Analysis of Sequential Pretreatments to Enhance the Early-Stage Biorefinery Designs

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

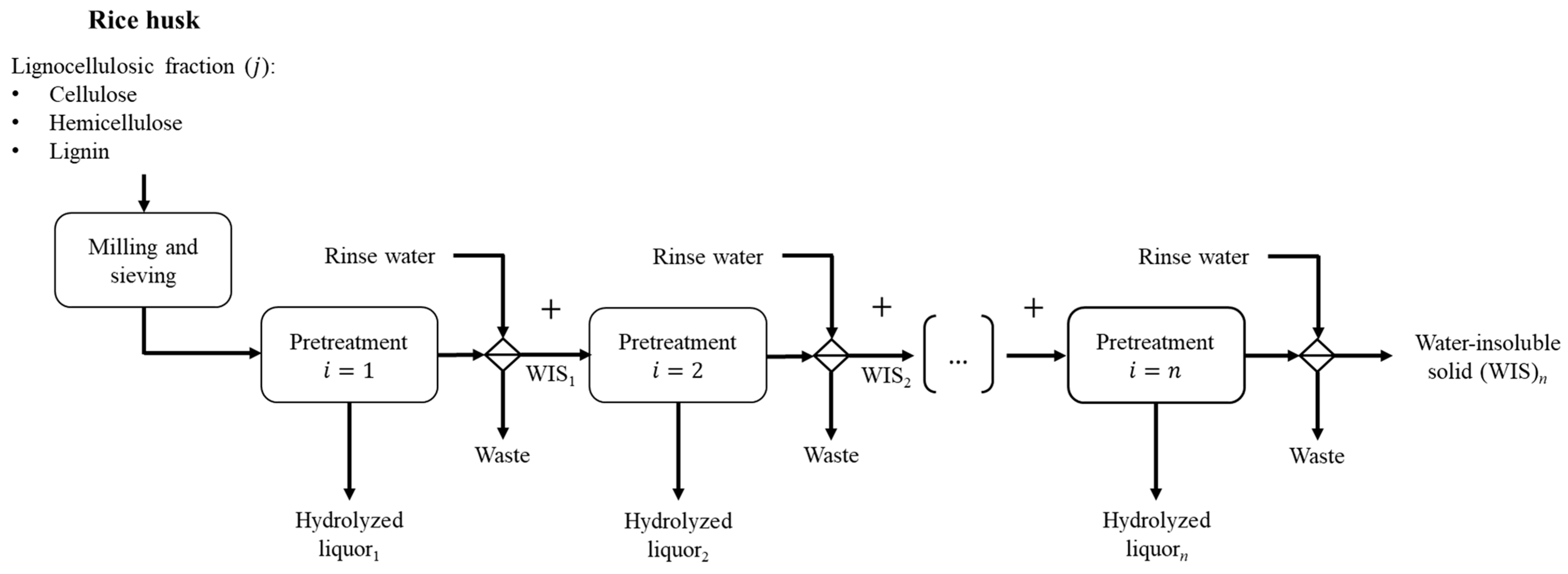

2.1. Pretreatment Screening

2.2. Heuristic Analysis

2.2.1. Indicators’ Description

2.2.2. Simulation Procedure

2.2.3. Integral Assessment

3. Results

3.1. Pretreatment Screening

3.2. Feedstock Analysis

3.3. Techno-Economic Analysis

3.4. Heuristic Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ammonia recycled percolation | |

| Capital expenditure, M-USD | |

| Cellulose | |

| Dilute acid | |

| Hemicellulose | |

| Indicator, units based on the indicator | |

| Non-centrifuge sugarcane | |

| National Renewable Energy Laboratory | |

| Non-Random Two Liquids | |

| Liquid hot water | |

| Lignin | |

| Operating expenditure, M-USD year−1 | |

| Maximum regional value | |

| Minimum regional value | |

| Severity factor | |

| Steam explosion | |

| Maximum scale value | |

| Technology readiness level | |

| Unwanted lignocellulosic composition, % | |

| Recovered compounds, % | |

| United States dollars, US dollars | |

| Wet air oxidation | |

| Water-insoluble solid | |

| Greek | |

| Weight factor, % | |

| Subscripts | |

| Accessibility, % | |

| Capital expenditure, M-USD | |

| Cellulose removal, % | |

| Utility yields, ton ton−1 (steam), m3 kg−1 (cooling water), kW ton−1 (electricity) | |

