Mechanical and Energy Evolution Characteristics of Sandstone under True Triaxial Cyclic Loading

Abstract

1. Introduction

2. Test Equipment and Programs

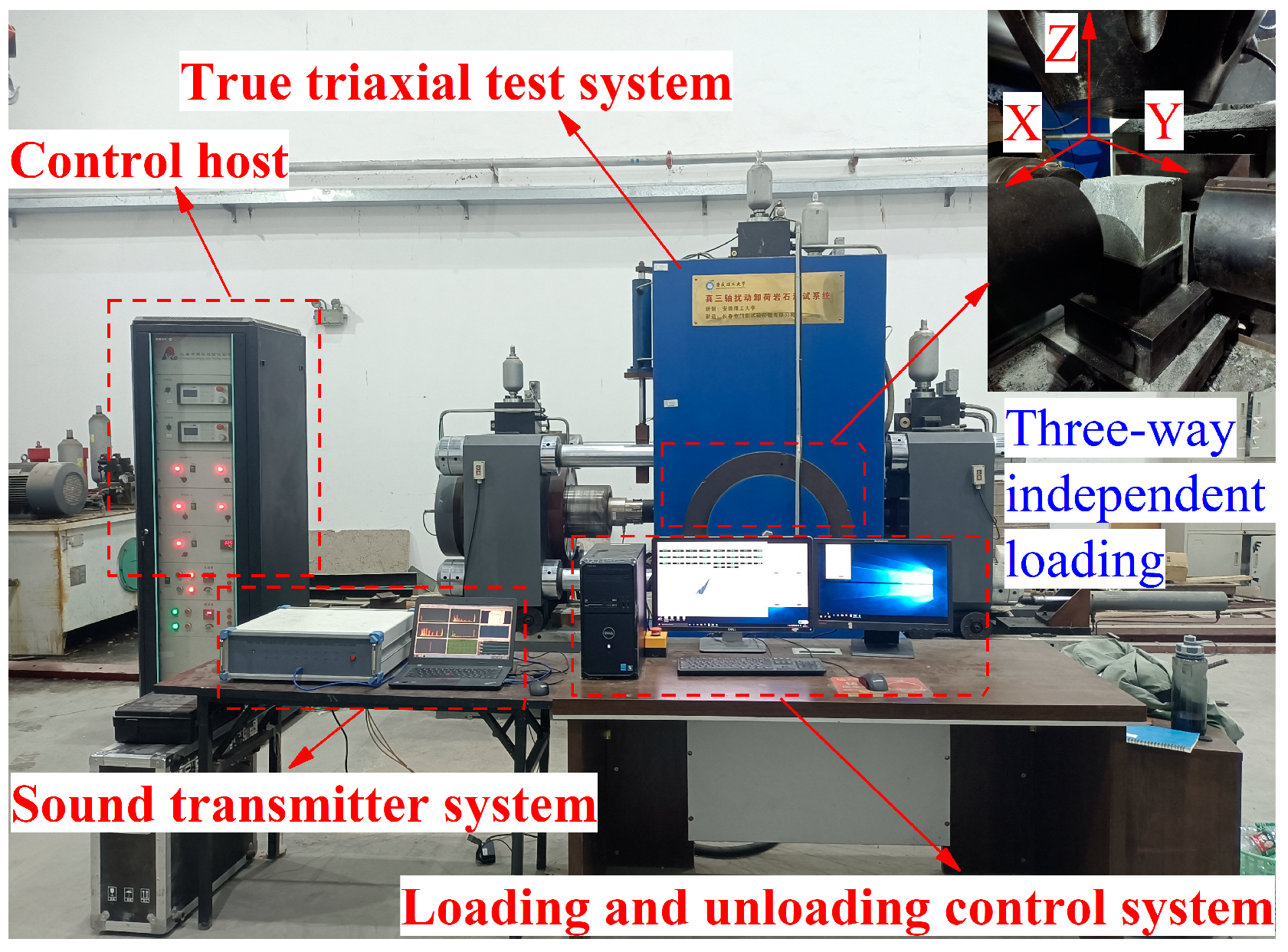

2.1. Test Equipment

- (1)

- The true triaxial testing machine consists of the main loading structure, horizontal and vertical loading modules, a 3D independent loading chamber, a pressure displacement sensor, a computer that can control loading and unloading, and software that can collect and analyze data. A digital servo controller controls all three directions. A maximum pressure of 5000 kN can be applied in the vertical (Z) direction, and a maximum pressure of 3000 kN can be applied in the horizontal (X, Y) direction. The control computer can realize the displacement or stress of one-way, two-way, three-way, step, and cyclic loading as well as unloading, and an axial disturbance test was conducted to examine the real rock mass under different loading and unloading paths of mechanical properties.

- (2)

- The acoustic emission (A.E.) monitoring system is Beijing Soft Island DS5, and it uses six A.E. probes to collect A.E. events, frequency, amplitude, energy, and other parameters in real time. In the test, the preamplifier was set to 40 dB. To minimize the influence of external interference on the test, the noise threshold value was set to 45 dB, and the sampling frequency was set between 1 kHz and 1 MHz to monitor the damage characteristics of the rock during the test.

