Modification of Values for the Horizontal Force of Tillage Implements Estimated from the ASABE Form Using an Artificial Neural Network

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sources of the Required Data for Modeling the Modified Horizontal Force via the ANN Method

2.2. The Methodology Steps of This Study

- Collecting the clay content in the soil (percentage), sand content in the soil (percentage), and silt content in the soil (percentage);

- Calculating the STN with Equation (4);

- Calculating the new—Fi-parameter with Equation (5);

- Collecting the tillage depth (d, cm), tillage speed (S, km/h), tractor power (TP, kW), initial soil bulk density (BD, g/cm3), the plow width (cm) for disk and moldboard plows, and the no. of tools for chisel plows;

- Calculating the WFC with Equation (6);

- Selecting the parameters in Equation (1) for chisel plows (Table 2) as follows: No. of tools, A = 91, B = 5.4, C = 0, tillage speed, and tillage depth;

- Calculating the horizontal force estimated from Equation (1) using the new—Fi-parameter for the chisel plows;

- Selecting the parameters in Equation (1) for the moldboard plow (Table 2) as follows: A = 652, B = 0, tillage speed, tillage depth, and plow width;

- Calculating the horizontal force estimated from Equation (1) using the new—Fi-parameter for moldboard plows;

- Selecting the parameters in Equation (1) for disk plows (Table 2) as follows: A = 124, B = 6.4, C = 0, tillage speed, tillage depth, and plow width;

- Calculating the horizontal force estimated from Equation (1) using the new—Fi-parameter for disk plows.