| Pretreatment stage | |

| Lignocellulosic fraction | |

| Lignocellulosic indicator | |

| Total number heuristic indicators | |

| Total number of pretreatment stages | |

| Operating expenditures, M-USD year−1 | |

| Cumulative removal, % | |

| Severity | |

| Valorization potential, % | |

| Water demand, m3 ton−1 | |

| Mass yield, kg 100 kg−1 | |

References

- Conteratto, C.; Artuzo, F.D.; Santos, O.I.B.; Talamini, E. Biorefinery: A comprehensive concept for the sociotechnical transition toward bioeconomy. Renew. Sustain. Energy Rev. 2021, 151, 111527. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Piedrahita-Rodríguez, S.; Aristizabal, N.S.; Salas-Moreno, M.; Alzate, C.A.C. Prefeasibility analysis of small-scale biorefineries: The annatto and açai case to improve the incomes of rural communities. Biomass Convers. Biorefin. 2022. [Google Scholar] [CrossRef]

- Piedrahita-Rodríguez, S.; Solarte-Toro, J.C.; Piñeres, P.P.; Ortiz-Sánchez, M.; Pérez-Cordero, A.; Cardona-Alzate, C.A. Analysis of a biorefinery with multiple raw materials in the context of post-conflict zones in Colombia: Plantain and avocado integration in the Montes de María region. Biomass Convers. Biorefin. 2022, 12, 4531–4548. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Alzate, C.A.C. Biorefineries as the base for accomplishing the sustainable development goals (SDGs) and the transition to bioeconomy: Technical aspects, challenges and perspectives. Bioresour. Technol. 2021, 340, 125626. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front. Energy Res. 2018, 6, 18. [Google Scholar] [CrossRef]

- Cardona-Alzate, C.A.; Serna-Loaiza, S.; Ortiz-Sanchez, M. Sustainable biorefineries: What was learned from the design, analysis and implementation. J. Sustain. Dev. Energy Water Environ. Syst. 2020, 8, 88–117. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Madhavan, A.; Sirohi, R.; Pugazhendhi, A.; Binod, P.; Awasthi, M.K.; Vivek, N.; Kumar, V.; Sindhu, R. Lignocellulose in future biorefineries: Strategies for cost-effective production of biomaterials and bioenergy. Bioresour. Technol. 2022, 344, 126241. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Cardona, C.A. Biorefinery potential of Eucalyptus grandis to produce phenolic compounds and biogas. Can. J. For. Res. 2021, 51, 89–100. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Garcia-Vallejo, M.C.; Alzate, C.A.C. Analysis of Single-Step Pretreatments for Lignocellulosic Platform Isolation as the Basis of Biorefinery Design. Molecules 2023, 28, 1278. [Google Scholar] [CrossRef]

- Mood, S.H.; Golfeshan, A.H.; Tabatabaei, M.; Jouzani, G.S.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Alzate, C.A.C.; Aristiza, V.; Botero, J.M. Biorefineries: Design and Analysis; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Zhang, C.; Pang, F.; Li, B.; Xue, S.; Kang, Y. Recycled aqueous ammonia expansion (RAAE) pretreatment to improve enzymatic digestibility of corn stalks. Bioresour. Technol. 2013, 138, 314–320. [Google Scholar] [CrossRef]

- Hoşgün, E.Z.; Ay, S.B.; Boza, B. Effect of sequential pretreatment combinations on the composition and enzymatic hydrolysis of hazelnut shells. Prep. Biochem. Biotechnol. 2020, 51, 570–579. [Google Scholar] [CrossRef]

- Aggarwal, N.; Pal, P.; Sharma, N.; Saravanamurugan, S. Consecutive Organosolv and Alkaline Pretreatment: An Efficient Approach toward the Production of Cellulose from Rice Straw. ACS Omega 2021, 6, 27247–27258. [Google Scholar] [CrossRef]

