Estimation of Compressive Resistance of Briquettes Obtained from Groundnut Shells with Different Machine Learning Algorithms

Abstract

:1. Introduction

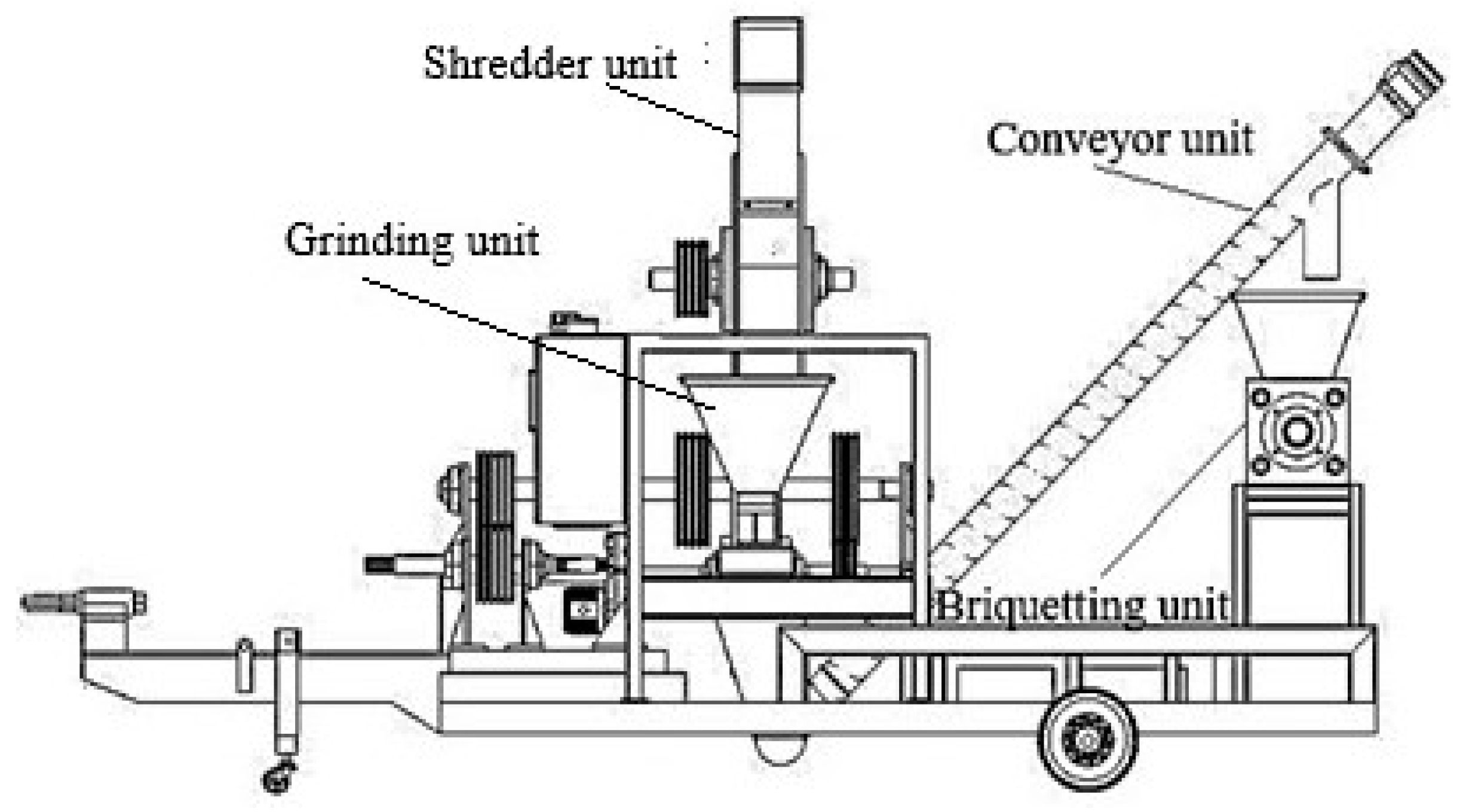

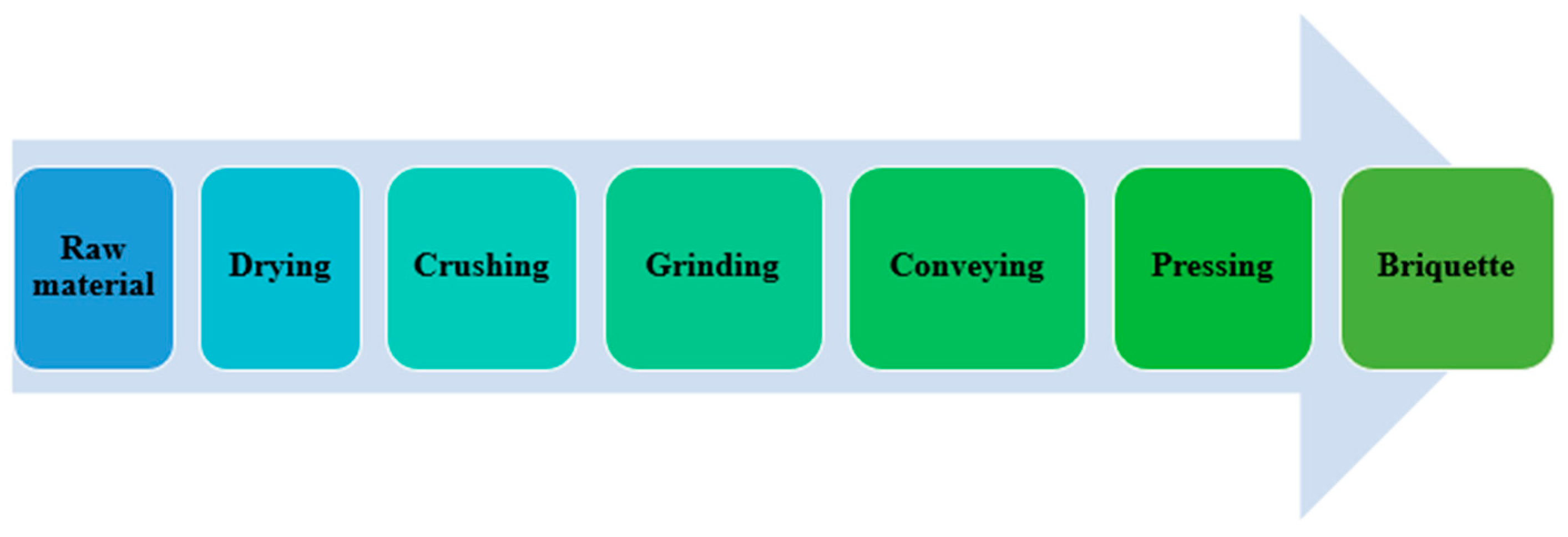

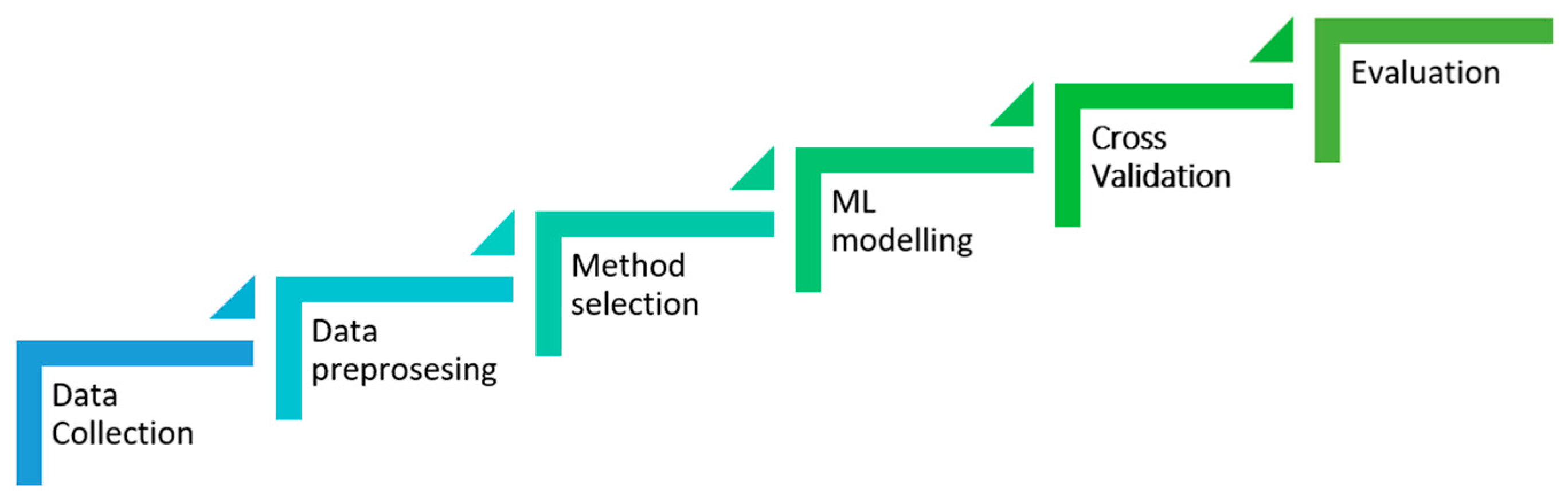

2. Materials and Methods

2.1. Briquetting Procedure

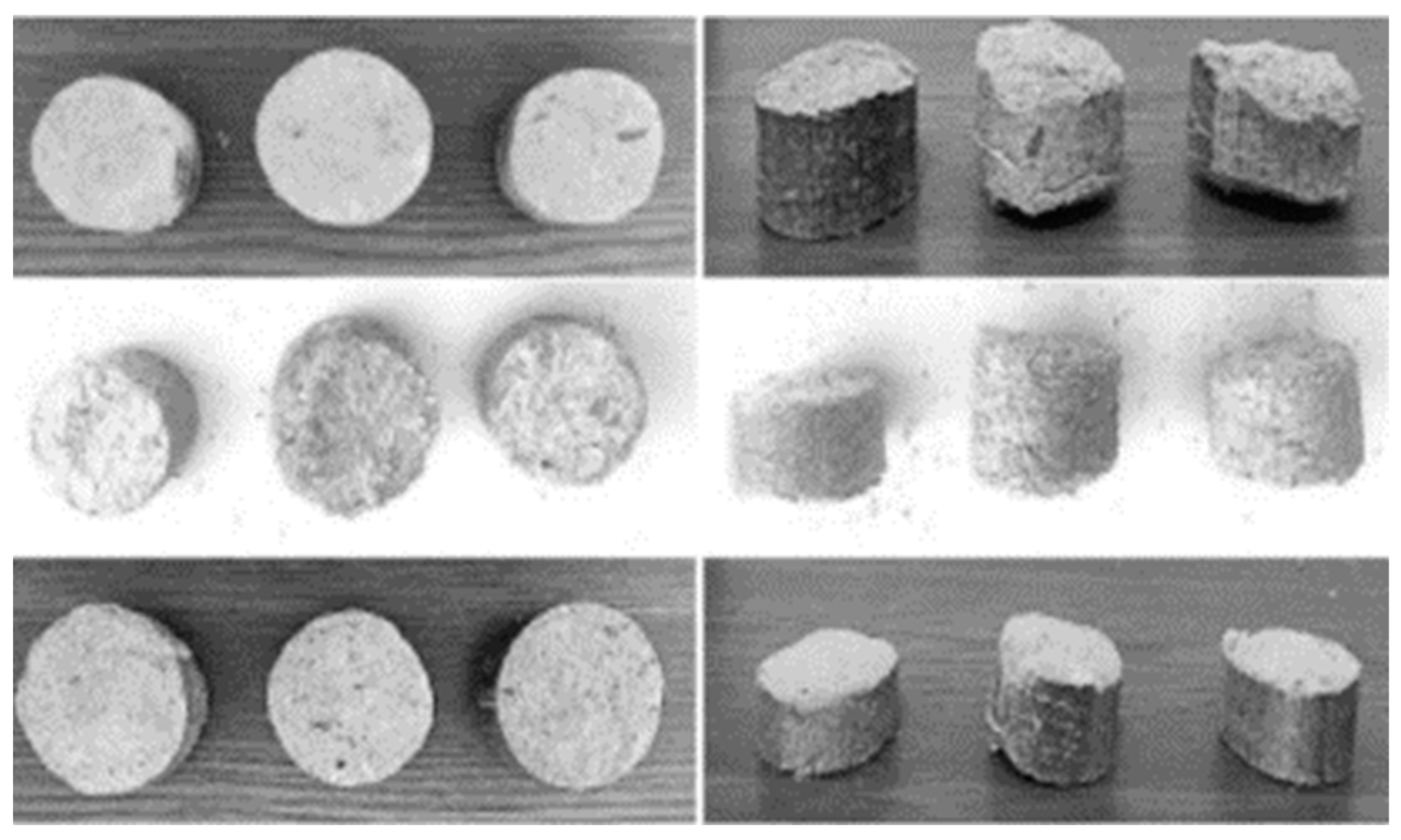

