Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality

Abstract

1. Introduction

2. Related Work

3. Materials and Methods

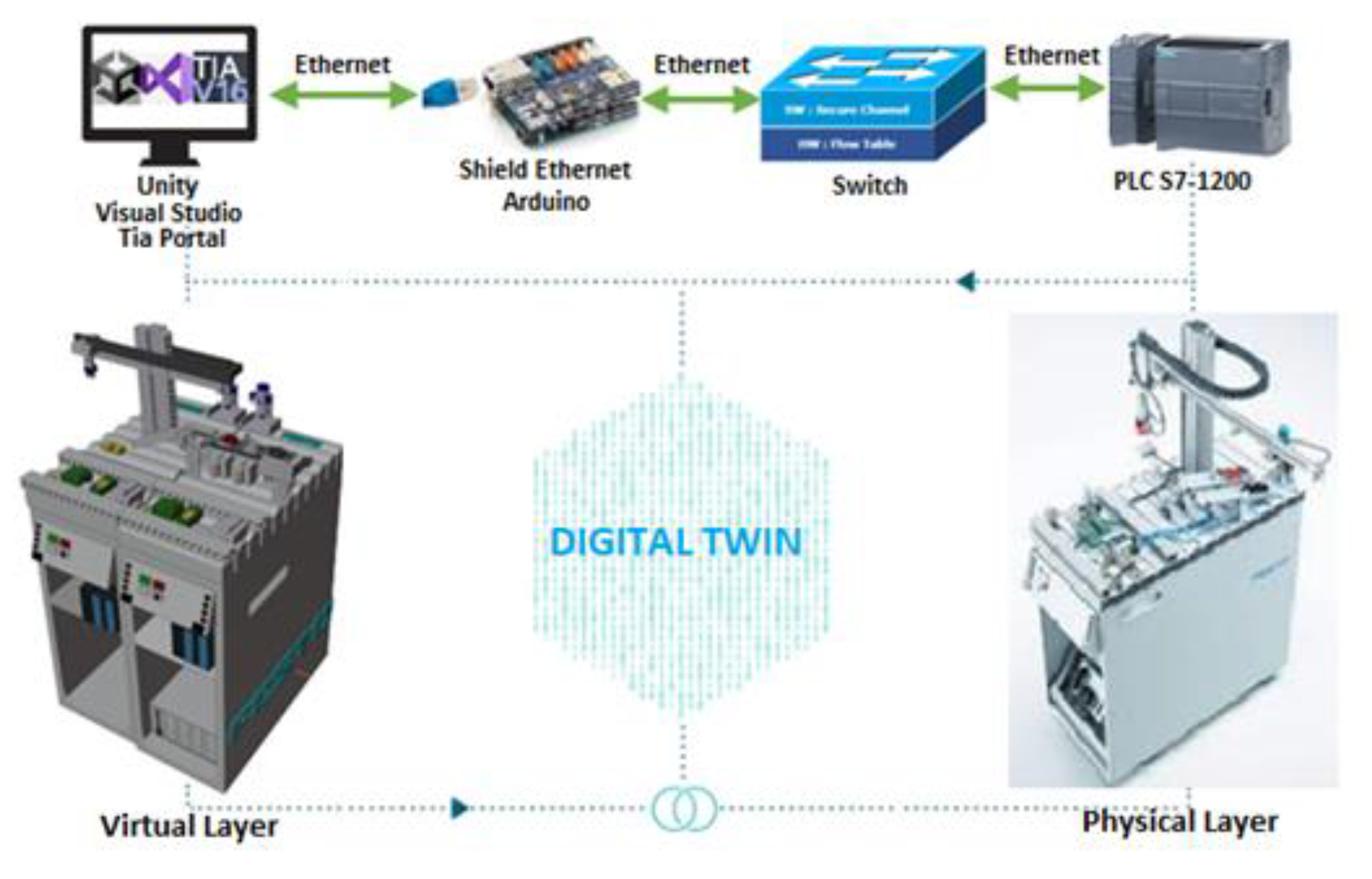

3.1. Digital Twin

- i.

