New Trends in 4D Printing: A Critical Review

Abstract

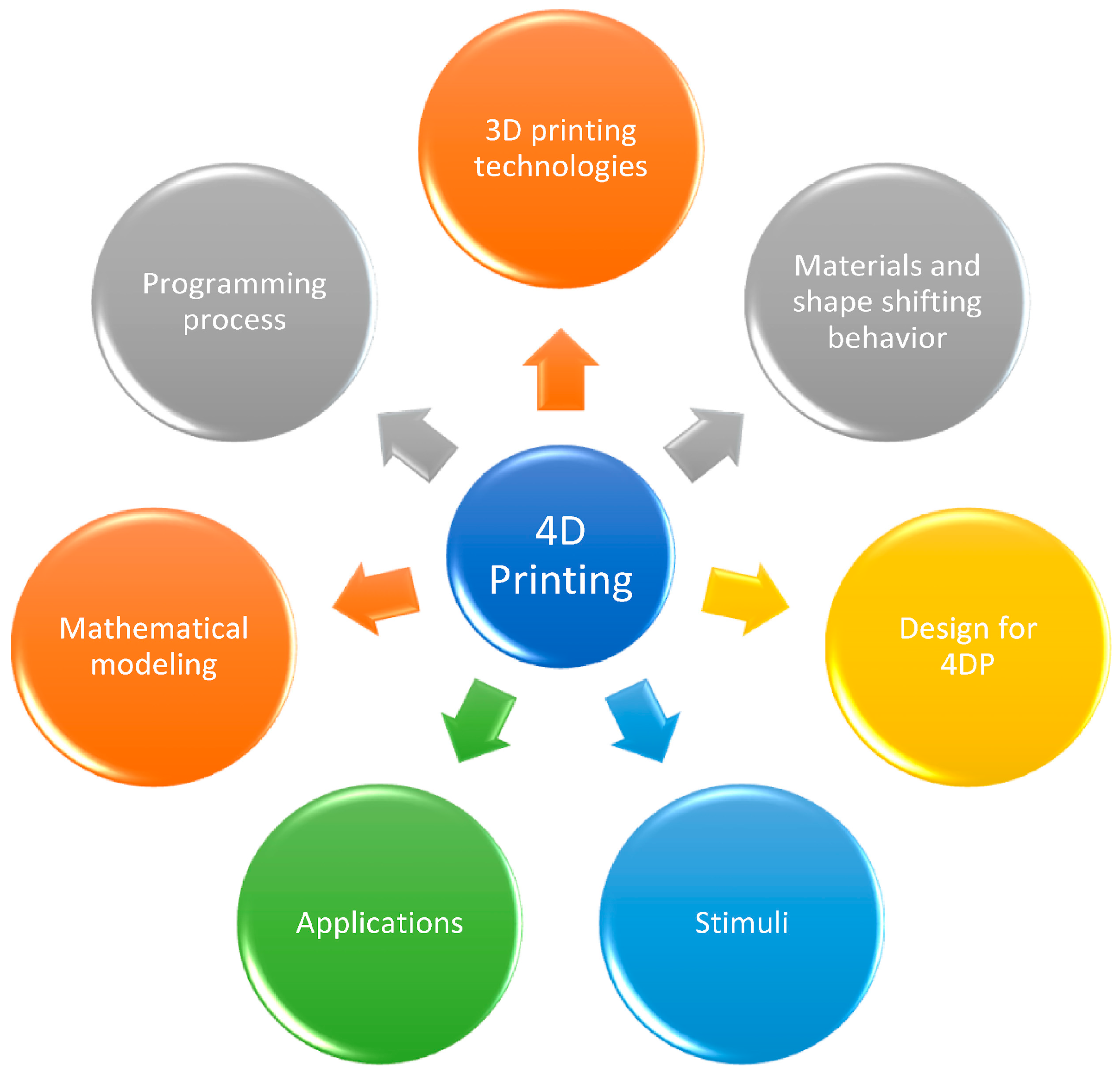

:1. Introduction

Advantages and Challenges

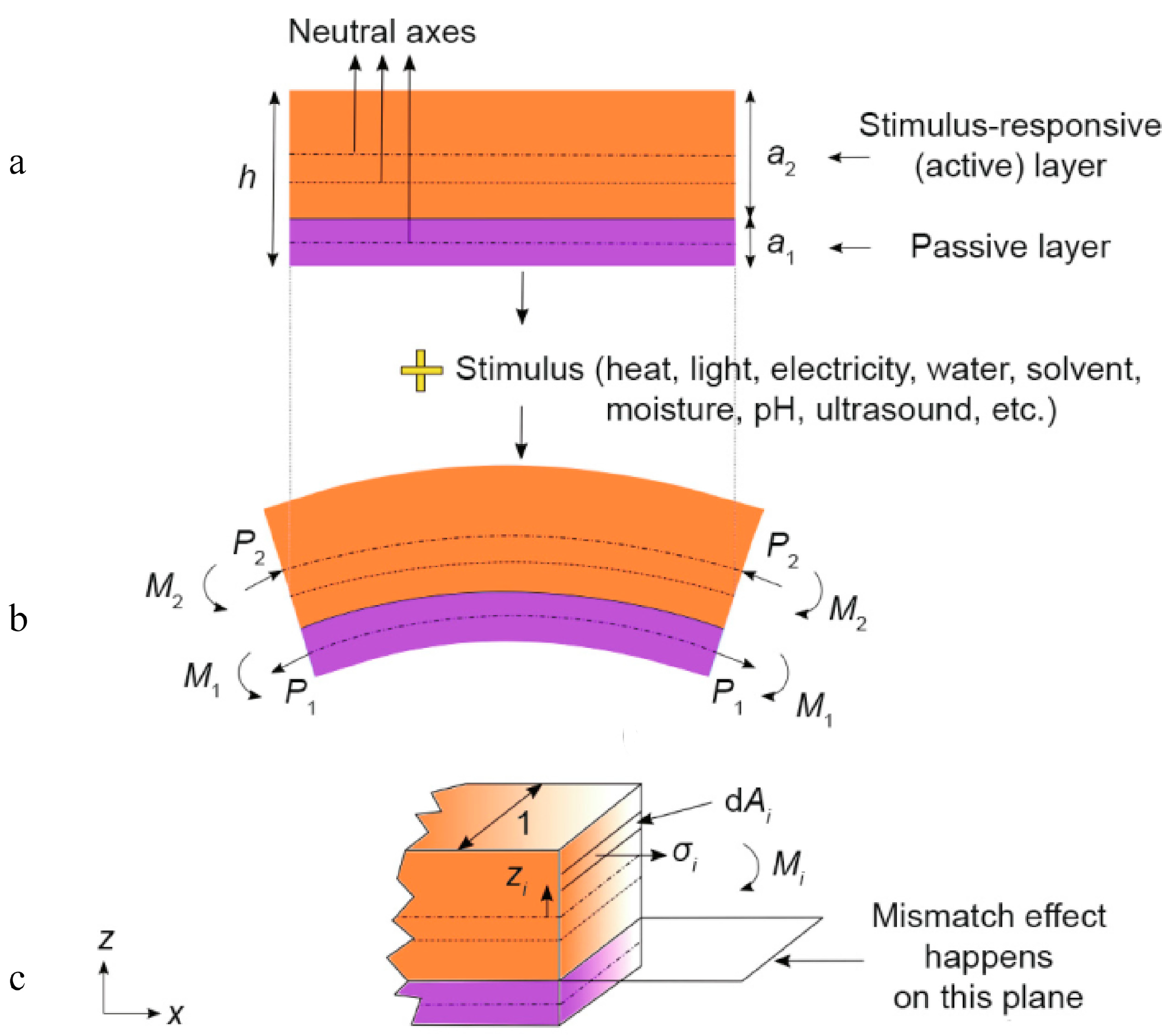

2. Modeling and Simulation

3. Design for 4DP

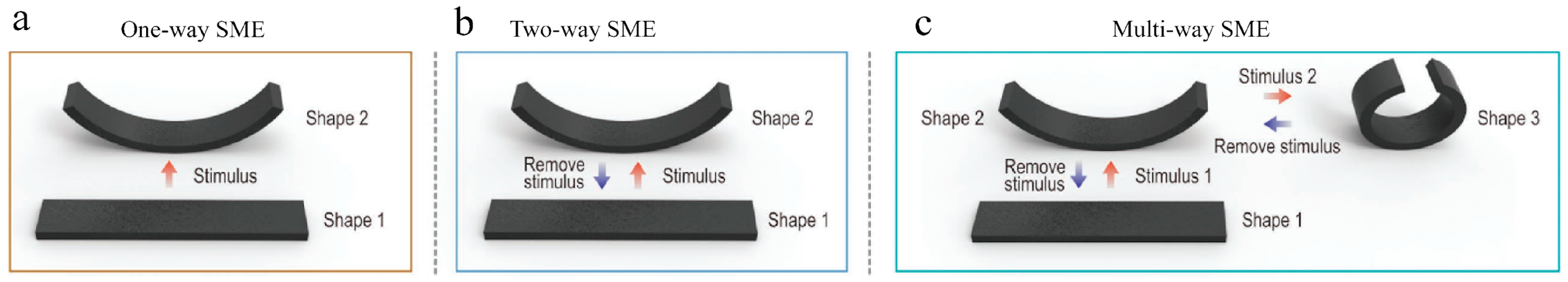

4. Shape Memory Materials

4.1. Material Specification

4.2. External Transition Stimuli for 4DP

4.2.1. Thermal Stimuli

4.2.2. Liquid/Moisture

4.2.3. Light Stimuli

4.2.4. pH Stimuli

4.2.5. Magnetic

4.3. Shape Memory Alloys (SMAs)

4.4. Shape Memory Polymers

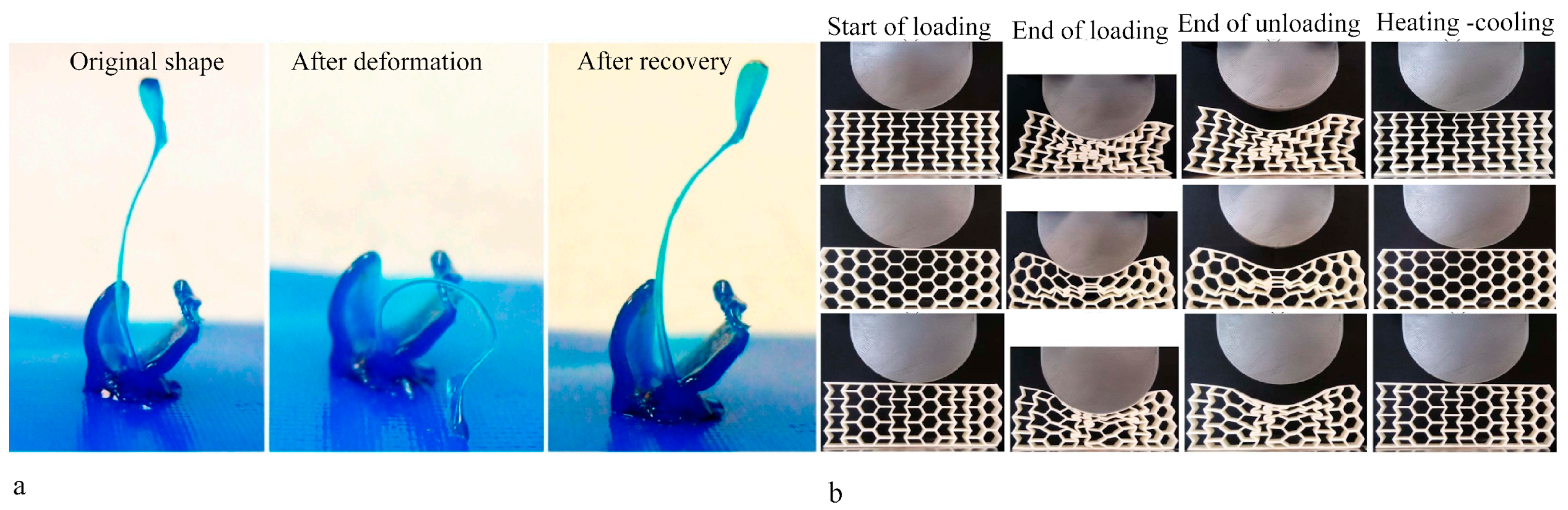

4.5. Hydrogels and Hydrophilic Polymers

5. AM Technologies Used in 4DP

5.1. Extrusion-Based Technologies

5.2. Vat-Polymerization Techniques

5.3. Powder Bed Fusion Techniques

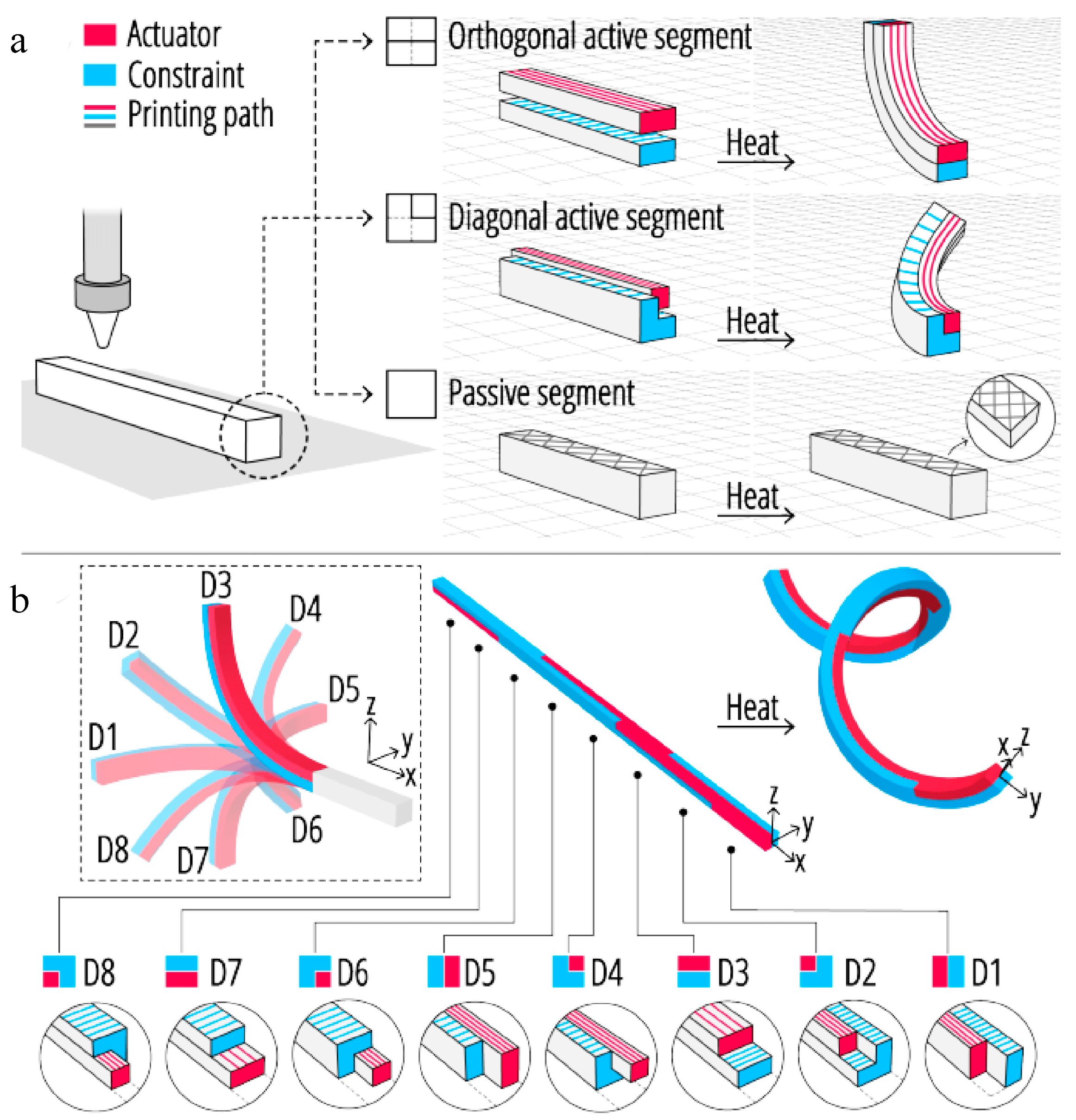

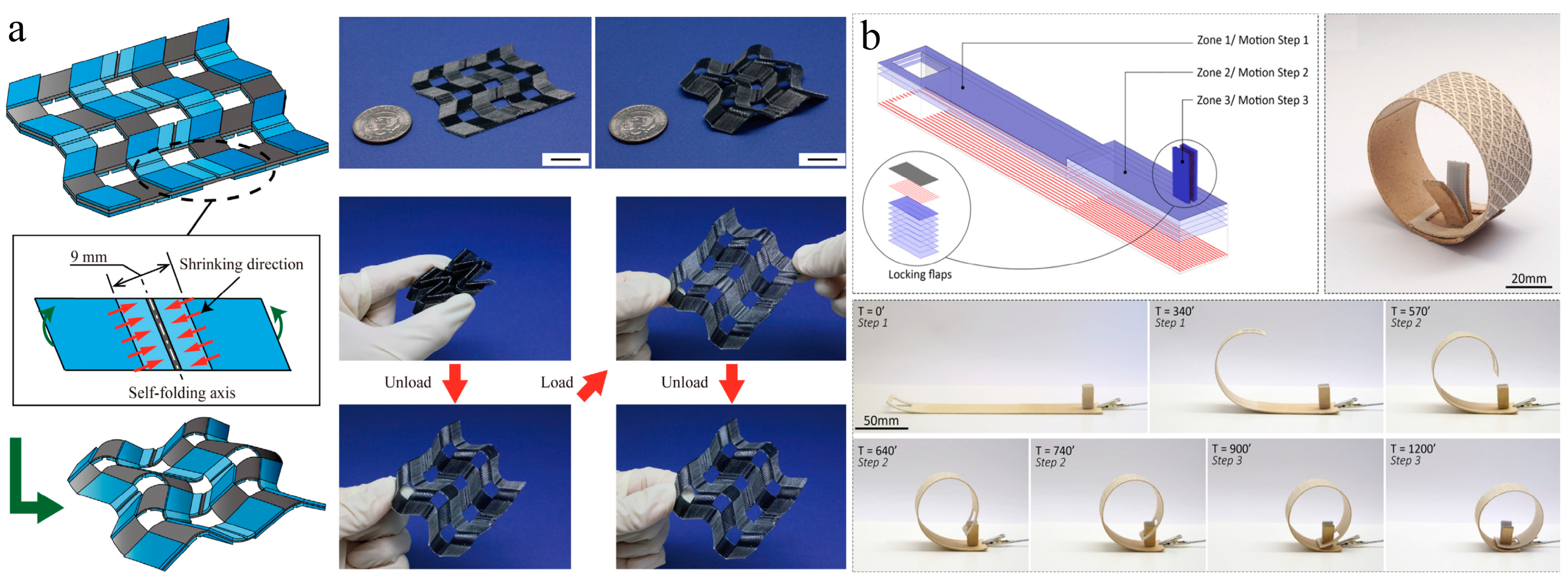

6. Printing and Programming Strategies

6.1. Stimuli-Responsive Materials

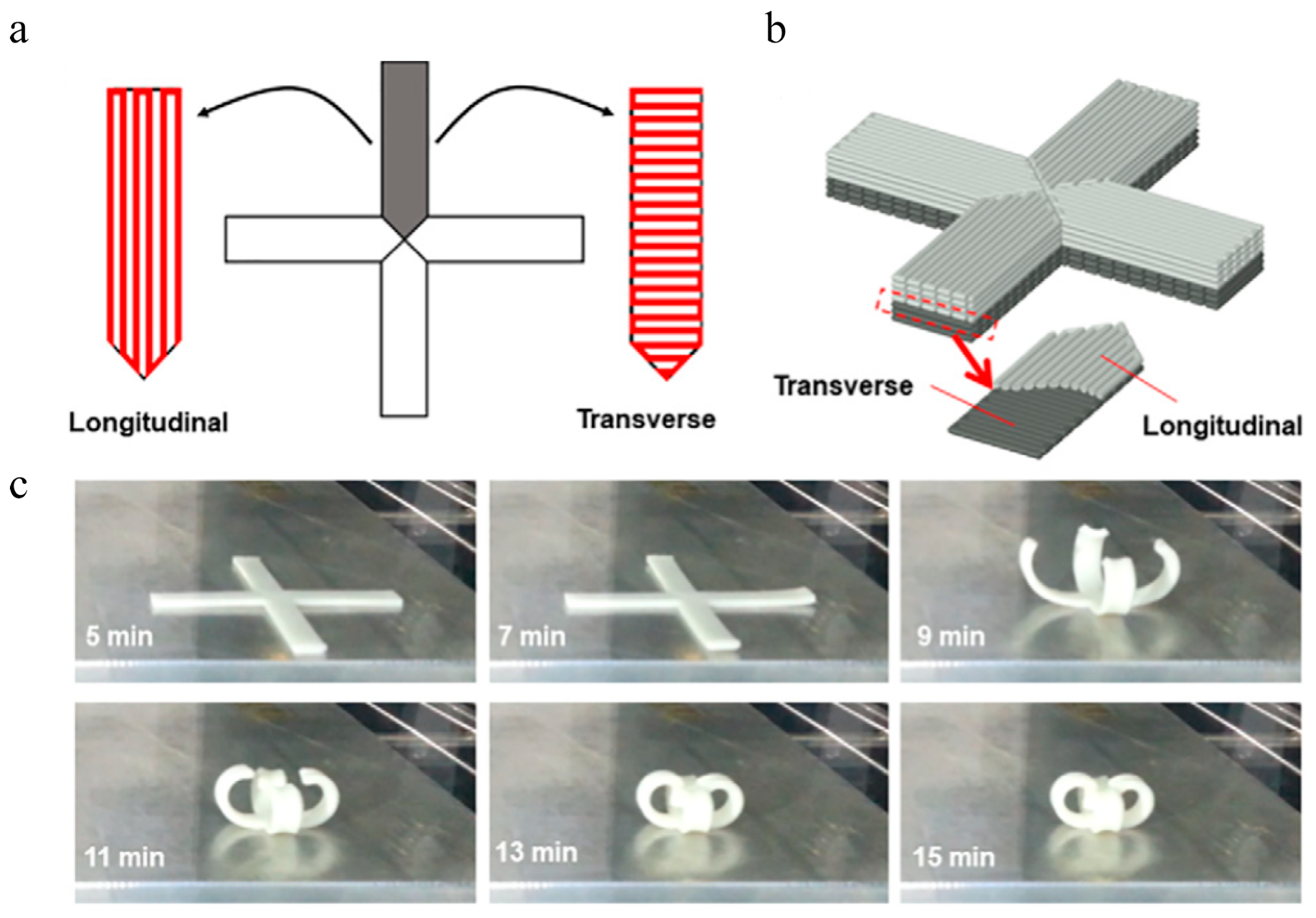

6.2. Stress-Induced and Printing Strategies

6.3. Multi-Material Approaches

6.4. Print Strategies for Shape Memory Alloys

7. Application and Case Studies

7.1. Aerospace and Automotive

7.2. Biomedical

7.3. Soft Robotics

7.4. Electronics

8. Future Position in Industry

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| 3DP | 3D Printing |

| 4DP | 4D Printing |

| AM | Additive Manufacturing |

| DIW | Direct Ink Writing |

| DLP | Digital Light Processing |

| FFF | Fused Filament Fabrication |

| PLA | Polylactic Acid |

| SLA | Stereolithography |

| SLM | Selective Laser Melting |

