Acoustics of Compressed Earth Blocks Bound Using Sugarcane Bagasse Ash and Water Hyacinth Ash

Abstract

1. Introduction

2. Materials and Methods

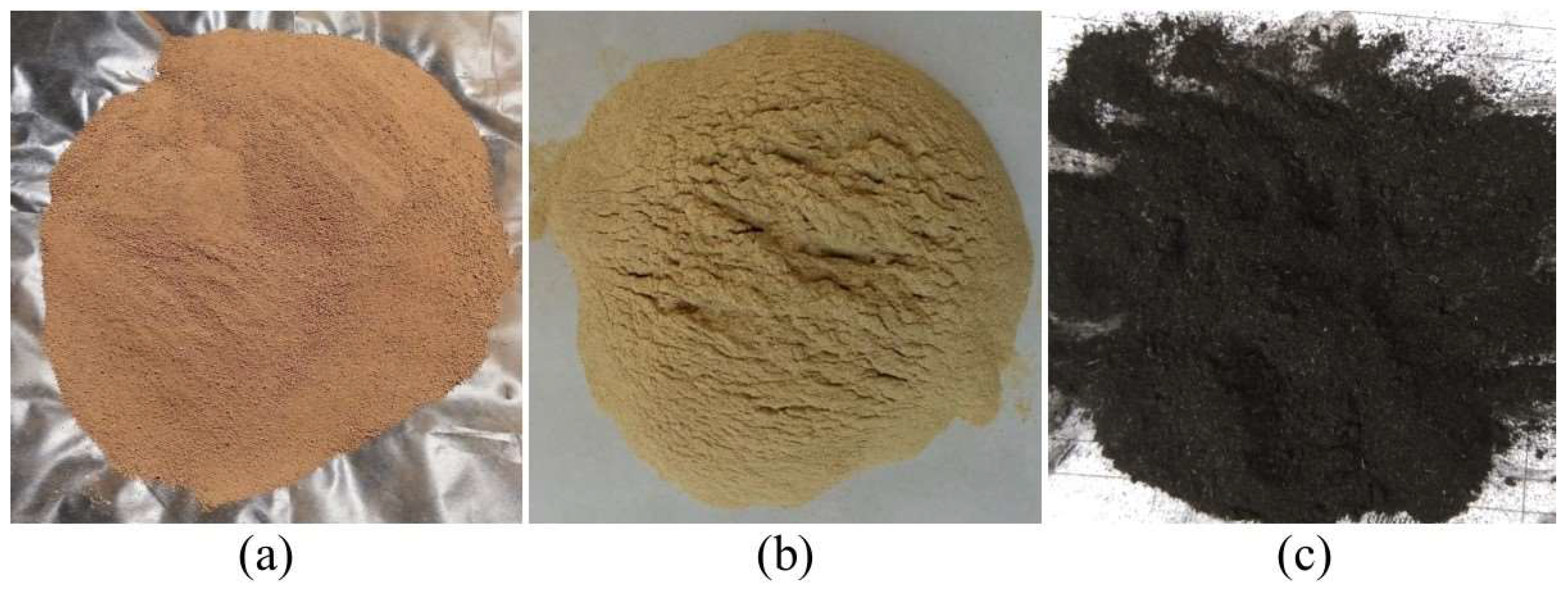

2.1. Sample Preparation

2.2. Measurements

3. Results and Discussion

3.1. Transmission Coefficient

3.2. Inversion of the Transmission Coefficient Data Using the EFM Interaction Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meskhi, B.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Shilov, A.A.; El’shaeva, D.; Shilova, K.; Karalar, M.; Aksoylu, C.; et al. Analytical review of geopolymer concrete: Retrospective and current issues. Materials 2023, 16, 3792. [Google Scholar] [CrossRef] [PubMed]

- Acar, M.C.; Çelik, A.I.; Kayabaşı, R.; Şener, S.; Özdöner, N.; Özkılıç, Y.O. Production of perlite-based-aerated geopolymer using hydrogen peroxide as eco-friendly material for energy-efficient buildings. J. Mater. 2023, 24, 81–99. [Google Scholar] [CrossRef]

- Çelik, A.I.; Özkılıç, Y.O. Geopolymer concrete with high strength, workability and setting time using recycled steel wires and basalt powder. Steel Compos. Struct. 2023, 46, 689. [Google Scholar] [CrossRef]

- Çelik, A.I.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, A.O.; Alomayri, T.; Özkılıç, Y.O. Use of waste glass powder toward more sustainable geopolymer concrete. J. Mater. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Çelik, A.I.; Tunç, U.; Karalar, M.; Deifalla, A. The use of crushed recycled glass for alkali activated fly ash based geopolymer concrete and prediction of its capacity. J. Mater. 2023, 24, 8267–8281. [Google Scholar] [CrossRef]

- Heger, M.P.; Vashold, L.; Hentschel, J. Managing Maghreb’s Eroding Coasts for Future Generations. 2021. Available online: https://www.worldbank.org/en/news/feature/2021/10/29/managing-maghreb-s-eroding-coasts-for-future-generations (accessed on 29 October 2021).