- Digital model (DM): A digital representation of a physical object that does not use automatic data exchange between the digital model and the physical object.

- ii.

- Digital shadow (DS): This is a DM with unidirectional automatic flow between the state of the existing physical object and the digital counterpart.

- iii.

- Digital twin: There is a bidirectional flow between the state of the physical object and the digital object for total integration.

3.2. Cyber-Physical Systems (CPS)

3.3. Industry 4.0

3.4. Industrial Internet of Things

3.5. META 2 Glasses

4. Implementation and Results

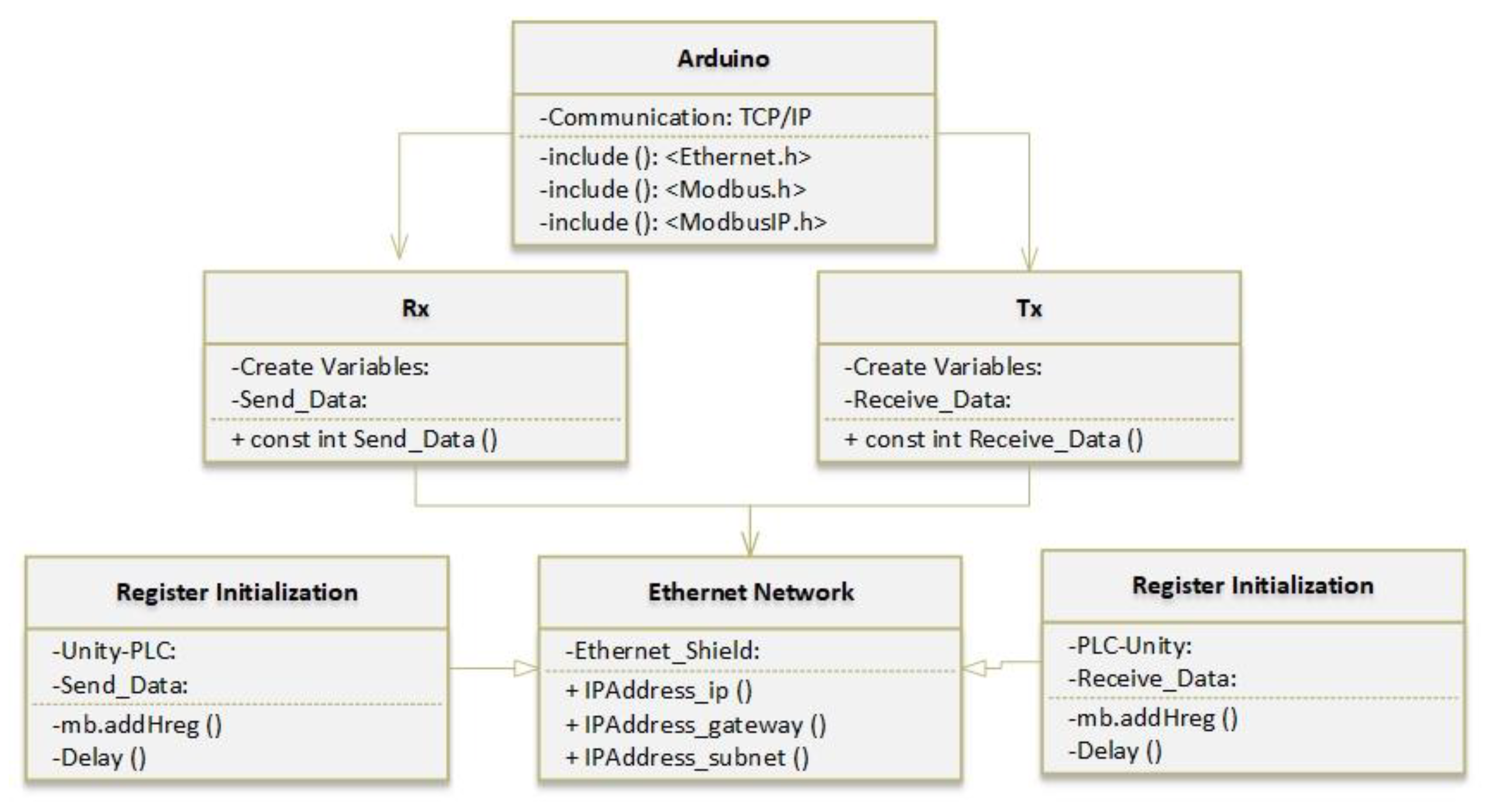

4.1. Communication

4.2. Digital Twin Implementation

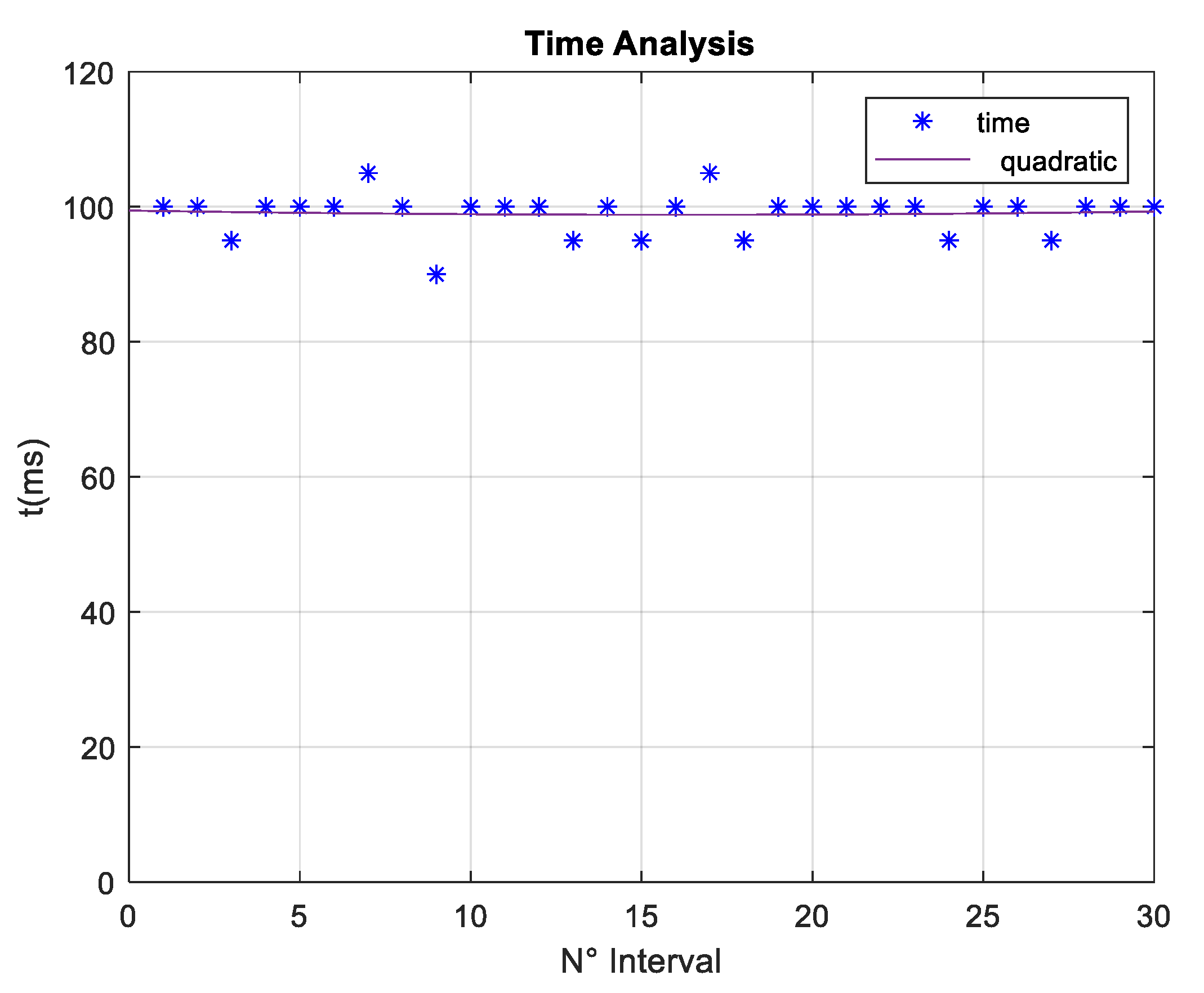

4.3. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Lin, W.D.; Low, M.Y.H. Concept design of a system architecture for a manufacturing cyber-physical digital twin system. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 14–17 December 2020; pp. 1320–1324. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Xu, W.; Cui, J.; Li, L.; Yao, B.; Tian, S.; Zhou, Z. Digital twin-based industrial cloud robotics: Framework, control approach, and implementation. J. Manuf. Syst. 2021, 58, 196–209. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, X.; Liang, W.; Zeng, Z.; Shimizu, S.; Yang, L.T.; Jin, Q. Intelligent Small Object Detection Based on Digital Twinning for Smart Manufacturing in Industrial CPS. IEEE Trans. Ind. Inform. 2021, 18, 1377–1386. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Kong, Z.; Liu, X.; Snoussi, H.; Lv, H. Digital twin improved via visual question answering for vision-language interactive mode in human–machine collaboration. J. Manuf. Syst. 2021, 58, 261–269. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Khan, A.; Shahid, F.; Maple, C.; Ahmad, A.; Jeon, G. Towards Smart Manufacturing Using Spiral Digital Twin Framework and Twinchain. IEEE Trans. Ind. Inform. 2020, 18, 1359–1366. [Google Scholar] [CrossRef]

- Sjarov, M.; Lechler, T.; Fuchs, J.; Brossog, M.; Selmaier, A.; Faltus, F.; Donhauser, T.; Franke, J. The Digital Twin Concept in Industry—A Review and Systematization. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation, Vienna, Austria, 8–11 September 2020; pp. 1789–1796. [Google Scholar] [CrossRef]

- Wang, K.; Lee, T.; Hsu, Y.; Lee, T. Revolution on digital twin technology—A patent research approach. Int. J. Adv. Manuf. Technol. 2020, 107, 4687–4704. [Google Scholar] [CrossRef]

