Anaerobic Digestion of Olive Mill Wastewater and Process Derivatives—Biomethane Potential, Operation of a Continuous Fixed Bed Digester, and Germination Index

Abstract

:1. Introduction

2. Materials and Methods

3. Results

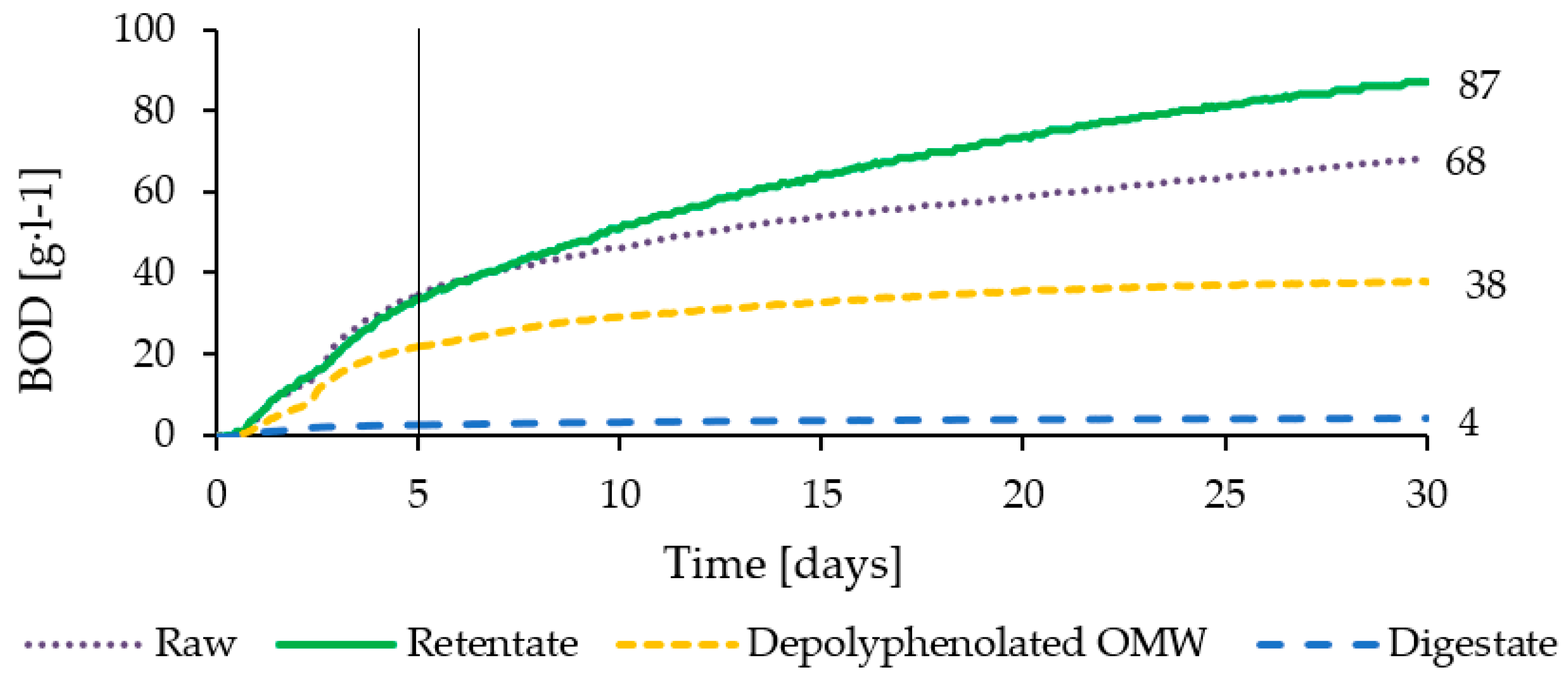

3.1. Biological Oxygen Demand

3.2. Biomethane Potential

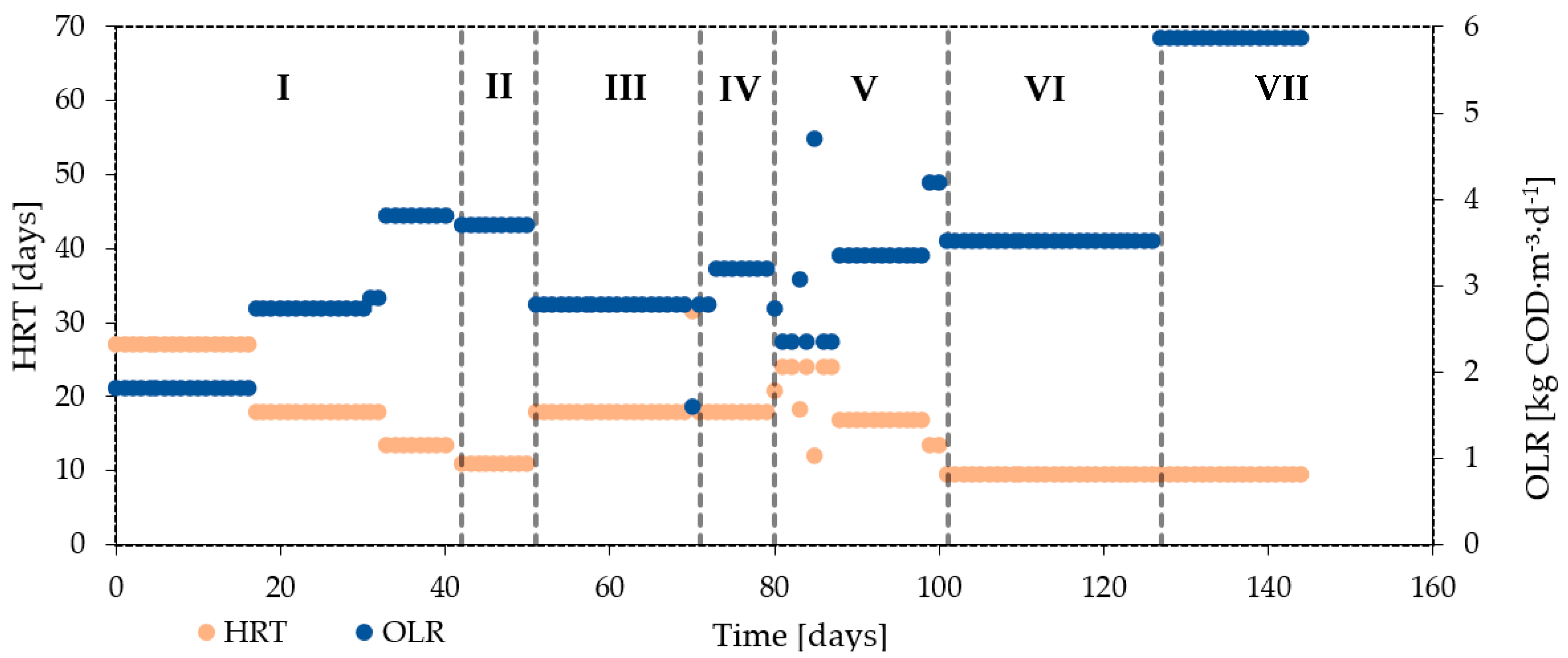

3.3. Continuous Anaerobic Digestion of Raw and Derived OMW

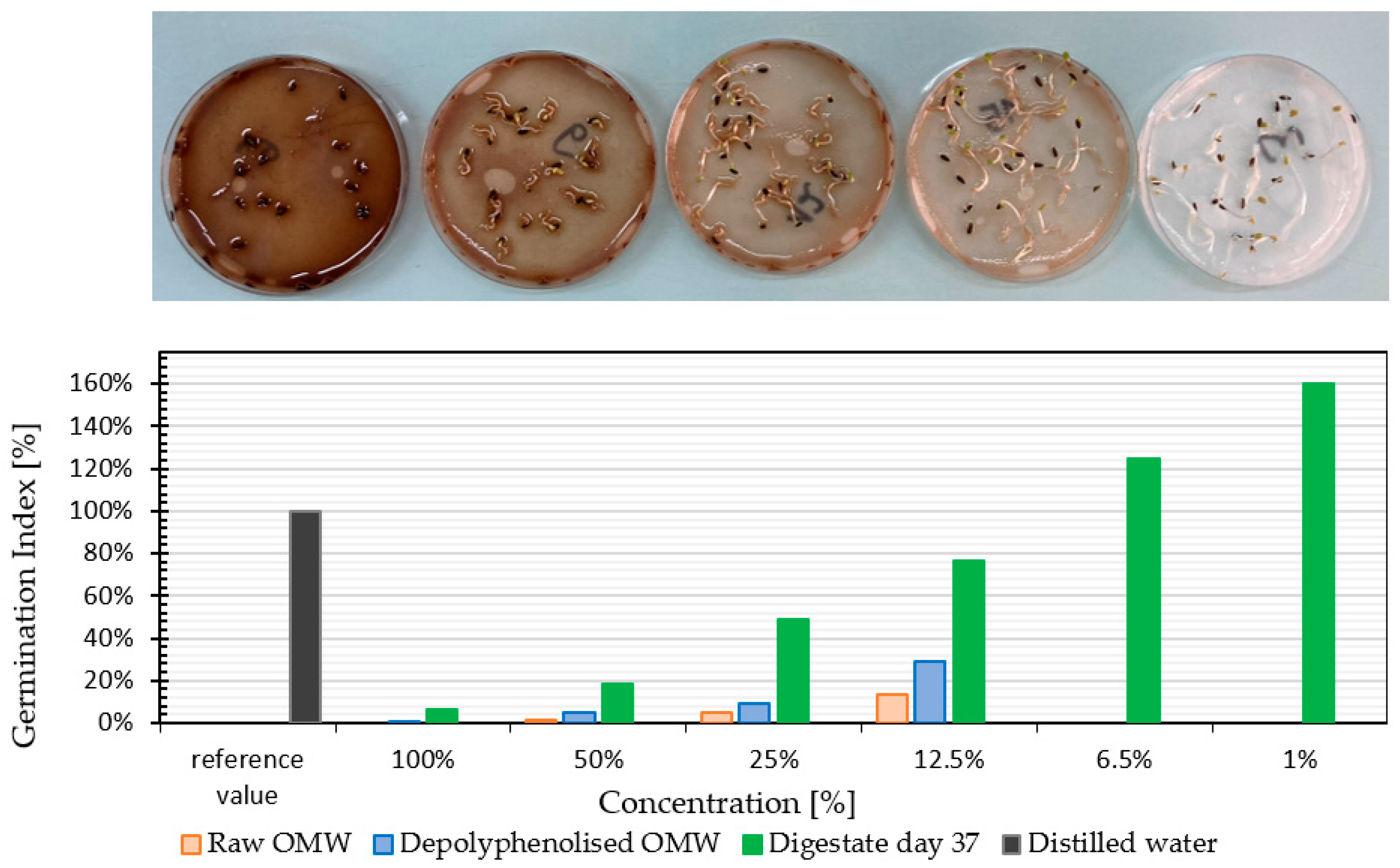

3.4. Germination Index

4. Discussion

5. Conclusions

- Biomethane yields are comparable to those of renewable raw materials

- Process stability

