Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency

Abstract

1. Introduction

- Long operating times;

- High productivity;

- Extension of cognitive functions that are required to properly interpret human intent and therefore take expected actions;

- Autonomy in terms of long operating time without recharging;

- Accuracy of operation, which is a result of additional sensing elements, whatever the operating conditions might be;

- Meeting environmental requirements to the extent that they can be used in various fields and working environments (e.g., underwater) without risk of environmental pollution [1].

- The search for alternatives to current raw materials and structural solutions without technological change—battery surrogacy, even at the expense of deterioration in performance;

- The search for innovative design solutions, e.g., hydrogen generators, which are less vulnerable to crises and sanctions (renewable locally).

2. Power Requirements for Mobile Robots

- Distance to be traveled and difficulty of the terrain;

- Required speed and acceleration;

- Power consumption (including computing, sensing, communication during work);

- Weight of the payload (also its loss or increase along the route);

- Effect of the weather (e.g., increased power consumption at low or elevated temperatures);

- Required operating time between charges;

- Density and availability of the charging stations;

- Possibility of recharging/refueling at the right time;

- Ability to change batteries between shifts;

- The chemical composition of the batteries and their environmental effect;

- Battery size and weight.

2.1. Mobile Robots’ Actuation Systems

- Energy storage—including batteries, capacitors, and super capacitors;

- Energy generation—including classical electromagnetic generators, fuel cells, and solar cells;

- Energy harvesting—including electrochemical, wireless, thermoelectric, photovoltaic and nano-generators.

2.2. Walking Robots and Wheeled Mobile Robots

2.3. Critical Issues: Powering of Medical Robots

3. Energy Sources of Mobile Robots

3.1. Energy Storage and Battery Technologies

3.1.1. Types of Rechargeable Batteries

3.1.2. Battery Ratings

3.1.3. Battery Technologies

- Technological: novel breakthrough technology as a game-changer;

- Strategic: a new competitor coming to the market;

- Compliance and regulatory: introduction of new rules or legislation;

- Financial: global crisis can result in more non-paying customers;

- Operational: breakdown or theft of key industrial equipment based on advanced microprocessors and software.

