Uniaxial Testing of Soil–Cement Composites to Obtain Correlations to Be Used in Numerical Modeling

Abstract

1. Introduction

2. The Current State of Knowledge and Basic Data on the Research Project

- Preliminary concepts of technology modification;

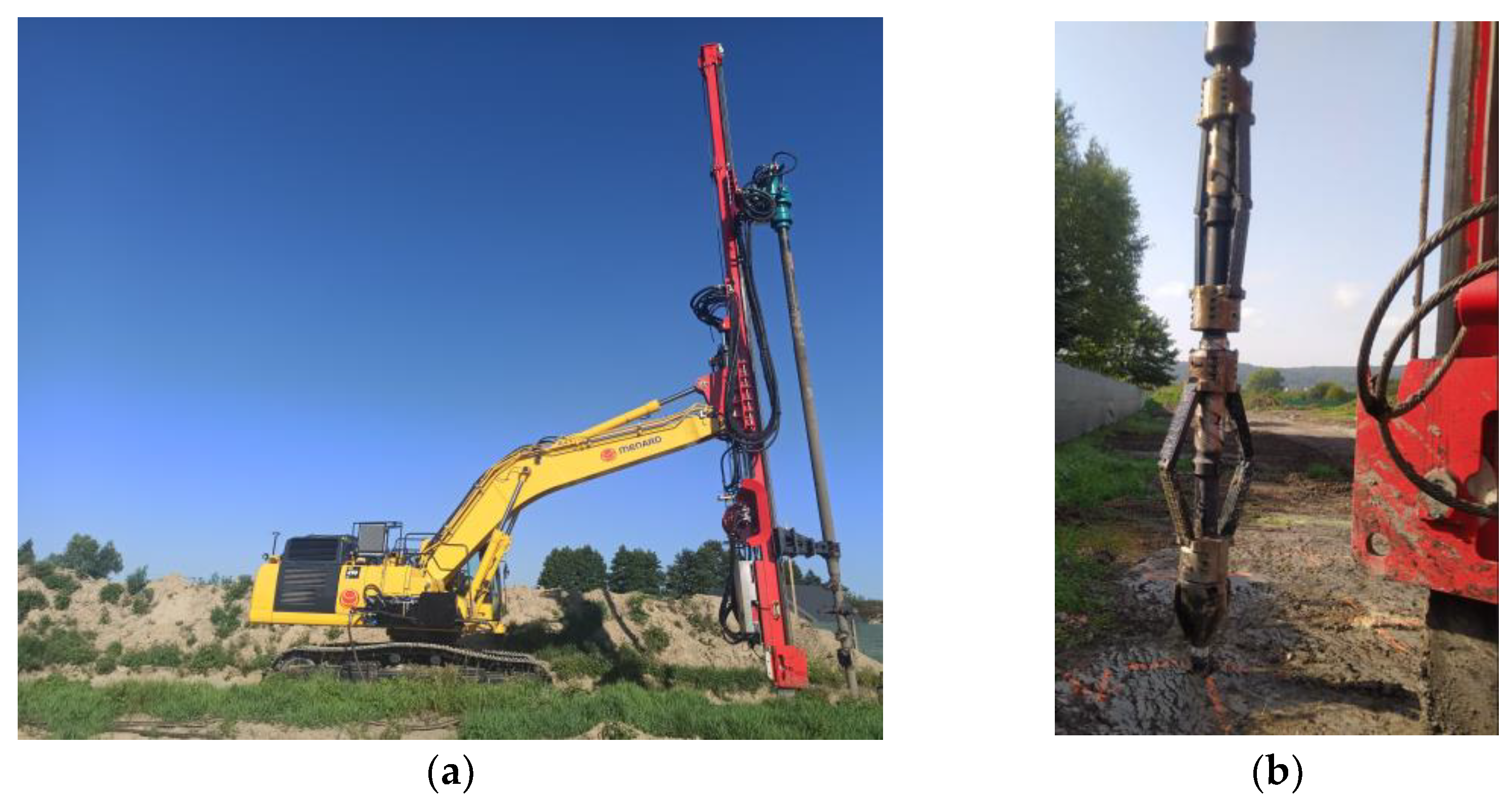

- Analysis of the possibility of hardware modifications in the field of mixing tools, hydraulic binder transport, and mobility of mixing devices;

- Detailed research projects carried out in field conditions on a natural scale with various methods of sampling for laboratory tests;

- Execution of DSM columns with various technological parameters monitored during the production process, with the sampling method adjusted to the assumed technology and time of probing;

- Laboratory procedures spread over time allowing for the validation and final assessment of the modified soil parameters. The entire testing program was based on tests of uniaxial compression strength and an oedometric compressibility modulus and, to a limited extent, tests in a triaxial compression apparatus.