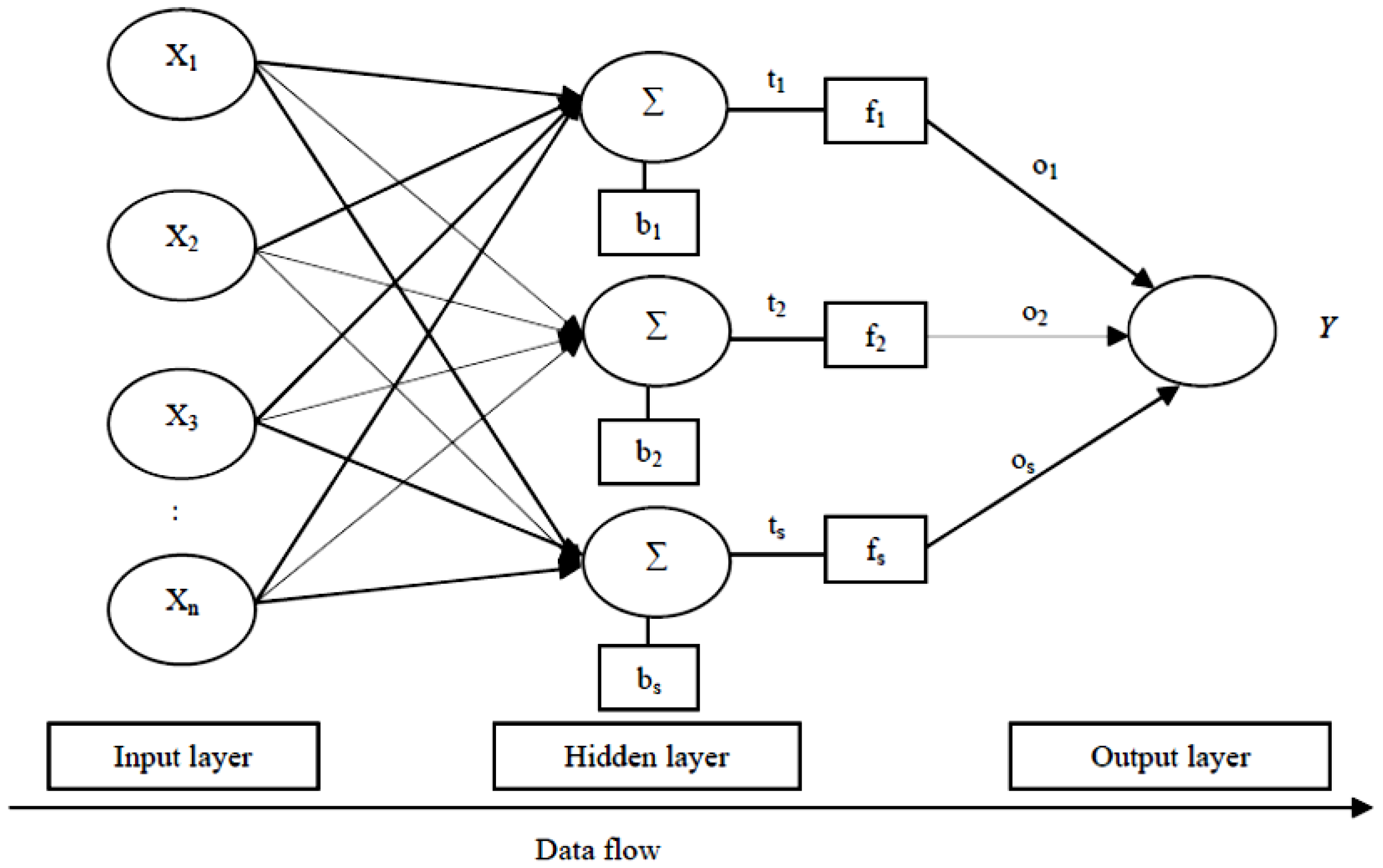

2.3. Artificial Neural Network Development

2.4. Calculation of Variable Contribution Percentage on Predictors

2.5. Criteria for Evaluating ANN Model Performance

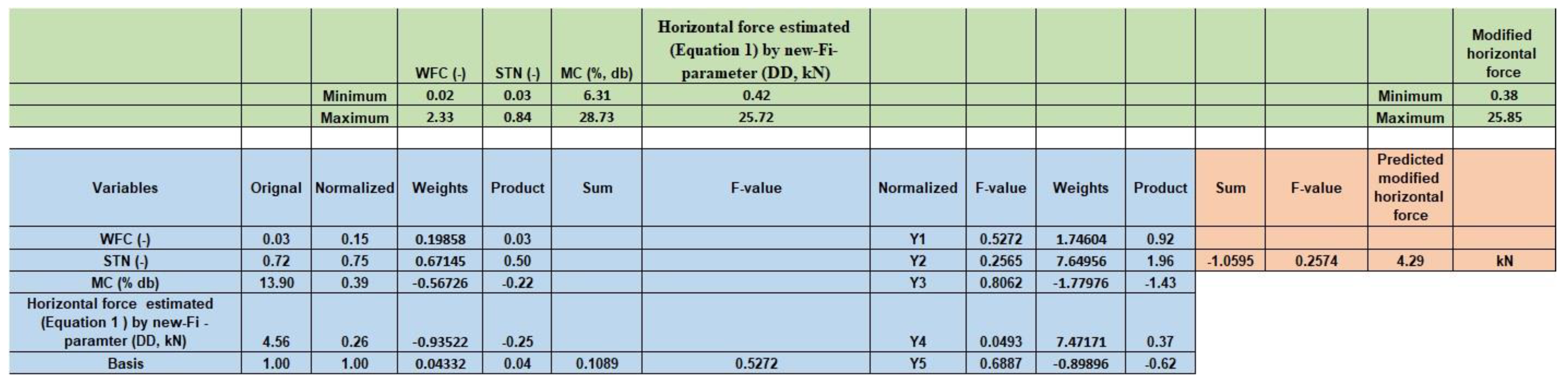

2.6. The Required Equations for Creating the Excel Spreadsheet

3. Results and Discussion

3.1. Analysis of the New—Fi-Parameter

3.2. Pearson’s Correlation Coefficients for Explanatory Variables

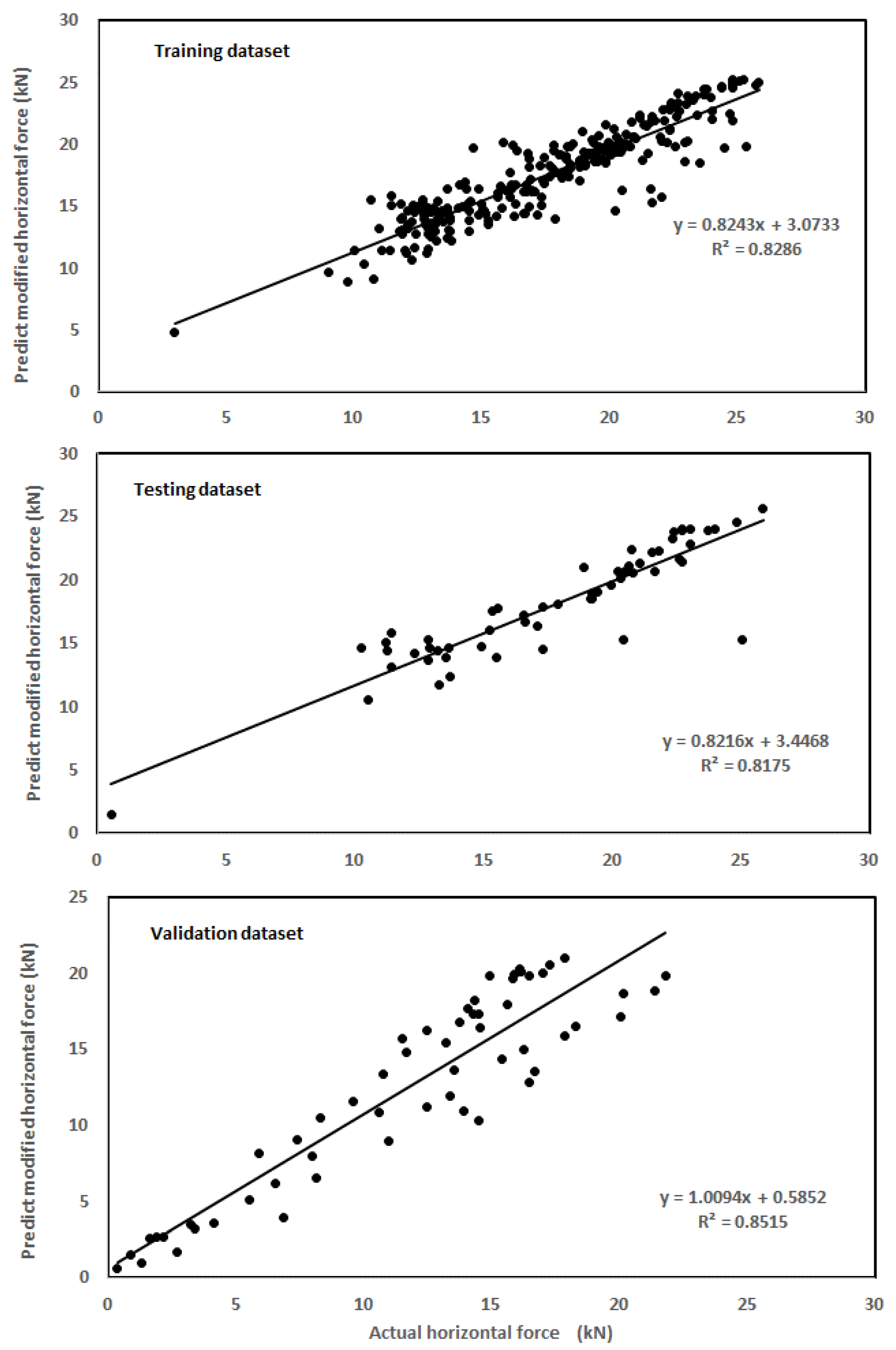

3.3. Performance of the Development of the ANN Model

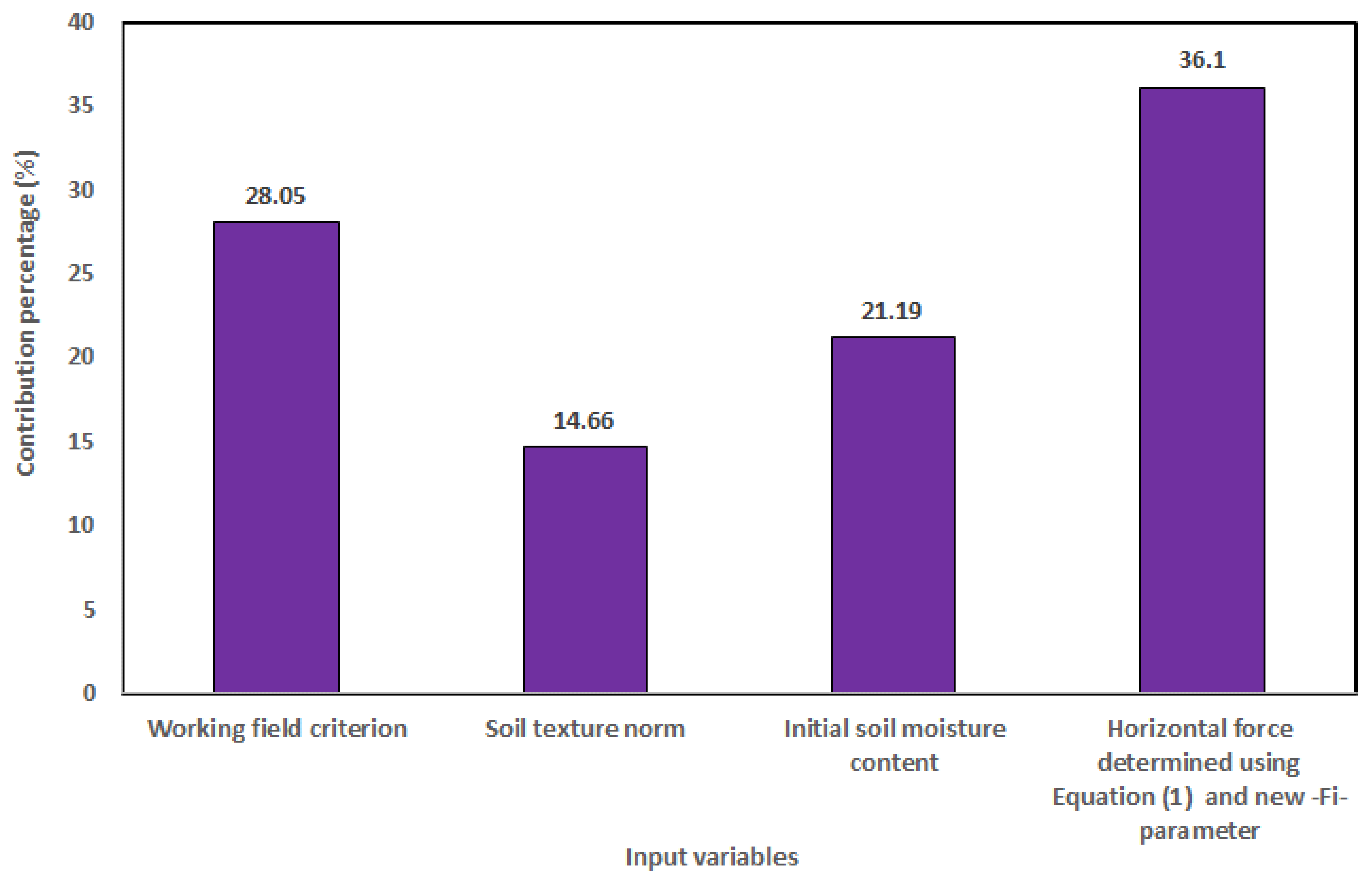

3.4. Examining the Effects of Independent Input Variables

3.5. Creating an Excel Spreadsheet for Calculation of the Modified Horizontal Force (MHF)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nkakini, S.O.; Vurasi, N.M. Effects of moisture content, bulk density and tractor forward speeds on energy requirement of disc plough. Int. J. Adv. Res. Eng. Technol. (IJARET) 2015, 6, 69–79. [Google Scholar]

- Szostek, M.; Szpunar-Krok, E.; Pawlak, R.; Stanek-Tarkowska, J.; Ilek, A. Effect of different tillage systems on soil organic carbon and enzymatic activity. Agronomy 2022, 12, 208. [Google Scholar] [CrossRef]

- Gajda, A.M.; Czyż, E.A.; Klimkowicz-Pawlas, A. Effects of different tillage intensities on physicochemical and microbial properties of a Eutric Fluvisol Soil. Agronomy 2021, 11, 1497. [Google Scholar] [CrossRef]