2.2. Experimental Measurements of Briquettes Quality

2.3. Data Collection

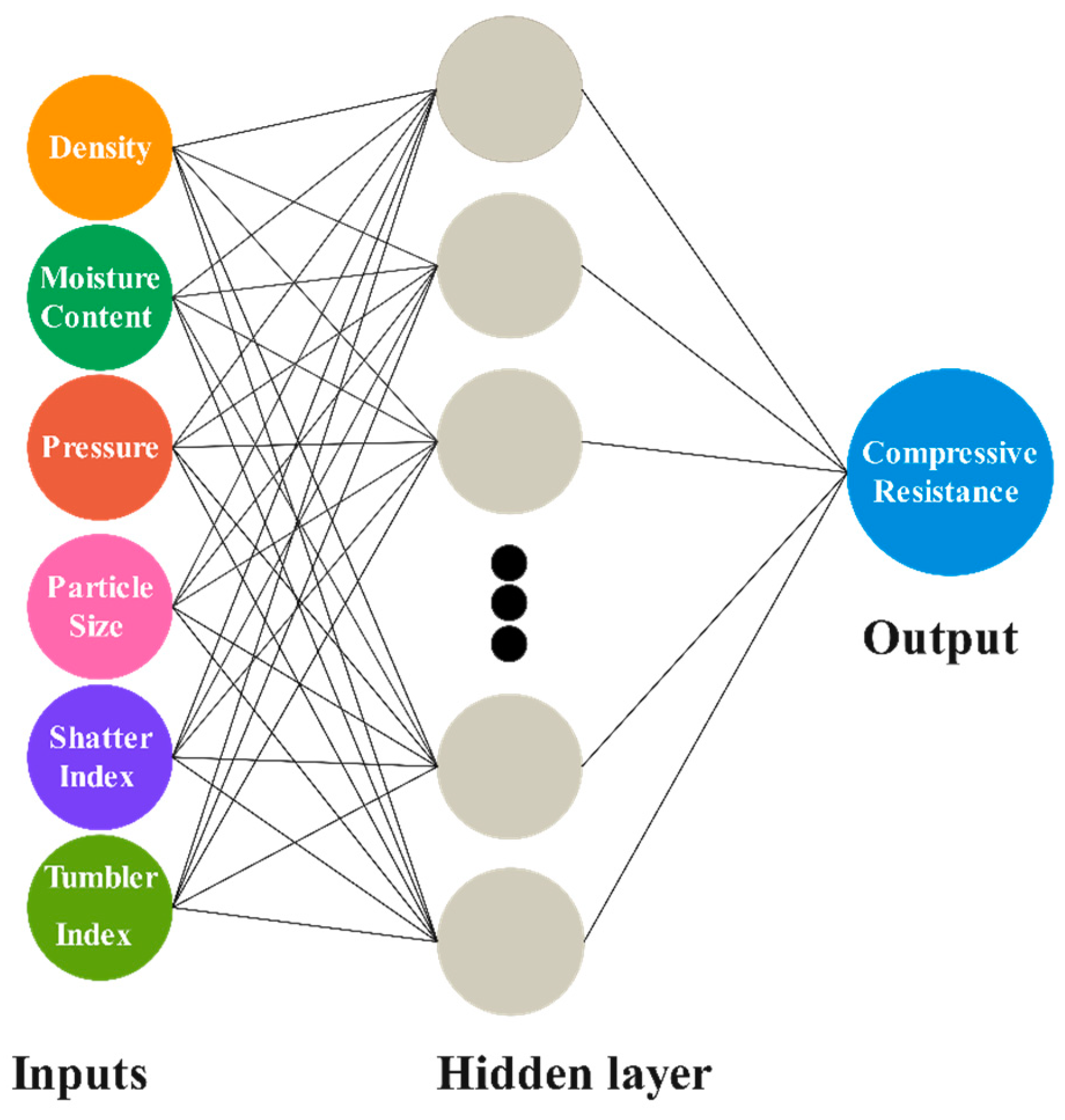

2.4. Machine Learning Models

2.4.1. Random Forest

2.4.2. Extra Trees

2.4.3. Light Gradient Boosting

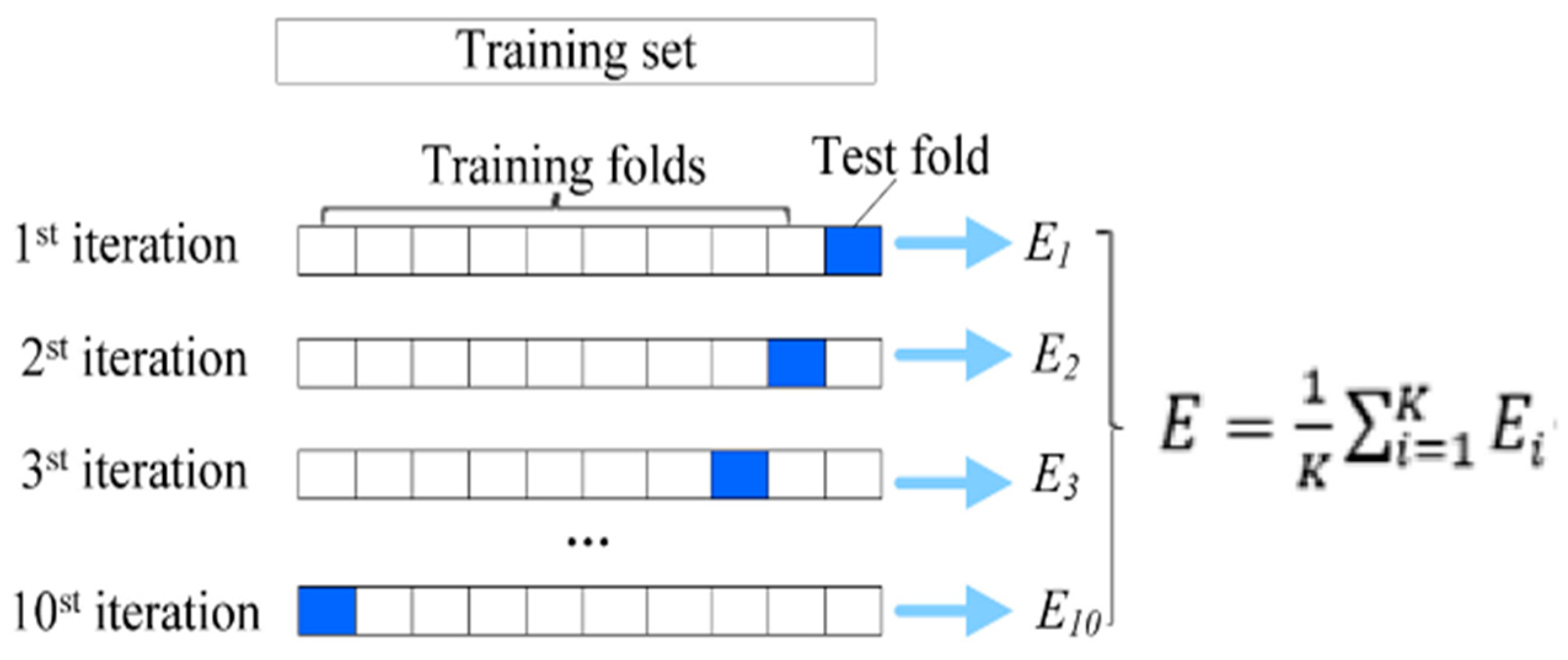

2.5. K-Fold Cross-Validation

2.6. Model Evaluation

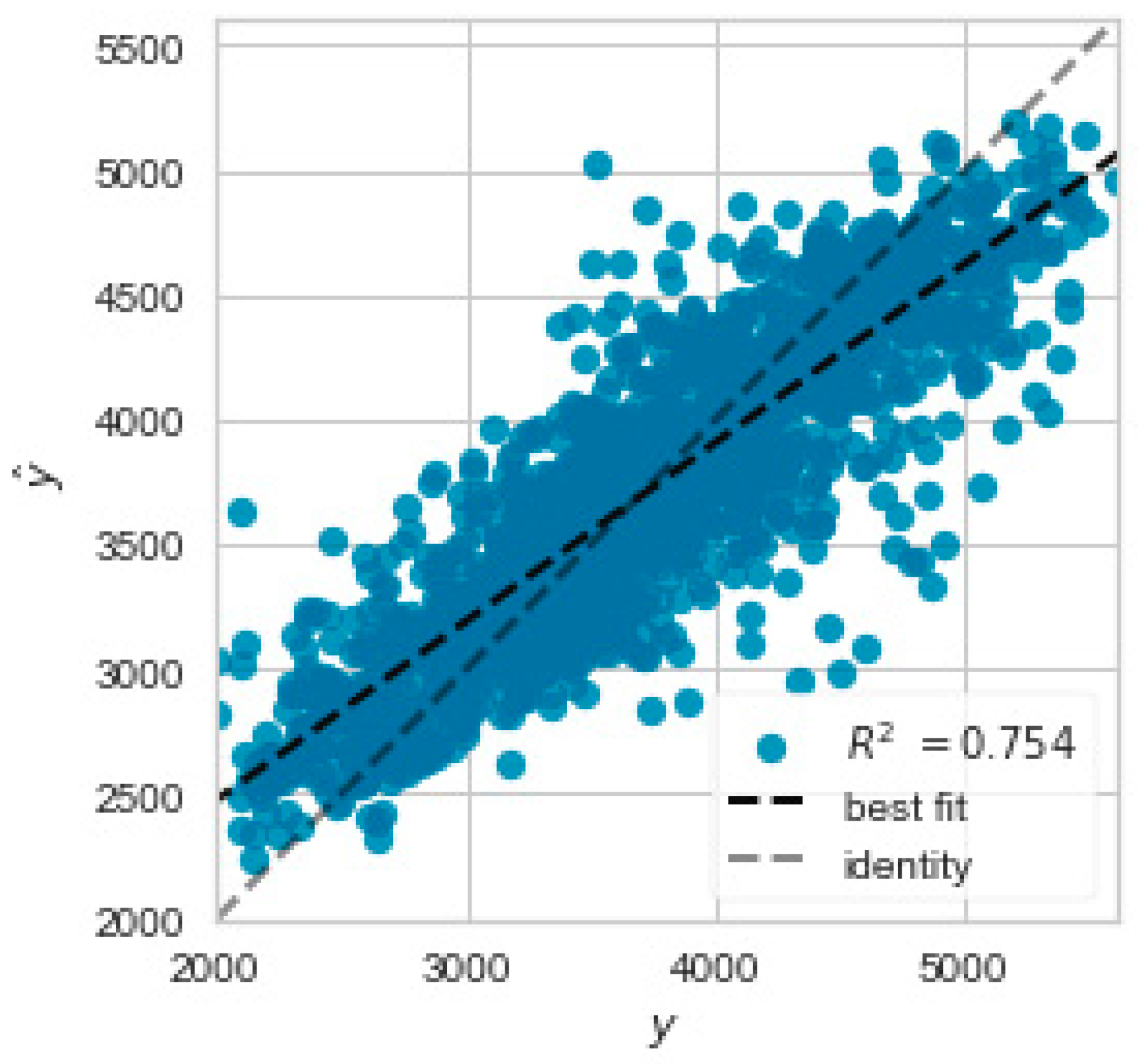

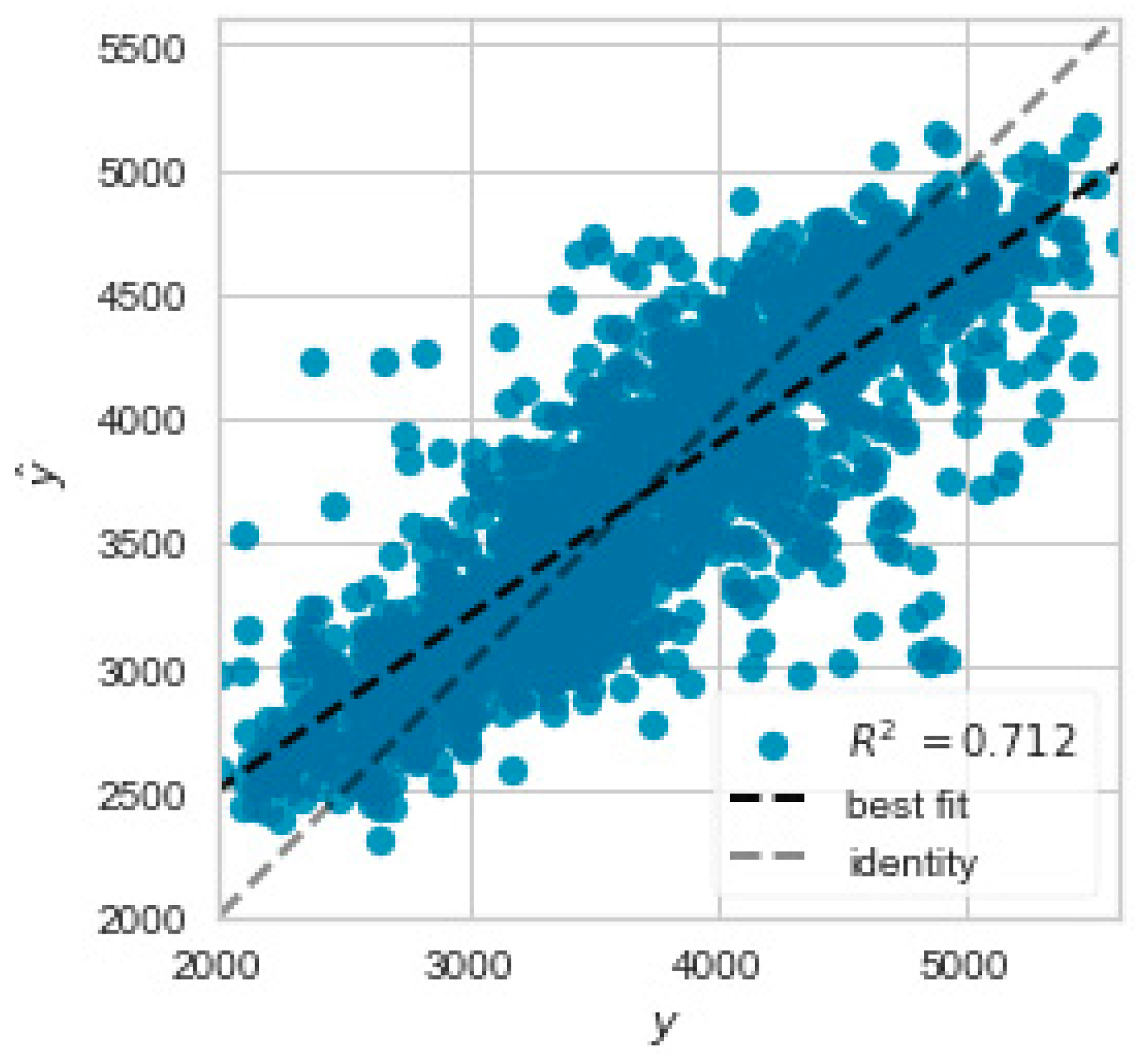

