Abstract

Aiming at the time-consuming, laborious, and inefficient process of removing abnormal rape plants during breeding, combined with the agronomic requirements for planting rapeseed, a clamping manipulator was designed. This manipulator is mainly composed of hollow splints, grip-force sensors, connecting rods, cylinders and other components. Additionally, a removing test platform was built. Single-factor and Box-Behnken experiments were conducted. Taking the output air pressure, pulling angle and pulling speed as the test factors, the rape uprooted removal rate, rape removal breakage rate and pulling force were the test indicators. Mathematical models for multiple regression were established separately for each evaluation index, and analysis of variance was conducted. Objective optimization was performed using the Numerical component to obtain the optimal combination of operating parameters: output air pressure of 0.47 MPa, pulling angle of 68.8° and extraction speed of 8 cm/s. The field validation test showed that the uprooted removal rate was 83.33%, the removal breakage rate was 6.67% and the pulling force was 84.9 N at the output air pressure of 0.5 MPa, pulling angle of 70° and pulling speed of 8 cm/s. The validation test values are in good agreement with the parameter optimization values, indicating that the parameter optimization model is reasonable.

1. Introduction

Rapeseed is the third largest oil crop in the world. It is also an important edible and industrial raw material and plays an important role in food and other industries [1,2,3,4]. Hybrid oilseed rape exhibits significant advantages in terms of yield and traits, including robust plants with vigorous nutrition [5,6,7]. The promotion and increased production of hybrid oilseed rape can better meet the market demand for agriculture and increase farmers’ income. In China, the area of hybrid rape planting has accounted for more than 45% of the total rape planting area, and there is an increasing demand for seeds [8]. Seed production is an important part of the hybrid rape production process, but rape seed production field management is difficult. The presence of abnormal rape plants can seriously affect the purity and yield of seeds. Ensuring seed purity is a crucial factor in meeting seed production quality standards. Therefore, in the process of seed production, it is very important to remove abnormal plants to ensure purity. At present, the manual removal of weedy plants in seed rape fields both at home and abroad is common practice, as mechanized operations are currently lacking. However, relying solely on large-scale manual operations would require significant human, material and financial resources while being inefficient. Moreover, the time-sensitive and labor-intensive nature of the hybrid rapeseed production industry hinders the implementation of certain technical requirements due to insufficient labor availability, thereby restricting its development [9]. Therefore, the only way to effectively reduce operating costs, improve productivity and increase economic benefits is to increase research and development of mechanized operations in the oilseed rape industry. Research results can help mechanize the whole process of hybrid oilseed rape seed production, which is of great practical significance in improving the capacity and efficiency of large-scale operations.

Abnormal rape plants, including heteromorphic plants, deteriorated plants, sterile plants and other varieties, should be uprooted as far as possible before the first flowering stage to prevent residual rhizomes from regenerating root branches and causing secondary pollination. At present, domestic and foreign scholars have conducted extensive research on the end-effector that destroys the plant rhizomes [10,11]. Based on their working principles and methods, they can be broadly categorized into cutting type, digging type, pulling type and clamping type (manipulator).

Zhang et al. [12] designed a single-row cabbage harvester with two symmetrical disc-type cutting knives to cut cabbage roots and determined suitable working parameters to ensure the stability of root cutting. Yang et al. [13] found that slotted circular blades with beveled edges cut garlic roots better and optimized the double circular blade cutting module by experiment. Hou et al. [14] designed a disc-type castor cutting device and optimized the tool parameters using simulation tests. The cutting end-effector uses a knife to remove the part of the crop above the rhizome, but the residual rhizome remains in the soil after cutting, which cannot achieve the effect of root removal.

Dave Koenig and Orthman in the United States employed a symmetrical double-disc planter as a representative model for cotton stalk excavation [15]. Typically, the excavating end-effector initially rotates or cuts into the soil before pulling the rootstock upward from beneath, thereby enhancing operational efficiency.

The Australian Muti stalk puller and the American AMADAS stalk puller use rubber pairs of rollers to clamp the straw and then complete the straw-pulling operation; these are representative models of stalk pulling. Mostofi et al. [16] designed a cotton stalk plucker with two wedge-shaped discs for pulling cotton stalks and conducted field trials to find the optimal operating parameters. Ramadan et al. [17] designed a cotton stalk puller and investigated the effect of stalk-pulling roller inclination and speed on the effect of stalk pulling. The pulling type end-effector has a high pull-out rate and few residual rhizomes, but a relatively high number of failure cases occur.

