1. Introduction

Society has advanced quickly thanks to the development and use of machines and specialized tools that have made it possible to automate complex, repetitive, demanding, or dangerous tasks for human beings [

1]. An important part of these devices is made up of mechanisms, i.e., rigid bodies joined together that interact through prismatic or rotational movements to generate, as a whole, more complex particular motions for different purposes [

2]. The applications of different types of mechanisms can be found in the area of construction [

3], in the automotive industry [

4], in health and rehabilitation [

5], in the development of androids [

6], in aviation [

7], or in specific processes for various industries [

8].

One way to classify the above mechanisms is by the way in which the rigid bodies that make them up are arranged. In this way, the mechanisms can be open, closed, or hybrid kinematic chains [

9]. In the first class are the well-known anthropomorphic robotic arms, which consist of several links sequentially linked from a fixed or base one [

10]. The end effector in these systems (i.e., the tool used for a specific task) is typically located in the last link of the chain, and the rest of the links must coordinate to manipulate the position and orientation of the effector. Unlike robotic arms, in closed kinematic chain mechanisms, the first and last links are fixed in a loop [

2]. In this class of mechanisms, the effector is located at some particular point with respect to one of the links that creates the loop. Therefore, open-chain mechanisms are relatively easier to design and control, since each link is governed independently with respect to the previous one. In addition, their working space is larger and not limited by the location of their fixed links, which is contrary to what happens in closed-chain mechanisms. On the other hand, closed-chain mechanisms are more precise and robust regarding external disturbances [

11]. As for hybrid mechanisms, they contain both closed and open elements to take advantage, to some extent, of the strengths of each class, but they also face their difficulties [

12].

Both open and closed kinematic chain mechanisms can be overactuated, fully actuated, or underactuated, i.e., they can have, respectively, a greater, equal, or smaller number of motion-generating elements or actuators than the number of degrees of freedom required to perform a motion with the complete mechanism [

10].

Among the most important kinematic chain mechanisms is the four-bar one. Many examples of the successful use of this mechanism in real-world applications can be found in the specialized literature [

13,

14,

15,

16]. The widespread use of the four-bar mechanism is due to its ability to follow highly nonlinear closed trajectories with only one degree of freedom, in contrast to open-chain alternatives that require at least two degrees of freedom to produce similar trajectories, or closed-mechanism alternatives with a larger number of loops or degrees of freedom, thus resulting in significant savings in the cost involved in actuators and their control. For this, four-bar mechanisms must satisfy a series of constraints in their design that are known as Grashof’s laws [

17]. These laws establish relationships between the dimensions of the links in a four-bar mechanism that must be fulfilled in order for one or more of the links to be able to work as a crank, i.e., to be able to rotate completely, thereby producing complex closed trajectories with respect to points of interest in the mechanism.

Therefore, one of the most relevant tasks in the design of four-bar Grashof-type mechanisms is the adjustment of the dimensions and locations of the links, which is a task known as dimensional synthesis [

18]. Three types of dimensional synthesis exist: motion generation (body guidance), function generation, and path generation. The last one is the topic related to our work. It is worth mentioning that the dimensional synthesis of a simple mechanism such as a four-bar mechanism is not a trivial task and can essentially be performed by graphical [

19], algebraic [

20], analytic [

19], or optimization [

21] methods. The first three methods are helpful for synthesizing four-bar mechanisms when the trajectories (paths) are relatively simple. As trajectories become more complicated, the optimization method turns out to be more effective, so its use is now widespread [

22,

23,

24,

25,

26].

The optimization-based synthesis method involves formulating and solving an optimization or mathematical programming problem. This problem consists of finding the dimensional information of the links of a mechanism whose movement minimizes the differences between the trajectory produced by a point of interest in the mechanism and the desired path while at the same time satisfying a series of constraints related to manufacturing limitations, space conditions available for the operation of the mechanism, or even compliance with Grashof’s laws, to mention a few examples.

