Research on Fast Detection Technology of Dark Currents in a Ge–Si Detector Array

Abstract

1. Introduction

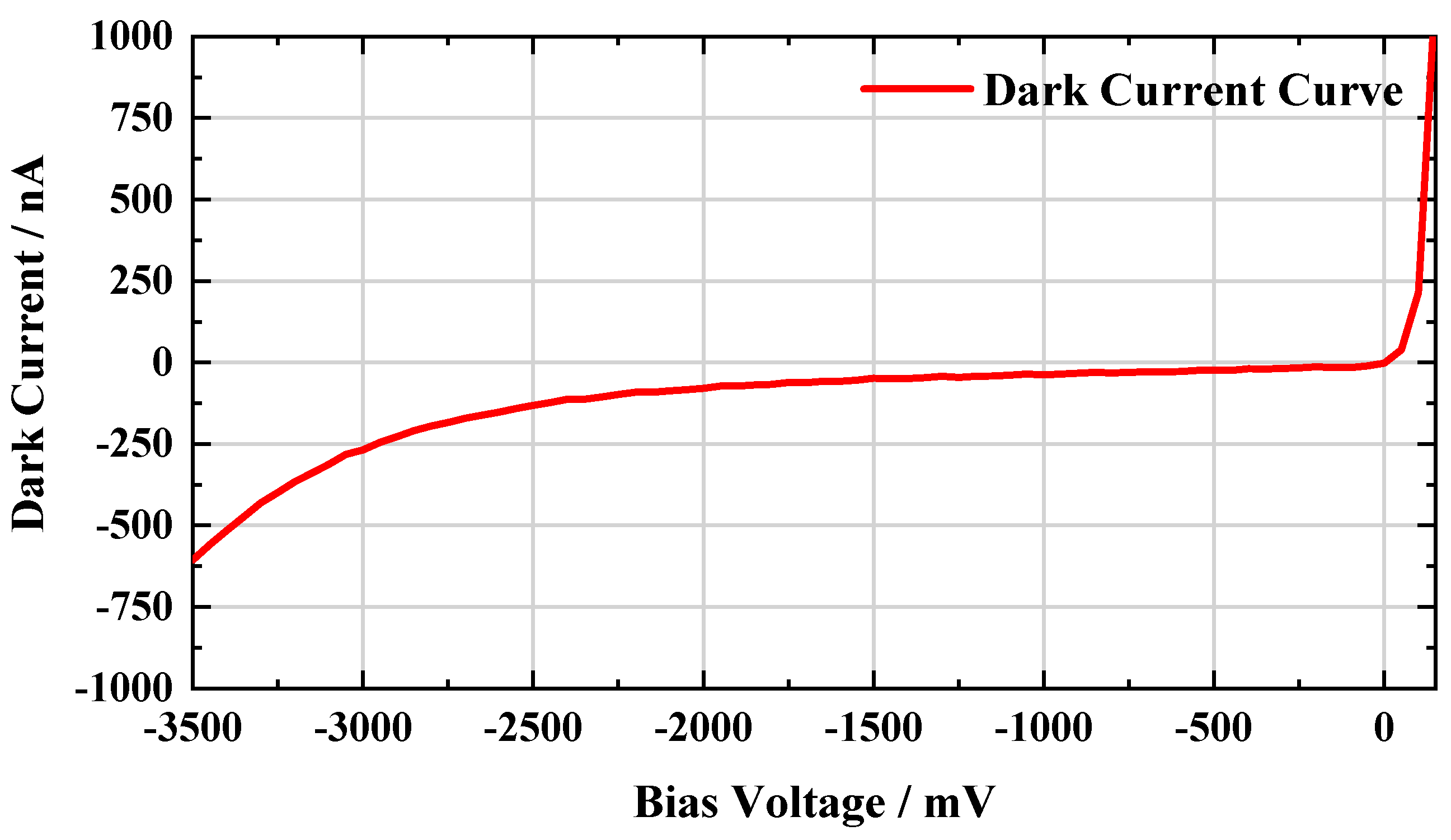

2. Principle and System

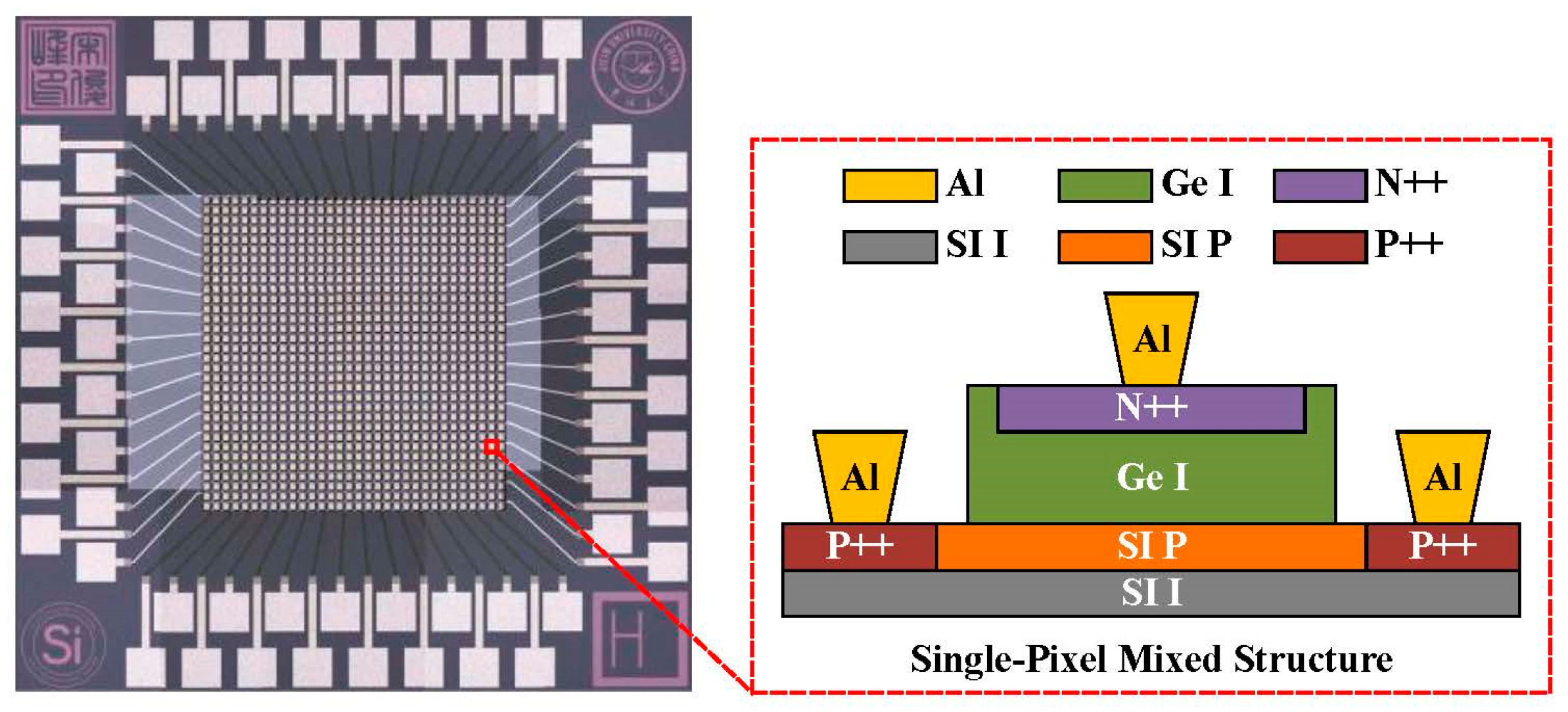