3.1.4. Sustainability of Powering Robots

3.2. Battery Management

3.2.1. Power Control of Batteries

3.2.2. Voltage Level Shifting

3.3. AI-Based Optimization of Robots’ Power System and Battery Management

3.4. Case Studies

3.4.1. Case Study: Powering of Robots for IoT and Metaverse Purposes

3.4.2. Case Study: Alternative Robot Power Sources

4. Energy Efficiency of the Mobile Robot’s Motion

4.1. Definition of Energy Efficiency of a Mobile Robot

4.2. Comparison of Energy Efficiency Mobile Robots

5. Discussion

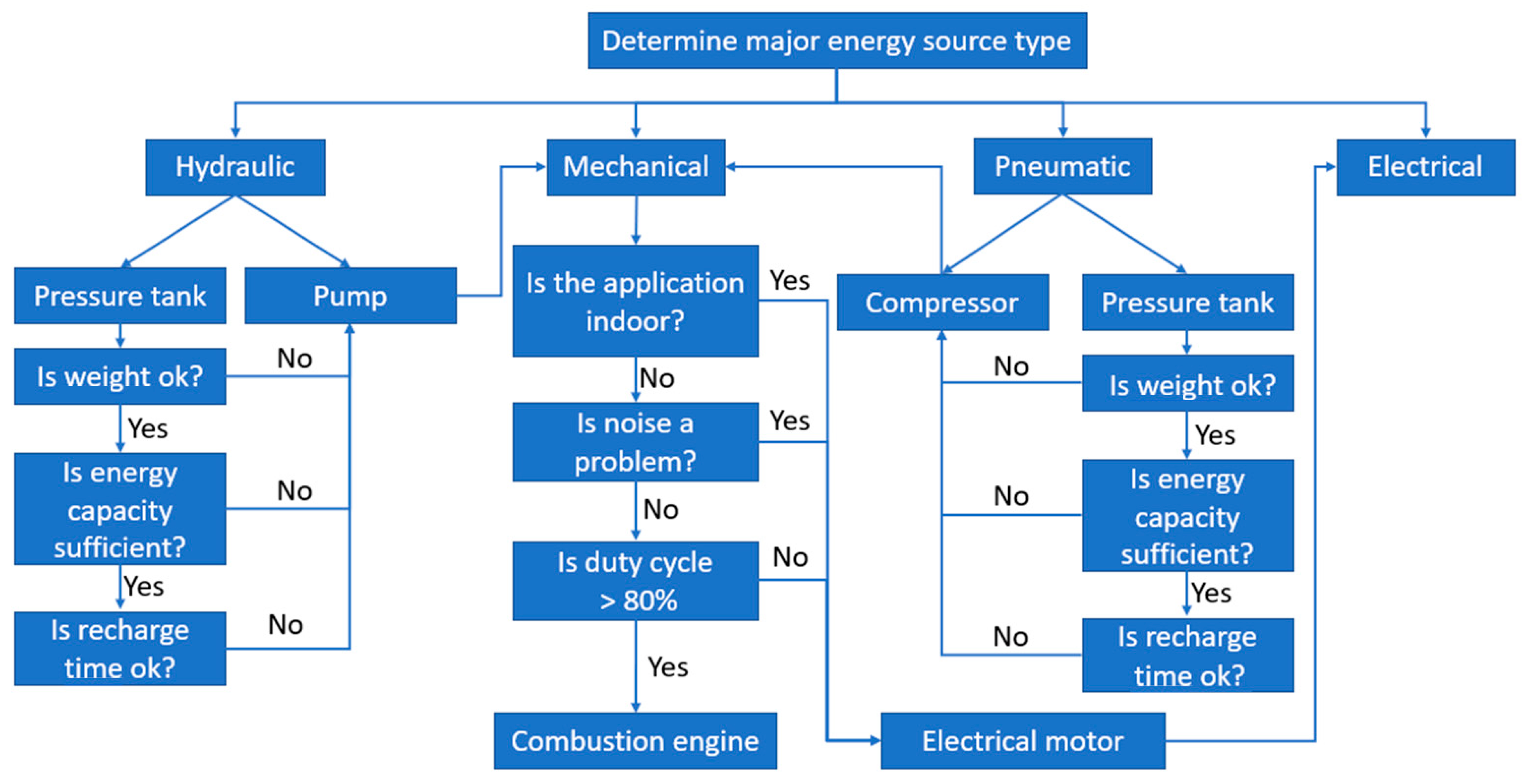

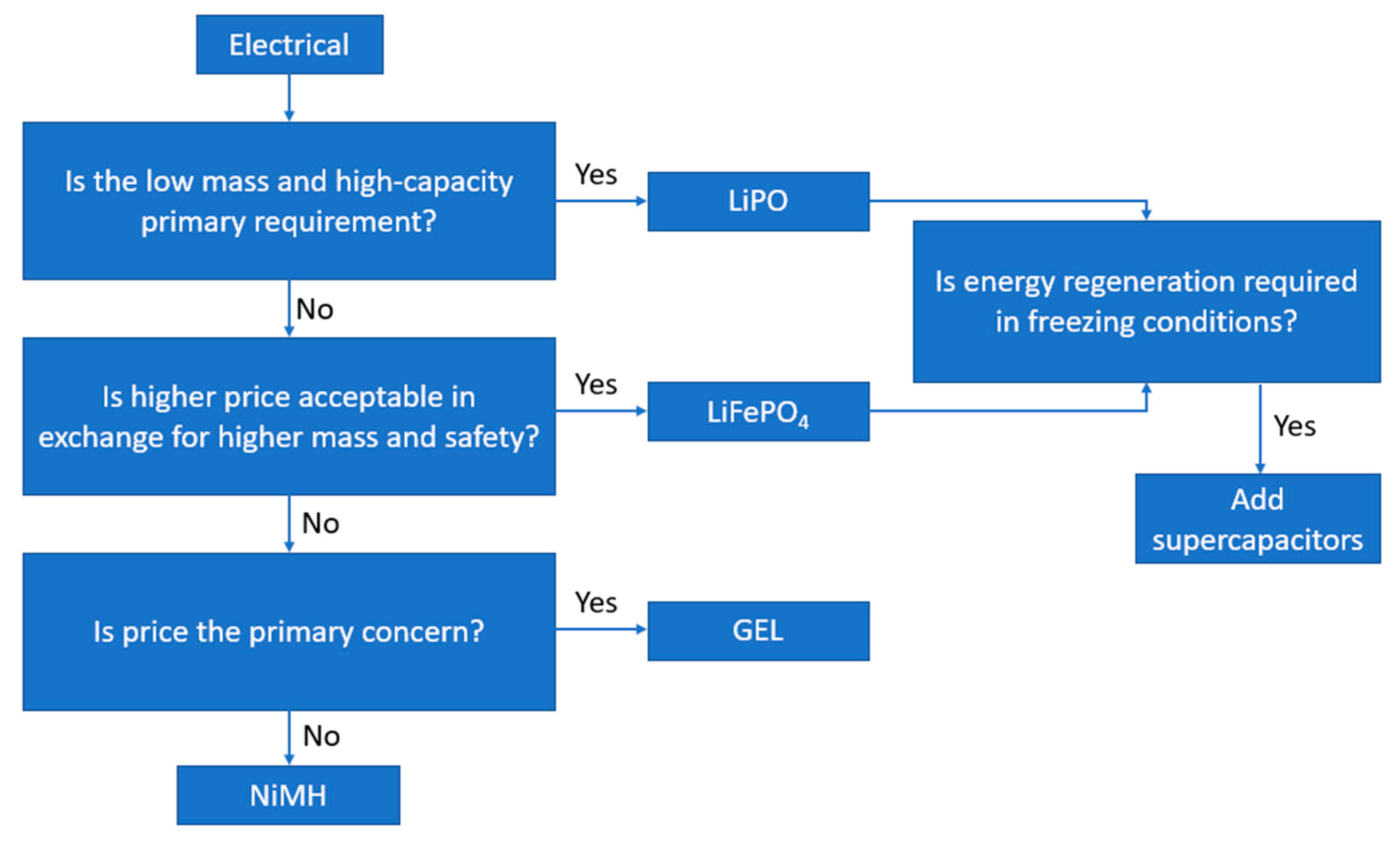

5.1. Power Supply System Selection Process

- Storing data files and backing them up (both for the status of the robot and documentation of its tasks: movement trajectories, photos, videos, classified objects, etc.), even after cessation of operation (movement, search of terrain or body of water);

- Powering the robot’s actuation system (movement and, for example, moving arms or cameras);

- Control of the robotic system, including wired and wireless interaction and communication devices, including program file storage.

- An alarm or warning indicating low battery levels, in several places, including on the device used to remotely control the robot) and on the controller itself;

- An indication of an inability to save data or errors indicating low battery levels;

- A power reserve when the robot shuts down, allowing the battery to be replaced without losing any data.

