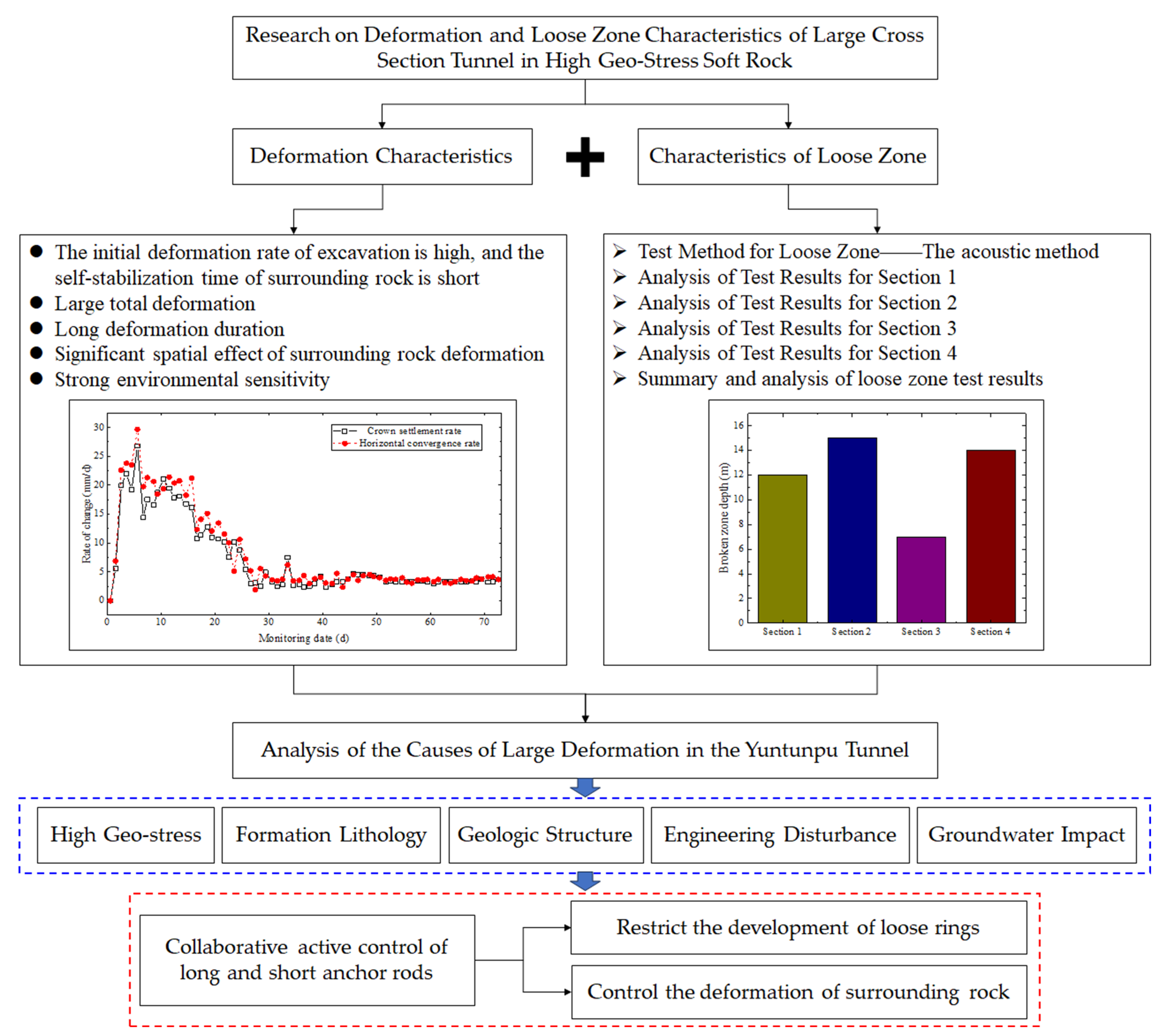

Research on Deformation and Loose Zone Characteristics of Large Cross Section Tunnel in High Geo-Stress Soft Rock

