Abstract

High-modulus asphalt mixes are effective means to solve rutting problems, but they perform poorly at low temperatures. This study aims to enhance the modulus and low-temperature properties of mixes. Firstly, composite-modified asphalts and mixes were prepared by incorporating rubber powder and rock asphalt. Secondly, their mechanical and viscoelastic properties were investigated to determine the appropriate mass ratios of rubber powder and rock asphalt in asphalt to be 20% and 6%, respectively. The results show that both rock asphalt and rubber powder can enhance the softening point and viscosity of basic asphalt while reducing penetration. Furthermore, their combination significantly improves the high-temperature performance of the material. It is noteworthy that the rubber powder also improves the weakening of rock asphalt for mixtures at low temperatures. Finally, this study employs dynamic and static modulus tests, rutting tests, and beam bending tests to clarify the road properties of composite-modified asphalt mixes. The results indicate that mixes have high-modulus and water damage resistance while considering acceptable low-temperature performance. This paper not only enhances the adaptability of high-modulus asphalt in different environments but also expands its application range.

1. Introduction

In recent years, the rapid increase in traffic volume and the presence of oversize, heavy, and channelizing vehicles have resulted in increasingly severe early damage to asphalt concrete pavement. Rutting is particularly prominent and directly affects driving comfort, pavement service life, and driving safety [1]. Especially for continuous long and steep slope sections of highways, the pavement is constructed with SBS-modified asphalt and neutral or alkaline stone with excellent performance. However, even with these measures in place, severe rutting damage may still occur after the road has been put into use. Therefore, developing a modified asphalt with a higher modulus is of great engineering and practical importance in improving the rutting resistance of long steep slope sections as well as heavy load and overload sections [2,3].

To solve the problem of rutting in asphalt pavement, France pioneered the use of hard asphalt to prepare high-modulus asphalt (HMA) and its mixture (HMAM) [4]. In recent years, more attention has been paid to the various properties of HMAM. EME2 is the highest level of HMAM in the French standard, which not only reduces the thickness of full-depth asphalt pavement but also provides exceptional properties of high-modulus, fatigue resistance, and deformation resistance [5]. The French HMAMs were used for pavement subgrade in the UK and produced good results [6]. In 2006, American scholars Lee et al. found that SBS and high boiling point petroleum high-modulus composite-modified asphalt (HMAM) had better performance in water stability, rutting resistance, and aging resistance than conventional asphalt mixtures [7]. In 2011, domestic scholars Wu et al. designed AC20, Sup20, and EME20 using high-modulus additives and AH70# asphalt. The results showed that the temperature stability and fatigue resistance test results of AC20 and Sup20 were consistent with those of EME20, indicating that HMAM is a viable option for satisfying Chinese specifications [8].

The preparation of high-modulus asphalt relies on the following technical approaches: (1) using low-grade hard asphalt; (2) adding high-modulus agents to the matrix asphalt; (3) using SBS composite-modified asphalt. In 1998, Lu et al. found that various SBS modifiers could significantly increase the complex modulus of asphalt [9]. In 2006, Zhu et al. conducted a comparative study of the rutting resistance of hard asphalt and SBS-modified asphalt. The results showed that the asphalt mixes prepared with hard asphalt met the requirements of specification for dynamic stability, but the overall rutting resistance was significantly inferior to that of modified asphalt [10].

In 2007, Liang et al. found that the dynamic stability of a 30# hard asphalt mixture was lower than that of SBS-modified asphalt and higher than that of ordinary 70# asphalt [11]. In 2008, Meng et al. prepared high-modulus modified asphalt using different SBS and proposed the technical concept of utilizing various SBS-modified asphalts for different types of asphalt pavements [12]. In 2011, Zou et al. found that the water damage resistance and high-temperature performance of hard asphalt were significantly higher than those of A-70 asphalt, and there was a difficult balance between its high-low-temperature performance [13]. In 2012, Yang et al. found that PE and SBS composite modification improved the high-temperature stability, mechanical properties, and water damage resistance of high-modulus asphalt mixes and reduced the low-temperature properties and fatigue resistance [14].

Although hard asphalt exhibits excellent high-temperature stability, it is prone to cracking at low temperatures. While SBS-modified asphalt can meet the temperature-sensitive requirements of pavement paving, its cost is expensive. Rubber powder is readily available, inexpensive, and environmentally friendly. Therefore, researchers have shifted their focus to developing rubber powder-modified asphalt with proven excellent low-temperature properties. In 2010, Cui studied the fine structure and low-temperature rheological properties of modified asphalt using SEM and DSR tests. The results indicated that the surface mesh structure of rubber powder particles could effectively adsorb asphalt and maintain stability at −20 °C. As the temperature decreases, there is a moderate change in the trend of dynamic modulus and phase angle. The modified asphalt always maintains a certain degree of fluidity, which enhances flexibility and significantly improves resistance to low-temperature cracking. Therefore, it is suitable for use in northern areas of China [15]. In 2017, Huang found that increasing the mass fraction of rubber powder can effectively enhance the low-temperature plastic deformation capacity and rheological properties of asphalt [16]. In 2021, Zhang found that compared with the basic asphalt, TB rubber power modified asphalt had excellent low-temperature performance, and the low-temperature crack resistance of the mixes was enhanced with the increase in TB rubber power [17].

In 2016, Liu et al. found that the high-modulus asphalt mixture compound modified by Qingchuan rock asphalt and rubber powder had excellent high-temperature stability, water stability, and fatigue durability. Additionally, the best blending ratio was recommended to be 10% Qingchuan rock asphalt + 18% rubber powder [18]. In 2017, Qin found that the addition of Qingchuan rock asphalt and SBS significantly improved the high-temperature performance of TB rubber powder-modified asphalt and its mixes and retained the low-temperature characteristics to some extent [19]. In 2016, Wu et al. found that the pavement performance of asphalt mixtures was significantly improved with rubber powder dosed at 8–10%. The incorporation of rock asphalt allows asphalt to reach a more desirable high-temperature and service condition [20].

Recently, there has been insufficient research on the fundamental mechanical and viscoelastic properties of hard asphalt and rubber power composite-modified asphalt, as well as their impact on HMAM [21,22]. Therefore, further investigation into the performance of these materials in asphalt mixtures is highly worthwhile. Based on the properties of hard asphalt and rubber powder, this study presents a comprehensive discussion on the preparation and performance of composite-modified asphalt and its mixes. The aim is to enhance and improve their modulus and low-temperature performance, which is crucial for promoting the application of high-modulus composite-modified asphalt mixes while providing technical support.

2. Design Idea

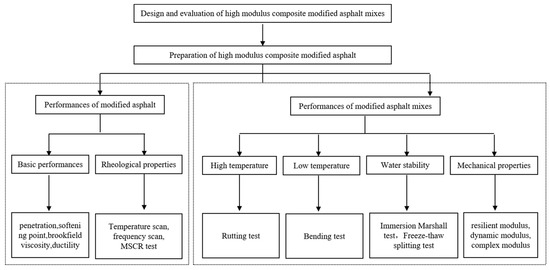

With the increasing frequency of rutting problems in asphalt pavement, enhancing the mixture modulus has become one of the effective measures to address this issue. High-modulus asphalts have undergone stages including rigid asphalt, SBS-modified asphalt, and composite-modified asphalt. Although hard asphalt exhibits excellent high-temperature performance, its low-temperature performance is lacking. SBS, which has exceptional high-low-temperature properties, is expensive. Rubber powder, which is inexpensive and easily obtained, demonstrates favorable anti-aging and low-temperature performances. Therefore, the compounding of hard asphalt with rubber powder has become a prevailing trend in preparing high-modulus asphalt. However, there is still insufficient research on its basic mechanical and viscoelastic properties, as well as the influence of these properties on HMAM. Additionally, for high-modulus asphalt to be applied effectively in pavement layers, it must exhibit excellent high-low temperatures performance, water damage resistance, and fatigue resistance. From a practical perspective on pavement, this paper has designed and evaluated a high-modulus asphalt mixture modified with rock asphalt and rubber powder. The specific technical process is illustrated in Figure 1.