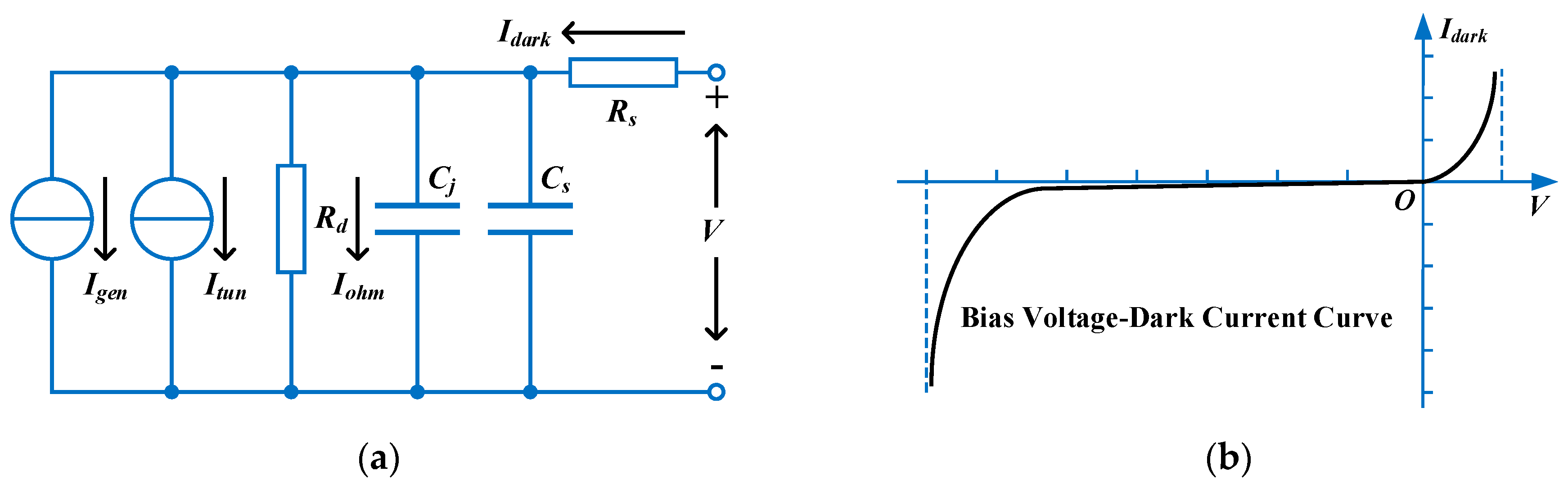

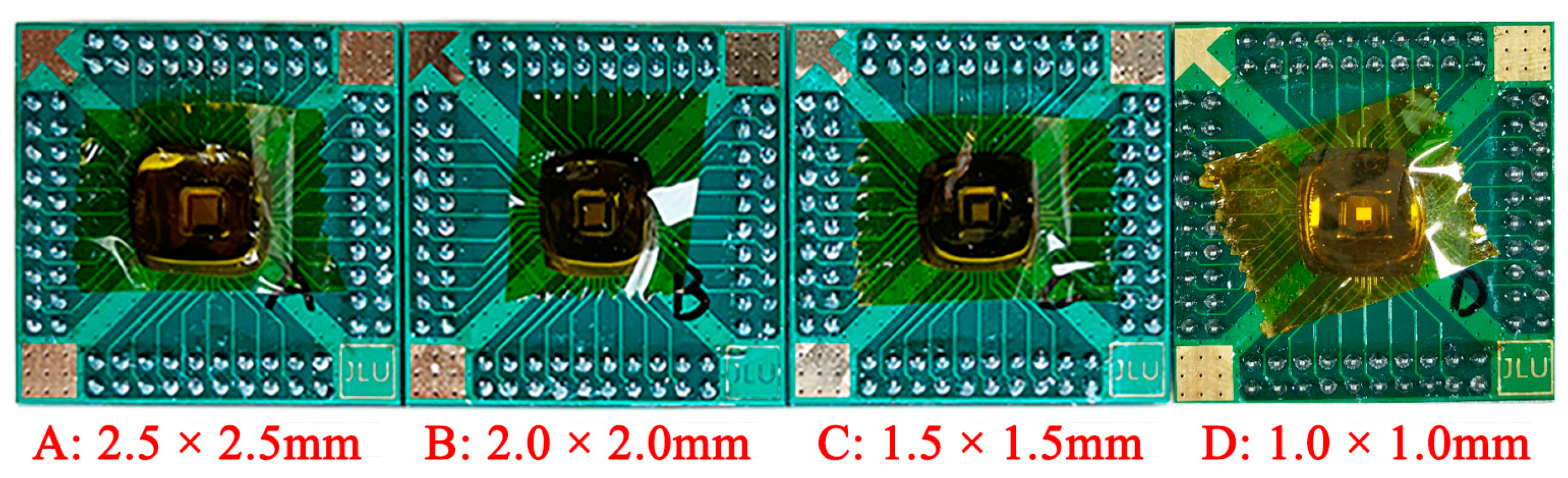

2.1. New Ge–Si Detector Array

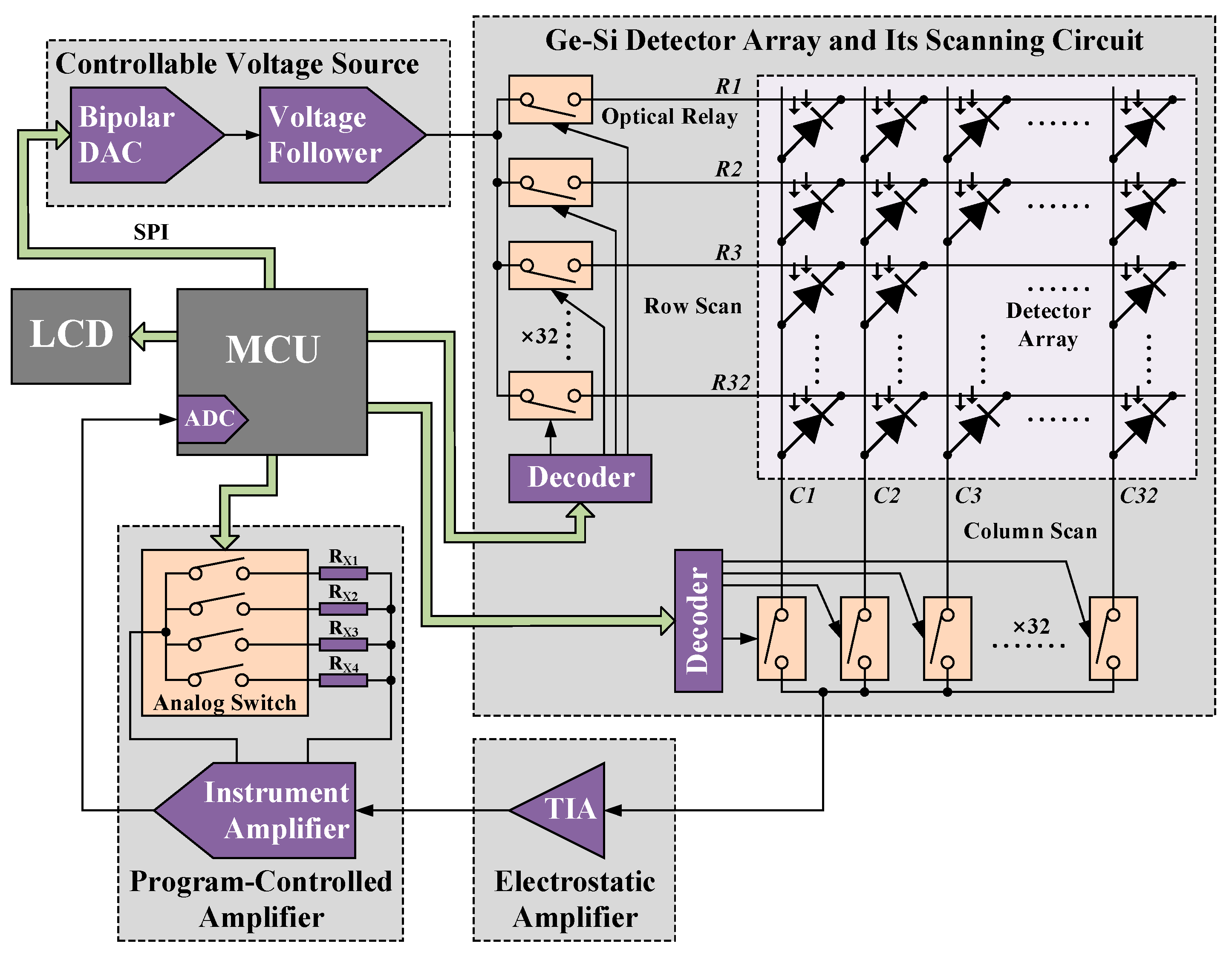

2.2. Scanning Detection Method and System

3. Array Test and Data Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, F. Analysis of Lidar Technology Development Based on Autonomous Driving Competition. In Proceedings of the International Conference of Optical Imaging and Measurement (ICOIM), Xi’an, China, 27–29 August 2021. [Google Scholar]

- Roriz, R.; Cabral, J.; Gomes, T. Automotive LiDAR Technology: A Survey. IEEE Trans. Intell. Transp. Syst. 2022, 23, 6282–6297. [Google Scholar] [CrossRef]