2.2. Test Specimens

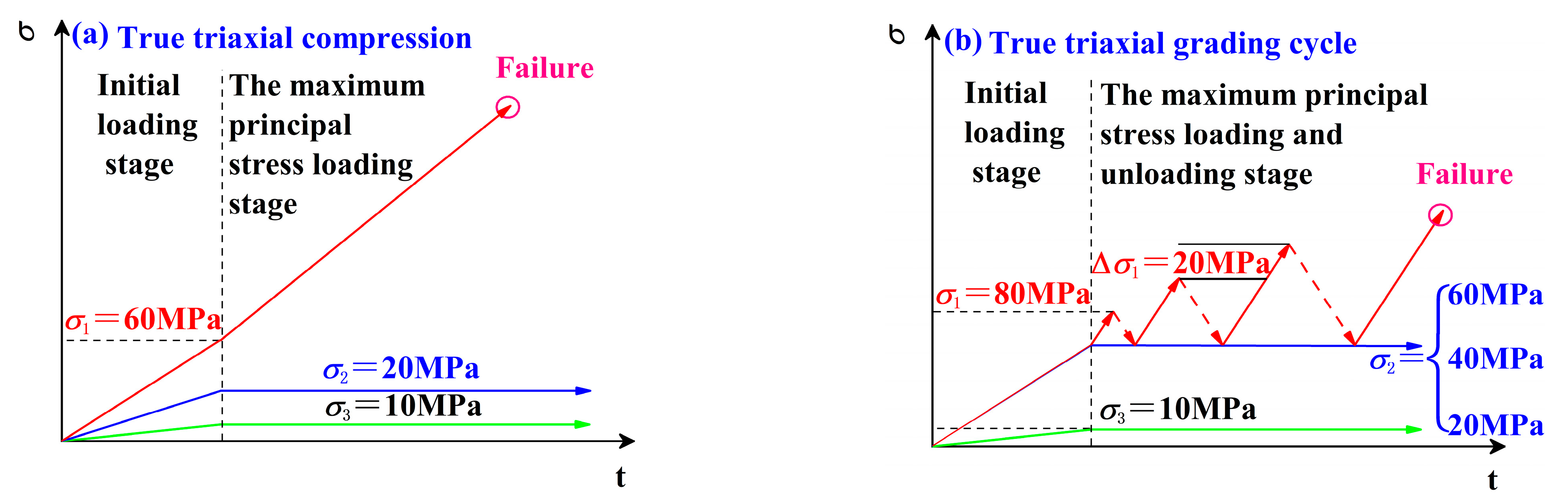

2.3. Test Methods and Contents

3. Test Results and Analysis

3.1. Analysis of Deformation and Failure Characteristics of Specimens

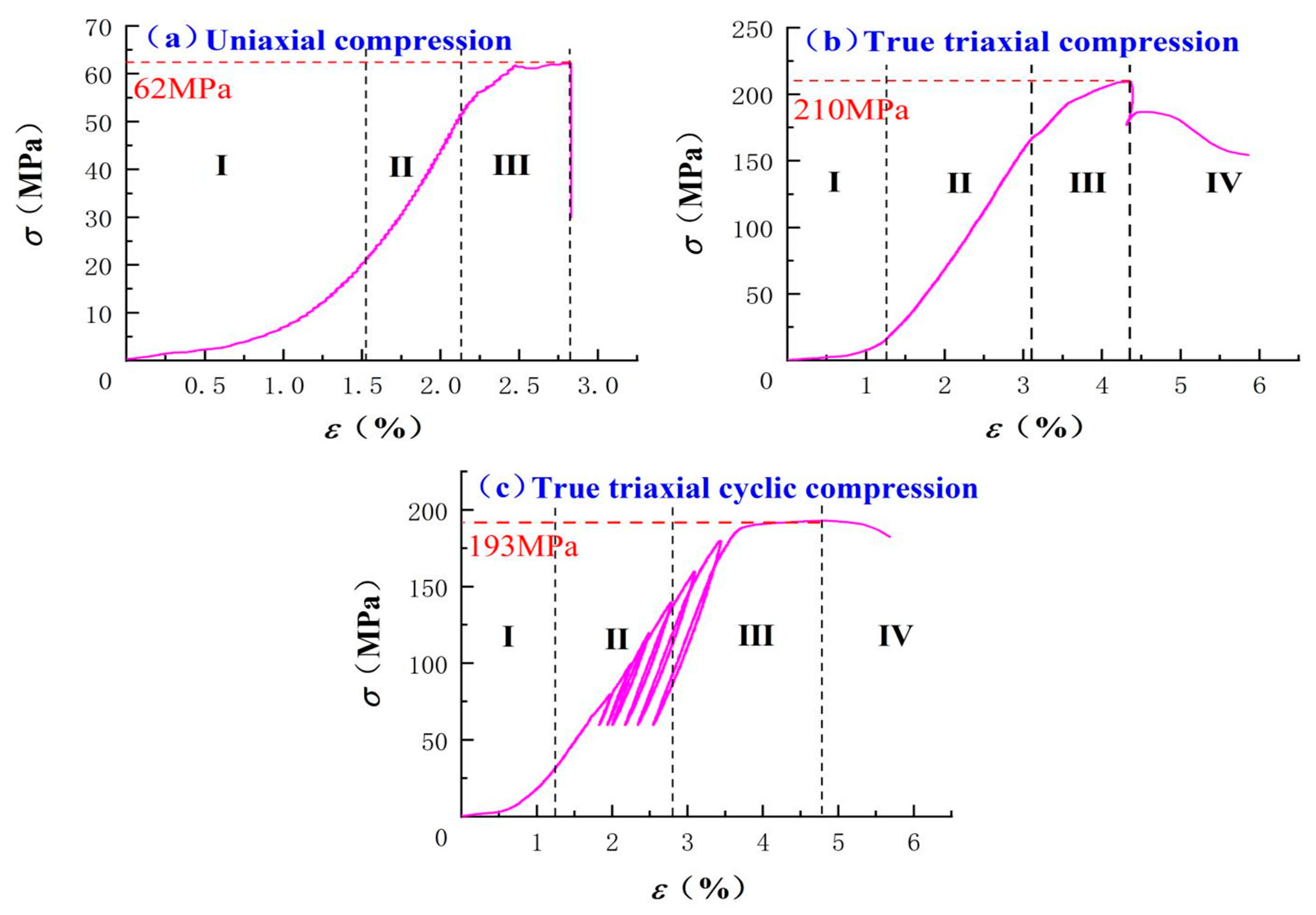

3.1.1. Strength and Deformation Analysis of Sandstone under Different Stress Paths