- A suitable long-year co-substrate plan with alternative biomass for anaerobic digestion between March and November

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Overview of the Olive Sector in Tunisia. In Official journal of the International Olive Council; OLIVEA: Kingston, ON, Canada, 2017; p. 124.

- El Alami, A.; Fattah, A. Olive mill wastewater causing pollution in the Oum Er Rbia River and potential environmental effects and impact on the Eurasian Otter. J. Anal. Sci. Appl. Biotechnol. 2020, 2, 110–115. [Google Scholar] [CrossRef]

- Figueiredo, F.; Marques, P.; Geraldes Castanheira, É.; Kulay, L.; Freire, F. Greenhouse gas assessment of olive oil in Portugal addressing the valorization of olive mill waste. In Proceedings of the Symbiosis International Conference, Athens, Greece, 19–21 June 2014. [Google Scholar]

- Comegna, A.; Dragonetti, G.; Kodesova, R.; Coppola, A. Impact of olive mill wastewater (OMW) on the soil hydraulic and solute transport properties. Int. J. Environ. Sci. Technol. 2022, 19, 7079–7092. [Google Scholar] [CrossRef]

- Hamdi, M. Future prospects and constraints of olive mill wastewaters use and treatment: A review. Bioprocess Eng. 1993, 8, 209–214. [Google Scholar] [CrossRef]

