Abstract

The development of the fast protection system (FPS) was driven by the critical need to safeguard internal components of the accelerator from beam damage and minimize operational downtime. During accelerator operation, various faults can occur, posing a significant risk. The FPS acts as a rapid response system, initiating a shutdown signal to a reliable chopper system to prevent beam damage and ensure the operational availability of the accelerator. To meet the stringent shut off time requirements specific to critical faults, the FPS was designed to respond within 50 µs, while the total FPS time, including acquisition, redundancy, and processing, needed to be less than 20 µs. In order to achieve these goals, a customized FPS was developed for the RAON heavy-ion accelerator, utilizing the Xilinx ZYNQ system-on-chip (SoC). The FPS system comprised seven acquisition modules, one mitigation module with an embedded SoC, and employed optical fiber connections for efficient data transmission. This article provides a comprehensive account of the design, development, and testing of the FPS system. Experimental tests were conducted to validate its performance. These tests included verifying the accuracy of cyclic redundancy checks, acquiring interlock signals in short pulses, and measuring the delay time during abnormal signal occurrences. Of particular significance is the measurement of the total signal processing time for a 1 km optical cable in the RAON system, which was determined to be 9.8 µs. This result successfully met the stringent requirement of 20 µs for the FPS time. The ability of the FPS to operate within the desired time frame demonstrates its effectiveness in protecting the accelerator’s components from beam damage and minimizing downtime. Consequently, the FPS ensures the operational availability of the accelerator while maintaining the safety and integrity of its internal systems. By providing a detailed account of the FPS’s design, development, and testing, this article contributes valuable insights into the capabilities of the FPS in real-world accelerator scenarios. The successful implementation of the RAON-optimized FPS with the Xilinx ZYNQ SoC reaffirms its effectiveness as a fast and reliable protection system, thus enhancing the overall operational performance of the accelerator.

1. Introduction

The Rare Isotope Science Project (RISP), conducted by the Institute for Basic Science (IBS) in Korea, aims to develop a rare isotope accelerator facility with high beam energy and power output capabilities []. The accelerator consists of various subsystems, including control, radio frequency, injector, vacuum, magnet, and cryogenic systems. Among these subsystems, the Machine Protection System (MPS) plays a crucial role in safeguarding the internal components of the accelerator from beam-induced damage. As the beam power increases, the need for swift accelerator shutdown to mitigate potential damage becomes imperative. To achieve this, a transition from a programmable logic controller (PLC)-based interlock system to a field-programmable gate array (FPGA)-based interlock system is necessary. The MPS is responsible for detecting abnormal signals from local devices within the accelerator, such as low-level radio frequency, beam diagnostics, magnet power supplies, and cryogenic systems []. When a trip signal is detected, the MPS activates the beam stop device, consisting of components like the low-energy beam transfer, chopper, radio frequency quadrupole, and low-level radio frequency, to rapidly halt the beam. The MPS is divided into two main systems based on signal acquisition time: the fast protection system (FPS) [] and the slow interlock system (SIS) []. The FPS, which has attracted significant attention as accelerator technology advances, focuses on achieving high equipment availability and stability. To improve availability and stability, the FPS must be carefully designed to meet the specific requirements of the diverse devices within the accelerator.

The MPS is responsible for detecting abnormal signals from local devices within the accelerator, such as low-level radio frequency, beam diagnostics, magnet power supplies, and cryogenic systems. When a trip signal is detected, the MPS activates the beam stop device, consisting of components like the low-energy beam transfer, chopper, radio frequency quadrupole, and low-level radio frequency, to rapidly halt the beam. The MPS is divided into two main systems based on signal acquisition time: the fast protection system (FPS) and the slow interlock system (SIS). The FPS, which has gained significant attention as accelerator technology advances, focuses on achieving high equipment availability and stability. To improve availability and stability, the FPS must be carefully designed to meet the specific requirements of the diverse devices within the accelerator []. In heavy-ion accelerators, a device yield stress may occur when the beam collides with the accelerator main device [], depending on the type of ion beam mass, kinetic energy, and angle of incidence.

The design and functionality of the FPS are critical in ensuring its effectiveness as a fast and reliable beam protection system. Therefore, it is crucial to set clear requirements for the FPS prior to its production and assess its practicality by benchmarking against desired outcomes. In heavy-ion accelerators, the occurrence of yield stress in accelerator components due to beam collisions depends on factors such as the ion beam mass, kinetic energy, and incident angle []. The heavier the ion weight, the greater the stopping power, and the higher the angle of incidence, the greater the effect [], where the stopping power of an ion beam is calculated using the Stopping and Range of Ions in Matter (SRIM) code. Previous studies at the Spallation Neutron Source (SNS) and the Facility for Rare Isotope Beams (FRIB) have investigated the impact of beam energy and incident angle on yield stress time, providing valuable insights [,].