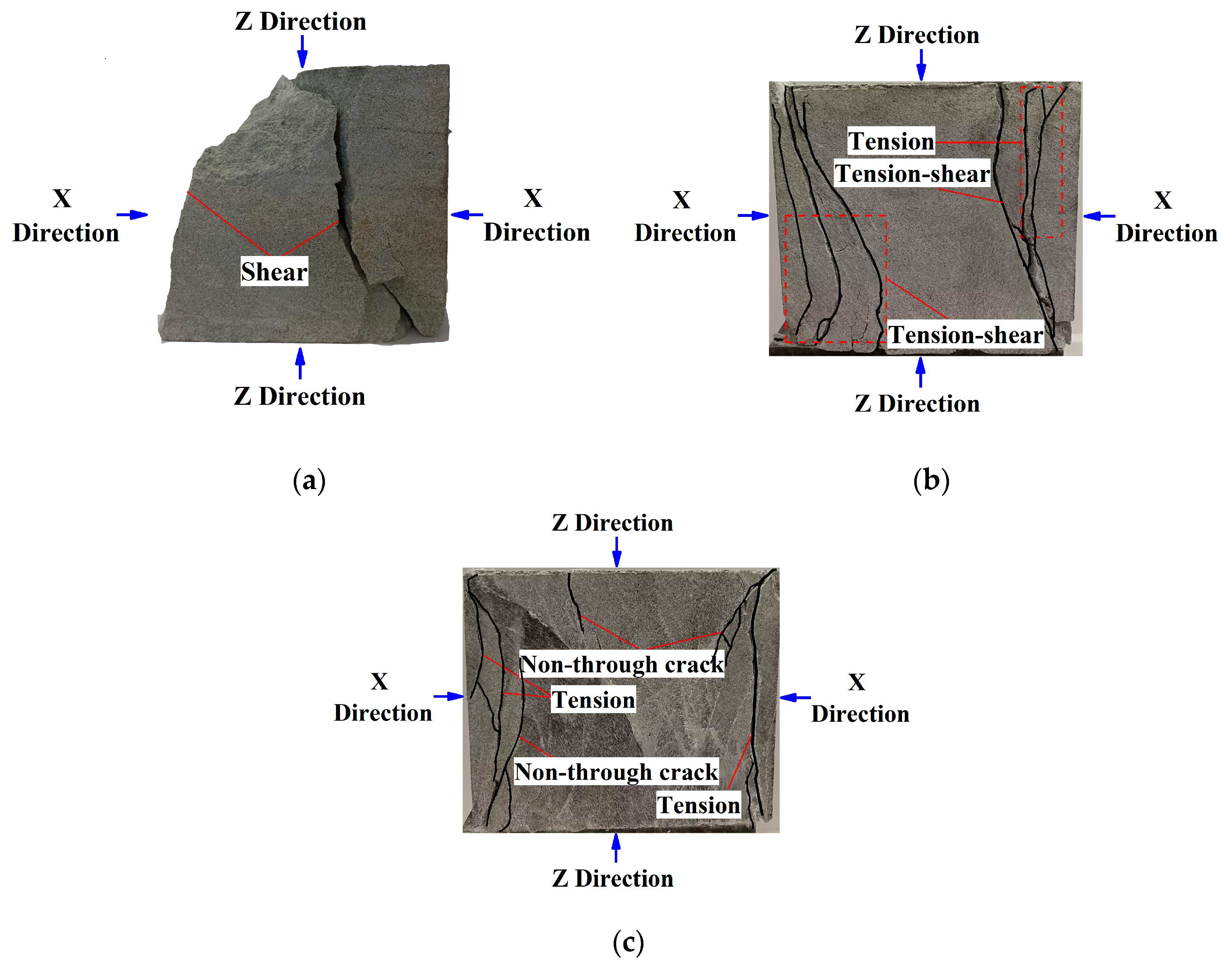

3.1.2. Analysis of Sandstone Failure Characteristics under Different Stress Paths

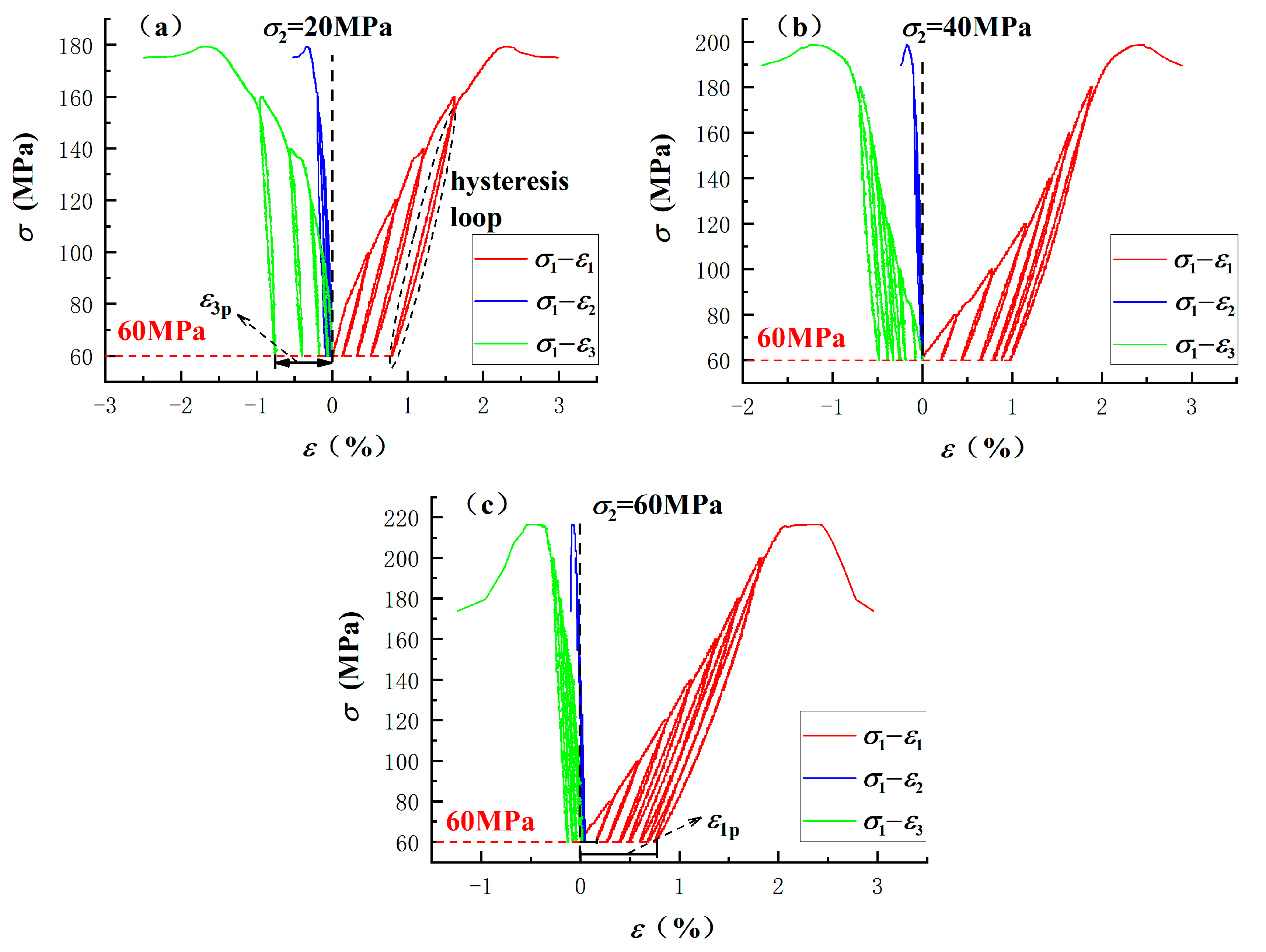

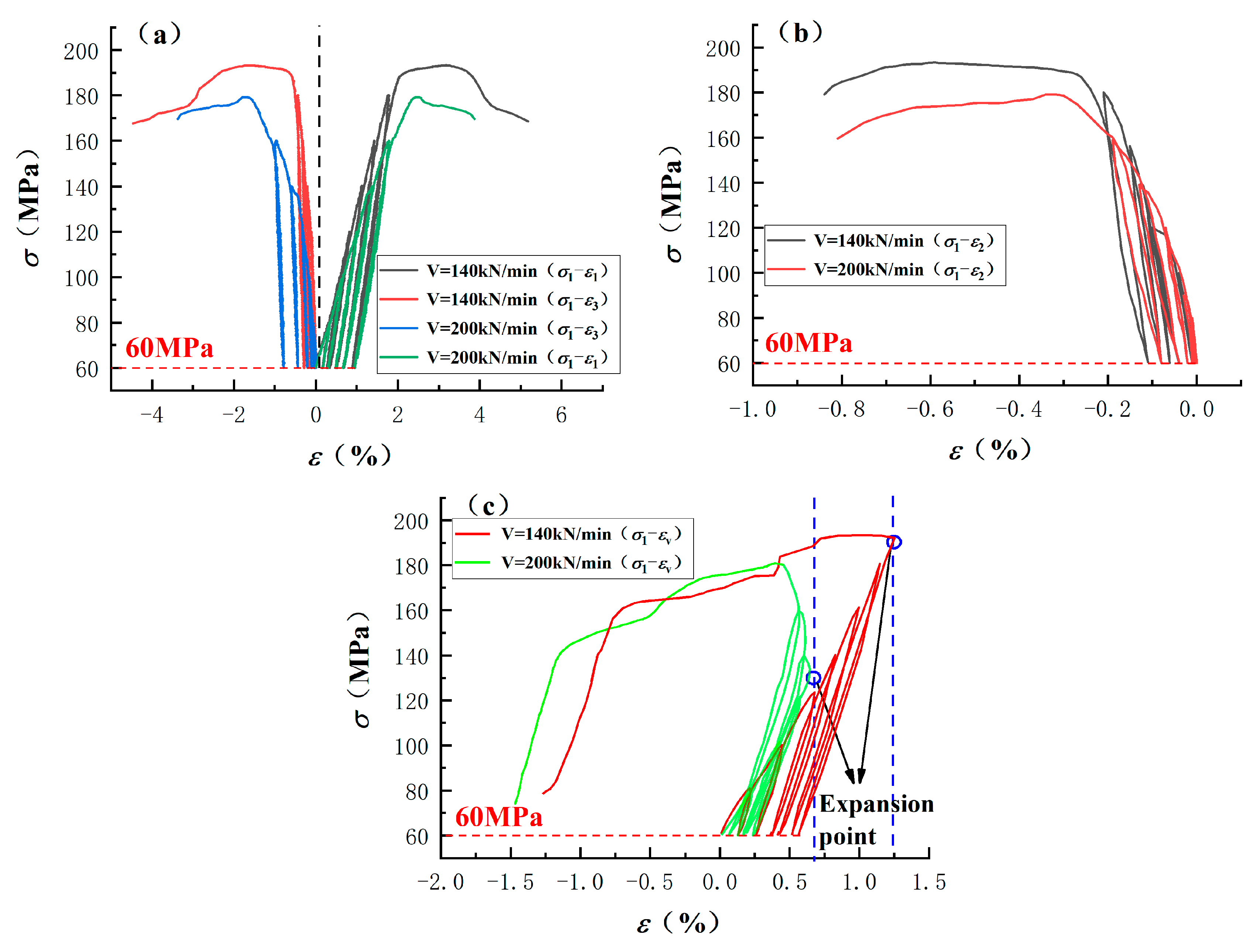

3.1.3. Strength and Deformation Analysis of Sandstone under Graded Cyclic Loading

