Experimental Investigation of Precast Rocking Walls Incorporating Tension-Compression and Shear Steel Energy Dissipaters

Abstract

1. Introduction

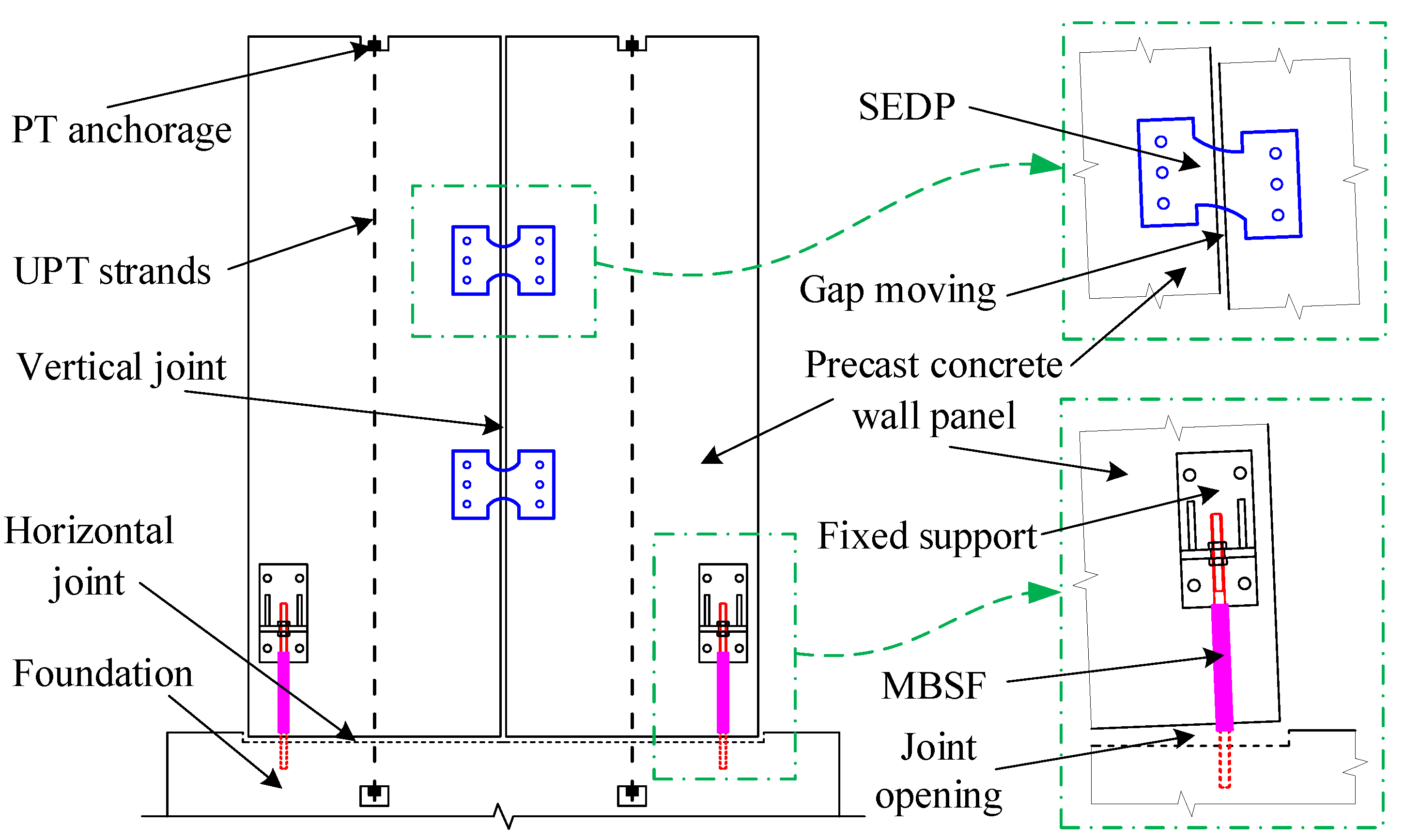

2. Concept and Configuration of the Proposed System

3. Experimental Program

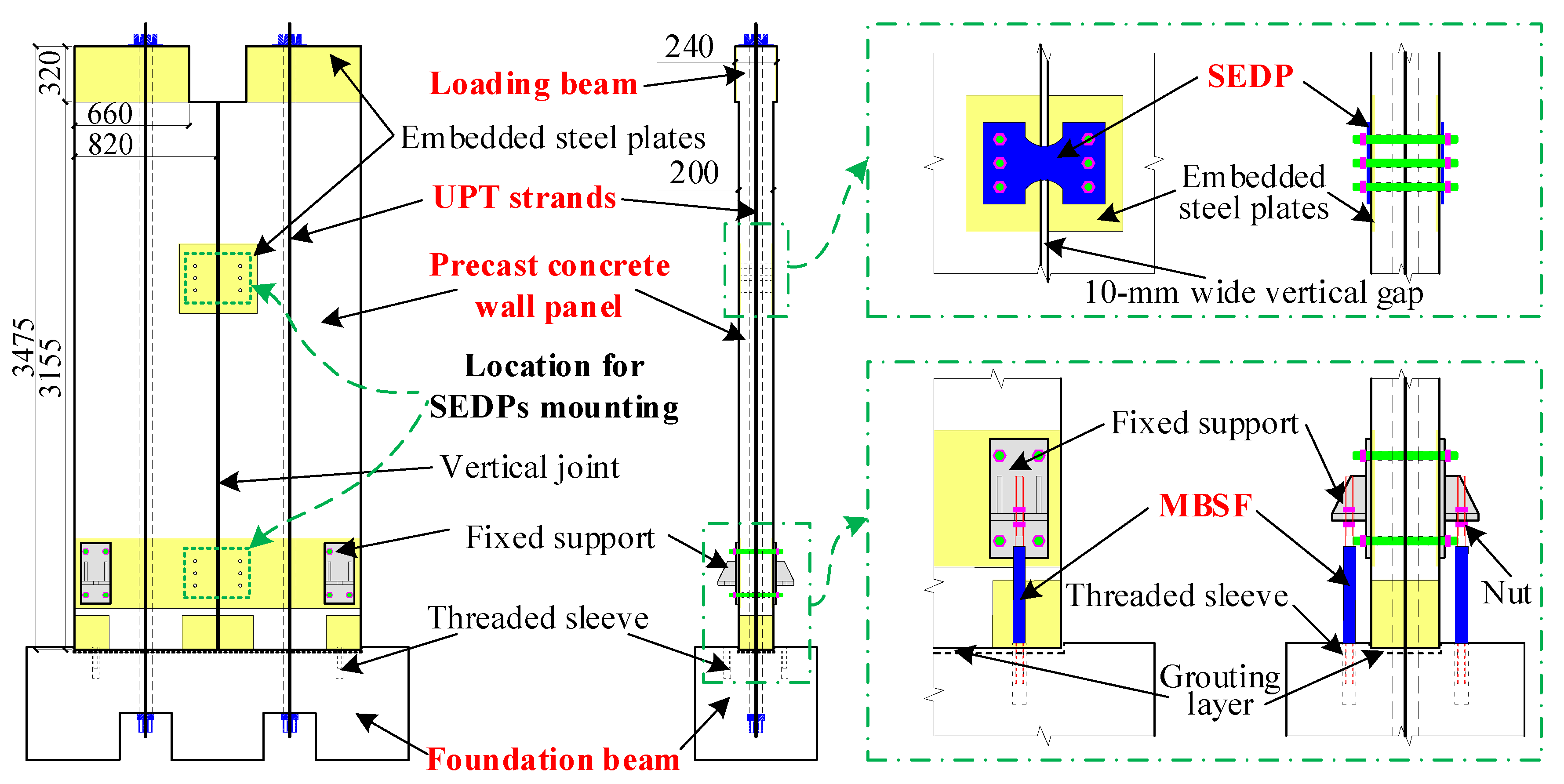