5.2. Future of Mobile Robot Energy Sources for Power Systems

- The cost of higher capacity batteries, which practically limits mobile robots for light tasks;

- Limited working speed, also due to the safety concerns of surrounding people and objects;

- Requirements for the area of use (more weight usually means less maneuverability);

- Specific charging time and frequency.

5.2.1. Directions for Further Research

5.2.2. Limitations of Previous Studies

6. Conclusions

- Comparison of different types of batteries (lead-acid, AGM, Gel, NiMH, LiPo, LiFePO4) shows that the most versatile solution currently available, characterized by high specific energy and specific power, low self-discharge rate per month, and good safety, is LiFePO4 technology.

- New types of batteries with excellent qualities are the subject of research (batteries based on seawater, iron-flow batteries, silicon as the anode in a lithium-ion battery, organosilicon-based liquid solvents, magnesium metal batteries, lithium-sulfur battery technology made of B4C-hemp, lithium-tungsten batteries, gold nanowire gel electrolyte batteries).

- An important parameter of batteries in applications is energy efficiency, which depends both on battery chemistry and the drive system of the robot.

- A summary of the bipedal walking robots and driving robots is presented with examples.

- AMRs are a very important factor in the development of Industry 4.0. Distinct types of AMR are available: fetching, picking, or sorting. These robots with different structure require different batteries (voltages, current supply, and capacity) to function efficiently. Li-ion batteries are mainly used as the power source.

- The use of Li-ion batteries containing a LiFePO4 cathode and a graphite anode is increasing. For AMR application, batteries from 12 to 96 V and capacities from 10 to 200 Ah are used. Individual (3.27 V) cells are combined in series/parallel connections to build such battery packs. The run time of robots is mostly targeting (∼8.4 h), which is more than 3 times than the charging time (∼2.7 h).

- Modern batteries in applications have many benefits, including:

- ○

- Higher operating voltage and higher capacity;

- ○

- Longer operating time;

- ○

- Shorter down time;

- ○

- Longer cycle life.

- Based on the review of power systems in the paper we propose:

- ○

- An algorithm for selecting the main energy source for robot application in which we can consider the main source type (hydraulic, mechanical, pneumatic, electric);

- ○

- An algorithm for selecting the electrical system power supply, which can help to find the optimal electrical source (NiMH, LiPo, LiFePO4, supercapacitors).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farooq, M.U.; Eizad, A.; Bae, H.K. Power solutions for autonomous mobile robots: A survey. Robot. Auton. Syst. 2023, 159, 104285. [Google Scholar] [CrossRef]

- Rubio, F.; Valero, F.; Llopis-Albert, C. A review of mobile robots: Concepts, methods, theoretical framework, and applications. Int. J. Adv. Robot. Syst. 2019, 16, 2. [Google Scholar] [CrossRef]

- Ballestar, M.T.; Díaz-Chao, Á.; Sainz, J.; Torrent-Sellens, J. Knowledge, robots and productivity in SMEs: Explaining the second digital wave. J. Bus. Res. 2020, 108, 119–131. [Google Scholar] [CrossRef]

- Gul, O.M.; Erkmen, A.M. Energy-Efficient Cluster-Based Data Collection by a UAV with a Limited-Capacity Battery in Robotic Wireless Sensor Networks. Sensors 2020, 20, 5865. [Google Scholar] [CrossRef]

- Chen, T.-S.; Chen, J.-J.; Gao, X.-Y.; Chen, T.-C. Mobile Charging Strategy for Wireless Rechargeable Sensor Networks. Sensors 2022, 22, 359. [Google Scholar] [CrossRef]

- Madden, J.D. Mobile robots: Motor challenges and materials solutions. Science 2007, 318, 1094–1097. [Google Scholar] [CrossRef]

- Sánchez-Ibáñez, J.R.; Pérez-Del-Pulgar, C.J.; García-Cerezo, A. Path Planning for Autonomous Mobile Robots: A Review. Sensors 2021, 21, 7898. [Google Scholar] [CrossRef]

- Abdallaoui, S.; Aglzim, E.-H.; Chaibet, A.; Kribèche, A. Thorough Review Analysis of Safe Control of Autonomous Vehicles: Path Planning and Navigation Techniques. Energies 2022, 15, 1358. [Google Scholar] [CrossRef]

- Szrek, J.; Jakubiak, J.; Zimroz, R. A Mobile Robot-Based System for Automatic Inspection of Belt Conveyors in Mining Industry. Energies 2022, 15, 327. [Google Scholar] [CrossRef]

- Szczepanski, R.; Bereit, A.; Tarczewski, T. Efficient Local Path Planning Algorithm Using Artificial Potential Field Supported by Augmented Reality. Energies 2021, 14, 6642. [Google Scholar] [CrossRef]

- Industry 4.0 in agriculture: Focus on IoT aspects. Digital Transformation Monitor 2017, 6p. Available online: https://ati.ec.europa.eu/sites/default/files/2020-07/Industry%204.0%20in%20Agriculture%20-%20Focus%20on%20IoT%20aspects%20%28v1%29.pdf (accessed on 23 May 2023).