The time required for the FPS to operate effectively includes abnormal beam signal detection, FPS processing, and mitigation device operation. By analyzing abnormal beam operation scenarios for various ions, including uranium and oxygen, as well as the melting time of accelerator components like cavities and vacuum chambers, the FPS requirements can be accurately determined []. In most cases, a response time of approximately 50 µs is sufficient to prevent beam damage on the beam line components, considering the incident beam’s grazing angle. Moreover, the melting time of beam line components made of materials like SUS304 for vacuum chambers or niobium for superconducting cavities has been calculated as ~46 μs and ~69 μs, respectively, when it is hit by a uranium beam energy of 18.9 MeV/u in a right angle, which is the fastest loss case, providing crucial insights into protection time requirements.

The FPS and SIS operate at microsecond and a millisecond scales, respectively. Abnormal signals from most of the collected devices go through the SIS to reach the FPS, and some of the other collected devices directly send their abnormal signals to FPS. Upon receiving abnormal signals, the MPS must fully execute the entire process within 50 μs to protect the accelerator from sudden beam losses by alerting the mitigation devices, such as LEBT chopper and RFQ amp to shut down the beam. Equations (1)–(3) show the calculation of beam shut-off latency using the parameters used for the equation, as presented in Table 1.

Table 1.

Parameters used to calculate beam shut-off latency.

In summary, the FPS and SIS play vital roles in protecting the accelerator from sudden beam losses. The FPS operates at the microsecond scale and ensures swift response times for abnormal signals, while the SIS operates at the millisecond scale, facilitating the transmission of abnormal signals to the FPS. To effectively protect the accelerator, the entire MPS process, including signal detection and mitigation device activation, must be completed within a specified time frame. In this article, we present a detailed account of the design, development, and testing of the RAON-optimized custom FPS, utilizing the Xilinx ZYNQ system-on-chip (SoC), in order to meet the fast shut-off requirement within 20 µs.

2. RAON Central Control System

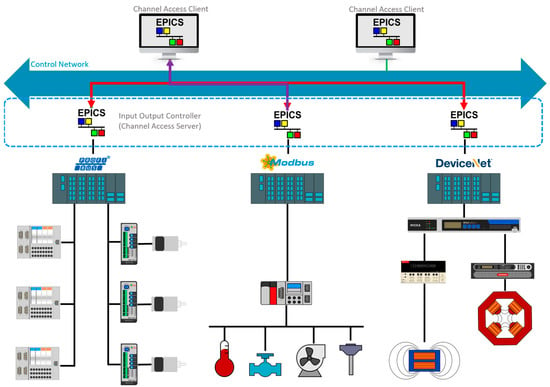

The RAON central control system has a middleware to combine multiple experimental devices into one united control system. It uses EPICS middleware to integrate local control systems into RAON central control systems. The RAON central control system has a three-tier architecture. Figure 1 shows a simplified architecture of the RAON central control system. The EPICS middleware framework is used to integrate various systems into one unified system. The unified central control system, installed in a central control room, supervises every component of the accelerator by monitoring all signals from distributed local devices. Basically, by integrating different systems into one, the central control system classifies all possible derived systems by its functionality and standardizes them. By doing so, it assures safety, reliability, scalability, and availability.

Figure 1.

RAON central control system architecture.

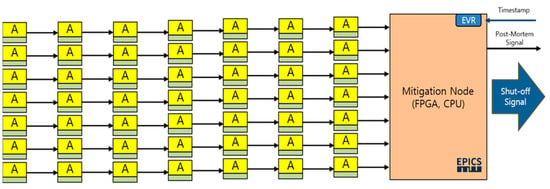

3. Composition of Fast Protection System

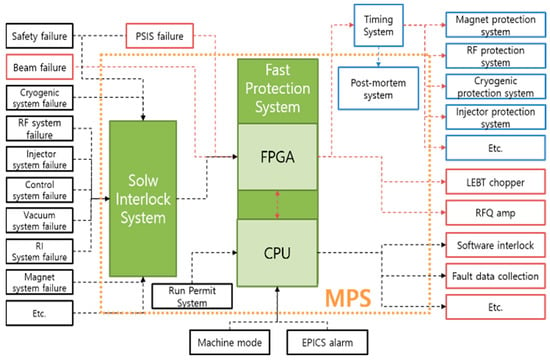

The FPS mainly protects the internal components of the accelerator from beam damage. Prior to designing the FPS, an investigation was performed on the FPS of major accelerator facilities. The FPS consists of two distinct parts, namely, FPGA and a central processing unit (CPU), which play a role in parameter management, fast protection, fault data, and fault analysis. Figure 2 shows the block diagram that protects equipment in various modes of operation, integrating subsystem interfaces, software development using PLCs, hardware configuration and control interlocks, and FPGA control-based timing systems.

Figure 2.

RAON machine protection system architecture.