3.1. Description of the Test Specimen

3.1.1. Specimen Details

3.1.2. Details of the Concrete Elements

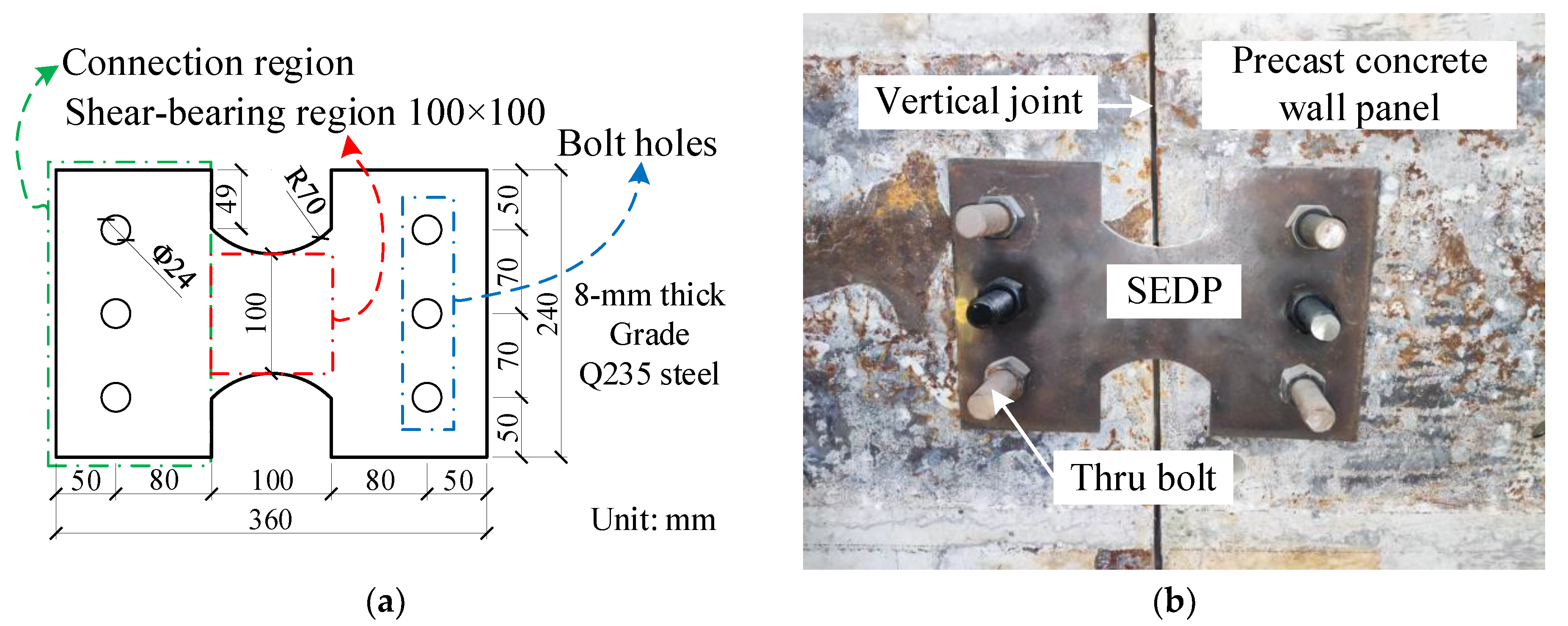

3.1.3. Details of Shear Energy Dissipation Plates

3.1.4. Details of Miniature Bar-Type Structural Fuses

3.1.5. Material Properties