Figure 1.

The technical route of this paper.

3. Experimental Design of Composite-Modified Asphalt

3.1. Materials

3.1.1. Basic Asphalt

In this study, 70# asphalt was used to prepare the composite-modified asphalt. Basic performance tests were conducted in accordance with the “Test Procedure for Asphalt and Asphalt Mixture for Highway Engineering” [23]. The test results presented in Table 1 demonstrate that the fundamental performance indicators satisfy the technical requirements of relevant specifications.

Table 1.

Technical parameters of 70# asphalt.

3.1.2. Rock Asphalt

Rock asphalt is a substance formed by complex physical and chemical changes in nature, as crude oil-like material constantly rises to the surface due to crustal movement and fractures. It has a vein-like structure intermixed with various rocks and minerals, predominantly black-brown granular in nature. Additionally, it contains very fine limestone particles and emits a slightly kerosene-like odor. This mineral formation occurs within mountains and rock fissures, requiring the ability to withstand high pressure. The polymerization degree is high, as well as the molecular weight, resulting in a high softening point. Rock asphalt exhibits high-temperature and weathering resistance, as well as a high nitrogen content and absence of wax; consequently, it possesses strong resistance to rutting, water damage, and aging while also enhancing the quality of wax-containing asphalt.

Currently, the predominant sources of natural asphalt in the world are Albanian rock asphalt (ARA), Buton rock asphalt (BRA), Iranian rock asphalt (YRA), Qingchuan rock asphalt (QRA), and North American rock asphalt (AG). The technical properties of these five types of natural asphalts were tested according to “Asphalt mixture modification additives Part 5: natural asphalt” [24], and the results are presented in Table 2. From Table 2, it is evident that Buton rock asphalt (BRA) exhibits a higher ash content and coarser particle size distribution compared to the other four types of rock asphalt, making it unsuitable for wet modification. In contrast, Qingchuan rock asphalt (QRA) has a higher asphalt content and finer particle size distribution, which allows for optimal blending with mastic asphalt at lower proportions to achieve superior compounding effects.

Table 2.

Performance of different types of rock asphalt.

To further investigate the modification effect and compatibility of different types of rock asphalt on petroleum asphalt, 70# asphalt was selected as the base material. Five types of rock asphalt were blended with a ratio of 10% to the base material to prepare a modified mixture. According to the test procedure for waterproof materials in highway engineering [23], penetration, ductility, softening point, and other indicators were analyzed for the five modified mixtures. The results are presented in Table 3. It is evident from the table that various rock bitumen-modified asphalts exhibit distinct degrees of reduction in penetration and ductility, indicating the influence of rock bitumen on enhancing viscosity and improving the low-temperature properties of asphalt. The softening points of the modified asphalts were all enhanced, and rock asphalt had a positive impact on the high-temperature performance of asphalt. Among them, QRA-modified asphalt exhibited the most significant improvement in softening point, with only minimal reduction in penetration and ductility compared to other modified asphalts. After considering various characteristics of rocks and modified materials, as well as cost issues, QRA was ultimately chosen as the raw material for preparing composite modifiers in this study.

Table 3.

Results of modified asphalt tests.

3.1.3. Rubber Power

In this study, the 60 mesh waste rubber powder selected was manufactured by Hebei Jiaoke Material Technology Co., Ltd., Shijiazhuang, China. The specific performance parameters presented in Table 4 meet the requirements of relevant specifications.

Table 4.

Technical parameters of the rubber powder.

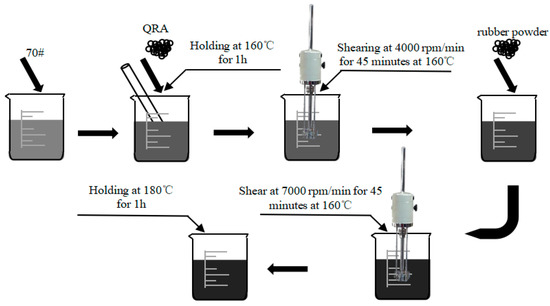

3.2. Preparation of Composite-Modified Asphalt

In this study, an HMA was prepared using 70# asphalt. The addition of rock asphalt and rubber powder significantly increased the viscosity of the asphalt, which limited the amount of these modifiers that could be used. Additionally, considering the impact of modifiers on asphalt performance, a test program was conducted to determine optimal doping levels for rubber powder at 20%, 25%, and 30% and Qingchuan rock asphalt at 0%, 3%, 6%, 9%, and 12%. The percentage of the doping is referenced to the mass of matrix asphalt, and the control group is 70# asphalt, 6% rock asphalt modified asphalt, or 12% rock asphalt modified asphalt. Table 5 shows the modified asphalt proportioning design scheme. The specific preparation process is shown in Figure 2.

Table 5.

Modified asphalt ratio.

Figure 2.

Preparation process of compound modified asphalt.

3.3. Determination of Compound Modifier Dosing

3.3.1. Penetration and Softening Point

Penetration is used to characterize the deformation resistance of asphalt under external forces. A lower value indicates a higher resistance. Softening point is used to evaluate the high-temperature durability of asphalt, with a higher value indicating superior high-temperature stability. According to the technical requirements, prepared asphalt was tested for 25 °C penetration and softening point [23].

Table 6 presents the results of penetration tests for various modified asphalts. The addition of both rubber powder and rock asphalt resulted in a significant decrease in asphalt penetration. Specifically, compared to 70# asphalt, modified asphalts containing 6% and 12% rock asphalt reduced penetration by 11.9% and 19.3%, respectively, while those containing 20%, 25%, and 30% rubber powder experienced reductions of 20.5%, 33.7%, and 39.2%. Maintaining the rubber powder content at 20%, an increase in rock asphalt content leads to a gradual reduction in asphalt penetration, which is also observed in other rubber powder-modified asphalts. Similarly, keeping the rock asphalt content constant at 6% results in a gradual decrease in penetration with an increase in rubber powder. Similar behavior is found in other mixtures containing rock asphalt. These findings suggest that both factors have an impact on performance, resulting in an increase in heavy fractions and thickening and hardening of the asphalt.

Table 6.

Test results of penetration (0.1 mm).