- Zhaohua, L.; Bochao, G. Radar Sensors in Automatic Driving Cars. In Proceedings of the International Conference on Electromechanical Control Technology and Transportation (ICECTT), Nanchang, China, 15–17 May 2020. [Google Scholar]

- Shan, Y.; Yao, X.; Lin, H.; Zou, X.; Huang, K. Lidar-Based Stable Navigable Region Detection for Unmanned Surface Vehicles. IEEE Trans. Instrum. Meas. 2021, 70, 8501613. [Google Scholar] [CrossRef]

- Chiang, K.W.; Tsai, G.J.; Li, Y.H.; El-Sheimy, N. Development of LiDAR-Based UAV System for Environment Reconstruction. IEEE Geosci. Remote Sens. Lett. 2017, 14, 1790–1794. [Google Scholar] [CrossRef]

- Molebny, V.; McManamon, P.; Steinvall, O.; Kobayashi, T.; Chen, W. Laser radar: Historical prospective—From the East to the West. Opt. Eng. 2016, 56, 031220. [Google Scholar] [CrossRef]

- Månefjord, H.; Müller, L.; Li, M.; Salvador, J.; Blomqvist, S.; Runemark, A.; Kirkeby, C.; Ignell, R.; Bood, J.; Brydegaard, M.; et al. 3D-Printed Fluorescence Hyperspectral Lidar for Monitoring Tagged Insects. IEEE J. Sel. Top. Quantum Electron. 2022, 28, 7100109. [Google Scholar] [CrossRef]

- Sanjaya, K.; Henning, F.; Purba, K.R. 3D LIDAR City Model Application and Marketing Plan Development. In Proceedings of the International Conference on Soft Computing, Intelligent System and Information Technology (ICSIIT), Denpasar, Indonesia, 26–29 September 2017. [Google Scholar]

- Mongus, D.; Žalik, B. Computationally Efficient Method for the Generation of a Digital Terrain Model from Airborne LiDAR Data Using Connected Operators. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2014, 7, 340–351. [Google Scholar] [CrossRef]

- Dai, J.; Zhao, X.; Li, L.P.; Ma, X.F. GCD-YOLOv5: An Armored Target Recognition Algorithm in Complex Environments Based on Array Lidar. IEEE Photonics J. 2022, 14, 3937711. [Google Scholar] [CrossRef]

- Singh, L.; Srivastava, A.; Sarkate, A.J. Thermal gradient effect on focus shift of laser & infrared optical assembly & thermal lensing by Nd-Yag laser rod in laser assembly of Optical Detection & Ranging System of Fighter Aircraft. In Proceedings of the IEEE Uttar Pradesh Section International Conference on Electrical, Computer and Electronics (UPCON), Mathura, India, 26–28 October 2017. [Google Scholar]

- Zhou, G.; Li, C.; Zhang, D.; Liu, D.; Zhou, X.; Zhan, J. Overview of Underwater Transmission Characteristics of Oceanic LiDAR. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2021, 14, 8144–8159. [Google Scholar] [CrossRef]

- Hecht, J. Laser instruments earn their place in space for communications and lidar. Laser Focus World Mag. Photonics Optoelectron. Ind. 2014, 50, 27–31. [Google Scholar]

- Pham, T.; Du, W.; Tran, H.; Margetis, J.; Tolle, J.; Sun, G.; Soref, R.A.; Naseem, H.A.; Li, B.; Yu, S.Q. Systematic study of Si-based GeSn photodiodes with 26m detector cutoff for short-wave infrared detection. Opt. Express 2016, 24, 4519. [Google Scholar] [CrossRef]

- Batshev, V.I.; Boritko, S.V.; Kozlov, A.B.; Sharikova, M.O.; Lomonov, V.A. Optical System of Visible and Short-Wave Infrared AOTF-based Spectral Imaging Device. In Proceedings of the Wave Electronics and its Application in Information and Telecommunication Systems (WECONF), St. Petersburg, Russia, 31 May–4 June 2021. [Google Scholar]

- Xu, M.; Wang, J.L.; Chen, T. Study on application of short wave infrared to detecting satellites in the daytime. Opt. Technol. 2008, 34, 277–280. [Google Scholar]