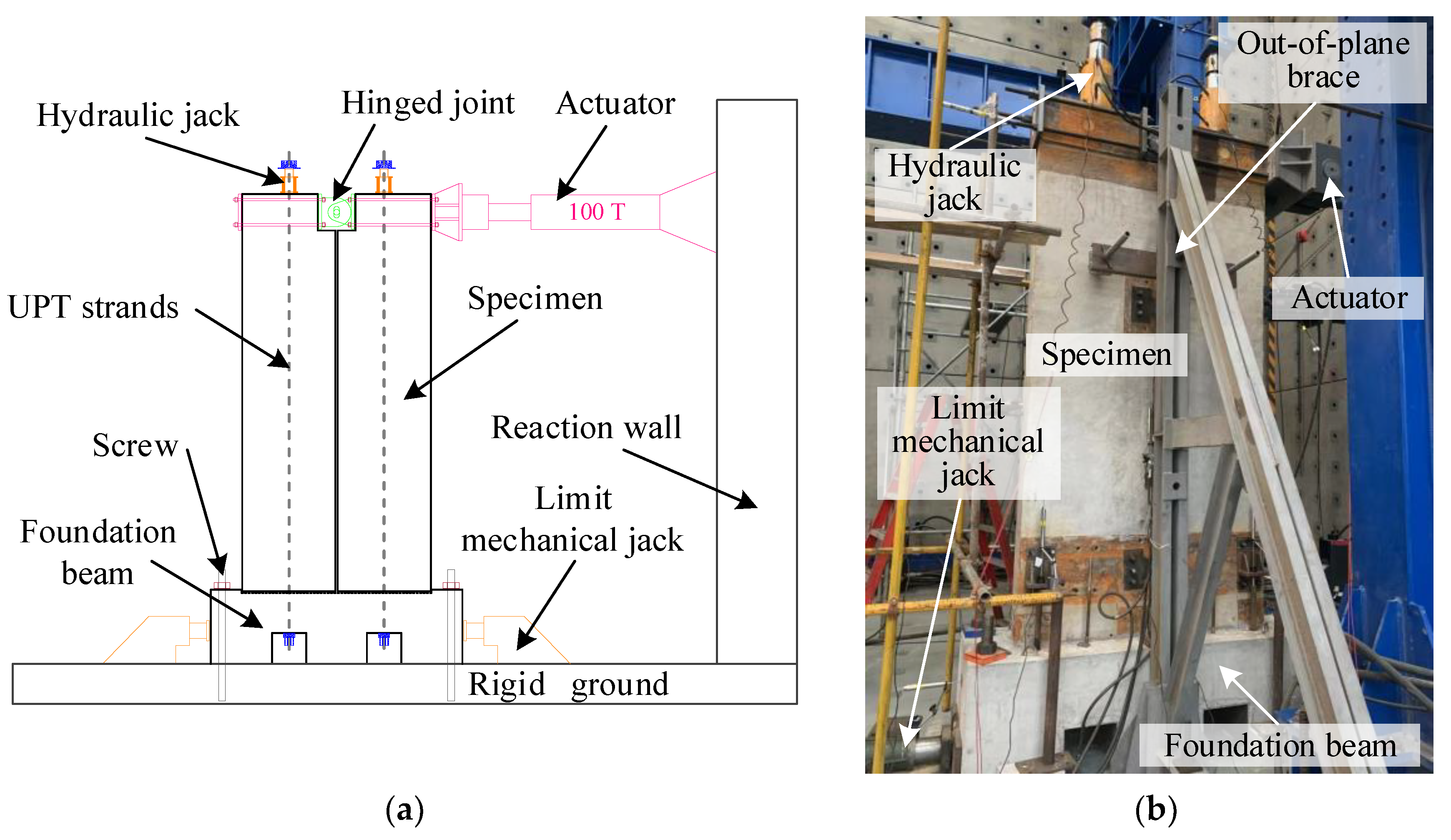

3.2. Test Setup

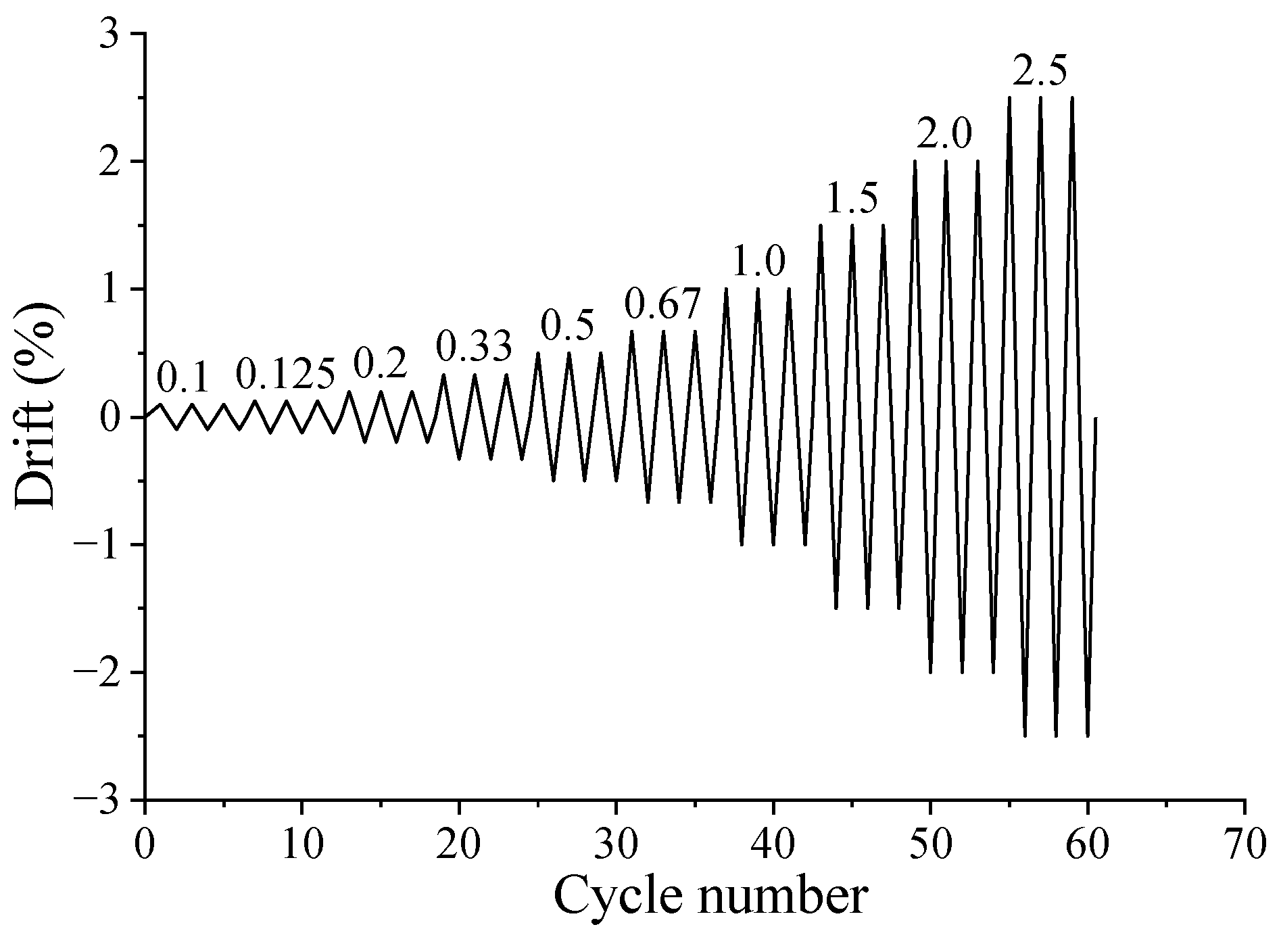

3.3. Loading Protocol

4. Experimental Results and Discussion

4.1. Test Observation

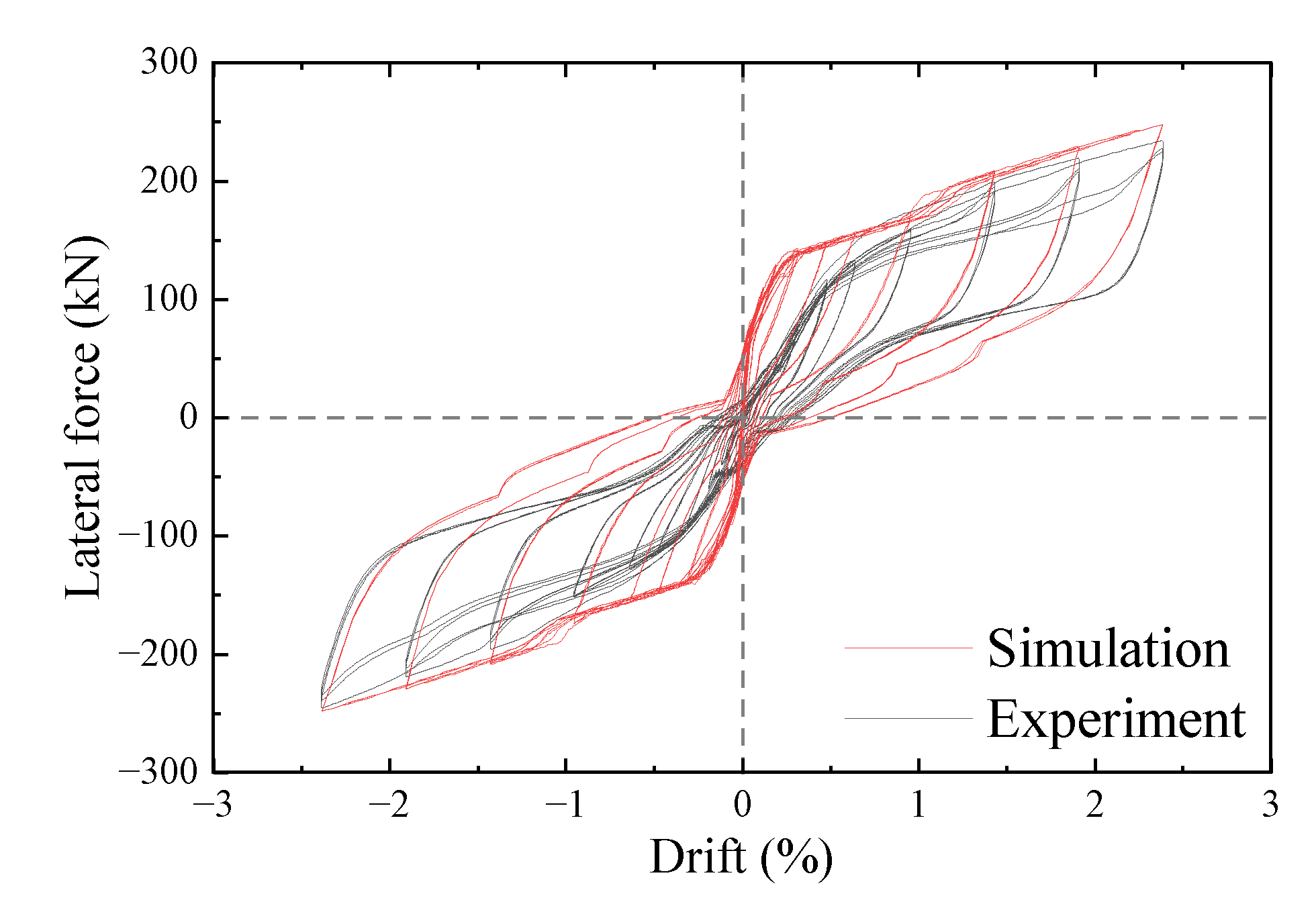

4.2. Hysteretic Curves

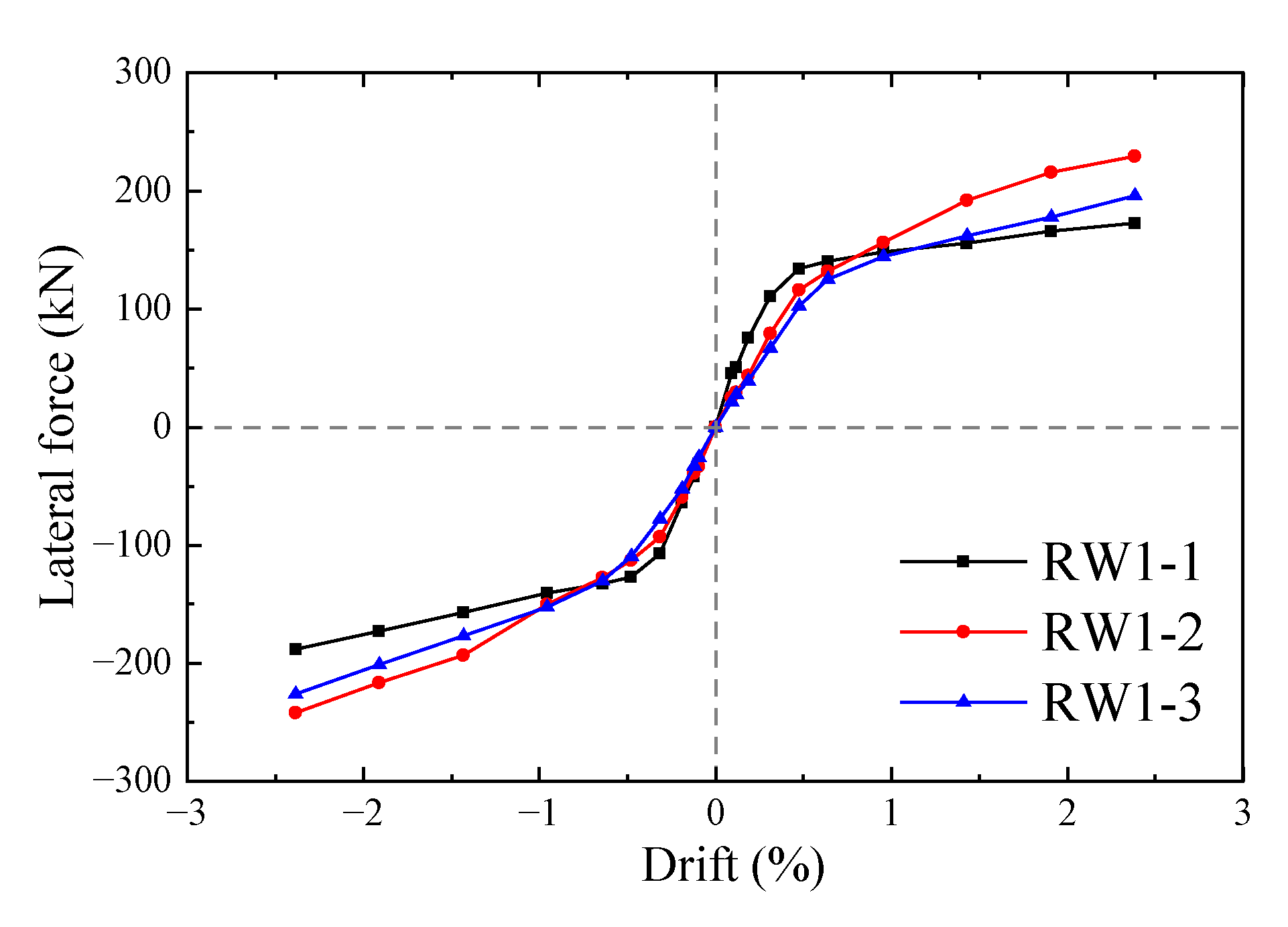