2.1. Preliminary Literature Analyses and Past Experience

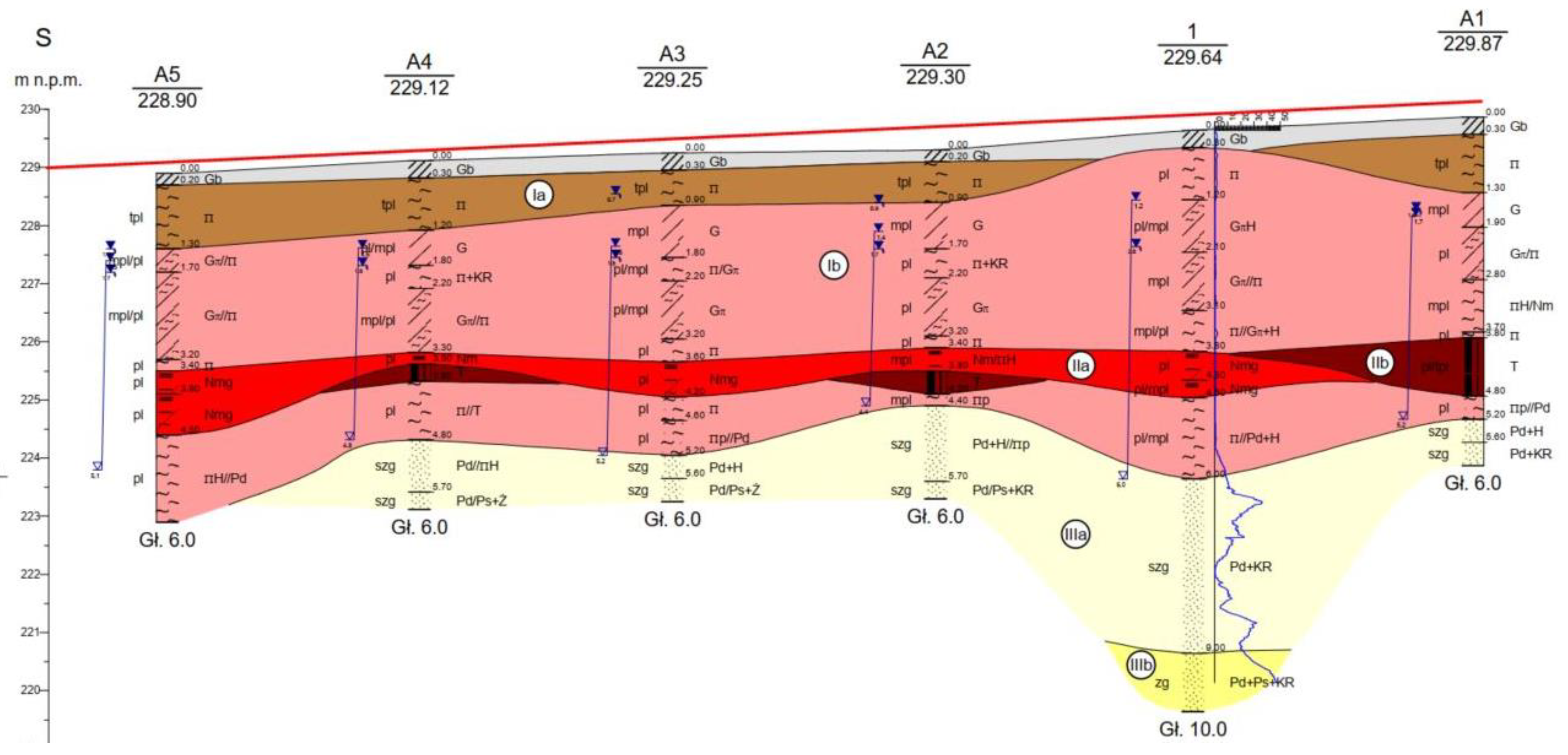

2.2. Geotechnical Conditions at the Site of the Test Columns

2.3. Implementation of Test Columns

2.4. Methods of Preparing Samples for Laboratory Tests

2.5. Laboratory Procedures Used to Test the Composite

3. Methodology of Laboratory Tests

3.1. General Comments on the Methods of Sample Preparation and Collection

3.2. Compression in a Testing Machine

3.3. Testing of Cylindrical Samples

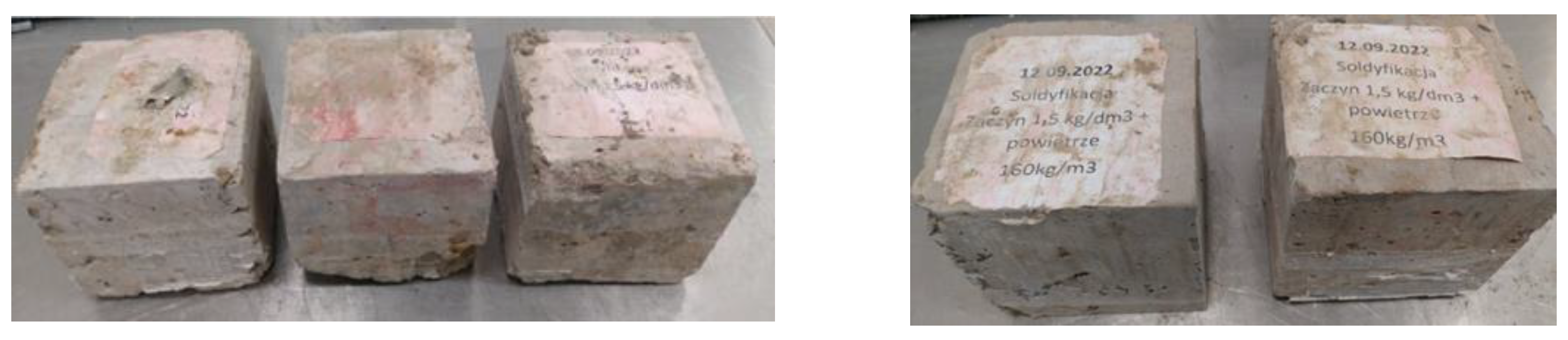

3.4. Cubic Sample Testing (Laboratory Prepared)