- Sasan, A. (Ed.) Mobile Health: A Technology Road Map; Springer Series in Bio-/Neuroinformatics; Springer: Berlin/Heidelberg, Germany, 2015; Volume 5, p. 1. ISBN 978-3-319-12817-7. [Google Scholar] [CrossRef]

- McNulty, D.; Hennessy, A.; Li, M.; Armstrong, E.; Ryan, K.M. A review of Li-ion batteries for autonomous mobile robots: Perspectives and outlook for the future. J. Power Sources 2022, 545, 231943. [Google Scholar] [CrossRef]

- Ali, J.; Li, Y.; Gao, P.; Hao, T.; Song, J.; Zhang, Q.; Zhu, L.; Wang, J.; Feng, W.; Hu, H.; et al. Interfacial and structural modifications in perovskite solar cells. Nanoscale 2020, 12, 5719–5745. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sakama, S.; Nakano, K.; Kosodo, H. Comparative study on dynamic characteristics of hydraulic, pneumatic and electric motors. In Proceedings of the Fluid Power Systems Technology, Sarasota, FL, USA, 6–9 October 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; p. V001T01A037. [Google Scholar]

- Yang, G.; Bellingham, J.; Dupont, P.; Fischer, P.; Floridi, L.; Full, R.; Jacobstein, N.; Kumar, V.; McNutt, M.; Merrifield, R.; et al. The grand challenges of science robotics. Sci. Robot. 2018, 3, eaar7650. [Google Scholar] [CrossRef]

- Gielis, J.; Shankar, A.; Prorok, A. A Critical Review of Communications in Multi-robot Systems. Curr. Robot. Rep. 2022, 3, 213–225. [Google Scholar] [CrossRef]

- Santoro, C.; Arbizzani, C.; Erable, B.; Ieropoulos, I. Microbial fuel cells: From fundamentals to applications. A review. J. Power Sources 2017, 356, 225–244. [Google Scholar] [CrossRef]

- Xing, Y.; Tang, K.; Wang, J.; Hu, K.; Xiao, Y.; Lyu, J.; Li, J.; Liu, Y.; Zhou, P.; Yan, Y.; et al. High-Performance Wearable Bi2Te3-Based Thermoelectric Generator. Appl. Sci. 2023, 13, 5971. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, W.; Shao, Z. Perovskite/Carbon Composites: Applications in Oxygen Electrocatalysis. Small 2017, 13, 12. [Google Scholar] [CrossRef]

- Góra, K.; Smyczyński, P.; Kujawiński, M.; Granosik, G. Machine Learning in Creating Energy Consumption Model for UAV. Energies 2022, 15, 6810. [Google Scholar] [CrossRef]

- MQTT Specification. Available online: https://mqtt.org/mqtt-specification (accessed on 20 November 2022).

- Xiao, X.; Whittaker, W.L. Energy Considerations for Wheeled Mobile Robots Operating on a Single Battery Discharge; CMU-RI-TR-14-16; Carnegie Mellon University: Pittsburgh, PA, USA, 2014. [Google Scholar]

- Farris, D.J.; Sawicki, G.S. The mechanics and energetics of human walking and running: A joint level perspective. J. R. Soc. Interface 2012, 9, 110–118. [Google Scholar] [CrossRef]

- Boston Dynamics’ Atlas Robot Now Does Gymnastics, Too. Available online: https://www.youtube.com/watch?v=kq6mJOktIvM (accessed on 20 November 2022).

- BigDog—The Most Advanced Rough-Terrain Robot on Earth. Boston Dynamics. Available online: https://web.archive.org/web/20170518204101/http:/www.bostondynamics.com/robot_bigdog.html (accessed on 20 November 2022).

- Vanderborght, B.; Van Ham, R.; Verrelst, B.; Van Damme, M.; Lefeber, D. Overview of the Lucy project: Dynamic stabilization of a biped powered by pneumatic artificial muscles. Adv. Robot. 2008, 22, 1027–1051. [Google Scholar] [CrossRef]

- Alexander, R.M. Bipedal animals, and their differences from humans. J. Anat. 2004, 204, 321–330. [Google Scholar] [CrossRef] [PubMed]

- Guizzo, E. By leaps and bounds: An exclusive look at how boston dynamics is redefining robot agility. IEEE Spectr. 2019, 56, 34–39. [Google Scholar] [CrossRef]

- Thangavelautham, J.; Gallardo, D.; Strawser, D.; Dubowsky, S. Hybrid fuel cell power for long duration robot missions in field environments. In Field Robotics; World Scientific: Singapore, 2011; pp. 471–478. [Google Scholar]

- RoBeetle: A Micro Robot Powered by Liquid Fuel. Available online: https://www.youtube.com/watch?v=vd6tN19wilQ (accessed on 20 November 2022).

- Can Photovoltaics Power Humanoid Robots? Available online: https://www.azorobotics.com/Article.aspx?ArticleID=328 (accessed on 20 November 2022).

- Solar Walking Robot. Available online: https://www.youtube.com/watch?v=JSGqPvRPWEY (accessed on 20 November 2022).

- Meet Tertill. Available online: https://www.youtube.com/watch?v=VwTWhMbnq9g (accessed on 20 November 2022).

- Vitirover. Available online: https://www.pv-magazine.com/2022/02/24/solar-powered-robotic-mower-for-vineyards/ (accessed on 20 November 2022).

- Swift IAM Robotics, (Pennsylvania, United States of America). Available online: https://www.lotsofbots.com/media/robots/assets/SwiftBC0_Draft062020.pdf (accessed on 20 November 2022).

- Matthews AMR Matthews Automation Solutions, (Pennsylvania, United States of America). Available online: https://matthewsautomation.com/autonomous-mobile-robots/ (accessed on 20 November 2022).

- GR 1500 UPS KAZE Robotics, (Singapore). Available online: https://kazerobotics.com/products (accessed on 20 November 2022).

- RA660 Navi XL CleanfiX Reinigungssysteme AG, (Uzwil, Switzerland). Available online: https://www.ra660navi.com/ (accessed on 20 November 2022).

- RB-Volcano Base Robotnik Automation S.L.L., (Valencia, Spain). Available online: https://robotnik.eu/products/mobile-manipulators/rb-vulcano-en/ (accessed on 20 November 2022).