Table 7 presents the results of softening point tests for various modified asphalts. It is evident that adding both rubber powder and rock asphalt can significantly enhance the softening point of asphalt. Compared to 70# asphalt, incorporating 6% and 12% rock asphalt modified asphalt resulted in a rise in softening points by 14.8% and 23.9%, respectively, while using rubber powder at concentrations of 20%, 25%, and 30% led to an increase in softening points by as much as 48.9%, 71.6%, and 83.0%. Maintaining a constant rubber powder dose of 20%, an increase in the amount of rock asphalt leads to an elevation in the softening point of asphalt. This effect is also observed in other rubber powder-modified asphalts. When the content of rock asphalt remains constant at 6%, increasing the amount of rubber powder results in a higher softening point, although this effect becomes less significant as more rubber powder is added. Similar outcomes are noted across various mixtures containing rock asphalt. These findings demonstrate that both rubber powder and rock asphalt can enhance the high-temperature performance of asphalt.

Table 7.

Test results of softening points (°C).

3.3.2. Ductility and Brookfield Viscosity

Ductility characterizes the plasticity of asphalt, and the ductility test is commonly used in China to evaluate its low-temperature performance. Asphalt viscosity reflects its shear deformation resistance under high-temperature. However, it should be noted that excessively high viscosity may increase mixing and construction difficulties despite indicating stronger shear deformation resistance. Therefore, the asphalt viscosity should be controlled within a reasonable range. In accordance with the technical requirements of “Highway Engineering Asphalt and Asphalt Mixture Test Procedure”, prepared asphalt was tested for 5 °C ductility and 180 °C Brookfield viscosity [23].

The results of the ductility test are presented in Table 8. It is evident that the addition of rock asphalt to the matrix asphalt significantly reduces its ductility, with a greater reduction observed as the mass of rock asphalt added increases. When compared to 70# asphalt, the asphalt modified with 12% rock asphalt becomes brittle and fractures at an early stage during tensile testing. This suggests that rock asphalt has a pronounced weakening effect on low-temperature properties. Additionally, compared to 70# asphalt, the addition of 20%, 25%, and 30% rubber powder-modified asphalt increases ductility by 150%, 202%, and 275%, respectively. This indicates that rubber powder modification significantly improves the low-temperature performance of matrix asphalt. As the mass of rubber powder increases, the ductility of rock asphalt gradually increases while maintaining a content of 6%. This suggests that rubber powder can compensate for weakened low-temperature performance in rock asphalt. To produce high-modulus asphalt with adequate ductility in low-temperature environments, it is recommended that the ductility should exceed 5 cm at 5 °C and a minimum rubber powder content of 20% be used.

Table 8.

Test results of ductility (cm).

In addition to the same factors that contribute to decreased penetration and increased softening point, the analysis of rock asphalt must also consider its physical premixing with rubber powder and matrix asphalt. In rubber powder-modified asphalt, the distribution of rock asphalt particles is relatively independent; however, stress concentration and early fracture may occur on the surface of rock asphalt particles at low temperatures.

The results of the viscosity test for modified asphalt are presented in Table 9. It is evident from the table that adding rubber powder and rock asphalt can significantly enhance the viscosity of asphalt. Maintaining a 6% admixture of rock asphalt and increasing the content of rubber powder from 20% to 30% resulted in a viscosity increase of 0.7 Pa·s. Similarly, maintaining the rubber powder content at 25% and increasing the rock asphalt content from 0% to 12% led to a viscosity increase of 1 Pa·s. These indicate a positive contribution of rock asphalt and mastic powder to improving asphalt viscosity. To ensure optimal flowability and workability of the asphalt mixture, it is crucial that the viscosity of the asphalt does not exceed 3.0 Pa·s. When the rubber powder content in modified asphalt reaches 25% or 30%, regardless of variations in rock asphalt content, the viscosity typically exceeds this limit. To obtain high-quality and high-modulus asphalt material, it is recommended to control the rubber powder levels at 20% and conduct subsequent experimentation.

Table 9.

Test results of viscosity (Pa·s).

3.3.3. Rheological Properties of Modified Asphalt

In this paper, a DSR was used to perform temperature scans, frequency scans, and MSCR (multi-stress creep recovery) tests on the composite-modified asphalt. This was performed to determine the rheological properties of rubber powder and rock asphalt in the asphalt system.

- (1)

- Temperature scan

The temperature susceptibility of asphalt binders directly affects the service life of asphalt pavements, which are subjected to a combination of temperature and load during service. Their rutting resistance and riding comfort are closely related to their high-temperature rheological properties. This test conducts a temperature scan on original and short-term aged samples of composite-modified asphalt over a continuous range of temperatures. The specific test conditions are detailed in Table 10.

Table 10.

The Parameters of Temperature Scan Test.

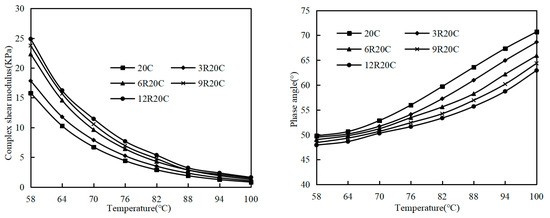

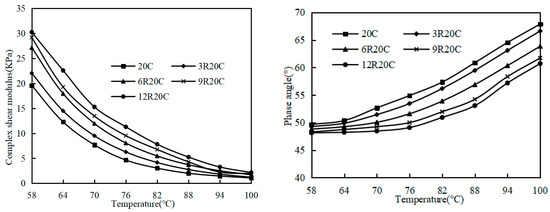

The complex modulus G* indicates the shear deformation resistance of asphalt, with larger values indicating better stability at high temperatures. The phase angle δ reflects the viscous behavior of asphalt and indicates the time delay between stress application and generation. A perfectly elastic material following Hooke’s law exhibits no strain hysteresis, resulting in a phase angle δ of zero. Smaller values of δ at high temperatures indicate greater elasticity. Figure 3 and Figure 4 present the temperature scan results for the original and short-term aged modified asphalt, respectively.

Figure 3.

The G* and δ of original samples.

Figure 4.

The G* and δ of short-term aged samples.

From Figure 3 and Figure 4, it can be observed that the G* value of both original and short-term aged samples gradually decreases with increasing temperature. This phenomenon is attributed to a decrease in elastic modulus and an increase in the viscous modulus of the asphalt material with increasing temperature. Compared to rubber powder-modified asphalt, composite-modified asphalt exhibits a higher G* value. The G* is further enhanced by the addition of a certain amount of Qingchuan rock asphalt. Therefore, incorporating rock asphalt at high temperatures can effectively improve the deformation resistance of rubber powder-modified asphalt. Additionally, mastic powder-modified asphalt exhibits a larger δ and maintains a higher viscosity compared to other composite-modified asphalts. As temperature increases, the viscous portion also increases. The addition of rock asphalt tends to decrease the δ of the composite-modified asphalt, indicating that rock asphalt can enhance its elastic proportion. Short-term aged samples exhibit higher G* values and lower δ values compared to those of the original samples. This indicates that the aging process increases the elastic component of the asphalt and decreases its viscous component, leading to increased brittleness. However, an increase in rock asphalt diminishes changes in G* and δ, indicating that rock asphalt can enhance the aging resistance of asphalt.

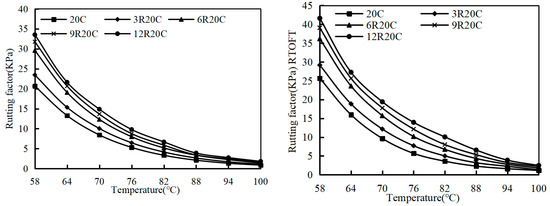

The rutting factor (G*/sinδ) is derived from G* and δ to further characterize the viscoelasticity of asphalt. A higher rutting factor indicates greater deformation resistance, suggesting superior performance at high temperatures for bonding materials. Table 11 and Table 12 present corresponding rutting factor values for original and short-term aged samples.