- Tang, W.; Wu, X.; Huang, C.; Huang, C.; Lai, C.; Yong, Q. Enhancing enzymatic digestibility of waste wheat straw by presoaking to reduce the ash-influencing effect on autohydrolysis. Biotechnol. Biofuels 2019, 12, 222. [Google Scholar] [CrossRef]

- Fockink, D.H.; Sánchez, J.H.; Ramos, L.P. Comprehensive analysis of sugarcane bagasse steam explosion using autocatalysis and dilute acid hydrolysis (H3PO4 and H2SO4) at equivalent combined severity factors. Ind. Crops Prod. 2018, 123, 563–572. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Alzate, C.A.C. A biorefinery for the valorization of marigold (Calendula officinalis) residues to produce biogas and phenolic compounds. Food Bioprod. Process. 2021, 125, 91–104. [Google Scholar] [CrossRef]

- Wooley, R.J.; Putsche, V. Development of an ASPEN PLUS Physical Property Database for Biofuels Components; National Renewable Energy Laboratory: Golden, CO, USA, 1996. [Google Scholar]

- García-Velásquez, C.A.; Cardona, C.A. Comparison of the biochemical and thermochemical routes for bioenergy production: A techno-economic (TEA), energetic and environmental assessment. Energy 2019, 172, 232–242. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the Uniter Nations AQUASTAT. FAO. 2021. Available online: https://tableau.apps.fao.org/views/ReviewDashboard-v1/country_dashboard?%3Aembed=y&%3AisGuestRedirectFromVizportal=y (accessed on 16 November 2022).

- Restrepo-Serna, D.L.; Martínez-Ruano, J.A.; Cardona-Alzate, C.A. Energy efficiency of biorefinery schemes using sugarcane bagasse as raw material. Energies 2018, 11, 3474. [Google Scholar] [CrossRef]

- Serna-loaiza, S.; Carmona-garcia, E.; Cardona, C.A. Potential raw materials for biorefineries to ensure food security: The Cocoyam case. Ind. Crops Prod. 2018, 126, 92–102. [Google Scholar] [CrossRef]

- Martinkus, N.; Latta, G.; Rijkhoff, S.A.M.; Mueller, D.; Hoard, S.; Sasatani, D.; Pierobon, F.; Wolcott, M. A multi-criteria decision support tool for biorefinery siting: Using economic, environmental, and social metrics for a refined siting analysis. Biomass Bioenergy 2019, 128, 105330. [Google Scholar] [CrossRef]

- Yuan, Y.; Jiang, B.; Chen, H.; Wu, W.; Wu, S.; Jin, Y.; Xiao, H. Recent advances in understanding the effects of lignin structural characteristics on enzymatic hydrolysis. Biotechnol. Biofuels 2021, 14, 205. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Z.; Fei, B.; Cai, Z.; Pan, X. Comparison of bamboo green, timber and yellow in sulfite, sulfuric acid and sodium hydroxide pretreatments for enzymatic saccharification. Bioresour. Technol. 2014, 151, 91–99. [Google Scholar] [CrossRef]

- Mathew, A.K.; Abraham, A.; Mallapureddy, K.K.; Sukumaran, R.K. Lignocellulosic Biorefinery Wastes, or Resources? In Waste Biorefinery: Potential and Perspectives; Elsevier: Oxford, UK, 2018; pp. 267–297. [Google Scholar] [CrossRef]

- Tae, H.K.; Lee, Y.Y. Pretreatment and fractionation of corn stover by ammonia recycle percolation process. Bioresour. Technol. 2005, 96, 2007–2013. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Alriksson, B.; Nilvebrant, N.O. Bioconversion of lignocellulose: Inhibitors and detoxification. Biotechnol. Biofuels 2013, 6, 16. [Google Scholar] [CrossRef]

- Unidad de Planificación Rural Agropecuaria (UPRA) Análisis de Resultados. Evaluaciones Agropecuarias Municipales 2021; Unidad de Planificación Rural Agropecuaria: Bogotá, Colombia, 2021.