| SM | Smart Material |

| SMA | Shape Memory Alloy |

| SME | Shape Memory Effect |

| SMM | Shape Memory Material |

| SMP | Shape Memory Polymer |

| Tg | Glass transition temperature |

References

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.W.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymer 2021, 228, 3101. [Google Scholar] [CrossRef]

- McLellan, K.; Sun, Y.C.; Naguib, H.E. A review of 4D printing: Materials, structures, and designs towards the printing of biomedical wearable devices. Bioprinting 2022, 27, e00217. [Google Scholar] [CrossRef]

- Muehlenfeld, C.; Roberts, S.A. 3D/4D Printing in Additive Manufacturing: Process Engineering and Novel Excipients. In 3D and 4D Printing in Biomedical Applications; Wiley-VCH: Weinheim, Germany, 2019; pp. 1–25. [Google Scholar]

- Rajput, G.S.; Vora, J.; Prajapati, P.; Chaudhari, R. Areas of recent developments for shape memory alloy: A review. Mater. Today Proc. 2022, 62, 7194–7198. [Google Scholar] [CrossRef]

- Raina, A.; Haq, M.I.U.; Javaid, M.; Rab, S.; Haleem, A. 4D Printing for Automotive Industry Applications. J. Inst. Eng. India Ser. D 2021, 102, 521–529. [Google Scholar] [CrossRef]

- Husbands, P.; Shim, Y.; Garvie, M.; Dewar, A.; Domcsek, N.; Graham, P.; Knight, J.; Nowotny, T.; Philippides, A. Recent advances in evolutionary and bio-inspired adaptive robotics: Exploiting embodied dynamics. Appl. Intell. 2021, 51, 6467–6496. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.H.; Lee, J.W.; Choi, K.H. 3D printing for soft robotics—A review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef] [Green Version]