- Minke, G. Building with Earth: Design and Technology for a Sustainable Architecture; Birkhauser Architecture: Basel, Switzerland, 2009. [Google Scholar]

- Earth Building Association of Australia. 2019. Available online: https://www.ebaa.asn.au/ (accessed on 28 July 2021).

- Marsh, A.T.; Kulshreshtha, Y. The state of earthen housing worldwide: How development affects attitudes and adoption. Build. 2021, 50, 485–501. [Google Scholar] [CrossRef]

- Namango, S. Development of Cost-Effective Earthen Building Material for Housing Wall Construction. Doctoral Dissertation, Moi University, Cheptiret, Kenya, 2006. Available online: https://www.researchgate.net/publication/283068265 (accessed on 13 August 2006).

- Donkor, P.; Obonyo, E. Earthen construction materials: Assessing the feasibility of improving strength and deformability of compressed earth blocks using polypropylene fibers. Mater. Des. 2015, 83, 813–819. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Sore, S.O.; Hema, C.; Zoungrana, O.; Messan, A.; Courard, L. A discussion of “optimisation of compressed earth blocks (CEBs) using natural origin materials: A systematic literature review”. Constr. Build. Mater. 2022, 325, 126887. [Google Scholar] [CrossRef]

- Lindh, P.; Lemenkova, P. Effects of GGBS and fly ash in binders on soil stabilization for road construction. Rom. J. Transp. Infrastruct. 2022, 11, 1–13. [Google Scholar] [CrossRef]

- Abdullah, H.; Shahin, M.; Walske, M.L. Review of fly-ash-based geopolymers for soil stabilisation with special reference to clay. Geosciences 2020, 10, 249. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Dhir, R.K. Towards maximising the use of fly ash as a binder. Fuel 1999, 78, 121–132. [Google Scholar] [CrossRef]

- Murugesh, V.; Balasundaram, N. Experimental investigation on water hyacinth ash as the partial replacement of cement in concrete. Int. J. Civ. Eng. Technol. 2017, 8, 1013–1018. [Google Scholar]

- Lima, S.A.; Varum, H.; Sales, A.; Neto, V.F. Analysis of the mechanical properties of compressed earth block masonry using the sugarcane bagasse ash. Constr. Build. Mater. 2012, 35, 829–837. [Google Scholar] [CrossRef]

- Zeybek, O.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.I.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of replacing cement with waste glass on mechanical properties of concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef] [PubMed]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkılıç, Y.O.; Sabri, M.M.S. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Dughaishi, H.A.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Çelik, A.I.; Özkılıç, Y.O.; Zeybek, O.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical behaviour of crushed waste glass as replacement of aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri, M.M.S.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M. Flexural behaviour of reinforced concrete beams using waste marble powder towards application of sustainable concrete. Front. Mater. 2022, 9, 1068791. [Google Scholar] [CrossRef]

- Chang, Q.; Liu, L.; Farooqi, M.U.; Thomas, B.; Özkılıç, Y.O. Data-driven based estimation of waste-derived ceramic concrete from experimental results with its environmental assessment. J. Mater. 2023, 24, 6348–6368. [Google Scholar] [CrossRef]

- Boban, J.M.; Nair, P.V.; Shiji, S.T.; Cherian, S.E. Incorporation of water hyacinth in concrete. Int. J. Eng. Res. Technol. 2017, 6, 540–544. [Google Scholar]

- Murugesh, V.; Balasundaram, N.; Vadivel, T.S. Experimental studies on durability studies of concrete with partial replacement of cement by water hyacinth ash. Int. J. Eng. Technol. 2018, 7, 22–24. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition component influence on concrete properties with the additive of rubber tree seed shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-weight concrete with improved stress–strain characteristics reinforced with dispersed coconut fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.; Hakeem, I.; Dulaimi, A.F.; Özkılıç, Y.; Sabri, M.; Sergeev, V. Investigation of the physical-mechanical properties and durability of high-strength concrete with recycled PET as a partial replacement for fine aggregates. Front. Mater. 2023, 10, 1101146. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Özkılıç, Y.O.; Sabri, M.M.S. Effects of waste powder, fine and coarse marble aggregates on concrete compressive strength. Sustainability 2022, 14, 14388. [Google Scholar] [CrossRef]

- Fayed, S.; Madenci, E.; Özkiliç, Y.O.; Mansour, W. Improving bond performance of ribbed steel bars embedded in recycled aggregate concrete using steel mesh fabric confinement. Constr. build. Mater. 2023, 369, 130452. [Google Scholar] [CrossRef]

- Manikandan, A.T.; Moganraj, M. Consolidation and rebound characteristics of expansive soil by using lime and bagasse ash. Int. J. Res. Eng. Technol. 2014, 3, 403–411. [Google Scholar]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of bagasse ash as a pozzolanic material in concrete. Constr. build. Mater. 2009, 23, 3352–3358. [Google Scholar] [CrossRef]