- Jackal Clearpath Robotics, Inc., (Ontario, Canada). Available online: https://clearpathrobotics.com/jackal-small-unmanned-ground-vehicle/ (accessed on 20 November 2022).

- Star Robots (Star-L, Star-H). Available online: https://www.hansrobot.net/star (accessed on 20 November 2022).

- Caster Zhikete Robot Technology Co., Ltd., (Beijing, China). Available online: https://www.youtube.com/watch?v=Vcpu5TK23gU (accessed on 20 November 2022).

- AMB UR5 Seer Intelligent Technology Corporation, (Shanghai, China). Available online: https://www.seer-group.com/ (accessed on 20 November 2022).

- Handle Robot, (Boston Dynamics USA). Available online: https://robots.ieee.org/robots/handle/ (accessed on 20 November 2022).

- Connor, RobotLAB Inc., (Delaware, United States of America). Available online: https://www.robotlab.com/store/connor-uvc-disinfection-robot (accessed on 20 November 2022).

- Fetch Robotics, Inc., (California, United States of America). Available online: https://fetchrobotics.com/ (accessed on 20 November 2022).

- Mikolajczyk, T.; Musial, J.; Romanowski, Ł.; Domagalski, A.; Kamieniecki, L.; Murawski, M. Multipurpose Mobile Robot. Appl. Mech. Mater. 2013, 282, 152–157. [Google Scholar] [CrossRef]

- Robotics—Power Source for Robots. 2013. Available online: https://www.azorobotics.com/Article.aspx?ArticleID=139 (accessed on 20 November 2022).

- May, G.J.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2018, 15, 145–157. [Google Scholar] [CrossRef]

- Great Power Group. Square Lithium-Ion Cell. Available online: http://www.greatpower.net/cplb/info_159.aspx?itemid=292&cid=25 (accessed on 20 November 2022).

- Lithium-Ion Battery. Available online: https://www.cei.washington.edu/education/science-of-solar/battery-technology/ (accessed on 20 November 2022).

- Ultra-Light Battery Pack for Walking Robot. Available online: https://www.cie-solutions.com/robotics-battery-pack (accessed on 27 May 2022).

- Budde-Meiwes, H.; Drillkens, J.; Lunz, B.; Muennix, J.; Rothgang, S.; Kowal, J.; Sauer, D.U. A review of current automotive battery technology and future prospects. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 761–776. [Google Scholar] [CrossRef]

- Roy, K.; Banerjee, A.; Ogale, S. Search for New Anode Materials for High Performance Li-Ion Batteries. ACS Appl. Mater. Interfaces 2022, 14, 20326–20348. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, S.; Guo, J.; Qin, T. Remaining capacity estimation of lithium-ion batteries based on the constant voltage charging profile. PLoS ONE 2018, 13, e0200169. [Google Scholar] [CrossRef]

- Che, Y.; Hu, Y.; Lin, X.; Guo, J.; Teodorescu, R. Health prognostics for lithium-ion batteries: Mechanisms, methods, and prospects. Energy Environ. Sci. 2023, 16, 338–371. [Google Scholar] [CrossRef]

- Shen, W.; Vo, T.T.; Kapoor, A. Charging algorithms of lithium-ion batteries: An overview. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; pp. 1567–1572. [Google Scholar] [CrossRef]

- Yamada, I. Novel catalytic properties of quadruple perovskites. Sci. Technol. Adv. Mater. 2017, 18, 541–548. [Google Scholar] [CrossRef]

- Kanoun, O.; Bradai, S.; Khriji, S.; Bouattour, G.; El Houssaini, D.; Ben Ammar, M.; Naifar, S.; Bouhamed, A.; Derbel, F.; Viehweger, C. Energy-Aware System Design for Autonomous Wireless Sensor Nodes: A Comprehensive Review. Sensors 2021, 21, 548. [Google Scholar] [CrossRef]

- Sperling, M.; Kivelä, T. Concept of a Dual Energy Storage System for Sustainable Energy Supply of Automated Guided Vehicles. Energies 2022, 15, 479. [Google Scholar] [CrossRef]

- Cao, Y.; Yao, M.; Sun, X. An Overview of Modelling and Energy Management Strategies for Hybrid Electric Vehicles. Appl. Sci. 2023, 13, 5947. [Google Scholar] [CrossRef]

- Cheng, F.; Liang, J.; Tao, Z.; Chen, J. Functional materials for rechargeable batteries. Adv. Mater. 2011, 23, 1695–1715. [Google Scholar] [CrossRef]

- de Vasconcelos, L.S.; Xu, R.; Xu, Z.; Zhang, J.; Sharma, N.; Shah, S.R.; Han, J.; He, X.; Wu, X.; Sun, H.; et al. Chemomechanics of Rechargeable Batteries: Status, Theories, and Perspectives. Chem. Rev. 2022, 122, 13043–13107. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, F. Combination of lightweight elements and nanostructured materials for batteries. Acc. Chem. Res. 2009, 42, 713–723. [Google Scholar] [CrossRef]

- Brose, S.W.; Weber, D.J.; Salatin, B.A.; Grindle, G.G.; Wang, H.; Vazquez, J.J.; Cooper, R.A. The role of assistive robotics in the lives of persons with disability. Am. J. Phys. Med. Rehabil. 2010, 89, 509–521. [Google Scholar] [CrossRef]

- Deshpande, A.; Smith, G.W.; Smith, A.J. Biofouling of surgical power tools during routine use. J. Hosp. Infect. 2015, 90, 179–185. [Google Scholar] [CrossRef]