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grover, P.D.; Mishra, S.K. Biomass Briquetting: Technology and Practices; FAO Regional Wood Energy Development Programme in Asia: Bangkok, Thailand, 1996. [Google Scholar]

- Gürdil, G.A.K.; Demirel, B. Effect of moisture content, particle size and pressure on some briquetting properties of hazelnut residues. Anadolu J. Agric. Sci. 2020, 35, 330–338. [Google Scholar] [CrossRef]

- Sims, R.; Mabee, W.; Saddler, J.; Taylor, M. An overview of second generation biofuel technologies. Bioresour. Technol. 2010, 101, 1570–1580. [Google Scholar] [PubMed]

- Ajimotokan, H.; Ibitoye, S.; Odusote, J.; Omoniyi, P. Physico-mechanical properties of composite briquettes from corn-cob and rice husk. J. Bioresour. Bioprod. 2019, 4, 159–165. [Google Scholar]

- Ketov, A.; Sliusar, N.; Tsybina, A.; Ketov, I.; Chudinov, S.; Krasnovskikh, M. Plant Biomass Conversion to Vehicle Liquid Fuel as a Path to Sustainability. Resources 2022, 11, 75. [Google Scholar] [CrossRef]

- Kabaş, Ö.; Ünal, İ.; Sözer, S. Quality assessment of bio-briquettes obtained from nut fruit shells. Mitteilungen Klosterneubg. 2022, 72, 222–237. [Google Scholar]