- Wandkar, S.; Jadhav, P.P.; Gholap, B.S.; Gonjari, V.V. Influence of forward speed and tillage depth on draft of primary tillage implements in sandy loam soil. Int. Agric. Eng. J. 2013, 22, 26–30. [Google Scholar]

- Al-Suhaibani, S.A. Use Efficiency of Farm Machinery in Saudi Arabia; ASAE Paper No. 92-1044; ASAE: St. Joseph, MI, USA, 1992. [Google Scholar]

- Jyoti, B.; Ram Reddy, K.V.S.; Sawant, C.P.; Pandirwar, A.P.; Potdar, R.R.; Randhe, R.D. Predicting draft requirement of tillage implements using pull type load cell in Southern Region of Andhra Pradesh, India. Int. J. Curr. Microbiol. Appl. Sci. (IJCMAS) 2019, 8, 606–612. [Google Scholar] [CrossRef]

- Azimi-Nejadian, H.; Karparvarfard, S.H.; Naderi-Boldaji, M.; Rahmanian-Koushkaki, H. Combined finite element and statistical models for predicting force components on a cylindrical mouldboard plough. Biosyst. Eng. 2019, 186, 168–181. [Google Scholar] [CrossRef]

- Godwin, R.J. A review of the effect of implement geometry on soil failure and implement forces. Soil Tillage Res. 2007, 97, 331–340. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, M.; Shahgoli, G.; Abbaspour-Gilandeh, Y.; Herrera-Miranda, M.A.; Hernández-Hernández, J.L.; Herrera-Miranda, I. Measuring and comparing forces acting on moldboard plow and para-plow with wing to replace moldboard plow with para-plow for tillage and modeling it using adaptive neuro-fuzzy interface system (ANFIS). Agriculture 2020, 10, 633. [Google Scholar] [CrossRef]