Abstract

1. Introduction

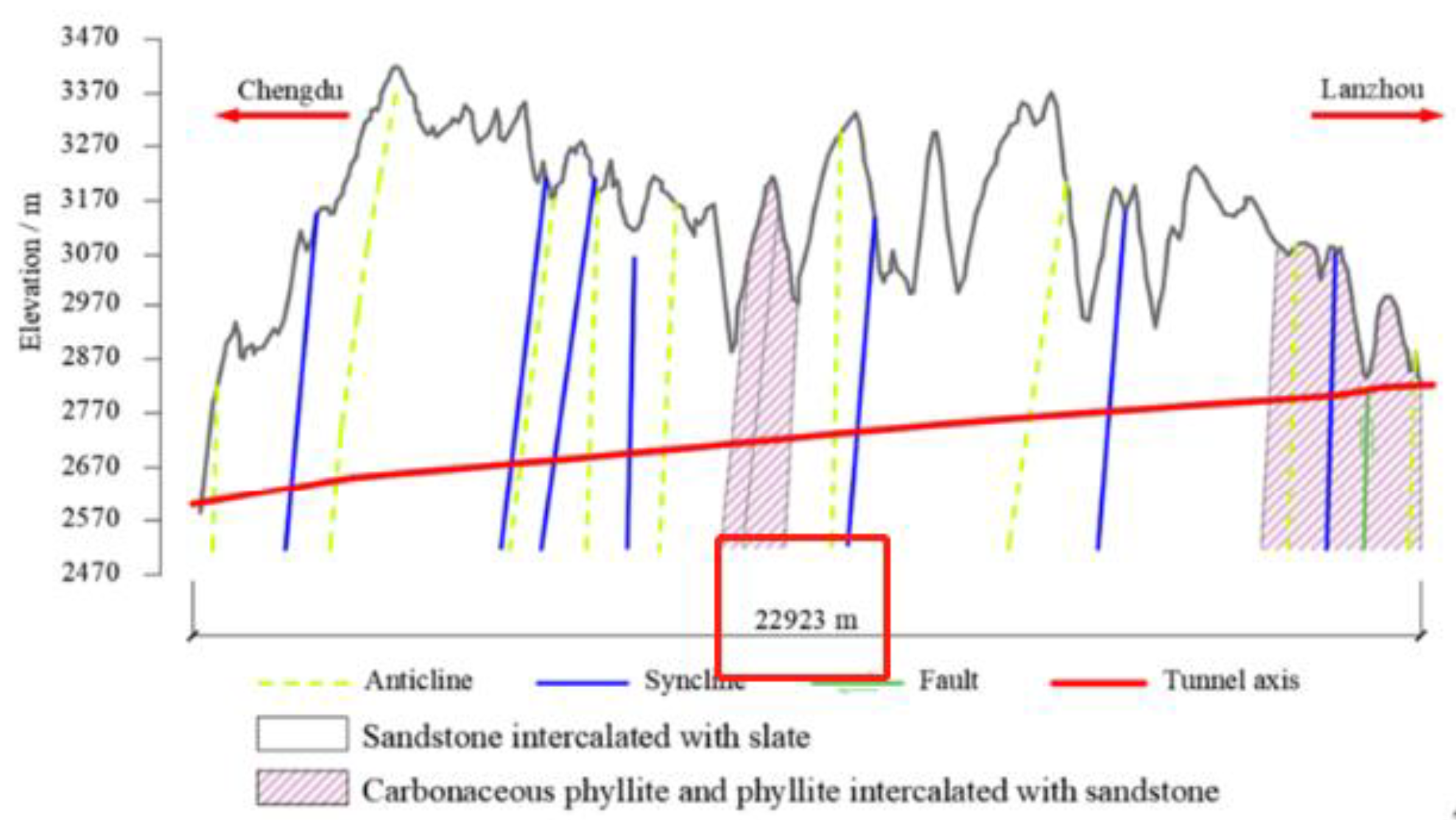

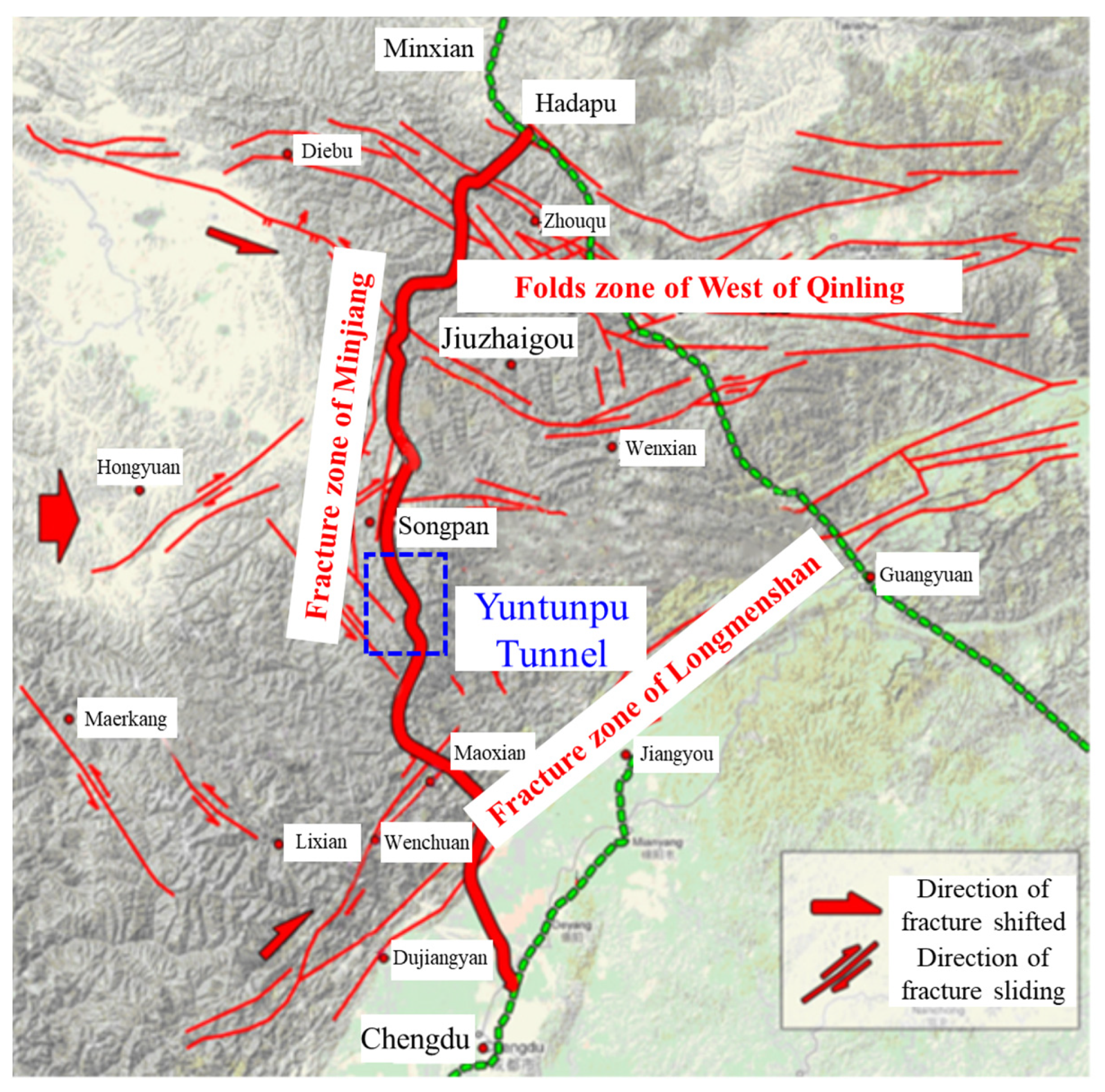

2. Project Overview

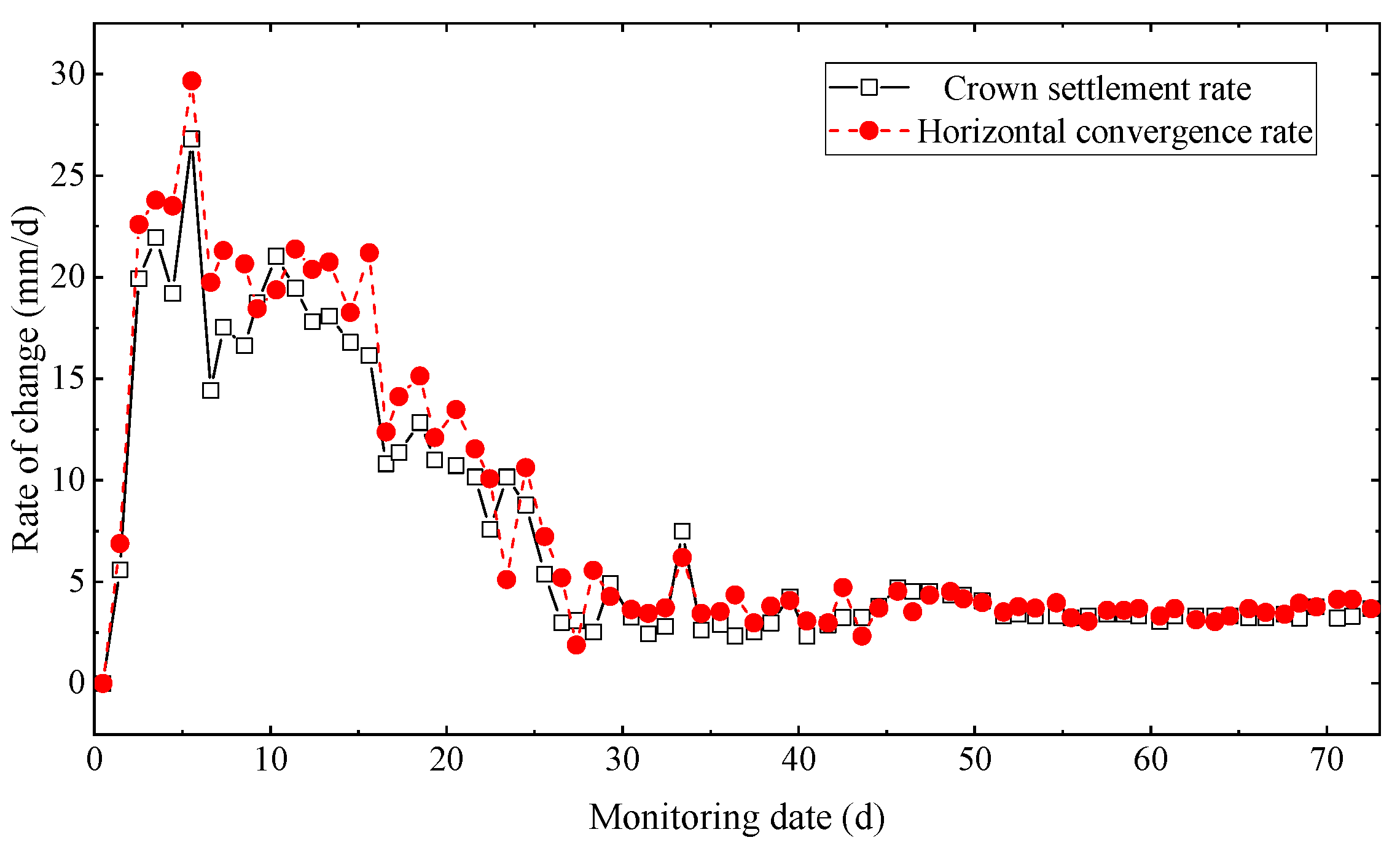