Scholars at home and abroad have researched extensively on picking robotic clamping manipulators, which have similarities between clamping fruits and vegetables and clamping stalks. Germany’s Festo developed a two-finger apple clamping picking end-effector [18]. Xu et al. [19] designed a front-driven navel orange double V-shaped finger-picking manipulator that cuts the fruit handle through a rotating cutting mechanism. Because the rape hybrid plant should be removed as far as possible and the hybrid plant removal mechanism should be relatively small and flexible, the clamping and drawing end-effector is more suitable. Because abnormal rape plants should be uprooted as far as possible and the removal mechanism should be relatively small and flexible, the clamping and pulling end-effector is more suitable.

In summary, there is no research on end-effectors for pulling out seed rape stray plants at home and abroad, and the clamping and pulling end-effector is more suitable for removing abnormal plants. In response to this situation, a clamping manipulator was designed, and a test bench was built in this paper. A single-factor test was conducted to determine the key parameters of the clamping manipulator. Furthermore, a Box-Behnken experiment was designed to obtain the optimal operating parameters for the clamping manipulator. Finally, the rationality of the parameter optimization model was verified by field validation tests to ensure that the clamped manipulator could remove the abnormal rape plants with a high pulling rate and low energy consumption. This paper provides a reference for the research and optimization of the removal device for abnormal plants.

2. Materials and Methods

2.1. Planting Parameters and Basic Physical Parameters of Rape

Rape is a taproot crop with a well-developed primary root and lateral roots that grow attached to the primary root. In accordance with the principle of integrating agricultural machinery and agronomy, it is imperative to elucidate the planting parameters and fundamental physical characteristics of crops prior to determining specific agricultural machinery parameters [20]. This paper focuses on rape in the bud stage, with Xiaoji Green Garden Vegetable Specialized Cooperative in Yangzhou City, Jiangsu Province as the research object, and conducts a research experiment. The sampling process was carried out in accordance with GB/T 5268-2008 “General rules for test conditions and determination methods”, and the field test sampling was conducted using the “five-point method” [21]. Five test samples were selected for the experiment, and 10 rape plants were chosen from each sample. A tape measure and vernier caliper were used to measure the parameters, and then the average was calculated. The planting parameters and basic physical parameters of rape are shown in Table 1.

Table 1.

Planting parameters and basic physical parameters.

2.2. Structure and Principles of the Clamping Test Bench

2.2.1. Dimensions of the Entire Structure

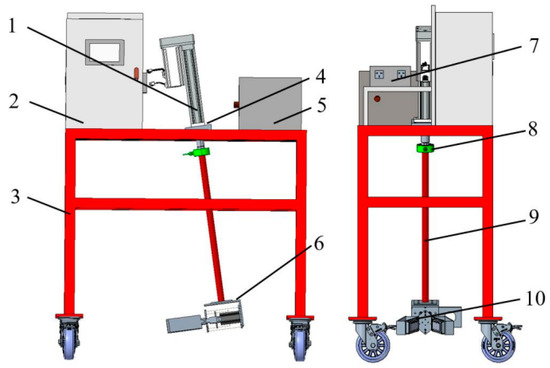

Based on the requirements of a clamping manipulator for removing rape plants and combined with the basic physical parameters of rape, a test bench for clamping removal was designed. The test bench mainly consists of a servo-cylinder, control cabinet, mobile bench, angle plate and clamping manipulator. The overall structure is shown in Figure 1. The dimensions of the test bench are 1100 mm × 600 mm × 1400 mm.

Figure 1.

Overall structure diagram of the test bed: 1—servo-cylinder; 2—control cabinet; 3—mobile bench; 4—mobile bench; 5—cell; 6—connecting plate; 7—inverter; 8—pulling force sensor; 9—connecting rod; 10—clamping manipulator.

2.2.2. Working Principles of the Test Bench

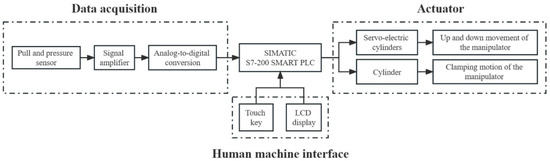

The test bench can simulate the extraction process and method of hybrid plants in the rapeseed field and can collect the pulling force and clamping force. The working principles are shown in Figure 2. During the field experiment, the distance and position of the rape plant and clamping manipulator were adjusted using a moving bench. Different pulling speeds, pulling heights, clamping times and other test parameters can be specified through the human–computer interaction interface touchscreen according to the testing requirements. The human–computer interaction transmits input information to the PLC, which then controls the movement of the servo-electric drive mechanism based on specified operating parameters. During system operation, data acquisition and storage can be performed to facilitate subsequent data processing and analysis after testing.

Figure 2.

Schematic diagram of test bench.

