Strengthening Mechanisms in a Medium-Carbon Steel Subjected to Thermo-Mechanical Processing

Abstract

:1. Introduction

2. Materials and Methods

3. Results

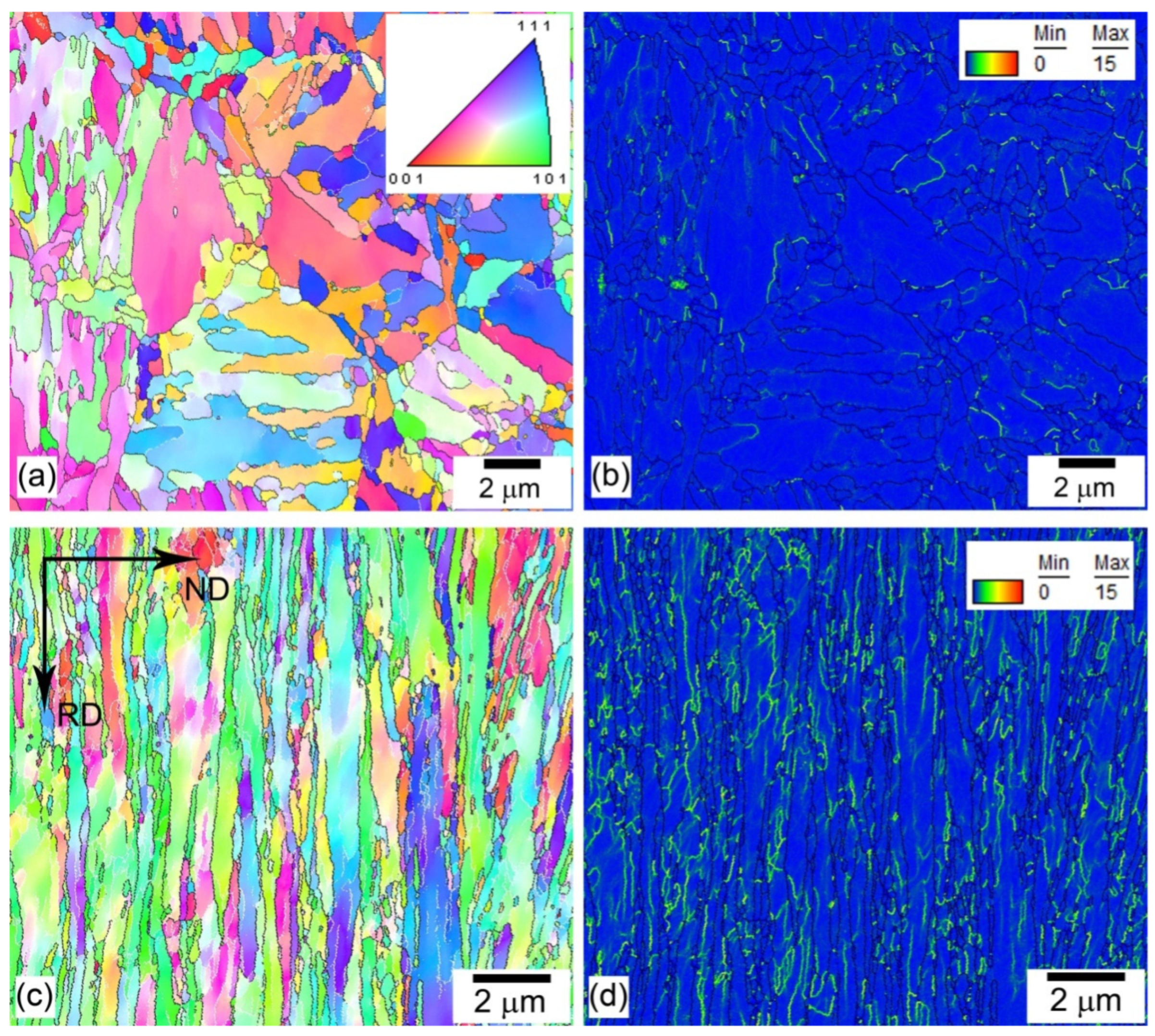

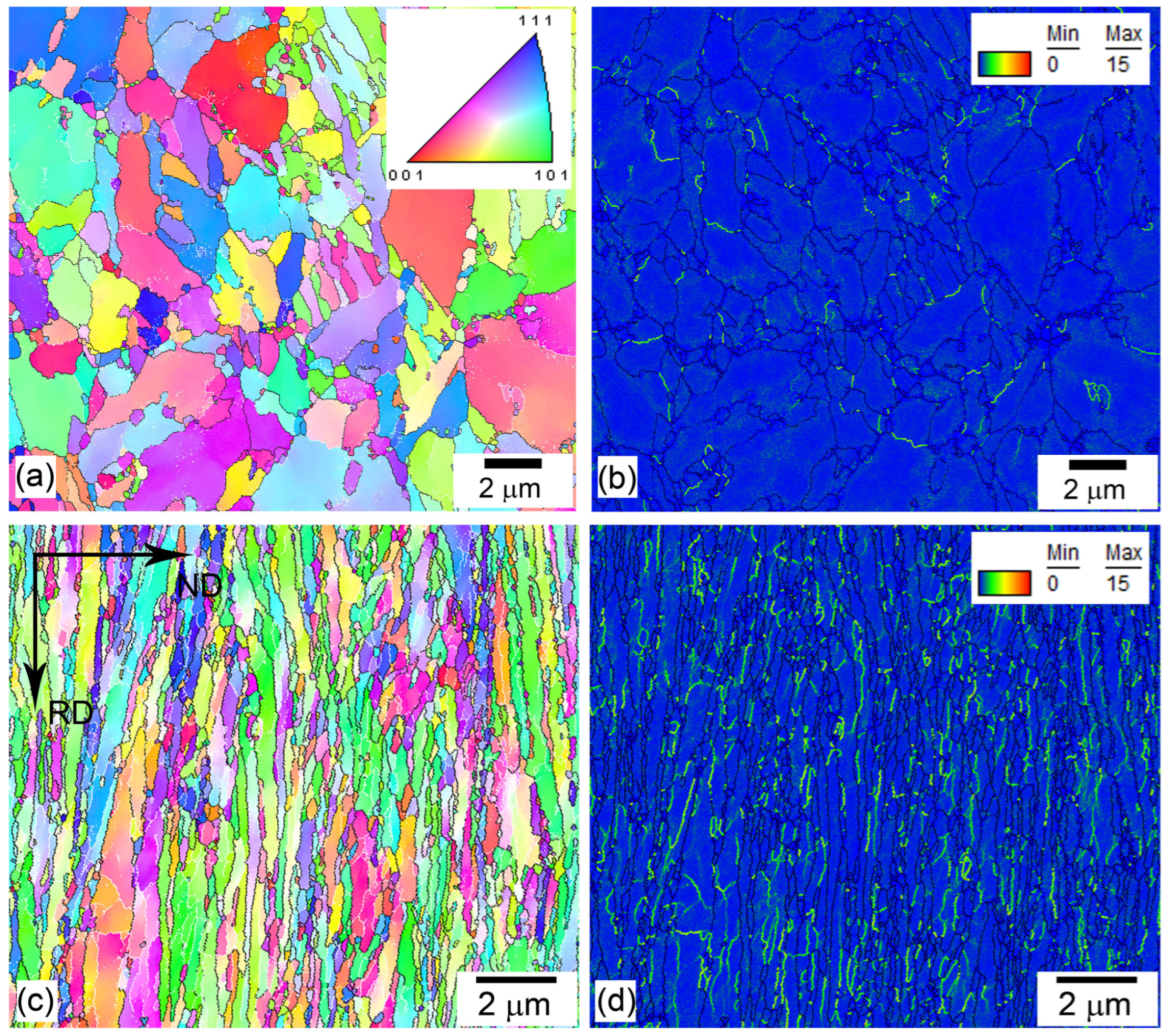

3.1. Microstructure

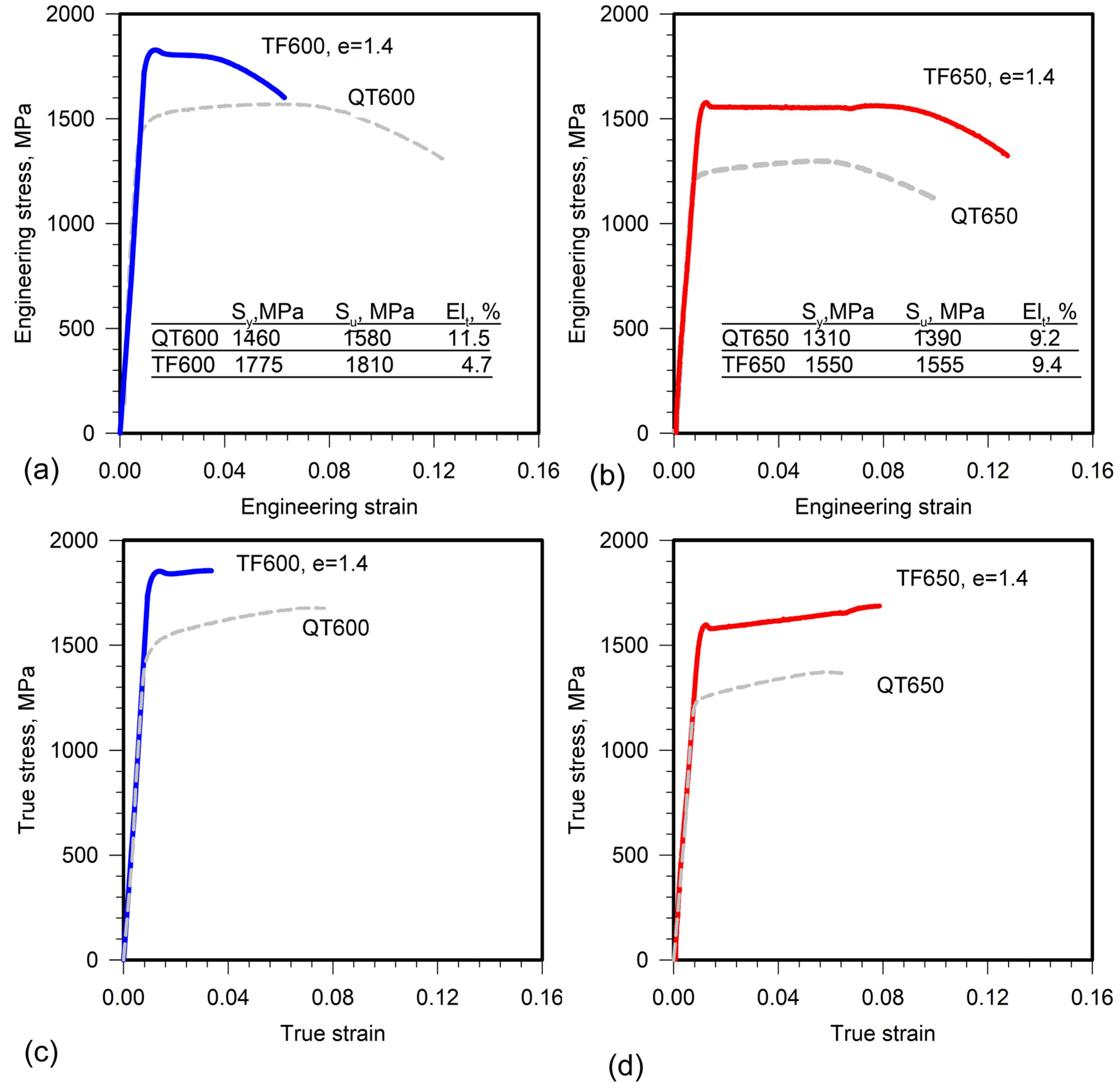

3.2. Tension Mechanical Properties

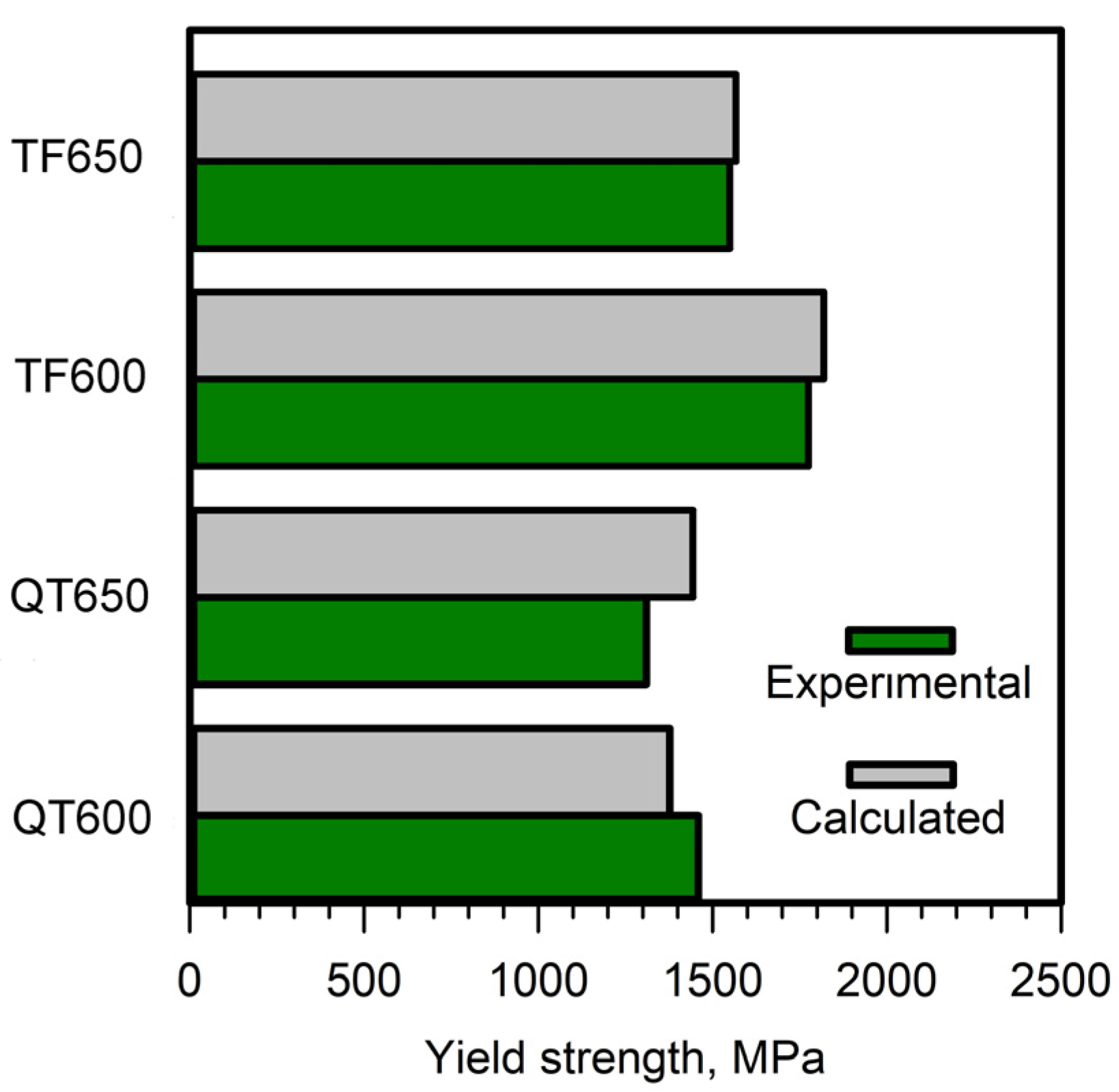

4. Discussion

5. Conclusions

- Dislocation strengthening gives the largest contribution to the overall yield strength of ~1400 MPa in the medium-carbon low-alloy steel in tempered condition due to small lath thickness and internal stresses originating from lath boundaries. Thin laths also provide relatively high values of grain size strengthening and dispersion strengthening. Low-angle boundaries in lamellar