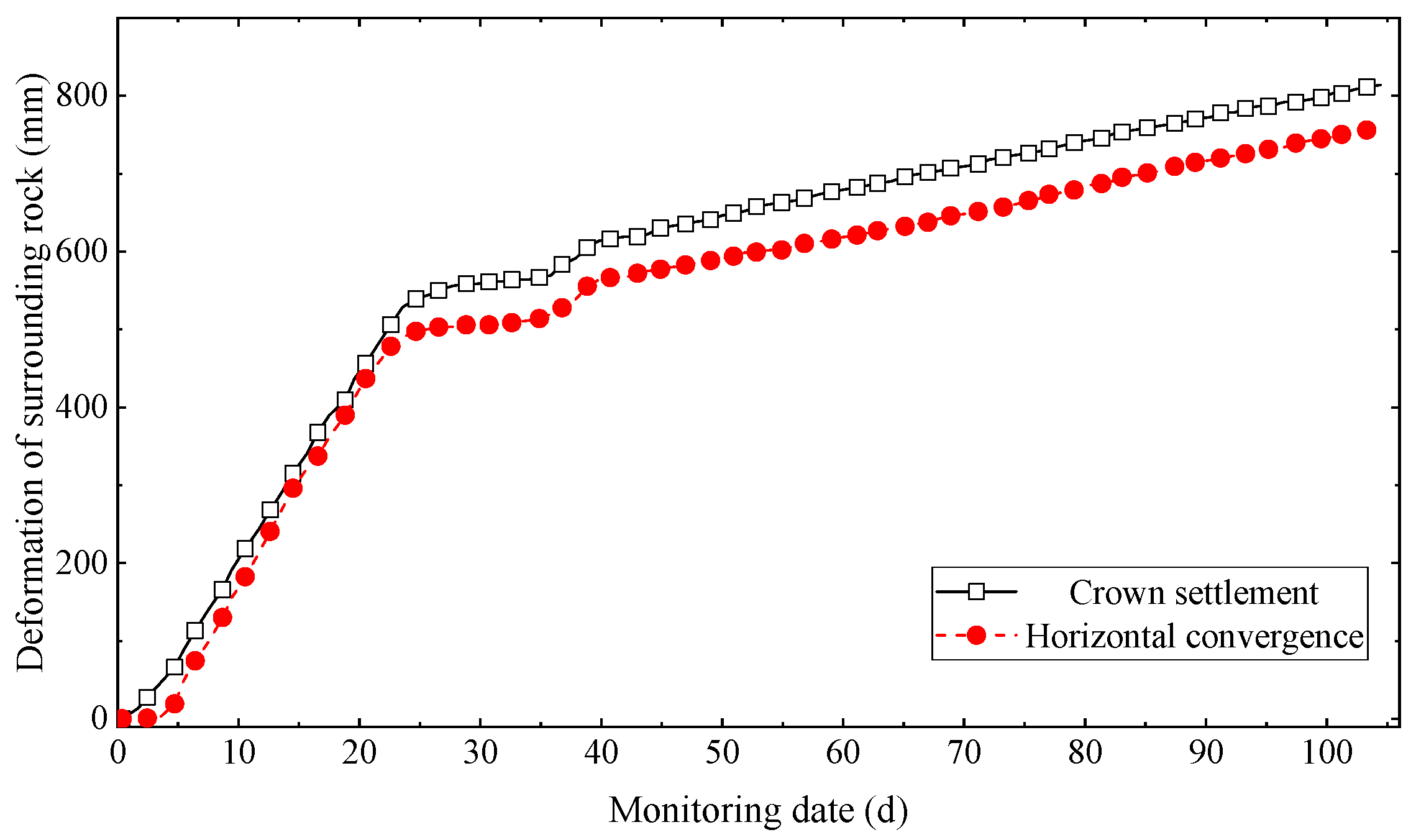

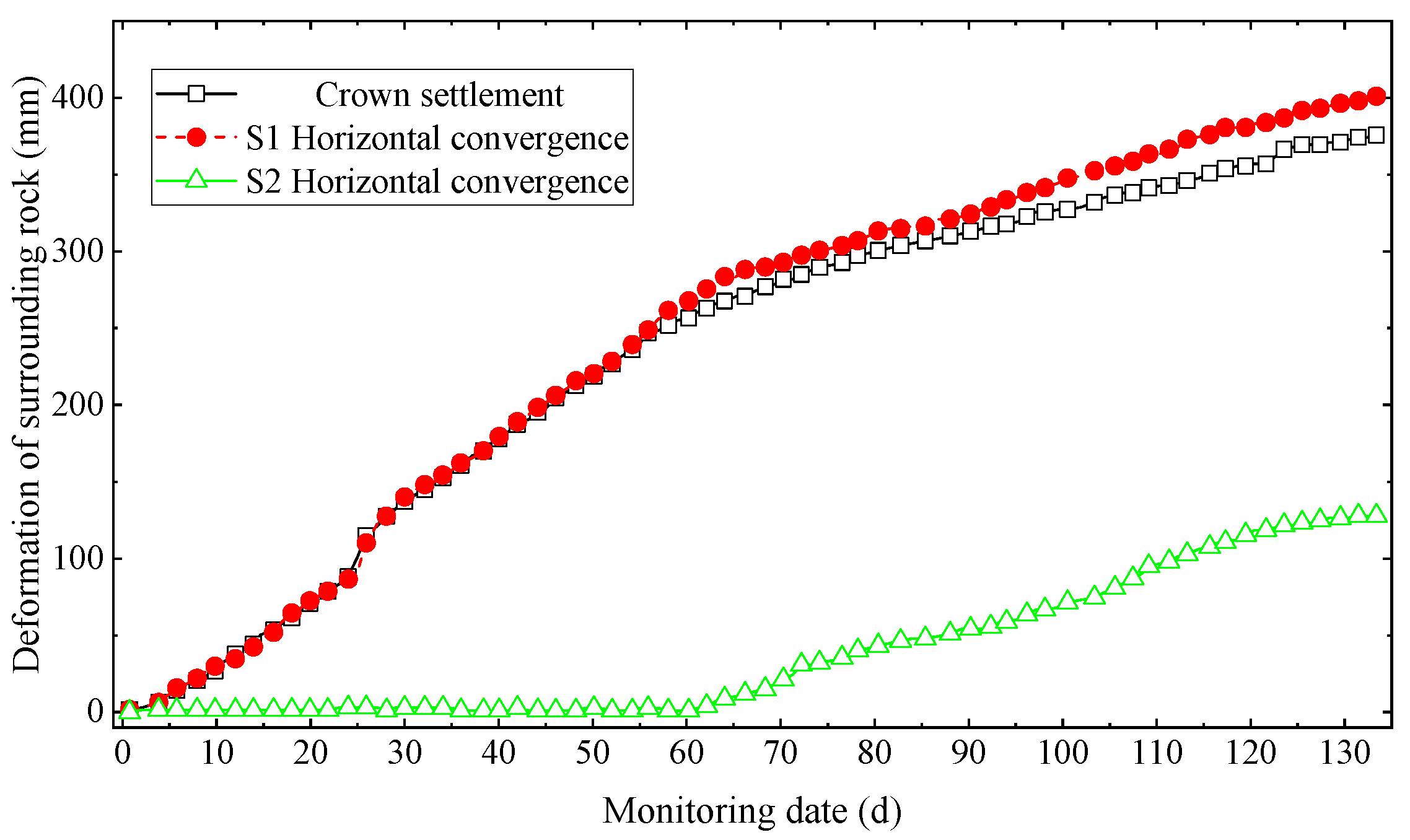

3. Deformation Characteristics of Yuntunpu Tunnel

- (1)

- The initial deformation rate of excavation is high, and the self-stabilization time of surrounding rock is short.

- (2)

- Large total deformation

- (3)

- Long deformation duration

- (4)

- Significant spatial effect of surrounding rock deformation

- (5)