- Jiang, X.; Tong, J.; Ma, Y.; Sun, J. Development and verification of a mathematical model for the specific resistance of a curved subsoiler. Biosyst. Eng. 2020, 190, 107–119. [Google Scholar] [CrossRef]

- Alameri, H.; Almaliki, S. Designing an electronic system to measure the performance indicators of the tractor-implement system. Ann. For. Res. 2022, 65, 6182–6200. [Google Scholar]

- ASABE Standards. Agricultural Machinery Management Data; ASAE D497.7, MAR2011 (R2015); American Society of Agricultural and Biological Engineers ASABE: St. Joseph, MI, USA, 2015. [Google Scholar]

- McLaughlin, N.B.; Drury, C.F.; Reynolds, W.D.; Yang, X.M.; Li, Y.X.; Welacky, T.W.; Stewart, G. Energy inputs for conservation and conventional primary tillage implements in a clay loam soil. Trans. ASABE 2008, 51, 1153–1163. [Google Scholar] [CrossRef]

- Tianmanee, K.; Wongpichet, S.; Taira, E.; Ueno, M. The study of the soil texture parameter in the upland of Khon Kaen Province; Thailand. KKU Eng. J. 2016, 43, 354–358. [Google Scholar]

- Kumar, A.A.; Tewari, V.K.; Gupta, C.; Kumar, N. A visual basic program and instrumentation system for power and energy mapping of tractor implement. Eng. Agric. Environ. Food 2017, 10, 121–132. [Google Scholar] [CrossRef]

- Askari, M.; Komarizade, M.H.; Nikbakht, A.M.; Nobakht, N.; Teimourlou, R.F. A novel three-point hitch dynamometer to measure the draft requirement of mounted implements. Res. Agric. Eng. Czech Acad. Agric. Sci. 2011, 57, 128–136. [Google Scholar] [CrossRef] [Green Version]

- Igoni, A.H.; Ekemube, R.A.; Nkakini, S.O. Predicting tractor fuel consumption during ridging on a sandy loam soil in a humid tropical climate. J. Eng. Technol. Res. 2019, 11, 29–40. [Google Scholar]

- Shukla, D.; Pandey, T. Development of an android app for predicting stability of a tractor. Int. Adv. Res. J. Sci. Eng. Technol. 2020, 7, 45–55. [Google Scholar]

- Sadek, M.A.; Chen, Y.; Zeng, Z. Draft force prediction for a high-speed disc implement using discrete element modelling. Biosyst. Eng. 2021, 202, 133–141. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, T.J.; Kim, Y.J.; Lee, S.D.; Park, S.U.; Kim, W.S. Development of a real-time tillage depth measurement system for agricultural tractors: Application to the effect analysis of tillage depth on draft force during plow tillage. Sensors 2020, 20, 912. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ishola, T.A.; Ogunlela, A.O.; Abubakar, M.S. An object-oriented program for matching tractors and implements. Int. J. Eng. Technol. IJET-IJENS 2010, 10, 1–6. [Google Scholar]

- Kim, Y.S.; Siddique, M.A.; Kim, W.S.; Kim, Y.J.; Lee, S.D.; Lee, D.K.; Hwang, S.J.; Nam, J.S.; Park, S.U.; Lim, R.G. DEM simulation for draft force prediction of moldboard plow according to the tillage depth in cohesive soil. Comput. Electron. Agric. 2021, 189, 106368. [Google Scholar] [CrossRef]

- Okoko, P.; Ajav, E.A.; Olosunde, W.A. Draft and power requirements for some tillage implements operating in clay loam soil. Agric. Eng. Int. CIGR J. 2018, 20, 95–102. [Google Scholar]

- Ranjbar, I.; Rashidi, M.; Najjarzadeh, I.; Niazkhani, A.; Niyazadeh, M. Modeling of moldboard plow draft force based on tillage depth and operation speed. Middle-East J. Sci. Res. 2013, 17, 891–897. [Google Scholar]

- Ibrahmi, A.; Bentaher, H.; Hbaieb, M.; Maalej, A.; Mouazen, A.M. Study the effect of tool geometry and operational conditions on mouldboard plough forces and energy requirement: Part 1. Finite element simulation. Comput. Electron. Agric. 2015, 117, 258–267. [Google Scholar] [CrossRef]

- Mak, J.; Chen, Y. Simulation of draft forces of a sweep in a loamy sand soil using the discrete element method. Can. Biosyst. Eng. 2015, 56, 2.1–2.7. [Google Scholar] [CrossRef]

- Ahmadi, I. Development and evaluation of a draft force calculator for moldboard plow using the laws of classical mechanics. Soil Tillage Res. 2016, 161, 129–134. [Google Scholar] [CrossRef]

- Roul, A.K.; Kushwaha, H.L. Modelling draft requirement of secondary tillage tools in vertisol. Pantnagar J. Res. 2020, 18, 180–187. [Google Scholar]

- Choi, Y.S.; Lee, K.S.; Park, W.Y. Application of a neural network to dynamic draft model. Agric. Biosyst. Eng. 2000, 1, 67–72. [Google Scholar]

- Roul, A.K.; Raheman, H.; Pansare, M.S.; Machavaram, R. Predicting the draught requirement of tillage implements in sandy clay loam soil using an artificial neural network. Biosyst. Eng. 2009, 104, 476–485. [Google Scholar] [CrossRef]

- Marakoǧlu, T.; Çarman, K. Fuzzy knowledge-based model for prediction of soil loosening and draft efficiency in tillage. J. Terramech. 2010, 47, 173–178. [Google Scholar] [CrossRef]

- Al-Hamed, S.A.; Wahby, M.F.; Al-Saqer, S.M.; Aboukarima, A.M.; Sayedahmed, A.A. Artificial neural network model for predicting draft and energy requirements of a disk plow. J. Anim. Plant Sci. 2013, 23, 1714–1724. [Google Scholar]

- Shafaei, S.M.; Loghavi, M.; Kamgar, S. A comparative study between mathematical models and the ANN data mining technique in draft force prediction of disk plow implement in clay loam soil. Agric. Eng. Int. CIGR J. 2018, 20, 71–79. [Google Scholar]