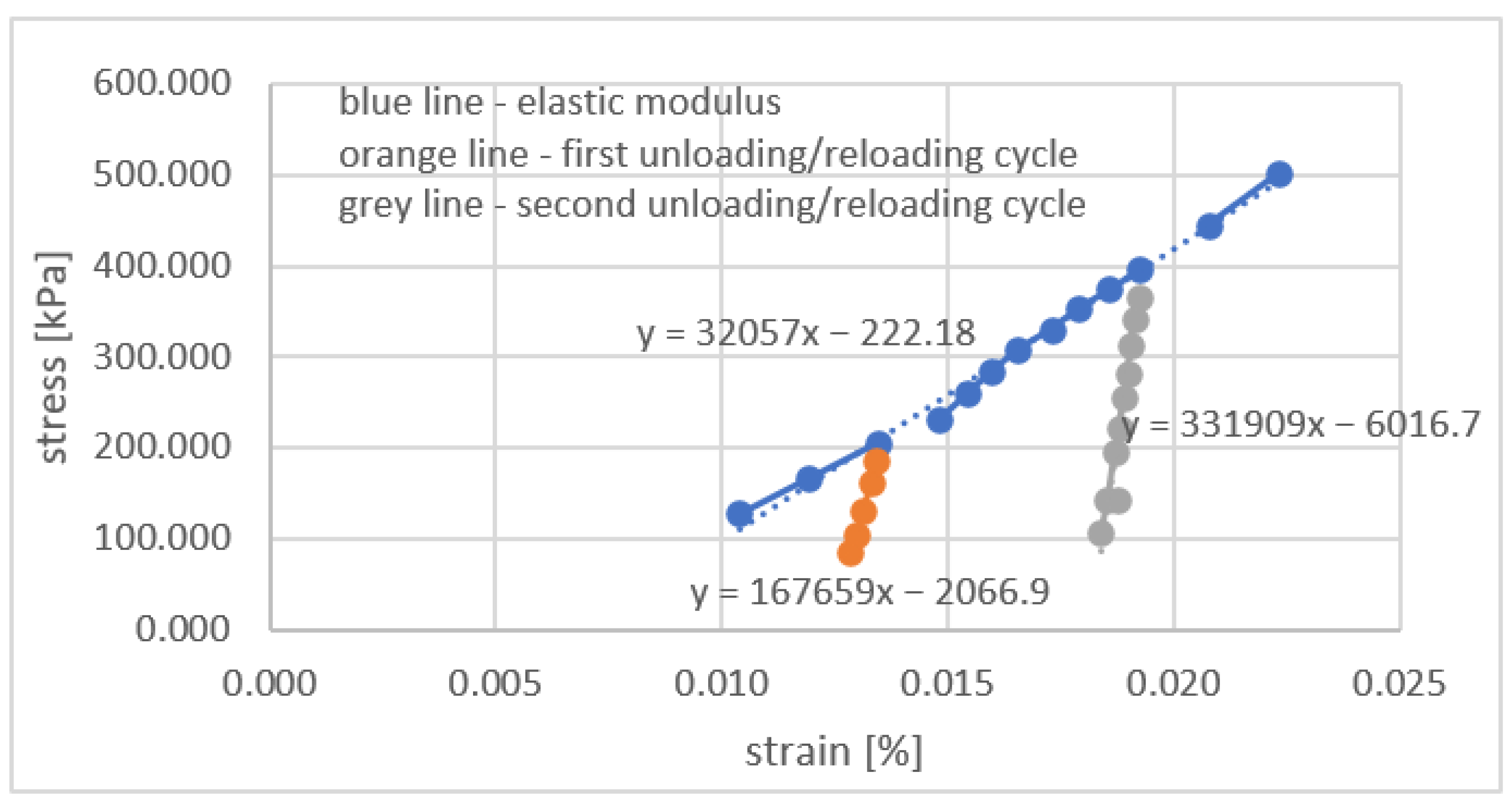

3.5. Unloading/Reloading Procedures Derive Material Stiffness in Cycling Loading

4. Laboratory Test Results and Discussion of the Obtained Results

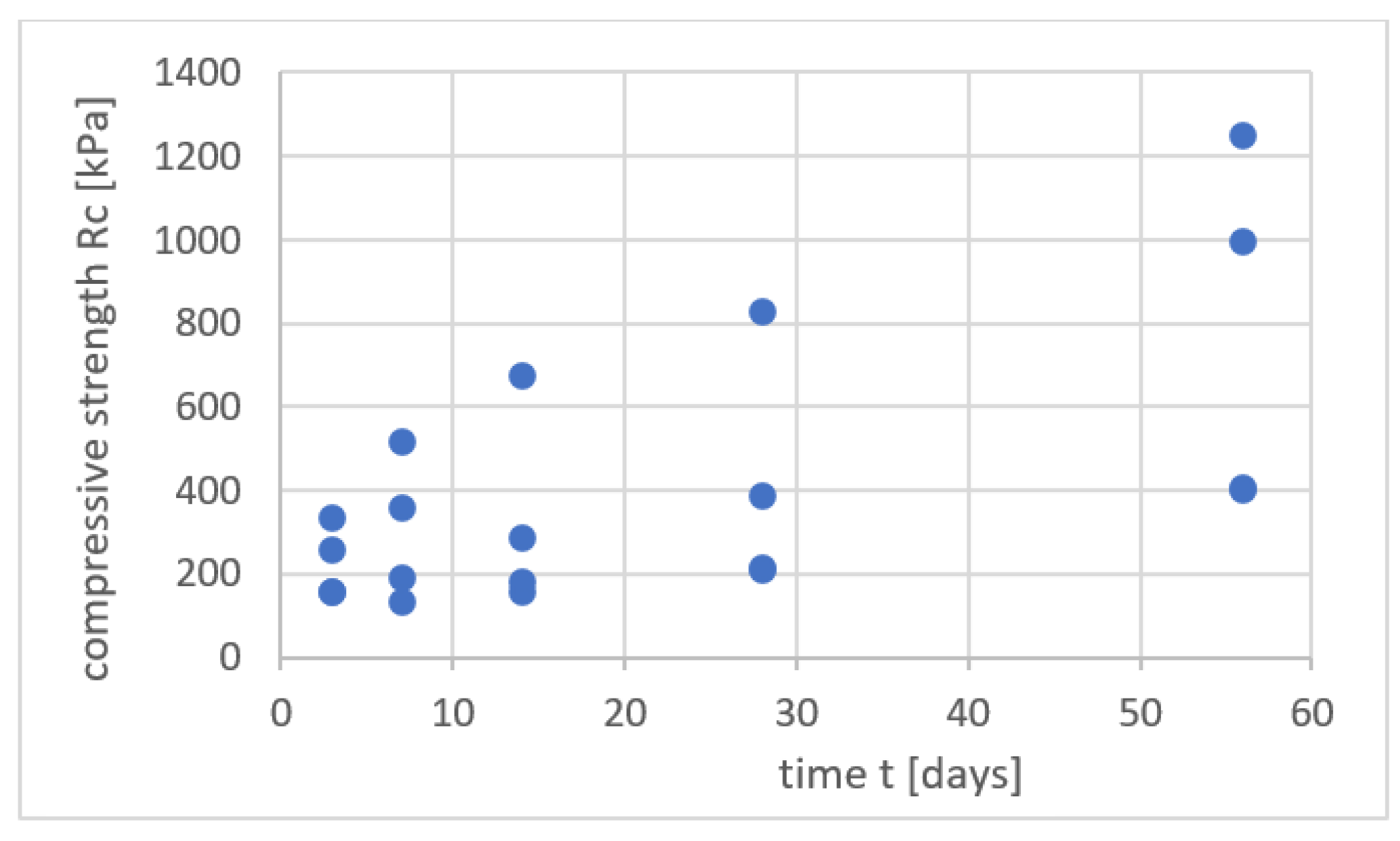

4.1. Testing of Laboratory Made Samples

- Type I—soil taken from a depth of 1–3 m + cement grout (1500 kg/m3).

- Type II—soil taken from a depth of 3–6 m + cement grout (1500 kg/m3).

- Type III—soil taken from a depth of 1–3 m + cement grout (1400 kg/m3).

- Type IV—soil taken from a depth of 1–3 m + cement grout (1400 kg/m3).