- Mitigation node

- Acquisition node

Basically, the FPS consists of a mitigation (master) node and an acquisition (slave) node. A proper firmware configuration design of the mitigation and acquisition nodes is required to enable the nodes to transmit and store fault data for fault analysis.

3.1. Mitigation Node

The mitigation node consists of a main board for signal processing and data storage and a daughter board for FPS device control. The main board has a memory and buffer arranged around the multiprocessor system-on-chip (MPSoC). The front panel consists of eight SFP+ transceiver modules, Ethernet transceivers, SD cards, and USB to JTAG ports, and the rear panel consists of connectors for data output to the daughter board. Table 2 presents the specification of the mitigation node prototype.

Table 2.

Specification of the mitigation node.

The PL of the mitigation node receives the status information of the FPS external device input from the acquisition node at 1 μs interval to the postmortem system (PMS) data module through the GTH interface. If an abnormal signal is detected, the cutoff signal is transmitted to bthe output of 24 channels, and then status information is stored in the BRAM inside the PL, and a log file is created []. In addition, the time stamp and event code received from the event generator (EVG) are delivered to the EVR module via the GTH interface. The time stamp data is stored in BRAM along with external device status information stored in real time. BRAM stores not only the status signals of external devices but also built-in test (BIT) data, such as firmware version, temperature data, and status information of the mitigation node [].

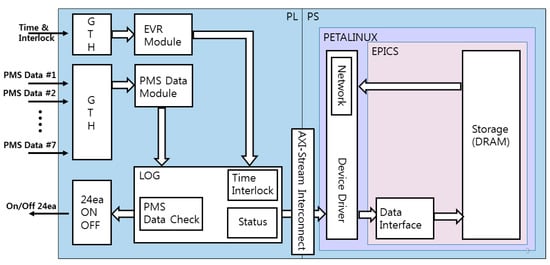

PetaLinux is ported in the PS area. In addition, the EPICS IOC operates the FPS system. The interface with the PL is connected to the AXI Interconnect using the device driver inside the kernel to control BRAM and external devices. The EPICS IOC uses processing values (PVs) to create the elements that are needed for system operation and data transfer. OPI is used to control and monitor the generated PV []. Figure 3 shows the PL and PS configurations of the mitigation node.

Figure 3.

Configuration of the mitigation node firmware.

3.2. Acquisition Node

The acquisition node consists of a main board for signal processing and data storage and a daughter board for external device input. The main board has a memory and buffer arranged around the SoC. The front panel contains four SFP+ transceiver modules, an Ethernet transceiver, an SD card, and a USB-to-JTAG port. The rear panel consists of a connector to receive data from the daughter board. Table 3 presents the specification of the acquisition node prototype.

Table 3.

Specification of the acquisition node.

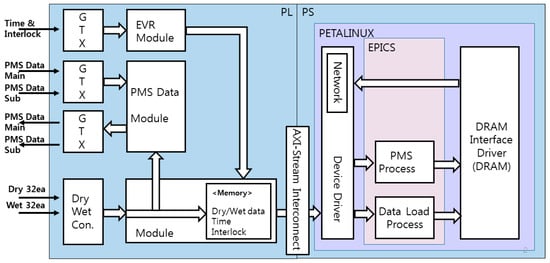

The acquisition node PL area receives 64 input data in the FPS external device. This data is stored in BRAM along with the time stamp data received from the EVR. Data stored in BRAM is transferred to the upper acquisition node or mitigation node. When the PMS event code is received from the EVG, the reception time is transmitted to the PS. PetaLinux is ported in the PS area. The EPICS IOC operates the FPS. The PS uses AXI Interconnect to control the interworking with the PL and external devices. The data stored in BRAM in the PL area is continuously stored in the DDR memory. When the PMS event code is received from EVG, ±200 µs data are generated in the form of a file with a time stamp and stored in SDRAM based on the time of occurrence. The EPICS IOC generates and transmits BIT and other necessary elements in a PV form, and OPI controls and monitors the PV. Figure 4 shows the firmware configuration of the acquisition node.

Figure 4.

Configuration of the acquisition node firmware.