Table 11.

Rutting factor of original samples (kPa).

Table 12.

Rutting factor of short-term aged samples (kPa).

Figure 5 compares the rutting factors of original and short-term aged samples. The samples exhibit significant differences in rutting factor at lower temperatures, with a notable increase in G*/sinδ observed when rock asphalt is added up to 6%. However, there is minimal variation in rutting factors among different types of asphalt at higher temperatures. Comparison of the rutting factor data between original and short-term aged samples reveals that aging can enhance the rutting factor and improve resistance to high-temperature deformation of asphalt. The trend of high-temperature performance remains consistent for several asphalts.

Figure 5.

Comparison of rutting factors between original and short-term aging samples.

To quantify the correlation between the rutting factor and temperature more accurately, this study uses Origin 2017 and regression Equation (1) to fit the curve. The fitting results are presented in Table 13.

where T is the test temperature, A and B are constants related to the properties of the asphalt material.

G*/sinδ = AeBT

Table 13.

The curve fitting parameters of G*/sinδ with T.

Based on the fitted results, Equation (1) shows correlation coefficients A and B higher than 0.9900, accurately describing the variation of the rutting factor with temperature. The similar values of B indicate a general consistency in the trend of several asphalts with temperature.

- (2)

- Frequency scan

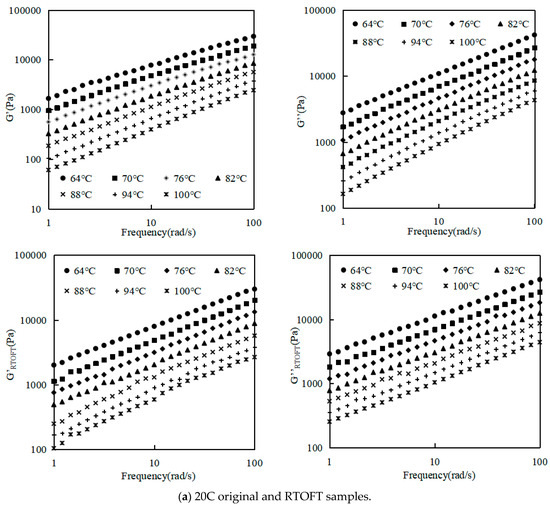

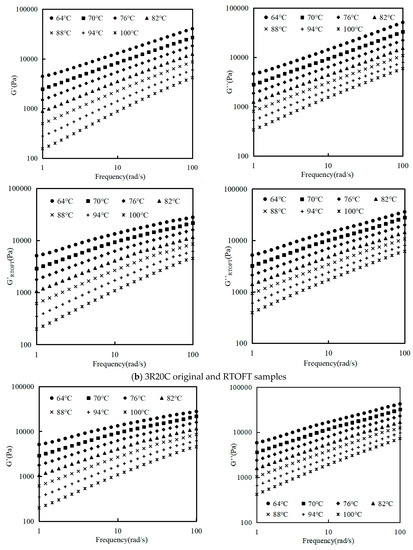

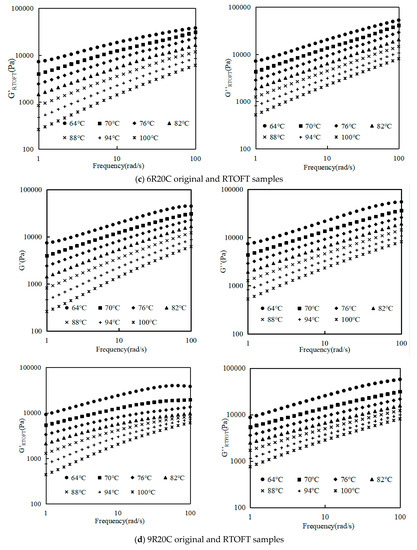

The frequency scan test was conducted to reflect the changes in the viscoelasticity of asphalt pavements under vehicle loading. This test involves applying continuously varying frequencies to asphalt samples and obtaining their dynamic mechanical response spectra as well as various viscoelasticity parameters. Table 14 presents the parameters obtained from the frequency scan test.

Table 14.

The Parameters of the frequency scan test.

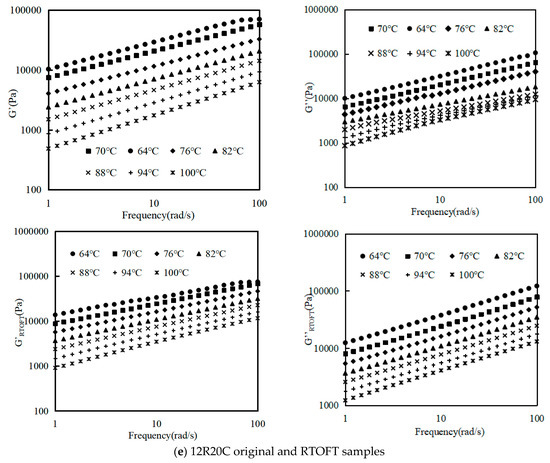

The complex shear modulus G* is composed of two components: the elastic energy storage modulus G′ (G′ = G* cosδ) and the viscous loss modulus G″(G″ = G* sinδ). Specifically, G′ represents the energy stored in asphalt during deformation, while G″ characterizes the energy dissipated by the asphalt during thermal shear. Based on the frequency scan test, the G′ and G″ of the modified asphalt were analyzed within a specific temperature range. As depicted in Figure 6, both G′ and G″ of the modified asphalt gradually decreased with increasing test temperature. This phenomenon can be attributed to enhanced molecular chain mobility within the asphalt system at high temperatures. Meanwhile, as loading frequency increases, both G′ and G″ of the modified asphalt gradually increase. According to the principle of time-temperature equivalence, modified asphalt typically exhibits reduced fluidity and increased elastic components at low temperatures, while higher modulus values are also observed in the high-frequency region.

Figure 6.

Frequency scan results of multiple samples at different temperatures.

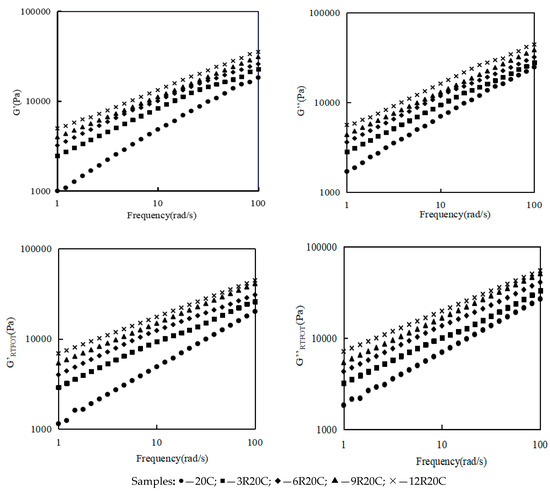

To further investigate the impact of rock bitumen on modified asphalt performance, this paper presents the modulus-frequency curve of modified bitumen at 70 °C, as illustrated in Figure 7. The results indicate that an increasing mass of rock asphalt leads to a dominant viscous component in the composite-modified asphalt at high temperatures. After aging, the storage modulus (G′) of rock asphalt-modified asphalt increases while the loss modulus (G″) decreases, indicating an enhancement in the elastic component. With increasing content of rock asphalt, the slope of the modulus-frequency curve of the composite-modified asphalt decreases, indicating improved high-temperature shear resistance. Furthermore, the modulus of aged composite-modified bitumen also increases. Specifically, the growth rate of modulus decelerates during short-term aging at 20C, indicating reduced low-temperature sensitivity and improved internal network structure stability. Notably, after incorporating rock asphalt, the composite-modified asphalt exhibits enhanced resistance to high-temperature aging without significantly affecting its modulus-frequency slope.