- Qi, J.; Sun, C.; Zebibula, A.; Zhang, H.; Kwok, R.T.; Zhao, X.; Xi, W.; Lam, J.W.Y.; Qian, J.; Tang, B.Z. Real-Time and High-Resolution Bioimaging with Bright Aggregation-Induced Emission Dots in Short-Wave Infrared Region. Adv. Mater. 2018, 30, 1706856. [Google Scholar] [CrossRef]

- Basyooni, M.A.; Gaballah, A.E.H.; Tihtih, M.; Derkaoui, I.; Zaki, S.E.; Eker, Y.R.; Ateş, Ş. Thermionic Emission of Atomic Layer Deposited MoO3/Si UV Photodetectors. Materials 2023, 16, 2766. [Google Scholar] [CrossRef]

- Millar, R.W.; Kirdoda, J.; Kuzmenko, K.; Vines, P.; Halimi, A.; Collins, R.J.; Maccarone, A.; McCarthy, A.; Greener, Z.M.; Thorburn, F.; et al. Ge-on-Si Single Photon Avalanche Diode Detectors for LIDAR in the Short Wave Infrared. In Proceedings of the Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 10–15 May 2020. [Google Scholar]

- Hamamatsu Photonics Co., Ltd. InGaAs PIN Photodiode Arrays G12430 Series; Hamamatsu Photonics Co., Ltd.: Hamamatsu City, Japan, 2017. [Google Scholar]

- Vines, P.; Kuzmenko, K.; Kirdoda, J.; Dumas, D.C.; Mirza, M.M.; Millar, R.W.; Paul, D.J.; Buller, G.S. High performance planar germanium-on-silicon single-photon avalanche diode detectors. Nat. Commun. 2019, 10, 1086. [Google Scholar] [CrossRef]

- Duan, N.; Liow, T.Y.; Lim AE, J.; Ding, L.; Lo, G. 310 GHz gain-bandwidth product Ge/Si avalanche photodetector for 1550 nm light detection. Opt. Express 2012, 20, 11031. [Google Scholar] [CrossRef]

- Kang, Y.; Liu, H.D.; Morse, M.; Paniccia, M.J.; Zadka, M.; Litski, S.; Sarid, G.; Pauchard, A.; Kuo, Y.H.; Chen, H.W.; et al. Monolithic germanium/silicon avalanche photodiodes with 340 GHz gain–bandwidth product. Nat. Photonics 2009, 3, 59–63. [Google Scholar] [CrossRef]

- Virot, L.; Crozat, P.; Fédéli, J.M.; Hartmann, J.M.; Marris-Morini, D.; Cassan, E.; Boeuf, F.; Vivien, L. Germanium avalanche receiver for low power interconnects. Nat. Commun. 2014, 5, 4957. [Google Scholar] [CrossRef] [PubMed]

- Warburton, R.E.; Intermite, G.; Myronov, M.; Allred, P.; Leadley, D.R.; Gallacher, K.; Paul, D.J.; Pilgrim, N.J.; Lever, L.J.M.; Ikonic, Z.; et al. Ge-on-Si Single-Photon Avalanche Diode Detectors: Design, Modeling, Fabrication, and Characterization at Wavelengths 1310 and 1550 nm. IEEE Trans. Electron Devices 2013, 60, 3807–3813. [Google Scholar] [CrossRef]

- Martinez, N.J.; Gehl, M.; Derose, C.T.; Starbuck, A.L.; Pomerene, A.T.; Lentine, A.L.; Trotter, D.C.; Davids, P.S. Single photon detection in a waveguide-coupled Ge-on-Si lateral avalanche photodiode. Opt. Express 2017, 25, 16130–16139. [Google Scholar] [CrossRef]

- Li, Y.; Luo, X.-S.; Liang, G.; Lo, G.Q. Demonstration of Ge/Si Avalanche Photodetector Arrays for Lidar Application; Optica Publishing Group: Washington, DC, USA, 2019. [Google Scholar]

- Zhang, D.L.; Cheng, B.W.; Xue, C.L.; Zhang, X.; Cong, H.; Liu, Z.; Zhang, G.Z.; Wang, Q.M. Theoretical study of the optical gain characteristics of a Ge1xSnx alloy for a short-wave infrared laser. Chin. Phys. B 2015, 7, 024211. [Google Scholar] [CrossRef]

- Zhimeng, C.; Liqun, C.; Cheng, L. Characteristics of SOI-Based RCE-Ge photodetectors. J. Fuzhou Univ. 2016, 44, 656. [Google Scholar]

