1. Introduction

The water surface covers almost three-fourths of our planet’s total surface area, providing humans with a variety of mineral and natural resources. With terrestrial reserves being depleted, a growing focus has arisen on exploring the seabed for resources such as gas, oil, and minerals. However, traditional manned systems and human divers are limited in investigating vast and often hazardous underwater environments. To overcome these challenges, remotely operated vehicles (ROVs) have gained popularity among governmental agencies and commercial companies as they can undertake complex missions without risking human lives [

1]. ROVs are often equipped with cameras, sensors, and manipulator’s arms, allowing operators to remotely navigate and interact with the underwater environment [

2,

3,

4,

5,

6]. They are operated from a surface vessel or a control room onshore, using a tether that provides power and communication between the vehicle and the operator. ROVs have revolutionized how we explore the ocean, allowing us to gather data and samples, perform maintenance and repairs on underwater infrastructure, and conduct scientific research in inaccessible areas [

7,

8,

9,

10].

Ali et al. [

11] developed a twin-controller approach using Matlab to regulate the behavior of underwater ROVs. The controller design comprises proportional-integral-derivative (PID) to tune the adaptive gains of the aquatic system and model reference adaptive control (MRAC) to mitigate the dynamic system’s disturbance. Dong et al. [

12] proposed a depth control strategy that combines fuzzy PID and dynamic compensation. Using ANSYS, the hydrodynamics analysis of ROV was conducted to find out the relationship between the resistance of water and moving velocity in the heave direction. The depth control can vary by 3 cm, which is practical for the reactor pool.

Bykanova et al. [

13] developed a small-sized ROV for shipwrecks with a variable storing moment by rotating the wing in the vehicle’s plane. The ROV had four horizontal thrusters to increase the range of maneuverability. Furthermore, the ROV was enhanced with a lithium battery to reduce the tether’s weight and return to the coast in case of emergency or damage to the cable.

Omerdic et al. [

14] designed a prototype platform to test and validate new technologies for marine operations. The designed ROV was equipped with advanced 3D visual displays, an easy pilot interface, voice control navigation, and low-level controllers with an auto-tuning system. The position of a fully actuated underwater ROV with a manipulator was stabilized by Ali et al. [

9]. They applied the proposed control algorithm on an eight degrees-of-freedom (DOF) ROV to control the erratic deviations. The simulations proved that the designed ROV could effectively reach the desired position.

Other researchers assessed different control methods using neural networks, demonstrating their benefits, shortcomings, and applications [

15,

16]. Caccia and Veruggio [

17] developed an ROV navigation system through pre-programmed controllers to control the speed. Do et al. [

18] designed an adaptive control mechanism to ensure a 6-DOF ROV follows the desired route. Hoang and Kreuzer [

19] proposed a hybrid PID controller for the dynamic orientation of ROVs to ensure the accurate execution of tasks near underwater structures.

Despite the efforts of previous researchers to enhance the performance of ROVs, little attention has been paid to integrating the various phases of design and fabrication. Thus, the main objective of this study is to develop an entire framework that considers the design, manufacturing, and assembling of a portable ROV system. Furthermore, a coating technique of track width in the printed circuit board (PCB) is presented to reduce the size of the electrical enclosure and, consequently, the vehicle’s size. Subsequently, an image processing technique is developed to enhance the ROV’s capabilities for performing various tasks in underwater environments. This paper is arranged as follows:

Section 1 provides a background and literature survey,

Section 2 presents the mathematical model of ROV,

Section 3 illustrates the mechanical design structure,

Section 4 discusses the electrical system design,

Section 5 presents the software system,

Section 6 presents the experimental setup,

Section 7 presents the results and discussion, and finally,

Section 8 presents the conclusions, limitations, and recommendations for future work.

3. Mechanical Design Structure

The proposed mechanical design should provide an easy-to-assemble, lightly weighted, and maneuverable ROV capable of performing tasks efficiently in a reasonable time. Accordingly, we sought a balance between high performance and innovative design of ROV [

22].