- Rajamani, S.; Kolla, S.S.N.; Gudivada, R.; Raghunath, R.; Ramesh, K.; Jadhav, S.A. Valorization of Rice Husk to Value-Added Chemicals and Functional Materials. Int. J. Environ. Res. 2023, 17, 22. [Google Scholar] [CrossRef]

- Ministerio de Agricultura y Desarrollo Rural Evaluaciones Agropecuarias Municipales 2018. Segundo Informe de Costos de Producción; Bogotá DC, Colombia, 2018. Available online: https://www.agronet.gov.co/estadistica/Paginas/home.aspx?cod=87 (accessed on 29 March 2023).

- Nikoo, M.B.; Mahinpey, N. Evaluation of wet air oxidation as a pretreatment strategy for bioethanol production from rice husk and process optimization. Biomass Bioenergy 2009, 33, 1680–1686. [Google Scholar] [CrossRef]

- Peters, M.; Timmerhaus, K.; West, R. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Zhao, X.; van der Heide, E.; Zhang, T.; Liu, D. Delignification of Sugarcane Bagasse with Alkali and Peracetic Acid and Characterization of the Pulp. Bioresources 2010, 5, 1565–1580. [Google Scholar]

- Chen, H. Lignocellulose biorefinery feedstock engineering. In Lignocellulose Biorefinery Engineering; Woodhead Publishing: Sawston, UK, 2015; pp. 37–86. [Google Scholar] [CrossRef]

- Bhagia, S.; Li, H.; Gao, X.; Kumar, R.; Wyman, C.E. Flowthrough pretreatment with very dilute acid provides insights into high lignin contribution to biomass recalcitrance. Biotechnol. Biofuels 2016, 9, 245. [Google Scholar] [CrossRef]

- Bhatia, R.; Winters, A.; Bryant, D.N.; Bosch, M.; Clifton-Brown, J.; Leak, D.; Gallagher, J. Pilot-scale production of xylo-oligosaccharides and fermentable sugars from Miscanthus using steam explosion pretreatment. Bioresour. Technol. 2020, 296, 122285. [Google Scholar] [CrossRef]

- Reyes, P.; Márquez, N.; Troncoso, E.; Parra, C.; Mendonça, R.T.; Rodríguez, J. Evaluation of combined dilute acid-kraft and steam explosion-kraft processes as pretreatment for enzymatic hydrolysis of Pinus radiata wood chips. Bioresources 2016, 11, 612–625. [Google Scholar] [CrossRef]

- Borrega, M.; Nieminen, K.; Sixta, H. Effects of hot water extraction in a batch reactor on the delignification of birch wood. Bioresources 2011, 6, 1890–1903. [Google Scholar]

- Saito, K.; Horikawa, Y.; Sugiyama, J.; Watanabe, T.; Kobayashi, Y.; Takabe, K. Effect of thermochemical pretreatment on lignin alteration and cell wall microstructural degradation in Eucalyptus globulus: Comparison of acid, alkali, and water pretreatments. J. Wood Sci. 2016, 62, 276–284. [Google Scholar] [CrossRef]

- Alzate, C.A.C.; Toro, J.C.S.; Peña, Á.G. Fermentation, thermochemical and catalytic processes in the transformation of biomass through efficient biorefineries. Catal. Today 2018, 302, 61–72. [Google Scholar] [CrossRef]

- Wang, W.; Ling, H.; Zhao, H. Steam explosion pretreatment of corn straw on xylose recovery and xylitol production using hydrolysate without detoxification. Process Biochem. 2015, 50, 1623–1628. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Solarte-Toro, J.C.; Alzate, C.A.C. The potential use of lignin as a platform product in biorefineries: A review. Renew. Sustain. Energy Rev. 2021, 138, 110688. [Google Scholar] [CrossRef]

- Lee, J.M.; Jameel, H.; Venditti, R.A. A comparison of the autohydrolysis and ammonia fiber explosion (AFEX) pretreatments on the subsequent enzymatic hydrolysis of coastal Bermuda grass. Bioresour. Technol. 2010, 101, 5449–5458. [Google Scholar] [CrossRef]