4. Development of FPS with Xilinx ZYNQ for Minimizing a Latency

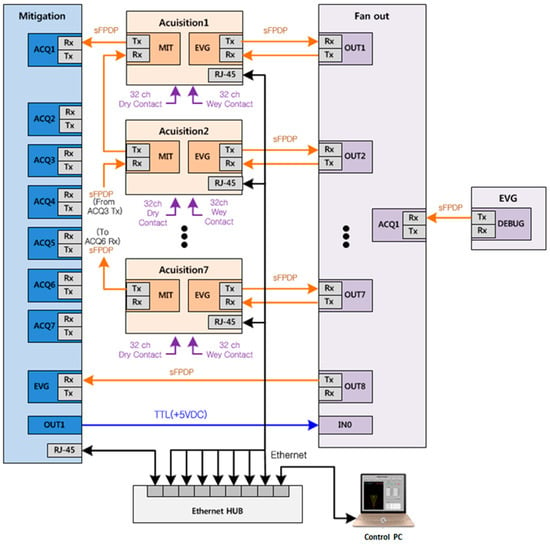

In order to reduce the latency for quick shut off, the device drive software and the minimization of the distance between the two gates in FPGA were optimized. As shown in Figure 5, two mitigation nodes and seven acquisition daisy chains can be found in each of the FPS primary products. One of the two mitigation nodes acts as a backup in case of failure. Each acquisition chain is composed of seven acquisition nodes that are connected linearly. One mitigation node and one acquisition chain are randomly selected to be tested. With the test result, the remaining one mitigation node and six acquisitions chains are modified for improvement. In the case of the mitigation node, the SoC chip was replaced with XC7Z100-2FFG900I for bidirectional communication with the acquisition node.

Figure 5.

FPS layout.

Minimizing latency is a crucial aspect of developing a highly efficient Fast Protection System (FPS). This article presents a descriptive analysis of a study conducted to optimize latency reduction in FPS using Xilinx ZYNQ, a powerful embedded OS porting system. This research aims to enhance device drive software and FPGA gate distance for quick shut off. Xilinx ZYNQ emerges as a powerful solution for minimizing latency in the FPS. Its versatile functionality, adaptability to changing requirements, real-time processing capability, reduced power consumption, and independent power rails enable the development of a highly efficient and flexible FPS control system. By leveraging the advantages and features of Xilinx ZYNQ, developers can enhance the device drive software and FPGA gate distance, resulting in significant latency reduction and improved performance in the FPS. ZYNQ XC7Z100-2FFG900I [] and ZYNQ XCZU9EG-2FFVB1156I [] are implemented for RAON fast protection system.

A spare of the front SFP+ port is created and modified, giving a total of nine SFP+ ports. A masking function is added to prevent a BPS mode setting or input/output of a false trigger signal. In the case of the acquisition node, a spare SFP+ port was also created, giving a total of five SFP+ ports. To receive the BPM output signals directly, the converter terminals were modified to 16 SMA-type input ports. A software change was made to check the BIT of communication status, temperature, time, and timing through LED, LCD, and OPI on the node front. The IP and configuration files for each node were automatically updated at each node boot. Additionally, a node self-test mode was added via a software developed.

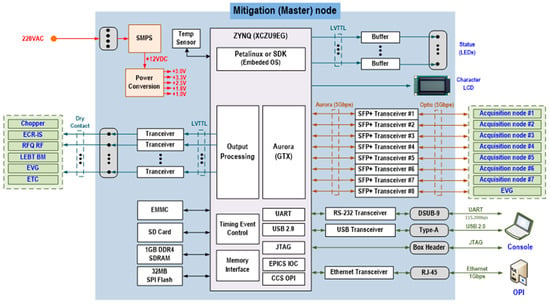

4.1. Modified Mitigation Node

The modified mitigation node is a 2U-high 19-inch rack module. The interior of the module consists of one PCB with FPGA, one power supply, cables, and chassis. The following are the changes in the modified mitigation node.

- SFP+ port on the main board (9 EA to 10 EA)

- MPSoC to ZYNQ XC7Z100

- Ethernet PHY (Marvell to TI)

- Dip-type connector for booting device selection

- Wet contact driver in the daughter board

- Change in the SMA library

- Front SFP+ port (8 EA to 9 EA)

Table 4 presents the specification of the modified mitigation node.

Table 4.

Hardware specification of the modified mitigation node.

Figure 6 shows the configuration diagram of the modified mitigation node.

Figure 6.

Configuration diagram of the modified mitigation node.

The modified mitigation node consists of a main board for signal processing and data storage and a daughter board for outputting signals to the FPS devices. The main board is equipped with ZYNQ for PetaLinux, memory, buffer, and sensor, where PetaLinux is ported. The front interface consists of nine SFP+ transceiver modules, Ethernet transceivers, SD cards, and USB to JTAG port. The rear panel is composed of a connector for outputting data to the daughter board. The daughter board then converts output signal that is received from the main board to wet signal and transmits the signal to an external device through an SMA connector.

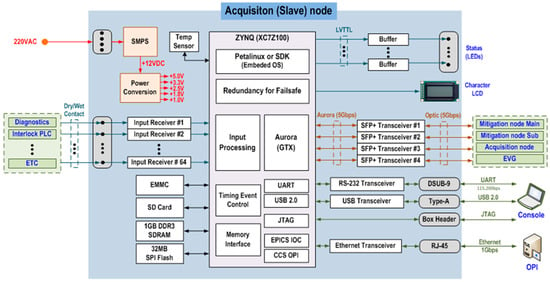

4.2. Modified Acquisition Node

The modified acquisition node is a 2U-high 19-inch rack module. The module consists of a PCB with FPGA and a power supply, cables, and chassis to supply power. The following are the changes in the modified acquisition node.