4.2. Test Results of Cylindrical Samples from the Test Site

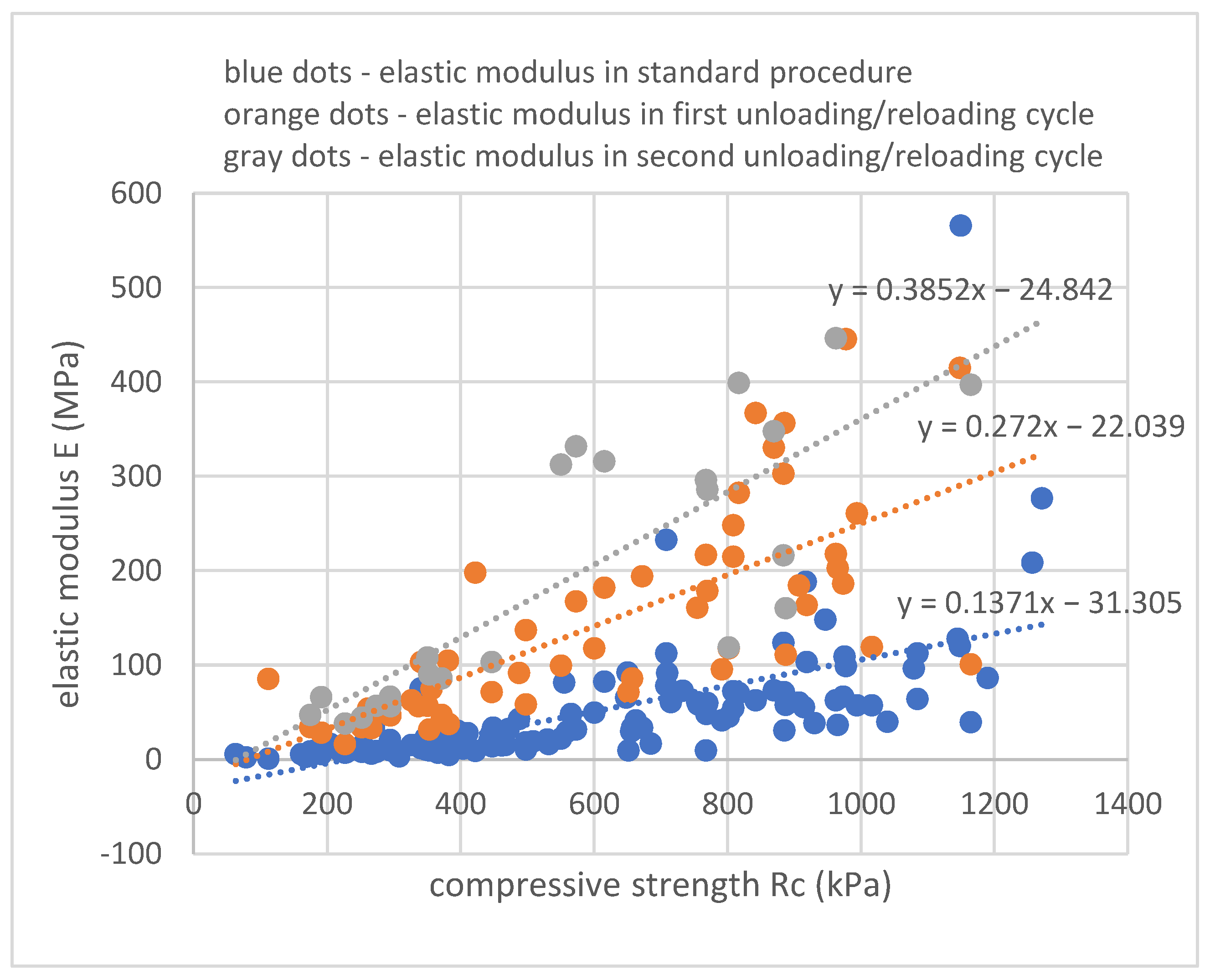

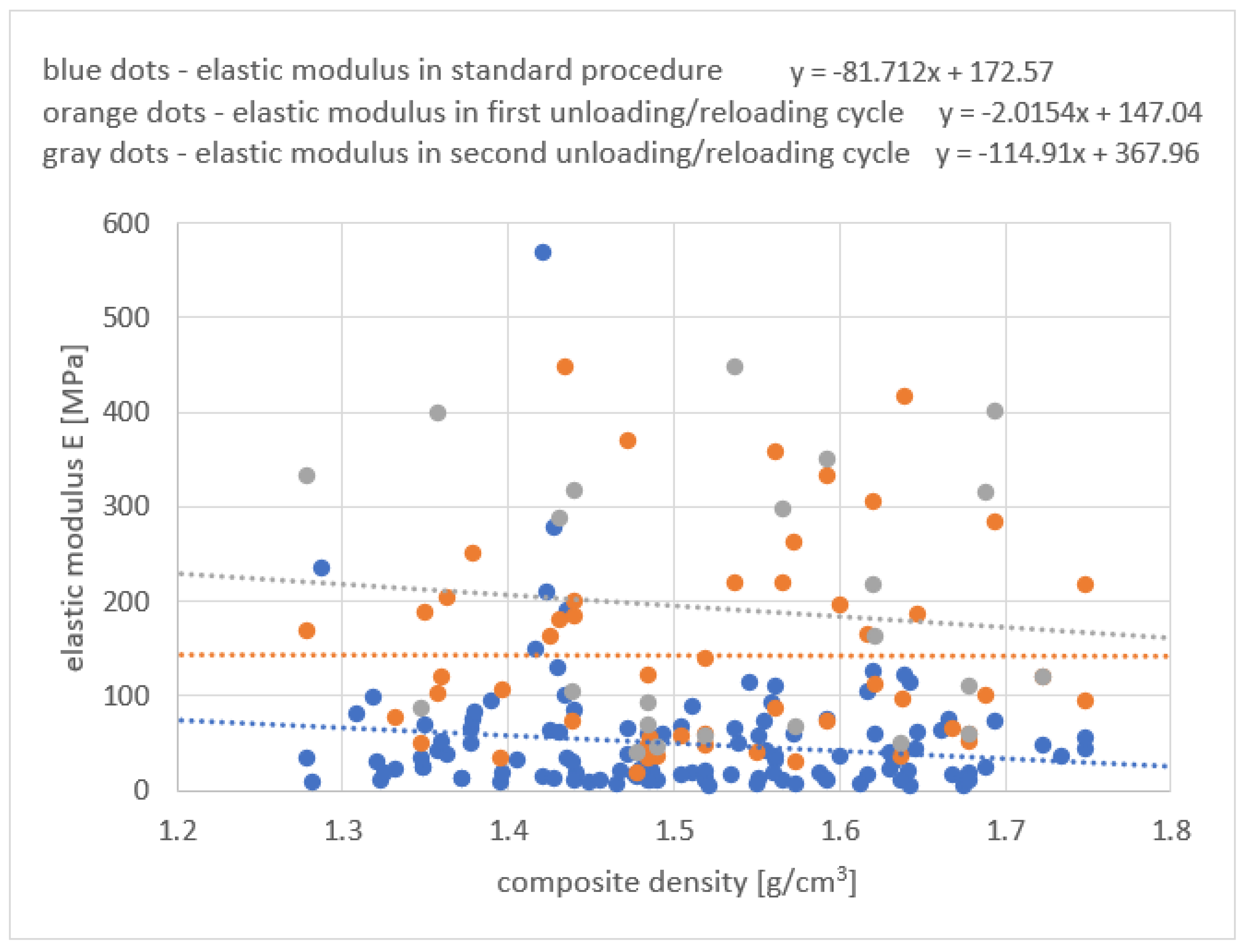

4.3. Results of Unloading/Reloading Procedures Derive Material Stiffness in Cycling Loading

4.4. Cubic Sample Test Results (From Spoils)

5. Discussion on the Conducted Research

- Despite the discussed variability of the achieved results, the general conclusion concerning the efficiency of soil improvement using deep mixing is positive. The increase in material stiffness is very significant. If we compare the initial values of the elastic modulus of plastic and organic clays and silts from Table 1 with the values gathered from the trial (reference) samples of the composite and further samples from core drilling, one may observe a very significant increase ranging from 20 to 50 times and higher. That increase in stiffness directly decreases the potential settlements of the structure founded in the improved area. Similar values can be found in other studies [12,17,26] where composite stiffness was defined by elastic modulus.