3.1. Structure of ROV

There are three phases to build the structure of ROV. Firstly, in the brainstorming phase, various free-hand sketches have been drawn, edited, and discussed to reach an efficient design for ROV. Subsequently, the design that could meet the electrical requirements was chosen. Accordingly, we designed our ROV in a circular shape to allow easy rotational movement, smoothness of motion, and reduction in turbulent flow. The curvature in the electrical enclosure enables the reduction in drag force due to the streamlined shape.

Several computer-aided design (CAD) programs were utilized for the design process. Inventor was used for simulating the solid model and assemblage of ROV. AutoCAD was used for preparing the final files of ROV for printing and fabrication. At the end of the two phases, we discussed the materials based on the calculations and costs of the suggested materials for ROV’s upper plate, lower plate, and electrical enclosure.

Figure 2 illustrates the ROV’s structure.

3.2. Material Selection

Selecting materials for an ROV depends on various factors, such as the intended use of the ROV, operating conditions, budget, and performance requirements. The ROV consists of upper and lower plates held together by four shafts. The electronic enclosure is connected to the upper plate via six bolts, and the lower plate is for the four horizontal thrusters. Two cameras were installed on the ROV. The upper and lower plates were made of acrylic with 10 thicknesses to resist corrosion and ease manufacturing. The electric housing dome was also made of acrylic due to its light transmittance, ability to withstand water pressure, and ease of insulation.

Stainless steel was chosen for shafts, rivets, washers, and nuts because of its ability to resist corrosion under water. Additionally, it can withstand high strength and power. Two holders were placed for the vertical thrusters between the two plates. Many screw holes were located on the upper and lower plates to enable easy installation of tools in the plates and for motor positioning.

Figure 3 illustrates the developed prototype.

3.3. Configuration of Thrusters

We calculated the maximum force to move our vehicle up and down to choose the suitable type of thruster and determine whether the thrusters could dive. We used six Blue-robotics T100 thrusters. Compared to bilge pumps, they have a greater thrust-to-physical size ratio [

6]. Accordingly, they can provide more free space to install the mechanisms required for the required tasks. However, the T100 thrusters have a high-power consumption at high-speed operations. Equation (14) expresses the computation of the drag force

D:

where

is the drag force,

is the ROV’s cross-sectional area, ρ is the fluid’s density,

is the object’s speed relative to the fluid, and

is the drag coefficient.