- Ethernet PHY (Marvell to TI)

- Dip-type connector for booting device selection

- Replaced dry contact 16 EA to SMA

- Modified SMA driver

- SMA library

Table 5 presents the product specification of the modified acquisition node.

Table 5.

Hardware specification of the modified acquisition node.

Figure 7 shows the configuration diagram of the modified acquisition node.

Figure 7.

Configuration diagram of the modified acquisition node.

The modified acquisition node consists of a main board for signal processing and data storage and a daughter board for receiving input signals from the FPS devices. The main board is equipped with a memory, buffer, and sensor mainly on ZYNQ, where PetaLinux is ported. The front interface consists of five SFP+ transceiver modules, an Ethernet transceiver, an SD card, and a USB to JTAG port, and the rear panel consists of a connector for outputting data to the daughter board. The daughter board is equipped with a terminal block and an SMA to receive 32 dry contacts and 32 wet contacts from the external FPS devices. The signal received from the external device is converted into low-level TTL (LVTTL) signal and transmitted to the main board.

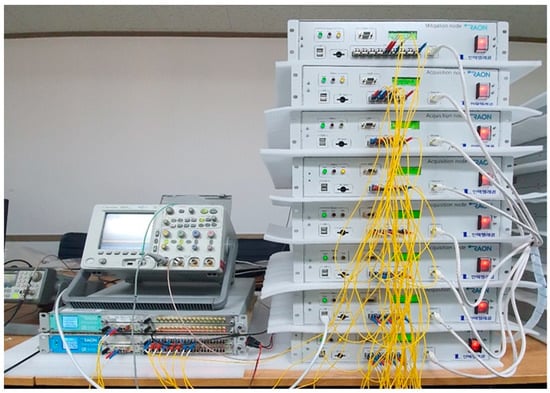

5. Testing of the FPS

Tests were performed on the time of the signal from the input of the modified acquisition node to the output of the modified mitigation node. Figure 8 shows the configuration for the FPS test. Figure 9 shows the diagram. Prior to this test, the control board and test equipment were initialized.

Figure 8.

Installation of the FPS.

Figure 9.

Test schematic of the FPS.

5.1. Initial State of the Test Equipment

The control boards and test equipment must be prepared for initialization and test preparation in the following order.

- The power switch of the test equipment must be kept off.

- Measures must be taken to prevent static electricity during the test.

- It must be ensured that the power cables and other connecting cables of the test equipment are connected properly.

- It must be checked that the power required for the test is set to the specified power conditions.

- The equipment and all instruments required for the test must be warmed up prior to the test.

- A 220 V AC power must be applied to the modified mitigation node, modified acquisition node, EVG, waveform generator, Ethernet hub, and oscilloscope.

5.2. First Test for Communication Check

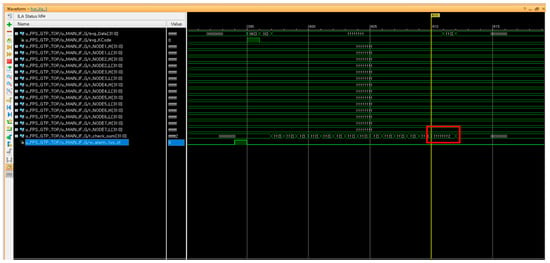

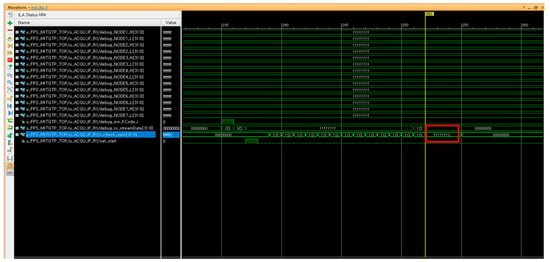

The first test examines the cyclic redundancy check (CRC) per packet at the end of the packet. The CRC shows that the input signal is the same as the output signal. The test program used Vivado, a Xilinx FPGA program. The CRC of the data sent to the modified acquisition node is fffffff2, as shown in Figure 10. At this time, the CRC data of the received signal of the modified mitigation node are fffffff2, as can be seen in the chip scope screen of Figure 11. It can be found that the input and output signals are the same by checking the input signal of the modified acquisition node as the input signal of the modified mitigation node.

Figure 10.

CRC data of the packet sent by the modified acquisition node.

Figure 11.

CRC data of the packed received from the modified mitigation node.