- Orisaleye, J.; Jekayinfa, S.; Dittrich, C.; Obi, O.; Pecenka, R. Effects of Feeding Speed and Temperature on Properties of Briquettes from Poplar Wood Using a Hydraulic Briquetting Press. Resources 2023, 12, 12. [Google Scholar]

- Kabaş, Ö.; Ünal, İ.; Sözer, S.; Selvi, K.; Ungureanu, N. Quality Assessment of Biofuel Briquettes Obtained from Green-house Waste Using a Mobile Prototype Briquetting Machine with PTO Drive. Energies 2022, 15, 8371. [Google Scholar] [CrossRef]

- Aldarabseh, S.M. Experimental investigation of the durability and stability of compressed jojoba cake briquettes. Biomass Convers Biorefinery 2023. [Google Scholar] [CrossRef]

- Pecenka, R.; Clifford, M.; Obi, O.F.; Clifford, M.J. A review of biomass briquette binders and quality parameters. Energies 2022, 15, 2426. [Google Scholar] [CrossRef]

- Kumar, G.; Thampi, B.S.G.; Mondal, P.K. Predicting Performance of Briquette Made from Millet Bran: A Neural Net-work Approach. Adv. J. Grad. Res. 2020, 9, 1–13. [Google Scholar] [CrossRef]

- Benli, H. Determination of thermal performance calculation of two different types solar air collectors with the use of artificial neural networks. Int. J. Heat Mass. Transf. 2013, 60, 1–7. [Google Scholar] [CrossRef]

- Tian, Z.; Qian, C.; Gu, B.; Yang, L.; Liu, F. Electric vehicle air conditioning system performance prediction based on artificial neural network. Appl. Therm. Eng. 2015, 89, 101–114. [Google Scholar] [CrossRef]

- Zhong, H.; Wei, Z.; Man, Y.; Pan, S.; Zhang, J.; Niu, B.; Yu, X.; Ouyang, Y.; Xiong, Q. Prediction of instantaneous yield of bio-oil in fluidized bio-mass pyrolysis using long short-term memory network based on computational fluid dynamics data. J. Clean. Prod. 2023, 391, 136192. [Google Scholar] [CrossRef]

- Yağmur, A.; Kayakuş, M.; Terzioğlu, M. Predicting renewable energy production by machine learning methods: The case of Turkey. Environ. Prog. Sustain. Energy 2023, 42, e14077. [Google Scholar] [CrossRef]

- Musharavati, F.; Khoshnevisan, A.; Alirahmi, S.; Ahmadi, P. Multi-objective optimization of a biomass gasification to generate electricity and desalinated water using Grey Wolf Optimizer and artificial neural network. Chemosphere 2022, 287, 131980. [Google Scholar] [CrossRef]

- Yatim, F.; Boumanchar, I.; Srhir, B.; Chhiti, Y.; Jama, C.; Alaoui, F. Waste-to-energy as a tool of circular economy: Prediction of higher heating value of biomass by artificial neural network (ANN) and multivariate linear. Waste Manag. 2022, 153, 293–303. [Google Scholar] [CrossRef]

- Kartal, F.; Özveren, U. Prediction of torrefied biomass properties from raw biomass. Renew. Energy 2022, 182, 578–591. [Google Scholar] [CrossRef]

- Neto, J.; Ozorio, L.; Abreu, T.; de Dos Santos, B.; Pradelle, F. Modeling of biogas production from food, fruits and vegetables wastes using artificial neural network (ANN). Fuel 2021, 285, 119081. [Google Scholar] [CrossRef]

- Almomani, F. Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network. Fuel 2020, 280, 118573. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Adeniyi, A.G.; Marques, G. Application of artificial neural networks in predicting biomass higher heating value: An early appraisal. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–8. [Google Scholar] [CrossRef]

- Obafemi, O.; Stephen, A.; Ajayi, O.; Nkosinathi, M. A survey of artificial neural network-based prediction models for thermal properties of biomass. Procedia Manuf. 2019, 33, 184–191. [Google Scholar] [CrossRef]

- George, J.; Arun, P.; Muraleedharan, C. Assessment of producer gas composition in air gasification of biomass using artificial neural network model. Int. J. Hydrogen Energy 2018, 43, 9558–9568. [Google Scholar] [CrossRef]

- Merdun, H.; Sezgin, I.V. Modelling of pyrolysis product yields by artificial neural networks. Int. J. Renew. Energy Res. 2018, 8, 1178–1188. [Google Scholar]

- Francik, S.; Łapczyńska-Kordon, B.; Francik, R.; Wójcik, A. Modeling and Simulation of Biomass Drying Using Artificial Neural Networks. In Renewable Energy Sources: Engineering, Technology, Innovation: ICORES 2017; Springer International Publishing: Cham, Switzerland, 2017; pp. 571–581. [Google Scholar] [CrossRef]

- Kelly Orhorhoro, E.; Sadjere, G.; Okechukwu Ebunilo, P.; Ejuvwedia Sadjere, G. Development of a predictive model for biogas yield using artificial neural networks (ANNs) approach. ResearchgateNet 2017, 4, 71–77. [Google Scholar]

- Beltramo, T.; Ranzan, C.; Hinrichs, J.; Hitzmann, B. Artificial neural network prediction of the biogas flow rate optimised with an ant colony algorithm. Biosyst. Eng. 2016, 143, 68–78. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Hernández, J.; Bruno, J.; Coronas, A. Artificial neural network models for biomass gasification in fluidized bed gasifiers. Biomass Biornergy 2013, 49, 279–289. [Google Scholar] [CrossRef]

- Kana, E.; Oloke, J.; Lateef, A.; Adesiyan, M. Modeling and optimization of biogas production on saw dust and other co-substrates using artificial neural network and genetic algorithm. Renew. Energy 2012, 46, 276–281. [Google Scholar] [CrossRef]