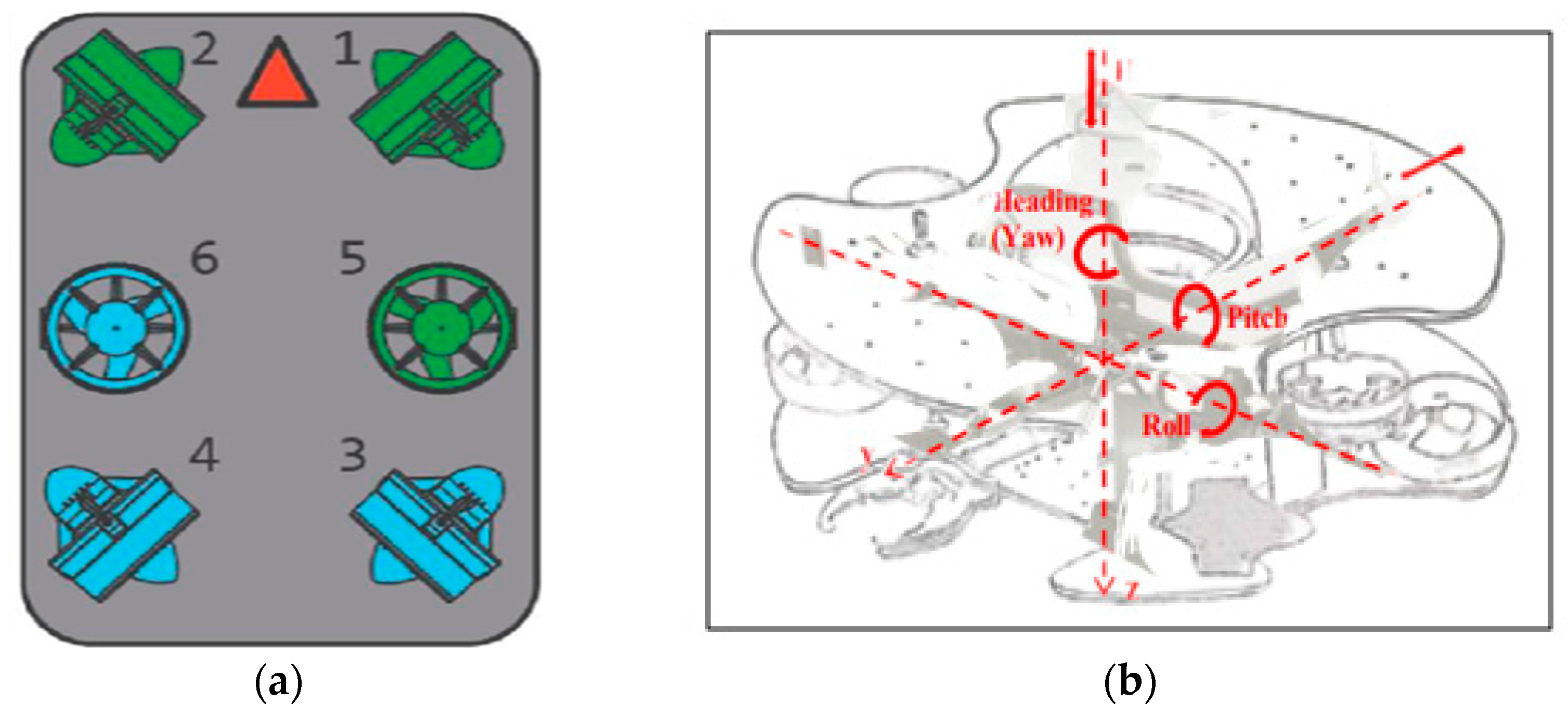

According to Equation (14), to achieve suitable maneuverability and to introduce lateral translation, four equally spaced thrusters were located on a prevalent plane and were vectored at 45° angles in the corners as shown in

Figure 4a. The two motors were in front of ROV (a forward position), and the two thrusters were in the back of ROV (a backward position). Two vertical thrusters were installed on the vehicle’s right and left sides. As a result, the vehicle could achieve six-DOF (namely, Surge, Sway, Heave, Yaw, Roll, Pitch). The 6-DOF of the ROV is illustrated in

Figure 4b.

This configuration allows the thrusters to contribute to the power efficiently towards better propulsion. It also reduces flow interference, considering the overcoming drag that might interrupt the vehicle and the drag of the tether. Each blue-robotics T100 thruster has a maximum forward thruster = 23.15 N and a maximum backward thruster = 17.85 N [

24,

25].

Figure 4.

Thruster configuration: (

a) Motor Positioning [

26], (

b) Motion of ROV in 6-DOF. The red triangle represents the direction of motion.

Figure 4.

Thruster configuration: (

a) Motor Positioning [

26], (

b) Motion of ROV in 6-DOF. The red triangle represents the direction of motion.

3.4. Gripper and Camera Enclosure

A pneumatically actuated manipulator was designed to perform underwater tasks successfully. The actuator is a pneumatic cylinder (bore 30 mm and stroke 60 mm). It depends on the mechanism of the parallel link to convert the linear motion of the cylinder to a gripping action. The gripper’s jaws were designed especially for the missions as shown in

Figure 5a.

To perform the tasks appropriately, we set up two cameras to allow the pilot to control the vehicle. The main camera is set in the electronic enclosure and faces the front side of the ROV. The cameras were also used for image processing at the request of our software tasks. The second camera was installed to capture photos of the gripper. The enclosure was made of artelon, with a gland at its end to pass the camera’s cable through. An acrylic drum was added to allow the light to pass through for a better vision. The camera enclosure is shown in

Figure 5b.

3.5. Stress Analysis

Taking the weight and strength factors into consideration, a stress analysis was conducted to determine the following:

The maximum pressure that the upper plate and lower plate can withstand.

The weight effect of the mechanical parts fixed to the upper and lower plates.