5.3. Second Test for Mitigation Processing Time

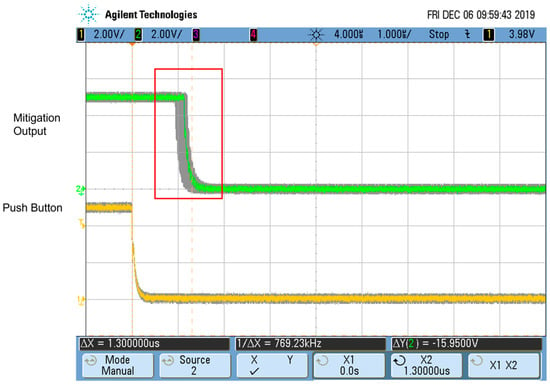

The second test checks an interlock signal coming into modified acquisition node 7, which is the last node in the chain, sent to the 24 outputs of the modified mitigation node. In this case, instead of using an input signal from the actual diagnostic devices, an input signal from a signal generator that sends 100 ms period pulse and 100 μs pulse width signals was used, as shown in Figure 12. The signal generated from the signal generator is a wet signal of 2 V/0 V. As shown in Figure 13, it can be observed that after the signal generated for an abnormal signal input, the control signal output at the modified mitigation node increases from low (0 V) to high (+5 VDC).

Figure 12.

Input signal for test (100 ms pulse, pulse width 100 µs).

Figure 13.

Control signal output at the modified mitigation node.

5.4. Third Test for FPS Processing Time

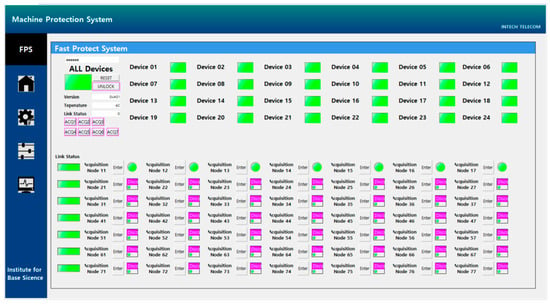

The third test is the abnormal signal monitoring and control test in the UI for the operator. The UI was developed with CSS OPI. As shown in Figure 14, the UI can check the status of 49 acquisition nodes and one master node on a single screen. It was developed so that detailed node status can be checked by clicking the enter icon next to the node status.

Figure 14.

Main user interface of fast protection system.

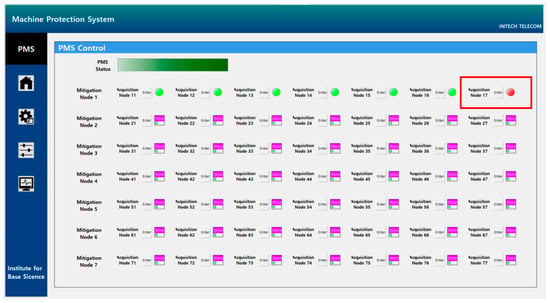

When an abnormal signal enters the acquisition node, the acquisition node at which the abnormal signal entered is displayed in the UI, as shown in Figure 15. If you click enter next to the node status window with an error, you can check the detailed status of the node, and you can also check the function of saving the PMS data at this time to the master node as shown in Figure 16.

Figure 15.

Anomaly signal monitoring screen of FPS UI.

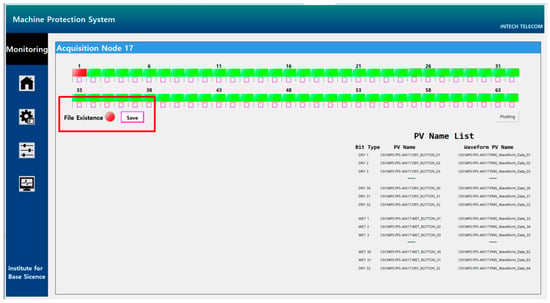

Figure 16.

Anomaly signal monitoring screen of acquisition UI and PMS data save button.

5.5. Forth Test for Delay Time in Cable

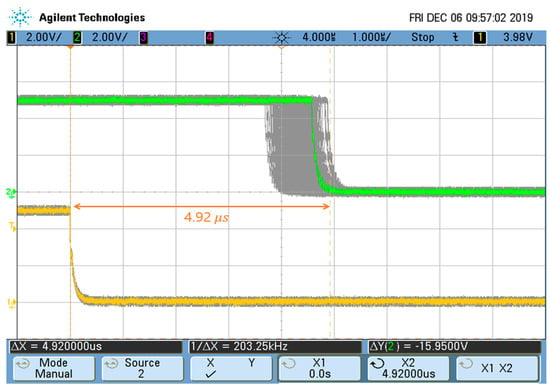

The fourth test is one of the most important parts of the MPS, which is a delay test from the occurrence of the interlock signal input to the modified acquisition node to the output of 24 control signals connected to the modified mitigation node. The expected delay time for the initial design of optical cable in length of 440 m was 8.3 μs, and it was confirmed that the delay time was within 10 μs.

The delay time for the 1 m optical fiber length is up to 4.92 μs, as shown in Figure 17. The expected delay time of this FPS for a 340 m optical cable was 6.52 μs, and it was confirmed that its delay time was not only within 10 μs, but was also shorter than that of the previous prototype version of the FPS, which was 7.8 μs for a 340 m optical cable. Considering that the delay time of the optical cable was 5 μs at 1 km, the response time measurement results of the RAON FPS met the expected results, which is fast enough to protect the accelerator from beam loss.