- Alshebly, Y.S.; Nafea, M.; Mohamed Ali, M.S.; Almurib, H.A.F. Review on recent advances in 4D printing of shape memory polymers. Eur. Polym. 2021, 159, 110708. [Google Scholar] [CrossRef]

- Tibbits, S. 4D Printing: Multi-Material Shape Change. Archit. Des. 2013, 84, 116–121. [Google Scholar] [CrossRef]

- Aldawood, F.K. A Comprehensive Review of 4D Printing: State of the Arts, Opportunities, and Challenges. Actuators 2023, 12, 101. [Google Scholar] [CrossRef]

- Kumar, S.B.; Jeevamalar, J.; Ramu, P.; Suresh, G.; Senthilnathan, K. Evaluation in 4D printing—A review. Mater. Today Proc. 2021, 45, 1433–1437. [Google Scholar] [CrossRef]

- Yousuf, M.H.; Abuzaid, W.; Alkhader, M. 4D printed auxetic structures with tunable mechanical properties. Addit. Manuf. 2020, 35, 101364. [Google Scholar] [CrossRef]

- Goo, B.; Hong, C.H.; Park, K. 4D printing using anisotropic thermal deformation of 3D-printed thermoplastic parts. Mater. Des. 2020, 188, 108485. [Google Scholar] [CrossRef]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications and challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Ntouanoglou, K.; Stavropoulos, P.; Mourtzis, D. 4D Printing Prospects for the Aerospace Industry: A critical review. Procedia Manuf. 2018, 18, 120–129. [Google Scholar] [CrossRef]

- Wu, D.; Leng, Y.M.; Fan, C.J.; Xu, Z.Y.; Li, L.; Shi, L.Y.; Yang, K.K.; Wang, Y.Z. 4D Printing of a Fully Biobased Shape Memory Copolyester via a UV-Assisted FDM Strategy. ACS Sustain. Chem. Eng. 2022, 10, 6304–6312. [Google Scholar] [CrossRef]