Hence, optimization problems related to the dimensional synthesis of four-bar Grashof-type mechanisms are complex, and classical optimizers such as Sequential Quadratic Programming or the least square optimization technique may have difficulties in finding appropriate solutions, as reported in the specialized literature [

22]. It is difficult for practitioners to execute the classical optimizers because of the challenges in defining the initial conditions and the algorithms’ reliance on gradient information. Fortunately, stochastic techniques known as metaheuristics can find good solutions to complex optimization problems, such as mechanism synthesis, at a reasonable computational cost [

27].

Metaheuristics in engineering applications have grown considerably due to their high effectiveness [

28]. This has led to the development of different alternatives to these techniques to solve more and more specific problems [

28]. However, the operation of these alternatives takes as a starting point the operation of state-of-the-art metaheuristics [

29]. Among these metaheuristic techniques, Differential Evolution (DE) [

30] along with its various variants, are recurring options for solving mechanism synthesis problems [

31,

32,

33].

The four-bar mechanism is one of the most widely used in various applications and complex machines such as sewing machines, round balers, suspension systems of automobiles, pumpjacks, prosthetic knees, and others, because this mechanism can trace complex trajectories by appropriately setting link lengths without the need to use complex mechanisms, even though the latter can provide significant flexibility in the synthesis [

34]. Thus, nowadays, researchers are continually coming up with new approaches to state and resolve the four-bar mechanism’s synthesis problem [

26,

35] to improve the quality of design objectives. Thus, this work developed a comparative study of the most-used variants of DE in search of the solution to the most common conceptualizations of the dimensional synthesis problem of four-bar Grashof-type mechanisms.