- Zhong, Y.; Ding, Y.; Jiang, G.; Lu, K.; Li, C. Comparison of Artificial Neural Networks and kinetic inverse modeling to predict biomass pyrolysis behavior. J. Anal. Appl. Pyrolysis 2023, 169, 105802. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Y.; Yu, L.; Cao, Y.; Liu, X.; Yao, A.; Cao, Y. Self-heating optimization of integrated system of supercritical water gasification of biomass for power generation using artificial neural network combined with. Energy 2023, 272, 127134. [Google Scholar] [CrossRef]

- Francik, S.; Knapczyk, A.A.; Francik, R. Decision support system for the production of Miscanthus and willow briquettes. Energies 2020, 13, 1364. [Google Scholar] [CrossRef]

- Zafari, A.; Kianmehr, M.H.; Abdolahzadeh, R. Modeling the effect of extrusion parameters on density of biomass pel-let using artificial neural network. Int. J. Recycl. Org. Waste Agric. 2013, 2, 9. [Google Scholar] [CrossRef]

- Mungale, N.; Awari, G.; Singh, M.; Sakhale, C. Model formulation and Analysis of Total Weight of Briquettes after mixing for Briquette making operation. Int. J. Eng. Res. Appl. 2016, 6, 25–29. [Google Scholar]

- Shankar, T.J.; Sokhansanj, S.; Bandyopadhyay, S.; Bawa, A.S. A case study on optimization of biomass flow during single-screw extrusion cooking using genetic algorithm (GA) and response surface method (RSM). Food Bioprocess. Technol. 2010, 3, 498–510. [Google Scholar] [CrossRef]

- Mancini, M.; Mircoli, A.; Potena, D.; Diamantini, C.; Duca, D. Prediction of pellet quality through machine learning techniques and near-infrared spectroscopy. Comput. Ind. Eng. 2020, 147, 106566. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Ercan, U. Determining Airline Customer Satisfaction with Ensemble Learning Methods. Alanya Acad. Rev. 2022, 6, 2763–2774. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Reynolds, J.; Rezgui, Y. Predictive modelling for solar thermal energy systems: A comparison of support vector regression, random forest, extra trees and regression trees. J. Clean. Prod. 2018, 203, 810–821. [Google Scholar] [CrossRef]

- Fan, J.; Ma, X.; Wu, L.; Zhang, F.; Yu, X.; Zeng, W. Light Gradient Boosting Machine: An efficient soft computing model for estimating daily reference evapotranspiration with local and external meteorological data. Agric. Water Manag. 2019, 225, 105758. [Google Scholar] [CrossRef]

- Ercan, U. Estimating of Households Shopping on The Internet Using Random Forest Method. Kafkas Üniversi-Tesi İktisadi İdari Bilim Fakültesi Derg 2021, 12, 728–752. [Google Scholar] [CrossRef]

- Niu, M.; Li, Y.; Wang, C.; Han, K. A web server for predicting amyloid proteins. Int. J. Mol. Sci. 2018, 19, 2071. [Google Scholar] [CrossRef]

- Ercan, U. Konut Kira Fiyatlarının Makine Öğrenmesi Yöntemleriyle Tahmin Edilmesi: Destek Vektör Regresyonu ve Yapay Sinir Ağları Karşılaştırması. In Ampirik Yöntemlerle İktisadi ve Finans Çözümlemeler; Gazi Kitabevi: Ankara, Türkiye, 2022; pp. 373–390. [Google Scholar]

- Jebli, I.; Belouadha, F.Z.; Kabbaj, M.I.; Tilioua, A. Prediction of solar energy guided by pearson correlation using machine learning. Energy 2021, 224, 120109. [Google Scholar] [CrossRef]

- Saglam, C.; Cetin, N. Prediction of Pistachio (Pistacia vera L.) Mass Based on Shape and Size Attributes by Using Machine Learning Algorithms. Food Anal. Methods 2022, 15, 739–750. [Google Scholar] [CrossRef]

| Density (kg m−3) | Moisture Content (%) | Pressure (MPa) | Particle Size (mm) | Shatter Index (%) | Tumbler Index (%) | Compressive Resistance (N) | |