- Messineo, A.; Maniscalco, M.P.; Volpe, R. Biomethane recovery from olive mill residues through anaerobic digestion: A review of the state of the art technology. Sci. Total Environ. 2020, 703, 135508. [Google Scholar] [CrossRef]

- Hamdi, M.; Garcia, J.L.; Ellouz, R. Integrated biological process for olive mill wastewater treatment, Sfax. Bioprocess Biosyst. Eng. 1992, 8, 79–84. Available online: https://core.ac.uk/download/pdf/39861081.pdf (accessed on 18 June 2023). [CrossRef]

- Gunay, A.; Karadag, D. Recent developments in the anaerobic digestion of olive mill effluents. Process Biochem. 2015, 50, 1893–1903, ISSN 1359-5113. [Google Scholar] [CrossRef]

- Majer, S.; Kornatz, P.; Daniel-Gromke, J.; Rensberg, N.; Brosowski, A.; Oehmichen, K.; Liebetrau, J. Stand und Perspektiven der Biogaserzeugung aus Gülle; DBFZ: Leipzig, Germany, 2019; ISBN 978-3-946629-48-1. [Google Scholar]

- Debbabi, O.S.; Amar, F.B.; Rahmani, S.M.; Taranto, F.; Montemurro, C.; Miazzi, M.M. The Status of Genetic Resources and Olive Breeding in Tunisia. Plants 2022, 11, 1759. [Google Scholar] [CrossRef]

- Al-Qodah, Z.; Al-Zoubi, H.; Hudaib, B.; Omar, W.; Soleimani, M.; Abu-Romman, S.; Frontistis, Z. Sustainable vs. Conventional Approach for Olive Oil Wastewater Management: A Review of the State of the Art. Water 2022, 14, 1695. [Google Scholar] [CrossRef]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; de Wilde, V.; et al. Towards a Standardization of Biomethane Potential Tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef]

- Karray, R.; Elloumi, W.; Ben Ali, R.; Loukil, S.; Chamkha, M.; Karray, F.; Sayadi, S. A Novel Bioprocess Combining Anaerobic Co-Digestion Followed by Ultra-Filtration and Microalgae Culture for Optimal Olive Mill Wastewater Treatment. J. Environ. Manag. 2022, 303, 114188. [Google Scholar] [CrossRef]

- Chaher, N.E.H.; Hemidat, S.; Chakchouk, M.; Nassour, A.; Hamdi, M.; Nelles, M. From anaerobic to aerobic treatment: Upcycling of digestate as a moisturizing agent for in-vessel composting process. Bioresour. Bioprocess 2020, 7, 60. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Fòlino, A.; Tamburino, V.; Zappia, G.; Zema, D.A. Increasing the Tolerance to Polyphenols of the Anaerobic Digestion of Olive Wastewater through Microbial Adaptation. Biosyst. Eng. 2018, 172, 19–28. [Google Scholar] [CrossRef]

- Micoli, L.; Di Rauso Simeone, G.; Turco, M.; Toscano, G.; Rao, M.A. Anaerobic Digestion of Olive Mill Wastewater in the Presence of Biochar. Energies 2023, 16, 3259. [Google Scholar] [CrossRef]

- Henze, M.; Harremoës, P.; Jansen, J.L.C.; Arvin, E. Wastewater Treatment—Biological and Chemical Processes, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2002; ISBN 978-3-540-42228-0. [Google Scholar]

- Blika, P.S.; Stamatelatou, K.; Kornaros, M.; Lyberatos, G. Anaerobic Digestion of Olive Mill. Glob. Nest J. 2009, 11, 364–372. [Google Scholar]

- Philipp, M.; Ackermann, H.; Barbana, N.; Pluschke, J.; Geißen, S.U. Possibilities for Anaerobic Digestion of Slaughter Waste and Flotates for Biomethane Production. Water 2023, 15, 1818. [Google Scholar] [CrossRef]

- Rosenwinkel, K.-H.; Kroiss, H.; Dichtl, N.; Seyfried, C.-F.; Weiland, P. (Eds.) Anaerobtechnik; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-642-24894-8. [Google Scholar]

- Henze, M.; van Loosdrecht, M.C.M.; Ekama, G.A.; Brdjanovic, D. Biological Wastewater Treatment: Principles, Modelling and Design; IWA Publishing: London, UK, 2008; ISBN 978-1-78040-186-7. [Google Scholar]