- Guleria, A.; Kumari, G.; Saravanamurugan, S. Cellulose valorization to potential platform chemicals. In Biomass, Biofuels, Biochemicals: Recent Advances in Development of Platform Chemicals; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 433–457. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, W.J.; Pang, B.; Sun, Z.; Lam, S.S.; Sonne, C.; Yuan, T.Q. Ultrastructural change in lignocellulosic biomass during hydrothermal pretreatment. Bioresour. Technol. 2021, 341, 125807. [Google Scholar] [CrossRef]

| Item | Cost | Unit | Reference |

|---|---|---|---|

| Feedstock | |||

| Rice husk | 20 | USD ton−1 | Regional market |

| NCSC-bagasse | 15 | ||

| Chemical reagents | |||

| Sulfuric acid | 240 | USD ton−1 | Means of Alibaba * |

| Sodium hydroxide | 950 | ||

| Sodium sulfide | 500 | ||

| Sodium carbonate | 250 | ||

| Ethanol | 0.84 | USD L−1 | Regional market |

| Utilities | |||

| Low-pressure steam | 7.89 | USD ton−1 | [19] |

| Medium-pressure steam | 8.07 | ||

| High-pressure steam | 8.15 | ||

| Electricity | 0.055 | USD kWh−1 | Industrial regional market |

| Fraction | Sequential Scheme | |||||

|---|---|---|---|---|---|---|

| Cellulose | DA + alkali | 15.90 | 86.69 | 84.11 | 7.08 | 69.60 |

| DA + WAO | 16.27 | 98.62 | 83.73 | 7.63 | 71.51 | |

| Kraft + DA | 18.89 | 93.04 | 81.11 | 6.93 | 63.39 | |

| Kraft + SE | 12.10 | 91.07 | 87.90 | 6.19 | 72.26 | |

| Kraft + WAO | 16.38 | 95.64 | 83.62 | 6.89 | 51.90 | |

| SE + WAO | 9.25 | 97.57 | 90.75 | 7.52 | 72.34 | |

| Hemicellulose | LHW + DA | 99.87 | 66.48 | 63.25 | 7.67 | 34.07 |

| LHW + organosolv | 99.26 | 62.67 | 56.42 | 7.21 | 48.69 | |

| Organosolv + DA | 99.90 | 64.01 | 72.46 | 7.20 | 44.59 | |

| SE + DA | 99.80 | 75.55 | 88.02 | 6.82 | 32.18 | |

| SE + LHW | 97.90 | 71.70 | 68.54 | 7.56 | 31.86 | |

| SE + organosolv | 98.80 | 71.27 | 78.53 | 7.09 | 46.85 | |

| Lignin | DA + alkali | 69.70 | 77.72 | 84.11 | 7.08 | 59.04 |

| DA + kraft | 87.20 | 77.44 | 81.11 | 6.93 | 67.28 | |

| DA + WAO | 97.80 | 78.40 | 83.73 | 7.63 | 75.19 | |

| SE + alkali | 68.00 | 76.66 | 91.16 | 6.97 | 62.56 | |

| SE + kraft | 86.50 | 76.50 | 87.90 | 6.82 | 69.86 | |

| SE + WAO | 97.60 | 76.81 | 87.9 | 7.52 | 78.87 |

| Parameter | Feedstock Data | Residue Scoring | |||

|---|---|---|---|---|---|

| NCSC | Rice | NCSC-Bagasse | Rice Husk | ||

| Cultivated crop area in 2021 (Ha) * | 11.1 | 210,533 | 324,794 | 3 | 6 |

| Average crop yield (tons Ha−1year−1) * | 18.5 | 49.74 | 5.20 | 8 | 3 |

| Crop production (tons year−1) * | 18.5 | 12.41 × 106 | 1.93 × 106 | 8 | 3 |

| Crop time for harvest (months) * | 22.2 | 15.5 | 4.5 | 3 | 9 |

| Production cost (USD Ha−1) ** | 3.7 | 1.29 | 1.15 | 7 | 8 |

| Residue production (kg 100 kg−1) *** | 14.8 | 0.84 | 1.45 | 4 | 8 |

| Residue composition (% wt.) **** | 11.1 | NCSC-bagasse | Rice husk | 8 | 5 |

| Initial moisture | 19.11 | 12.50 | |||

| Extractives | 22.24 | 7.86 | |||

| Cellulose | 35.18 | 29.34 | |||

| Hemicellulose | 21.69 | 15.02 | |||

| Lignin | 19.80 | 29.14 | |||

| Ash | 1.10 | 18.64 | |||

| Total | 5.70 | 5.81 | |||

| Fraction | Sequential Scheme | * (kg 100 kg−1) | ** (m3 ton−1) | |||

|---|---|---|---|---|---|---|

| Steam *** (ton ton−1) | Cooling Water (m3 kg−1) | Electricity (kW ton−1) | ||||