- Perno, M.; Hvam, L.; Haug, A. Enablers and barriers to the implementation of digital twins in the process industry: A systematic literature review. IEEE Int. Conf. Ind. Eng. Eng. Manag. 2020, 2020, 959–964. [Google Scholar] [CrossRef]

- Josifovska, K.; Yigitbas, E.; Engels, G. Reference Framework for Digital Twins within Cyber-Physical Systems. In Proceedings of the 2019 IEEE/ACM 5th International Workshop on Software Engineering for Smart Cyber-Physical Systems SEsCPS, Montreal, QC, Canada, 28 May 2019; pp. 25–31. [Google Scholar] [CrossRef]

- Nagy, B.G.; Dóka, J.; Rácz, S.; Szabó, G.; Pelle, I.; Czentye, J.; Toka, L.; Sonkoly, B. Towards human-robot collaboration: An industry 4.0 VR platform with clouds under the hood. In Proceedings of the 2019 IEEE 27th International Conference on Network Protocols, Chicago, IL, USA, 7–10 October 2019; pp. 4–5. [Google Scholar] [CrossRef]

- Yin, Y.; Zheng, P.; Li, C.; Wang, L. A state-of-the-art survey on Augmented Reality-assisted Digital Twin for futuristic human-centric industry transformation. Robot. Comput. Integr. Manuf. 2023, 81, 102515. [Google Scholar] [CrossRef]

- Padovano, A.; Longo, F.; Nicoletti, L.; Mirabelli, G. A Digital Twin based Service Oriented Application for a 4.0 Knowledge Navigation in the Smart Factory. IFAC-Pap. 2018, 51, 631–636. [Google Scholar] [CrossRef]