The ability of the electric enclosure to withstand pressure under 7-m depth.

4. Electrical System Design

In terms of electrical design, standards must be set that regulate the electrical circuit. It is important to know the distribution of energy in the ROVs, and to reach an electrical circuit that works with the suitable efficiency and the least capabilities. This section aims to develop a customer-oriented design that would optimize performance while maintaining modularity and flexibility. The electrical system consists of the following primary components: (i) surface control station, (ii) tether system, and (iii) onboard electronics [

27].

Figure 6 shows the flowchart of the electrical system integration diagram (SID).

The ROV was controlled from the surface using a laptop and a gaming controller. Firstly, the electrical circuit was drawn as a hand sketch, enabling each component to be placed in the electric circuit, extending each element that needs power. Subsequently, the desired area of the electrical circuit was calculated, and the electrical circuit was modeled using Eagle and Easy EDA software programs, and every part was determined in the electrical circuit as shown in

Figure 7.

Control data was sent from the Arduino to a passive high-definition composite video interface (HDCVI) transceiver connected by another passive HDCVI transceiver in the ROV’s electric enclosure using a Category 6 cable connecting to the onboard Arduino mega through two wires. A Category 6 cable was utilized because it provides high data. Through put for the Ethernet cameras on the ROV. Since Arduino boards already have support circuitry built in, the carrier board design was made simpler by using them throughout the system. Additionally, because of their low cost, it is sometimes simpler and less expensive to replace a whole defective Arduino board rather than isolated components.

A 48 V power supply was delivered to the ROV’s PCB using 14 American wire gauge (AWG) wires with an in-line 25-A fuse. The electric enclosure consists of three levels. The first level contains the Power PCB, the second has the electronic speed controller (ESC), and the third includes the Arduino Mega with a shield and a passive HDCVI transceiver. The 48 V enters the Power PCB and is converted to 12 V through the Murata DC-DC converter [

28]. Subsequently, the 12 V is distributed by the Power PCB to the ESCs, cameras, and a power converter from 12 V to 5 V to feed the Arduino [

3].

4.1. Power Distribution

When all power usages are determined, the adequate DC power supply rating and power distribution are selected [

29]. Here, DC was used rather than AC because it is simpler and more accessible for the portable ROV to use power supply by the generator. The total available power is computed as follows:

The ROV electricity consists of the following components: T100 thruster, ESC, cameras, and Arduino digital video recorder (DVR).

Table 1 tabulates the power distribution for each component and the tether power loss due to temperature. The table shows that the power consumption is lower than the available power [

2].

4.2. Power Board

The track width was estimated using Equation (16):

For every 1 A, 1 mm track width is required for PCB input. Thus, a 30 mm track width is necessary to meet the desired current (30A), resulting in a massive space for the electronics in the electric enclosure [

30]. To maintain a smaller track width size, we coated it with a composite mixture of silver, tin, and gold. As the PCB thickness increases, the track decreases.

Figure 8 depicts the power board.

The power PCB receives 48 V from the tether and uses 2 Murata DC-DC converters (buck) to convert the 48 V to 12 V with an excellent nominal efficiency of 96% [

31]. They were used due to their small size and low weight. Designing the power PCB that can handle the required current in a small size to fit in the electric enclosure was a challenge. After conversion, the 12 V bus was distributed into two buses; the first bus was converted to 5 V to DC-DC converter, and the second was distributed using terminals to provide the ESCs and the cameras with the required operating power.

4.3. Control Board

The control board was connected to the PCB board, as shown in

Figure 9. The control shield was mounted to Arduino. The shield was used to deliver the signals from the Ardunio Mega to the components through terminals to fasten the wires gently and avoid disconnection. The shield contains 20 terminals (7 for the signal, 7 for the ground, and 6 for the small power). A Tether cable was mounted between the vehicle and the tether management system (TMS) for transmitting electrical power, optical signals and mechanical loads using a thin, flexible, and durable cable [

31].

5. Software System

The first step of the software system involves the station between the Arduino microcontroller and the joystick. The second step involves the bottom side between the top side Arduino and the bottom side Arduino.