4.3. Skeleton Curves

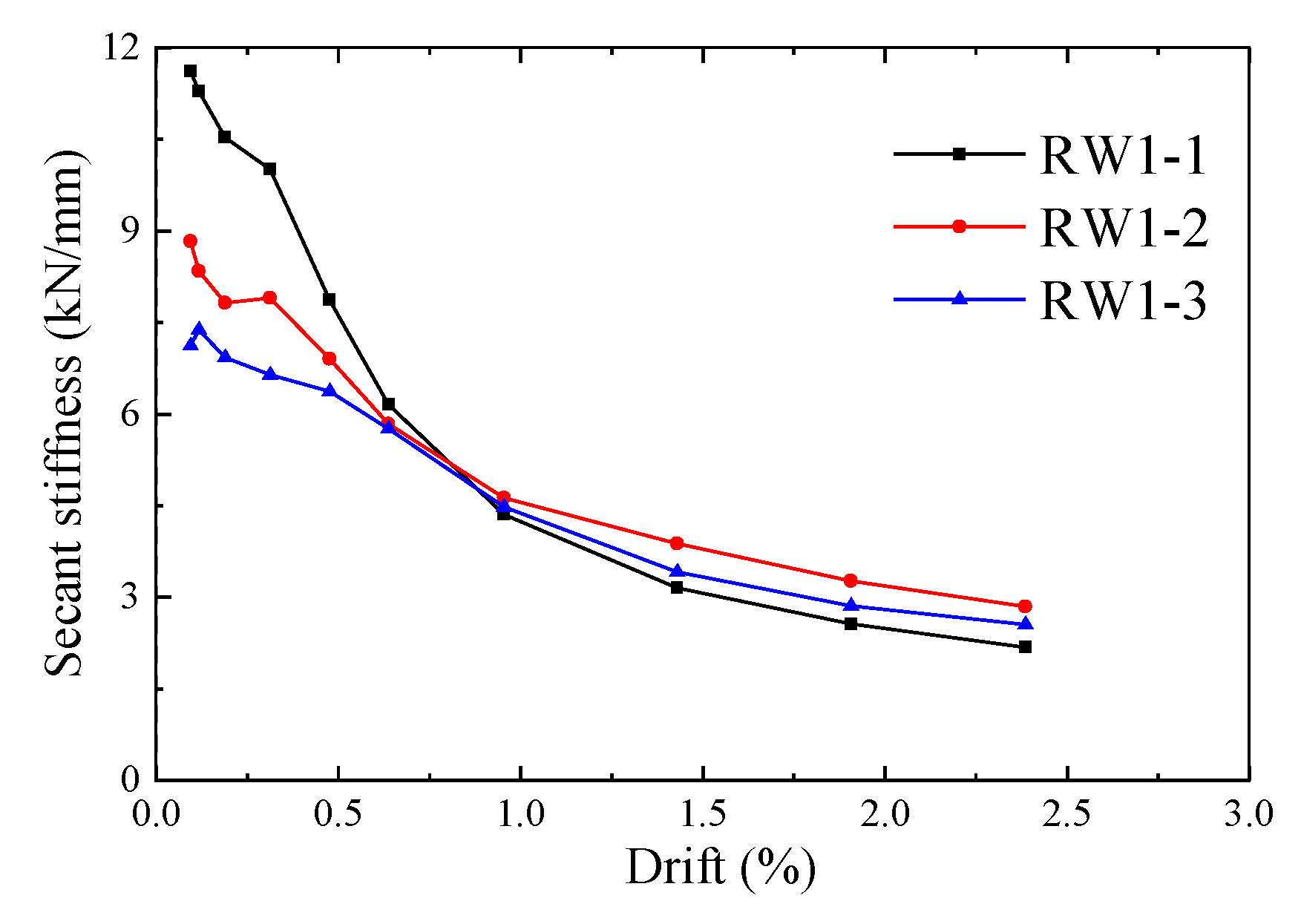

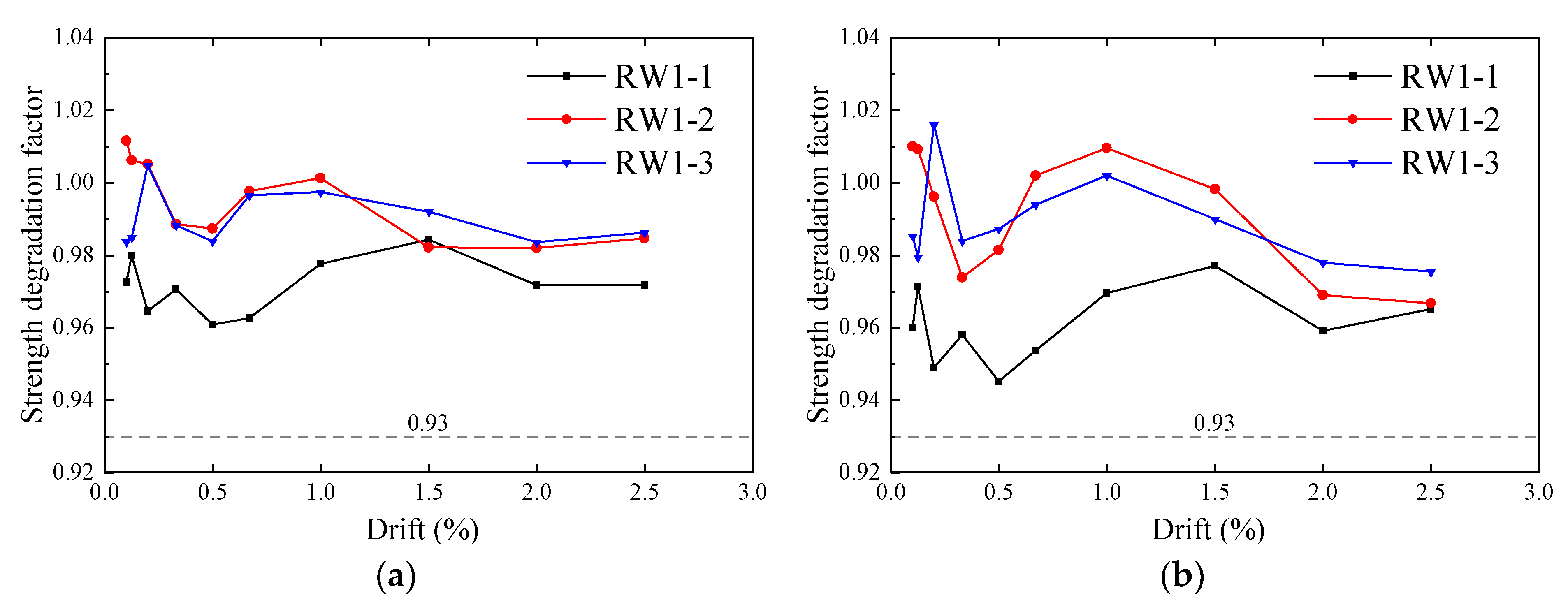

4.4. Stiffness and Strength Deterioration

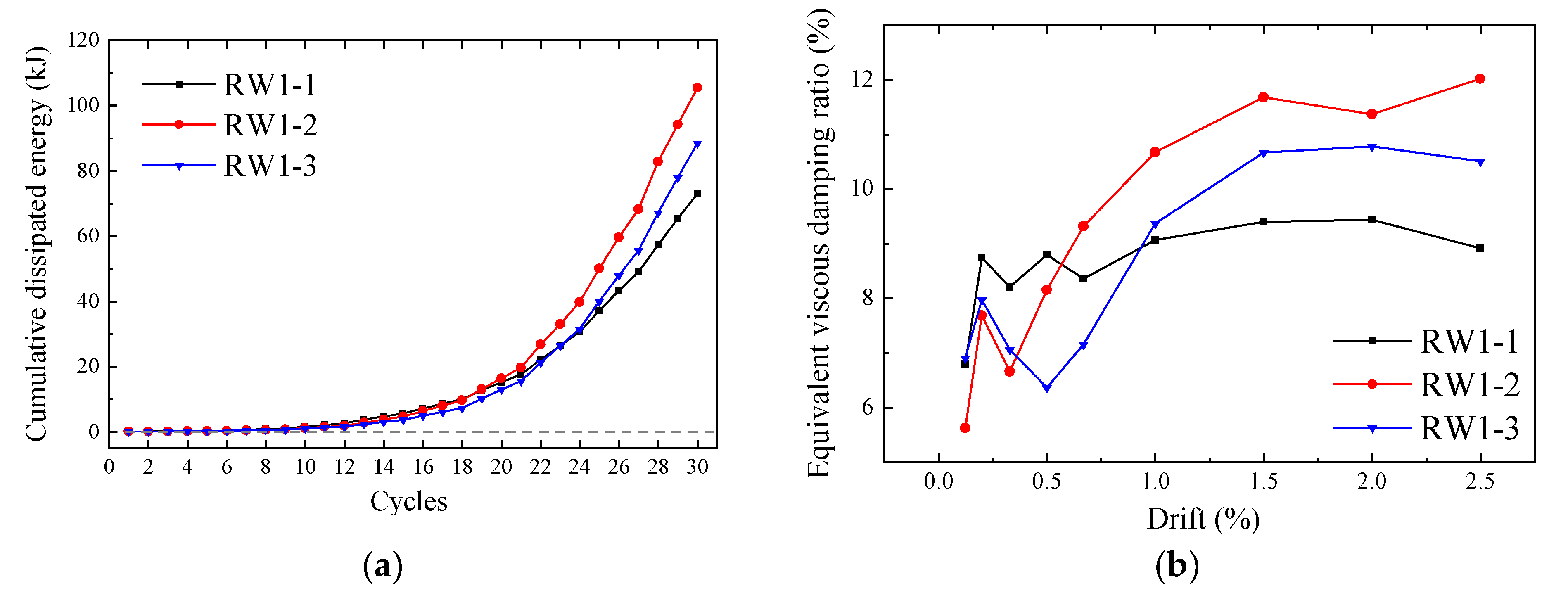

4.5. Energy Dissipation Capacity

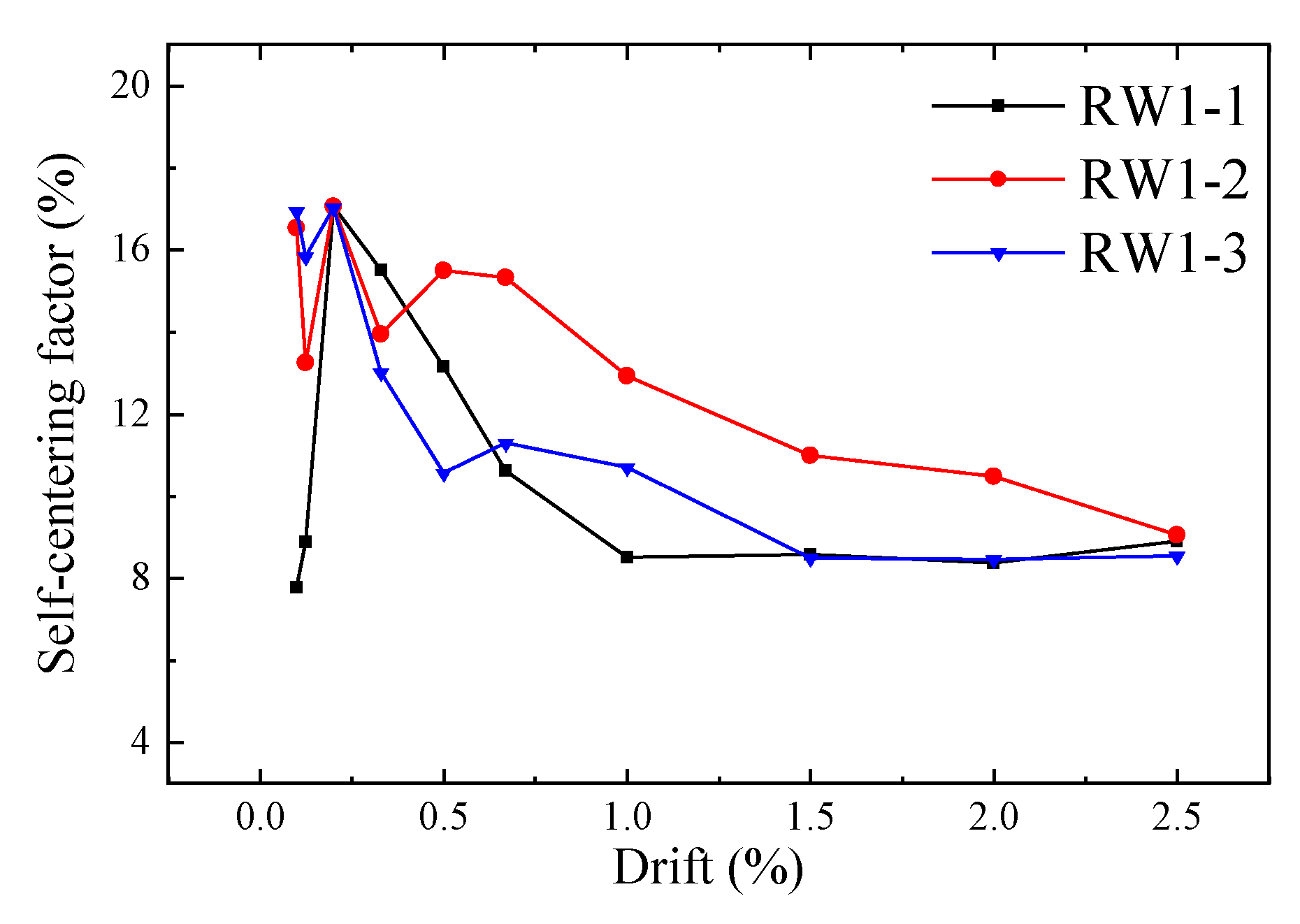

4.6. Self-Centering Capacities