- Jeon, S.M.; Schuesslbauer, S. Digital twin application for production optimization. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 14–17 December 2020; pp. 542–545. [Google Scholar] [CrossRef]

- Sierla, S.; Sorsamäki, L.; Azangoo, M.; Villberg, A.; Hytönen, E.; Vyatkin, V. Towards semi-automatic generation of a steady state digital twin of a brownfield process plant. Appl. Sci. 2020, 10, 6959. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Dogan, D. Digital Transformation Revolution with Digital Twin Technology. In Proceedings of the 4th International Symposium on Multidisciplinary Studies and Innovative Technologies ISMSIT 2020, Istanbul, Turkey, 22–24 October 2020. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.K.; Gosine, R.G.; James, L.A.; De Silva, O.; Man, G.K.I.; Warrian, P.J. Digital Twin for the Oil and Gas Industry: Overview, Research Trends, Opportunities, and Challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Singh, J.; Siahpour, S. Integration of digital twin and deep learning in cyber-physical systems: Towards smart manufacturing. IET Collab. Intell. Manuf. 2020, 2, 34–36. [Google Scholar] [CrossRef]

- Biesinger, F.; Weyrich, M. The Facets of Digital Twins in Production and the Automotive Industry. In Proceedings of the 2019 23rd International Conference on Mechatronics Technology (ICMT), Salerno, Italy, 23–26 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Aheleroff, S.; Zhong, R.Y.; Xu, X. A digital twin reference for mass personalization in industry 4.0. Procedia CIRP 2020, 93, 228–233. [Google Scholar] [CrossRef]

- Caiza, G.; Sanz, R. Digital Twin for Monitoring an Industrial Process Using Augmented Reality. In Proceedings of the 2022 17th Iberian Conference on Information Systems and Technologies, Madrid, Spain, 22–25 June 2022; pp. 22–25. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G.; Tancredi, G.P.C. A digital twin model of a pasteurization system for food beverages: Tools and architecture. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation ICE/ITMC, Cardiff, UK, 15–17 June 2020. [Google Scholar] [CrossRef]

- Assawaarayakul, C.; Srisawat, W.; Ayuthaya, S.D.N.; Wattanasirichaigoon, S. Integrate Digital Twin to Exist Production System for Industry 4.0. In Proceedings of the TIMES-iCON 2019—2019 4th Technology Innovation Management and Engineering Science International Conference, Bangkok, Thailand, 11–13 December 2019. [Google Scholar] [CrossRef]

- Vachalek, J.; Bartalsky, L.; Rovny, O.; Sismisova, D.; Morhac, M.; Loksik, M. The digital twin of an industrial production line within the industry 4.0 concept. In Proceedings of the 2017 21st International Conference on Process Control PC, Pleso, Slovakia, 6–9 June 2017; pp. 258–262. [Google Scholar] [CrossRef]

- Rolle, R.P.; Martucci, V.D.O.; Godoy, E.P. Architecture for Digital Twin implementation focusing on Industry 4.0. IEEE Lat. Am. Trans. 2020, 18, 889–898. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Zhuang, C.; Miao, T.; Liu, J.; Xiong, H. The connotation of the digital twin, and the construction and application method of shop-floor digital twin. Robot. Comput. Integr. Manuf. 2021, 68, 102075. [Google Scholar] [CrossRef]

- Hao, Q.; Hongwei, W.; Yu, Z. Constructing Digital Twin for Smart Manufacturing. In Proceedings of the 2021 IEEE 24th International Conference on Computer Supported Cooperative Work in Design (CSCWD), Dalian, China, 5–7 May 2021; pp. 638–642. [Google Scholar]

- Henrique, C.; Gabriel, G.T.; Victor, J.; Arnaldo, J.; Montevechi, B.; De Queiroz, J.A. Decision-making in a fast fashion company in the Industry 4.0 era: A Digital Twin proposal to support operational planning. Int. J. Adv. Manuf. Technol. 2021, 116, 1653–1666. [Google Scholar]