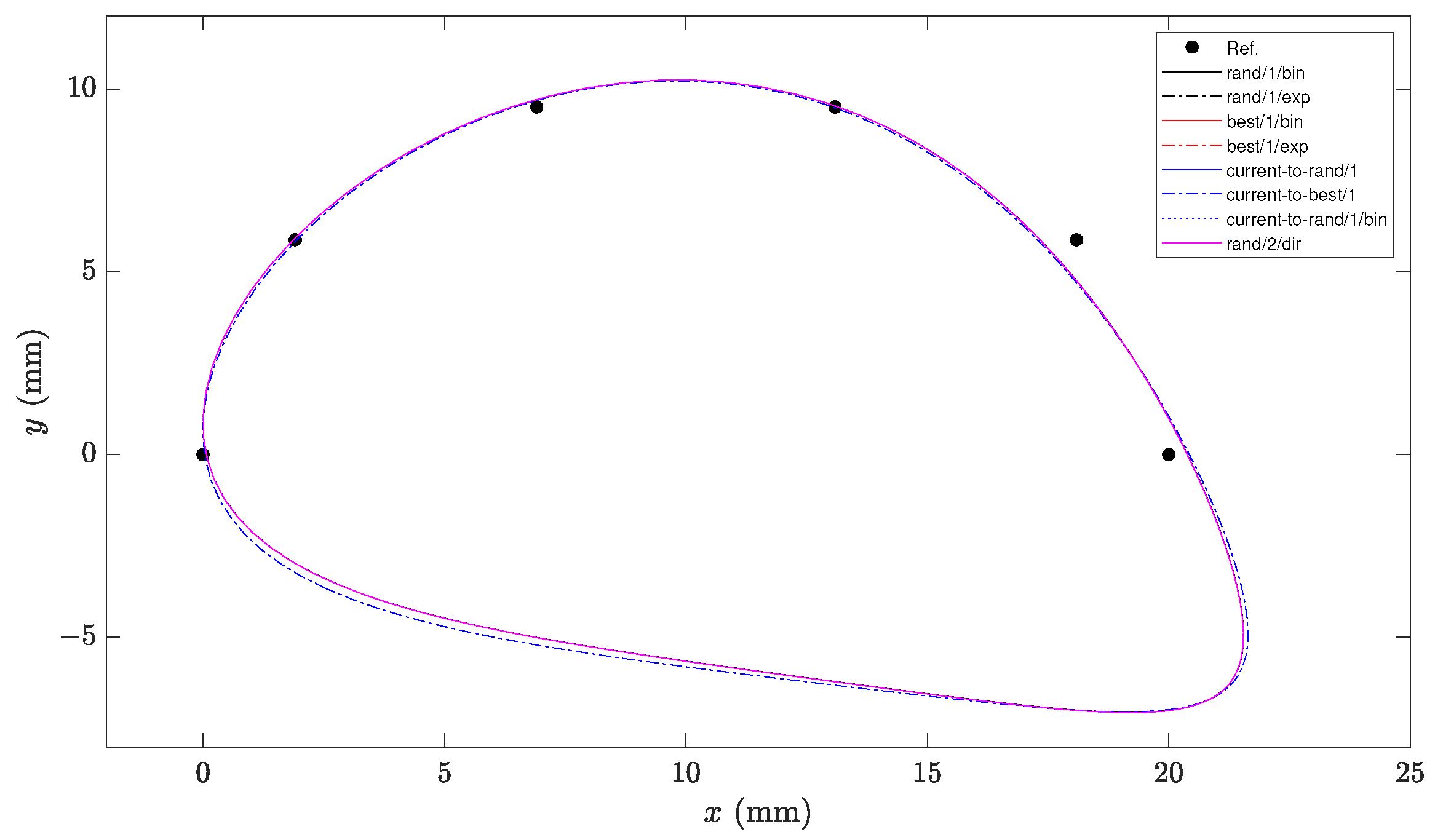

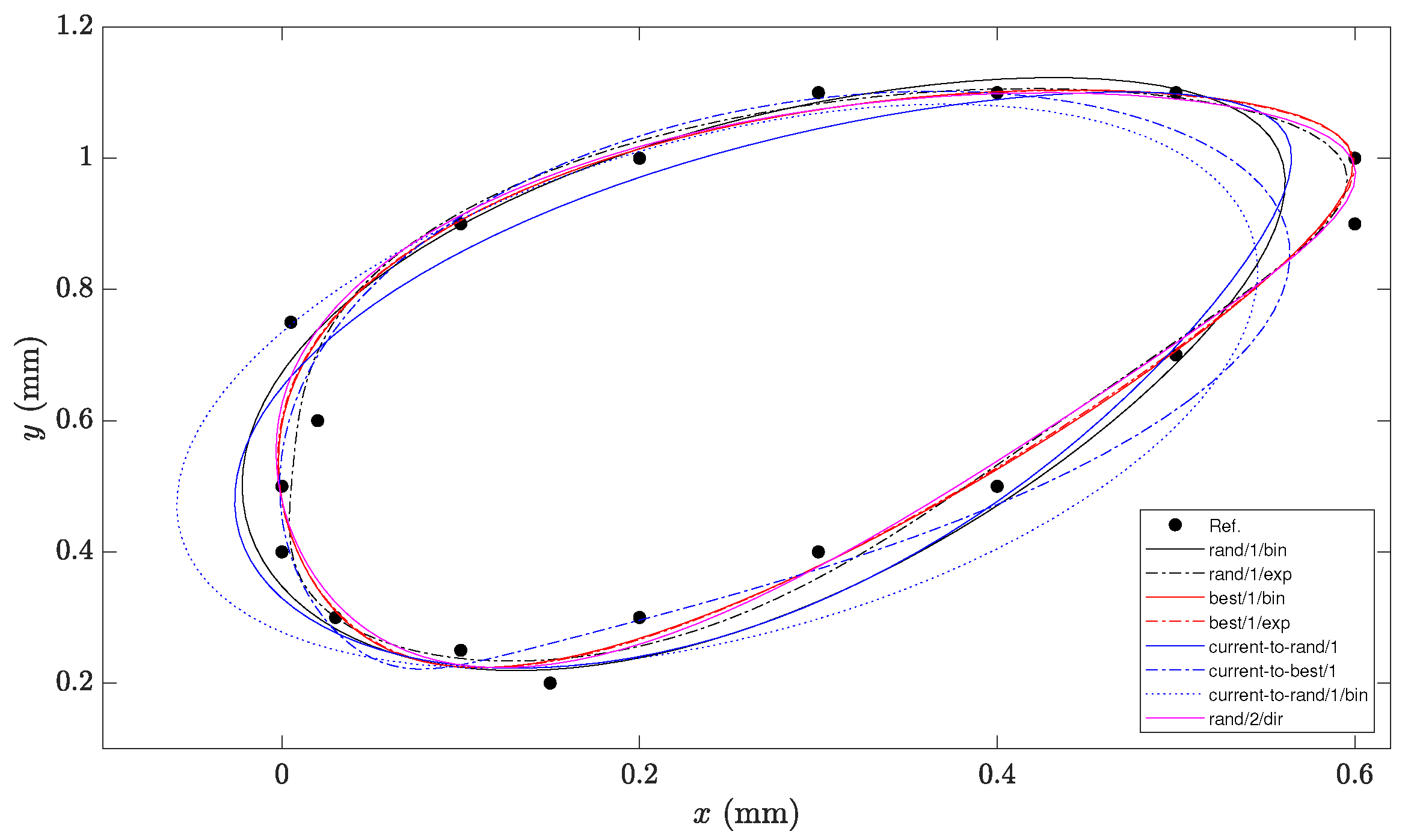

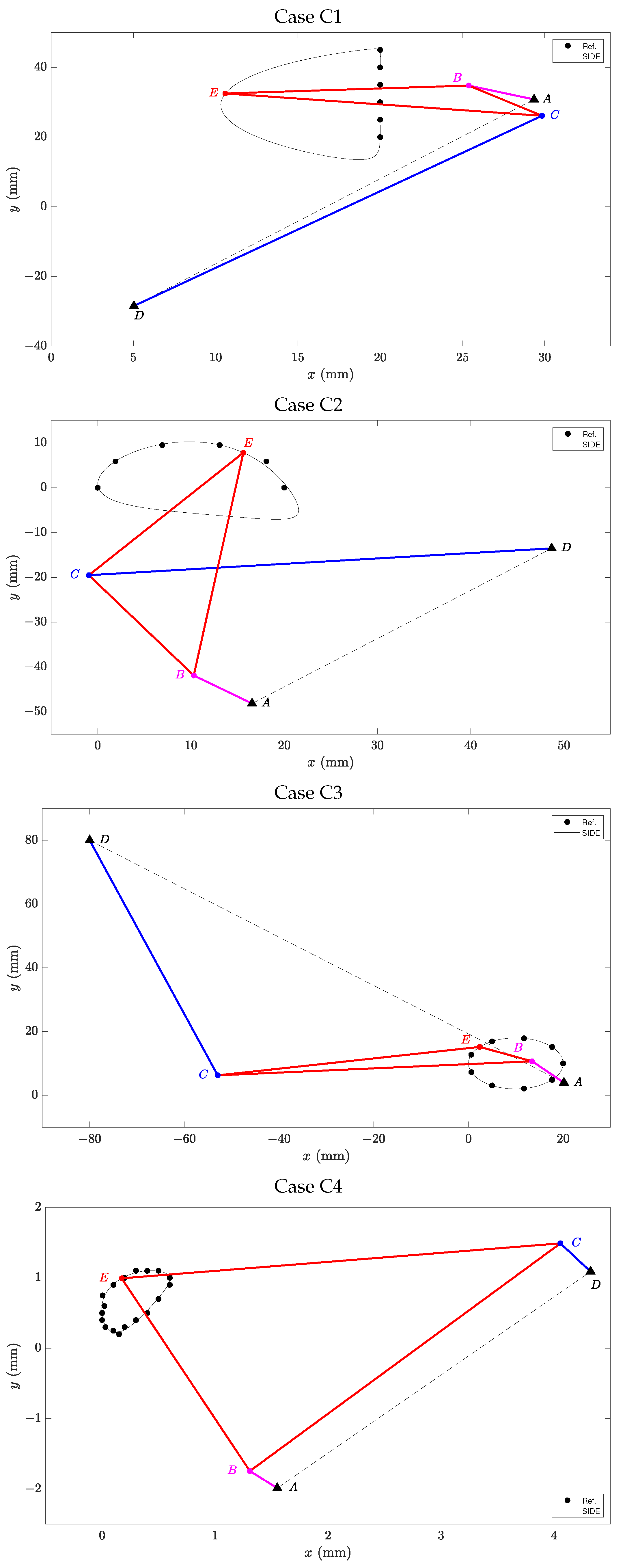

The study is intended to serve as a tool for choosing the most suitable alternative to solve this type of problem and as a support for developing algorithms that can solve specific related cases more effectively. To illustrate the study’s usefulness, a Simple and Improved version of DE (SIDE) was proposed that combines the functionality of the DE variants with the best results from the dimensional synthesis problem. This version of the DE enhances the results obtained with the original variants and also with respect to the cutting-edge methods employed in the four-bar mechanism synthesis problem. The obtained mechanism with the proposed SIDE generates paths more accurately with an increment in the computational effort of the algorithm. Therefore, the proposal’s main value is based on engineering applications, where accuracy is one of the most important criteria to consider.

Thus, the main contributions of this work include the following: (i) The proposal of a simple and improved version of the DE to solve the four-bar Grashof-type mechanism dimensional synthesis problem for path generation and (ii) the comparative study of the results among the main variants of the DE and the cutting-edge methods used in solving the dimensional synthesis problem of four-bar Grashof-type mechanisms.

The rest of this paper is organized as follows. The four-bar Grashof-type mechanism is fully described in

Section 2.

Section 3 presents the two most common conceptualizations of the problem of the dimensional synthesis of four-bar Grashof-type mechanisms. The DE operation, its variants, and the SIDE are explained in

Section 4. The case studies and results are discussed in

Section 5. Finally,

Section 6 draws the conclusions.