5. Numerical Simulation

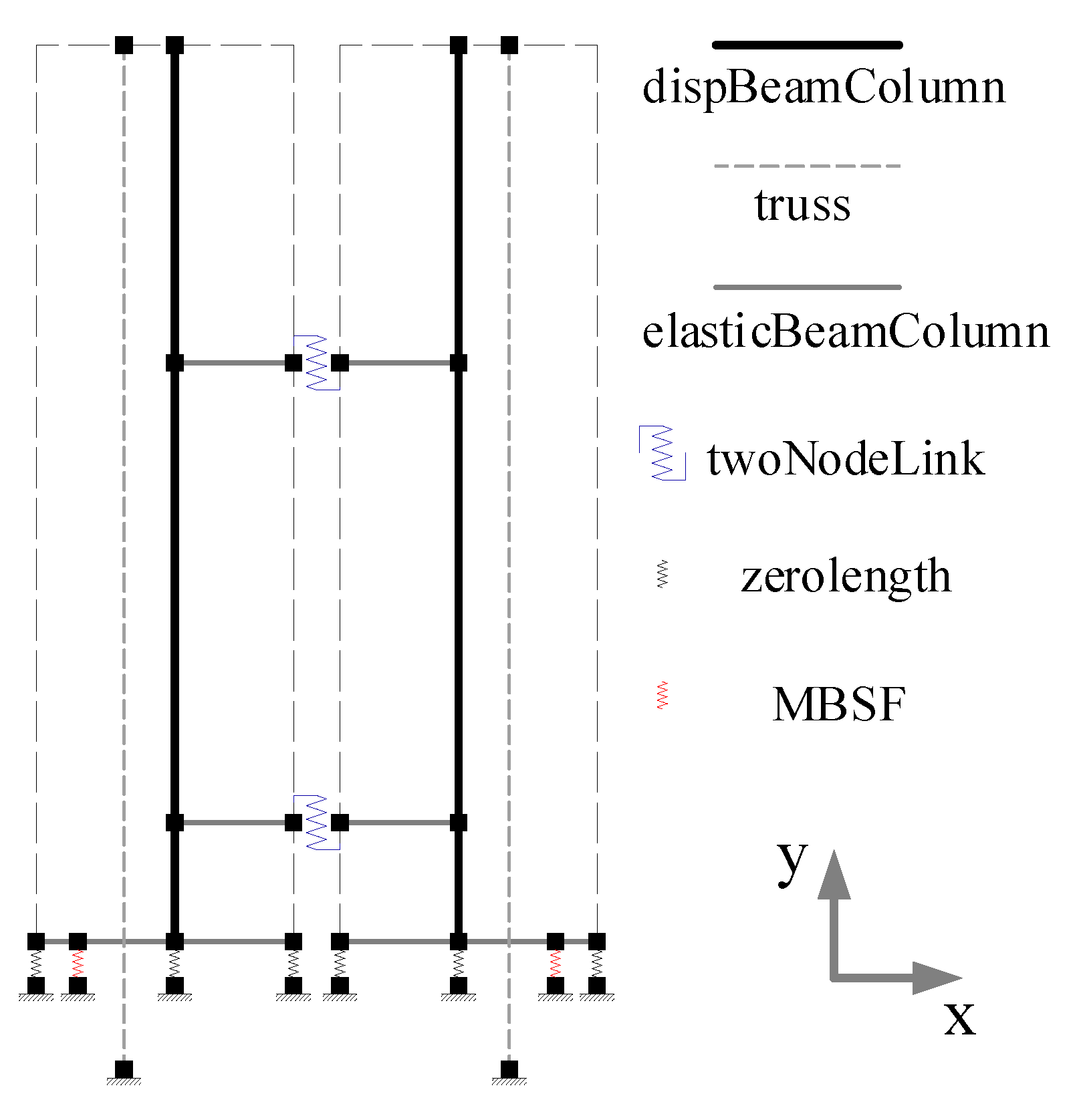

5.1. Finite Element Modeling

5.2. Simulation Results

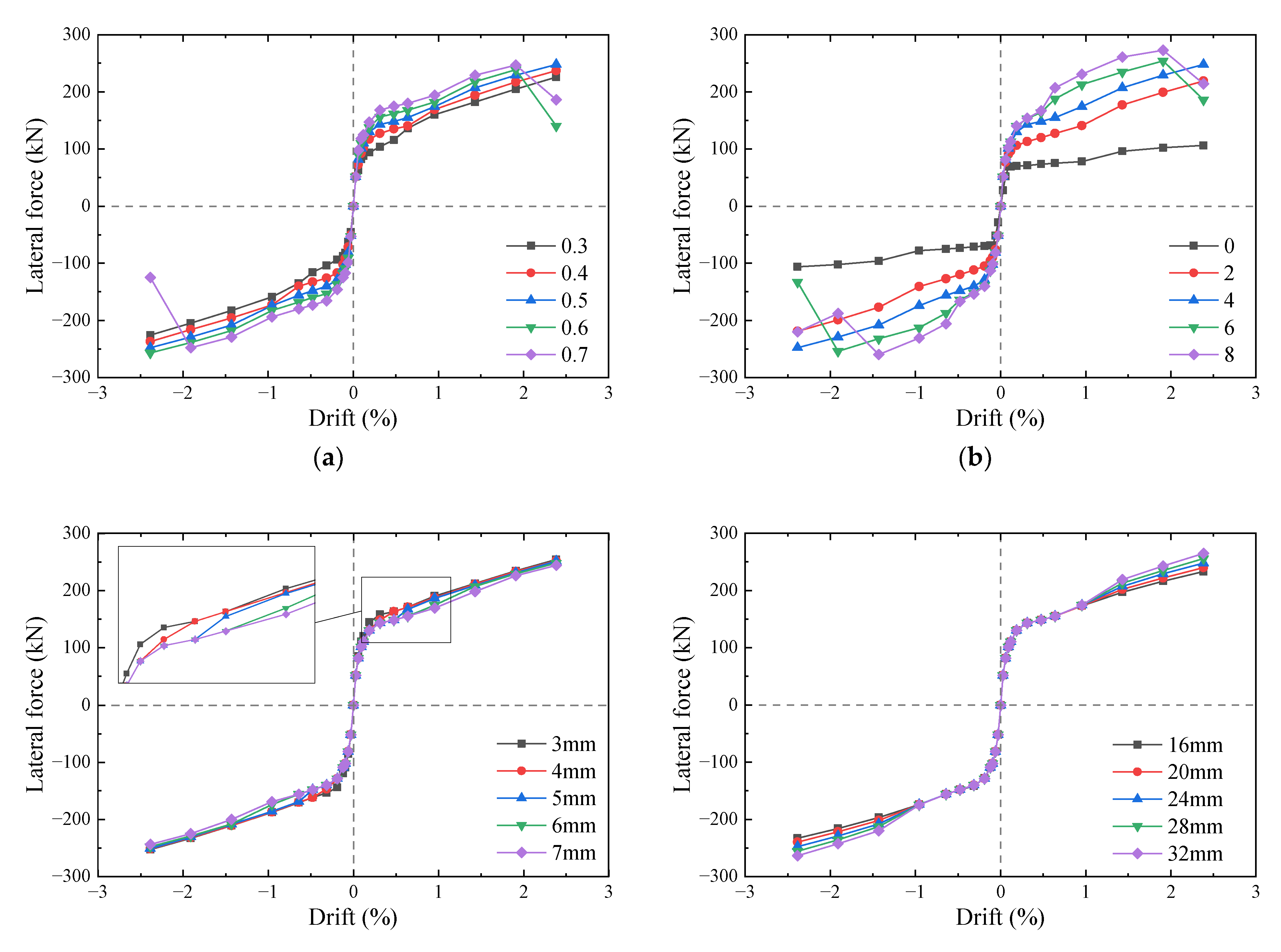

5.3. Parametric Analysis

6. Conclusions

- The wall panels showed no significant damage but good self-centering capacity, indicating the satisfactory resilience of the proposed system. Both the shear energy dissipation plates and the miniature bar-type structural fuses exhibited good energy dissipation performance during the test process, leading to flag-shaped hysteresis loops of the proposed system.