- Strong environmental sensitivity

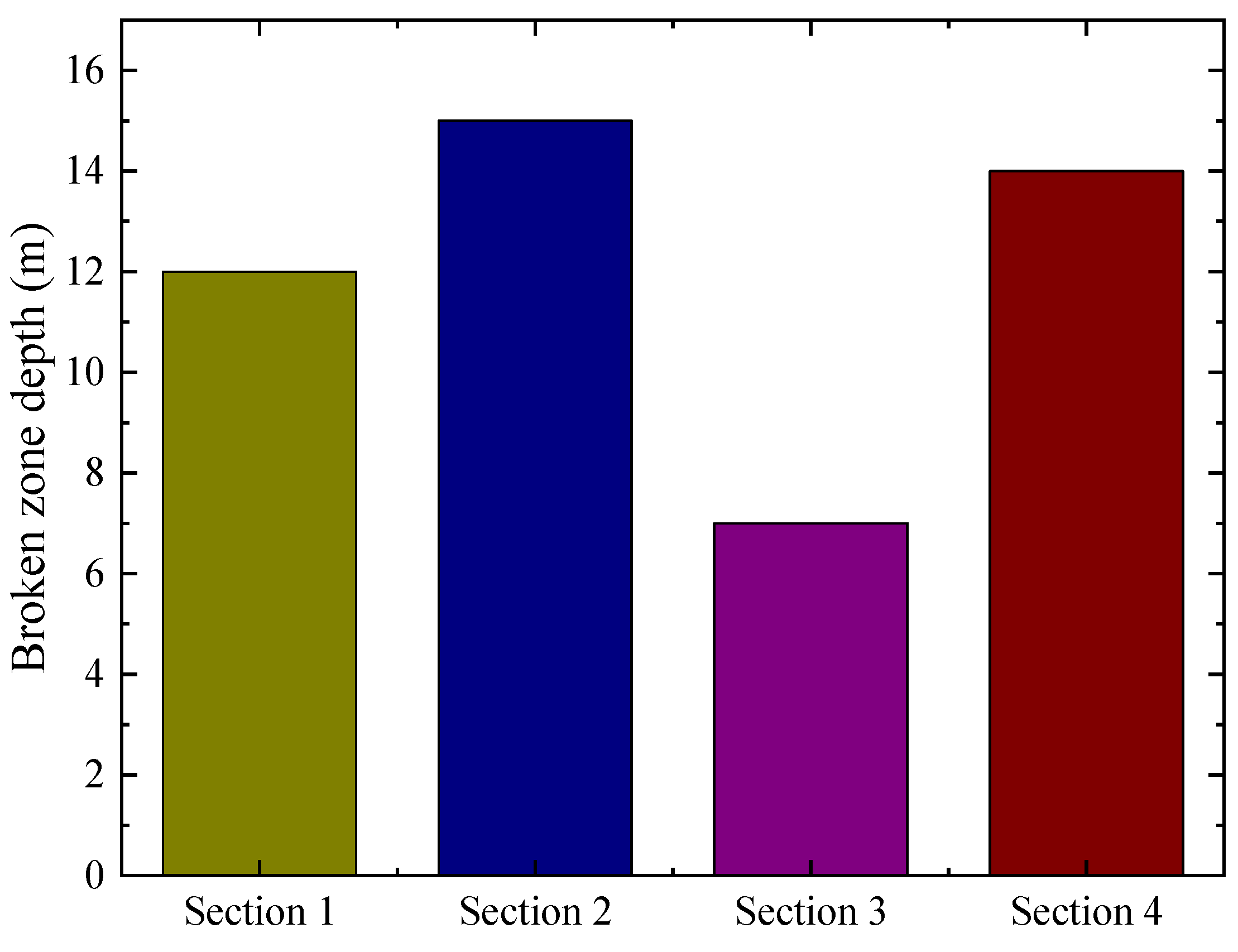

4. Characteristics of Loose Zone in Yuntunpu Tunnel

4.1. Test Method for Loose Zone

4.2. Analysis of Loose Zone Test Results

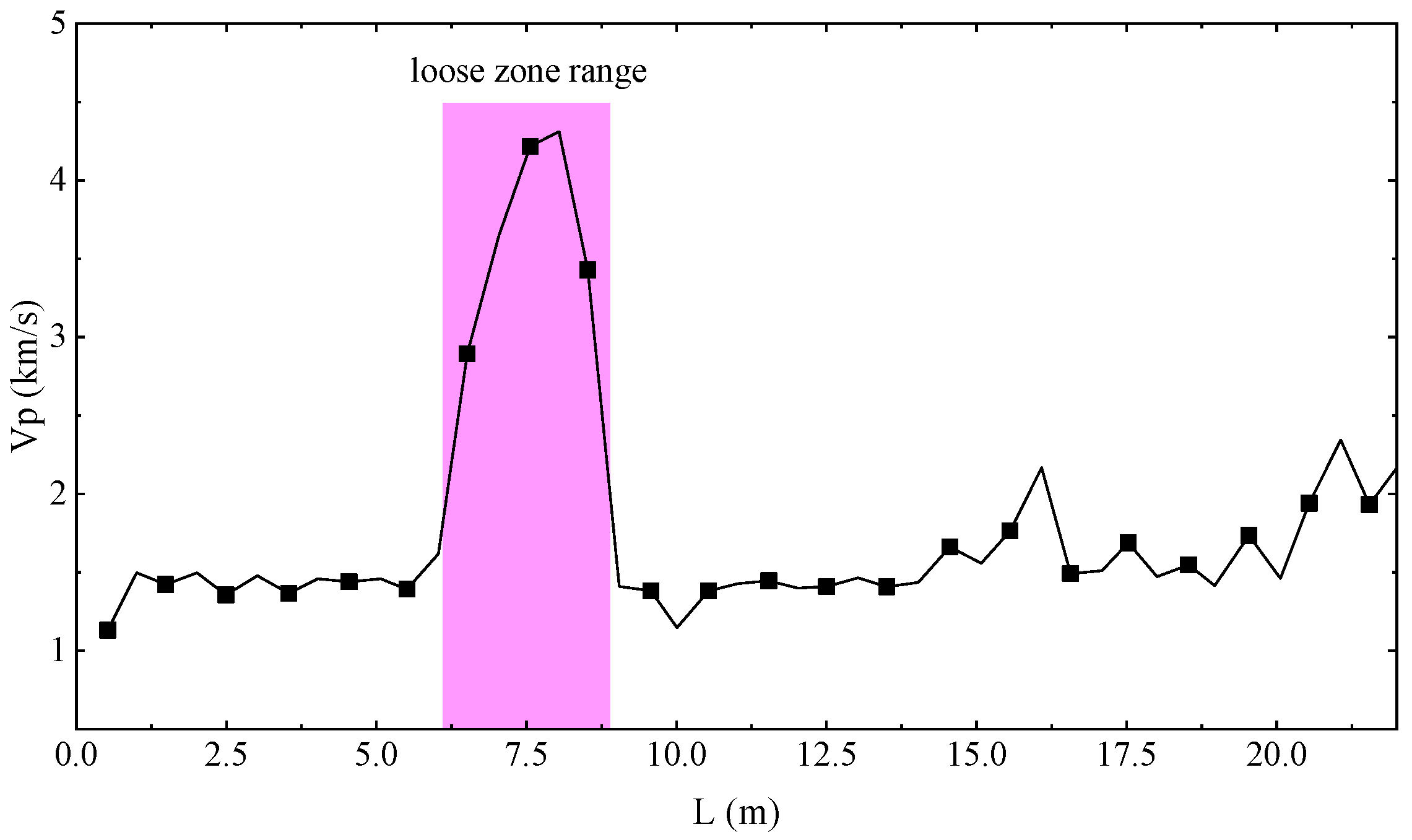

- (1)

- Analysis of Test Results for Section 1

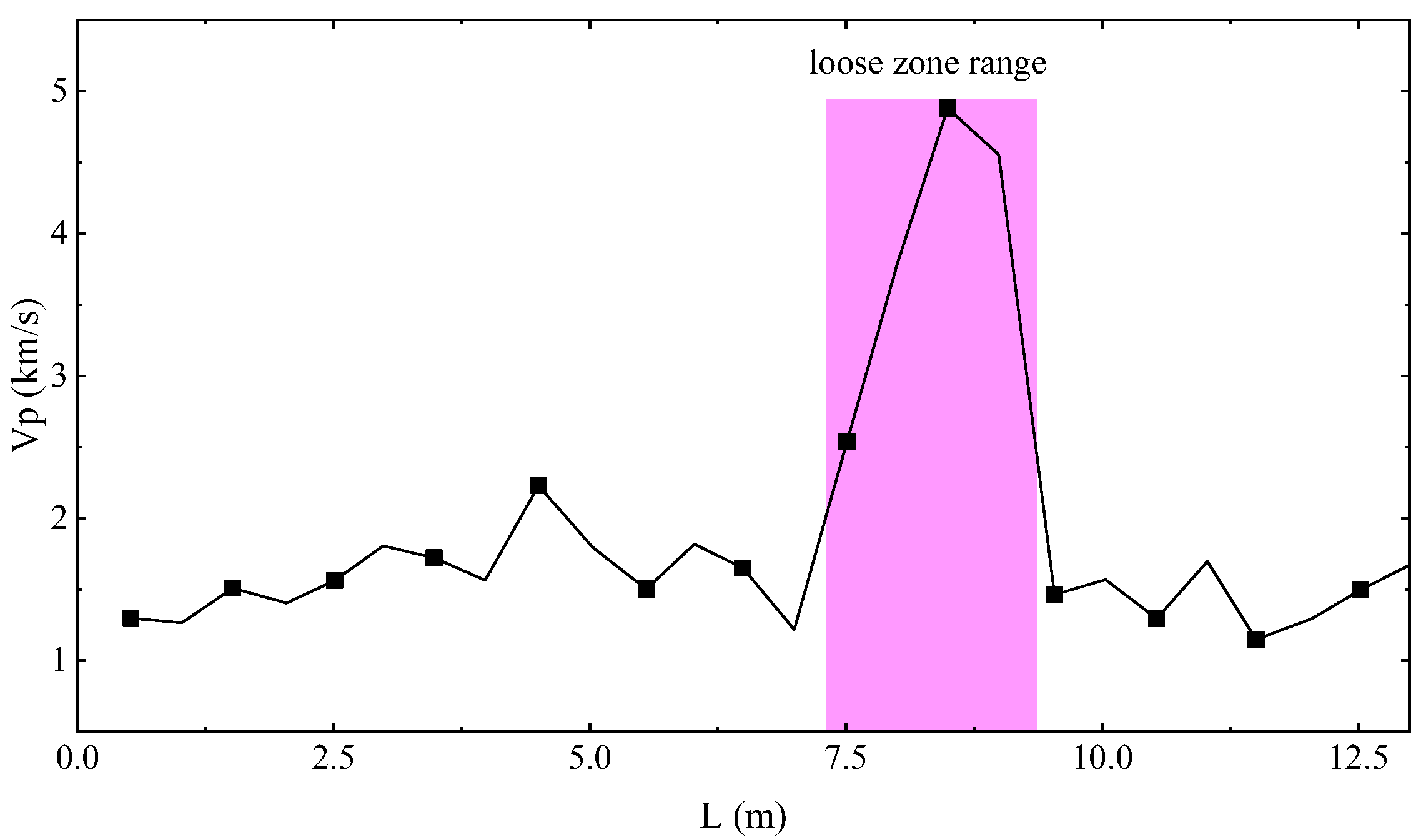

- (2)

