Comparison of Damage Indexes for Assessing Seismic Fragility of Bearings in an Offshore Bridge

Abstract

:1. Introduction

2. Methodology

2.1. Time-Dependent Deterioration of Materials

2.2. Time-Dependent Bond-Slip Behavior

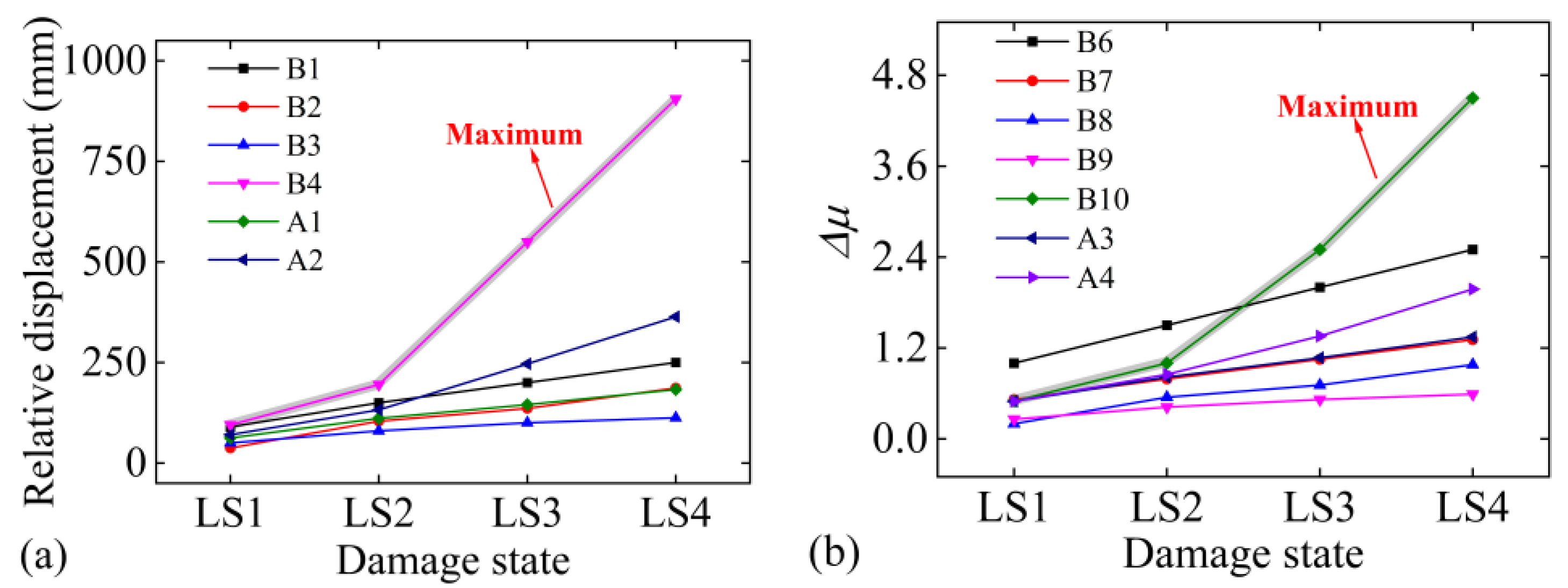

2.3. Definition of Damage Indexes for Bearings

2.4. Fragility Analysis Method for Bearing

3. Problem Definition

3.1. Detailed Numerical Model of the Bridge Structure

3.2. Ground Motion Input

4. Results and Discussion

4.1. Incremental Dynamic Analysis

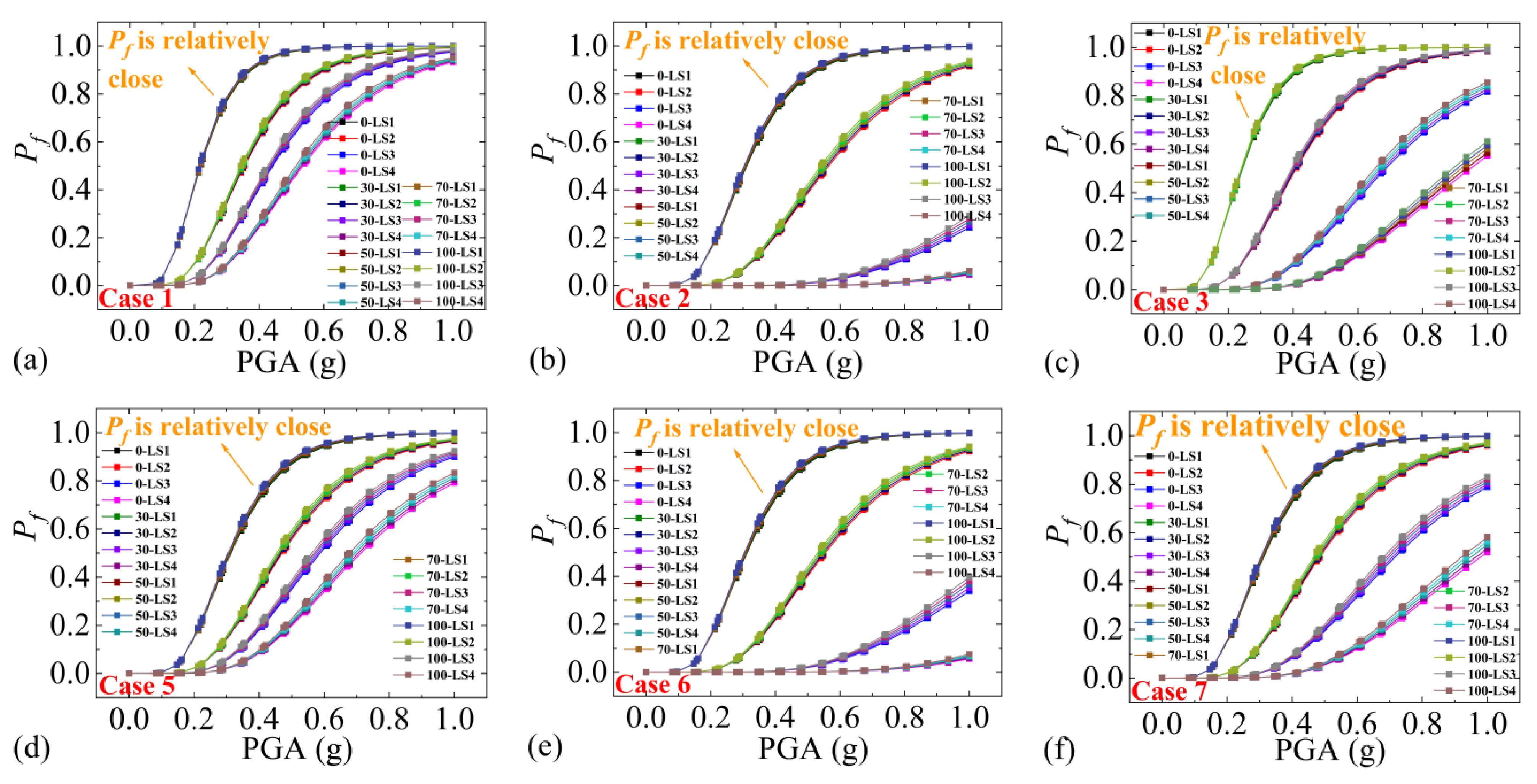

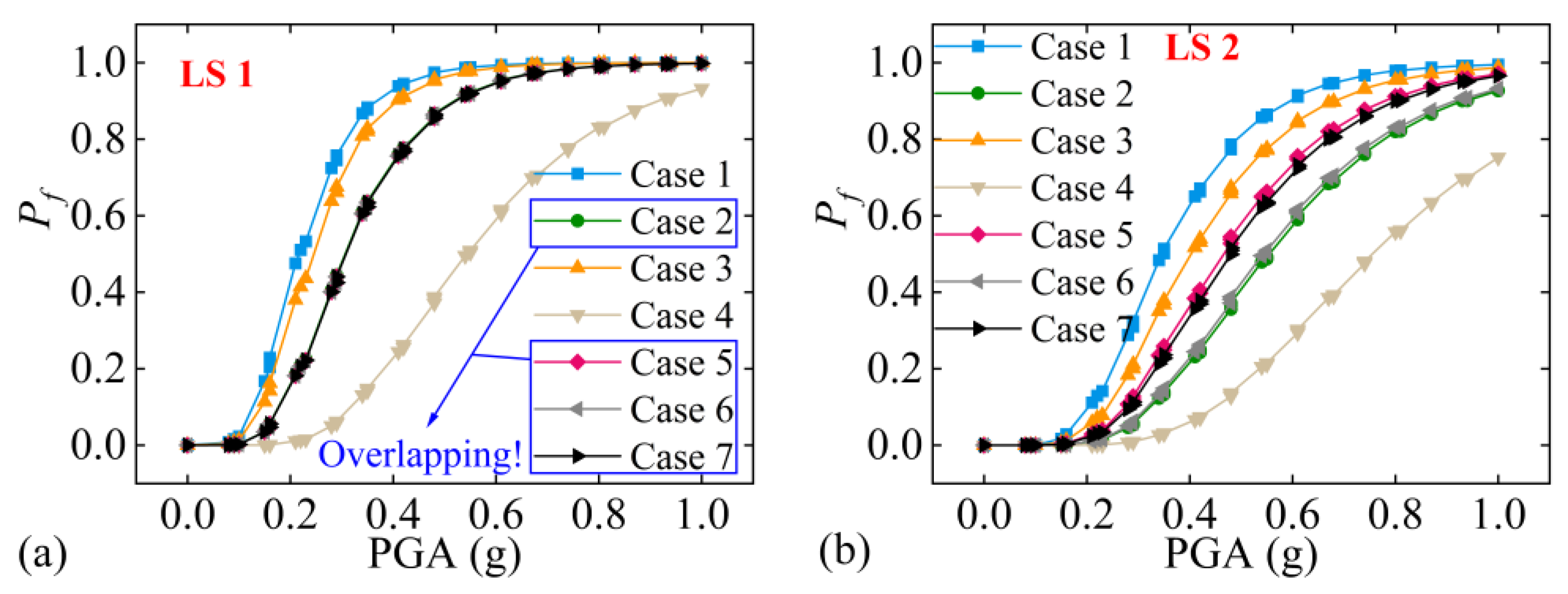

4.2. Comparison of Various Damage Indexes for Bearings