structure give no contribution to the dislocation strengthening of the present steel subjected to tempforming. High values of the grain size strengthening are attributed to small spacing between lamellar boundaries in the steel after tempforming.

- Dispersion strengthening is the major contributor to the overall yield strength ranging from 1550 to 1775 MPa in tempformed steel due to the formation of frequent M23C6 carbide chains on lamellar boundaries and small interboundary spacing of lamellar structure. The latter also provides high values of grain size strengthening. The high density of free dislocations induced by warm rolling is the third factor providing high yield strength.

- The dispersion of boundary M23C6 carbides and matrix (V,Nb)C carbides plays a key role in the yield strength of the steel in tempered and tempformed conditions. The direct effect of dispersoids on the yield strength is associated with dispersion strengthening, whereas indirect enhancement of the strength is attributed to the influence of M23C6 carbides and (V,Nb)C carbides on the characteristics of the tempered martensite lath structure and the lamellar structure that provides high values of the grain size strengthening and the dislocation strengthening.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krauss, G. Steels: Processing Structure, and Performance, 2nd ed.; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Kimura, Y.; Inoue, T.; Tsuzaki, K. Tempforming in Medium-Carbon Low-Alloy Steel. J. Alloys Compd. 2013, 577, S538. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Mechanical Property of Ultrafine Elongated Grain Structure Steel Processed by Warm Tempforming and Its Application to Ultrahigh-Strength Bolt. ISIJ Int. 2020, 60, 1108–1126. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Pydrin, A.; Gaidar, S.; Kaibyshev, R.; Belyakov, A. Microstructure and Strengthening Mechanisms in an Hsla Steel Subjected to Tempforming. Metals 2022, 12, 48. [Google Scholar] [CrossRef]

- Yuzbekova, D.; Dudko, V.; Pydrin, A.; Gaidar, S.; Mironov, S.; Kaibyshev, R. Effect of Tempforming on Strength and Toughness of Medium-Carbon Law-Alloy Steel. Materials 2023, 16, 1202. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Kaibyshev, R.; Belyakov, A. Tempforming as an Advanced Processing Method for Carbon Steels. Metals 2020, 10, 1566. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, M.; Cao, K.; Ning, J.; Feng, Y. Effect of Annealing Time on Microstructure Stability and Mechanical Behavior of Ferrite-Cementite Steel with Multiscale Lamellar Structure. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2021, 52, 1023–1033. [Google Scholar] [CrossRef]

- Zhang, X.; Godfrey, A.; Huang, X.; Hansen, N.; Liu, Q. Microstructure and Strengthening Mechanisms in Cold-Drawn Pearlitic Steel Wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation Gradients and Geometrically Necessary Dislocations in Ultrafine Grained Dual-Phase Steels Studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Dudko, V.; Yuzbekova, D.; Gaidar, S.; Vetrova, S.; Kaibyshev, R. Tempering Behaviour of Novel Low-Alloy High-Strength Steel. Metals 2022, 12, 2177. [Google Scholar] [CrossRef]