- Analysis of Test Results for Section 2

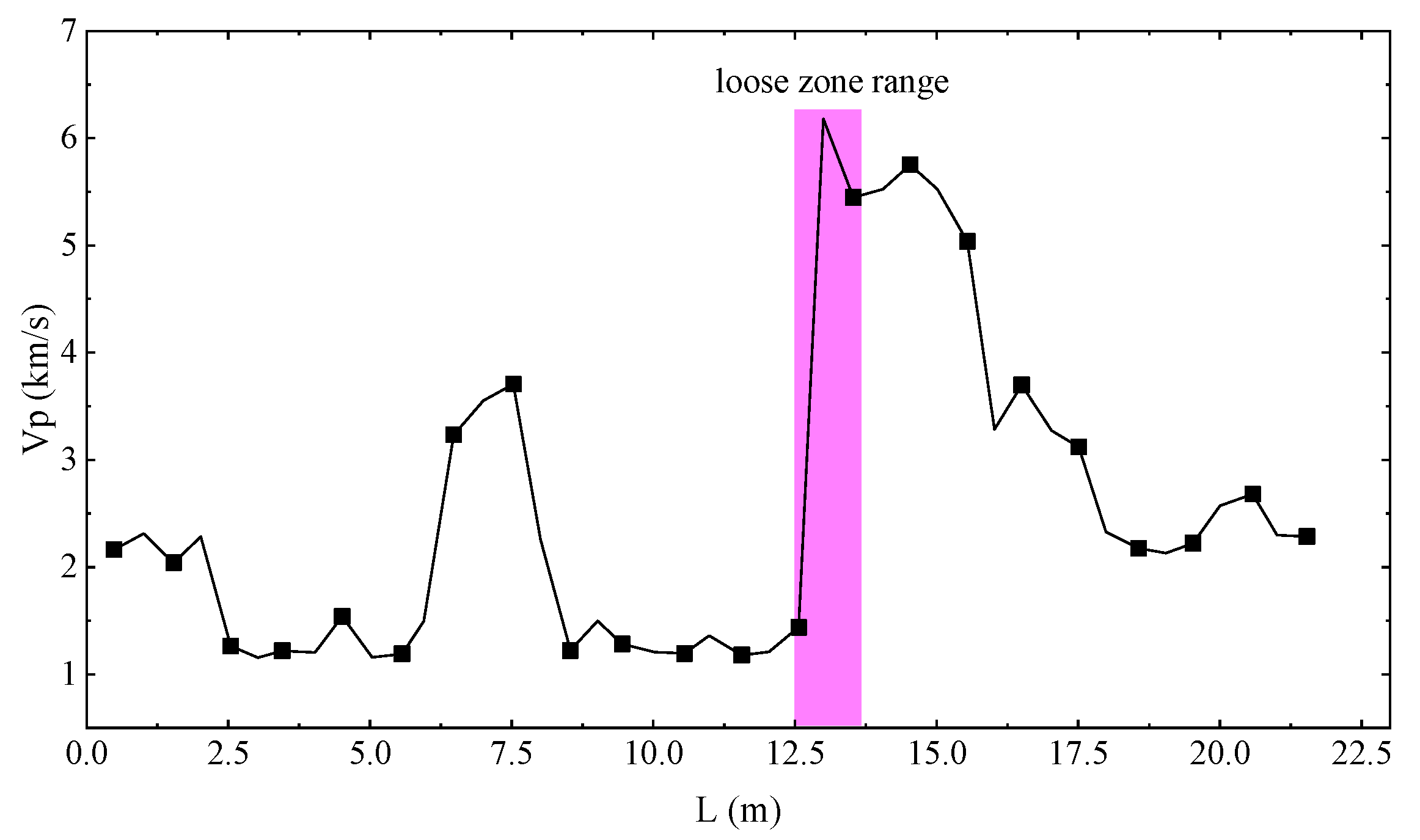

- (3)

- Analysis of Test Results for Section 3

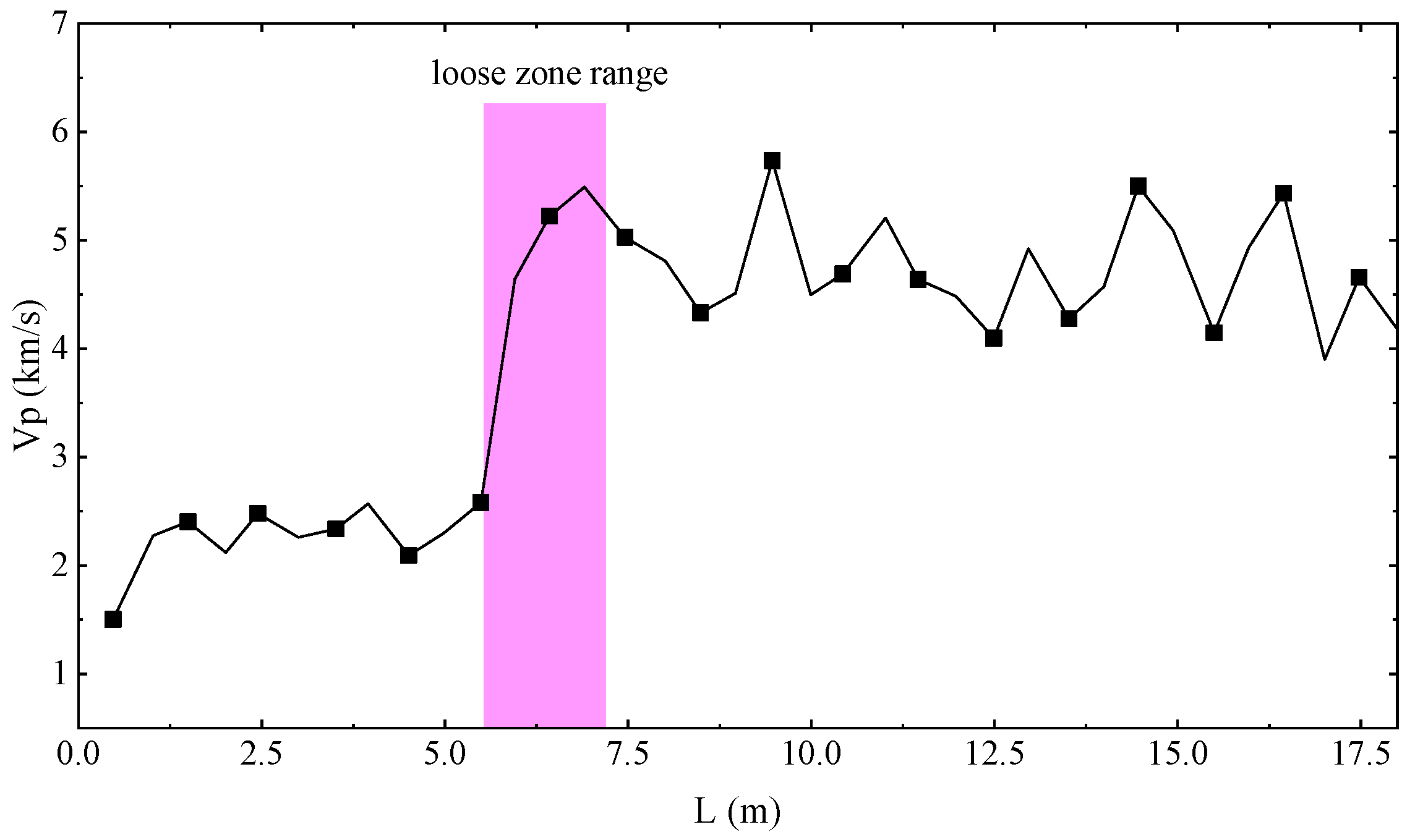

- (4)