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, W.P.; Li, L.F.; Shao, X.D. Seismic Assessment of Medium-Span Concrete Cable-Stayed Bridges Using the Component and System Fragility Functions. J. Bridge Eng. 2016, 21, 04016027. [Google Scholar] [CrossRef]

- Hwang, H.; Liu, J.; Chiu, Y. Seismic Fragility Analysis of Highway Bridges; The University of Memphis: Memphis, TN, USA, 2001. [Google Scholar]

- Nielson, B. Analytical Fragility Curves for Highway Bridges in Moderate Seismic Zones; Georgia Institute of Technology: Atlanta, GA, USA, 2005. [Google Scholar]

- Zhang, J.; Huo, Y.L. Evaluating effectiveness and optimum design of isolation devices for highway bridges using the fragility function method. Eng. Struct. 2009, 31, 1648–1660. [Google Scholar] [CrossRef]

- Alam, M.S.; Bhuiyan, M.; Billah, A. Seismic fragility assessment of SMA-bar restrained multi-span continuous highway bridge isolated by different laminated rubber bearings in medium to strong seismic risk zones. Bull. Earthq. Eng. 2012, 10, 1885–1909. [Google Scholar] [CrossRef]

- Shinozuka, M.; Feng, M.Q.; Kim, H.K.; Kim, S.H. Nonlinear static procedure for fragility curve development. J. Eng. Mech. 2000, 126, 1287–1295. [Google Scholar] [CrossRef] [Green Version]

- Parool, N.; Rai, D.C. Seismic Fragility of Multispan Simply Supported Bridge with Drop Spans and Steel Bearings. J. Bridge Eng. 2014, 20, 04015021. [Google Scholar] [CrossRef]