- Afif, R.A.; Pfeifer, C. Biochemical Methane Potential of Three-Phase Olive Mill Solid Waste: Influence of Temperature and Supplemental Enzymes. Carbon Resour. Convers. 2022, 5, 248–254. [Google Scholar] [CrossRef]

- Gonçalves, M.; Freitas, P.; Marques, I. Bioenergy recovery from olive mill effluent in a hybrid reactor. Biomass Bioenergy 2012, 39, 253–260, ISSN 0961-9534. [Google Scholar] [CrossRef]

- Azbar, N.; Keskin, T.; Yuruyen, A. Enhancement of biogas production from olive mill effluent (OME) by co-digestion. Biomass Bioenergy 2008, 32, 1195–1201. [Google Scholar] [CrossRef]

- González-González, A.; Cuadros, F. Effect of aerobic pretreatment on anaerobic digestion of olive mill wastewater (OMWW): An ecoefficient treatment. Food Bioprod. Process. 2014, 95, 339–345. [Google Scholar] [CrossRef]

- Beltrán-Heredia, J.; Torregrosa, J.; Garcia, J.; Domínguez, J.R.; Tierno, J.C. Degradation of olive mill wastewater by the combination of Fenton’s reagent and ozonation processes with an aerobic biological treatment. Water Sci. Technol. 2001, 44, 103–108. [Google Scholar] [CrossRef]

- Ruggeri, B.; Battista, F.; Bernardi, M.; Fino, D.; Mancini, G. The selection of pretreatment options for anaerobic digestion (AD): A case study in olive oil waste production. Chem. Eng. J. 2015, 259, 630–639, ISSN 1385-8947. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Aghbashlo, M.; Valijanian, E.; Panahi, H.K.S.; Nizami, A.-S.; Ghanavati, H.; Sulaiman, A.; Mirmohamadsadeghi, S.; Karimi, K. A comprehensive review on recent biological innovations to improve biogas production, Part 2: Mainstream and downstream strategies. Renew. Energy 2020, 146, 1392–1407. [Google Scholar] [CrossRef]

- Komilis, D.P.; Karatzas, E.; Halvadakis, C.P. The Effect of Olive Mill Wastewater on Seed Germination after Various Pretreatment Techniques. J. Environ. Manag. 2005, 74, 339–348. [Google Scholar] [CrossRef] [PubMed]

- Mekki, A.; Dhouib, A.; Feki, F.; Sayadi, S. Assessment of toxicity of the untreated and treated olive mill wastewaters and soil irrigated by using microbiotests. Ecotoxicol. Environ. Saf. 2008, 69, 488–495. [Google Scholar] [CrossRef]

- Ramos, L.F.; Pluschke, J.; Bernardes, A.M.; Geißen, S.-U. Polyphenols in food processing wastewaters: A review on their identification and recovery. Clean. Circ. Bioeconomy 2023, 5, 100048, ISSN 2772-8013. [Google Scholar] [CrossRef]

| OMW | Experiment a | Total Polyphenols b/Hydroxytyrosol c | TOC/ DOC | TS/VS | COD | SO42− | K+ | PO4−2 | Total Nitrogen | Treatment and Mixture |

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | Experiment (Days) | g·L−1 | g·L−1 | g·L−1 | g·L−1 | g·L−1 | g·L−1 | g·L−1 | g·L−1 | - |

| OMW 1 raw | BMP, GI, BOD | 3.36/- | 37.6/24.0 | 74.1/60.6 | 90.3 | - | - | 0.45 | 0.60 | OMW 1 Permeate after adsorption (to recover polyphenols) |

| OMW 1retentate | BMP, BOD | 2.64/- | 59.8/25.0 | 100.5/86.3 | 193.3 | - | - | 0.50 | 1.26 | OMW 1 sieved + filtered with ceramic ultrafiltration membranes |

| OMW 1 treated | I AD: (40), GI, BOD, BMP | 1.4–2.4/ 0.18–0.54 | 17.9/16.8 | 39.1/27.6 | 49.1 | 1.3–1.7 | 4.8 | 0.31–0.41 | 0.18 | 100% 3-phase OMW after membrane filtration and adsorption |