- Negri, E.; Berardi, S.; Fumagalli, L.; Macchi, M. MES-integrated digital twin frameworks. J. Manuf. Syst. 2020, 56, 58–71. [Google Scholar] [CrossRef]

- Santos, C.H.; de Queiroz, J.A.; Leal, F.; Montevechi, J.A.B. Use of simulation in the industry 4.0 context: Creation of a Digital Twin to optimise decision making on non-automated process. J. Simul. 2020, 16, 284–297. [Google Scholar] [CrossRef]

- Alam, K.M.; El Saddik, A. C2PS: A digital twin architecture reference model for the cloud-based cyber-physical systems. IEEE Access 2017, 5, 2050–2062. [Google Scholar] [CrossRef]

- Berezovskyi, A.; Inam, R.; El-Khoury, J.; Torngren, M.; Fersman, E. Efficient state update exchange in a CPS environment for linked data-based digital twins. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics, Helsinki, Finland, 22–25 July 2019; pp. 983–989. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Cimino, C.; MacChi, M. FMU-supported simulation for CPS digital twin. Procedia Manuf. 2019, 28, 201–206. [Google Scholar] [CrossRef]

- Sun, W.; Lei, S.; Wang, L.; Liu, Z.; Zhang, Y. Adaptive Federated Learning and Digital Twin for Industrial Internet of Things. IEEE Trans. Ind. Inform. 2020, 17, 5605–5614. [Google Scholar] [CrossRef]

- Castellani, A.; Schmitt, S.; Squartini, S. Real-World Anomaly Detection by using Digital Twin Systems and Weakly-Supervised Learning. IEEE Trans. Ind. Inform. 2020, 17, 4733–4742. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-Pap. 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Xia, L.; Lu, J.; Zhang, H. Research on Construction Method of Digital Twin Workshop Based on Digital Twin Engine. In Proceedings of the 2020 IEEE International Conference on Advances in Electrical Engineering and Computer Applications AEECA, Dalian, China, 22–25 August 2020; pp. 417–421. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges, and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Moyne, J.; Qamsane, Y.; Balta, E.C.; Kovalenko, I.; Faris, J.; Barton, K.; Tilbury, D.M. A Requirements Driven Digital Twin Framework: Specification and Opportunities. IEEE Access 2020, 8, 107781–107801. [Google Scholar] [CrossRef]

- Hasan, S.M.; Lee, K.; Moon, D.; Kwon, S.; Jinwoo, S.; Lee, S. Augmented reality and digital twin system for interaction with construction machinery. J. Asian Archit. Build. Eng. 2021, 21, 564–574. [Google Scholar] [CrossRef]

- Caiza, G.; Garcia, C.A.; Naranjo, J.E.; Garcia, M.V. Flexible robotic teleoperation architecture for intelligent oil fields. Heliyon 2020, 6, e03833. [Google Scholar] [CrossRef] [PubMed]

- Stary, C. Digital twin generation: Re-conceptualizing agent systems for behavior-centered cyber-physical system development. Sensors 2021, 21, 1096. [Google Scholar] [CrossRef] [PubMed]

- Radanliev, P.; De Roure, D.; Nicolescu, R.; Huth, M.; Santos, O. Digital twins: Artificial intelligence and the IoT cyber-physical systems. Int. J. Intell. Robot. Appl. 2022, 6, 171–185. [Google Scholar] [CrossRef]

- Guo, D.; Ling, S.; Li, H.; Ao, D.; Zhang, T.; Rong, Y.; Huang, G.Q. A framework for personalized production based on digital twin, blockchain and additive manufacturing in the context of Industry 4.0. In Proceedings of the 2020 IEEE 16th International Conference on Automation Science and Engineering, Hong Kong, 20–21 August 2020; pp. 1181–1186. [Google Scholar] [CrossRef]