- Taskari, O.; Sextos, A. Multi-angle, multi-damage fragility curves for seismic assessment of bridges. Earthq. Eng. Struct. Dyn. 2015, 44, 2281–2301. [Google Scholar] [CrossRef]

- Liang, Y.; Yan, J.L.; Cheng, Z.Q.; Chen, P.; Ren, C. Time-varying seismic fragility analysis of offshore bridges with continuous rigid-frame girder under main aftershock sequences. J. Bridge Eng. 2020, 25, 04020055. [Google Scholar] [CrossRef]

- Liang, Y.; Yan, J.L.; Qian, W.X.; Cheng, Z.Q.; Chen, H. Analysis of collapse resistance of offshore rigid frame—Continuous girder bridge based on time-varying fragility. Mar. Struct. 2021, 75, 102844. [Google Scholar] [CrossRef]

- Ghosh, J.; Padgett, J.E. Aging Considerations in the Development of Time-Dependent Seismic Fragility Curves. J. Struct. Eng. 2010, 136, 1497–1511. [Google Scholar] [CrossRef]

- Shekhar, S.; Ghosh, J. Seismic Fragility of Highway Bridges Considering Improved Bearing Deterioration Modeling. In Maintenance, Safety, Risk, Management and Life-Cycle Performance of Bridges; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Cornell, C.A. Engineering seismic risk analysis. Bull. Seismol. Soc. Am. 1968, 58, 1583–1606. [Google Scholar] [CrossRef]

- Qian, J.; Cheng, L.; Zhou, D. Behavior of axially loaded concrete columns confined with ordinary hoops. J. Tsinghua Univ. 2002, 42, 1369–1373. [Google Scholar]

- Wu, W.; Li, L.; Shao, X.; Hu, S. Seismic evaluation of the aged high-pier and long-span bridges subjected to extremely halobiotic condition. In Proceedings of the 7th International Conference, Bridge Maintenance, Safety and Management, Shanghai, China, 7–11 July 2014; pp. 2031–2037. [Google Scholar]

- Sung, Y.C.; Su, C.K. Time-dependent seismic fragility curves on optimal retrofitting of neutralised reinforced concrete bridges. Struct. Infrastruct. Eng. 2011, 7, 797–805. [Google Scholar] [CrossRef]

- Yan, J.L.; Liang, Y.; Zhao, B.Y.; Qian, W.X.; Chen, H. Influence of time-varying attenuation effect of damage index on seismic fragility of bridge. Earthq. Struct. 2020, 19, 287–301. [Google Scholar] [CrossRef]

- Zhao, J.; Sritharan, S. Modeling of Strain Penetration Effects in Fiber-Based Analysis of Reinforced Concrete Structures Concrete Structures. ACI Struct. J. 2007, 104, 133–141. [Google Scholar]

- Mazzoni, S.; McKenna, F.; Scott, M.H.; Fenves, G.L. OpenSees command language manual. Pac. Earthq. Eng. Res. (PEER) Cent. 2006, 264, 137–158. [Google Scholar]

- Jiao, C.Y. Seismic Vulnerability Analysis of Long Span Stayed-Cable Bridge Based on Performance; Tongji University: Shanghai, China, 2008. [Google Scholar]

- Xu, D.L. Seismic Vulnerability Analysis of High Pier Continuous Rigid Bridge under the Influence of Hydrodynamic Pressure; Southwest Jiaotong University: Chengdu, China, 2018. [Google Scholar]

- Li, L.F.; Wu, W.P.; Hu, S.C.; Liu, S.M. Time-dependent seismic fragility analysis of high pier bridge based on chloride ion induced corrosion. Eng. Mech. 2016, 33, 171–178. [Google Scholar]

- Kircher, C.A.; Whitman, R.V.; Holmes, W.T. HAZUS earthquake loss estimation methods. Nat. Hazards. Rev. 2006, 7, 45–59. [Google Scholar] [CrossRef]

- Choi, E.; Desroches, R.; Nielson, B. Seismic fragility of typical bridges in moderate seismic zones. KSCE J. Civ. Eng. 2004, 26, 187–199. [Google Scholar] [CrossRef]