| OMW 2_1 diluted | II AD: (16) | 1.32/- | 12.1/10.9 | 25.0/19.6 | 40.0 | 0.8 | 2.7 | 0.15 | 0.11 | 43% sieved OMW 2 (traditional method), 57% water |

| OMW 2_2 diluted | III AD: (22) | 1.66 | 15.2/13.6 | 31.4/24.6 | 50.2 | 1.0 | 3.4 | 0.19 | 0.14 | 53% sieved OMW 2, 47% water |

| OMW 3treated | V AD: (43) | 1.56/0.57 | 18.8/11.9 | 39.5/29.0 | 56.6 | 2.1 | 3.3 | 0.27 | 0.37 | 75% 3-phase OMW after membrane filtration and adsorption, 25% retentate from the membrane filtration treating OMW |

| OMW 4treated | VI AD: (26) | 1.56/0.98 | 12.2/11.5 | 24.5/17.7 | 33.9 | 0.4 | 3.0 | 0.28 | 0.16 | |

| Co-Substrate | BMP | - | - | 89.2 d/ 81.8 d | 85.0 | - | - | - | - | Solid organic food-market waste |

| Inoculum | BMP | - | 12.37/ 1.86 | 28.6/ 17.5 | - | 0.01 | 1.76 | Digestate from an anaerobic reactor that is fed with market waste | ||

| Digestateday 37 | GI | 0.68 | 2.34/2.00 | 22.3/11.4 | 8.79 | 0.19 | 4.79 | 0.08 | 0.14 | Digestate of the fixed bed reactor used for the continuous experiment |

| 1 Inoculum | 2 Raw | 3 Depolyphenolized OMW | 4 Co-Substrate | 5 Retentate | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Volume | VS | Volume | VS | Volume | VS | Volume | VS | Volume | VS | |

| Sample Name | L | g | L | g | L | g | L | g | L | g |

| Inoculum | 0.35 | 6.11 | 0.35 | 6.11 | 0.35 | 6.11 | 0.35 | 6.11 | 0.35 | 6.11 |

| OMW | 0.10 | 6.11 | 0.07 | 4.28 | ||||||

| Depolyphenolized OMW | 0.21 | 6.11 | 0.10 | 3.06 | ||||||

| Co-Substrate | 0.02 | 1.83 | ||||||||

| Retentate | 0.04 | 3.06 | ||||||||

| Water | 0.32 | 0.22 | 0.11 | 0.22 | 0.18 | |||||

| Total | 0.67 | 6.11 | 0.67 | 12.23 | 0.67 | 12.23 | 0.67 | 12.23 | 0.67 | 12.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pluschke, J.; Faßlrinner, K.; Hadrich, F.; Loukil, S.; Chamkha, M.; Geißen, S.-U.; Sayadi, S. Anaerobic Digestion of Olive Mill Wastewater and Process Derivatives—Biomethane Potential, Operation of a Continuous Fixed Bed Digester, and Germination Index. Appl. Sci. 2023, 13, 9613. https://doi.org/10.3390/app13179613

Pluschke J, Faßlrinner K, Hadrich F, Loukil S, Chamkha M, Geißen S-U, Sayadi S. Anaerobic Digestion of Olive Mill Wastewater and Process Derivatives—Biomethane Potential, Operation of a Continuous Fixed Bed Digester, and Germination Index. Applied Sciences. 2023; 13(17):9613. https://doi.org/10.3390/app13179613

Chicago/Turabian StylePluschke, Jonas, Katharina Faßlrinner, Fatma Hadrich, Slim Loukil, Mohamed Chamkha, Sven-Uwe Geißen, and Sami Sayadi. 2023. "Anaerobic Digestion of Olive Mill Wastewater and Process Derivatives—Biomethane Potential, Operation of a Continuous Fixed Bed Digester, and Germination Index" Applied Sciences 13, no. 17: 9613. https://doi.org/10.3390/app13179613

APA StylePluschke, J., Faßlrinner, K., Hadrich, F., Loukil, S., Chamkha, M., Geißen, S.-U., & Sayadi, S. (2023). Anaerobic Digestion of Olive Mill Wastewater and Process Derivatives—Biomethane Potential, Operation of a Continuous Fixed Bed Digester, and Germination Index. Applied Sciences, 13(17), 9613. https://doi.org/10.3390/app13179613