Figure 7.

Frequency scan results of original and short-term aged samples at 70 °C.

- (3)

- MSCR test

Multiple stress creep recovery (MSCR) tests were conducted on the original samples of composite-modified asphalt under two stresses of 0.1 kPa and 3.2 kPa. The test conditions are shown in Table 15.

Table 15.

The parameters of MSCR tests.

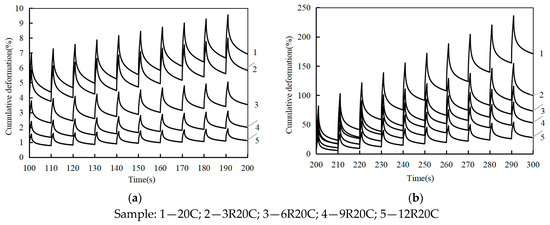

Figure 8 illustrates the cumulative deformation behavior of composite-modified asphalt under stress loading over time, as obtained from MSCR test results. The cumulative deformation of composite-modified asphalt gradually increases with an increase in the number of cycles at a constant loading stress. When subjected to higher stress, accumulated deformation also increased proportionally. Additionally, the increased rock asphalt content resulted in the composite-modified asphalt exhibiting less cumulative deformation for the same loading cycles at loading stresses of 0.1 and 3.2 kPa. The final cumulative deformation of the composite-modified asphalt increased by 326.8% (20CMA), 198.4% (3R20CMA), 108.6% (6R20CMA), 57.1% (9R20CMA), and 27.7% (12R20CMA), respectively. This is mainly due to the addition of rubber powder and rock asphalt, which increases the elastic component and the recovery capacity of asphalt under identical stress and loading cycles, resulting in significantly reduced permanent deformation.

Figure 8.

Cumulative deformation-time curves of modified asphalt at (a) 0.1 kpa and (b) 3.2 kpa loading cycles.

According to Equations (2)–(4), the deformation resilience and permanent deformation resistance of the composite-modified asphalt can be further evaluated.

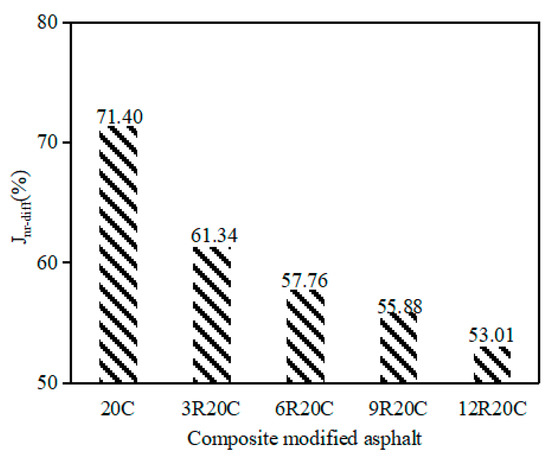

where εp is the maximum deformation during loading, εμ is the unrecovered permanent deformation, σ is the shear stress during loading, R is the deformation recovery rate, Jnr is the irrecoverable creep compliance, and Jnr−diff is the deformation-stress sensitivity index.

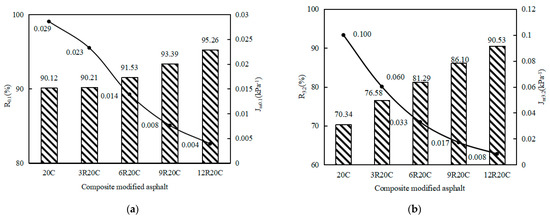

The calculated results are presented in Figure 9 and Figure 10, respectively. Rock asphalt content has a positive correlation with both R0.1 and R3.2, but it has a negative effect on both Jnr0.1 and Jnr3.2. The deformation recovery of composite-modified asphalt gradually increases while the permanent deformation decreases. In the same asphalt, R0.1 is greater than R3.2, whereas Jnr0.1 is less than Jnr3.2. The deformation resilience in asphalt decreases with increasing stress. The addition of rock asphalt can mitigate the weakened elastic recovery of the modified asphalt and enhance its load-bearing capacity, thus reducing its sensitivity under large stress loads. Specifically, R0.1 of 20C was 19.78% higher than R3.2, while Jnr0.1 was only 0.071 kPa−1 lower than Jnr3.2; when the proportion of rock asphalt reached 12%, R0.1 exceeded R3.2 by only 4.73%, and Jnr0.l was reduced by merely 0.004 kPa−1 compared with Jnr3.2.

Figure 9.

Variation of R and Jnr for different modified asphalts at (a) 0.1 KPa and (b) 3.2 KPa.

Figure 10.

Jnr−diff of different compound-modified asphalt.

Figure 10 shows that the Jnr−diff value gradually decreases with increasing mass of rock asphalt, indicating that rock asphalt effectively mitigates the stress sensitivity of asphalt. Additionally, when the Jnr−diff of modified asphalt is less than 75%, it remains undamaged under load creep. None of the types of modified asphalt reached a Jnr−diff value of 75% and therefore did not suffer any creep damage.

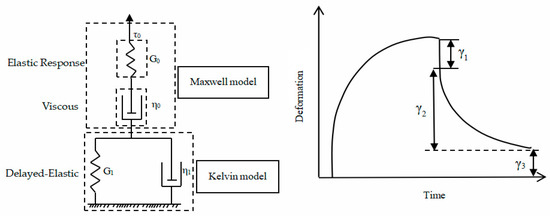

To investigate the mechanical response of asphalt under cyclic loading in depth, this paper employs the widely adopted viscoelasticity mechanical model (Burgers model) to characterize MSCR test data, as shown in Figure 11 [25]. This model accurately captures the instantaneous elastic response, delayed elastic response, and the viscous response of asphalt and its mixture under stress.

Figure 11.

Burger model and creep recovery.

As the total stress and each sub-stress are connected in series, and the cumulative strains of each element equal the total strain, the instantaneous equation for Burgers creep can be derived. The Burgers equation was used to fit the 10th cyclic loading process of MSCR at 3.2 kPa, and the values of the four parameters were obtained, as detailed in Table 16.

where γ represents the total strain during loading, τ0 is the applied shear stress, and G0, η0, G1, and η1 are parameters in Burgers equation [26].

Table 16.

Fitting parameters of the Burgers equation.

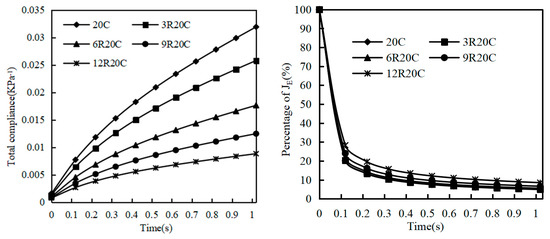

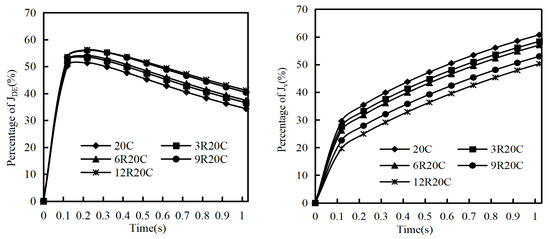

Corresponding creep compliance:

is the coefficient of instantaneous elastic deformation during 1 s loading;

is the coefficient of delayed elastic deformation during 1 s loading;

is the coefficient of viscous deformation compliance during 1 s loading.