- Baumgartner, M.; Hartmann, F.; Drack, M.; Preninger, D.; Wirthl, D.; Gerstmayr, R.; Lehner, L.; Mao, G.; Pruckner, R.; Demchyshyn, S.; et al. Resilient yet entirely degradable gelatin-based biogels for soft robots and electronics. Nat. Mater. 2020, 19, 1102–1109. [Google Scholar] [CrossRef] [PubMed]

- Miao, S.; Castro, N.; Nowicki, M.; Xia, L.; Preninger, D.; Wirthl, D.; Gerstmayr, R.; Lehner, L.; Mao, G.; Pruckner, R.; et al. 4D printing of polymeric materials for tissue and organ regeneration. Mater. Today 2017, 20, 577–591. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Gonzalez-Gutierrez, J.; Mertz, G.; Ruch, D.; Schmidt, D.; Westermann, S. 4D Printing of Multicomponent Shape-Memory Polymer Formulations. Appl. Sci. 2022, 12, 7880. [Google Scholar] [CrossRef]

- Kuang, X.; Chen, K.; Dunn, C.K.; Wu, J.; Li, V.W.; Qi, H.R. 3D Printing of Highly Stretchable, Shape-Memory, and Self-Healing Elastomer toward Novel 4D Printing. ACS Appl. Mater. Interfaces 2018, 10, 7381–7388. [Google Scholar] [CrossRef] [PubMed]

- Yamamura, S.; Iwase, E. Hybrid hinge structure with elastic hinge on self-folding of 4D printing using a fused deposition modeling 3D printer. Mater. Des. 2021, 203, 109605. [Google Scholar] [CrossRef]

- ISM. In-Space Manufacturing; NASA: Washington, DC, USA, (n.d.). Available online: https://www.nasa.gov/oem/inspacemanufacturing (accessed on 26 June 2023).

- Haleem, A.; Javaid, M.; Singh, R.P.; Suman, R. Significant roles of 4D printing using smart materials in the field of manufacturing. Adv. Ind. Eng. Polym. Res. 2021, 4, 301–311. [Google Scholar] [CrossRef]

- Nezhad, I.S.; Golzar, M.; Behravesh, A.H.; Zare, S. Comprehensive study on shape shifting behaviors in FDM-based 4D printing of bilayer structures. Adv. Manuf. Technol. 2022, 120, 59–97. [Google Scholar] [CrossRef]

- Xin, X.; Liu, L.; Liu, Y.; Leng, J. 4D Printing Auxetic Metamaterials with Tunable, Programmable, and Reconfigurable Mechanical Properties. Adv. Funct. Mater. 2020, 30, 200–226. [Google Scholar] [CrossRef]

- Gladman, A.S.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413–419. [Google Scholar] [CrossRef]

- Farid, M.S.; Wu, W.; Liu, X.; Wang, P. Additive manufacturing landscape and materials perspective in 4D printing. Int. J. Adv. Manuf. Technol. 2021, 115, 2973–2988. [Google Scholar] [CrossRef]

- Cheng, C.; Xie, H.; Xu, Z.; Li, L.; Jiang, M.; Tang, L.; Yang, K.; Wang, Y. 4D printing of shape memory aliphatic copolyester via UV-assisted FDM strategy for medical protective devices. Chem. Eng. J. 2020, 396, 125242. [Google Scholar] [CrossRef]

- Duigou, A.L.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A review of 3D and 4D printing of natural fibre biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Zhou, Y.; Parker, C.T.; Joshi, P.C.; Naskar, A.K.; Glass, J.T.; Cao, C. 4D Printing of Stretchable Supercapacitors via Hybrid Composite Materials. Adv. Mater. Technol. 2021, 6, 2001055. [Google Scholar] [CrossRef]

- Leist, S.K.; Zhou, J.G. Current status of 4D printing technology and the potential of light-reactive smart materials as 4D printable materials. Virtual Phys. Prototyp. 2016, 11, 249–262. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Noroozi, R.; Zolfagharian, A.; Bodaghi, M. 4D printing of shape memory polymer composites: A review on fabrication techniques, applications, and future perspectives. Manuf. Process. 2022, 81, 759–797. [Google Scholar] [CrossRef]

- Ilami, M.; Bagheri, H.; Ahmed, R.; Skowronek, E.O.; Marvi, H. Materials, Actuators, and Sensors for Soft Bioinspired Robots. Adv. Mater. 2021, 33, 2003139. [Google Scholar] [CrossRef] [PubMed]

- Saritha, D.; Boyina, D. A concise review on 4D printing technology. Mater. Today: Proc. 2021, 46, 629–695. [Google Scholar] [CrossRef]

- Walker, J.; Zidek, T.; Harbel, C.; Yoon, S.; Strickland, F.S.; Kumar, S.; Shin, M. Soft Robotics: A Review of Recent Developments of Pneumatic Soft Actuators. Actuators 2020, 9, 3. [Google Scholar] [CrossRef] [Green Version]

- Mehta, P.; Sahlot, P. Application of phase change materials in 4D printing: A review. Mater. Today: Proc. 2021, 47, 4746–4752. [Google Scholar] [CrossRef]

- Sharma, A.; Rai, A. Fused deposition modelling (FDM) based 3D & 4D Printing: A state of art review. Mater. Today: Proc. 2022, 62, 367–372. [Google Scholar]

- Nazir, A.; Gokcekaya, O.; Billah, K.M.M.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Pusateri, V.; Goulas, C.; Olsen, S.I. Technical Challenges and Future Environmentally Sustainable Applications for Multi-Material Additive Manufacturing for Metals; IntechOpen eBooks: London, UK, 2023. [Google Scholar] [CrossRef]

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Hirano, Y.; Matsuzaki, R.; Mizukami, K.; Iizuka, K.; et al. 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Applicat. Application, and Prospective. Chin. J. Mech. Eng. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Pingale, P.; Dawre, S.; Dhapte-Pawar, V.; Dhas, N.; Rajput, A. Advances in 4D printing: From stimulation to simulation. Drug Deliv. Transl. Res. 2023, 13, 164–188. [Google Scholar] [CrossRef]

- Wang, L.C.; Song, W.L.; Fang, D. Twistable Origami and Kirigami: From Structure-Guided Smartness to Mechanical Energy Storage. ACS Appl. Mater. Interfaces 2019, 11, 3450–3458. [Google Scholar] [CrossRef]

- Sossou, G.; Demoly, F.; Belkebir, H.; Qi, H.J.; Gomes, S.; Montavon, G. Design for 4D printing: Modeling and computation of smart materials distributions. Mater. Des. 2019, 181, 108074. [Google Scholar] [CrossRef]

- Baghani, M.; Mohammadi, H.; Naghdabadi, R. An analytical solution for shape-memory-polymer Euler–Bernoulli beams under bending. Int. J. Mech. Sci. 2014, 84, 84–90. [Google Scholar] [CrossRef]

- Timoshenko, S. Analysis of Bi-Metal Thermostats. Opt. Soc. Am. 1925, 11, 233–255. [Google Scholar] [CrossRef]

- Naficy, S.; Gately, R.D.; Gorkin, R.; Xin, H.; Spinks, G.M. 4D Printing of Reversible Shape Morphing Hydrogel Structures. Macromol. Mater. Eng. 2016, 302, 1600212. [Google Scholar] [CrossRef]

- Cui, J.; Adams, J.H.; Zhu, Y. Controlled bending and folding of a bilayer structure consisting of a thin stiff film and a heat shrinkable polymer sheet. Smart Mater. Struct. 2018, 27, 055009. [Google Scholar] [CrossRef]

- Su, J.; Tao, X.; Deng, H.; Zhang, C.; Jiang, S.; Lin, Y.; Lin, J. 4D printing of a self-morphing polymer driven by a swellable guest medium. Soft Matter 2018, 14, 765–772. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Hao, X.; Xiao, R.; Lin, J.; Wu, Z.L.; Yin, J.; Qian, J. Controllable Bending of Bi-hydrogel Strips with Differential Swelling. Acta Mech. Solida Sin. 2019, 32, 652–662. [Google Scholar] [CrossRef]

- Momeni, F.; Ni, J. Laws of 4D Printing. Engineering 2020, 6, 1035–1055. [Google Scholar] [CrossRef]

- Boleya, J.W.; van Reesb, W.M.; Lissandrelloe, C.; Horenstein, M.N.; Truby, R.L.; Kotikian, A.; Lewis, J.A.; Mahadevan, L. Shape-shifting structured lattices via multimaterial 4D printing. Proc. Natl. Acad. Sci. USA 2019, 116, 20856–20862. [Google Scholar] [CrossRef] [Green Version]

- Dimassi, S.; Demoly, F.; Cruz, C.; Qi, H.J.; Kim, K.Y.; André, J.C.; Gomes, S. An ontology-based framework to formalize and represent 4D printing knowledge in design. Comput. Ind. 2021, 126, 103374. [Google Scholar] [CrossRef]

- Akbar, I.; El Hadrouz, M.; Lagoudas, D. Toward enabling manufacturing paradigm of 4D printing of shape memory materials: Open literature review. Eur. Polym. 2022, 168, 111106. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Zhang, Y.; Wang, T.; Yang, Z.; Wang, Q.; Zhang, X. Dual-method molding of 4D shape memory polyimide ink. Mater. Des. 2020, 191, 108606. [Google Scholar] [CrossRef]