- Shome, N.; Cornell, C.A.; Bazzurro, P. Earthquakes, Records, and Nonlinear Responses. Heart Rhythm Off. J. Heart Rhythm Soc. 2012, 6, 85. [Google Scholar] [CrossRef]

- Zhang, J.H. Study on Seismic Vulnerability Analysis of Normal Beam Bridge Piers Based on Numerical Simulation; Tongji University: Shanghai, China, 2006. [Google Scholar]

- Ye, A.J. Seismic Design of Bridges; China Communications Press: Beijing, China, 2017. [Google Scholar]

- Song, Y.T.; Zhu, J.C. Artificially generate earthquake records compatible with code design spectrum and structural responses. J. Build. Struct. 1983, 3, 43–54. [Google Scholar]

- Bertero, V.V. Strength and deformation capacities of buildings under extreme environments. Struct. Eng. Struct. Mech. 1977, 53, 211–215. [Google Scholar]

- Vamvatsikos, D.; Cornell, C. Incremental dynamic analysis. Earthq. Eng. Struct. Dyn. 2002, 31, 491–514. [Google Scholar] [CrossRef]

- Zhang, H.Y. Displacement-Based Probabilistic Seismic Demand Analysis and Structure Seismic Design Research; Hunan University: Changsha, China, 2000. [Google Scholar]

- Wang, M.P.; Cao, X.J.; Sun, W.L. Incremental dynamic analysis applied to seismic risk assessment of hybrid structure. Earthq. Resist. Eng. Retrofit. 2010, 32, 109–121. [Google Scholar]

- Yan, J.L.; Guo, A.X.; Li, H. Comparative analysis of different types of damage indexes of coastal bridges based on time-varying seismic fragility. Mar. Struct. 2022, 86, 103288. [Google Scholar] [CrossRef]

| Theme | Year | Main Contribution |

|---|---|---|

| Definitions of damage state | 2001 | Hwang, Liu [2] defined a damage index for a neoprene bearing pad. |

| 2005 | Nielson [3] updated damage index limits for movable and fixed steel bearings. | |

| 2009 | Zhang and Huo [4] proposed classification criteria for different damage states using the shear strain, displacement angle, and displacement. | |

| 2016 | Wu, Li [1] proposed a damage index using a displacement ductility ratio and displacement for a plate rubber bearing and polytetrafluoroethylene (PTFE) sliding plate bearing. | |

| 2012 | Alam, Bhuiyan [5] proposed damage indexes for elastomeric pads and sliding bearings. | |

| Assessment of the seismic performance | 2000, 2001, and 2005 | Shinozuka, Feng [6], Hwang, Liu [2], and Nielson [3] proposed a fragility analysis theory based on traditional reliability theory. |

| 2014 | Parool and Rai [7] analyzed the fragility curves for bearings along two horizontal directions. | |

| 2015 | Taskari and Sextos [8] conducted a seismic fragility analysis of the movable steel bearings. | |

| Durability damage | 2020 and 2021 | Liang, Yan [9] and Liang, Yan [10] found that material deterioration leads to an increase in the seismic response and failure probability of bearings. |

| 2010 | Ghosh and Padgett [11] discovered that the peak deformation of bearings increases significantly when an aging factor is taken into account. | |

| 2018 | Shekhar and Ghosh [12] highlighted the importance of realistic bearing degradation models for bridges. |

| Time (Year) | Peak Stress (MPa) | Peak Strain (ε) | Ultimate Strain (ε) | Elastic Modulus (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| C40 | C50 | C40 | C50 | C40 | C50 | C40 | C50 | |

| 0 | 34.00 | 42.50 | −0.002000 | −0.002000 | −0.004000 | −0.004000 | 32,500.00 | 34,500.00 |

| 30 | 34.18 | 42.60 | −0.001999 | −0.001999 | −0.003988 | −0.003993 | 32,609.50 | 34,567.39 |

| 50 | 34.21 | 42.63 | −0.001998 | −0.001999 | −0.003984 | −0.003991 | 32,640.59 | 34,587.04 |

| 70 | 34.24 | 42.66 | −0.001998 | −0.001999 | −0.003981 | −0.003989 | 32,666.78 | 34,602.83 |