Then, the proportion of each part of deformation compliance to creep compliance is determined.

Equation (7) represents the three components of asphalt viscoelastic compliance with loading time, as illustrated in Figure 12. The overall creep compliance of asphalt gradually increases as the stress loading time extends. The percentage of instantaneous elastic deformation JE decreases rapidly after 0.1 s, while delayed elastic deformation JDE and viscous flow deformation JV increase rapidly. This implies that the high-temperature deformation of modified asphalt is primarily dominated by its viscous component. Meanwhile, an increase in rock asphalt admixture within the same loading time will correspondingly decrease the overall creep compliance of composite-modified asphalt while also reducing the degree of plastic deformation exhibited by the material.

Figure 12.

Variation of total and partial creep compliance of modified asphalt with time.

JE decreases rapidly with increasing rock asphalt content during loading. The rubber-modified asphalt decreased the fastest, while the 12R20C composite-modified asphalt decreased the slowest. After unloading, the percentage of JE increased by 4% (3R20C), 13% (6R20C), 35% (9R20C), and 74% (12R20C) compared with 20C for composite-modified asphalts.

JDE first increases and then decreases with the extension of stress loading time. The delayed elastic creep compliance of rubber powder-modified asphalt has the smallest proportion, while JDE increases after adding rock asphalt under the same loading time. Compared to 20C, the JDE of the final composite-modified asphalt increased by 6% (3R20C), 9% (6R20C), 18% (9R20C), and 20% (12R20C).

The JV of the composite-modified asphalt increased rapidly with increasing loading time, while its deformation recovery capacity decreased rapidly. The JV gradually decreased under the same loading time with an increase in the mass of rock asphalt. Compared to 20C, the JV percentage of 12R20C was reduced by 17%, effectively controlling permanent deformation.

Rock asphalt enhances the high-temperature deformation resistance of asphalt by increasing its instantaneous and delayed elastic components while decreasing the viscous flow component. Notably, the increase in the proportion of instantaneous elastic components is more pronounced. Moreover, rock asphalt can gradually enhance the viscosity of asphalt and accelerate its hardening process, thereby enhancing instant elastic recovery after force application. This enables faster deformation recovery even under prolonged heavy loads, ultimately reducing permanent deformation.

In this paper, the performance of composite-modified asphalt is comprehensively analyzed. The optimal mass of rubber powder is finally determined to be 20%, and the amount of rock asphalt is 6%. Subsequently, the performance of the high-modulus composite-modified asphalt mixture will be verified.

4. Design and Performance Evaluation of High-Modulus Asphalt Mixtures

4.1. Materials

4.1.1. Asphalt

This study uses asphalt modified with 20% rubber powder (20C) and composite-modified asphalt with 20% rubber powder and 6% rock asphalt (6R20C).

4.1.2. Aggregates

The asphalt mixtures used in the tests are ARHM-13 and ARHM-20. The coarse aggregates of ARHM-13 consist of three sizes of gravel, including basalt 10–15 mm, 5–10 mm, and limestone 3–5 mm, while those of ARHM-20 consist of four sizes of limestone gravel: 10–20 mm, 10–15 mm, 5–5 mm, and 3–5 mm. Both gradings use the same manufactured sand as fine aggregate. Table 17, Table 18 and Table 19 present the technical specifications for coarse basalt, coarse limestone and fine aggregates, respectively.

Table 17.

Technical specifications of coarse basalt aggregate.

Table 18.

Technical specifications of limestone coarse aggregate.

Table 19.

Technical specifications of fine aggregates.

4.1.3. Limestone Mineral Powder

The mineral powder is limestone mineral powder, and the technical specifications are shown in Table 20.

Table 20.

Technical specifications of mineral power.

4.2. Preparation of High-Modulus Asphalt Mixtures

In this study, the preparation of high-modulus asphalt mixtures was carried out using the aggregate gradations in Table 21 and Table 22. The preparation process for a high-modulus asphalt mixture is similar to that of an ordinary asphalt mixture but with higher requirements. Specifically: (1) High-modulus asphalt must be mixed with the aggregate at a temperature of 185 ± 5 °C due to its elevated softening point and viscosity; (2) Compared to ordinary asphalt mixture, the mixing time should be extended by at least 10 s, and it is recommended to maintain a duration of 50 s; and (3) the forming temperature must be carefully controlled at 170 °C.

Table 21.

ARHM-13 gradation.

Table 22.

ARHM-20 gradation.

Additionally, the Marshall compaction method specified in “Technical Specification for Highway Asphalt Pavement Construction” can be used to determine the optimal asphalt dosage for a high-modulus asphalt mixture [27]. Test results are presented in Table 23 and Table 24, which show that the best oil-to-stone ratio for ARHM-13 is 5.73%, and for ARHM-20 is 4.80%.

Table 23.

ARHM-13 Marshall test results.

Table 24.

ARHM-20 Marshall test results.

4.3. Performance Evaluation of High-Modulus Asphalt Mixtures

4.3.1. Mechanical Performance

Static Modulus Test

The compressive resilience modulus of the asphalt layer directly affects the calculation of road surface rebound deflection and low tensile stress in the asphalt layer. In the analysis of elastic layered system theory, it is an important material mechanics parameter. It has been demonstrated that the rutting performance of asphalt mixtures is inversely proportional to their modulus, with a greater effect observed at high temperatures. Therefore, the experimental study of the compressive resilience modulus of asphalt mixtures can provide an important basis for designing high-modulus asphalt pavement structures.

According to the “Asphalt and Asphalt Mixture Test Procedure”, cylindrical specimens were compacted and shaped into a height of 150 mm and diameter of 150 mm using a rotary compactor to control the specimen height mode. Specimens with dimensions of 100 mm × 100 mm were obtained by coring with a core drilling machine. The molded specimens were left at room temperature for 24 h while strictly controlling the void ratio to approximately 4%. The uniaxial compression test was conducted on a universal material testing machine at a loading rate of 1 mm/min. It is recommended to use the ambient temperature box provided with the equipment to maintain warmth during the test.

Table 25 displays the maximum bearing capacity and rebound modulus of the four asphalts at 15 °C and 20 °C under different grading conditions. The table indicates that the maximum load and compressive resilience modulus of various asphalt mixtures decrease with increasing temperature. Moreover, larger nominal sizes correspond to higher maximum load and compressive resilience modulus at identical temperatures. The incorporation of high-modulus composite-modified asphalt in the mixture significantly enhances both the maximum load and compressive rebound modulus, indicating a positive impact on improving the mixture’s modulus.

Table 25.

Comparison of the compressive resilience modulus of asphalt mixtures.