- Zhu, P.; Yang, W.; Wang, R.; Gao, S.; Li, B.; Li, Q. 4D Printing of Complex Structures with a Fast Response Time to Magnetic Stimulus. ACS Appl. Mater. Interfaces 2018, 10, 36435–36442. [Google Scholar] [CrossRef]

- Wang, G.; Tao, Y.; Capunaman, O.; Yang, H.; Yao, L. A-line: 4D Printing Morphing Linear Composite Structures. In Proceedings of the CHI Conference on Human Factors in Computing Systems, Glasgow, UK, 4–9 May 2019. [Google Scholar]

- Yue, C.; Zhao, W.; Li, F.; Liu, L.; Liu, Y.; Leng, J. Shape recovery properties and load-carrying capacity of a 4D printed thick-walled kirigami-inspired honeycomb structure. Bio-Des. Manuf. 2023, 6, 189–203. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Q.; Zhang, J. Light-responsive shape memory polymer composites. Eur. Polym. J. 2022, 173, 111314. [Google Scholar] [CrossRef]

- Benyahia, K.; Seriket, H.; Prod’hon, R.; Gomes, S.; André, J.-C.; Qi, H.J.; Demoly, F. A computational design approach for multi-material 4D printing based on interlocking blocks assembly. Addit. Manuf. 2022, 58, 102993. [Google Scholar] [CrossRef]

- Demoly, F.; Andre, J. 4D Printing, Volume 1: Between Disruptive Research and Industrial Applications; John Wiley & Sons: London, UK, 2022. [Google Scholar]

- Demoly, F.; Andre, J. 4D Printing, Volume 2: Between Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Athinarayanarao, D.; Prod’hon, R.; Chamoret, D.; Qi, H.J.; Bodaghi, M.; André, J.; Demoly, F. Computational design for 4D printing of topology optimized multi-material active composites. NPJ Comput. Mater. 2023, 9, 1. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.F.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Yu, Y.; Qian, K.; Yang, H.; Yao, L.; Zhang, Y. Hybrid IGA-FEA of fiber reinforced thermoplastic composites for forward design of AI-enabled 4D printing. J. Mater. Process. Technol. 2022, 302, 117497. [Google Scholar] [CrossRef]

- Tan, R.Y.H.; Lee, C.S.; Pichika, M.R.; Cheng, S.F.; Lam, K.Y. pH Responsive Polyurethane for the Advancement of Biomedical and Drug Delivery. Polymers 2022, 14, 1672. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W. 4D Printing: Technological and Manufacturing Renaissance. Macromol. Mater. Eng. 2022, 307, 2200003. [Google Scholar] [CrossRef]

- Wan, M.; Yu, K.; Sun, H. 4D printed programmable auxetic metamaterials with shape memory effects. Compos. Struct. 2022, 279, 114791. [Google Scholar] [CrossRef]

- Kantareddy, S.N.R.; Simpson, T.W.; Ounaies, Z.; Frecker, M. 3D Printing of Shape Changing Polymer Structures: Design and Characterization of Materials. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Abuzaid, W.; Alkhader, M.; Omari, M.E. Experimental analysis of heterogeneous shape recovery in 4d printed honeycomb structures. Polym. Test. 2018, 68, 100–109. [Google Scholar] [CrossRef]

- Zhao, J.; Han, M.; Li, L. Modeling and characterization of shape memory properties and decays for 4D printed parts using stereolithography. Mater. Des. 2021, 203, 109617. [Google Scholar] [CrossRef]

- Zhang, X.; Qian, M. An Overview on Magnetic Shape. In Magnetic Shape Memory Alloys; Harbin Institute of Technology Press: Harbin, China, 2022; pp. 1–33. [Google Scholar]

- Xin, X.; Liu, L.; Liu, Y.; Leng, J. Origami-inspired self-deployment 4D printed honeycomb sandwich structure with large shape transformation. Smart Mater. Struct. 2020, 29, 065015. [Google Scholar] [CrossRef]

- Song, Z.; Ren, L.; Zhao, C. Biomimetic Nonuniform, Dual-Stimuli Self-Morphing Enabled by Gradient Four-Dimensional Printing. ACS Appl. Mater. Interfaces 2020, 12, 6351–6361. [Google Scholar] [CrossRef]

- Hart, L.R.; He, Y.; Ruiz, L.; Zhou, Z. 3D and 4D printing of biomaterials and biocomposites, bioinspired composites, and related transformers. In 3D and 4D Printing of Polymer Nanocomposite Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 467–497. [Google Scholar]

- Momeni, F.; HassaniN, S.M.; Liu, X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Pinho, A.C.M.; Buga, C.; Piedade, A.P. The chemistry behind 4D printing. Appl. Mater. Today 2020, 19, 100611. [Google Scholar] [CrossRef]

- Bodaghi, M.; Zolfagharian, A. 4D printing principles and manufacturing. In Smart Materials in Additive Manufacturing, Volume 1: 4D Printing Principles and Fabrication; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Baghani, M.; Baniassadi, M.; Remond, Y. A detailed review on constitutive models for thermoresponsive shape memory polymers. In Computational Modeling of Intelligent Soft Matter: Shape Memory Polymers and Hydrogels; Elsevier: Amsterdam, The Netherlands, 2023; pp. 15–75. [Google Scholar]

- Hippler, M.; Weißenbruch, K.; Richler, K.; Lemma, E.D.; Nakahata, M.; Richter, B.; Barner-Kowollik, C.; Takashima, Y.; Harada, A.; Blasco, E.; et al. Mechanical stimulation of single cells by reversible host-guest interactions in 3D microscaffolds. Sci. Adv. 2020, 6, eabc2648. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Zhang, R.; Zhang, L.; Cao, X. 4D Printing of Robust Hydrogels Consisted of Agarose Nanofibers and Polyacrylamide. ACS Macro Lett. 2018, 7, 442–446. [Google Scholar] [CrossRef] [PubMed]

- Mallik, M. 3D Printing of Smart Materials A Path toward Evolution of 4D Printing. In Smart 3D Nanoprinting: Fundamentals, Materials, and Applications; CRC Press: Boca Raton, FL, USA, 2022; pp. 239–259. [Google Scholar]

- Löwenberg, C.; Balk, M.; Wischke, C.; Behl, M.; Lendlein, A. Shape-Memory Hydrogels: Evolution of Structural Principles to Enable Shape Switching of Hydrophilic Polymer Networks. Acc. Chem. Res. 2017, 50, 723–732. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, X.; Jing, K.; Chang, L.; Bao, W. Study on the pore structure and oxygen-containing functional groups devoting to the hydrophilic force of dewatered lignite. Appl. Surf. Sci. 2015, 324, 90–98. [Google Scholar] [CrossRef]

- Ji, Z.; Yan, C.; Yu, B.; Zhang, X.; Cai, M.; Jia, X.; Wang, X.; Zhou, F. 3D Printing of Hydrogel Architectures with Complex and Controllable Shape Deformation. Adv. Mater. Technol. 2019, 4, 1800713. [Google Scholar] [CrossRef]

- Lui, Y.S.; Sow, W.T.; Tan, L.P.; Wu, Y.; Lai, Y.; Li, H. 4D printing and stimuli-responsive materials in biomedical aspects. Acta Biomater. 2019, 92, 19–36. [Google Scholar] [CrossRef]

- Strzelec, K.; Sienkiewicz, N.; Szmechtyk, T. Classification of Shape-Memory Polymers, Polymer Blends, and Composites. In Shape Memory Polymers, Blends and Composites: Advances and Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 21–52. [Google Scholar]

- Sonatkar, J.; Kandasubramanian, B.; Ismail, S.O. 4D printing: Pragmatic progression in biofabrication. Eur. Polym. J. 2022, 169, 111128. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic Shape Memory Polymers with Integrated Multifunctional Shape Manipulation. Adv. Mater. 2019, 32, 1906657. [Google Scholar] [CrossRef]

- Adam, G.; Benouhiba, A.; Rabenorosoa, K.; Clévy, C.; Cappelleri, D.J. 4D Printing: Enabling Technology for Microrobotics Applications. Adv. Intell. Syst. 2021, 3, 2000216. [Google Scholar] [CrossRef]

- Tamay, D.G.; Usal, T.D.; Alagoz, A.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D Printing of Polymers for Tissue Engineering Applications. Front. Bioeng. Biotechnol. 2019, 7, 164. [Google Scholar] [CrossRef]

- Lexcellent, C. Shape-Memory Alloys Handbook, 1st ed.; Wiley-ISTE: Hoboken, NJ, USA, 2013. [Google Scholar]

- Alaneme, K.K.; Anaele, J.U.; Bodunrin, M.O. Hot deformation processing of shape memory alloys: A review of effects on plastic flow behaviour, deformation mechanisms, and functional characteristics. Alex. Eng. 2022, 61, 12759–12783. [Google Scholar] [CrossRef]

- Concilio, A.; Antonucci, V.; Auricchio, F.; Lecce, L.; Sacco, E. Shape Memory Alloy Engineering: For Aerospace, Structural, and Biomedical Applications, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2021. [Google Scholar]