5.1. Top Side System

The station was designed to allow the user to control the system thoroughly. The station consists of a power supply, computer, screen, joystick controller, laptop, and upper Arduino as a controller for the upper control station. The joystick and the upper Arduino (transmitter) were connected to the laptop and was connected to the joystick. The upper Arduino receives the information (i.e., coordinates) from the joystick and transmits it to the bottom Arduino to operate the motors using “Processing IDE”. We developed a graphical user interface (GUI) to allow the pilot to control the speed and motion of motors. The top Arduino communicates with the bottom Arduino underneath the water through a universal asynchronous receiver-transmitter (UART) to simplify the process that any of two Arduino can send and receive data from each other.

The purpose of the code in the processing is to handle the top-side system and connects the Logitech extreme with the upper Arduino. The joystick sends the speed to the upper Arduino in a hexadecimal arrangement to save memory since the maximum speed (255 ms) can be saved only in 2 bytes. The upper Arduino receives the speed and sends it through serial communication in a UART cable to the bottom Arduino underneath the water. We used Logitech 3D pro joystick. We programmed Logitech 3D pro joystick using “Processing” and controlled motors using a Proportional-integral-derivative (PID) control PID.

5.2. Bottom Side System

On the bottom side, the underwater software is managed by an Arduino Mega that receives the motor speed and converts it into a decimal system which subscribes to the node that maps the values and drives the thrusters through the ESCs. Accordingly, the motors publish the readings of the sensors responsible for localization. The camera’s system transmits the underwater data to the laptop by cat-6 Ethernet cable and passive transverse module for image processing.

Figure 10 illustrates the software map.

5.3. Image Processing

Python was used for image processing because it is open source, has decent documentation, and has a great performance with relatively low-level libraries. Matplotlib and NumPy were used. The process starts with capturing a frame from the camera feed and saving it to the appropriate directory on the control laptop. Subsequently, several filters (from OpenCV) were applied to compensate for the ‘fuzziness’ caused by shooting under the water. Eventually, the images become processed.

6. Experimental Setup

The experimental investigation was conducted to test the ROV’s applicability to various missions. Prior to submerging ROV in a swimming pool, we ran extensive testing to ensure it would be fully waterproof. We used a vacuum pump to pull a vacuum inside the electronics enclosure, adjusting the seal if there was any sign of pressure change. Next, we covered the enclosure in soapy water and pressurized the interior so that escaping air would create bubbles and be easy to detect. We also allowed the ROV to run for 15 min with the enclosure sealed to ensure that the interior did not get too hot.

The dimensions of the enclosed swimming pool used in the experimental investigation are 25 × 20 × 7 m (

Figure 11). First, the objects required for performing the missions of ROV are placed in the swimming pool. To ensure the insulation of the electrical enclosure, the ROV was tied with a rope and left underwater for twenty minutes without activating the power. Subsequently, the pilot activates the power and uses the joystick to control the vehicle in the desired direction through the GUI platform. During the experiment, the installed cameras allow the pilot to display the desired objects on the laptop.

8. Conclusions

In this paper, we developed an integrated system for an underwater ROV that considers mechanical, electrical, and software design and manufacturing. The PCB was designed with a small track width to reduce the ROV’s overall dimensions. All independent systems of the proposed ROV were tested individually before assembly to ensure they were fully operational and ready for integration. The vehicle’s structural integrity and insulation were examined by submerging the vehicle underwater for long periods. The experimental outcomes demonstrate the image processing’s robustness in performing various tasks in underwater environments.

In the current investigation, the allowable depth was limited to 7 m. Thus, researchers could consider using autonomous underwater vehicles to explore greater depths in future work. The present study did not consider shape analysis; accordingly, the corresponding theoretical and experimental research regarding shape selection was insufficient to present significant findings. Thus, we recommended the investigation of the ROV’s shape on its performance and hydrodynamics in future work. This could be achieved through shape optimization, considering the various operational scenarios. Moreover, computer vision applications could be integrated to develop the capability of ROVs to identify benthic species under hazardous and unstable conditions.