- Dudko, V.; Belyakov, A.; Kaibyshev, R. Evolution of Lath Substructure and Internal Stresses in a 9% Cr Steel during Creep. ISIJ Int. 2016, 57, 3–6. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Schwab, R.; Ruff, V. On the Nature of the Yield Point Phenomenon. Acta Mater. 2013, 61, 1798–1808. [Google Scholar] [CrossRef]

- Antolovich, S.D.; Armstrong, R.W. Plastic Strain Localization in Metals: Origins and Consequences. Prog. Mater. Sci. 2014, 59, 1–160. [Google Scholar] [CrossRef]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, Nano-Scale Precipitation and Strengthening of Steels. Prog. Mater. Sci. 2021, 118, 100764. [Google Scholar] [CrossRef]

- Gutiérrez, I.; Altuna, M.A. Work-Hardening of Ferrite and Microstructure-Based Modelling of Its Mechanical Behaviour under Tension. Acta Mater. 2008, 56, 4682–4690. [Google Scholar] [CrossRef]

- Queyreau, S.; Monnet, G.; Devincre, B. Orowan Strengthening and Forest Hardening Superposition Examined by Dislocation Dynamics Simulations. Acta Mater. 2010, 58, 5586–5595. [Google Scholar] [CrossRef]

- Na, H.; Nambu, S.; Ojima, M.; Inoue, J.; Koseki, T. Crystallographic and Microstructural Studies of Lath Martensitic Steel during Tensile Deformation. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2014, 45, 5029–5043. [Google Scholar] [CrossRef]

- Inoue, J.; Sadeghi, A.; Koseki, T. Slip Band Formation at Free Surface of Lath Martensite in Low Carbon Steel. Acta Mater. 2019, 165, 129–141. [Google Scholar] [CrossRef]

- Koppenaal, T.J.; Kuhlmann-Wilsdorf, D. The Effect of Prestressing on the Strength of Neutron-Irradiated Copper Single Crystals. Appl. Phys. Lett. 1964, 4, 59–61. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel III Discussion of Results. Proc. Phys. Society. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Takaki, S.; Akama, D.; Nakada, N.; Tsuchiyama, T. Effect of Grain Boundary Segregation of Interstitial Elements on Hallpetch Coefficient in Steels. Mater. Trans. 2014, 55, 28–34. [Google Scholar] [CrossRef]

- Naylor, J.P. The Influence of the Lath Morphology on the Yield Stress and Transition Temperature of Martensitic-Bainitic Steels. Metall. Trans. A 1979, 10, 861–873. [Google Scholar] [CrossRef]

- Harrell, T.J.; Topping, T.D.; Wen, H.; Hu, T.; Schoenung, J.M.; Lavernia, E.J. Microstructure and Strengthening Mechanisms in an Ultrafine Grained Al-Mg-Sc Alloy Produced by Powder Metallurgy. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2014, 45, 6329–6343. [Google Scholar] [CrossRef]

- Argon, A.S. Strengthening Mechanisms in Crystal Plasticity; Oxford University Press: New York, NY, USA, 2008. [Google Scholar]

- Mishnev, R.; Dudova, N.; Kaibyshev, R. On the Origin of the Superior Long-Term Creep Resistance of a 10% Cr Steel. Mater. Sci. Eng. A 2018, 713, 161–173. [Google Scholar] [CrossRef]

| Processing | QT600 | QT650 | TF600 | TF650 |

|---|---|---|---|---|

| Distance between HAB, µm | 1.1 ± 0.2 | 1.3 ± 0.3 | 0.280± 0.008 | 0.195± 0.005 |