- Elahinia, M.H. Shape Memory Alloy Actuators: Design, Fabrication, and Experimental Evaluation, 1st ed.; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Lagoudas, D.C. Shape Memory Alloys: Modeling and Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Kim, D.; Ferretto, I.; Leinenbach, C.; Lee, W. 3D and 4D Printing of Complex Structures of Fe-Mn-Si-Based Shape Memory Alloy Using Laser Powder Bed Fusion. Adv. Mater. Interfaces 2022, 9, 2200171. [Google Scholar] [CrossRef]

- Sahafnejad-Mohammadi, I.; Karamimoghadam, M.; Zolfagharian, A.; Akrami, M.; Bodaghi, M. 4D printing technology in medical engineering: A narrative review. Soc. Mech. Sci. Eng. 2022, 44, 233. [Google Scholar] [CrossRef]

- Cui, J.; Yao, S.; Huang, Q.; Adams, J.G.M.; Zhu, Y. Controlling the self-folding of a polymer sheet using a local heater: The effect of the polymer–heater interface. Soft Mater. 2017, 13, 3863–3870. [Google Scholar] [CrossRef]

- Wu, C.Y.; Chen, J.R.; Su, C.K. 4D-printed pH sensing claw. Anal. Chim. Acta 2022, 1204, 339733. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Janbaz, S.; Darafsheh, A.; Mazur, T.R.; Ramakrishna, S. 4D printing of shape memory polylactic acid (PLA). Polymer 2021, 230, 124080. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H. Technological considerations for 4D printing: An overview. Prog. Addit. Manuf. 2018, 3, 95–107. [Google Scholar] [CrossRef] [Green Version]

- Khorsandi, D.; Fahimipour, A.; Abasian, P.; Saber, S.; Seyedi, M.; Ghanavati, S.; Ahmad, A.; Stephanis, A.; Taghavinezhaddilami, F.; Leonova, A.; et al. 3D and 4D printing in dentistry and maxillofacial surgery: Printing techniques, materials, and applications. Acta Biomater. 2021, 122, 26–49. [Google Scholar] [CrossRef]

- Kabirian, F.; Mela, P.; Heying, R. 4D Printing Applications in the Development of Smart Cardiovascular Implants. Front. Bioeng. Biotechnol. 2022, 10, 873453. [Google Scholar] [CrossRef]

- Tahouni, Y.; Krüger, F.; Poppinga, S.; Wood, D.; Pfaff, M.; Rühe, J.; Speck, T.; Menges, A. Programming sequential motion steps in 4D-printed hygromorphs by architected mesostructure and differential hygro-responsiveness. Bioinspiration Biomim. 2021, 16, 055002. [Google Scholar] [CrossRef]

- Zafar, M.; Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 2020, 26, 564–585. [Google Scholar] [CrossRef]

- Roach, D.; Kuang, X.; Yuan, C.; Chen, K.; Qi, H. Novel ink for ambient condition printing of liquid crystal elastomers for 4D printing. Smart Mater. Struct. 2018, 27, 125011. [Google Scholar] [CrossRef]

- Namvar, N.; Zolfagharian, A.; Vakili-Tahami, F.; Bodaghi, M. Reversible energy absorption of elasto-plastic auxetic, hexagonal, and AuxHex structures fabricated by FDM 4D printing. Smart Mater. Struct. 2022, 31, 055021. [Google Scholar] [CrossRef]

- Li, B.; Liang, W.; Ren, F. Electrohydrodynamic (EHD) inkjet printing flexible pressure sensors with a multilayer structure and periodically patterned Ag nanoparticles. J. Mater. Sci. Mater. Electron. 2022, 33, 18734–18750. [Google Scholar] [CrossRef]

- Scalet, G. Two-Way and Multiple-Way Shape Memory Polymers for Soft Robotics: An Overview. Actuators 2020, 9, 10. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, X. 4D-printed bi-material composite laminate for manufacturing reversible shape-change structures. Compos. Part B Eng. 2021, 219, 108918. [Google Scholar] [CrossRef]

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers 2018, 10, 629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shen, B.; Erol, O.; Fang, L.; Kang, S.H. Programming the time into 3D printing: Current advances and future directions in 4D printing. Multifunct. Mater. 2020, 3, 012001. [Google Scholar] [CrossRef]

- Bercea, M. Self-Healing Behavior of Polymer/Protein Hybrid Hydrogels. Polymers 2022, 14, 130. [Google Scholar] [CrossRef]

- Wang, Q.; Tian, X.; Huang, L.; Li, D.; Malakhov, A.; Polilov, A. Programmable morphing composites with embedded continuous fibers by 4D printing. Mater. Des. 2018, 155, 404–413. [Google Scholar] [CrossRef]

- Sadasivuni, K.; Deshmukh, K.; Al-Maadeed, M.; Sadasivuni, K.K. Introduction to 3D and 4D printing technology: State of the art and recent trends. In 3D and 4D Printing of Polymer Nanocomposite Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–21. [Google Scholar]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct Ink Writing Based 4D Printing of Materials and Their Applications. Adv. Sci. 2020, 7, 2001000. [Google Scholar] [CrossRef]

- Keneth, E.S.; Kamyshny, A.; Totaro, M.; Beccai, L.; Magdassi, S. 3D Printing Materials for Soft Robotics. Adv. Mater. 2020, 33, 2003387. [Google Scholar] [CrossRef] [PubMed]

- Mazzer, E.; da Silva, M.; Gargarella, P. Revisiting Cu-based shape memory alloys: Recent developments and new perspectives. Mater. Res. 2022, 37, 162–182. [Google Scholar] [CrossRef]

- Saghaian, S.E.; Amerinatanzi, A.; Moghaddam, N.S.; Majumdar, A.; Nematollahi, M.; Saedi, S.; Elahinia, M.; Karaca, H.E. Mechanical and shape memory properties of triply periodic minimal surface (TPMS) NiTi structures fabricated by selective laser melting. Biol. Eng. Med. 2018, 3, 1–7. [Google Scholar]

- Lee, A.Y.; An, J.; Chua, C.K. Two-Way 4D Printing: A Review on the Reversibility of 3D-Printed Shape Memory Materials. Engineering 2017, 3, 663–674. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Bidsorkhi, H.C. MEMS Applications of NiTi Based Shape Memory Alloys: A Review. Micro Nanosyst. 2017, 8, 79–91. [Google Scholar] [CrossRef]

- Yang, G.H.; Yeo, M.; Koo, Y.W.; Kim, G.H. 4D Bioprinting: Technological Advances in Biofabrication. Macromol. Biosci. 2019, 19, e1800441. [Google Scholar] [CrossRef]

- Hu, J. Shape Memory Polymers and Textiles; Woodhead Publishing: Cambridge, UK, 2007. [Google Scholar]

- Gebrehiwot, S.Z.; Espinosa Leal, L.; Eickhoff, J.N.; Rechenberg, L. The influence of stiffener geometry on flexural properties of 3D printed polylactic acid (PLA) beams. Prog. Addit. Manuf. 2020, 6, 71–81. [Google Scholar] [CrossRef]

- Yang, W.; Lu, H.; Huang, W.; Qi, H.; Wu, X.; Sun, K. Advanced Shape Memory Technology to Reshape Product Design, Manufacturing and Recycling. Polymers 2014, 6, 2287–2308. [Google Scholar] [CrossRef] [Green Version]

- Leist, S.; Gao, D.; Chiou, R.; Zhou, J. Investigating the shape memory properties of 4D printed polylactic acid (PLA) and the concept of 4D printing onto nylon fabrics for the creation of smart textiles. Virtual Phys. Prototyp. 2017, 12, 290–300. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Zhang, F.; Lan, X.; Leng, J.; Liu, S.; Jia, X.; Cotton, C.; Sun, B.; Gu, B.; et al. Shape memory behavior and recovery force of 4D printed laminated Miura-origami structures subjected to compressive loading. Compos. Part B Eng. 2018, 153, 233–242. [Google Scholar] [CrossRef]

- Jamalimehr, A.; Mirzajanzadeh, M.; Akbarzadeh, A.; Pasini, D. Rigidly flat-foldable class of lockable origami-inspired metamaterials with topological stiff states. Nat. Commun. 2022, 13, 1816. [Google Scholar] [CrossRef] [PubMed]

- Ehrmann, G.; Ehrmann, A. Investigation of the Shape-Memory Properties of 3D Printed PLA Structures with Different Infills. Polymers 2021, 13, 164. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Ma, J.; Zhou, X.; Wang, H. Quasi-static mechanical properties of origami-inspired cellular metamaterials made by metallic 3D printing. Mech. Adv. Mater. Struct. 2022, 1–14. [Google Scholar] [CrossRef]

- Wagner, M.; Chen, T.; Shea, K. Large Shape Transforming 4D Auxetic Structures. 3d Print. Addit. Manuf. 2017, 4, 133–142. [Google Scholar] [CrossRef]

- Pandini, S.; Inverardi, N.; Scalet, G.; Battini, D.; Bignotti, F.; Marconi, S.; Auricchio, F. Shape memory response and hierarchical motion capabilities of 4D printed auxetic structures. Mech. Res. Commun. 2020, 103, 103463. [Google Scholar] [CrossRef]

- Hann, S.Y.; Cui, H.; Nowicki, M.; Zhang, L.G. 4D printing soft robotics for biomedical applications. Addit. Manuf. 2020, 36, 101567. [Google Scholar] [CrossRef]