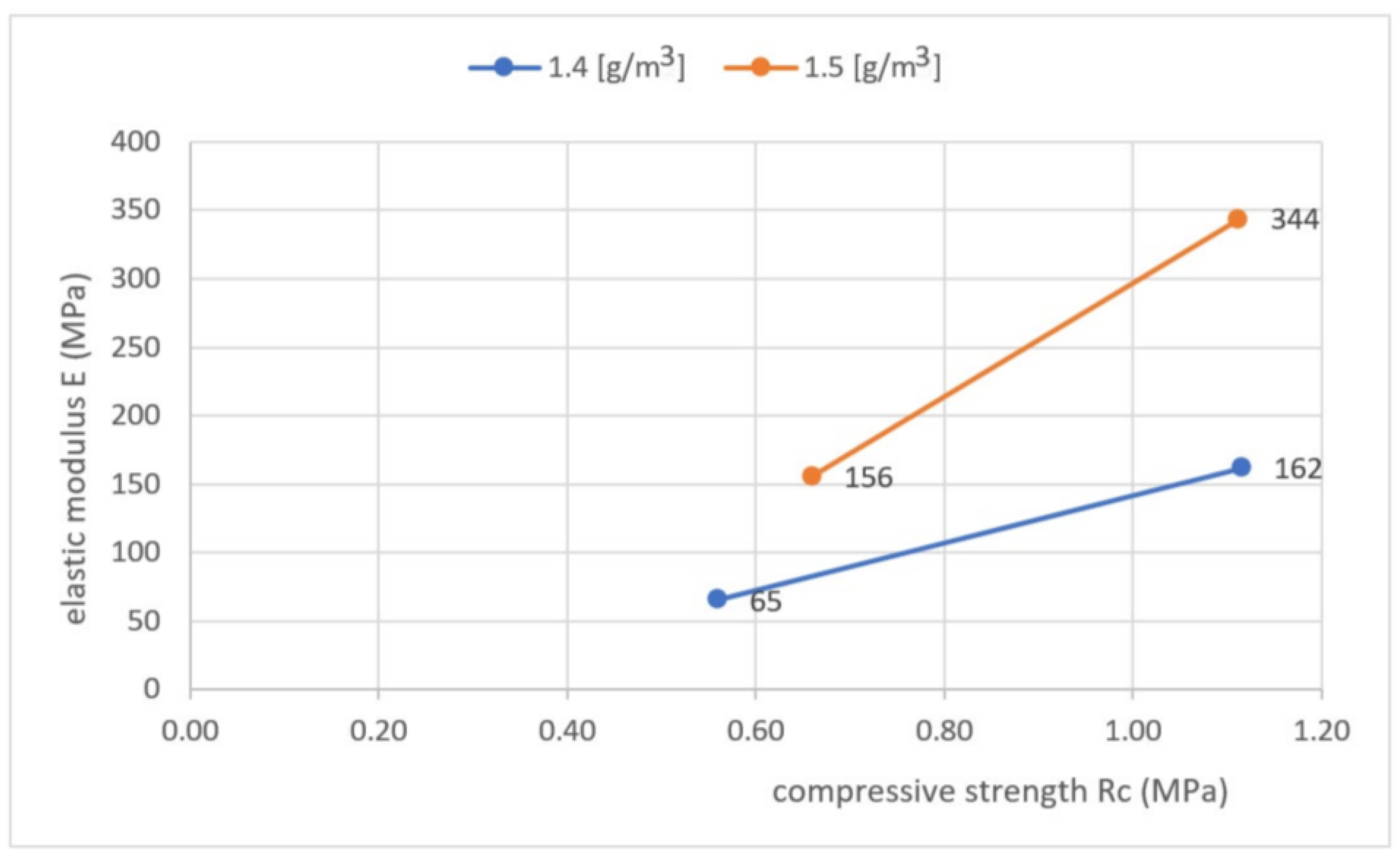

- Excessive dilution of cement grout with mixing water (increasing the water/cement W/C ratio) may facilitate the immersion of the mixing tool and speed up the execution of the works. However, it ultimately leads to increased porosity of the ground–cement material, and it potentially weakens the composite, as stated in work [12] (concerning clayey soils). Detailed studies on that issue are still in progress. The results given in Figure 15 suggest a positive impact of the opposite practice, meaning lowering the W/C ratio in order to obtain a higher capacity and stiffness of the composite. In real-world practice, that would mean a longer mixing time and, inevitably, a higher cost of execution. That is the prize for the composite’s quality.

- The use of compressed air also facilitates the immersion of the mixing tool and speeds up the execution of work. However, it also leads to a significantly increased porosity of the soil–cement composite and a very significant decrease in parameters. Looking at Figure 15, we can see again that compressed-air-supported mixing tends to lower the composite parameters.

- It should always be kept in mind that an increased porosity will lead to a decrease in the stiffness of the obtained composite (smaller modules) and a decrease in the compressive strength. In the case of “wet” mixed composites, it is not possible to “densify” them before the setting process, so any measures to facilitate the work should be cautiously considered in light of this comment. Considering dry mixing (adding a dry binding agent), it has already been confirmed (reference [26]) that mechanical compaction of the composite before setting provides positive outcomes in terms of strength and stiffness. Additional research is recommended to cover the impact of various mixing technologies on the resulting composite’s density.

- Diverse results of strength and stiffness of the samples from different levels of deep mixing indicate a lack of homogenization of the parameters of the obtained composite within the column. Each weaker interbedding (e.g., due to an increased content of organic matter) is reflected in the results of the cement–soil samples (cores) taken from this depth. The assessment of column reliability is then determined by the relationship between the thickness of the weak interbedding and the diameter of the column. Based on the observed mechanisms of destruction of cylindrical samples in triaxial tests, it can be assumed that columns with large diameters have a much greater tolerance for weak interbedding or possible inclusions (unmixed soil lumps within the column). The risk of arranging weakened zones on potential failure surfaces is lower. Similar comments were already presented by Karpisz et al. [15].

- Considering the fact that only whole fragments of the cores (not crushed during sampling) were tested, there may be doubts as to their representativeness for the entire cross-section of the column. This problem is often raised in talks with the construction supervision, which rightly somewhat questions the simple transfer of the test results of the core pieces to the entire column. On the other hand, the chaotic (random) distribution of the stronger zones reduces the probability that the weaker zones will be arranged on the failure surface. Reference samples from test batches are mixed very thoroughly and resemble those from columns formed in injection technologies, e.g., jet grouting. The advantage of DSM columns, however, is the guaranteed diameter (sometimes enlarged in relation to the dimensions of the mixing tool), which ensures column strength despite the potential lack of perfect mixing. That issue was already discussed in the work [36], where the variability of composite parameters was presented in light of statistical analysis.

6. Short Conclusions

- Soil–cement composites manifest a large variability of results concerning both compressive strength and the elastic modulus.

- The stiffness of soil–cement composites increases significantly in the subsequent stages of loading. The pre-loading of soil–cement composites is recommended.

- The quality of mixing plays a decisive role in material homogenization, but the effect of size should not be neglected. A one-week sample within a column should not question the quality of the whole structure.