| Cellulose | DA + alkali | 46.01 | 18.57 | 4.54 | 0.65 | 74.76 |

| DA + WAO | 53.35 | 24.84 | 16.39 | 3.01 | 82.28 | |

| Kraft + DA | 50.55 | 29.68 | 60.31 | 12.29 | 88.92 | |

| Kraft + SE | 50.14 | 27.35 | 60.31 | 12.29 | 78.57 | |

| Kraft + WAO | 52.12 | 35.27 | 62.60 | 12.15 | 90.60 | |

| SE + WAO | 54.56 | 39.85 | 3.61 | 6.79 | 63.52 | |

| Hemicellulose | LHW + DA | 37.06 | 18.57 | 5.96 | 0.92 | 75.24 |

| LHW + organosolv | 42.22 | 17.02 | 37.50 | 4.93 | 83.16 | |

| Organosolv + DA | 43.98 | 15.65 | 309.85 | 99.39 | 354.47 | |

| SE + DA | 38.67 | 33.69 | 1.30 | 6.74 | 52.67 | |

| SE + LHW | 37.39 | 33.65 | 1.16 | 6.65 | 52.67 | |

| SE + organosolv | 45.40 | 31.45 | 17.12 | 12.05 | 87.96 | |

| Lignin | DA + alkali | 47.25 | 27.15 | 6.92 | 1.01 | 104.53 |

| DA + kraft | 50.32 | 18.53 | 5.43 | 0.80 | 65.63 | |

| DA + WAO | 53.47 | 24.84 | 16.39 | 0.73 | 82.28 | |

| SE + kraft | 50.38 | 33.20 | 0.62 | 6.35 | 52.19 | |

| SE + alkali | 46.30 | 33.64 | 0.39 | 6.37 | 55.79 | |

| SE + WAO | 54.55 | 39.85 | 3.61 | 6.79 | 63.52 | |

| Fraction | Sequential Scheme | (M-USD) | (M-USD Year−1) | |||

|---|---|---|---|---|---|---|

| Raw Materials | Utilities | Others * | Total | |||

| Cellulose | DA + alkali | 1.60 | 5.20 | 2.06 | 0.37 | 7.62 |

| DA + WAO | 2.98 | 1.63 | 6.28 | 0.63 | 8.54 | |

| Kraft + DA | 2.82 | 2.72 | 2.23 | 0.60 | 5.55 | |

| Kraft + SE | 2.64 | 2.70 | 2.23 | 0.57 | 5.50 | |

| Kraft + WAO | 2.87 | 2.69 | 2.25 | 0.61 | 5.55 | |

| SE + WAO | 2.84 | 1.31 | 8.26 | 0.61 | 10.18 | |

| Hemicellulose | LHW + DA | 1.51 | 1.8 | 2.55 | 0.35 | 4.7 |

| LHW + organosolv | 2.35 | 17.29 | 11.15 | 0.51 | 28.96 | |

| Organosolv + DA | 10.3 | 50.43 | 148.43 | 2.04 | 200.90 | |

| SE + DA | 1.44 | 1.75 | 7.85 | 0.34 | 9.93 | |

| SE + LHW | 1.36 | 1.18 | 7.73 | 0.32 | 9.23 | |

| SE + organosolv | 2.97 | 20.57 | 15.65 | 0.63 | 36.85 | |

| Lignin | DA + alkali | 1.96 | 6.18 | 2.81 | 0.44 | 9.42 |

| DA + kraft | 1.53 | 2.84 | 2.33 | 0.35 | 5.53 | |

| DA + WAO | 2.98 | 1.56 | 3.92 | 0.63 | 6.1 | |

| SE + kraft | 1.45 | 10.37 | 7.34 | 0.34 | 18.06 | |

| SE + alkali | 1.47 | 6.25 | 7.34 | 0.34 | 13.92 | |

| SE + WAO | 2.84 | 1.31 | 8.26 | 0.61 | 10.18 | |

| Fraction | Sequential Scheme | Indicators | Total | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8.5 | 9.5 | 11.6 | 7.6 | 12.5 | 4.7 | 2.5 | 17.8 | 12.7 | 12.7 | |||