2.3. Design of the Clamping Manipulator

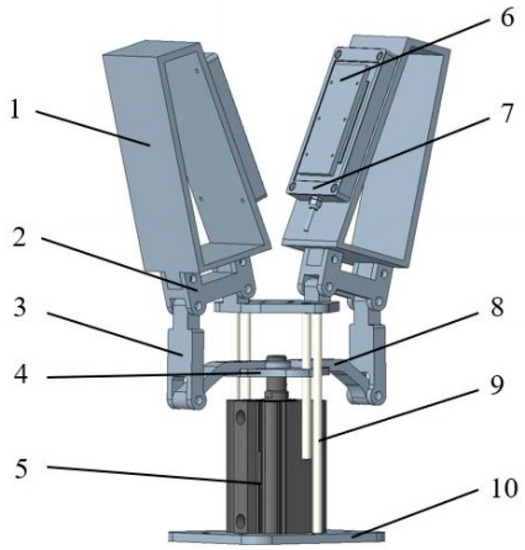

The clamping manipulator is a crucial component of the test bench, responsible for clamping and removing the rape plants. The structure is shown in Figure 3. Through investigation of rape planting parameters and basic physical parameters, it was found that the stem diameter of the hybrid plant before initial flowering is between 8–16 mm, and the plant height is between 25–50 mm. Therefore, two hollow splints were designed with a maximum opening angle of 45°, and the overall size of the manipulator is 280 mm × 200 mm × 120 mm. The manipulator has an adjustable clamping diameter.

Figure 3.

Clamping manipulator structure diagram: 1—hollow splint; 2—rotating part; 3—connecting rod 1; 4—cylinder push plate; 5—cylinder; 6—splint; 7—clamping force sensor; 8—connecting rod 2; 9—bracing piece; 10—dead plate.

The air pump continuously compresses air into the gas storage tank through electricity to produce air pressure, and different gas pressures can be output through the gas pressure regulating valve. The gas storage tank is connected to the cylinder through the trachea. Different gas pressures in the gas storage tank can output different thrusts to the cylinder and then control the output of different clamping forces. The pressure sensor of the manipulator is mounted on the hollow splint, and the splint is fixed on the pressure sensor of the manipulator. The surface of the splint is covered with flexible anti-skid material. When the manipulator clamps miscellaneous plants, the clamping force data can be collected by the clamping force sensor for subsequent data processing and analysis.

2.4. Test Design

2.4.1. Single-Factor Test

The greater the output pressure of the gas storage tank, the greater the thrust of the cylinder and the greater the clamping force of the manipulator, which affects the clamping effect. The pulling angle has an important influence on the pulling force [22], which not only affects the pulling effect but also affects the power consumption of the whole machine. Slow removal speed affects both the efficiency and effectiveness of the operation. Therefore, by designing a single-factor test, we studied the influence of the output pressure on the clamping force of the manipulator and the influence of the output pressure (X1), the pulling angle (X2) and the pulling speed (X3) on the rape uprooted removal rate (Y1), the rape removal breakage rate (Y2) and the pulling force (Y3). The rape uprooted removal rate is the ratio of the number of rapes successfully removed by the clamping manipulator in a test group to the number of all rapes in a test group, which can be expressed as Formula (1). The rape removal breakage rate is the ratio of the number of rapes broken by the clamping manipulator in a test group to the number of all rapes in a test group, which can be expressed as Formula (2). The pulling force is the ratio of the total pull-out force of the rape successfully pulled out by the clamping manipulator in a test group to the number of rapes successfully pulled out in a test group, which can be expressed as Formula (3).

where Y1 is the rape uprooted removal rate, %; M1 is the number of rapes successfully removed by a clamping manipulator in a test group; and M is the number of all rapes in a test group.

where Y2 is the rape removal breakage rate, %; M2 is the number of rapes broken by a clamping manipulator in a test group; and M is the number of all rapes in a test group.

where Y3 is the average pulling force of rape in the experimental group, N; Fn is the pulling force of the clamping manipulator to successfully pull out the nth rape plant; and N is the number of rapes successfully uprooted in a test group.

The fixed parameters used in the single-factor test were output air pressure 0.5 MPa, pulling angle 75° and pulling speed 10 cm/s. The specific test factors and levels are shown in Table 2. Each group of experiments was carried out 20 times, and the rapes were selected with a diameter of about 14 mm. According to Formulas (1)–(3), the rape uprooted removal rate, the rape removal breakage rate and the pulling force were obtained, and the data were recorded and analyzed.

Table 2.

Factors and levels of single-factor design.

2.4.2. Box–Behnken Design Test

After determining the range of influencing factors from single-factor test results, a three-factor three-level Box-Behnken test was designed to optimize the key parameters of the clamping manipulator. The rape uprooted removal rate (Y1), the rape removal breakage rate (Y2) and the pulling force (Y3) were used as the evaluation indexes, and a response surface test was carried out on the output air pressure (X1), the pulling angle (X2) and the pulling speed (X3). The experimental factors and levels are shown in Table 3.