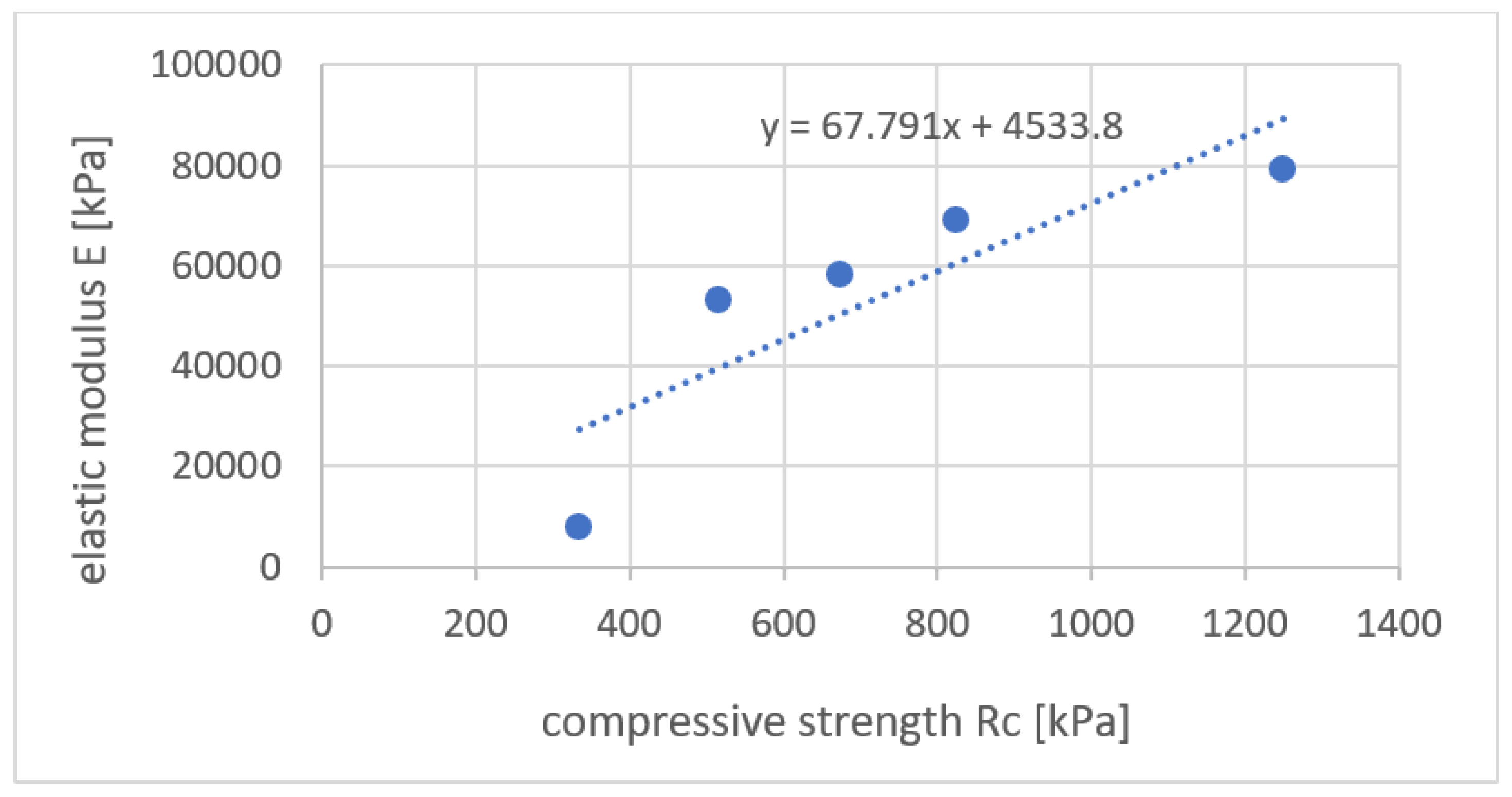

- The presented studies provide valuable qualitative information for the numerical modeling of soil–cement composites. The elastic modulus for the simplest elastic model of a soil body may be derived on the basis of uniaxial compressive strength.

- In every case, field testing before the execution of work is the best way to avoid negative surprises concerning material quality due to the interaction between the soil, binder, and mixing tools. Our study tended to point to some trends that should be considered at an early stage of deep soil mixing design (outline proposals).

7. Recommendations for Further Activities

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Terashi, M. Theme lecture: Deep mixing method—Brief state of the art. In Proceedings of the 14th International Conference of Soil Mechanics and Foundation Engineering, Hamburg, Germany, 6–12 September 1997; Volume 4, pp. 2475–2478. [Google Scholar]

- IHS BRE. Design Guide: Soft Soil Stabilisation: EuroSoilStab: Development of Design and Construction Methods to Stabilise Soft Organic Soils; IHS BRE Press: Reading, UK, 2010; ISBN -1860815995. [Google Scholar]

- Topolnicki, M. Design and execution practice of wet Soil Mixing in Poland. In Proceedings of the International Symposium on Deep Mixing & Admixture Stabilization, Okinawa, Japan, 19–21 May 2009; pp. 195–202. [Google Scholar]

- Topolnicki, M. Geotechnical design and performance of road and railway viaducts supported on DSM columns—A summary of practice. In Proceedings of the International Conference on Deep Mixing, San Francisco, CA, USA, 2–5 June 2015; pp. 1–20. [Google Scholar]

- Duszyński, R.; Duszyńska, A.; Cantré, S. New experiences in dike construction with soil-ash composites and fine-grained dredged materials. Stud. Geotech. Mech. 2017, 39, 17–24. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, L.; Yang, Q.; Wang, Z.; Cheng, A.; Mo, L.; Yan, J. Permeability and Disintegration Characteristics of Composite Improved Phyllite Soil by Red Clay and Cement. Minerals 2023, 13, 32. [Google Scholar] [CrossRef]

- Xia, W.-Y.; Du, Y.-J.; Li, F.-S.; Li, C.-P.; Yan, X.-L.; Arulrajah, A.; Wang, F.; Song, D.-J. In-situ solidification/stabilization of heavy metals contaminated site soil using a dry jet mixing method and new hydroxyapatite based binder. J. Hazard. Mater. 2019, 369, 353–361. [Google Scholar] [CrossRef]

- Prakash, K.G.; Krishnamoorthy, A. Effectiveness of Stone and Deep Mixing Lime Columns on Stability of Embankments Constructed on Soft Consolidating Soil. Geotech. Geol. Eng. 2023, 41, 533–552. [Google Scholar] [CrossRef]

- Muhmed, A.; Mohamed, M.; Khan, A. The Impact of Moisture and Clay Content on the Unconfined Compressive Strength of Lime Treated Highly Reactive Clays. Geotech. Geol. Eng. 2022, 40, 5869–5893. [Google Scholar] [CrossRef]

- Lindh, P.; Lemenkova, P. Shear bond and compressive strength of clay stabilised with lime/cement jet grouting and deep mixing: A case of Norvik, Nynäshamn. Nonlinear Eng. 2022, 11, 693–710. [Google Scholar] [CrossRef]

- Leśniewska, A. Strength and technological issues of soil improvement by means of Deep Soil Mixing Wet technology. Ph.D. Thesis, Gdańsk University of Science and Technology, Gdańsk, Poland, 2007. (In Polish). [Google Scholar]

- Brasse, K.; Tracz, T.; Zdeb, T.; Rychlewski, P. Influence of Soil-Cement Composition on its Selected Properties. MATEC Web Conf. 2018, 163, 06006. [Google Scholar] [CrossRef][Green Version]

- Jendrysik, K.; Kiecana, M.; Szabowicz, H. Preliminary results of dry Deep Soil Mixing soil-cement composite testing. MATEC Web Conf. 2018, 251, 01025. [Google Scholar] [CrossRef]

- Dou, H.; Wang, Y. Strength of deep mixed soft clay with cement. In Proceedings of the 16th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, ARC 2019, Taipei, Taiwan, 14–18 October 2019. [Google Scholar]

- Karpisz, I.; Pyda, J.; Cichy, L.; Sobala, D. Study of the effect of cement amount on the soil-cement sample strength. IOP Conf. Ser. Mater. Sci. Eng. 2018, 365, 042061. [Google Scholar] [CrossRef]

- Tatsuoka, F.; Kohata, Y.; Uchida, K.; Imai, K. Deformation and Strength Characteristics of Cement-Treated Soils in Trans-Tokyo Bay Highway Project. In Proceedings of the Grouting and Deep Mixing: Proceedings of IS-Tokyo 96 2nd International Conference on Ground Improvement Geosystems, Tokyo, Japan, 14–17 May 1996; pp. 453–459.