- de Haan, L.T.; Sanchez-Rexach, E.; Smith, P.T.; Gomez-Lopez, A.; Fernandez, M.; Cortajarena, A.L.; Sardon, H.; Nelson, A. 3D-Printed Bioplastics with Shape-Memory Behavior Based on Native Bovine Serum Albumin. ACS Appl. Mater. Interfaces 2021, 13, 19193–19199. [Google Scholar]

- Aßhoff, S.J.; Lancia, F.; Iamsaard, S.; Matt, B.; Kudernac, T.; Fletcher, S.P.; Katsonis, N. High-Power Actuation from Molecular Photoswitches in Enantiomerically Paired Soft Springs. Angew. Chem. Int. Ed. 2017, 56, 3261–3265. [Google Scholar] [CrossRef]

- Pivar, M.; Gregor-Svetec, D.; Muck, D. Effect of Printing Process Parameters on the Shape Transformation Capability of 3D Printed Structures. Polymers 2021, 14, 117. [Google Scholar] [CrossRef]

- Kiendl, J.; Gao, C. Controlling toughness and strength of FDM 3D-printed PLA components through the raster layup. Compos. Part B Eng. 2020, 180, 107562. [Google Scholar] [CrossRef]

- Ding, S.; Kong, L.; Jin, Y.; Lin, J.; Chang, C.; Li, H.; Liu, E.; Liu, H. Influence of the molding angle on tensile properties of FDM parts with orthogonal layering. Polym. Adv. Technol. 2019, 31, 873–884. [Google Scholar] [CrossRef]

- Vazquez, E.; Gursoy, B.; Duarte, J. Designing for Shape Change—A Case study on 3D Printing Composite Materials for Responsive Architectures. In Proceedings of the 24th Conference on Computer Aided Architectural Design Research in Asia (CAADRIA), Wellington, New Zealand, 15–18 April 2019; Volume 2, pp. 391–400. [Google Scholar] [CrossRef]

- Podstawczyk, D.; Nizioł, M.; Szymczyk-Ziółkowska, P.; Fiedot-Toboła, M. Development of Thermoinks for 4D Direct Printing of Temperature-Induced Self-Rolling Hydrogel Actuators. Adv. Funct. Mater. 2021, 31, 2009664. [Google Scholar] [CrossRef]

- Ren, L.; Li, B.; He, Y.; Song, Z.; Zhou, X.; Liu, Q.; Ren, L. Programming Shape-Morphing Behavior of Liquid Crystal Elastomers via Parameter-Encoded 4D Printing. ACS Appl. Mater. Interfaces 2020, 12, 15562–15572. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, A.; Baigent, A.; Raghav, S.; Brádaigh, C.; Koutsos, V.; Radacsi, N. 4D Printing: Materials, Technologies, and Future Applications in the Biomedical Field. Sustainability 2020, 12, 10628. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, Z.; Wang, M.; Zhang, L.; Liang, Y.; Zhang, Z.; Ren, L.; Ren, L. 4D printing of PLA/PCL shape memory composites with controllable sequential deformation. Bio-Des. Manuf. 2021, 4, 867–878. [Google Scholar] [CrossRef]

- Shin, S.; So, H. Effect of 3D printing raster angle on reversible thermo-responsive composites using PLA/paper bilayer. Smart Mater. Struct. 2020, 29, 105016. [Google Scholar] [CrossRef]

- del Pozo, M.; Sol, J.A.H.P.; Schenning, A.P.H.J.; Debije, M.G. 4D Printing of Liquid Crystals: What’s Right for Me? Adv. Mater. 2021, 34, 2104390. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.Y.; An, J.; Chua, C.K.; Zhang, Y. Preliminary Investigation of the Reversible 4D Printing of a Dual-Layer Component. Engineering 2019, 5, 1159–1170. [Google Scholar] [CrossRef]

- Correa, D.; Poppinga, S.; Mylo, M.D.; Westermeier, A.S.; Bruchmann, B.; Menges, A.; Speck, T. 4D pine scale: Biomimetic 4D printed autonomous scale and flap structures capable of multi-phase movement. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2020, 378, 20190445. [Google Scholar] [CrossRef]

- Ding, S.; Sun, M.; Li, Y.; Ma, W.; Zhang, Z. Novel Deployable Panel Structure Integrated with Thick Origami and Morphing Bistable Composite Structures. Materials 2022, 15, 1942. [Google Scholar] [CrossRef]

- Tong, K.J.; Saad Alshebly, Y.; Nafea, M. Development of a 4D-Printed PLA Microgripper. In Proceedings of the IEEE 19th Student Conference on Research and Development (SCOReD), Kota Kinabalu, Malaysia, 23–25 November 2021. [Google Scholar]

- Smith, P.T.; Narupai, B.; Tsui, J.H.; Millik, S.C.; Shafranek, R.T.; Kim, D.H.; Nelson, A. Additive Manufacturing of Bovine Serum Albumin-Based Hydrogels and Bioplastics. Biomacromolecules 2019, 21, 484–492. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Wang, F.; Ge, Q. Multimaterial direct 4D printing of high stiffness structures with large bending curvature. Extrem. Mech. Lett. 2021, 42, 101122. [Google Scholar] [CrossRef]

- Deng, H.; Dong, Y.; Su, J.W.; Zhang, C.; Xie, Y.; Zhang, C.; Maschmann, M.R.; Lin, Y.; Lin, J. Bioinspired Programmable Polymer Gel Controlled by Swellable Guest Medium. ACS Appl. Mater. Interfaces 2017, 9, 30900–30908. [Google Scholar] [CrossRef]

- Zhao, Z.; Kuang, X.; Yuan, C.; Qi, H.J.; Fang, D. Hydrophilic/Hydrophobic Composite Shape-Shifting Structures. ACS Appl. Mater. Interfaces 2018, 10, 19932–19939. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.Y.; Zhou, A.; An, J.; Chua, C.K.; Zhang, Y. Contactless reversible 4D-printing for 3D-to-3D shape morphing. Virtual Phys. Prototyp. 2020, 154, 481–495. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Khoo, S.Y.; Kouzani, A. Pattern-driven 4D printing. Sens. Actuators A Phys. 2018, 274, 231–243. [Google Scholar] [CrossRef]

- Naranda, J.; Bračič, M.; Vogrin, M.; Maver, U. Recent Advancements in 3D Printing of Polysaccharide Hydrogels in Cartilage Tissue Engineering. Materials 2021, 14, 3977. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, Q.; Dong, W.; Liu, S.; Zhang, H.; Gu, Y. Alginate/Gelatin-Based Hydrogel with Soy Protein/Peptide Powder for 3D Printing Tissue-Engineering Scaffolds to Promote Angiogenesis. Macromol. Biosci. 2022, 22, e2100413. [Google Scholar] [CrossRef]

- Davari, N.; Bakhtiary, N.; Khajehmohammadi, M.; Sarkari, S.; Tolabi, H.; Ghorbani, F.; Ghalandari, B. Protein-Based Hydrogels: Promising Materials for Tissue Engineering. Polymers 2022, 14, 986. [Google Scholar] [CrossRef]

- Narupai, B.; Smith, P.T.; Nelson, A. 4D Printing of Multi-Stimuli Responsive Protein-Based Hydrogels for Autonomous Shape Transformations. Adv. Funct. Mater. 2021, 31, 2011012. [Google Scholar] [CrossRef]

- Khoury, L.R.; Slawinski, M.; Collison, D.R.; Popa, I. Cation-induced shape programming and morphing in protein-based hydrogels. Sci. Adv. 2020, 6, eaba6112. [Google Scholar] [CrossRef] [PubMed]

- Simińska-Stanny, J.; Nizioł, M.; Szymczyk-Ziółkowska, P.; Brożyna, M.; Junka, A.; Shavandi, A.; Podstawczyk, D. 4D printing of patterned multimaterial magnetic hydrogel actuators. Addit. Manuf. 2022, 49, 102506. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Zheng, Z.; Liu, Y.; Leng, J. Magnetic programming of 4D printed shape memory composite structures, Composites. Appl. Sci. Manuf. 2019, 125, 105571. [Google Scholar] [CrossRef]

- Kačergis, L.; Mitkus, R.; Sinapius, M. Influence of fused deposition modeling process parameters on the transformation of 4D printed morphing structures. Smart Mater. Struct. 2019, 28, 105042. [Google Scholar] [CrossRef]

- Fu, P.; Li, H.; Gong, J.; Fan, Z.; Smith, A.T.; Shen, K.; Khalfalla, T.O.; Huang, H.; Qian, X.; McCutcheon, J.R.; et al. 4D printing of polymers: Techniques, materials, and prospects. Prog. Polym. Sci. 2022, 126, 101506. [Google Scholar] [CrossRef]

- Alagha, A.N.; Hussain, S.; Zaki, W. Additive manufacturing of shape memory alloys: A review with emphasis on powder bed systems. Mater. Des. 2021, 204, 109654. [Google Scholar] [CrossRef]

- Ke, W.; Oliveira, J.; Cong, B.; Ao, S.; Qi, Z.; Peng, B.; Zeng, Z. Multi-layer deposition mechanism in ultra-high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102513. [Google Scholar] [CrossRef]

- Yao, T.; Wang, Y.; Zhu, B.; Wei, D.; Yang, Y.; Han, X. 4D printing and collaborative design of highly flexible shape memory alloy structures: A case study for a metallic robot prototype. Smart Mater. Struct. 2020, 30, 015018. [Google Scholar] [CrossRef]

- Cao, Y.; Zhou, X.; Cong, D.; Zheng, H.; Cao, Y.; Nie, Z.; Chen, Z.; Li, S.; Xu, N.; Gao, Z.; et al. Large tunable elastocaloric effect in additively manufactured Ni–Ti shape memory alloys. Acta Mater. 2020, 194, 178–189. [Google Scholar] [CrossRef]

- Caputo, M.P.; Berkowitz, A.E.; Armstrong, A.; Müllner, P.; Solomon, C.V. 4D printing of net shape parts made from Ni-Mn-Ga magnetic shape-memory alloys. Addit. Manuf. 2018, 21, 579–588. [Google Scholar] [CrossRef]

- Airbus, Newsroom, 4D Printing and Digital Materials. Airbus. 23 March 2016. Available online: https://www.airbus.com/en/newsroom/news/2016-03-4d-printing-and-digital-materials (accessed on 26 June 2023).

