 | 2 | 0 | 0 | 0 | 345 | 16 | 51.3 | 106.0 |

| 19 | 10 | 0 | −2 | 0 | 0 | 329 | 21 | 58.4 | 117.7 |

| 20 | 24 | 0 | 2 | 0 | 0 | 349 | 17 | 56.7 | 115.4 |

| 21 | 15 | 0 | 0 | −2 | 0 | 306 | 40 | 60.4 | 113.5 |

| 22 | 16 | 0 | 0 | 2 | 0 | 358 | 13 | 57.4 | 114.0 |

| 23 | 14 | 0 | 0 | 0 | −2 | 370 | 12 | 57.5 | 114.6 |

| 24 | 19 | 0 | 0 | 0 | 2 | 282 | 52 | 58.8 | 110.0 |

| 25 | 4 | 0 | 0 | 0 | 0 | 342 | 18 | 60.2 | 108.2 |

| 26 | 7 | 0 | 0 | 0 | 0 | 339 | 21 | 58.7 | 107.2 |

| 27 | 13 | 0 | 0 | 0 | 0 | 332 | 19 | 58.5 | 111.7 |

| 28 | 12 | 0 | 0 | 0 | 0 | 348 | 17 | 56.1 | 113.8 |

| 29 | 3 | 0 | 0 | 0 | 0 | 338 | 19 | 59.2 | 117.7 |

| 30 | 28 | 0 | 0 | 0 | 0 | 338 | 24 | 61.7 | * |

| Levels | Y1 | Y2 | Y3 | Y4 |

|---|---|---|---|---|

| D-Flow (mm) | T-Funnel (s) | CS24h * (MPa) | CS28d * (MPa) | |

| Minimum | 229 | 12 | 51.3 | 101.8 |

| Maximum | 377 | 162 | 62.9 | 117.7 |

| Mean | 332 | 29 | 58.4 | 110.9 |

| Std. Dev. | 32 | 31 | 3.1 | 4.4 |

| CV (%) | 10 | 106 | 5.3 | 4.0 |

| Source | Sum of Squares | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 12,633.5 | 3158.4 | 47.7 | <0.0001 |

| A-w/c | 1266.9 | 1266.9 | 19.1 | 0.0002 |

| B-Sp/p | 314.3 | 314.3 | 4.8 | 0.0399 |

| C-w/p | 4079.9 | 4079.9 | 61.6 | <0.0001 |

| D-s/m | 8303.5 | 8303.5 | 125.4 | <0.0001 |

| Residual | 1523.0 | 66.2 | ||

| Lack of Fit | 1382.7 | 76.8 | 2.74 | 0.135 |

| Pure Error | 140.4 | 28.1 | ||

| Cor Total | 14,156.5 | - |

| Factor | Intercept | A—w/c | B—Sp/p | C—w/p | D—s/m |

|---|---|---|---|---|---|

| Coefficient Estimate | 335.32 | 8.27 | 3.71 | 13.38 | −19.09 |

| Standard Error | 1.56 | 1.89 | 1.70 | 1.70 | 1.70 |

| 95% CI Low | 332.10 | 4.36 | 0.19 | 9.85 | −22.62 |

| 95% CI High | 338.54 | 12.19 | 7.24 | 16.91 | −15.56 |

| VIF | - | 1.01 | 1.01 | 1.01 | 1.01 |

| Source | Sum of Squares | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 0.0117 | 0.0029 | 101.78 | <0.0001 |

| A-w/c | 0.0019 | 0.0019 | 65.19 | <0.0001 |

| B-Sp/p | 0.0001 | 0.0001 | 4.70 | 0.0398 |

| C-w/p | 0.0037 | 0.0037 | 128.64 | <0.0001 |

| D-s/m | 0.0060 | 0.0060 | 208.57 | <0.0001 |

| Residual | 0.0007 | 0.0000 | ||

| Lack of Fit | 0.0005 | 0.0000 | 0.7718 | 0.6949 |

| Pure Error | 0.0002 | 0.0000 | ||

| Cor Total | 0.0124 | - |

| Factor | Intercept | A–w/c | B–Sp/p | C–w/p | D–s/m |

|---|---|---|---|---|---|

| Coefficient Estimate | 0.0499 | 0.0088 | 0.0024 | 0.0124 | −0.0158 |

| Standard Error | 0.0010 | 0.0011 | 0.0011 | 0.0011 | 0.0011 |

| 95% CI Low | 0.0479 | 0.0066 | 0.0001 | 0.0102 | −0.0181 |

| 95% CI High | 0.0519 | 0.0111 | 0.0046 | 0.0147 | −0.0136 |

| VIF | 1.00 | 1.00 | 1.00 | 1.00 |

| Source | Sum of Squares | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 227.36 | 75.79 | 37.54 | <0.0001 |