|---|---|---|---|---|---|---|---|

| count | 270.00 | 270.00 | 270.00 | 270.00 | 270.00 | 270.00 | 270.00 |

| mean | 1125.08 | 6.44 | 180 | 3.64 | 94.08 | 88.08 | 3348.78 |

| std | 152.79 | 1.80 | 10.02 | 1.51 | 3.87 | 3.91 | 722.60 |

| min | 731.15 | 4.22 | 170 | 1.78 | 84.28 | 77.98 | 1964.66 |

| 25% | 1009.16 | 4.22 | 170 | 1.78 | 91.38 | 85.25 | 2826.33 |

| 50% | 1125.23 | 6.48 | 180 | 3.66 | 94.96 | 88.08 | 3304.27 |

| 75% | 1227.59 | 8.63 | 190 | 5.47 | 97.24 | 90.974 | 3871.97 |

| max | 1493.01 | 8.63 | 190 | 5.47 | 99.99 | 98.95 | 5017.30 |

| Regression Model | R2 | MAPE | MAE | RMSE |

|---|---|---|---|---|

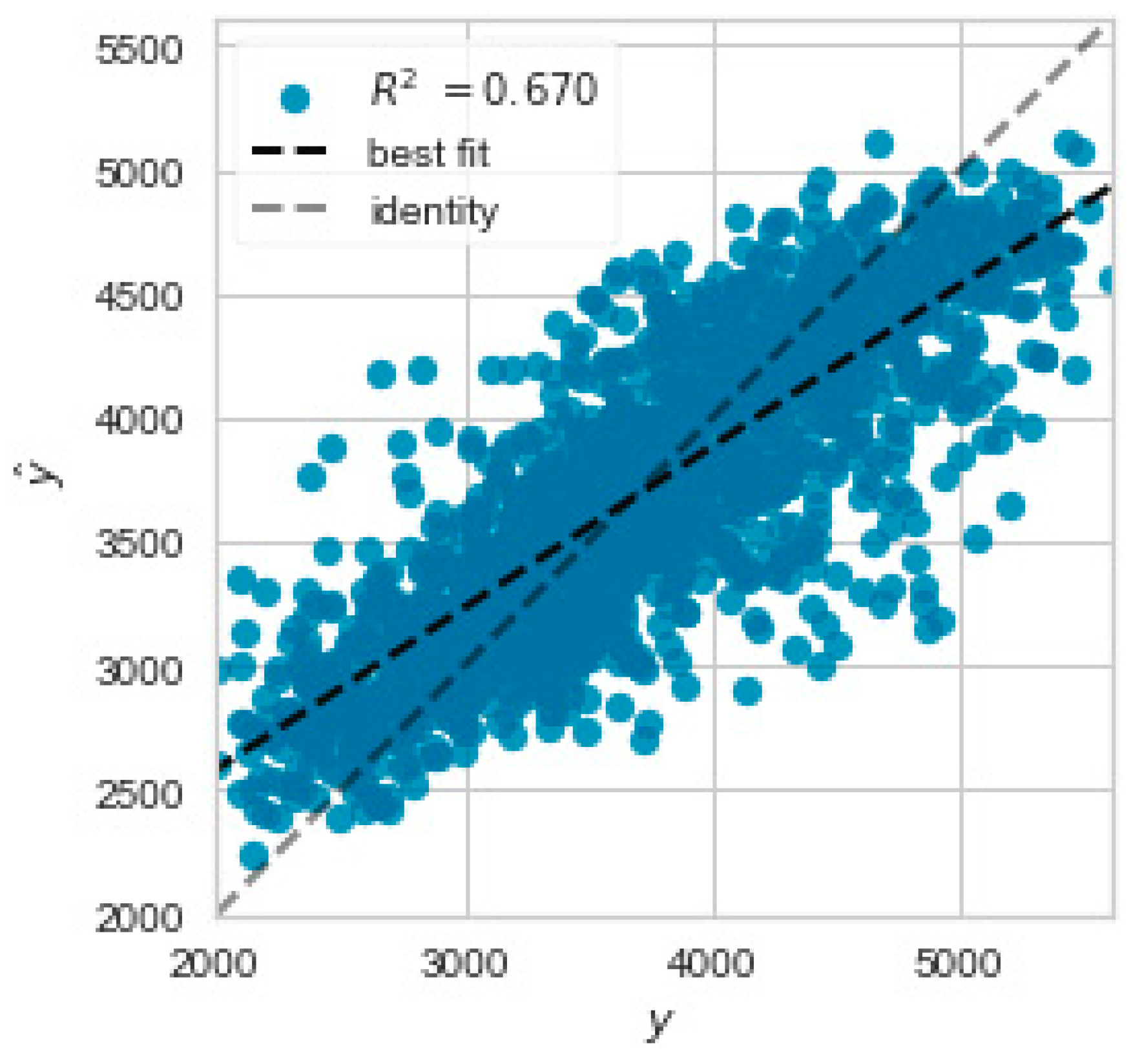

| Extra Trees | 0.7595 | 0.0799 | 284.0107 | 368.1077 |

| Random Forest | 0.7287 | 0.0845 | 300.6592 | 390.9278 |

| Light Gradient Boosting | 0.6838 | 0.0922 | 328.6430 | 422.0057 |

| Regression Model | R2 | MAPE | MAE | RMSE |

| Extra Trees | Random Forest | Light Gradient Boosting | ||||

|---|---|---|---|---|---|---|

| Fold | R2 | MAPE | R2 | MAPE | R2 | MAPE |

| 0 | 0.7610 | 0.0843 | 0.7346 | 0.0873 | 0.6932 | 0.0953 |

| 1 | 0.7315 | 0.0809 | 0.7042 | 0.0851 | 0.6792 | 0.0924 |

| 2 | 0.7715 | 0.0829 | 0.7286 | 0.0902 | 0.7052 | 0.0946 |

| 3 | 0.7735 | 0.0810 | 0.7627 | 0.0852 | 0.7150 | 0.0927 |

| 4 | 0.7262 | 0.0855 | 0.6983 | 0.0902 | 0.6555 | 0.0976 |

| 5 | 0.7769 | 0.0777 | 0.7573 | 0.0812 | 0.6903 | 0.0911 |

| 6 | 0.7500 | 0.0826 | 0.7098 | 0.0871 | 0.6541 | 0.0961 |

| 7 | 0.7714 | 0.0733 | 0.7232 | 0.0783 | 0.6892 | 0.0865 |

| 8 | 0.7824 | 0.0715 | 0.7456 | 0.0775 | 0.6764 | 0.0880 |

| 9 | 0.7500 | 0.0791 | 0.7225 | 0.0835 | 0.6797 | 0.0882 |

| Mean | 0.7595 | 0.0799 | 0.7287 | 0.0845 | 0.6838 | 0.0922 |

| Std | 0.0184 | 0.0043 | 0.0206 | 0.0042 | 0.0183 | 0.0036 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kocer, A.; Kabas, O.; Zabava, B.S. Estimation of Compressive Resistance of Briquettes Obtained from Groundnut Shells with Different Machine Learning Algorithms. Appl. Sci. 2023, 13, 9826. https://doi.org/10.3390/app13179826

Kocer A, Kabas O, Zabava BS. Estimation of Compressive Resistance of Briquettes Obtained from Groundnut Shells with Different Machine Learning Algorithms. Applied Sciences. 2023; 13(17):9826. https://doi.org/10.3390/app13179826

Chicago/Turabian StyleKocer, Abdulkadir, Onder Kabas, and Bianca Stefania Zabava. 2023. "Estimation of Compressive Resistance of Briquettes Obtained from Groundnut Shells with Different Machine Learning Algorithms" Applied Sciences 13, no. 17: 9826. https://doi.org/10.3390/app13179826

APA StyleKocer, A., Kabas, O., & Zabava, B. S. (2023). Estimation of Compressive Resistance of Briquettes Obtained from Groundnut Shells with Different Machine Learning Algorithms. Applied Sciences, 13(17), 9826. https://doi.org/10.3390/app13179826