- Askari, M.; Abbaspour-Gilandeh, Y. Assessment of adaptive neuro-fuzzy inference system and response surface methodology approaches in draft force prediction of subsoiling tines. Soil Tillage Res. 2019, 194, 104338. [Google Scholar] [CrossRef]

- Al-Janobi, A.; Al-Hamed, S.; Aboukarima, A.; Almajhadi, Y. Modeling of draft and energy requirements of a moldboard plow using artificial neural networks based on two novel variables. Eng. Agríc. Jaboticab. 2020, 40, 363–373. [Google Scholar] [CrossRef]

- Al-Dosary, N.M.N.; Aboukarima, A.M.; Al-Hamed, S.A. Evaluation of artificial neural network to model performance attributes of a mechanization unit (tractor-chisel plow) under different working variables. Agriculture 2022, 12, 840. [Google Scholar] [CrossRef]

- Akbarnia, A.; Mohammadi, A.; Farhani, F.; Alimardani, R. Simulation of draft force of winged share tillage tool using artificial neural network model. Agric. Eng. Int. CIGR J. 2014, 16, 57–65. [Google Scholar]

- Pentoś, K.; Pieczarka, K. Applying an artificial neural network approach to the analysis of tractive properties in changing soil conditions. Soil Tillage Res. 2017, 165, 113–120. [Google Scholar] [CrossRef]

- Çarman, K.; Çıtıl, E.; Taner, A. Artificial neural network model for predicting specific draft force and fuel consumption requirement of a mouldboard plough. Selcuk. J. Agric. Food Sci. 2019, 33, 241–247. [Google Scholar] [CrossRef]

- Nitin, K.; Anil, K.; Amarjit, K.; Mukesh, S.; Vijaya, R. Prediction of tractor power take-off performance using artificial neural network. J. Krishi Vigyan 2022, 10, 251–258. [Google Scholar] [CrossRef]

- Raja, T.V.; Venkatachalapathy, R.T.; Kannan, A.; Bindu, K.A. Determination of best-fitted regression model for prediction of body weight in Attappady black goats. Int. J. Agric. Sci. 2015, 5, 423–457. [Google Scholar]

- Preethi, A.L.; Tarafdar, A.; Ahmad, S.F.; Panda, S.; Tamilarasan, K.; Ruchay, A.; Gaur, G.K. Weight prediction of landlly pigs from morphometric traits in different age classes using ANN and non-linear regression models. Agriculture 2023, 13, 362. [Google Scholar] [CrossRef]

- Cardei, P.; Muraru, S.L.; Sfiru, R.; Muraru, V. General structure of tillage draft force consequences in experimental and applicative researches. INMATH Agric. Eng. 2019, 59, 253. [Google Scholar]

- Askari, M.; Khalifahamzehghasem, S. Draft force inputs for primary and secondary tillage implements in a clay loam soil. World Appl. Sci. J. 2013, 21, 1789–1794. [Google Scholar]

- Ranjbarian, S.; Askari, M.; Jannatkhah, J. Performance of tractor and tillage implements in clay soil. J. Saudi Soc. Agric. Sci. 2017, 16, 154–162. [Google Scholar] [CrossRef] [Green Version]

- Askari, M.; Shahgholi, G.; Abbaspour-Gilandeh, Y.; Tash-Shamsabadi, H. The effect of new wings on subsoiler performance. Appl. Eng. Agric. 2016, 32, 353–362. [Google Scholar] [CrossRef]

- Abrahám, R.; Majdan, R.; Kollárová, K.; Tkáč, Z.; Hajdu, Š.; Kubík, L.; Masarovičová, S. Fatigue analysis of spike segment of special tractor wheels in terms of design improvement for Chernozem Soil. Agriculture 2022, 12, 471. [Google Scholar] [CrossRef]

- Okoko, P. Draft and Power Requirements of Some Tillage Implements for Selected Soils in Uyo Local Government Area of Akwa-Ibom State. Ph.D. Thesis, Department of Agricultural and Environmental Engineering, University of Ibadan, Ibadan, Nigeria, 2017. [Google Scholar]

- El Khadrawy, A.A. Estimating of Used Energy in the Production of Some Egyptian Crops. Master’s Thesis, Agricultural Mechanization Department, Faculty of Agriculture, Mansoura University, El-Mansoura, Egypt, 1990; pp. 71–140. [Google Scholar]

- Obaia, A.R.A. Agricultural Machinery Selection Based on Tillage Power Requirements. Master’s Thesis, Agricultural Mechanization Department, Faculty of Agriculture, Mansoura University, El-Mansoura, Egypt, 1991; pp. 139–143. [Google Scholar]

- Bahnas, O.T.S. Evaluation of Some Farm Machinery under the Egyptian Conditions. Ph.D. Thesis, Agricultural Mechanization Department, Faculty of Agriculture, Mansoura University, El-Mansoura, Egypt, 1999; pp. 17–147. [Google Scholar]

- El Sayed, R.A. Effects of a Combined Active and Passive Tillage Tools on Soil Compaction and the Required Energy. Master’s Thesis, Department of Agricultural Engineering, Ain Shams University, Cairo, Egypt, 2000; pp. 56–61. [Google Scholar]

- Ghazy, M.I.A. Soil Mechanics and Water. Master’s Thesis, Agricultural Mechanization Department, Faculty of Agriculture, Mansoura University, El-Mansoura, Egypt, 2000; pp. 82–133. [Google Scholar]

- Ahmed, M.M. Evaluation of Some Standards for Tillage Implement’s Draft Requirements in Soba Area, Khartoum State, Sudan. Master’s Thesis, Department of Agricultural Engineering, Faculty of Engineering, University of Khartoum, Khartoum, Sudan, 2009.