| 100 | 34.26 | 42.69 | −0.001997 | −0.001999 | −0.003978 | −0.003987 | 32,699.55 | 34,623.32 |

| Time (Year) | Diameter (mm) | Yield Strength (MPa) | Elastic Modulus (×105 MPa) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C50 | C40 | C50 | C40 | C50 | C40 | |||||||

| L | S | L | S | L | S | L | S | L | S | L | S | |

| 0 | 32.00 | 16.00 | 32.00 | 16.00 | 335.00 | 235.00 | 335.00 | 235.00 | 2.00 | 2.10 | 2.00 | 2.10 |

| 30 | 31.92 | 15.70 | 31.76 | 15.67 | 334.43 | 232.07 | 333.30 | 231.75 | 1.99 | 2.01 | 1.97 | 2.00 |

| 50 | 31.65 | 15.29 | 31.54 | 15.26 | 332.53 | 228.10 | 331.72 | 227.85 | 1.95 | 1.89 | 1.93 | 1.88 |

| 70 | 31.36 | 14.88 | 31.26 | 14.86 | 330.51 | 224.24 | 329.78 | 224.05 | 1.91 | 1.77 | 1.89 | 1.76 |

| 100 | 30.93 | 14.26 | 30.79 | 14.25 | 327.56 | 218.65 | 326.56 | 218.54 | 1.85 | 1.60 | 1.83 | 1.59 |

| Type | LS1 | LS2 | LS3 | LS4 | |

|---|---|---|---|---|---|

| Relative displacement (mm) | B1 [22] | 90.00 | 150.00 | 200.00 | 250.00 |

| B2 [3] | 37.40 | 104.20 | 136.10 | 186.60 | |

| B3 [20] | 50.00 | 80.00 | 100.00 | 112.50 | |

| A1 | 62.50 | 111.40 | 145.40 | 183.00 | |

| B4 [21] | 95.00 | 195.00 | 550.00 | 905.00 | |

| A2 | 70.60 | 132.30 | 246.50 | 363.50 | |

| Shear strain (%) | B5 [4] | 100.00 | 150.00 | 200.00 | 250.00 |

| Relative displacement ductility ratio | B6 [22] | 1.00 | 1.50 | 2.00 | 2.50 |

| B7 [22] | 0.52 | 0.79 | 1.05 | 1.31 | |

| B8 [22] | 0.20 | 0.55 | 0.71 | 0.98 | |

| B9 [20] | 0.26 | 0.42 | 0.52 | 0.59 | |

| A3 | 0.50 | 0.82 | 1.07 | 1.35 | |

| B10 [21] | 0.50 | 1.00 | 2.50 | 4.50 | |

| A4 | 0.50 | 0.85 | 1.36 | 1.98 | |

| Relative Displacement | Shear Strain | Relative Displacement Ductility Ratio | ||||

|---|---|---|---|---|---|---|

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 |

| A1 | B4 | A2 | B5 | A3 | B10 | A4 |

| Number of Bearings | Type of Bearings | N (kN) | K1 (kN/m) | K2 (kN/m) | K3 (kN/m) |