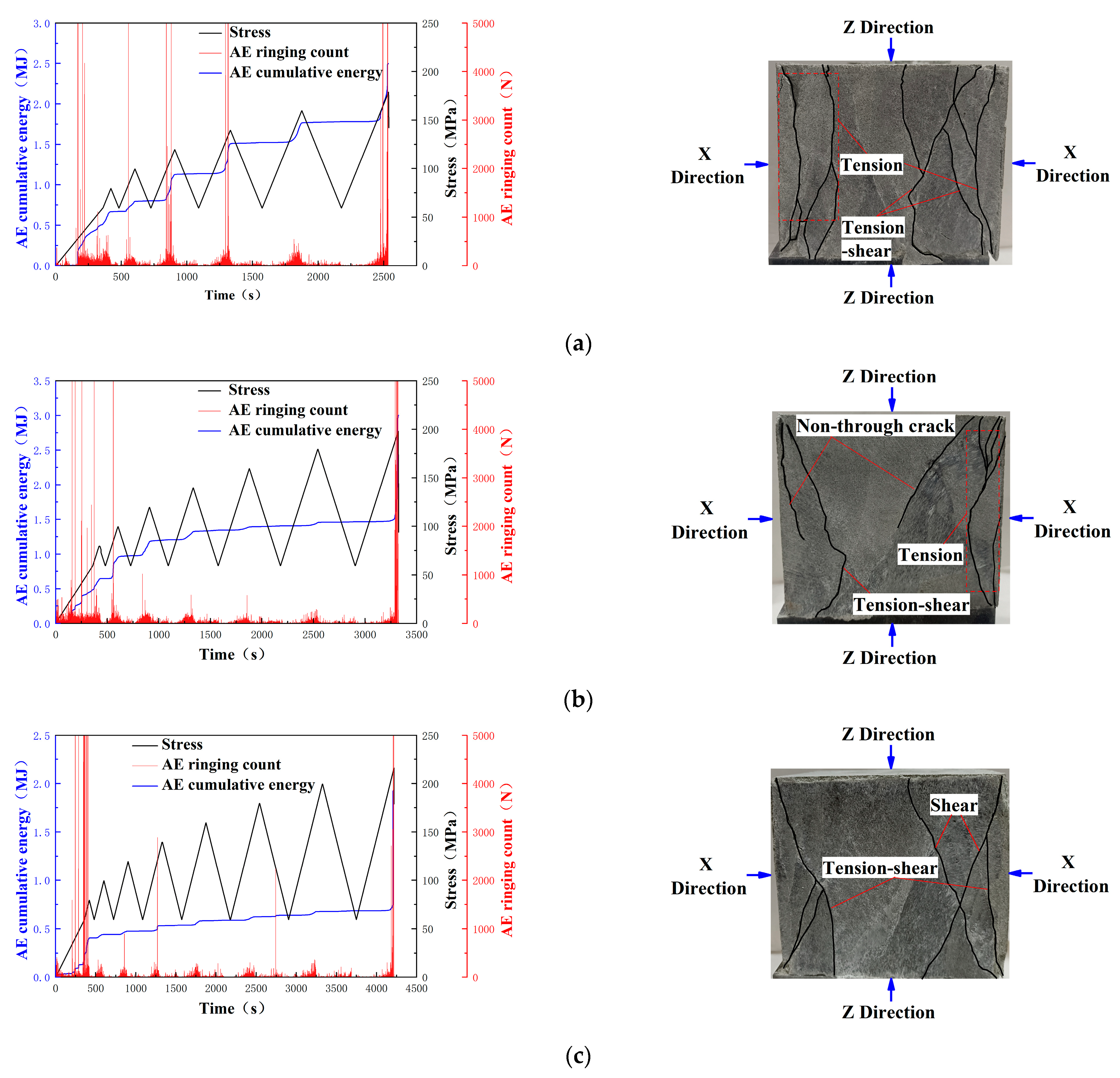

3.1.4. Analysis of Acoustic Emission and Failure Characteristics of Sandstone under Graded Cyclic Loading

3.2. Analysis of Energy Evolution and Damage Characteristics of Sandstone True Triaxial Loading and Unloading under Different Conditions