- The minor damage in the wall panels after several reversal cyclic loading tests weakened the stiffness of the proposed system, resulting in a relatively worse performance of the energy dissipaters, which should be avoided by improving the structural details of the wall panels.

- Test RW1-2 verified the possibility of applying multiple energy dissipaters to achieve a hierarchical energy dissipation (HED) mechanism of a structure, providing a new method for the development of highly efficient structural energy dissipating systems.

- The effect of SEDPs on the rotation mode of the wall panels influenced the elastic-plastic status of the prestressing tendons and the local concrete at greater drift levels based on parametric analysis. The combination of Belleville springs with MBSFs provided significant effectiveness in achieving HED mechanism for the structure.

- The finite element model proposed in this paper effectively simulated the effects of the Belleville springs, and parametric analysis showed that the springs cleverly controlled the yielding of MBSFs at the designed drift level. The numerical model accurately simulated the global hysteresis behavior of PRW-TSD with cyclic loading tests as well, which provided a foundation for the subsequent dynamic analysis. However, the numerical model idealizes the deformation pattern of the wall panels and slightly overestimates the structural strength compared to the experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasanali, M.; Roy, K.; Mojtabaei, S.M.; Hajirasouliha, I.; Clifton, G.C.; Lim, J.B. A critical review of cold-formed steel seismic resistant systems: Recent developments, challenges and future directions. Thin-Walled Struct. 2022, 180, 109953. [Google Scholar] [CrossRef]

- Yilmaz, F.; Mojtabaei, S.M.; Hajirasouliha, I.; Becque, J. Behaviour and performance of OSB-sheathed cold-formed steel stud wall panels under combined vertical and seismic loading. Thin-Walled Struct. 2023, 183, 110419. [Google Scholar] [CrossRef]

- Papargyriou, I.; Mojtabaei, S.M.; Hajirasouliha, I.; Becque, J.; Pilakoutas, K. Cold-formed steel beam-to-column bolted connections for seismic applications. Thin-Walled Struct. 2022, 172, 108876. [Google Scholar] [CrossRef]

- Priestley, M.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the PRESSS five-story precast concrete test building. PCI J. 1999, 44, 42–67. [Google Scholar] [CrossRef]

- Twigden, K.M.; Sritharan, S.; Henry, R.S. Cyclic testing of unbonded post-tensioned concrete wall systems with and without supplemental damping. Eng. Struct. 2017, 140, 406–420. [Google Scholar] [CrossRef]

- Asadolahi, S.M.; Fanaie, N. Performance of self-centering steel moment frame considering stress relaxation in prestressed cables. Adv. Struct. Eng. 2020, 23, 1813–1822. [Google Scholar] [CrossRef]

- Zhu, L.H.; Zhao, C. Self-centering steel frame systems for seismic-resistant structures. Adv. Civ. Eng. 2020, 2020, 8859881. [Google Scholar] [CrossRef]

- Guo, T.; Xu, Z.; Song, L.; Wang, L.; Zhang, Z. Seismic Resilience Upgrade of RC Frame Building Using Self-Centering Concrete Walls with Distributed Friction Devices. J. Struct. Eng. 2017, 143, 04017160. [Google Scholar] [CrossRef]

- Qu, Z.; Wada, A.; Ye, L. Seismic retrofit of frame structures using rocking wall system. J. Build. Struct. 2011, 32, 11–19. [Google Scholar]

- Kurama, Y.; Pessiki, S.; Sause, R.; Lu, L.W. Seismic behavior and design of unbonded post-tensioned precast concrete walls. PCI J. 1999, 44, 72–89. [Google Scholar] [CrossRef]

- Perez, F.J.; Pessiki, S.; Sause, R. Experimental Lateral Load Response of Unbonded Post-Tensioned Precast Concrete Walls. ACI Struct. J. 2013, 110, 1045–1055. [Google Scholar]

- Perez, F.J.; Sause, R.; Pessiki, S. Analytical and experimental lateral load Behavior of unbonded posttensioned precast concrete walls. J. Struct. Eng. 2007, 133, 1531–1540. [Google Scholar] [CrossRef]

- Erkmen, B.; Schultz, A.E. Self-Centering Behavior of Unbonded, Post-Tensioned Precast Concrete Shear Walls. J. Earthq. Eng. 2009, 13, 1047–1064. [Google Scholar] [CrossRef]

- Kurama, Y.C. Seismic design of partially post-tensioned precast concrete walls. PCI J. 2005, 50, 100. [Google Scholar] [CrossRef]

- Smith, B.J.; Kurama, Y.C.; McGinnis, M.J. Behavior of Precast Concrete Shear Walls for Seismic Regions: Comparison of Hybrid and Emulative Specimens. J. Struct. Eng. 2013, 139, 1917–1927. [Google Scholar] [CrossRef]

- Restrepo, J.I.; Rahman, A. Seismic performance of self-centering structural walls incorporating energy dissipators. J. Struct. Eng. 2007, 133, 1560–1570. [Google Scholar] [CrossRef]

- Kurama, Y.C. Hybrid post-tensioned precast concrete walls for use in seismic regions. PCI J. 2002, 47, 36–59. [Google Scholar] [CrossRef]

- Smith, B.J.; Kurama, Y.C.; McGinnis, M.J. Design and Measured Behavior of a Hybrid Precast Concrete Wall Specimen for Seismic Regions. J. Struct. Eng. 2011, 137, 1052–1062. [Google Scholar] [CrossRef]

- Lu, X.L.; Yang, B.Y.; Zhao, B. Shake-table testing of a self-centering precast reinforced concrete frame with shear walls. Earthq. Eng. Eng. Vib. 2018, 17, 221–233. [Google Scholar] [CrossRef]

- Sritharan, S.; Aaleti, S.; Thomas, D.J. Seismic Analysis and Design of Precast Concrete Jointed Wall Systems; ISU-ERI-Ames Report ERI-07404; Iowa State University: Ames, IA, USA, 2007. [Google Scholar]

- Aaleti, S.; Sritharan, S. A simplified analysis method for characterizing unbonded post-tensioned precast wall systems. Eng. Struct. 2009, 31, 2966–2975. [Google Scholar] [CrossRef]

- Henry, R.S.; Aaleti, S.; Sritharan, S.; Ingham, J.M. Concept and Finite-Element Modeling of New Steel Shear Connectors for Self-Centering Wall Systems. J. Eng. Mech. 2010, 136, 220–229. [Google Scholar] [CrossRef]

- Sritharan, S.; Aaleti, S.; Henry, R.S.; Liu, K.Y.; Tsai, K.C. Precast concrete wall with end columns (PreWEC) for earthquake resistant design. Earthq. Eng. Struct. Dyn. 2015, 44, 2075–2092. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, G.D.; Chen, C. Experimental Study on Self-Centering Concrete Wall with Distributed Friction Devices. J. Earthq. Eng. 2014, 18, 214–230. [Google Scholar] [CrossRef]