- Cui, J.; Zhou, Z. High-performance Ge-on-Si photodetector with optimized DBR location. Opt. Lett. 2017, 42, 5141–5144. [Google Scholar] [CrossRef]

- Xu, S.; Deng, Z.; Xu, H.; Feng, J. Design of preamplifier and range automatic switching circuit using in light intensity detection. Electron. Des. Eng. 2015, 23, 99–104. [Google Scholar]

- De Marcellis, A.; Palange, E.; Leone, S.; Stanchieri, G.D.P.; Faccio, M. Photodiode Bridge-Based Differential Readout Circuit for High-Sensitivity Measurements of Energy Variations of Laser Pulses for Optoelectronic Sensing Systems. In Proceedings of the 2018 New Generation of CAS (NGCAS), Valletta, Malta, 20–23 November 2018. [Google Scholar]

- Pallares, J.; Cabre, R.; Marsal, L.F.; Schropp, R.E.I. A compact equivalent circuit for the dark current-voltage characteristics of nonideal solar cells. J. Appl. Phys. 2006, 100, 465. [Google Scholar] [CrossRef]

- Hwang, Y.S.; Wang, S.C.; Lai, B.P.; Chen, J.J. Controllable readout circuit for indium gallium arsenide photodiode array applications. IET Circuits Devices Syst. 2009, 3, 125–134. [Google Scholar] [CrossRef]

- Zhang, H.; Ke, C.; Liu, Z. Modeling and simulation analysis of PIN photodetector. J. Appl. Opt. 2019, 40, 723–730. [Google Scholar]

- Zhao, J. Research on Photodetector Equivalent Circuit Model and Experiment; Chongqing University: Chongqing, China, 2015. [Google Scholar]