- Karpisz, I.; Jaworski, K. Study of compressive strength evolution in soil cement samples with fly-ash admixtures. IOP Conf. Ser. Mater. Sci. Eng. 2018, 365, 032049. [Google Scholar] [CrossRef]

- Jamsawang, P.; Adulyamet, B.; Voottipruex, P.; Jongpradist, P.; Likitlersuang, S.; Tantayopin, K. The free swell potential of expansive clays stabilized with the shallow bottom ash mixing method. Eng. Geol. 2023, 315, 107027. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, M.; Disfani, M.M.; Horpibulsuk, S.; Bo, M.W.; Leong, M. Evaluation of fly ash- and slag-based geopolymers for the improvement of a soft marine clay by deep soil mixing. Soils Found. 2018, 58, 1358–1370. [Google Scholar] [CrossRef]

- Mypati, V.N.K.; Saride, S. Feasibility of Alkali-Activated Low-Calcium Fly Ash as a Binder for Deep Soil Mixing. J. Mater. Civ. Eng. 2022, 34, 04021410. [Google Scholar] [CrossRef]

- Paniagua, P.; Ritter, S.; Moseid, M.; Okkenhaug, G. Bioashes and steel slag as alternative binders in ground improvement of quick clays. In Geo-Congress 2023; American Society of Civil Engineers: Reston, VA, USA, 2023; pp. 25–34. [Google Scholar] [CrossRef]

- Sharma, J.K.; Grover, K.S.; Tak, D. Experimental Study of Engineering Properties of Kota Stone Slurry Powder and Fly Ash Mixed Expansive Soil. Lect. Notes Civ. Eng. 2021, 134, 201–216. [Google Scholar] [CrossRef]

- Toksöz Hozatlıoğlu, D.; Yılmaz, I. Shallow mixing and column performances of lime, fly ash and gypsum on the stabilization of swelling soils. Eng. Geol. 2021, 280, 105931. [Google Scholar] [CrossRef]

- Ermolovich, E.A.; Ivannikov, A.L.; Khayrutdinov, M.M.; Kongar-Syuryun, C.B.; Tyulyaeva, Y.S. Creation of a Nanomodified Backfill Based on the Waste from Enrichment of Water-Soluble Ores. Materials 2022, 15, 3689. [Google Scholar] [CrossRef] [PubMed]

- Khayrutdinov, A.; Paleev, I.; Artemov, S. Replacement of traditional components of the backfill mixture with man-made waste. IOP Conf. Ser. Earth Environ. Sci. 2021, 942, 012005. [Google Scholar] [CrossRef]

- Ding, F.; Song, L.; Yue, F. Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method. Processes 2022, 10, 324. [Google Scholar] [CrossRef]

- Forsman, J.; Jyrävä, H.; Lahtinen, P.; Niemelin, T.; Hyvönen, I. Mass Stabilization Manual. Available online: http://projektit.ramboll.fi/massastabilointi/materials/mass_stabilization_manual_2015.pdf (accessed on 10 May 2023).

- Jendrysik, K.; Jończyk, M.; Kanty, P. Mass stabilization as a modern method of substrate strengthening. Mater. Today Proc. 2021, 38, 2068. [Google Scholar] [CrossRef]

- Egorova, A.A.; Rybak, J.; Stefaniuk, D.; Zajączkowski, P. Basic aspects of deep soil mixing technology control. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022019. [Google Scholar] [CrossRef]

- Kanty, P.; Rybak, J.; Stefaniuk, D. Some remarks on practical aspects of laboratory testing of deep soil mixing composites achieved in organic soils. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022018. [Google Scholar] [CrossRef]

- Kiecana, M.; Kanty, P.; Łużyńska, K. Optimal control time evaluation for “dry DSM” soil-cement composites. MATEC Web Conf. 2018, 251, 01023. [Google Scholar] [CrossRef]

- Chaumeny, J.L.; Kanty, P.; Reitmeier, T. Remarks on wet deep soil mixing quality control. In Proceedings of the XVI DECGE 2018 Proceedings of the 16th Danube—European Conference on Geotechnical Engineering, Skopje, Republic of Macedonia, 7–9 June 2018; Paper No. 039.

- Jendrysik, K.; Pachnicz, M.; Dudziński, P. Parameters of the constitutive model of geomaterials formed with the use of DSM dry technology. E3S Web Conf. 2019, 97, 02028. [Google Scholar] [CrossRef]

- Abdullah, H.H.; Shahin, M.A. Geomechanical Behaviour of Clay Stabilised with Fly-Ash-Based Geopolymer for Deep Mixing. Geosciences 2022, 12, 207. [Google Scholar] [CrossRef]

- Sakai, T.; Nakano, M. Attempt to reproduce the mechanical behavior of cement-treated soil using elasto-plastic model considering soil skeleton structure. Soils Found. 2021, 61, 1464–1474. [Google Scholar] [CrossRef]

- Kanty, P.; Kiecana, M.; Prokopowicz, P. Some remarks on statistic approach to strength testing of soil-cement composites. E3S Web Conf. 2019, 97, 04045. [Google Scholar] [CrossRef]

- Wincenty Solecki. Geotechnical Opinion for the Determination of Soil and Water Conditions on Plots No. 723/1 and 727/1 in Bolechowice; GeoVis Wincenty Solecki: Więckowice, Poland, 2021. [Google Scholar]

- Ostrowski, L. Determination of Strength and Deformation Parameters of Cement-Soils. Tests of Uniaxial Compressive Strength and Oedometric Compressibility Modulus; AGH University of Science and Technology: Kraków, Poland, 2022. [Google Scholar]

- Bruce, M.E.C.; Berg, R.R.; Collin, J.G.; Filz, G.M.; Terashi, M.; Yang, D.S. Federal Highway Administration Design Manual: Deep Mixing for Embankment and Foundation Support. Report No. FHWA-HRT-13-046. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/structures/bridge/13046/index.cfm (accessed on 10 May 2023).

- EN ISO 17892-7:2018; Geotechnical Investigation and Testing—Laboratory Testing of soil—Part 7: Unconfined Compression Test. ISO: Geneva, Switzerland, 2018.