| Average KAM, degree | 0.46 ± 0.2 | 0.56 ± 0.2 | 0.92 ± 0.2 | 0.85 ± 0.2 |

| ρKAM, 1015 m−2 | 2.2 ± 0.9 | 2.6 ± 0.9 | 4.3 ± 0.9 | 4.0 ± 0.9 |

| Taylor factor (M) | 3.16 | 3.06 | 3.17 | 2.98 |

| Transverse lath/subgrain size, nm | 200 ± 12 | 199 ± 18 | 72 ± 29 | 127 ± 65 |

| Dislocation density in subgrain interiors, 1014 m−2 | 5.9 ± 1.3 | 3.4 ± 0.9 | 11.0 ± 6.5 | 10.0 ± 3.8 |

| M23C6 particle size/volume fraction, nm/% | (49 ± 17)/7.2 | (48 ± 3)/7.3 | (41 ± 4)/7.2 | (61 ± 4)/7.3 |

| Mo6C particle size/volume fraction, nm/% | (208 ± 7)/0.6 | (208 ± 10)/0.6 | (208 ± 7)/0.6 | (190 ± 49)/0.6 |

| (V,Nb)C carbides particle size/volume fraction, nm/% | (46 ± 5)/0.41 | (37 ± 11)/0.37 | (46 ± 5)/0.41 | (46 ± 5)/0.37 |

| Temperature, °C | Concentrations of Elements × 105, Mass% | |||

|---|---|---|---|---|

| C | Mn | Cr | Mo | |

| 600 | 358 | 0.9 | 13,000 | 2500 |

| 650 | 620 | 2.9 | 20,000 | 5700 |

| Processing | QT600 | QT650 | TF600 | TF650 |

|---|---|---|---|---|

| Grain size strengthening, σHP, MPa | 209 ± 17 | 192 ± 19 | 414 ± 6 | 496 ± 6 |

| Dispersion strengthening by (V,Nb)C carbides, MPa | 240 ± 19 | 276 ± 52 | 263 ± 23 | 239 ± 22 |

| Dispersion strengthening by M23C6, MPa | 322 ± 18 | 311 ± 25 | 794 ± 80 | 482 ± 58 |

| Total dispersion strengthening, σP, MPa | 402 ± 25 | 416 ± 52 | 837 ± 83 | 543 ± 62 |

| Peierls–Nabarro or friction stress, , MPa | 45 | 45 | 45 | 45 |

| Solid solution strengthening, σSS, MPa | 16 | 29 | 16 | 29 |

| Dislocation strengthening attributed to free dislocations within laths/lamellae (ρ), σd, MPa | 370 ± 9 | 272 ± 34 | 507 ± 132 | 454 ± 79 |

| Dislocation strengthening attributed to dislocations with like sign (ρKAM), , MPa | 706 ± 135 | 762 ± 119 | 1000 ± 100 | 909 ± 97 |

| , MPa | - | - | 1819 ± 221 | 1567 ± 147 |

| , MPa | 1378 ± 177 | 1444 ± 190 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudko, V.; Yuzbekova, D.; Kaibyshev, R. Strengthening Mechanisms in a Medium-Carbon Steel Subjected to Thermo-Mechanical Processing. Appl. Sci. 2023, 13, 9614. https://doi.org/10.3390/app13179614

Dudko V, Yuzbekova D, Kaibyshev R. Strengthening Mechanisms in a Medium-Carbon Steel Subjected to Thermo-Mechanical Processing. Applied Sciences. 2023; 13(17):9614. https://doi.org/10.3390/app13179614

Chicago/Turabian StyleDudko, Valeriy, Diana Yuzbekova, and Rustam Kaibyshev. 2023. "Strengthening Mechanisms in a Medium-Carbon Steel Subjected to Thermo-Mechanical Processing" Applied Sciences 13, no. 17: 9614. https://doi.org/10.3390/app13179614

APA StyleDudko, V., Yuzbekova, D., & Kaibyshev, R. (2023). Strengthening Mechanisms in a Medium-Carbon Steel Subjected to Thermo-Mechanical Processing. Applied Sciences, 13(17), 9614. https://doi.org/10.3390/app13179614