Dynamic Modulus Test

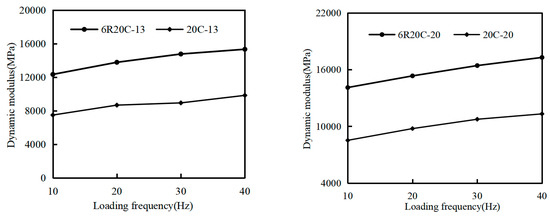

Currently, the static modulus test for asphalt pavement design in China is characterized by a slow rate of load change and prolonged maintenance at a certain level, which significantly deviates from actual force conditions. Conversely, dynamic modulus testing is employed abroad, exhibiting much higher values than the design modulus of domestic specification. From the perspective of international pavement design development, the transition from static to dynamic methods is an inevitable trend. This study conducted tests on four different types of mixes using trapezoidal specimens subjected to a two-point bending loading mode at various frequencies (15 °C, 10 Hz, 20 Hz, 30 Hz, and 40 Hz), as illustrated in Figure 13.

Figure 13.

Dynamic modulus test results.

As depicted in Figure 13, the dynamic modulus of asphalt mixes increased significantly with increasing loading frequency. The dynamic modulus of high-modulus asphalt mixes is higher than that of rubber power-modified asphalt mixes. Furthermore, the dynamic modulus of 6R20C-20 exceeds 14,000 Hz at 15 °C and 10 Hz loading frequency and basically meets the standard of high-modulus asphalt mixes.

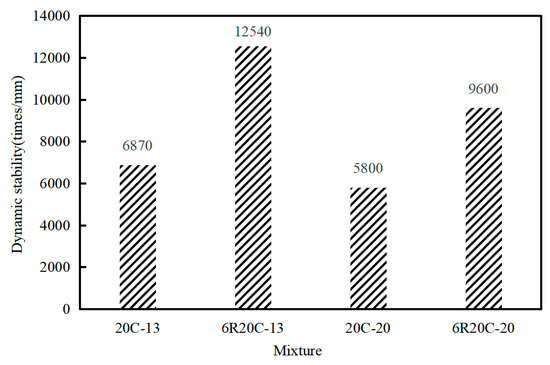

4.3.2. High-Temperature Performance

Rutting tests were conducted to evaluate the deformation resistance performance of various asphalt mixtures under high-temperature conditions, and the results are presented in Figure 14. The dynamic stability of asphalt mixtures increases with decreasing nominal size under the same binder. High-modulus composite-modified asphalt mixes exhibit significantly better dynamic stability than rubber power-modified asphalt for identical mixture grading. For instance, 6R20C-13 improved dynamic stability by approximately 82% compared to 20C-13, and 6R20C-20 enhanced it by about 66% relative to 20C-20.

Figure 14.

Asphalt mixture rutting test results.

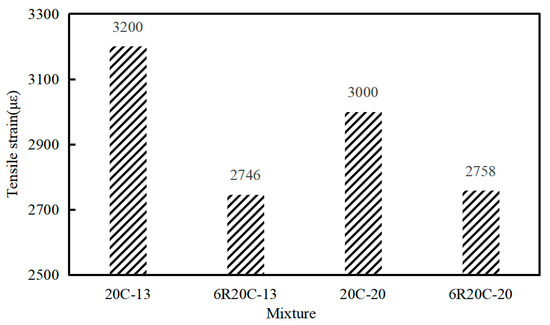

4.3.3. Low-Temperature Performance

High-modulus asphalt mixes originated in France and are mainly used in high-temperature areas. However, due to the significant temperature fluctuations between northern and southern China, as well as the frequent occurrence of low-temperature cracking in asphalt pavements, it is imperative to strictly regulate the low-temperature performance of asphalt mixtures. In this study, beam bending tests were conducted at a loading rate of 50 mm/min and −10 °C. The results shown in Figure 15 indicate that both grades of high-modulus composite-modified asphalt mixture exhibited reduced tensile strains, suggesting a slight weakening in low-temperature performance. However, they still maintain an excellent value of over 2700 με.

Figure 15.

Results of bending test.

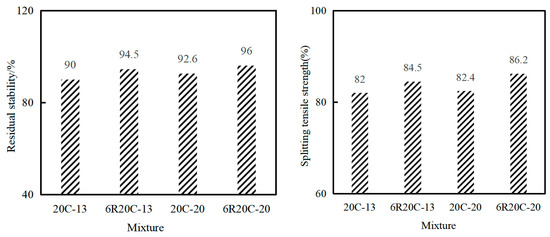

4.3.4. Water Stability

This study investigates the water resistance of high-modulus asphalt mixtures through immersion Marshall testing and frozen-thaw splitting testing. The results of residual Marshall stability and frozen-thaw splitting strength are summarized in Figure 16, which shows that the high-modulus composite-modified asphalt mixtures exhibit higher residual stability and frozen-thaw splitting strength compared to rubber powder-modified asphalt. Additionally, rubber powder and rock asphalt modification significantly improved adhesion, while high-modulus asphalt mixes exhibited superior water damage resistance.

Figure 16.

Results of water stability tests.

4.3.5. Fatigue Performance

To assess the fatigue performance of asphalt mixtures, four-point bending fatigue tests were conducted in accordance with American standard SHRPM-009 using strain control [28]. The tests were carried out at 10 °C and a loading frequency of 10 Hz, with strain levels set at 300 µε, 400 µε and 500 µε. The fatigue test results are presented in Table 26, indicating that the high-modulus composite-modified asphalt mix exhibits comparable fatigue life to the rubber power-modified asphalt mixture at different strain levels. Furthermore, it is observed that high-modulus asphalt does not have a significant impact on the performance of fatigue resistance.

Table 26.

Fatigue test results.

5. Conclusions

High-modulus asphalt and its mixes have become crucial engineering materials for addressing heavy traffic issues in China. However, their limited low-temperature performance restricts their widespread use during the cold winter season in northern regions. Therefore, this study aims to obtain high-modulus composite-modified asphalt and mixture by adding rock asphalt to improve the modulus and rubber powder to improve low-temperature performance. The basic properties of asphalt were evaluated through indoor tests using various masses of rubber powder and rock asphalt. Dynamic mechanical analysis of asphalt was employed to investigate the viscoelastic properties and determine the optimal dosage ratio for rubber powder and rock asphalt. Meanwhile, theoretical analysis was used to investigate the co-modification mechanism of asphalt between rubber powder and rock asphalt. Furthermore, the high-low-temperature properties, fatigue resistance, and mechanical properties of the high-modulus composite-modified asphalt mixture were evaluated. In summary, the following main conclusions were obtained:

- (1)

- Among the five different origins of rock asphalt, Qingchuan rock asphalt was preferred for this study due to its higher asphalt content, lower ash content, and more detailed particle size distribution. This enables a better modification effect when in full contact with the basic asphalt.

- (2)

- The addition of rock asphalt and rubber powder can increase both the softening point and viscosity of basic asphalt while decreasing needle penetration. Although this makes it more viscous, they are capable of enhancing shear resistance and high-temperature performance. Additionally, using rock asphalt can enhance aging resistance but negatively impact low-temperature performance for high-modulus asphalts. However, the weakening effect can be mitigated by adding an appropriate amount of rubber powder. After a comprehensive analysis of the performance characteristics of high-modulus asphalt, it was determined that 20% mastic powder is optimal.