- Mansour, M.B.; Ogam, E.; Jelidi, A.; Cherif, A.S.; Jabrallah, S.B. Influence of compaction pressure on the mechanical and acoustic properties of compacted earth blocks: An inverse multi-parameter acoustic problem. Appl. Acoust. 2017, 125, 128–135. [Google Scholar] [CrossRef]

- Mansour, M.B.; Ogam, E.; Fellah, Z.E.A.; Cherif, A.S.; Jelidi, A.; Jabrallah, S.B. Characterization of compressed earth blocks using low frequency guided acoustic waves. J. Acoust. 2018, 139, 2551–2560. [Google Scholar] [CrossRef] [PubMed]

- Ouma, J.; Ongwen, N.; Ogam, E.; Auma, M.; Fellah, Z.; Mageto, M.; Ben Mansour, M.; Oduor, A. Acoustical properties of compressed earth blocks: Effect of compaction pressure, water hyacinth ash and lime. Case Stud. 2023, 18, e01828. [Google Scholar] [CrossRef]

- Butko, D.; Holliday, L.; Reyes, M. Comparing the acoustical nature of a compressed earth block (ceb) residence to a wood-framed residence. Proc. Mtgs. Acoust. 2014, 22, 015002. [Google Scholar] [CrossRef]

- Johnson, D.L.; Koplik, J.; Dashen, R. Theory of dynamic permeability and tortuosity in fluid-saturated porous media. J. Fluid Mech. 1987, 176, 379–402. [Google Scholar] [CrossRef]

- Ogam, E.; Fellah, Z.E.A.; Ogam, G.; Ongwen, N.O.; Oduor, A.O. Investigation of long acoustic waveguides for the very low frequency characterization of monolayer and stratified air-saturated poroelastic materials. Appl. Acoust. 2021, 182, 108200. [Google Scholar] [CrossRef]

- Ogam, E.; Fellah, Z.E.A.; Fellah, M.; Depollier, C. Theoretical and experimental study of micropolar elastic materials using acoustic waves in air. J. Sound Vib. 2021, 510, 116298. [Google Scholar] [CrossRef]

- Wirgin, A. Retrieval of the equivalent acoustic constitutive parameters of an inhomogeneous fluid-like object by nonlinear full waveform inversion. Ultrasonics 2016, 65, 353–369. [Google Scholar] [CrossRef]

- Lefeuve-Mesgouez, G.; Mesgouez, A.; Ogam, E.; Scotti, T.; Wirgin, A. Retrieval of the physical properties of anelastic solid half space from seismic data. J. Appl. Geophys. 2013, 88, 70–82. [Google Scholar] [CrossRef]

| Sample ID | Soil | WHA | SBA | Water (mL) |

|---|---|---|---|---|

| SG1 | 100 | 0.0 | 0.0 | 60 |

| SG2 | 95 | 5.0 | 0.0 | 90 |

| SG3 | 90 | 10.0 | 0.0 | 160 |

| SG4 | 85 | 15.0 | 0.0 | 170 |

| SG5 | 85 | 12.0 | 3.0 | 110 |

| SG6 | 85 | 10.0 | 5.0 | 100 |

| SG7 | 85 | 7.0 | 8.0 | 120 |

| SG8 | 85 | 4.0 | 11.0 | 90 |

| Sample | SG1 | SG2 | SG3 | SG4 | SG5 | SG6 | SG7 | SG8 |

|---|---|---|---|---|---|---|---|---|

| Φ | 0.40 | 0.51 | 0.64 | 0.70 | 0.42 | 0.37 | 0.34 | 0.29 |

| σ (×103 pa·s·m−2) | 11.8 | 9.2 | 7.5 | 6.0 | 11.0 | 13.8 | 17.8 | 22.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ongwen, N.O.; Alruqi, A.B. Acoustics of Compressed Earth Blocks Bound Using Sugarcane Bagasse Ash and Water Hyacinth Ash. Appl. Sci. 2023, 13, 8223. https://doi.org/10.3390/app13148223

Ongwen NO, Alruqi AB. Acoustics of Compressed Earth Blocks Bound Using Sugarcane Bagasse Ash and Water Hyacinth Ash. Applied Sciences. 2023; 13(14):8223. https://doi.org/10.3390/app13148223

Chicago/Turabian StyleOngwen, Nicholas O., and Adel Bandar Alruqi. 2023. "Acoustics of Compressed Earth Blocks Bound Using Sugarcane Bagasse Ash and Water Hyacinth Ash" Applied Sciences 13, no. 14: 8223. https://doi.org/10.3390/app13148223

APA StyleOngwen, N. O., & Alruqi, A. B. (2023). Acoustics of Compressed Earth Blocks Bound Using Sugarcane Bagasse Ash and Water Hyacinth Ash. Applied Sciences, 13(14), 8223. https://doi.org/10.3390/app13148223