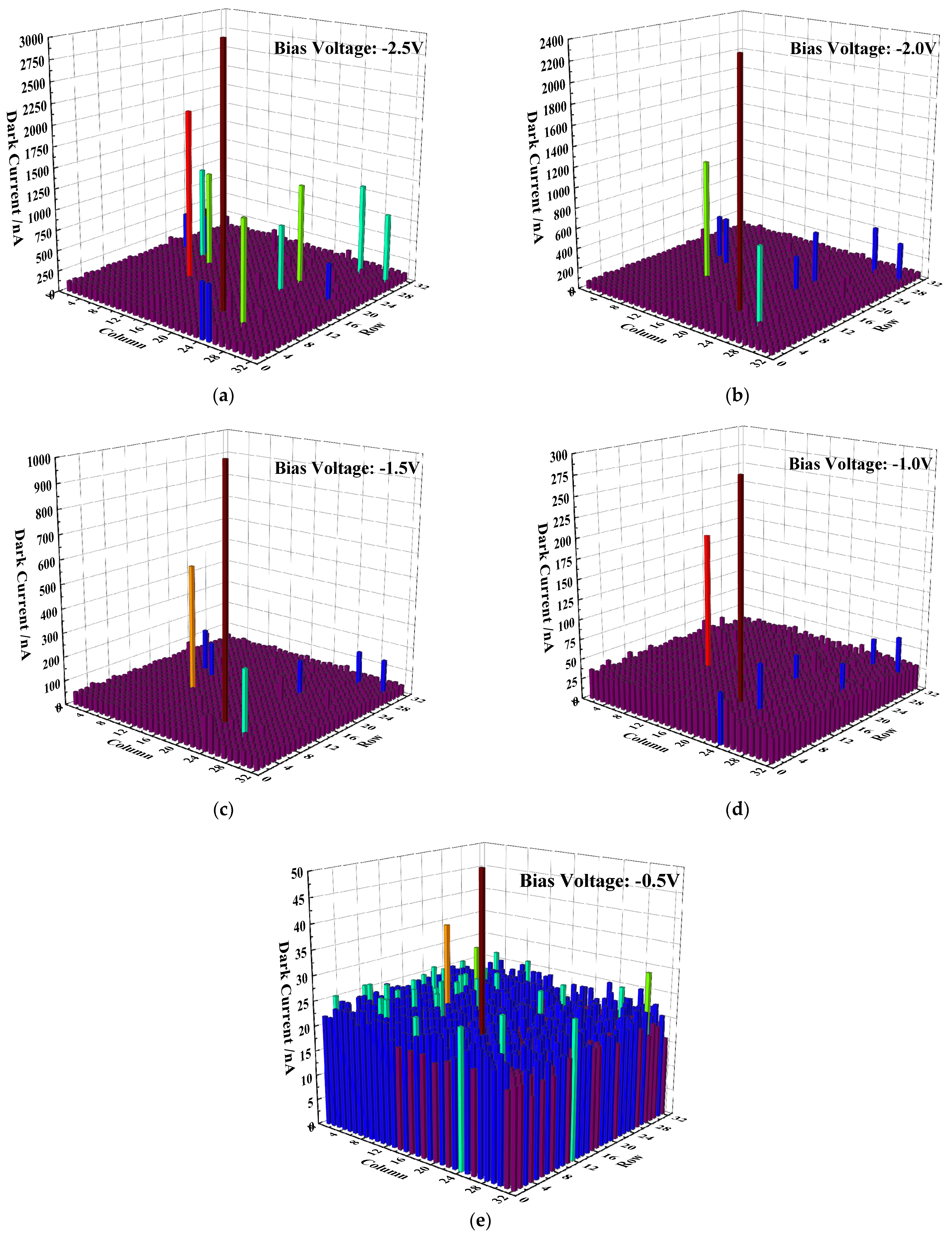

| Bias Voltage (V) | Average Dark Current (nA) | Number of Pixels > 10 Times the Average Dark Current | Number of Pixels > 5 Times the Average Dark Current |

|---|---|---|---|

| −2.5 | 147 | 2 | 9 |

| −2.0 | 86 | 2 | 7 |

| −1.5 | 54 | 2 | 3 |

| −1.0 | 35 | 0 | 2 |

| −0.5 | 22 | 0 | 0 |

| Bias Voltage (V) | Average Dark Current (nA) | Number of Pixels > 10 Times the Average Dark Current | Number of Pixels > 5 Times the Average Dark Current | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | A | B | C | D | A | B | C | D | |

| −2.5 | 147 | 75 | 28 | 24 | 2 | 10 | 4 | 3 | 9 | 11 | 8 | 5 |

| −2.0 | 86 | 47 | 15 | 15 | 2 | 7 | 1 | 0 | 7 | 11 | 6 | 5 |

| −1.5 | 54 | 27 | 8 | 12 | 2 | 5 | 1 | 0 | 3 | 8 | 4 | 1 |

| −1.0 | 35 | 16 | 5 | 9 | 0 | 4 | 1 | 0 | 2 | 5 | 2 | 0 |

| −0.5 | 22 | 9 | 2 | 8 | 0 | 1 | 0 | 0 | 0 | 1 | 5 | 0 |

| Bias Voltage (V) | Responsiveness (A/W) | |||

|---|---|---|---|---|

| A | B | C | D | |

| −2.5 | 0.417 | 0.418 | 0.325 | 0.213 |

| −2.0 | 0.435 | 0.421 | 0.335 | 0.226 |

| −1.5 | 0.448 | 0.443 | 0.350 | 0.256 |

| −1.0 | 0.456 | 0.452 | 0.376 | 0.263 |

| −0.5 | 0.478 | 0.455 | 0.383 | 0.286 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Tao, M.; Li, X.; Song, J.; Liu, Z.; Wang, Z.; Li, C. Research on Fast Detection Technology of Dark Currents in a Ge–Si Detector Array. Appl. Sci. 2023, 13, 6887. https://doi.org/10.3390/app13126887

Gao Z, Tao M, Li X, Song J, Liu Z, Wang Z, Li C. Research on Fast Detection Technology of Dark Currents in a Ge–Si Detector Array. Applied Sciences. 2023; 13(12):6887. https://doi.org/10.3390/app13126887

Chicago/Turabian StyleGao, Zhen, Min Tao, Xuetong Li, Junfeng Song, Zijian Liu, Ziming Wang, and Chengming Li. 2023. "Research on Fast Detection Technology of Dark Currents in a Ge–Si Detector Array" Applied Sciences 13, no. 12: 6887. https://doi.org/10.3390/app13126887

APA StyleGao, Z., Tao, M., Li, X., Song, J., Liu, Z., Wang, Z., & Li, C. (2023). Research on Fast Detection Technology of Dark Currents in a Ge–Si Detector Array. Applied Sciences, 13(12), 6887. https://doi.org/10.3390/app13126887