- (3)

- The amount of rubber powder is fixed, and the viscoelastic properties of composite-modified asphalt with different masses of rock asphalt are tested. The composite-modified asphalt exhibits superior elastic restoring force, and the effect becomes more pronounced as the mass of rock asphalt increases while its sensitivity to stress gradually decreases. After adding rock asphalt and mastic powder, the composite-modified asphalt showed improvements in both its instantaneous elastic component and delayed elastic part, resulting in enhanced rutting resistance factor and high-temperature performance. Considering all factors, suitable content would be 6%.

- (4)

- Compared to the rubber power-modified asphalt mixture, the high-modulus composite-modified asphalt mixture exhibits more significant improvements in resistance to deformation and water damage resistance at high temperatures. Although its low-temperature performance is slightly inferior to the former, the improved effect of rubber powder on low-temperature performance still provides some ductility for the high-modulus composite-modified asphalt mixture. In terms of fatigue life, the two materials exhibit comparable performance. Notably, high-modulus composite-modified asphalt is highly effective in enhancing mix modulus, and 20 °C asphalt mixes completely meet or exceed high-modulus standards.

Author Contributions

Conceptualization, L.W.; Methodology, L.W.; Software, L.W.; Validation, L.S. and Q.L.; Formal analysis, L.S.; Investigation, L.W.; Resources, L.S.; Data curation, L.W. and L.S.; Writing—original draft, L.W.; Writing—review & editing, L.S.; Visualization, Q.L.; Supervision, L.S. and Q.L.; Project administration, Q.L.; Funding acquisition, Q.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51778481, 51978518, and 51908426). The authors also acknowledge the financial support of the Postdoctoral Innovative Talent Support Program.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is not publicly available as the project is under development.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, B. Study on Modification Mechanism and Road Performance of High-Modulus Composite-Modified Asphalt Mixture. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2020. [Google Scholar]

- Gao, Y. Study on Durability of High-Modulus Agent-SBR Composite-Modified Asphalt Mixture in Seasonally Freezing Area. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2020. [Google Scholar]

- Cheng, Y.; Zhao, X.; Yan, K.; Huang, S. Study on Performance of High-modulus Asphalt and Asphalt Mixture. J. Highw. 2022, 67, 343–349. [Google Scholar]

- Corte, J.F. Development and Uses of Hard-Grade Asphalt and of High-Modulus Asphalt Mixs in France. Transp. Res. Circ. 2001, 503, 12–31. [Google Scholar]

- Laszlo, P.; Peter, B.; Jason, J.; Denneman, E. EME2 pavement and mix design. Road Transp. Res. 2016, 25, 3–14. [Google Scholar]

- Elhott, R.; Wilson, S. Implementing High-modulus Asphalt Technology in The UK. In Proceedings of the International Seminar Maintenance Technidues to Improve Pavement Performance, Paris, France, 24–26 August 2009; pp. 32–36. [Google Scholar]

- Lee, H.J.; Lee, J.H.; Park, H.M. Performance Evaluation of High-modulus Asphalt Mixtures for Long Life Asphalt Pavements. Constr. Build. Mater. 2007, 21, 1079–1087. [Google Scholar] [CrossRef]

- Wu, C.; Jing, B.; Li, X. Performance Evaluation of High-modulus Asphalt Mixture. Adv. Mater. Res. 2011, 311–313, 2138–2141. [Google Scholar] [CrossRef]

- Lu, X. Evaluation of Fundamental Properties of SBS Polymer Modified Road Bitumens. In Proceedings of the 3rd International Conference on Road & Airfield Pavement Technology, Beijing, China, 28 April 1998; pp. 578–586. [Google Scholar]

- Zhu, H.; Yang, J. Comparative Analysis of the Rutting Resistance of Hard Asphalt. J. China Foreign. Highw. 2006, 6, 214–216. [Google Scholar]

- Liang, C.; Liu, F. Experimental Study of 30~# Hard Asphalt for Asphalt Pavement Medium Subgrade. J. China Foreign Highw. 2007, 6, 185–188. [Google Scholar]

- Meng, Y. Study on the Rheological Properties of SBS-modified Asphalt with Different Block Ratios. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2008. [Google Scholar]

- Zou, G.; Xu, J.; Liu, Y. A Study on Performance of Moisture Damage Resistant Hard Asphalts and Asphalt Mixtures. Highway 2011, 1, 198–202. [Google Scholar]

- Yang, P.; Zhang, X. Pavement performance of high-modulus asphalt mixtures modified by PE and SBS. J. Cent. South Univ. (Sci. Technol.) 2012, 43, 4044–4049. [Google Scholar]

- Cui, Y.; Xing, Y.; Zhang, S. Low-Temperature Behavior of Crumb Rubber Modified Asphalt. New Build. Mater. 2010, 37, 70–87. [Google Scholar]

- Huang, W.; Yan, C.; Liu, S. Low-temperature Performance Comparison of Terminal Blend Rubberized/SBS-modified Asphalt. J. Build. Mater. 2016, 19, 1088–1091. [Google Scholar]

- Zhang, J.; Huang, W.; Lv, Q.; Guan, W. Low-temperature Performance of TB Crumb Rubber Composite SBS-modified Asphalt and Mixture. J. Build. Mater. 2021, 24, 131–152. [Google Scholar]

- Liu, L. Study on Technical Performance of NES Rock Asphalt and Rubber Powder Composite-modified Asphalt and Its Mixture. Highw. Eng. 2016, 41, 124–129. [Google Scholar]

- Qin, H. Study on Road Performance and Modification Mechanism of Domestic Asphalt and TB Rubber Composite-modified Asphalt and Its Mixture. Highw. Eng. 2017, 42, 364–372. [Google Scholar]

- Wu, C.; Ren, Z. Influence of Rubber Powder Content on Characteristics of High-modulus Asphalt and Its Mixture. Eng. J. Wuhan Univ. 2016, 49, 411–416. [Google Scholar]

- Zhang, S.; Wang, L.; Zhao, X.; Liu, Y. Performance and Viscoelastic Analysis of Rock Asphalt/Rubber Powder Co-Modified Asphalt. China Synth. Rubber Ind. 2022, 45, 479–486. [Google Scholar]

- Zhang, S.; Wang, L.; Duan, S.; Min, X. Study on Rheological and High-temperature Storage Characteristics of Rock Asphalt/Rubber Powder Composite-modified Asphalt. Contemp. Chem. Ind. 2022, 51, 2553–2558. [Google Scholar]

- JTG E20-2011; Test Procedure for Asphalt and Asphalt Mixture for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JT/T 860.5-2014; Modifier for Asphalt Mixture- Part 5: Natural Asphalt. Ministry of Transport of the People’s Republic of China: Beijing, China, 2014.

- Wu, H.; Wang, X.; Wang, R.; Zhang, W.; Chen, C. Creep characteristics and microstructure analysis of graphene/rubber powder composite-modified asphalt based on aging. J. Chang. Univ. (Nat. Sci. Ed.) 2020, 40, 97–115. [Google Scholar]

- Tan, H.; Lv, D.; Hu, S. High-temperature Rheological Properties and Classification of High Viscosity Modified Asphalt Based on MSCR Experiment. J. Mater. Sci. Eng. 2022, 40, 292–299. [Google Scholar]

- JTG F40-2004; Technical Specification for Highway Asphalt Pavement Construction. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- SHRPM-009; Standard Method of Test for Determining the Fatigue Life of Compacted Bituminous Mixtures Subjected to Repeated Flexural Bending. Program, National Research Council: Washington, DC, USA, 1994.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).