Table 3.

Test factors and levels.

Based on the Box-Behnken principle, 17 sets of experiments were designed. Each group of experiments was carried out 30 times, and the rapes were selected with a diameter of about 14 mm. The test data were analyzed using Design-Expert software, multiple regression mathematical models were established for the evaluation indexes, and variance analysis was carried out. Then, the interaction between these factors and effects was studied by response surface analysis. Using this analysis, the experimental results were optimized and verified by field experiments.

3. Results

3.1. Single-Factor Test Results

On 10 March 2023, the team conducted a single-factor field experiment using the clamping pull-out test bench in the Xiaoji Green Garden Vegetable Professional Cooperative, located in Yangzhou City, Jiangsu Province.

3.1.1. Influence of Output Air Pressure on the Clamping Force of the Manipulator

To investigate the influence of different output air pressures on the clamping force of the manipulator, a clamping force test was conducted. The gas storage tank is equipped with a pressure regulator, which can be adjusted with a screwdriver to adjust the output pressure. The output pressures of the test factors were selected to be 0.3 MPa, 0.4 MPa, 0.5 MPa, 0.6 MPa and 0.7 MPa for the clamping test, and each group of tests was performed 10 times. The clamping force data were recorded, and then the average clamping force was calculated. The diameter of the rape was chosen to be about 14 mm. The test results are shown in Table 4.

Table 4.

The influence of the output air pressure on the clamping force of the manipulator.

The test results show that the clamping force of the manipulator is significantly affected by the output air pressure, and there is a linear relationship between them. The clamping force of the manipulator increases with increasing output air pressure and decreases with decreasing output air pressure. When the output pressure is 0.3 MPa, the average clamping force of the manipulator is 109 N, and when the output pressure is 0.7 MPa, the average clamping force of the manipulator is 263 N.

3.1.2. Influence of Output Air Pressure on the Test Indicators

The test results are shown in Table 5. It can be seen that the output air pressure has a significant effect on the rape uprooted removal rate and the rape removal breakage rate and has no significant effect on the pulling force. When the output air pressure was 0.3 MPa, the rape uprooted removal rate was 65%, and the rape removal breakage rate was 5%. At this time, the clamping force of the manipulator was approximately 109 N, which is not particularly strong. Because the clamping force is not high enough, the number of times that the rape was not successfully pulled out was too high. When the output air pressure was 0.7 MPa, the rape uprooted removal rate was 75%, and the rape removal breakage rate was 25%. At this time, the clamping force of the manipulator was 263 N. Compared with the output air pressure of 0.5 MPa, the rape uprooted removal rate decreased, and the rape removal breakage rate increased significantly. Because the clamping force was too high, it would lead to an increase in the number of direct clamping breaks when clamping the rape stem or in the process of pulling out. Therefore, after comprehensively comparing the test data under different conditions, the output pressure was selected to be 0.5 MPa.

Table 5.

The influence of the output air pressure on the test indicators.

3.1.3. Influence of the Pulling Angle on the Test Indicators

The test results are shown in Table 6. It can be seen that the pulling angle has a certain influence on the rape uprooted removal rate and the rape removal breakage rate and has a significant effect on the pulling force. When the pulling angle is 90°, the pull-out resistance of the main root and all lateral roots needs to be overcome, the pulling force is larger and the rape removal breakage rate is higher. When the pulling angle is 75°, the pulling force has a significant decrease compared with the pulling angle of 90°. This is because pulling the rape along the inclined direction only needs to overcome the drawing resistance on the side of the rape root. When the pulling angle is 60°, the pulling force does not change significantly compared to that at a 75° angle, but the rape removal breakage rate slightly increases. This is because as the pulling angle decreases, although vertical resistance also decreases, horizontal resistance increases. Therefore, after comprehensively comparing test data under different conditions, a pulling angle of 75° was selected.

Table 6.

The influence of the pulling angle on the test indicators.

3.1.4. Influence of the Pulling Speed on the Test Indicators

The test results are shown in Table 7. It can be seen that the pulling speed has a certain influence on the rape uprooted removal rate, rape removal breakage rate and the pulling force, but the influence is small. The pulling force slightly increases with the increase in pulling speed. The rape uprooted removal rate first increases and then decreases with the increase in pulling speed. The rape removal breakage rate increases with the increase in pulling speed. When the pulling speed is too fast, the rape uprooted removal rate will decrease, the rape removal breakage rate will increase, and power consumption will increase. When the pulling speed is too slow, the operating efficiency will be reduced. Therefore, after comprehensively comparing the test data under different conditions, the pulling speed was selected as 10 cm/s.