Figure 17.

Control signal delay time at the modified mitigation node.

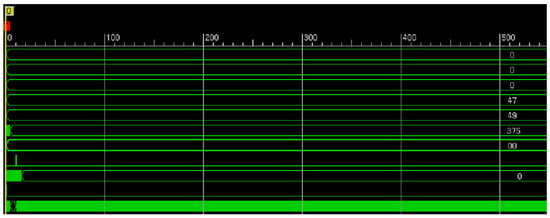

The time stamp and PMS event codes from external EVGs are input into all FPS nodes. Whether it can be received through the embedded EVR of each node or not was tested. Figure 18 displays the test results. On the chip scope screen of the mitigation and modified acquisition nodes, it can be observed that the year, month, day, hour, minute, second (per sec), second (per µs), and event codes are received normally.

Figure 18.

Received data in the embedded EVR.

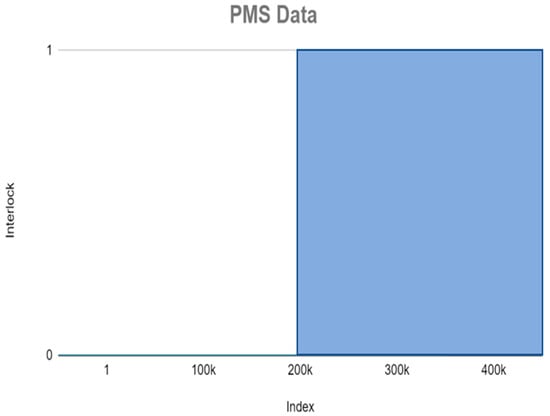

An external trigger was generated for the PMS test. The trigger stored processing data inside the modified acquisition node of ±200 µs in RAM associated with the ARM processor. The data are saved in the designated location in conjunction with the EPICS server. When an interlock occurs, the creation of a PMS file is displayed on the modified acquisition node. The interlock data are sent to the modified mitigation node remotely when the save button is pressed. The remotely transmitted data are contained in a .txt file, and 400,000 data are stored at ±200 µs, as shown in Figure 19.

Figure 19.

Value of index vs. interlock at ±200 µs.

6. Conclusions

The completion of the development process for the Fast Protection System (FPS) with Xilinx ZYNQ SoC for the RAON heavy-ion accelerator marks a significant milestone. The first FPS prototype demonstrated satisfactory performance, meeting the crucial requirement of protecting the internal components of the accelerator from potential beam damage []. Notably, the modified mitigation node, which incorporates a cost-effective SoC, was successfully optimized by increasing the number of SFP+ ports and implementing a modified driver and library. This enhancement resulted in even faster reaction times compared to the previous version of the FPS.

The measured total signal processing time, including measurement and interlock output, for a 1 km optical cable in the RAON system is 9.8 µs, well within the requirement of 20 µs for FPS time. The successful achievement of this performance milestone ensures that the FPS is capable of effectively responding to potential hazards and mitigating risks within the specified time constraints.

Figure 20 showcases the installation of the actual FPS, depicting the practical implementation of the system within the RAON accelerator facility. Looking ahead, future plans involve exploring the integration of artificial intelligence (AI) techniques into the Machine Protection System (MPS). By incorporating AI, the aim is to design a system that can predict and proactively control abnormal signals, further enhancing the safety and operational efficiency of the FPS.

Figure 20.

Installation of the actual FPS.

In summary, the successful development and performance evaluation of the FPS with Xilinx ZYNQ SoC for the RAON heavy-ion accelerator highlight the effectiveness and suitability of this integrated solution. The optimized system design, enhanced reaction times, and future plans for AI integration demonstrate the commitment to continuous improvement and innovation in the field of accelerator protection and control systems.

Author Contributions

Conceptualization, S.-H.N.; Methodology, C.S.; Software, S.-H.N.; Validation, C.S.; Formal analysis, S.-H.N.; Resources, C.S.; Data curation, C.S.; Writing—original draft, S.-H.N.; Writing—review & editing, J.B.; Project administration, J.B.; Funding acquisition, J.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Rare Isotope Science Project of Institute for Basic Science funded by Ministry of Science, ICT, and Future Planning and National Research Foundation of Korea (2013M7A1A1075764), by the INNOPOLIS Foundation of Korea funded by the Ministry of Science and ICT (Grant No. 1711149774), and by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2022R1F1A1076188).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

All authors declare no conflict of interest. We have read and agreed to the published version of the manuscript.