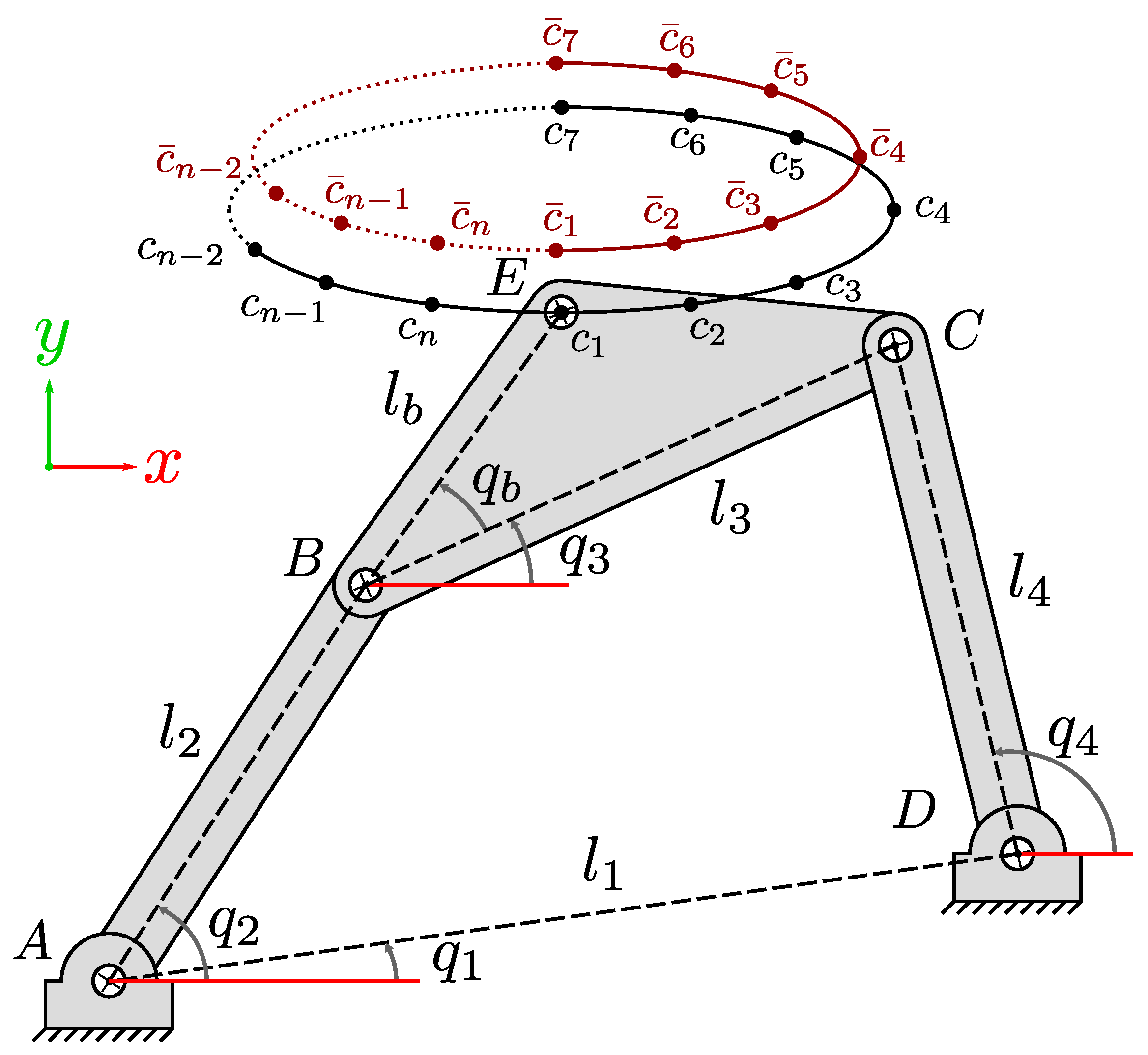

4. Differential Evolution

The synthesis problem presented in

Section 3 is highly nonlinear and subject to several constraints, and the possible combinations of dimensional parameters are incommensurable. Because of this, the metaheuristic techniques from evolutionary computation and swarm intelligence [

36] are alternatives used to obtain adequate solutions to this type of problem at an affordable computational cost [

27]. As previously discussed, the metaheuristic technique of Differential Evolution (DE) [

30] has been very successful in finding the solutions of dimensional synthesis problems of mechanisms [

31,

32,

33].

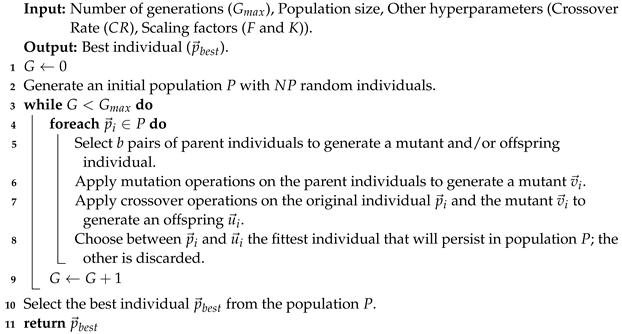

DE is a simple and effective stochastic algorithm for solving challenging optimization problems. This algorithm is inspired by the theory of the natural evolution of species according to Neo-Darwinism. Algorithm 1 summarizes the overall DE operation. At the beginning of the DE (lines 1 and 2), an initial population

P is generated with

random individuals (candidate solutions to an optimization problem randomly generated between bounds

and

). Subsequently, an evolutionary cycle is executed (lines 3 to 9), and different operations are performed on each individual

in the population

P (lines 4 to 8) to try to improve the original solutions and achieve convergence. Thus, for each

,

b pairs of parent individuals are selected (line 5). These generate a

mutant individual (line 6). Next, the mutant individual

is recombined with the original

to obtain an offspring

(line 7). Finally, the offspring individual

competes with the original

, and the fittest one persists in population

P, while the other is discarded. At the end of the evolutionary cycle, the fittest individuals are expected to be in the population

P, from which the best alternative is chosen as the solution to the optimization problem (lines 10 and 11).