Table 7.

The influence of the pulling speed on the test indicators.

3.2. Orthogonal Rotation Combination Design Test

To study the influence of various factors on the evaluation index, an orthogonal test was conducted by the team at Xiaoji Green Garden Vegetable Cooperative in Yangzhou City, Jiangsu Province on 11 March 2023.

3.2.1. Establishment of the Regression Model and Analysis of Variance

The test results are shown in Table 8. ANOVA analysis and data fitting were performed using Design-Expert software. Multiple regression equations were established by combining the three independent variables of output air pressure X1, pulling angle X2 and pulling speed X3 with the response values of rape uprooted removal rate Y1, rape removal breakage rate Y2 and pulling force Y3.

Table 8.

Experimental program and results.

Analysis of variance and significance test results are shown in Table 9. The regression model of rape uprooted removal rate Y1, rape removal breakage rate Y2 and pulling force Y3 was extremely significant (p < 0.05), indicating that the regression equation had a good fitting degree. The R2 for Y1, Y2 and Y3 are 0.989, 0.980 and 0.986, respectively, indicating that more than 90% of the response values could be explained by the regression model. In summary, the key operating parameters of the clamping manipulator can be analyzed and optimized by this model, and the test has research significance.

Table 9.

Analysis of variance and significance test.

The size of the p value can indicate the significance of each regression term’s influence on the regression model. In the Y1 regression model, the primary terms X1 and X2 had extremely significant effects (p < 0.01) and X3 had significant effects (p < 0.05), the interaction X1, X2 had significant effects (p < 0.05), the square terms X12 and X22 had extremely significant effects (p < 0.01) and X32 had significant effects (p < 0.05). In the Y2 regression model, the effects of the primary terms X1 and X2 were highly significant (p < 0.01) and X3 was significant (p < 0.05), the interaction X1X2 was significant (p < 0.05), and the square terms X12 and X22 were highly significant (p < 0.01). In the Y3 regression model, the effects of the primary terms X2 and X3 were highly significant (p < 0.01), the interaction X2X3 was significant (p < 0.05), and the secondary term X22 was highly significant (p < 0.01). Under the premise of ensuring that the model was significant and the lack of fit was not significant, the insignificant regression term was excluded. The regression equation optimization results were as follows:

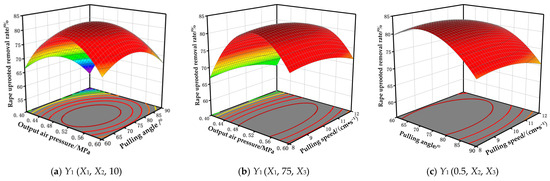

The effect degree of each influencing factor on the rape uprooted removal rate Y1 is X1, X2 and X3 in descending order. Figure 4 shows the effect of the interaction term on Y1. Figure 4a shows that the rape uprooted removal rate increases and then decreases with the increase in output air pressure when the pulling angle is the same; the rape uprooted removal rate increases and then decreases with the increase in pulling angle when the output air pressure is the same. Figure 4b shows that the rape uprooted removal rate increases and then decreases with the increase in pulling speed when the output air pressure is constant; the rape uprooted removal rate increases and then decreases with the increase in output air pressure when the pulling speed is constant. Figure 4c shows that the rape uprooted removal rate increases and then decreases with the increase in pulling speed when the pulling angle is fixed; the rape uprooted removal rate increases and then decreases with the increase in pulling angle when the pulling speed is fixed.

Figure 4.

The influence of interaction factors on the rape uprooted removal rate.

According to the response diagram of the test factors to Y1, the change rule of the response surface is consistent with the results of variance analysis (Table 9) and regression Equation (4). When the output air pressure, pulling angle, and pulling speed are moderate, the rape uprooted removal rate is higher. The main reasons are as follows: when the output air pressure is too low, the clamping force of the manipulator is not high enough to pull out the rape; when the output air pressure is too high, the clamping force of the manipulator is excessive and may damage or break off parts of the rape; when the pulling angle is small, the horizontal pulling resistance increases and only one side of the root system is under pressure, which is easy to pull out; when the pulling angle is large, the pulling force is high and it is not easy to pull out the rape; when the pulling speed is too high, the initial acceleration is too high, and the clamping is unstable, resulting in a lower rape uprooted removal rate.