- Balderas, D.; Ponce, P.; Molina, A. Empowering Digital Twin for Industry 4.0 using metaheuristic optimization algorithms: Case study PCB drilling optimization. Int. J. Adv. Manuf. Technol. 2021, 113, 1295–1306. [Google Scholar] [CrossRef]

- Ghita, M.; Siham, B.; Hicham, M.; Abdelhafid, A.; Laurent, D. Digital twins: Development and implementation challenges within Moroccan context. SN Appl. Sci. 2020, 2, 885. [Google Scholar] [CrossRef]

- Preuveneers, D.; Joosen, W.; Ilie-Zudor, E. Robust Digital Twin Compositions for Industry 4.0 Smart Manufacturing Systems. In Proceedings of the IEEE International Enterprise Distributed Object Computing Workshop EDOCW, Stockholm, Sweden, 16–19 October 2018; pp. 69–78. [Google Scholar] [CrossRef]

- Raza, M.; Kumar, P.M.; Hung, D.V.; Davis, W.; Nguyen, H.; Trestian, R. A Digital Twin Framework for Industry 4.0 Enabling Next-Gen Manufacturing. In Proceedings of the ICITM 2020—2020 9th International Conference on Industrial Technology and Management, Oxford, UK, 11–13 February 2020; pp. 73–77. [Google Scholar] [CrossRef]

- Vrana, J. The Core of the Fourth Revolutions: Industrial Internet of Things, Digital Twin, and Cyber-Physical Loops. J. Nondestruct. Eval. 2021, 40, 46. [Google Scholar] [CrossRef]

- Kamath, V.; Morgan, J.; Ali, M.I. Industrial IoT and Digital Twins for a Smart Factory: An open source toolkit for application design and benchmarking. In Proceedings of the GIoTS 2020—Global Internet of Things Summit, Dublin, Ireland, 3 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Caiza, G.; Bonilla-Vasconez, P.; Garcia, C.A.; Garcia, M.V. Augmented Reality for Robot Control in Low-cost Automation Context and IoT. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; pp. 1461–1464. [Google Scholar] [CrossRef]

- Wärmefjord, K.; Söderberg, R.; Schleich, B.; Wang, H. Digital twin for variation management: A general framework and identification of industrial challenges related to the implementation. Appl. Sci. 2020, 10, 3342. [Google Scholar] [CrossRef]

| Area | Requirements |

|---|---|

| R1. Communication | R1.1 The system provides communication services between the physical and virtual entities. |

| R1.2 The system has bidirectional communication. | |

| R1.3 The system has real-time communication | |

| R2. Operation | R2.1 The system receives the command from the operator. |

| R2.2 The system executes the command sent by the operator. | |

| R2.3 The system tracks the status of the process. | |

| R2.4 The system detects objects and events of interest in the environment. | |

| R3.1 The system displays the status of the process. | |

| R3.2 The system displays the relevant sensor data. | |

| R3. Information | R3.3 The system displays the simulation of the physical environment. |

| R3.4 The system manages simulation data and analysis data |

| N° | Question |

|---|---|

| R1 | Is the 3D digital environment created for the process simulation adequate? |

| R2 | Would you like to use the DTs with AR as training before actual practice? |

| R3 | Is the system capable of detecting events and objects of interest in the real environment? |

| R4 | The system is capable of managing and processing the simulation data? |

| R5 | Is there a perception in real time of the changes in the state of the process? |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caiza, G.; Sanz, R. Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality. Appl. Sci. 2023, 13, 7503. https://doi.org/10.3390/app13137503

Caiza G, Sanz R. Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality. Applied Sciences. 2023; 13(13):7503. https://doi.org/10.3390/app13137503

Chicago/Turabian StyleCaiza, Gustavo, and Ricardo Sanz. 2023. "Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality" Applied Sciences 13, no. 13: 7503. https://doi.org/10.3390/app13137503

APA StyleCaiza, G., & Sanz, R. (2023). Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality. Applied Sciences, 13(13), 7503. https://doi.org/10.3390/app13137503