- Al-Suhaibani, N.A.; Al-Janobi, A.; Ghaly, A.E. Determination of kinetic parameters of a super heavy chisel plow under various operating conditions. Am. J. Appl. Sci. 2010, 7, 1148–1156. [Google Scholar] [CrossRef] [Green Version]

- Al-Suhaibani, S.A.; Ghaly, A.E. Effect of plowing depth of tillage and forward speed on the performance of a medium size chisel plow operating in a sandy soil. Am. J. Agric. Biol. Sci. (ASABE) 2010, 5, 247–255. [Google Scholar] [CrossRef] [Green Version]

- Nkakini, S.O. Draught force requirements of a disc plough at various tractor forward speeds in loamy sand soil, during ploughing. Int. J. Adv. Res. Eng. Technol. (IJARET) 2015, 6, 52–68. [Google Scholar]

- Oskoui, K.E.; Harvey, S.J. Predicting Cone Index from Soil Physical Properties and Organic Matter Content. Paper No. 92-1056; American Society of Agricultural and Biological Engineers ASAE: St. Joseph, MI, USA, 1992; pp. 1–16. [Google Scholar]

- Kujawa, S.; Niedbała, G. Artificial neural networks in agriculture. Agriculture 2021, 11, 497. [Google Scholar] [CrossRef]

- Vesta Services, Inc. Qnet2000 Shareware; Vesta Services, Inc.: Winnetka, IL, USA, 2000. [Google Scholar]

- Ajagbe, W.O.; Ganiyu, A.A.; Owoyele, M.O.; Labiran, J.O. Modeling the effect of crude oil impacted sand on the properties of concrete using artificial neural networks. ISRN Civ. Eng. 2013, 2013, 609379. [Google Scholar] [CrossRef] [Green Version]

- Cao, M.; Qiao, P. Neural network committee-based sensitivity analysis strategy for geotechnical engineering problems. Neural Comput. Appl. 2008, 17, 509–519. [Google Scholar] [CrossRef]

- De Oña, J.; Garrido, C. Extracting the contribution of independent variables in neural network models: A new approach to handle instability. Neural Comput. Appl. 2014, 25, 859–869. [Google Scholar] [CrossRef]

- Brandić, I.; Pezo, L.; Bilandžija, N.; Peter, A.; Šurić, J.; Voća, N. Artificial neural network as a tool for estimation of the higher heating value of miscanthus based on ultimate analysis. Mathematics 2022, 10, 3732. [Google Scholar] [CrossRef]

- Kim, T.K. T test as a parametric statistic. Korean J. Anesth. 2015, 68, 540–546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Załuska, M.; Gładyszewska-Fiedoruk, K. Regression model of PM2.5 concentration in a single-family house. Sustainability 2020, 12, 5952. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Fazeli, M.; Roshanianfard, A.; Hernández-Hernández, J.; Penna, A.F.; Herrera-Miranda, I. Effect of different working and tool parameters on performance of several types of cultivators. Agriculture 2020, 10, 145. [Google Scholar] [CrossRef]

- Ndisya, J.; Gitau, A.; Mbuge, D.; Hiuhu, A. The effect of the operational parameters on the draft requirement of ripping in a sandy clay soil. Open J. Optim. 2016, 5, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Jebur, H.; Alsayyah, Y. Study of the soil moisture content and the tractor speed on the performance efficiency of the machinery unit. J. Agric. Vet. Sci. 2017, 10, 65–70. [Google Scholar] [CrossRef]

- Manikandan, G.; Shridar, B.; Jesudas, D.M. Draft measurement of five tyne duck foot plough in clay soil. J. Appl. Nat. Sci. 2021, 13, 73–79. [Google Scholar] [CrossRef]

- Elshami, O.M.E. Tillage, Draft, and Power as Influenced by Soil Moisture Content, Tractor forward Speed, and Plowing Depth in New Halfa Agricultural Scheme (Sudan). Ph.D. Thesis, University of Khartoum, Khartoum, Sudan, 2015. Available online: http://khartoumspace.uofk.edu/handle/123456789/12827 (accessed on 2 April 2023).

- Rashidi, M.; Lehmali, H.F.; Fayyazi, M.; Akbari, H.; Jaberinasab, B. Effect of soil moisture content, tillage depth and forward speed on draft force of double action disc harrow. Am.-Eurasian J. Agric. Environ. Sci. 2013, 13, 1124–1128. [Google Scholar]

- Novak, P.; Chyba, J.; Kumhala, F.; Prochazka, P. Measurement of stubble cultivator draught force under different soil conditions. Agron. Res. 2014, 12, 135–142. [Google Scholar]

- Chen, Y.; Munkholm, L.J.; Nyord, T. A discrete element model for soil–sweep interaction in three different soils. Soil Tillage Res. 2013, 126, 34–41. [Google Scholar] [CrossRef]

- Shahin, M.A. State-of-the-art review of some artificial intelligence applications in pile foundations. Geoscience Frontiers 2016, 7, 33–44. [Google Scholar] [CrossRef] [Green Version]

- Onoda, T. Neural Network Information Criterion for the Optimal Number of Hidden Units. In Proceedings of the International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; pp. 275–280. [Google Scholar]

- Hecht-Nielsen, R. Theory of the Backpropagation Neural Network. In Proceedings of the International Joint Conference on Neural Networks (IJCNN), Washington, DC, USA, 6 August 1989; pp. 593–605. [Google Scholar]

- Ripley, B.D. Neural networks and related methods for classification. J. R. Stat. Soc. Ser. B (Methodology) 1994, 56, 409–456. [Google Scholar] [CrossRef]

- Gautam, V.K.; Pande, C.B.; Moharir, K.N.; Varade, A.M.; Rane, N.L.; Egbueri, J.C.; Alshehri, F. Prediction of sodium hazard of irrigation purpose using artificial neural network modelling. Sustainability 2023, 15, 7593. [Google Scholar] [CrossRef]

- Loke, E.; Warnaars, E.A.; Jacobsen, P.; Nelen, F.; Do Céu Almeida, M. Artificial neural networks as a tool in urban storm drainage. Water Sci. Technol. 1997, 36, 101–109. [Google Scholar] [CrossRef]