- Analysis of Test Results for Section 4

- (5)

- Summary and analysis of loose zone test results

5. Analysis of the Causes of Large Deformation in the Yuntunpu Tunnel

5.1. High Geo-Stress

5.2. Formation Lithology

5.3. Geologic Structure

5.4. Engineering Disturbance

5.5. Groundwater Impact

6. Conclusions

- (1)

- The large deformation of the Yuntunpu Tunnel is characterized by a large deformation rate of the surrounding rock, short self-stabilization time of the surrounding rock, large cumulative deformation, and long deformation duration.

- (2)

- The range of tunnel loosening zones is 12–14 m. Affected by the grade and structure of the surrounding rock, the wave velocity variation characteristics exhibited by different grades of surrounding rock vary greatly.

- (3)

- It is recommended to use long and short anchor rods and to actively limit the scope of the loosening zones and control the deformation of the surrounding rock in collaboration with short prestressed anchor rods and long anchor rods.

- (4)

- High geo-stress and geological lithology are the decisive and important factors for the occurrence of large deformation disasters in the tunnel, and the reasons for the large deformation of the tunnel also include geological structures, engineering disturbances, and the influence of groundwater.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, C.; Lei, M.; Jia, C.; Zheng, K.; Song, Y.; Shi, Y. Asymmetric Large Deformation of Tunnel Induced by Groundwater in Carbonaceous Shale. Bull. Eng. Geol. Environ. 2022, 81, 260. [Google Scholar] [CrossRef]

- Deng, H.S.; Fu, H.L.; Shi, Y.; Zhao, Y.Y.; Hou, W.Z. Countermeasures against large deformation of deep-buried soft rock tunnels in areas with high geostress: A case study—ScienceDirect. Tunn. Undergr. Space Technol. 2022, 119, 104238. [Google Scholar] [CrossRef]

- Cui, G.; Qi, J.; Wang, D. Research on Large Deformation Control Technology of Tunnels in Squeezing Rock and Its Application. Sci. Prog. 2020, 103, 003685042092316. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Sui, Q.; Li, M.; Wang, Z.; Tao, Z. Compensation excavation method control for large deformation disaster of mountain soft rock tunnel. Int. J. Min. Sci. Technol. 2022, 32, 951–963. [Google Scholar] [CrossRef]

- Wang, R.; Liu, Y.; Deng, X.; Zhang, Y.; Huang, X.; Ding, X. Analysis on Loose Circle of Surrounding Rock of Large Deformation Soft-rock Tunnel. Adv. Civ. Eng. 2020, 2020, 8842976. [Google Scholar] [CrossRef]

- Fan, J.; Guo, Z.; Qiao, X.; Tao, Z.; Wang, F.; Zhang, C. Constant Resistance and Yielding Support Technology for Large Deformations of Surrounding Rocks in the Minxian Tunnel. Adv. Civ. Eng. 2020, 2020, 8850686. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, X.; Yang, K.; Guo, P.; Tao, Z. Model Test Study on Large Deformation Mechanism of Thin-bedded Metamorphic Sandstone Tunnel. Bull. Eng. Geol. Environ. 2022, 81, 436. [Google Scholar] [CrossRef]

- Bian, K.; Liu, J.; Liu, Z.; Liu, S.; Ai, F.; Zheng, X.; Ni, S.; Zhang, W. Mechanisms of Large Deformation in Soft Rock Tunnels: A Case Study of Huangjiazhai Tunnel. Bull. Eng. Geol. Environ. 2019, 78, 431–444. [Google Scholar] [CrossRef]

- Wang, F.N.; Guo, Z.B.; Qiao, X.B.; Fan, J.Y.; Li, W.; Mi, M.; He, M.C. Large deformation mechanism of thin-layered carbonaceous slate and energy coupling support technology of NPR anchor cable in Minxian Tunnel: A case study. Tunn. Undergr. Space Technol. 2021, 117, 104151. [Google Scholar] [CrossRef]

- Liu, W.; Chen, J.; Chen, L.; Luo, Y.; Shi, Z.; Wu, Y. Nonlinear deformation behaviors and a new approach for the classification and prediction of large deformation in tunnel construction stage: A case study. Eur. J. Environ. Civ. Eng. 2022, 26, 2008–2036. [Google Scholar] [CrossRef]

- Wu, F.; Miao, J.; Bao, H.; Wu, J. Large deformation of tunnel in slate-schistose rock: A case study on Muzhailing tunnel, Lan-Yu railway, China. Eng. Geol. Soc. Territ. 2015, 6, 17–23. [Google Scholar]

- Yang, J. Study on Large Deformation Prediction and Control Technology of Carbonaceous Slate Tunnel in Lixiang Railway. Geofluids 2022, 2022, 7236065. [Google Scholar] [CrossRef]

- Li, J.Q.; Wang, Z.F.; Wang, Y.Q.; Chang, H.T. Analysis and countermeasures of large deformation of deep-buried tunnel excavated in layered rock strata: A case study. Eng. Fail. Anal. 2023, 146, 107057. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Z.; Shao, S.; Zhao, Z.; Hu, K.; Wang, S. Monitoring and Analysis of Deformation Refinement Characteristics of a Loess Tunnel Based on 3D Laser Scanning Technology. Appl. Sci. 2022, 12, 5136. [Google Scholar] [CrossRef]

- Cao, P.; Hu, X.; Liu, E.; Guo, H. Mechanical properties and numerical simulation analysis on large deformation of Jiangluling Carbonaceous Shale Tunnel. Front. Earth Sci. 2023, 11, 1125410. [Google Scholar] [CrossRef]

- Tan, Z.; Li, S.; Yang, Y.; Wang, J. Large deformation characteristics and controlling measures of steeply inclined and layered soft rock of tunnels in plate suture zones. Eng. Fail. Anal. 2022, 131, 105831. [Google Scholar] [CrossRef]

- Liu, Q.; Zhi, C.; Yan, T. Numerical Study on Comparison and Selection of Water Tunnel Section Types. IOP Conf. Ser. Earth Environ. Sci. 2022, 455, 012161. [Google Scholar] [CrossRef]