| Algorithm 1: Differential Evolution |

![Applsci 13 06966 i001 Applsci 13 06966 i001]() |

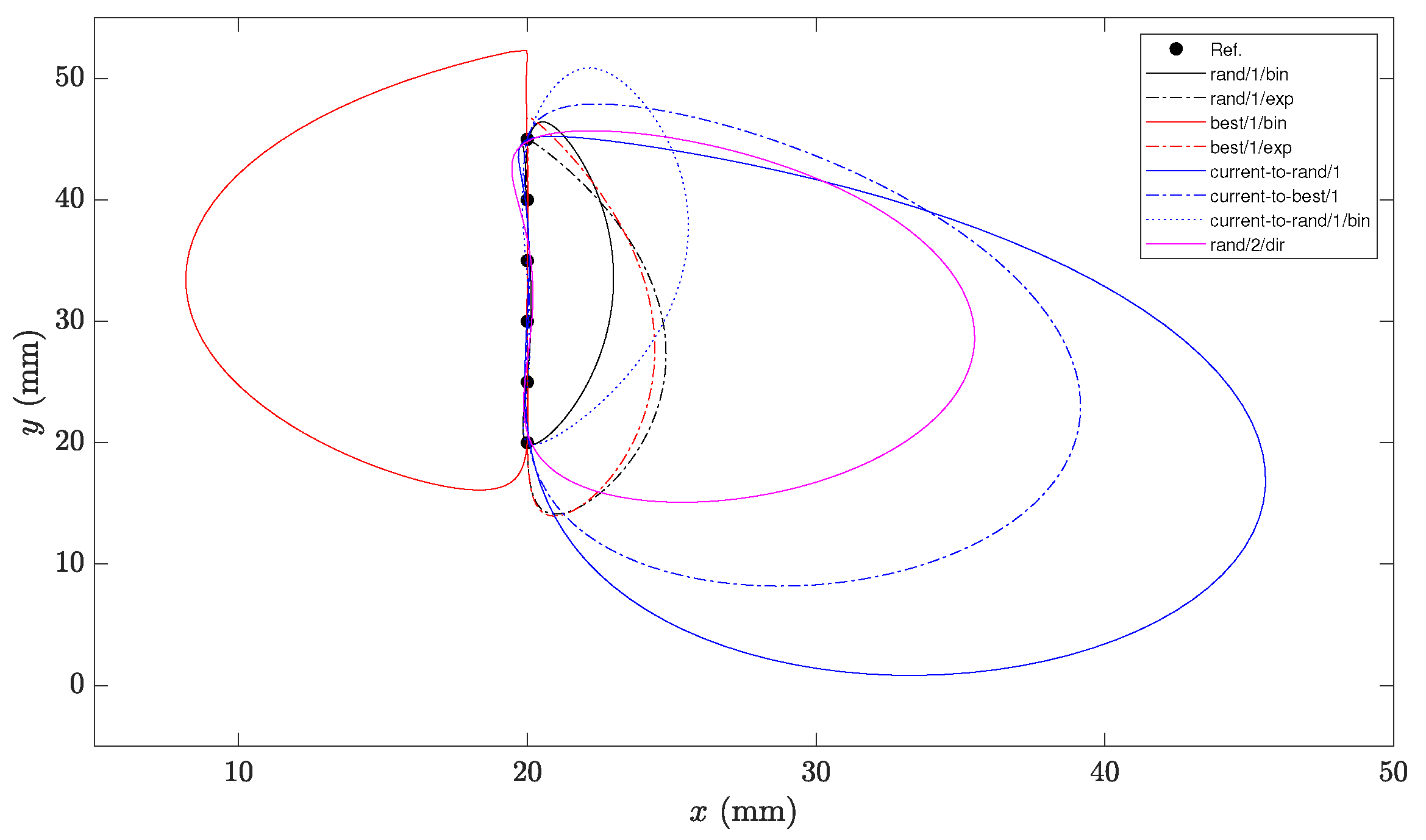

4.1. Differential Evolution Variants

DE has different variants that refer to different ways of performing the mutation and crossover operations in the algorithm 1 (lines 6 and 7). The nomenclature

is commonly used to denote each variant. In this nomenclature,

a refers to the strategy used to compute the mutant individual

,

b is the number of pairs of parent individuals used during this computation, and

c is the strategy to generate the offspring individual

. Some of the most commonly used variants of DE are described in [

37] and are summarized in

Table 1. In this table,

is a random number generated from a uniform probability distribution in the interval [0, 1],

j is the

j-th design variable of an individual, and

is a randomly selected design variable. On the other hand,

,

, and

for the first seven variants, are individuals randomly selected from the population

P, such that

, with

k as the number of parent pairs, while

is the fittest solution in

P. For the variant rand/2/dir,

,

,

, and

are individuals randomly selected from

P such that

, and they also satisfy

and

. Ultimately,

[0, 1] is the crossover rate, and

[0, 1] are scaling factors, which are all DE hyperparameters.