3.2.1. Definition of Rock Energy Parameters in the True Triaxial State

3.2.2. Energy Evolution Law of Maximum Principal Stress Direction under Different Conditions

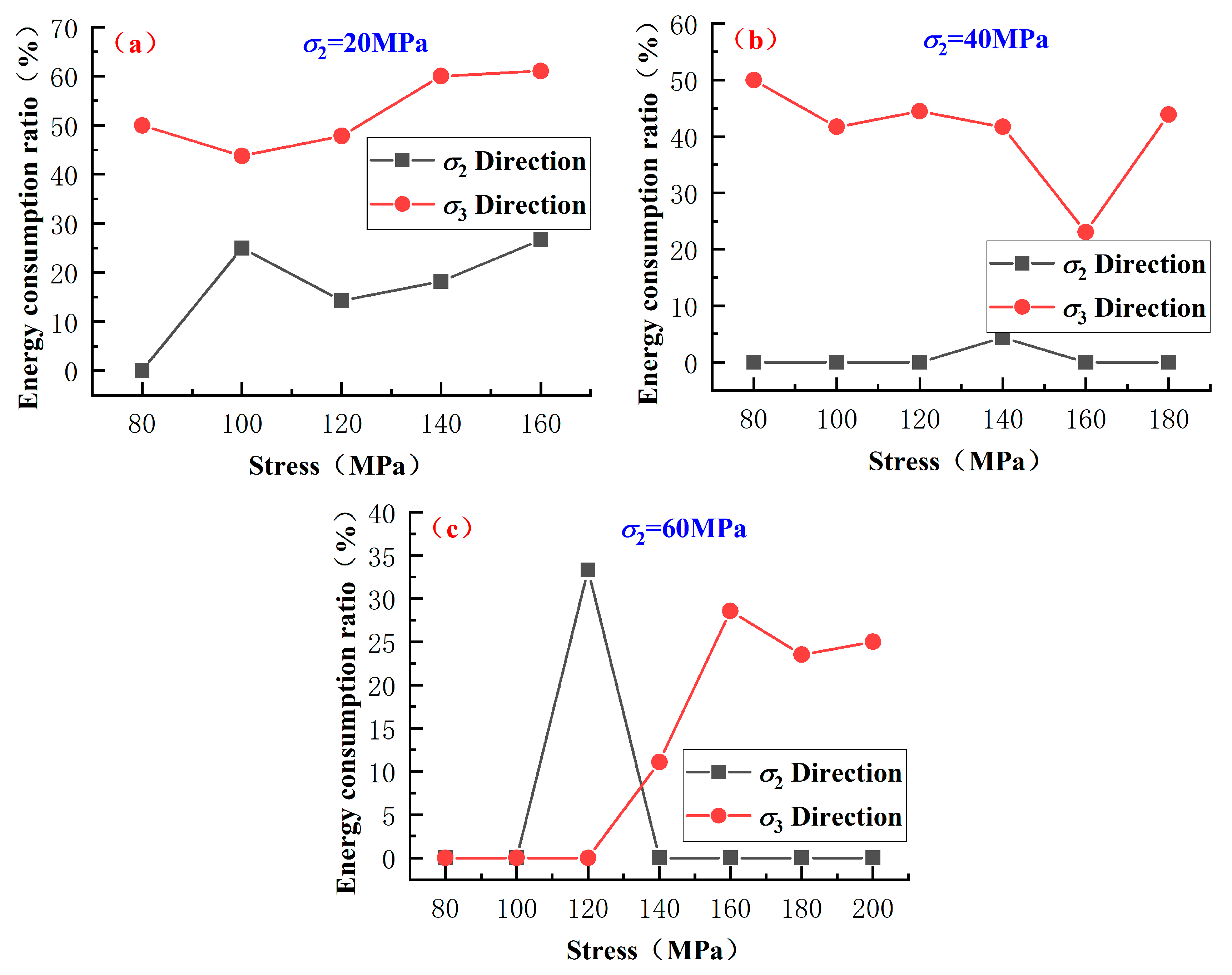

3.2.3. Energy Evolution Law of Medium and Minimum Principal Stress Directions under Different Conditions

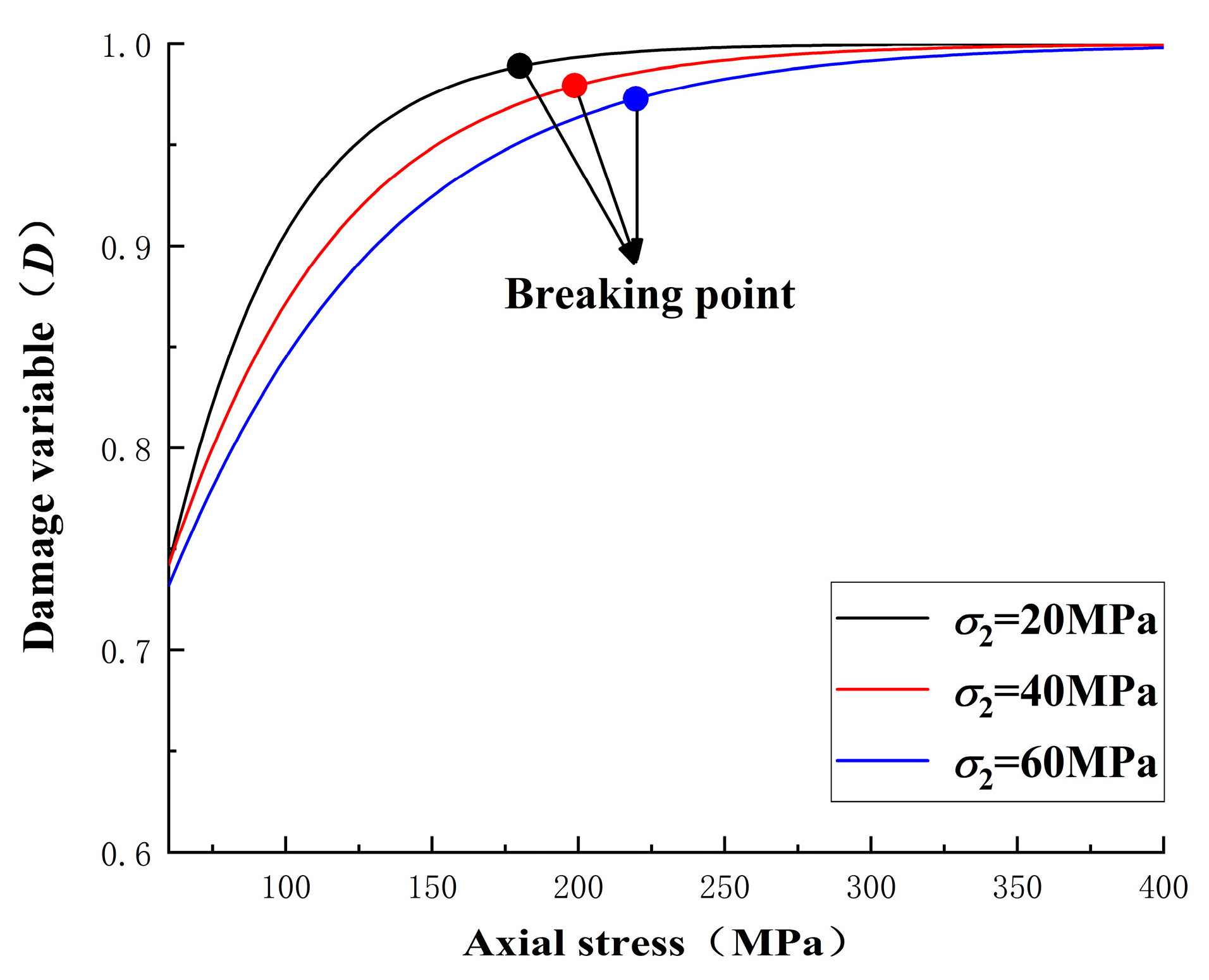

3.3. Dissipative Energy and Damage Evolution Law of Sandstone under Different Intermediate Principal Stresses

4. Conclusions

- Under the different stress paths, the axial bearing capacity and macroscopic failure characteristics of sandstone differed. The existence of confining pressure greatly improved the axial bearing capacity of the rock. The of sandstone under a true triaxial cycle was lower than that under true triaxial compression. Under uniaxial compression, sandstone mainly experienced shear failure. During true triaxial compression, sandstone was mainly subjected to tension–shear composite failure, and in the true triaxial cycle, sandstone mainly experienced tensile failure. This showed that the rock in the true triaxial environment in the project would reduce the axial strength of the rock and change its macroscopic failure characteristics from tensile–shear composite failure to tensile failure after repeated cyclic loading.

- In the process of true triaxial graded cyclic loading of sandstone, the stress–strain curves and failure characteristics under different conditions varied obviously. The larger was, the smaller the deformation in each principal stress direction was, and the failure mode gradually changed from tensile failure to shear failure. With the increase in the load rate, , , , and decreased when sandstone was destroyed. The expansion point was advanced, but the expansion capacity increased. The increase of could improve the strength of rock under a true triaxial environment. The lower loading and unloading rate could reduce the damage to the rock mass and improve the safety of the project.