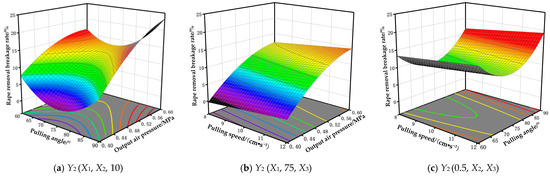

The effect degree of each influencing factor on the rape removal breakage rate Y2 is X1, X2 and X3 in descending order. The effect of the interaction term on Y2 is shown in Figure 5. In Figure 5a, at a certain pulling angle, an increase in output air pressure leads to an increase in the rape removal breakage rate; at a certain output air pressure, an increase in pulling angle initially decreases and then increases the breakage rate. Similarly, in Figure 5c, at a certain pulling angle, an increase in pulling speed results in higher breakage rates, whereas at a certain pulling speed, increasing the pulling angle first reduces and then raises the breakage rate.

Figure 5.

The influence of interaction factors on the rape removal breakage rate.

According to the response diagram of the test factors to Y2, the change rule of the response surface is consistent with the results of variance analysis (Table 9) and regression Equation (5). When the pulling angle is lower and the pulling speed is lower, the pulling force is lower; otherwise, the pulling force is higher. The pulling force is not directly related to the output air pressure, and the pulling speed has little effect on the pulling force. The main reasons are as follows: when the pulling angle is too large, it is necessary to overcome all the pull-out resistance of the main root and lateral root, and the pulling force is high; the output air pressure directly affects the clamping force of the manipulator. The clamping force directly affects the rape uprooted removal rate and the rape removal breakage rate and has no direct effect on the pulling force.

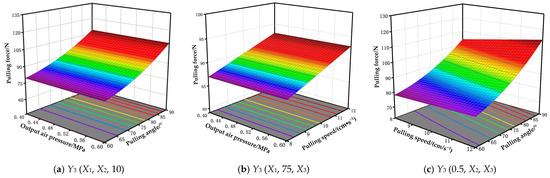

The effect degree of each influencing factor on the pulling force Y3 is X2, X3 and X1 in descending order. The effect of the interaction term on Y3 is shown in Figure 6. Figure 6a shows that at a certain output air pressure, the pulling force increases with the increase in pulling angle; at a certain pulling angle, the pulling force is not directly related to the output air pressure. Figure 6b shows that at a certain output air pressure, the pulling force increases with the increase in pulling speed; at a certain pulling speed, the pulling force is not directly related to the output air pressure. Figure 6c shows that the pulling force increases slightly with the increase in pulling speed at a certain pulling angle, and the pulling force increases with the increase in pulling angle at a certain pulling speed.

Figure 6.

The influence of interaction factors on the pulling force.

According to the response diagram of the test factors to Y3, the change rule of the response surface is consistent with the results of variance analysis (Table 9) and regression Equation (6). When the pulling angle and speed are lower, the pulling force is lower; otherwise, it is higher. The pulling force is not directly related to the output air pressure, and the pulling speed has little effect on it. The main reasons are as follows: when the pulling angle is too large, it becomes necessary to overcome all pull-out resistance from both the main root and the lateral root, resulting in a higher pulling force. The output air pressure directly affects the clamping force of the manipulator, which in turn affects the rape uprooted removal rate and removal breakage rate. However, it has no direct effect on the pulling force.

3.2.2. Parameter Optimization and Experimental Verification

The influencing factors in the above tests have been optimized. To increase the rape uprooted removal rate and reduce the rape removal breakage rate and pulling force, a mathematical model has been established using Numerical component software and incorporating factor boundary conditions. The objective function and the constraints can be expressed as Equation (10).

The Design-Expert software optimization module was used for multi-objective optimization. Optimum performance was achieved at the output air pressure of 0.47 MPa, the pulling angle of 68.8° and the pulling speed of 8 cm/s. At this time, the rape uprooted removal rate of rape was 80.14%, the rape removal breakage rate was 6.44% and the pulling force was 83.02 N.

3.3. Field Trial

To verify the reliability of the optimization results, the team conducted a field trial on 13 March 2023 at Xiaoji Green Garden Vegetable Cooperative in Yangzhou City, Jiangsu Province under optimal working parameters, as shown in Figure 7. The soil in the test field had a uniform texture, a flat surface, and a water content of 18.4%. Based on the actual situation in the field, the optimized manipulator operation parameters were adjusted for field verification testing. The output air pressure was set at 0.5 MPa, pulling angle at 70° and pulling speed at 8 cm/s. Three groups of uprooting tests were conducted, each consisting of 30 plants, and the test results were averaged. The results are shown in Table 10.

Figure 7.

Photos of field validation trials.

Table 10.

Test scheme and results.

Table 10 demonstrates a satisfactory agreement between the verification test value and the parameter optimization value, with a relative error of less than 5%. Therefore, it can be concluded that the parameter optimization model is reasonable. The optimal operating parameters for the clamping manipulator are a combination of an output air pressure of 0.5 MPa, a pulling angle of 70° and a pulling speed of 8 cm/s.