- Trochimczuk, R.; Łukaszewicz, A.; Mikołajczyk, T.; Aggogeri, F.; Borboni, A. Finite element method stiffness analysis of a novel telemanipulator for minimally invasive surgery. Simulation 2019, 95, 1015–1025. [Google Scholar] [CrossRef]

- Louie, D.R.; Eng, J.J. Powered robotic exoskeletons in post-stroke rehabilitation of gait: A scoping review. J Neuroeng. Rehabil. 2016, 13, 53. [Google Scholar] [CrossRef]

- Tucker, V.A. The energetic cost of moving about: Walking and running are extremely inefficient forms of locomotion. Much greater efficiency is achieved by birds, fish—And bicyclists. Am. Sci. 1975, 63, 413–419. [Google Scholar]

- Lim, C.; Yeap, G.H. The locomotion of bipedal walking robot with six degree of freedom. Procedia Eng. 2012, 41, 8–14. [Google Scholar] [CrossRef]

- Kajita, S.; Espiau, B. Legged robots. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Sakagami, Y.; Watanabe, R.; Aoyama, C.; Matsunaga, S.; Higaki, N.; Fujimura, K. The intelligent ASIMO: System overview and integration. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IEEE), Lausanne, Switzerland, 30 September–4 October2002; Volume 3, pp. 2478–2483. [Google Scholar]

- Kashiri, N.; Abate, A.; Abram, S.J.; Albu-Schaffer, A.; Clary, P.J.; Daley, M.; Faraji, S.; Furnemont, R.; Garabini, M.; Geyer, H.; et al. An overview on principles for energy efficient robot locomotion. Front. Robot. AI 2018, 5, 129. [Google Scholar] [CrossRef] [PubMed]

- DURUS: SRI’s Ultra-Efficient Walking Humanoid Robot. Available online: https://spectrum.ieee.org/durus-sri-ultra-efficient-humanoid-robot (accessed on 15 January 2022).

- Reher, J.; Cousineau, E.A.; Hereid, A.; Hubicki, C.M.; Ames, A.D. Realizing dynamic and efficient bipedal locomotion on the humanoid robot DURUS. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 1794–1801. [Google Scholar]

- SRI’S DURUS. Available online: https://www.youtube.com/watch?v=HyqT9Bdamt8 (accessed on 20 November 2022).

- Hobart, C.G.; Mazumdar, A.; Spencer, S.J.; Quigley, M.; Smith, J.P.; Bertrand, S.; Pratt, J.; Kuehl, M.; Buerger, S.P. Achieving Versatile Energy Efficiency With the WANDERER Biped Robot. IEEE Trans. Robot. 2020, 36, 959–966. [Google Scholar] [CrossRef]

- WANDERER. Available online: https://www.youtube.com/watch?v=tIm0muIOc5E (accessed on 20 November 2022).

- Cassie. Available online: https://robots.ieee.org/robots/cassie/ (accessed on 20 November 2022).

- Meet Cassie—The Highly Energy Efficient Walking Machine. Available online: https://www.borntoengineer.com/meet-cassie-highly-energy-efficient-walking-machine (accessed on 20 November 2022).

- Cassie Robot Runs Turf 5k. Available online: https://www.youtube.com/watch?v=FSaSjd_HOaI (accessed on 20 November 2022).

- Kim, K.; Spieler, P.; Lupu, E.-S.; Ramezani, A.; Chung, S.-J. A bipedal walking robot that can fly, slackline, and skateboard. Sci. Robot. 2021, 6, eabf8136. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, S.; Nateghi, M.R. Recent Advances in Solar Rechargeable Seawater Batteries Based on Semiconductor Photoelectrodes. Top Curr Chem 2022, 380, 28. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Li, Z.; Feng, G.; Yang, Z.; Fox, D.; Wang, M.; Zhou, H.; Zhai, L.; Kushima, A.; Du, Y.; et al. Stable, high-performance, dendrite-free, seawater-based aqueous batteries. Nat. Commun. 2021, 12, 237. [Google Scholar] [CrossRef]

- Yuan, Z.; Duan, Y.; Liu, T.; Zhang, H.; Li, X. Toward a Low-Cost Alkaline Zinc-Iron Flow Battery with a Polybenzimidazole Custom Membrane for Stationary Energy Storage. IScience 2018, 3, 40–49. [Google Scholar] [CrossRef]

- Xie, C.; Duan, Y.; Xu, W.; Zhang, H.; Li, X. A Low-Cost Neutral Zinc-Iron Flow Battery with High Energy Density for Stationary Energy Storage. Angew. Chem. Int. Ed. Engl. 2017, 56, 14953–14957. [Google Scholar] [CrossRef]

- Lee, S.; Ko, M.; Jung, S.C.; Han, Y.K. Silicon as the Anode Material for Multivalent-Ion Batteries: A First-Principles Dynamics Study. ACS Appl. Mater. Interfaces 2020, 12, 55746–55755. [Google Scholar] [CrossRef]

- Jiang, S.; Hu, B.; Sahore, R.; Zhang, L.; Liu, H.; Zhang, L.; Lu, W.; Zhao, B.; Zhang, Z. Surface-Functionalized Silicon Nanoparticles as Anode Material for Lithium-Ion Battery. ACS Appl. Mater. Interfaces 2018, 10, 44924–44931. [Google Scholar] [CrossRef]

- Zhang, N.; Cheng, F.; Liu, J.; Wang, L.; Long, X.; Liu, X.; Li, F.; Chen, J. Rechargeable aqueous zinc-manganese dioxide batteries with high energy and power densities. Nat Commun. 2017, 8, 405. [Google Scholar] [CrossRef]