- Akbari, S.; Sakhaei, A.H.; Panjwani, S.; Kowsari, K.; Ge, Q. Shape memory alloy-based 3D printed composite actuators with variable stiffness and large reversible deformation. Sens. Actuators A Phys. 2021, 321, 112598. [Google Scholar] [CrossRef]

- Weber, R.; Kuhlow, M.; Spierings, A.B.; Wegener, K. 4D printed assembly of sensors and actuators in complex formed metallic lightweight structures. J. Manuf. Process. 2023, 90, 406–417. [Google Scholar] [CrossRef]

- Ameta, K.L.; Solanki, V.S.; Haque, S.; Singh, V.; Devi, A.P.; Chundawat, R. Critical appraisal and systematic review of 3D & 4D printing in sustainable and environment-friendly smart manufacturing technologies. Sustain. Mater. Technol. 2022, 34, e00481. [Google Scholar]

- Narayana, H.; Hu, J.; Kumar, B.; Shang, S.; Han, J.; Liu, P.; Lin, T.; Ji, F.; Zhu, Y. Stress-memory polymeric filaments for advanced compression therapy. J. Mater. Chem. B 2017, 5, 1905–1916. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Liu, Q.; Han, Z.; Zhang, J.; Song, H.; Wang, K.; Song, Z.; Wen, S.; Zhou, Y.; Yan, C.; et al. 4D Printing Strain Self-Sensing and Temperature Self-Sensing Integrated Sensor–Actuator with Bioinspired Gradient Gaps. Adv. Sci. 2020, 7, 2000584. [Google Scholar] [CrossRef]

- Ali, M.; Alam, F.; Fah, Y.F.; Shiryayev, O.; Vahdati, N.; Butt, H. 4D printed thermochromic Fresnel lenses for sensing applications. Compos. Part B Eng. 2022, 230, 109514. [Google Scholar] [CrossRef]

- Hoa, S.; Abdali, M.; Jasmin, A.; Radeschi, D.; Prats, V.; Faour, H.; Kobaissi, B. Development of a new flexible wing concept for Unmanned Aerial Vehicle using corrugated core made by 4D printing of composites. Compos. Struct. 2022, 290, 115444. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Testoni, O.; Lumpe, T.; Huang, J.L.; Wagner, M.; Bodkhe, S.; Zhakypov, Z.; Spolenak, R.; Paik, J.; Ermanni, P.; Muñoz, L. A 4D printed active compliant hinge for potential space applications using shape memory alloys and polymers. Smart Mater. Struct. 2021, 30, 085004. [Google Scholar] [CrossRef]

- Valldosera Martinez, R.; Afonso, F.; Lau, F. Aerodynamic Shape Optimisation of a Camber Morphing Airfoil and Noise Estimation. Aerospace 2022, 9, 43. [Google Scholar] [CrossRef]

- Malekmohammadi, S.; Sedghi Aminabad, N.; Sabzi, A.; Zarebkohan, A.; Razavi, M.; Vosough, M.; Bodaghi, M.; Maleki, H. Smart and Biomimetic 3D and 4D Printed Composite Hydrogels: Opportunities for Different Biomedical Applications. Biomedicines 2021, 9, 1537. [Google Scholar] [CrossRef] [PubMed]

- Bakarich, S.E.; Gorkin, R.; Naficy, S.; Gately, R.; in het Panhuis, M.; Spinks, G.M. 3D/4D Printing Hydrogel Composites: A Pathway to Functional Devices. MRS Adv. 2015, 1, 521–526. [Google Scholar] [CrossRef] [Green Version]

- Stano, G.; Percoco, G. Additive manufacturing aimed to soft robots’ fabrication: A review. Extrem. Mech. Lett. 2021, 42, 101079. [Google Scholar] [CrossRef]

- Seo, B.R.; Mooney, D.J. Recent and Future Strategies of Mechanotherapy for Tissue Regenerative Rehabilitation. ACS Biomater. Sci. Eng. 2022, 8, 4639–4642. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, H.; Zhu, X.; Peng, Z.; Zhang, G.; Yang, J.; Wang, F.; Zhang, Y.-F.; Sun, L.; Wang, R.; et al. Directly Printed Embedded Metal Mesh for Flexible Transparent Electrode via Liquid Substrate Electric-Field-Driven Jet. Adv. Sci. 2022, 9, 2105331. [Google Scholar] [CrossRef]

- Byun, S.; Sim, J.Y.; Zou, Z.; Lee, J.; Qazi, R.; Walicki, M.; Parker, K.; Haney, M.; Choi, S.; Shon, A.; et al. Mechanically transformative electronics, sensors, and implantable devices. Sci. Adv. 2019, 5, eaay0418. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Kuang, X.; Deng, J.; Wang, Y.-C.; Wang, A.C.; Ding, W.; Lai, Y.-C.; Chen, J.; Wang, P.; Lin, Z.; et al. Shape Memory Polymers for Body Motion Energy Harvesting and Self-Powered Mechanosensing. Adv. Mater. 2018, 30, 1705195. [Google Scholar] [CrossRef]

- Wan, X.; Zhang, F.; Liu, Y.; Leng, J. CNT-based electro-responsive shape memory functionalized 3D printed nanocomposites for liquid sensors. Carbon 2019, 155, 77–87. [Google Scholar] [CrossRef]

- Deng, H.; Zhang, C.; Sattari, K.; Ling, Y.; Su, J.; Yan, Z.; Lin, J. 4D Printing Elastic Composites for Strain-Tailored Multistable Shape Morphing. ACS Appl. Mater. Interfaces 2020, 13, 12719–12725. [Google Scholar] [CrossRef]

- Ghi, A.; Rossetti, F. 4D Printing: An Emerging Technology in Manufacturing? In Lecture Notes in Information Systems and Organisation; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 171–178. [Google Scholar]

- Yu, Q.; Zhang, M.; Bhandari, B.; Li, J. Future perspective of additive manufacturing of food for children. Trends Food Sci. Technol. 2023, 136, 120–134. [Google Scholar] [CrossRef]

- Wu, C.; Xu, F.; Wang, H.; Liu, H.; Yan, F.; Ma, C. Manufacturing Technologies of Polymer Composites—A Review. Polymers 2023, 15, 712. [Google Scholar] [CrossRef] [PubMed]

- Georgantzinos, S.; Giannopoulos, G.; Bakalis, P. Additive Manufacturing for Effective Smart Structures: The Idea of 6D Printing. J. Compos. Sci. 2021, 5, 119. [Google Scholar] [CrossRef]

- Farid, M.I.; Wu, W.; Guiwei, L.; Yu, Z. Research on imminent enlargements of smart materials and structures towards novel 4D printing (4DP: SMs-SSs). Int. J. Adv. Manuf. Technol. 2023, 126, 2803–2823. [Google Scholar] [CrossRef]

| Sources | Web of Science, Springer, MDPI |

|---|---|

| Publication period | 2013–2023 |

| Keywords | 4D printing, additive manufacturing, smart materials, shape memory recovery, multi-material, shapeshifting |

| Scope | Applications, materials, stimuli, technologies, programming strategies, limitations, accuracy, repeatability |

| Publication type | Original research article |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vatanparast, S.; Boschetto, A.; Bottini, L.; Gaudenzi, P. New Trends in 4D Printing: A Critical Review. Appl. Sci. 2023, 13, 7744. https://doi.org/10.3390/app13137744

Vatanparast S, Boschetto A, Bottini L, Gaudenzi P. New Trends in 4D Printing: A Critical Review. Applied Sciences. 2023; 13(13):7744. https://doi.org/10.3390/app13137744

Chicago/Turabian StyleVatanparast, Somayeh, Alberto Boschetto, Luana Bottini, and Paolo Gaudenzi. 2023. "New Trends in 4D Printing: A Critical Review" Applied Sciences 13, no. 13: 7744. https://doi.org/10.3390/app13137744

APA StyleVatanparast, S., Boschetto, A., Bottini, L., & Gaudenzi, P. (2023). New Trends in 4D Printing: A Critical Review. Applied Sciences, 13(13), 7744. https://doi.org/10.3390/app13137744