4. Discussion

Compared with conventional rapeseed, hybrid rapeseed has excellent production performance, and the demand for hybrid rapeseed seeds is increasing. However, abnormal rape plants in breeding fields will seriously affect seed purity and yield. At present, there is no special research on the pull-out machinery of abnormal rape plants, mainly based on manual pull-out. In this paper, we propose adopting a clamping structure to uproot rape plants. We designed a gripping manipulator and built a test rig to determine the structural parameters of its components. The prototype was tested, and field trials were conducted to verify the feasibility of the gripping manipulator. In practical applications, manipulators can be mounted on robots or other mobile platforms. Because the number of abnormal plants in the field is so small, it is designed as intermittent work. First, the mobile platform moves to the operating position, and then the manipulator performs the operation.

Although some innovative structural designs have been carried out due to limited research time and design experience, there are still some limitations, as follows:

- (1)

- The currently designed clamping manipulator is only at the testing stage on the test bench and has not been integrated into the mobile working chassis. The next step should be to integrate the rest of the working chassis, design a carrying device for both the working chassis and manipulator, and carry out structural optimization as well as control system updates in order to achieve automated and mechanized pulling operations.

- (2)

- Currently, abnormal rape plant pulling is mainly done manually, both domestically and internationally, with little research on pulling devices. In this paper, we utilize a clamping structure to pull out weeds, and the next step will be to optimize the clamping end-effector’s structure in order to improve operational efficiency.

5. Conclusions

- (1)

- Based on the planting parameters and basic physical parameters of rape, a clamping manipulator was designed to remove abnormal plants. It mainly consists of hollow splints, grip-force sensors, connecting rods, cylinders and a bracing piece. Additionally, a clamping pull-out test bench was constructed.

- (2)

- By conducting a single-factor test, we investigated the effect of output air pressure on the clamping force of the manipulator. Additionally, we examined the effects of three factors—output air pressure, pulling angle, and pulling speed—on the rape uprooted removal rate, rape removal breakage rate, and pulling force. The results showed that the clamping force was linearly related to the output air pressure and increased. The rape uprooted removal rate initially increased, then decreased with increasing output air pressure, while the pulling angle first increased and then decreased with increasing pulling angle. The rape removal breakage rate also initially increased with increasing output air pressure but then decreased before increasing again.

- (3)

- We used the Box-Behnken experimental design method to establish a regression model between each test index and its influencing factors, subsequently analyzing the influence of each test index. We performed objective optimization using numerical components, which resulted in obtaining the optimal combination of operating parameters: output air pressure of 0.47 MPa, pulling angle of 68.8, and pulling speed of 8 cm/s.

- (4)

- The optimized parameters were used as the basis for selecting the working parameters of 0.5 MPa output air pressure, a pulling angle of 70° and a pulling speed of 8 cm/s for field verification testing. The verification test yielded the rape uprooted removal rate of 83.33%, rape removal breakage rate of 6.67% and pulling force of 84.9 N, which agreed well with the optimized parameters.

Author Contributions

Conceptualization, Q.X. and S.D.; methodology, Q.X.; software, Q.X. and L.C.; validation, Q.X.; formal analysis, X.X.; investigation, F.L.; resources, X.X.; data curation, Q.X.; writing—original draft preparation, Q.X. and S.D.; writing—review and editing, Q.X.; visualization, J.F.; supervision, S.D.; project administration, Q.X.; funding acquisition, S.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Independent Innovation Fund Project of Agricultural Science and Technology of Jiangsu Province, grant number CX (21)2007; the National Technology System of Rape Industry, grant number CARS-12.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guan, Z.; Mu, S.; Jiang, T.; Li, H.; Zhang, M.; Wu, C.; Jin, M. Development of Centrifugal Disc Spreader on Tracked Combine Harvester for Rape Undersowing Rice Based on DEM. Agriculture 2022, 12, 562. [Google Scholar] [CrossRef]

- Wu, J.; Tang, Q.; Mu, S.; Jiang, L.; Hu, Z. Test and Optimization of Oilseed Rape (Brassica napus L.) Threshing Device Based on DEM. Agriculture 2022, 12, 1580. [Google Scholar] [CrossRef]

- Qla, B.; Tao, R.; Yza, B.; Xla, B.; Rca, B.; Sla, B.; Xf, C.; Jla, B. Evaluating the application of controlled release urea for oilseed rape on Brassica napus in a regional scale: The optimal usage, yield and nitrogen use efficiency responses. Ind. Crops Prod. 2019, 140, 111560. [Google Scholar]

- Chen, B.; Bian, X.; Tu, M.; Yu, T.; Jiang, L.; Lu, Y.; Chen, X. Moderate Salinity Stress Increases the Seedling Biomass in Oilseed Rape (Brassica napus L.). Plants 2023, 12, 1650. [Google Scholar] [CrossRef] [PubMed]