- Shehta, Y.M.; Nabil, A.M.; Gaber, K.A.; Saifeldeen, A.M.; Kamel, E.W. Predicting and optimizing tillage draft using artificial network technique. Arab Univ. J. Agric. Sci. 2023, 31, 15–27. [Google Scholar] [CrossRef]

| The Experimental Sites | Tractor Power (kW) | Tillage Depth (cm) | Tillage Speed (km/h) | Initial Soil Moisture Content (% db) | Initial Soil Bulk Density (g/cm3) | Number of Data Points (-) |

|---|---|---|---|---|---|---|

| First experimental site | 67 | 14.0 | 2.5, 3.8, 4.8 | 18.2 | 1.28 | 3 |

| Second experimental site | 82 | 10, 12, 14, 15 | 3.5, 4.8, 5.7 | 18.2 | 1.40 | 12 |

| 10, 12, 15 | 4.8 | 18.2 | 1.40 | 3 | ||

| Third experimental site | 82 | 10, 13, 15, 16 | 2.5, 3.4, 4.8 | 17.4 | 1.35 | 12 |

| 10, 14, 17, 18 | 2.4, 3.5, 4.6, 5.1 | 17.6 | 1.30 | 12 | ||

| 10, 13, 14, 16 | 2.5, 3.2, 5.1 | 20.1 | 1.38 | 12 | ||

| 9, 11, 14, 16 | 3.2, 3.7, 4.7, 6.9 | 19.8 | 1.36 | 16 | ||

| Total Data Points | 70 | |||||

| Implement | Width | Machine Parameters | Soil Parameters | ||||

|---|---|---|---|---|---|---|---|

| Fi-Paramter | |||||||

| Units | A | B | C | F1 | F2 | F3 | |

| Fine | Medium | Coarse | |||||

| Soils With High Clay Content | Loamy Soils | Sandy Soils | |||||

| Moldboard plow | m | 652 | 0.0 | 5.1 | 1.0 | 0.70 | 0.45 |

| Chisel plow for 5 cm straight point | Tools | 91 | 5.4 | 0.0 | 1.0 | 0.85 | 0.65 |

| Disk gang, single for primary tillage | m | 124 | 6.4 | 0.0 | 1.0 | 0.88 | 0.78 |

| Implement | Soil Texture | Fi-Paramter Acording to Soil Texture |

|---|---|---|

| 5 cm straight point | Clay | 1 |

| Clay loam | 0.85 | |

| Sandy | 0.65 | |

| Sandy clay loam | 0.65 | |

| Silty clay | 0.85 | |

| Disk gang, single for primary tillage | Clay | 1 |

| Clay loam | 0.88 | |

| Loamy sand | 0.78 | |

| Sandy loam | 0.88 | |

| Moldboard plow | Clay | 1 |

| Clay loam | 0.7 |

| Working Parameters | Statistical Criteria | ||||

|---|---|---|---|---|---|

| Minimum | Maximum | Mean | Standard Deviation | No. of Data Points | |

| Tractor power (TP), (kW) | 44.76 | 104.44 | 60.77 | 17.47 | 377 |

| Initial soil moisture content (MC),(% db) | 6.31 | 28.73 | 20.20 | 4.41 | 377 |

| Initial soil bulk density (BD), (g/cm3) | 1.07 | 1.78 | 1.32 | 0.12 | 377 |

| Soil texture norm (STN),(-) | 0.03 | 0.84 | 0.50 | 0.27 | 377 |

| Old Fi-parameter (-) | 0.65 | 1.00 | 0.92 | 0.13 | 377 |

| New—Fi-parameter (-) | 0.713 | 1.003 | 0.924 | 0.108 | 377 |

| Tillage depth (d), (cm) | 10.00 | 30.00 | 20.47 | 4.52 | 377 |

| Tillage speed (S), (km/h) | 1.50 | 9.00 | 3.96 | 1.28 | 377 |

| Plow width (L), (cm) | 34.51 | 385.00 | 122.81 | 39.98 | 377 |

| No. of chisel tools (-) | 5 | 15 | 8.04 | 2.75 | 90 |

| Working field criterion (WFC), (-) | 0.019 | 2.328 | 0.134 | 0.213 | 377 |

| Horizontal force determined using Equation (1) and new—Fi-parameter (DD), (kN) | 0.42 | 25.72 | 14.88 | 4.33 | 377 |

| Measured horizontal force, (kN) | 0.38 | 25.85 | 16.92 | 5.01 | 377 |

| Weights | Input Variables | Basis (bi) | |||

|---|---|---|---|---|---|

| WFCN | STNN | MCN | DDN | ||

| W1j | 0.1986 | 0.6715 | −0.5673 | −0.9352 | 0.0433 |

| W2j | −5.7815 | −2.7118 | −3.9312 | −1.1553 | 3.6839 |

| W3j | 0.7341 | 0.8987 | 1.2139 | 0.1118 | 0.1409 |

| W4j | −11.6507 | −4.9535 | −1.0653 | 8.1518 | 0.8038 |

| W5j | 0.0264 | 0.5578 | 0.7884 | 0.1693 | 0.0233 |

| W6j | 1.4715 | −1.9147 | 7.9025 | 3.7653 | −5.9760 |

| W7j | −1.0805 | 1.9518 | 1.5860 | 1.4205 | 0.6643 |

| W8j | 0.8163 | 0.2288 | −0.5599 | −2.9521 | −0.3651 |

| W9j | −0.0259 | −0.0534 | 1.0571 | 0.6236 | −0.5466 |

| W10j | 2.7837 | 6.4499 | −18.5676 | −7.1681 | 5.6709 |

| W11j | 15.1903 | 5.0058 | −0.3010 | −4.4041 | −2.2968 |

| W12j | −1.2594 | 2.4725 | 1.7532 | 1.6324 | 0.4469 |

| W13j | −3.2729 | 6.3007 | 4.1236 | −1.4847 | −1.5261 |

| W14j | −0.0491 | 0.2883 | −1.8606 | −0.9303 | −1.1285 |

| W15j | −3.7142 | −4.2561 | 6.8057 | 1.8025 | 0.2621 |

| W16j | −0.2554 | 0.2380 | 0.8167 | 0.4158 | −0.1122 |

| W17j | −0.5280 | −1.2007 | 2.0617 | 0.8477 | 1.3782 |

| W18j | 9.2521 | 6.0748 | 1.6795 | −1.0984 | −1.7335 |

| W19j | 0.1171 | 0.7396 | 1.2181 | 0.0506 | 0.0642 |

| W20j | 0.1127 | 0.7203 | 1.0166 | −3.0348 | 1.3510 |

| Regression Statistics | Value |

|---|---|

| Coefficient of determination | 0.703 |

| Adjusted coefficient of determination | 0.702 |

| Standard error | 0.0706 |

| No. of observations | 377 |

| Input Variables | Working Field Criterion (WFC) | Soil Texture Norm (STN) | Initial Soil Moisture Content (MC) | Horizontal Force Determined Using Equation (1) Using New—Fi-Parameter (DD) |