| A—w/c | 215.95 | 215.95 | 106.96 | <0.0001 |

| C—w/p | 10.42 | 10.42 | 5.16 | 0.0316 |

| D—s/m | 0.9928 | 0.9928 | 0.4917 | 0.4894 |

| Residual | 52.49 | 2.02 | ||

| Lack of Fit | 35.04 | 1.67 | 0.4778 | 0.8934 |

| Pure Error | 17.46 | 3.49 | ||

| Cor Total | 279.86 | - |

| Factor | Intercept | A—w/c | C—w/p | D—s/m |

|---|---|---|---|---|

| Coefficient Estimate | 58.44 | −3.00 | −0.6589 | 0.2034 |

| Standard Error | 0.2594 | 0.290 | 0.2900 | 0.2900 |

| 95% CI Low | 57.91 | −3.60 | −1.26 | −0.3928 |

| 95% CI High | 58.97 | −2.40 | −0.0628 | 0.7996 |

| VIF | - | 1 | 1 | 1 |

| Source | Sum of Squares | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 239.43 | 79.81 | 6.99 | <0.0015 |

| A—w/c | 72.33 | 72.33 | 6.33 | <0.0189 |

| D—s/m | 59.12 | 59.12 | 5.18 | 0.0321 |

| A² | 161.61 | 161.61 | 14.15 | 0.0010 |

| Residual | 274.10 | 11.42 | ||

| Lack of Fit | 201.81 | 10.09 | 0.5584 | 0.8297 |

| Pure Error | 72.29 | 18.07 | ||

| Cor Total | 513.53 | - |

| Factor | Intercept | A-w/c | D-s/m | A² |

|---|---|---|---|---|

| Coefficient Estimate | 113.19 | −2.04 | −1.57 | −3.22 |

| Standard Error | 0.8726 | 0.8097 | 0.6898 | 0.8573 |

| 95% CI Low | 111.39 | −3.71 | −2.99 | −4.99 |

| 95% CI High | 114.99 | −0.3665 | −0.1457 | −1.46 |

| VIF | - | 1.14 | 1.00 | 1.14 |

| Factor | Goal | Lower Limit | Upper Limit | Weight | Importance |

|---|---|---|---|---|---|

| A: w/c | To be maximized | 0.8411 | 0.9485 | 1 | +++++ |

| B: Sp/p | To be in range | 0.0221 | 0.0249 | 1 | +++ |

| C: w/p | To be maximized | 0.5013 | 0.5653 | 1 | +++++ |

| D: s/m | To be maximized | 0.4512 | 0.5088 | 1 | +++++ |

| Y1: D-Flow (mm) | To be maximized | 282 | 377 | 1 | ++++ |

| Y2: T-Funnel (s) | To be in range | 11.78 | 162.22 | 1 | +++ |

| Y3: CS24h (MPa) | To be in range | 51.3066 | 62.88 | 1 | +++ |

| Y4: CS28d (MPa) | To be maximized | 110.00 | 117.69 | 1 | +++++ |

| Factor | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| A: w/c | 0.897 | 0.904 | 0.889 | 0.889 | 0.878 |

| B: Sp/p | 0.024 | 0.023 | 0.024 | 0.024 | 0.023 |

| C: w/p | 0.564 | 0.563 | 0.561 | 0.555 | 0.564 |

| D: s/m | 0.481 | 0.4894 | 0.499 | 0.495 | 0.485 |

| Y1: D-Flow (mm) | 350.05 | 342.67 | 336.12 | 334.94 | 341.24 |

| Y2: T-Funnel (s) | 15.95 | 17.46 | 19.79 | 20.22 | 18.10 |

| Y3: CS24h (MPa) | 57.68 | 57.37 | 58.32 | 58.44 | 58.80 |

| Y4: CS28d (MPa) | 113.06 | 112.27 | 112.35 | 112.57 | 113.27 |

| Desirability | 0.591 | 0.586 | 0.570 | 0.555 | 0.549 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rocha, S.; Ascensão, G.; Maia, L. Exploring Design Optimization of Self-Compacting Mortars with Response Surface Methodology. Appl. Sci. 2023, 13, 10428. https://doi.org/10.3390/app131810428

Rocha S, Ascensão G, Maia L. Exploring Design Optimization of Self-Compacting Mortars with Response Surface Methodology. Applied Sciences. 2023; 13(18):10428. https://doi.org/10.3390/app131810428

Chicago/Turabian StyleRocha, Stéphanie, Guilherme Ascensão, and Lino Maia. 2023. "Exploring Design Optimization of Self-Compacting Mortars with Response Surface Methodology" Applied Sciences 13, no. 18: 10428. https://doi.org/10.3390/app131810428

APA StyleRocha, S., Ascensão, G., & Maia, L. (2023). Exploring Design Optimization of Self-Compacting Mortars with Response Surface Methodology. Applied Sciences, 13(18), 10428. https://doi.org/10.3390/app131810428