- Szaa, L.; Kaczmarek, Z.; Popawska, W.; Liersch, A.; Cegielska-Taras, T. Estimation of seed yield in oilseed rape to identify the potential of semi-resynthesized parents for the development of new hybrid cultivars. PLoS ONE 2019, 14, e0215661. [Google Scholar] [CrossRef] [PubMed]

- Sohn, S.-I.; Thamilarasan, S.K.; Pandian, S.; Oh, Y.-J.; Ryu, T.-H.; Lee, G.-S.; Shin, E.-K. Interspecific Hybridization of Transgenic Brassica napus and Brassica rapa—An Overview. Genes 2022, 13, 1442. [Google Scholar] [CrossRef] [PubMed]

- Xiao, R. Research on High-Yield Planting of the Hybrid Rapeseed Yunyou za No.2. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2012. [Google Scholar]

- Zhao, J.; Hu, Q.; Dai, X. Analysis on Yield Advantage of Hybrid Rape (Brassica napus) Compared with Conventional Rape. Guizhou Agric. Sci. 2023, 51, 1–7. [Google Scholar]

- Cheng, S.; Li, G.; Luo, M.; Zhang, L.; Wang, Z. Mechanization Production Technique of Hybrid Rape Seed. Seed 2019, 38, 131–132. [Google Scholar]

- Dai, Z. Design and Research on Cotton Stalk Drawing Institutions of Pull-out Cotton Stalk Mechanism. Master’s Thesis, Hunan Agricultural University, Changsha, China, 2015. [Google Scholar]

- Yang, Q.; Zhang, C.; Liu, P.; Jiang, J. The Role of Root Morphology and Pulling Direction in Pullout Resistance of Alfalfa Roots. Front. Plant Sci. 2021, 12, 212. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, J.; Du, D.; Long, S.; Wang, Y.; You, X. Design and Experiment of Crawler Self-propelled Single-row Harvester for Chinese Cabbage. Trans. Chin. Soc. Agric. Mach. 2022, 53, 134–146. [Google Scholar]

- Yang, K.; Yu, Z.; Luo, W.; Fan, J.; Li, Y.; Gu, F.; Zhang, Y.; Wang, S.; Peng, B.; Hu, Z. Experiment and Study of Garlic Root Cutting Based on Continuous Force Feedback. Agronomy 2023, 13, 835. [Google Scholar] [CrossRef]

- Hou, J.; Bai, J.; Yao, E.; Zhu, H. Design and Parameter Optimization of Disc Type Cutting Device for Castor Stem. IEEE Access 2020, 8, 191152–191162. [Google Scholar] [CrossRef]

- Liu, K.; Chen, M.; Liao, P.; Hao, Y.; Wang, R.; Zhang, A.; Wang, C. Research and Analysis of Mechanized Harvesting Equipment of Cotton Stalk in the Region of the Yellow River. J. Anhui Agric. Sci. 2022, 50, 174–178. [Google Scholar]

- Mostofi, M.R. Evaluation of a cotton stalk puller performance. Am.-Eurasian J. Sustain. Agric. 2008, 2, 19–24. [Google Scholar]

- Ramadan, Y.Y.R. Development and Evaluation of a Cotton Stalks Puller. J. Soil Sci. Agric. Eng. 2010, 1, 1061–1073. [Google Scholar] [CrossRef]

- Best, S.; Baur, J.; Ringdahl, O.; Oberti, R.; Pekkeriet, E. CROPS: Clever Robots for Crops. Eng. Technol. Ref. 2015, 1, 1–11. [Google Scholar]

- Xu, L.; Liu, X.; Zhang, K.; Xing, J.; Yuan, Q.; Chen, J.; Duan, Z.; Ma, S.; Yu, C. Design and test of end-effector for navel orange picking robot. Trans. Chin. Soc. Agric. Eng. 2018, 34, 53–61. [Google Scholar]

- Xiong, D.; Wu, M.; Xie, W.; Luo, H. Design and Experimental Study of the Key Components of a Rape (Brassica campestris) Shoots (Changxiangtai 603) Flexible Clamping Harvester. Agriculture 2023, 13, 792. [Google Scholar] [CrossRef]

- GB/T 5262-2008; Measuring Methods for Agricultural Machinery Testing Conditions. General Rules. Standardization Administration of the P.R.C.: Beijing, China, 2008; Volume 3.

- Li, Y.; Zhang, G.; Zhou, Y.; Ji, W.; Li, Z.; Zhang, Y.; Zhai, K. Design and field experiment of drawing resistance measurement system for cotton stalk. Trans. Chin. Soc. Agric. Eng. 2013, 29, 8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).