Abbreviation

| Abbreviation | Description |

| RISP | Rare Isotope Science Project |

| IBS | Institute for Basic Science |

| SNS | Spallation Neutron Source |

| FRIB | Facility for Rare Isotope Beams |

| SRIM | Stopping and Range of Ions in Matter |

| EPICS | Experimental Physics and Industrial Control System |

| FPGA | Field Programmable Gate Arrays |

| CPU | Central Processing Unit |

| MPS | Machine Protection System |

| SIS | Slow Interlock System |

| FPS | Fast Protection System |

| SoC | System on Chip |

| MPSoC | Multi-Processor System on Chip |

| PS | Processing System |

| PL | Programmable Logic |

| EVG | Event Generator |

| EVR | Event Receiver |

| PMS | Post Mortem System |

| CSS | Control System Studio |

| OPI | Operator Interface |

| IOC | Input Output Controller |

| PV | Processing Value |

| CRC | Cycle Redundancy Check |

| LEBT | Low Energy Beam Transfer |

| RFQ | Radio Frequency Quadrupole |

References

- Jeon, D.; Hong, I.S.; Kim, H.J.; Kim, J.W.; Bodenstein, R.M.; Cha, H.J.; Kim, E.S. Design of the raon accelerator systems. J. Korean Phys. Soc. 2014, 65, 1010–1019. [Google Scholar] [CrossRef]

- Jin, H.; Choi, Y.; Lee, S.; Jang, H. Development and interlock test of the fast protection system prototype in the RAON accelerator control system. J. Korean Phys. Soc. 2018, 73, 1073–1079. [Google Scholar] [CrossRef]

- Jin, H.; Choi, Y.; Lee, S. Progress and plan of the fast protection system in the RAON accelerator. In Proceedings of the 61st ICFA ABDW on High-Intensity and High-Brightness Hadron Beams (HB’18), Daejeon, Republic of Korea, 17–22 June 2018; JACOW Publishing: Geneva, Switzerland, 2018; pp. 296–298. [Google Scholar]

- Jin, H.; Choi, Y. Development of fast protection system and slow interlock system in the RAON accelerator. J. Korean Phys. Soc. 2020, 76, 601–607. [Google Scholar] [CrossRef]

- Song, Y.G. Interlock system for machine protection of the KOMAC 100-MeV proton linac. J. Korean Phys. Soc. 2015, 66, 449–453. [Google Scholar] [CrossRef]

- Adolphsen, C.; Frisch, J.; Jobe, R.K.; McCormick, D.; Nelson, W.R.; Raubenheimer, T.O.; Walz, D.R. The next linear collider machine protection system. In Proceedings of the 1999 Particle Accelerator Conference (Cat. No. 99CH36366), New York, NY, USA, 27 March–2 April 1999; Volume 1, pp. 253–255. [Google Scholar]

- Ziegler, J.F. “Interactions of Ions with Matter” James Ziegler–SRIM & TRIM. Available online: http://www.srim.org/ (accessed on 26 August 2022).

- Shafer, R. “How Long a SNS Beam Pulse Would Damage a Copper Accelerating Structure?”. Available online: http://ics-web1.sns.orn1.gov/SUBSYSTEMS/MPS/index.html (accessed on 3 May 2018).

- Zhang, Y.; Stout, D.; Wei, J. Analysis of beam damage to S driver linac. In Proceedings of the SRF Workshop, Chicago, IL, USA, 25–29 July 2011. [Google Scholar]

- Cheon, Y.L.; Sung, C.K.; Moon, K.J.; Kwak, D.H.; Chung, Y.; Kim, G.D.; Chung, M. Design study of beam loss monitoring system for the rare isotope science project in Korea. J. Instrum. 2019, 14, P04007. [Google Scholar] [CrossRef]

- Parnassos, I.; Skrimponis, P.; Zindros, G.; Bellas, N. SoCLog: A real-time, automatically generated logging and profiling mechanism for FPGA-based systems on chip. In Proceedings of the 2016 26th International Conference on Field Programmable Logic and Applications (FPL), Lausanne, Switzerland, 29 August–2 September 2016; pp. 1–4. [Google Scholar]

- Gadlage, M.J.; Roach, A.H.; Duncan, A.R.; Williams, A.M.; Bossev, D.P.; Kay, M.J. Soft errors induced by high-energy electrons. IEEE Trans. Device Mater. Reliab. 2016, 17, 157–162. [Google Scholar] [CrossRef]

- Yan, J.; Wu, J.; Zhang, Y.; Xu, Y.; Zhang, J.; Zhang, X.; Jing, L. EPICS based beam energy measurement system for proton LINAC. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 945–949. [Google Scholar]

- AMD Xilinx. Zynq-7000 SoC Data Sheet: Overview (DS190). 2018. Available online: https://docs.xilinx.com/v/u/en-US/ds190-Zynq-7000-Overview (accessed on 12 December 2019).

- AMD Xilinx. UltraScale™ Architecture and Product Data Sheet: Overview (DS890). 2022. Available online: https://docs.xilinx.com/v/u/en-US/ds890-ultrascale-overviewlb (accessed on 28 November 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).