- Wu, P.; Fang, Z.; Wang, X.; Zhu, G. Reliability Evaluation and Prediction of Deep Buried Tunnel Based on Similarity Theory and Model Test. KSCE J. Civ. Eng. 2023, 27, 2654–2665. [Google Scholar] [CrossRef]

- Hu, Q.Z.; Zhang, R.; Gao, Y.; Hong, C.W. Study on the response mechanism of tunnel blasting dynamics and the spatial variation characteristics of the surrounding rock. IOP Conf. Ser. Earth Environ. Sci. 2020, 510, 052067. [Google Scholar] [CrossRef]

- Zhao, J.; Tan, Z.; Li, Q.; Li, L. Characteristics and mechanism of large deformation of squeezing tunnel in phyllite stratum. Can. Geotech. J. 2023, ja. [Google Scholar] [CrossRef]

- Zhao, J.P.; Tan, Z.S.; Li, L.; Wang, X.Y. Supporting structure failure caused by the squeezing tunnel creep and its reinforcement measure. J. Mt. Sci. 2023, 20, 1774–1789. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, X.; Zhang, B. Preliminary Study on Double Lining Support Design for Water Plugging of Highway Tunnel Under High Water Pressure in Mountain Area Based on Limited Drainage. Appl. Sci. 2022, 12, 7905. [Google Scholar] [CrossRef]

- Lei, G.; Wang, G.; Luo, J.; Hua, F.; Gong, X. Theoretical Study of Surrounding Rock Loose Zone Scope Based on Stress Transfer and Work–energy Relationship Theory. Appl. Sci. 2022, 12, 7292. [Google Scholar] [CrossRef]

- Wang, Y.S.; Wu, Z.Q.; Li, M.H.; Yang, Q.X. The Field Ultrasonic Test of the Disturbance of Surrounding Rock by the TBM Construction. Adv. Mater. Res. 2012, 446, 2101–2104. [Google Scholar] [CrossRef]

- Jiao, P.; Li, S.; Li, X. On-siteTest Study on DefiningLoose Range of Surrounding Rock of High-way Tunnel with Multi-measuring Method. In Proceedings of the 2016 International Conference on Civil, Transportation and Environment, Guangzhou, China, 30–31 January 2016; Atlantis Press: Paris, France, 2016; pp. 11–14. [Google Scholar]

- Cui, F.Z.; Xue, H.J.; He, T.Y.; Li, T.T.; Zuo, J.J.; Guan, X. Research on Loose Circle Test of Deep Broken Roadway. Appl. Mech. Mater. 2014, 638, 904–907. [Google Scholar] [CrossRef]

- Li, F.W.; Jin, L.Z.; Han, H.R.; Zhang, X.C. Structural Analysis and Study on Support Technology of Refuge Chamber of Mine. Appl. Mech. Mater. 2012, 204, 1356–1361. [Google Scholar] [CrossRef]

- Lei, M.; Liu, J.; Lin, Y.; Shi, C.; Liu, C. Deformation Characteristics and Influence Factors of a Shallow Tunnel Excavated in Soft Clay with High Plasticity. Adv. Civ. Eng. 2019, 2019, 7483628. [Google Scholar] [CrossRef]

- Zhou, Z.; Ding, H.; Miao, L.; Gong, C. Predictive model for the surface settlement caused by the excavation of twin tunnels. Tunn. Undergr. Space Technol. 2021, 114, 104014. [Google Scholar] [CrossRef]

- Hu, K.; Xu, P.; Wu, Y.; Zhao, Z.; Wang, S. Analysis of Causes for Large Deformation of Rich Water Tunnel in Loess and Countermeasures: A Case Study. In Proceedings of the CICTP; ASCE: Reston, VA, USA, 2021; pp. 852–862. [Google Scholar]

| Ground | Unit Weight γ (kN/m3) | Elastic Modulus E (MPa) | Deformation Modulus Ed (MPa) | Poisson’s Ratio μ | Internal Friction Angle φ (°) | Cohesion c (MPa) |

|---|---|---|---|---|---|---|

| Sandstone intercalated with slate | 22.8~23.6 | 3.2~4.6 | 2.37 | 0.22 | 25.6 | 0.26 |

| Carbonaceous phyllite | 23.8~24.5 | 0.8~1.2 | 0.89 | 0.24 | 23.5 | 0.15 |

| Phyllite intercalated with sandstone | 22.8~23.4 | 1.5~2.1 | 1.33 | 0.23 | 21.1 | 0.12 |

| Serial Number | Test Section Depth/(m) | Fracturing Parameter/(MPa) | Stress Value/(MPa) | SH Direction (°) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pb | Pr | Ps | PH | P0 | T | SH | Sh | Sv | |||

| 1 | 274.8–275.8 | 10.69 | 7.69 | 2.69 | 2.43 | / | 9.95 | 7.69 | 7.27 | ||

| 2 | 320.3–321.3 | 15.63 | 9.63 | 8.13 | 3.13 | 2.88 | 6 | 11.88 | 8.13 | 8.65 | N52° W |

| 3 | 356.8–357.8 | 13.99 | 8.99 | 8.49 | 3.49 | 3.24 | 5 | 13.24 | 8.49 | 9.44 | |

| 4 | 384.0–385.0 | 18.76 | 9.26 | 8.76 | 3.76 | 3.5 | 9.5 | 13.52 | 8.76 | 10.16 | N38° W |

| 5 | 392.4–393.4 | 17.84 | 11.94 | 9.84 | 3.84 | 3.59 | 5.9 | 13.99 | 9.84 | 10.38 | |

| 6 | 432.6–433.6 | 15.73 | 12.23 | 10.23 | 4.23 | 3.98 | 3 | 14.48 | 10.23 | 11.44 | N31° W |

| 7 | 445.1–446.1 | 11.86 | 10.36 | 4.36 | 4.1 | / | 15.12 | 10.36 | 11.77 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, D.; Tan, Z.; Bian, L.; Zhang, B.; Zhao, J. Research on Deformation and Loose Zone Characteristics of Large Cross Section Tunnel in High Geo-Stress Soft Rock. Appl. Sci. 2023, 13, 9009. https://doi.org/10.3390/app13159009

Ma D, Tan Z, Bian L, Zhang B, Zhao J. Research on Deformation and Loose Zone Characteristics of Large Cross Section Tunnel in High Geo-Stress Soft Rock. Applied Sciences. 2023; 13(15):9009. https://doi.org/10.3390/app13159009

Chicago/Turabian StyleMa, Dong, Zhongsheng Tan, Linlin Bian, Baojin Zhang, and Jinpeng Zhao. 2023. "Research on Deformation and Loose Zone Characteristics of Large Cross Section Tunnel in High Geo-Stress Soft Rock" Applied Sciences 13, no. 15: 9009. https://doi.org/10.3390/app13159009

APA StyleMa, D., Tan, Z., Bian, L., Zhang, B., & Zhao, J. (2023). Research on Deformation and Loose Zone Characteristics of Large Cross Section Tunnel in High Geo-Stress Soft Rock. Applied Sciences, 13(15), 9009. https://doi.org/10.3390/app13159009