|---|---|---|---|---|

| Working field criterion (WFC) | 1 | |||

| Soil texture norm (STN) | 0.018 | 1 | ||

| Initial soil moisture content (MC) | −0.181 | 0.346 | 1 | |

| Horizontal force determined using Equation (1) using new—Fi-parameter (DD) | −0.559 | 0.544 | 0.347 | 1 |

| Inputs | Output | ||||

|---|---|---|---|---|---|

| WFC: Combined Different Variables (-) | STN: Representing Soil Texture (-) | MC: Soil Moisture Content (% db) | DD Calculated Using ASABE form by the Modified Fi-Parameter (kN) | Measured: Draft Force Measured in the Field Experiments or from Previous Studies (kN) | Predicted: Modified Horizontal Force (kN) |

| 0.019 | 0.042 | 6.31 | 3.49 | 6.15 | 6.55 |

| 0.075 | 0.105 | 7.34 | 16.47 | 11.00 | 11.92 |

| 0.036 | 0.105 | 7.34 | 23.68 | 15.90 | 14.87 |

| 0.152 | 0.105 | 7.34 | 7.69 | 5.54 | 5.07 |

| 0.073 | 0.105 | 7.34 | 11.05 | 8.33 | 8.47 |

| 0.095 | 0.105 | 7.34 | 8.32 | 6.56 | 6.19 |

| 0.046 | 0.105 | 7.34 | 11.96 | 9.60 | 9.51 |

| 0.031 | 0.105 | 7.34 | 13.08 | 10.58 | 10.80 |

| 0.050 | 0.105 | 7.34 | 9.88 | 8.01 | 7.96 |

| 0.065 | 0.105 | 7.34 | 9.10 | 7.41 | 7.04 |

| 0.024 | 0.105 | 7.34 | 14.20 | 11.92 | 11.91 |

| 0.108 | 0.457 | 8.26 | 19.55 | 16.30 | 16.50 |

| 0.053 | 0.457 | 8.26 | 13.67 | 15.41 | 15.35 |

| 0.065 | 0.042 | 11.58 | 1.87 | 3.25 | 3.51 |

| 0.126 | 0.030 | 13.82 | 10.45 | 16.67 | 16.54 |

| 0.074 | 0.030 | 13.82 | 10.99 | 18.15 | 18.66 |

| 0.058 | 0.030 | 13.82 | 11.51 | 19.06 | 19.15 |

| 0.463 | 0.596 | 14.69 | 3.14 | 2.19 | 2.71 |

| 2.232 | 0.596 | 14.69 | 1.72 | 1.30 | 0.95 |

| 0.277 | 0.596 | 14.69 | 4.06 | 3.15 | 3.58 |

| 1.339 | 0.596 | 14.69 | 1.84 | 1.62 | 1.61 |

| 2.328 | 0.596 | 14.69 | 0.42 | 0.38 | 0.63 |

| Dataset | R2 | RMSE, kN | MAE, kN | No. of Data Points |

|---|---|---|---|---|

| Training | 0.8286 | 0.733 | 0.255 | 263 |

| Testing | 0.8175 | 2.105 | 1.349 | 57 |

| Validation | 0.8515 | 2.523 | 2.155 | 57 |

| Variable | Value | Unit |

|---|---|---|

| Tractor power | 40 | (kW) |

| Sand percentage | 25 | (%) |

| Silt percentage | 15 | (%) |

| Clay percentage | 60 | (%) |

| Soil texture | Clay | (-) |

| Soil texture norm | 0.705655 | (Dimensionless) |

| Working field criterion | 0.062147 | Dimensionless |

| Initial soil moisture content | 13 | (% db) |

| Soil bulk density | 1.35 | (g/cm3) |

| Tillage depth | 18 | (cm) |

| Tillage speed | 5 | (km/h) |

| Implement width | 1.08 | (m) |

| New—Fi-parameter | 1.000647 | (Dimensionless) |

| Measured horizontal force | 11.01 | (kN) |

| Horizontal force determined using Equation (1) and new—Fi-parameter (DD) | 12.68 | (kN) |

| Predicted MHF using ANN model based on the created Excel spreadsheet | 9.91 | (kN) |

| = 10% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naji Al-Dosary, N.M.; Aboukarima, A.M.; Al-Hamed, S.A.; Zayed, M.F.; Marey, S.A.; Kayad, A. Modification of Values for the Horizontal Force of Tillage Implements Estimated from the ASABE Form Using an Artificial Neural Network. Appl. Sci. 2023, 13, 7442. https://doi.org/10.3390/app13137442

Naji Al-Dosary NM, Aboukarima AM, Al-Hamed SA, Zayed MF, Marey SA, Kayad A. Modification of Values for the Horizontal Force of Tillage Implements Estimated from the ASABE Form Using an Artificial Neural Network. Applied Sciences. 2023; 13(13):7442. https://doi.org/10.3390/app13137442

Chicago/Turabian StyleNaji Al-Dosary, Naji Mordi, Abdulwahed M. Aboukarima, Saad A. Al-Hamed, Moamen F. Zayed, Samy A. Marey, and Ahmed Kayad. 2023. "Modification of Values for the Horizontal Force of Tillage Implements Estimated from the ASABE Form Using an Artificial Neural Network" Applied Sciences 13, no. 13: 7442. https://doi.org/10.3390/app13137442

APA StyleNaji Al-Dosary, N. M., Aboukarima, A. M., Al-Hamed, S. A., Zayed, M. F., Marey, S. A., & Kayad, A. (2023). Modification of Values for the Horizontal Force of Tillage Implements Estimated from the ASABE Form Using an Artificial Neural Network. Applied Sciences, 13(13), 7442. https://doi.org/10.3390/app13137442