- Under true triaxial cyclic loading, the input energy and elastic energy of sandstone in each principal stress direction increased nonlinearly. Similar to the direction of intermediate principal stress, in the two other principal stress directions, the dissipated energy increased nonlinearly with the increase in cyclic loading. Compared with the input energy and elastic energy in the and directions, the input energy and elastic energy in the direction increased with the increase in . On the basis of the definition of the energy parameters, an energy analysis method of true triaxial graded cyclic load was proposed, which has important guiding significance for the analysis of rock dynamic disasters.

- With graded cyclic load , the total dissipated energy of sandstone increased exponentially. Therefore, the damage variable equation was established by combining all the dissipated energies. The damage variable equation clearly described the damage evolution law of sandstone under different values. The larger was, the smaller the critical damage variable was. Therefore, the damage of sandstone under repeated loading and unloading could be reduced by reducing .

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martin, C.D.; Chandler, N.A. The progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B. Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int. J. Rock Mech. Min. Sci. 1999, 36, 361–380. [Google Scholar] [CrossRef]

- Qiu, S.L.; Feng, X.T.; Xiao, J.Q.; Zhang, C.Q. An experimental study on the pre-peak unloading damage evolution of marble. Rock Mech. Rock Eng. 2014, 47, 401–419. [Google Scholar] [CrossRef]

- Fu, J.W.; Zhang, X.Z.; Zhu, W.S.; Chen, K.; Guan, J.F. Simulating progressive failure in brittle jointed rock masses using a modified elastic-brittle model and the application. Eng. Fract. Mech. 2017, 178, 212–230. [Google Scholar] [CrossRef]

- Yintong, G.; Kelie, Z.; Guanhua, S.; Chunhe, Y.; Hongling, M.; Guimin, Z. Experimental study of fatigue deformation and damage characteristics of salt rock under cyclic loading. Rock Soil Mech. 2011, 32, 1353–1359. (In Chinese) [Google Scholar]

- Xiurun, G.; Yingfa, L. Discussion on fatigue failure and irreversible rock deformation under cyclic loading. Chin. J. Geotech. Eng. 1992, 14, 56–60. (In Chinese) [Google Scholar]

- Xiurun, G.; Yu, J.; Yunde, L.; Jianxi, R. Testing study on fatigue deformation law of rock under cyclic loading. Chin. J. Rock Mech. Eng. 2003, 22, 1581–1585. (In Chinese) [Google Scholar]