- Ma, Y.; Cui, Y.; Zuo, X.; Huang, S.; Hu, K.; Xiao, X.; Nan, J. Reclaiming the spent alkaline zinc manganese dioxide batteries collected from the manufacturers to prepare valuable electrolytic zinc and LiNi0.5Mn1.5O4 materials. Waste Manag. 2014, 34, 1793–1799. [Google Scholar] [CrossRef]

- Chen, P.; Li, G.R.; Li, T.T.; Gao, X.P. Solar-Driven Rechargeable Lithium-Sulfur Battery. Adv. Sci. 2019, 6, 1900620. [Google Scholar] [CrossRef]

- Li., L.; Wu, Z.P.; Sun, H.; Chen, D.; Gao, J.; Suresh, S.; Chow, P.; Singh, C.V.; Koratkar, N. A Foldable Lithium-Sulfur Battery. ACS Nano 2015, 9, 11342–11350. [Google Scholar] [CrossRef]

- Yu, B.; Fan, Y.; Mateti, S.; Kim, D.; Zhao, C.; Lu, S.; Liu, X.; Rong, Q.; Tao, T.; Tanwar, K.K.; et al. An Ultra-Long-Life Flexible Lithium-Sulfur Battery with Lithium Cloth Anode and Polysulfone-Functionalized Separator. ACS Nano 2021, 15, 1358–1369. [Google Scholar] [CrossRef]

- Griffith, K.J.; Wiaderek, K.M.; Cibin, G.; Marbella, L.E.; Grey, C.P. Niobium tungsten oxides for high-rate lithium-ion energy storage. Nature 2018, 559, 556–563. [Google Scholar] [CrossRef]

- Chang, U.; Eom, K. Enhancing the Capacity and Stability of a Tungsten Disulfide Anode in a Lithium-Ion Battery Using Excess Sulfur. ACS Appl. Mater. Interfaces 2021, 13, 20213–20221. [Google Scholar] [CrossRef]

- LeThun, M.; Chandran, G.T.; Dutta, R.K.; Li, X.; Penner, R.M. 100k Cycles and Beyond: Extraordinary Cycle Stability for MnO2 Nanowires Imparted by a Gel Electrolyte. ACS Energy Lett. 2016, 1, 57–63. [Google Scholar] [CrossRef]

- Battery Structures, Self-Organizing Structures and Related Methods. US Patent US8206469B2, 26 June 2012. Available online: https://patents.google.com/patent/US8206469 (accessed on 22 December 2022).

- Mikolajczyk, T.; Mikołajewska, E.; Al-Shuka, H.F.N.; Malinowski, T.; Kłodowski, A.; Pimenov, D.Y.; Paczkowski, T.; Hu, F.; Giasin, K.; Mikołajewski, D.; et al. Recent Advances in Bipedal Walking Robots: Review of Gait, Drive, Sensors and Control Systems. Sensors 2022, 22, 4440. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E.; Kopowski, J.; Macko, M.; Mikołajewski, D. AI-Based Support System for Monitoring the Quality of a Product within Industry 4.0 Paradigm. Sensors 2022, 22, 8107. [Google Scholar] [CrossRef]

- Dostatni, E.; Mikołajewski, D.; Dorożyński, J.; Rojek, I. Ecological Design with the Use of Selected Inventive Methods including AI-Based. Appl. Sci. 2022, 12, 9577. [Google Scholar] [CrossRef]

- Nowakowski, M.; Kurylo, J. Usability of Perception Sensors to Determine the Obstacles of Unmanned Ground Vehicles Operating in Off-Road Environments. Appl. Sci. 2023, 13, 4892. [Google Scholar] [CrossRef]

- Townsend, A.; Jiya, I.N.; Martinson, C.; Bessarabov, D.; Gouws, R. A comprehensive review of energy sources for unmanned aerial vehicles, their shortfalls and opportunities for improvements. Heliyon 2020, 6, e05285. [Google Scholar] [CrossRef] [PubMed]

- Grodzki, W.; Łukaszewicz, A. Design and manufacture of unmanned aerial vehicles (UAV) wing structure using composite materials. Mater. Werkst. 2015, 46, 269–278. [Google Scholar] [CrossRef]

- Łukaszewicz, A.; Szafran, K.; Jóźwik, J. CAx techniques used in UAV design process. In Proceedings of the 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22–24 June 2020; pp. 95–98. [Google Scholar] [CrossRef]

- Kranjec, B.; Sladic, S.; Giernacki, W.; Bulic, N. PV System Design and Flight Efficiency Considerations for Fixed-WingRadio-Controlled Aircraft—A Case Study. Energies 2018, 11, 2648. [Google Scholar] [CrossRef]

- Joshi, D.; Deb, D.; Muyeen, S.M. Comprehensive Review on Electric Propulsion System of Unmanned Aerial Vehicles. Front. Energy Res. 2022, 10, 752012. [Google Scholar] [CrossRef]

- Pham, K.L.; Leuchter, J.; Bystricky, R.; Andrle, M.; Pham, N.N.; Pham, V.T. The Study of Electrical Energy Power Supply System for UAVs Based on the Energy Storage Technology. Aerospace 2022, 9, 500. [Google Scholar] [CrossRef]

- Boukoberine, M.N.; Zhou, Z.; Benbouzid, M. A critical review on unmanned aerial vehicles power supply and energy management: Solutions, strategies, and prospects. Appl. Energy 2019, 255, 113823. [Google Scholar] [CrossRef]

- Giernacki, W. Minimum Energy Control of Quadrotor UAV: Synthesis and Performance Analysis of Control System with Neurobiologically Inspired Intelligent Controller (BELBIC). Energies 2022, 15, 7566. [Google Scholar] [CrossRef]