Each DE variant intends to improve its ability to perform exploratory searches (i.e., to find promising regions of the search space), exploitative searches (i.e., to find good solutions in particular regions of the search space), or to maintain an appropriate balance between the two.

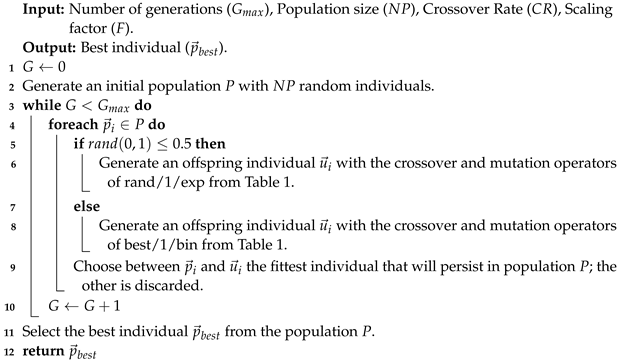

4.2. Simple and Improved Differential Evolution

Advancing the results of

Section 5, a Simple and Improved DE (SIDE) is now presented. The SIDE combines the behavior of the two most prominent variants of DE to solve the mechanism synthesis problem. These variants are rand/1/exp and best/1/bin. On the one hand, rand/1/exp has a great exploratory capacity that allows for finding different syntheses of mechanisms to follow a trajectory conformed by precision points. On the other hand, best/1/bin has a higher exploitative ability to refine the performance of a particular synthesis of the mechanism. In this way, SIDE takes advantage of the exploratory capacity of rand/1/exp and the exploitative ability of best/1/bin. The operation of SIDE is presented in Algorithm 2. Unlike the general functionality of the DE variants, described by Algorithm 1, in each generation

G (line 3) and for each individual

in the current population (line 4), SIDE decides randomly and with equal probability (line 5) which crossover and mutation operations to perform between those of rand/1/exp (line 6) and best/1/bin (line 8). This keeps the balance between exploration and exploitation simple.

4.3. Measuring the Fitness of Individuals

When an optimization problem includes neither equality nor inequality constraints, each individual’s fitness in the DE can be measured in terms of the value of the objective function. For minimization, the smaller the value of the objective function evaluated on an individual, the fitter the individual is. At the other extreme, where the optimization problem is subject to such constraints, the fitness must also consider the fulfillment of the constraints. One of the simplest and most efficient methods for comparing the fitness of two different solutions in terms of feasibility (compliance with equality and inequality constraints) and optimality (minimization of the objective function) is known as Deb’s rules [

38]. For two distinct solutions

and

, these rules state the following:

If is feasible and is unfeasible, then is fitter, i.e., . When the contrary occurs, i.e., is unfeasible and is feasible, then ;

If both and are feasible, the solution with the smaller objective function value is fitter (for minimization problems);

If both and are unfeasible, the solution with the smaller value of the constraint violation sum is fitter.

| Algorithm 2: SIDE: Simple and Improved Differential Evolution (based on the DE variants rand/1/exp and best/1/bin |

![Applsci 13 06966 i002 Applsci 13 06966 i002]() |

The constraint violation sum for a candidate solution

of any constrained optimization problem can be calculated as follows:

The rules described in this section are used in DE when it is necessary to choose the fittest solution (Algorithm 1 lines 8 and 10) or when some variant requires discriminating solutions to establish a suitable search direction in mutation or crossover operations (variant rand/2/dir in

Table 1).

4.4. Complexity of Differential Evolution

As described in [

39], the DE variants perform an evolutionary cycle of

generations to apply mutation and recombination operations on the

D design variables of each of the

individuals in the population. Thus, the execution time of this algorithm is proportional to the three variables above. Therefore, the computational complexity of DE and its variants, including SIDE, can be expressed in the

Big O notation as