- Yongjie, Y.; Yang, S.; Jun, C. Experimental study on characteristics of strength and deformation of coal under cyclic loading. Chin. J. Rock Mech. Eng. 2007, 26, 201–205. (In Chinese) [Google Scholar]

- Liu, E.L.; Huang, R.Q.; He, S.M. Effects of frequency on the dynamic properties of intact rock samples subjected to cyclic loading under confining pressure conditions. Rock Mech. Rock Eng. 2012, 45, 89–102. [Google Scholar] [CrossRef]

- Fuenkajom, K.; Phueakphum, D. Effects of cyclic loading on mechanical properties of Maha Sarakham salt. Eng. Geol. 2010, 112, 43–52. [Google Scholar] [CrossRef]

- Xiaoquan, L.; Guangzhi, Y.; Bo, C. Experimental study on deformation and seepage properties of outburst coal samples under cyclic loading. Chin. J. Rock Mech. Eng. 2010, 29, 3498–3504. (In Chinese) [Google Scholar]

- Liu, Y.; Dai, F.; Dong, L.; Xu, N.W.; Feng, P. Experimental investigation on the fatigue mechanical properties of intermittently jointed rock models under cyclic uniaxial compression with different loading parameters. Rock Mech. Rock Eng. 2018, 51, 47–68. [Google Scholar] [CrossRef]

- Huafeng, D.; Yu, H.; Jianlin, L.; Zhe, W.; Xiaojing, Z.; Anlong, H. The evolution of sandstone energy dissipation under cyclic loading and unloading. Chin. J. Rock Mech. Eng. 2016, 35, 2869–2875. (In Chinese) [Google Scholar]

- Meng, Q.; Zhang, M.; Han, L.; Nie, T. Experimental research on rock energy evolution under uniaxial cyclic loading and unloading compression. Geotech. Test. J. 2017, 41, 717–729. [Google Scholar] [CrossRef]

- Song, D.Z.; Wang, E.Y.; Liu, J. Relationship between EMR and dissipated energy of coal rock m ass during cyclic loading process. Saf. Sci. 2012, 50, 751–760. [Google Scholar] [CrossRef]

- Dai, B.; Shan, Q.W.; Chen, Y.; Luo, X.Y. Mechanical and energy dissipation characteristics of granite under cyclic impact loading. J. Cent. South Univ. 2022, 29, 116–128. [Google Scholar] [CrossRef]

- Moji, K. Effect of the triaxial stress system on fracture and flow of rocks. Phys. Earth Planet. Inter. 1972, 5, 318–324. [Google Scholar]

- Baumgarten, L.; Konietzky, H. Investigations on the fracture behaviour of rocks in a triaxial compression test. In Proceedings of the ISRM International Symposium-EUROCK 2013, Wroclaw, Poland, 23–26 October 2013; pp. 861–866. [Google Scholar]

- Ivan, P. The Strength Criterion for Rocks Under True Triaxial Stress. Procedia Struct. Integr. 2021, 32, 166–172. [Google Scholar]

- Kwaniewski, M.; Takahashi, M.; Li, X. On the dilatant behavior of sandstone under true triaxial compression conditions. Publ. Inst. Geophys. Pol. Acad. Sci. Ser. M. Misc. 2002, 24, 321–324. [Google Scholar]

- Gao, Y.H.; Feng, X.T. Study on damage evolution of intact and jointed marble subjected to cyclic true triaxial loading. Eng. Fract. Mech. 2019, 215, 224–234. [Google Scholar] [CrossRef]

- Feng, X.T.; Gao, Y.H.; Zhang, X.W.; Wang, Z.F.; Zhang, Y.; Han, Q. Evolution of the mechanical and strength parameters of hard rocks in the true triaxial cyclic loading and unloading tests. Int. J. Rock Mech. Min. Sci. 2020, 131, 104349. [Google Scholar] [CrossRef]

- Tao, W.; Yourong, L.; Zheng, H.; Chaoying, N.; Kang, W. Energy variation and damage analysis of sandstone under loading and unloading conditions in the high-stress area. Geol. Sci. Technol. Info. 2015, 34, 200–206. (In Chinese) [Google Scholar]

- Duan, M.K.; Jiang, C.B.; Gan, Q.; Li, M.; Peng, K.; Zhang, W. Experimental investigation on the permeability, acoustic emission and energy dissipation of coal under tiered cyclic unloading (Article). J. Nat. Gas. Sci. Eng. 2020, 73, 103054. [Google Scholar] [CrossRef]

- Minke, D.; Changbao, J.; Huan, Y.; Tian, Y.; Binwei, N.; Donglin, S. Experimental research on energy dissipation and seepage properties of coal under loading-unloading conditions at different stress levels. Rock Soil Mech. 2018, 39, 1346–1354. (In Chinese) [Google Scholar]

- Jiang, C.B.; Duan, M.K.; Yin, G.Y.; Wang, J.G.; Xu, J.; Zhang, D.M.; Huang, G. Experimental study on seepage properties, AE characteristics, and energy dissipation of coal under tiered cyclic loading. Eng. Geol. 2017, 221, 114–123. [Google Scholar] [CrossRef]

- Duan, M.K.; Jiang, C.B.; Yin, W.M.; Yang, K.; Li, J.Z.; Liu, Q.J. Experimental study on mechanical and damage characteristics of coal under true triaxial cyclic disturbance. Eng. Geol. 2021, 295, 106445. [Google Scholar] [CrossRef]

- Xiaobin, Y.; Hong-ming, C.; Jiaqi, L.; Xin, H.; Chaogang, N. Energy consumption ratio evolution law of sandstones under triaxial cyclic loading. Rock Soil Mech. 2019, 40, 3751–3757. (In Chinese) [Google Scholar]

- Luo, S.; Gong, F.Q.; Li, L.L.; Peng, K. Linear energy storage and dissipation laws and damage evolution characteristics of rock under triaxial cyclic compression with different confining pressures. Trans. Nonferrous. Met. Soc. 2022, 10, 1–26. Available online: http://kns.cnki.net/kcms/detail/43.1239.TG.20220630.1050.010.html (accessed on 8 November 2022).