|---|---|---|---|---|---|

| bearing 1# | MDMB | 4410.5 | 44,105 | 44,105 | 6,250,000 |

| bearing 3# | MDMB | 9580.0 | 95,800 | 95,800 | 6,250,000 |

| bearing 5# | MDMB | 5685.0 | 56,850 | 56,850 | 6,250,000 |

| bearing 2# | LMB | 4410.5 | 1,250,000 | 44,105 | 6,250,000 |

| bearing 4# | LMB | 9580.0 | 1,250,000 | 95,800 | 6,250,000 |

| bearing 6# | LMB | 5685.0 | 1,250,000 | 56,850 | 6,250,000 |

| No. | Name | Event | Time (Year) | Site | PGA (g) | Magnitude (M) |

|---|---|---|---|---|---|---|

| 1 | RSN-138 | Tabas, Iran | 1978 | Boshrooyeh | 0.24 | 7.35 |

| 2 | RSN-164 | Imperial Valley-06 | 1979 | Cerro Prieto | 0.37 | 6.53 |

| 3 | RSN-286 | Irpinia, Italy-01 | 1980 | Bisaccia | 0.25 | 6.90 |

| 4 | RSN-776 | Loma Prieta | 1989 | Hollister-South and Pine | 0.32 | 6.93 |

| 5 | RSN-827 | Cape Mendocino | 1992 | Fortuna-Fortuna Blvd | 0.22 | 7.01 |

| 6 | RSN-880 | Landers | 1992 | Mission Creek Fault | 0.31 | 7.28 |

| 7 | RSN-1008 | Northridge-01 | 1994 | LA-W 15th St | 0.32 | 6.69 |

| 8 | RSN-1100 | Kobe, Japan | 1995 | Abeno | 0.31 | 6.90 |

| 9 | RSN-4840 | Chuetsu-oki, Japan | 2007 | Joetsu Kita | 0.30 | 6.80 |

| 10 | RSN-6886 | Darfield, New Zealand | 2010 | Canterbury Aero Club | 0.35 | 7.00 |

| Damage State | Type | No Damage | LS 1 | LS 2 | LS 3 | LS 4 |

|---|---|---|---|---|---|---|

| Case 1 | Empirical method | PGA ≤ 0.14 | 0.14 < PGA ≤ 0.20 | 0.20 < PGA ≤ 0.25 | 0.25 < P GA ≤ 0.32 | PGA > 0.32 |

| Case 2 | Theoretical method | PGA ≤ 0.18 | 0.18 < PGA ≤ 0.34 | 0.34 < PGA ≤ 0.84 | PGA > 0.84 | - |

| Case 3 | Mean value | PGA ≤ 0.15 | 0.15 < PGA ≤ 0.23 | 0.23 < PGA ≤ 0.44 | 0.44 < PGA ≤ 0.64 | PGA > 0.64 |

| Case 4 | Empirical method | PGA ≤ 0.33 | 0.33 < PGA ≤ 0.52 | 0.52 < PGA ≤ 0.66 | 0.66 < PGA ≤ 0.78 | PGA > 0.78 |

| Case 5 | PGA ≤ 0.18 | 0.18 < PGA ≤ 0.27 | 0.27 < PGA ≤ 0.35 | 0.35 < PGA ≤ 0.48 | PGA > 0.48 | |

| Case 6 | Theoretical method | PGA ≤ 0.18 | 0.18 < PGA ≤ 0.33 | 0.33 < PGA ≤ 0.78 | PGA > 0.78 | - |

| Case 7 | Mean value | PGA ≤ 0.18 | 0.18 < PGA ≤ 0.28 | 0.28 < PGA ≤ 0.48 | 0.48 < PGA ≤ 0.66 | PGA > 0.66 |

| Type | When the Extent of Damage Is Low (LS1 and LS2) | When the Extent of Damage Is Significant (LS3 and LS4) |

|---|---|---|

| Security | Case 5, Case 6, and Case 7 | Case 2 and Case 6 |

| Economy | Case 1 | Case 1 and Case 5 |

| Type | LS1 | LS2 | LS3 | LS4 |

|---|---|---|---|---|

| Security | Case 1 | |||

| Economy | Case 3 | Case 5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Guo, A. Comparison of Damage Indexes for Assessing Seismic Fragility of Bearings in an Offshore Bridge. Appl. Sci. 2023, 13, 7494. https://doi.org/10.3390/app13137494

Yan J, Guo A. Comparison of Damage Indexes for Assessing Seismic Fragility of Bearings in an Offshore Bridge. Applied Sciences. 2023; 13(13):7494. https://doi.org/10.3390/app13137494

Chicago/Turabian StyleYan, Jialei, and Anxin Guo. 2023. "Comparison of Damage Indexes for Assessing Seismic Fragility of Bearings in an Offshore Bridge" Applied Sciences 13, no. 13: 7494. https://doi.org/10.3390/app13137494

APA StyleYan, J., & Guo, A. (2023). Comparison of Damage Indexes for Assessing Seismic Fragility of Bearings in an Offshore Bridge. Applied Sciences, 13(13), 7494. https://doi.org/10.3390/app13137494