- Marriott, D.; Pampanin, S.; Bull, D.; Palermo, A. Dynamic Testing of Precast, Post-Tensioned Rocking Wall Systems with Alternative Dissipating Solutions. In Proceedings of the 2008 NZSEE Conference, Wairakei, New Zealand, 11–13 April 2008. [Google Scholar]

- Kam, W.Y.; Pampanin, S.; Palermo, A.; Carr, A.J. Self-centering structural systems with combination of hysteretic and viscous energy dissipations. Earthq. Eng. Struct. Dyn. 2010, 39, 1083–1108. [Google Scholar] [CrossRef]

- Liu, C.; Peng, Z.; Cui, J.; Huang, X.; Li, Y.; Chen, W. Development of crack and damage in shield tunnel lining under seismic loading: Refined 3D finite element modeling and analyses. Thin-Walled Struct. 2023, 185, 110647. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.B.; Lin, G. Seismic performance of advanced three-dimensional base-isolated nuclear structures in complex-layered sites. Eng. Struct. 2023, 289, 116247. [Google Scholar] [CrossRef]

- Wei, J.; Xie, Z.; Zhang, W.; Luo, X.; Yang, Y.; Chen, B. Experimental study on circular steel tube-confined reinforced UHPC columns under axial loading. Eng. Struct. 2021, 230, 111599. [Google Scholar] [CrossRef]

- Guan, D.; Yang, S.; Liu, Y.; Ge, H.; Guo, Z. Concept and behaviour of all-steel miniature bar-typed structural fuses with torsional effect. J. Constr. Steel Res. 2020, 164, 105795. [Google Scholar] [CrossRef]

- Guan, D.; Yang, S.; Wang, Z.; Jia, L.J.; Guo, Z.; Ge, H. Concept and behaviour of miniature bar-typed structural fuses with eccentricity. J. Constr. Steel Res. 2020, 166, 105923. [Google Scholar] [CrossRef]

- Yang, S.; Lin, Y.; Guan, D.; Ge, H.; Guo, Z.; Yang, H.; Liu, W. Novel Hierarchical Energy Dissipation Systems for Seismic Protection of Buildings. J. Earthq. Eng. 2023, 27, 1–32. [Google Scholar] [CrossRef]

- GB 50011-2010; Code of Seismic Design of Buildings. China Building Industry Press: Beijing, China, 2016.

- GB 50010-2010; Code for Design of Concrete Structures. China Building Industry Press: Beijing, China, 2015.

- El-Tawil, S.; Harries, K.A.; Fortney, P.J.; Shahrooz, B.M.; Kurama, Y. Seismic Design of Hybrid Coupled Wall Systems: State of the Art. J. Struct. Eng. 2010, 136, 755–769. [Google Scholar] [CrossRef]

- Shen, S.D.; Pan, P.; Miao, Q.S.; Li, W.F.; Gong, R.H. Test and analysis of reinforced concrete (RC) precast shear wall assembled using steel shear key (SSK). Earthq. Eng. Struct. Dyn. 2019, 48, 1595–1612. [Google Scholar] [CrossRef]

- Xu, L.Y.; Nie, X.; Fan, J.S. Cyclic behaviour of low-yield-point steel shear panel dampers. Eng. Struct. 2016, 126, 391–404. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Building Industry Press: Beijing, China, 2019.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Building Industry Press: Beijing, China, 2021.

- ACI 374.1-05; Acceptance Criteria for Moment Frames Based on Structural Testing and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2005.

- Zhang, L. Research on the Seismic Performances of a Multistage Hybrid Energy Consumption Connection Prefabricated Concrete Shear Wall; Southeast University: Dhaka, Bangladesh, 2022. [Google Scholar]

- Zhu, Z.F.; Guo, Z.X. Seismic Behavior of Precast Concrete Shear Walls with Different Confined Boundary Elements. KSCE J. Civ. Eng. 2019, 23, 711–718. [Google Scholar] [CrossRef]

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. China Building Industry Press: Beijing, China, 2015.

- Li, G.; Li, R.H.; Yu, D.H. Experimental and Analytical Lateral Performance of Shear Walls with Variable Phases of Deformation. J. Struct. Eng. 2022, 148, 04022162. [Google Scholar] [CrossRef]

- McKenna, F.; Fenves, G.L.; Scott, M.H.; Jeremic, B. Open System for Earthquake Engineering Simulation (OpenSees); Berkeley, C.A., Ed.; Pacific Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 2013. [Google Scholar]

- Guo, T.; Wang, L.; Xu, Z.; Hao, Y. Experimental and numerical investigation of jointed self-centering concrete walls with friction connectors. Eng. Struct. 2018, 161, 192–206. [Google Scholar] [CrossRef]

- ACI Innovation Task Group 5. Requirements for Design of a Special Unbonded Post-Tensioned Precast Shear Wall Satisfying ACI ITG-5.1 (ITG5.2-09); American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

| Test No. | Post-Tension Force (kN) | Number of SEDPs | Number of MBSFs | Spacing of Belleville Spring (mm) |

|---|---|---|---|---|

| RW1-1 | 480.4 | 4 | 0 | \ |

| RW1-2 | 480.4 | 4 | 4 | 7 |

| RW1-3 | 480.4 | 4 | 4 | 0 |

| Model | Diameter/Thickness (mm) | Yield Stress (MPa) | Ultimate Stress (MPa) | Elongation (%) |

|---|---|---|---|---|

| HRB400 | 8 | 455 | 641 | 19 |

| HRB400 | 10 | 447 | 625 | 18.5 |

| HRB400 | 16 | 441 | 615 | 17.3 |

| HRB400 | 18 | 438 | 611 | 17.1 |

| Steel strand | 15.2 | 1728 | 1953 | 4.81 |

| Steel bar | 24 | 265 | 408.7 | 39.2 |

| Steel plate | 8 | 266.9 | 422.5 | 30.2 |

| Test No. | Yield Drift (%) | Yield Strength (kN) | Limit Drift (%) | Limit Strength (kN) | Ductility Factor |

|---|---|---|---|---|---|

| RW1-1 | 0.39 | 134.6 | 2.5 | 172.4 | 6.4 |

| RW1-2 | 0.57 | 132.6 | 2.5 | 229.2 | 4.4 |

| RW1-3 | 0.69 | 134.1 | 2.5 | 195.9 | 3.6 |

| Index | Drift | RW1-1 | RW1-2 | RW1-3 |

|---|---|---|---|---|

| Cumulative dissipated energy (kJ) | 1% | 12.7 | 13.1 | 10.1 |

| 2.5% | 57.4 | 82.9 | 67.1 | |

| Equivalent viscous damping (%) | 1% | 9.1 | 10.7 | 9.4 |

| 2.5% | 8.9 | 12.0 | 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Peng, Z.; Guan, D.; Lin, Y. Experimental Investigation of Precast Rocking Walls Incorporating Tension-Compression and Shear Steel Energy Dissipaters. Appl. Sci. 2023, 13, 8817. https://doi.org/10.3390/app13158817

Liu J, Peng Z, Guan D, Lin Y. Experimental Investigation of Precast Rocking Walls Incorporating Tension-Compression and Shear Steel Energy Dissipaters. Applied Sciences. 2023; 13(15):8817. https://doi.org/10.3390/app13158817

Chicago/Turabian StyleLiu, Jiabin, Zhanhui Peng, Dongzhi Guan, and Yu Lin. 2023. "Experimental Investigation of Precast Rocking Walls Incorporating Tension-Compression and Shear Steel Energy Dissipaters" Applied Sciences 13, no. 15: 8817. https://doi.org/10.3390/app13158817

APA StyleLiu, J., Peng, Z., Guan, D., & Lin, Y. (2023). Experimental Investigation of Precast Rocking Walls Incorporating Tension-Compression and Shear Steel Energy Dissipaters. Applied Sciences, 13(15), 8817. https://doi.org/10.3390/app13158817