- Niu, S.J.; Ge, S.S.; Yang, D.F.; Dang, Y.H.; Yu, J.; Zhang, S. Mechanical properties and energy mechanism of saturated sandstones. J. Cent. South Univ. 2018, 25, 1447–1463. [Google Scholar] [CrossRef]

- Li, P.; Cai, M.F. Energy evolution mechanism and failure criteria of jointed surrounding rock under uniaxial compression. J. Cent. South Univ. 2021, 28, 1857–1874. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.L.; Liu, X.S.; Zhao, Z.H.; Fan, D.Y.; Purev, L. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal-rock composite samples. J. Cent. South Univ. 2021, 28, 3207–3222. [Google Scholar] [CrossRef]

- Feng, J.J.; Wang, E.Y.; Chen, X.; Ding, H.C. Energy dissipation rate: An indicator of coal deformation and failure under static and dynamic compressive loads. Int. J. Min. Sci. Technol. 2018, 28, 397–406. [Google Scholar] [CrossRef]

- Yang, H.; Sinha, S.K.; Feng, Y.; Mccallen, D.B.; Jeremic, B. Energy dissipation analysis of elastic–plastic materials. Comput. Methods Appl. Mech. Eng. 2018, 331, 309–326. [Google Scholar] [CrossRef]

- Jiang, X.; Bobo, L.; Ting, Z.; Dong, L.; Jie, C.; Guibing, Y. Experimental study of deformation and energy evolution law of coal under cyclic loading. Chin. J. Rock Mech. Eng. 2014, 33, 3563–3572. (In Chinese) [Google Scholar]

- Fengnian, J.; Meirong, J.; Xiaoling, G. Defining damage variable based on energy dissipation. Chin. J. Rock Mech. Eng. 2004, 23, 1976–1980. (In Chinese) [Google Scholar]

- Jie, L.; Jianlin, L.; Yudeng, Z.; Ting, Z.; Shanshan, Y.; Yingxia, L. Analysis of energy characteristics and deformation parameters of rock mass under cyclic loading. Chin. J. Rock Mech. Eng. 2010, 29, 3505–3513. (In Chinese) [Google Scholar]

- Zhixi, L.; Xiangrui, M.; Guangming, Z.; Ruofei, Z.; Chongyan, L.; Siming, K.; Minjie, Q. Energy and damage analysis of sandstone under true triaxial compression. Chin. J. Rock Mech. Eng. 2023, 42, 327–341. (In Chinese) [Google Scholar]

- Fengqiang, G.; Jingyi, Y.; Xibing, L. A new criterion of rock burst proneness based on the linear energy storage law and the residual elastic energy index. Chin. J. Rock Mech. Eng. 2018, 37, 1993–2014. (In Chinese) [Google Scholar]

- Gong, F.Q.; Yan, J.Y.; Luo, S.; Li, X.B. Investigation on the linear energy storage and dissipation laws of rock materials under uniaxial compression. Rock Mech. Rock Eng. 2019, 52, 4237–4255. [Google Scholar] [CrossRef]

- Gong, F.Q.; Yan, J.Y.; Li, X.B.; Luo, S. A peak-strength strain energy storage index for rock burst proneness of rock materials. Int. J. Rock Mech. Min. 2019, 117, 76–89. [Google Scholar] [CrossRef]

- Ruidong, P.; Yang, J.; Feng, G.; Heping, X.; Peng, W. Energy analysis on damage of coal under cyclical triaxial loading and unloading conditions. J. Chin. Coal. Soc. 2014, 39, 245–252. (In Chinese) [Google Scholar]

| Sample Number of Rock | Predetermined Load (kN) | Loading Rate (kN/min) | Unloading Rate (kN/min) | ||

|---|---|---|---|---|---|

| 1# | 0 | 0 | 0 | 140 | / |

| 2# | 10 | 20 | 60 | 140 | / |

| 3# | 10 | 20 | 60 | 140 | 140 |

| 4# | 10 | 20 | 60 | 200 | 200 |

| 5# | 10 | 40 | 60 | 200 | 200 |

| 6# | 10 | 60 | 60 | 200 | 200 |

| Cycle Index/N | (kJ·m−3) | (kJ·m−3) | (kJ·m−3) | (kJ·m−3) | (kJ·m−3) | (kJ·m−3) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 20 | 40 | 60 | 20 | 40 | 60 | 20 | 40 | 60 | 20 | 40 | 60 | 20 | 40 | 60 | |

| 1 | 240.31 | 219.93 | 212 | 4 | 4 | 6 | 10 | 8 | 3 | 108.37 | 102.48 | 100.6 | 0 | 0 | 0 | 5 | 4 | 0 |

| 2 | 394.68 | 376.3 | 338.3 | 8 | 12 | 12 | 16 | 12 | 4 | 113.86 | 112.06 | 111.3 | 2 | 0 | 0 | 7 | 5 | 0 |

| 3 | 670.73 | 614.8 | 577.8 | 14 | 16 | 18 | 23 | 18 | 7 | 207.88 | 180.03 | 162.4 | 2 | 0 | −6 | 11 | 8 | 0 |

| 4 | 950.07 | 799.17 | 755.4 | 22 | 23 | 24 | 40 | 24 | 9 | 283.99 | 177.29 | 169.2 | 4 | 1 | 0 | 24 | 10 | 1 |

| 5 | 1309.25 | 1090.47 | 1000.25 | 30 | 32 | 36 | 54 | 26 | 14 | 443.5 | 248.58 | 205.33 | 8 | 0 | 0 | 33 | 6 | 4 |

| 6 | / | 1401.21 | 1209.48 | / | 36 | 42 | / | 41 | 17 | / | 258.65 | 195.22 | / | 0 | 0 | / | 18 | 4 |

| 7 | / | / | 1512.14 | / | / | 48 | / | / | 20 | / | / | 202.89 | / | / | 0 | / | / | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, C.; Fan, C.; Lu, X.; Zhao, G.; Qi, M.; Qin, R. Mechanical and Energy Evolution Characteristics of Sandstone under True Triaxial Cyclic Loading. Appl. Sci. 2023, 13, 7230. https://doi.org/10.3390/app13127230

Dong C, Fan C, Lu X, Zhao G, Qi M, Qin R. Mechanical and Energy Evolution Characteristics of Sandstone under True Triaxial Cyclic Loading. Applied Sciences. 2023; 13(12):7230. https://doi.org/10.3390/app13127230

Chicago/Turabian StyleDong, Chunliang, Chaotao Fan, Xiaoyu Lu, Guangming Zhao, Minjie Qi, and Ruipeng Qin. 2023. "Mechanical and Energy Evolution Characteristics of Sandstone under True Triaxial Cyclic Loading" Applied Sciences 13, no. 12: 7230. https://doi.org/10.3390/app13127230

APA StyleDong, C., Fan, C., Lu, X., Zhao, G., Qi, M., & Qin, R. (2023). Mechanical and Energy Evolution Characteristics of Sandstone under True Triaxial Cyclic Loading. Applied Sciences, 13(12), 7230. https://doi.org/10.3390/app13127230