- Decký, M.; Drusa, M.; Papán, D.; Šrámek, J. The Relationship between Dynamic and Static Deformation Modulus of Unbound Pavement Materials Used for Their Quality Control Methodology. Materials 2022, 15, 2922. [Google Scholar] [CrossRef] [PubMed]

- Gago, F.; Valletta, A.; Mužík, J. Formulation of a Basic Constitutive Model for Fine—Grained Soils Using the Hypoplastic Framework. Civ. Environ. Eng. 2021, 17, 450–455. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P. Analysis of Measuring the Deformation Resistance of the SubgradeSurface of a Modernised Line Považská Teplá—Žilina. Civ. Environ. Eng. 2020, 16, 210–218. [Google Scholar] [CrossRef]

- Izvolt, L.; Dobes, P.; Drusa, M.; Kadela, M.; Holesova, M. Experimental and Numerical Verification of the Railway Track Substructure with Innovative Thermal Insulation Materials. Materials 2022, 15, 160. [Google Scholar] [CrossRef]

| Type of Soil | Depth | Plasticity/Density Index | Density | Cohesion c | Internal Friction Angle ϕ | Elastic Modulus E |

|---|---|---|---|---|---|---|

| m | IL/ID | g/cm3 | kPa | ° (deg) | MPa | |

| Ia—silty clay | 0–1 | 0.10 | 2.08 | 8.9 | 31.7 | - |

| Ib—silt | 1–3, 4–6 | 0.42–0.81 | 1.96 | 1.2 | 17.7 | 1.8–7.7 |

| IIa—mud | 3–4 | 0.36 | 1.60 | 15.7 | 17.3 | 2.7 |

| Iib—peat | 4–5 | - | - | - | - | - |

| IIIa—sand | 6–9 | 0.78 | 1.90 | - | 31.2 | 34.9 |

| IIIb—sand | 9–10 | 0.78 | 2.00 | - | 35.9 | 79.6 |

| Time of Curing | Density | Compressive Strength | Critical Deformation | Elastic Modulus |

|---|---|---|---|---|

| Days | g/cm3 | kPa | % | MPa |

| 3 | 1.740 | 335.52 | 2.8 | 7.721 |

| 7 | 1.724 | 516.66 | 2.0 | 52.886 |

| 14 | 1.775 | 674.20 | 2.1 | 58.131 |

| 28 | 1.683 | 825.67 | 2.3 | 68.926 |

| 56 | 1.510 | 1249.45 | 1.9 | 79.153 |

| Time of Curing | Density | Compressive Strength | Critical Deformation | Elastic Modulus |

|---|---|---|---|---|

| Days | g/cm3 | kPa | % | MPa |

| 3 | 1.840 | 256.01 | 2.0 | 27.584 |

| 7 | 1.782 | 355.71 | 1.6 | 10.761 |

| 14 | 1.796 | 285.14 | 1.5 | 29.323 |

| 28 | 1.725 | 385.16 | 2.7 | 12.89 |

| 56 | 1.534 | 995.46 | 1.2 | 116.987 |

| Time of Curing | Density | Compressive Strength | Critical Deformation | Elastic Modulus |

|---|---|---|---|---|

| Days | g/cm3 | kPa | % | MPa |

| 3 | 1.720 | 158.43 | 4.3 | 7.131 |

| 7 | 1.724 | 133.45 | 5.6 | 7.117 |

| 14 | 1.764 | 154.74 | 2.6 | 7.030 |

| 28 | 1.674 | 215.22 | 4.9 | 6.560 |

| 56 | 1.474 | 407.57 | 4.6 | 9.193 |

| Time of Curing | Density | Compressive Strength | Critical Deformation | Elastic Modulus |

|---|---|---|---|---|

| Days | g/cm3 | kPa | % | MPa |

| 3 | 1.698 | 155.59 | 2.6 | 9.377 |

| 7 | 1.714 | 192.03 | 1.6 | 29.424 |

| 14 | 1.743 | 179.63 | 2.3 | 25.155 |

| 28 | 1.658 | 208.71 | 3.9 | 15.182 |

| 56 | 1.430 | 398.85 | 2.5 | 44.846 |

| Number of the Sample | Density | Compressive Strength | Critical Deformation | Elastic Modulus |

|---|---|---|---|---|

| g/cm3 | kPa | % | MPa | |

| 1 | 1.547 | 491.32 | 2.70% | 18.571 |

| 2 | 1.444 | 796.96 | 2.80% | 54.026 |

| 3 | 1.658 | 565.76 | 3.20% | 61.36 |

| 4 | 1.628 | 226.44 | 3.00% | 9.193 |

| 5 | 1.407 | 941.14 | 4.20% | 74.91 |

| 6 | 1.447 | 949.72 | 2.70% | 69.351 |

| 7 | 1.508 | 730.91 | 3.70% | 29.729 |

| 8 | 1.631 | 359.22 | 3.10% | 16.204 |

| 9 | ||||

| 10 | 1.536 | 802.55 | 2.40% | 87.131 |

| 11 | 1.424 | 317.04 | 3.60% | 10.958 |

| 12 | ||||

| 13 | 1.474 | 1315.14 | 1.60% | 124.869 |

| 14 | 1.509 | 518.64 | 3.00% | 27.207 |

| 15 | 1.432 | 702.72 | 3.20% | 15.983 |

| 16 | 1.603 | 760.64 | 3.40% | 24.394 |

| 17 | 1.393 | 868.24 | 1.90% | 96.733 |

| 18 | 1.671 | 1563.24 | 3.00% | 111.525 |

| 19 | 1.444 | 796.96 | 2.80% | 54.026 |

| 20 | 1.552 | 315.06 | 1.90% | 28.258 |

| 21 | 1.697 | 281.36 | 5.00% | 5.464 |

| 22 | 1.307 | 440.26 | 2.10% | 23.321 |

| 23 | 1.606 | 804.4 | 2.60% | 71.167 |

| 24 | 1.347 | 649.52 | 2.70% | 29.878 |

| 25 | 1.641 | 1045.67 | 2.70% | 196.195 |

| 26 | 1.512 | 436.46 | 2.80% | 19.493 |

| 27 | 1.67 | 364.09 | 3.70% | 38.004 |

| 28 | 1.53 | 1112.81 | 2.60% | 53.951 |

| Name of Sample | Density | Compressive Strength | Critical Deformation | Elastic Modulus |

|---|---|---|---|---|

| Days | g/cm3 | kPa | % | MPa |

| Solid 1.4 | 1.424 | 1116.354 | 1.20% | 161.791 |

| Solid 1.4 + air | 1.380 | 560.559 | 1.30% | 65.209 |

| Solid 1.4 | 1.429 | 1112.970 | 0.80% | 343.852 |

| Solid 1.4 + air | 1.298 | 660.505 | 1.30% | 155.771 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jończyk-Szostek, M.; Kanty, P.; Rybak, J.; Saloni, J.; Trybocka, K. Uniaxial Testing of Soil–Cement Composites to Obtain Correlations to Be Used in Numerical Modeling. Appl. Sci. 2023, 13, 10268. https://doi.org/10.3390/app131810268

Jończyk-Szostek M, Kanty P, Rybak J, Saloni J, Trybocka K. Uniaxial Testing of Soil–Cement Composites to Obtain Correlations to Be Used in Numerical Modeling. Applied Sciences. 2023; 13(18):10268. https://doi.org/10.3390/app131810268

Chicago/Turabian StyleJończyk-Szostek, Małgorzata, Piotr Kanty, Jarosław Rybak, Jakub Saloni, and Karolina Trybocka. 2023. "Uniaxial Testing of Soil–Cement Composites to Obtain Correlations to Be Used in Numerical Modeling" Applied Sciences 13, no. 18: 10268. https://doi.org/10.3390/app131810268

APA StyleJończyk-Szostek, M., Kanty, P., Rybak, J., Saloni, J., & Trybocka, K. (2023). Uniaxial Testing of Soil–Cement Composites to Obtain Correlations to Be Used in Numerical Modeling. Applied Sciences, 13(18), 10268. https://doi.org/10.3390/app131810268