- Rao, J.; Li, B.; Zhang, Z.; Chen, D.; Giernacki, W. Position Control of Quadrotor UAV Based on Cascade Fuzzy Neural Network. Energies 2022, 15, 1763. [Google Scholar] [CrossRef]

| Robots | Battery | Robot Description | ||||||

|---|---|---|---|---|---|---|---|---|

| Name | Manufacturer | Mass [kg] | Voltage [V] | Capacity [Ah] | Trun [h] | Tcharge [h] | Cycles | |

| LiFePO4/graphite | ||||||||

| Swift | IAM Robotics | 272.2 | 55 | 100 | 10 | - | 3000 | Mobile picking and transport robot [29] |

| Matthews AMR | Matthews Automation | 83 | 25.6 | 20 | 6–8 | 3 | - | AMR for specific tasks such as order picking and material transport [30] |

| GR-1500 UPS | Kaze Robotics | 250 | 48 | 60 | 8 | - | - | Robot for automated material handling [31] |

| RA660 Navi XL | CleanFix | 313 | 24 | 120 | 3–4 | 1 | - | Automated cleaning robot for industry [32] |

| RB-Vulcano Base | Robotnik | 750 | 48 | 200 | 10 | - | - | Mobile manipulator for carrying out industrial tasks (payload 1750 kg) [33] |

| Li-ion | ||||||||

| Jackal | Clearpath Robotics | 17 | 24 | 11.25 | 2–8 | 5 | - | Jackal is a small, fast, entry-level field robotics research platform [34] |

| Star-L | Hansrobot | 200 | 48 | 46 | 8 | 2 | - | Mobile manipulation robot with 100 kg payload and locomotion speed of 1.5 m/s [35] |

| Star-H | Hansrobot | 900 | 48 | 125 | 12 | 2.5 | - | Mobile manipulation robot with payload 600 kg, speed 1.5 m/s [35] |

| Caster | Iquotient Robotics | 40 | 24 | 40 | 5 | - | - | Caster is a diff-drive indoor unmanned ground vehicle, suitable for research and indoor service [36] |

| AMB-UR5 | Seer | 130 | 48 | 52 | - | 2 | >500 | Collaborative Hybrid Robot UR5 based on Auto Mobile Base AGVs [37] |

| Lead-Acid | AGM | Gel | NiMH | LiPo | LiFePO4 | |

|---|---|---|---|---|---|---|

| Specific energy [Wh/kg] | 35–40 | 35–40 | 35–40 | 60–120 | 100–265 | 90–160 |

| Specific power [W/kg] | 180 | 180 | 180 | 250–1000 | 245–430 | 2000–4500 |

| Charge current [C] | 0.2 C | 0.25 C | 0.25 C | 1 C | 1 C | 1 C |

| Discharge current [C] | 0.2 C | 0.25 C | 0.25 C | 5 C–15 C | 5 C | 30 C |

| Self-discharge per month [%] | 10–15 | 3–4 | 3–4 | 0.08–2.9 | 0.3 | 0.3 |

| Max cell voltage [V] | 2.15 | 2.15 | 2.15 | 1.4 | 4.2 | 3.65 |

| Nominal cell voltage [V] | 2.1 | 2.1 | 2.1 | 1.2 | 3.7 | 3.7 |

| Min cell voltage [V] | 1.8 | 1.8 | 1.8 | 0.9 | 2.7 | 2 |

| Cycle durability [cycles] | 350 | 500 | 500 | 180–2000 | 500 | 1200–2000 |

| Max discharge capacity [%] | 50 | 20 | 20 | 0 | 3 | 3 |

| Operating temperatures [°C] | −35 to +50 | −40 to +49 | −20 to +45 | −20 to +45 | −20 to +60 | −30 to +80 |

| Charge temp range [°C] | −20 to +50 | −20 to +50 | −20 to +50 | 0 to +45 | 0 to +45 | +5 to +45 |

| Price [EUR/Wh] | 0.14 | 0.21 | 0.26 | 0.63 | 1.04 | 2.96 |

| Strengths high safety light weight long life environmental suitability fast charging | Weaknesses high variety of solutions various requirements sophisticated technologies |

| Opportunities self-charging solutions novel, more common materials (e.g., salt) LCA recycling | Threats lack of materials environmental pollution legal regulations |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikołajczyk, T.; Mikołajewski, D.; Kłodowski, A.; Łukaszewicz, A.; Mikołajewska, E.; Paczkowski, T.; Macko, M.; Skornia, M. Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency. Appl. Sci. 2023, 13, 7547. https://doi.org/10.3390/app13137547

Mikołajczyk T, Mikołajewski D, Kłodowski A, Łukaszewicz A, Mikołajewska E, Paczkowski T, Macko M, Skornia M. Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency. Applied Sciences. 2023; 13(13):7547. https://doi.org/10.3390/app13137547

Chicago/Turabian StyleMikołajczyk, Tadeusz, Dariusz Mikołajewski, Adam Kłodowski, Andrzej Łukaszewicz, Emilia Mikołajewska, Tomasz Paczkowski, Marek Macko, and Marika Skornia. 2023. "Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency" Applied Sciences 13, no. 13: 7547. https://doi.org/10.3390/app13137547

APA StyleMikołajczyk, T., Mikołajewski, D., Kłodowski, A., Łukaszewicz, A., Mikołajewska, E., Paczkowski, T., Macko, M., & Skornia, M. (2023). Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency. Applied Sciences, 13(13), 7547. https://doi.org/10.3390/app13137547