| Cellulose | DA + alkali | 8.4 | 8.7 | 7.3 | 5.3 | 7.0 | 5.5 | 8.6 | 7.7 | 7.7 | 8.1 | 7.5 |

| DA + WAO | 8.4 | 9.9 | 9.7 | 4.2 | 7.2 | 5.3 | 7.7 | 7.7 | 7.7 | 8.1 | 7.8 | |

| Kraft + DA | 8.1 | 9.3 | 8.6 | 5.6 | 6.3 | 5.1 | 7.7 | 3.8 | 7.7 | 8.6 | 7.0 | |

| Kraft + SE | 8.8 | 9.1 | 8.2 | 7.0 | 7.2 | 5.0 | 7.7 | 3.8 | 7.7 | 8.6 | 7.2 | |

| Kraft + WAO | 8.4 | 9.6 | 9.1 | 5.6 | 5.2 | 5.2 | 7.7 | 3.8 | 7.7 | 8.6 | 6.9 | |

| SE + WAO | 9.1 | 9.8 | 9.5 | 4.4 | 7.2 | 4.6 | 7.7 | 5.8 | 7.7 | 6.7 | 7.3 | |

| Hemicellulose | LHW + DA | 10.0 | 6.6 | 5.4 | 4.1 | 3.4 | 3.7 | 8.6 | 8.6 | 7.7 | 8.6 | 6.8 |

| LHW + organosolv | 9.9 | 6.3 | 6.9 | 5.0 | 4.9 | 4.2 | 8.6 | 4.8 | 7.7 | 6.2 | 6.3 | |

| Organosolv + DA | 10.0 | 6.4 | 7.0 | 5.1 | 4.5 | 4.4 | 8.6 | 1.9 | 2.9 | 3.8 | 4.8 | |

| SE + DA | 10.0 | 7.6 | 5.5 | 5.8 | 3.2 | 3.9 | 7.7 | 8.6 | 7.7 | 8.1 | 7.0 | |

| SE + LHW | 9.8 | 7.2 | 5.4 | 4.4 | 3.2 | 3.7 | 7.7 | 7.7 | 7.7 | 8.1 | 6.6 | |

| SE + organosolv | 9.9 | 7.1 | 7.0 | 5.3 | 4.7 | 4.5 | 7.7 | 5.7 | 7.7 | 6.2 | 6.5 | |

| Lignin | DA + alkali | 7.0 | 7.8 | 7.3 | 5.3 | 5.9 | 4.7 | 7.7 | 6.7 | 7.7 | 8.6 | 7.0 |

| DA + kraft | 8.7 | 7.7 | 8.6 | 5.6 | 6.7 | 5.0 | 8.6 | 7.6 | 7.7 | 8.1 | 7.6 | |

| DA + WAO | 9.8 | 7.8 | 9.7 | 4.2 | 7.5 | 5.3 | 7.7 | 3.8 | 7.7 | 8.6 | 7.2 | |

| SE + alkali | 6.8 | 7.7 | 7.1 | 5.5 | 6.3 | 5.0 | 7.7 | 8.6 | 7.7 | 8.1 | 7.3 | |

| SE + kraft | 8.7 | 7.7 | 8.2 | 5.8 | 7.0 | 4.6 | 7.7 | 8.6 | 7.7 | 6.7 | 7.5 | |

| SE + WAO | 9.8 | 7.7 | 9.5 | 4.4 | 7.9 | 5.5 | 7.7 | 6.7 | 7.7 | 6.7 | 7.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poveda-Giraldo, J.A.; Cardona Alzate, C.A. Analysis of Sequential Pretreatments to Enhance the Early-Stage Biorefinery Designs. Appl. Sci. 2023, 13, 6758. https://doi.org/10.3390/app13116758

Poveda-Giraldo JA, Cardona Alzate CA. Analysis of Sequential Pretreatments to Enhance the Early-Stage Biorefinery Designs. Applied Sciences. 2023; 13(11):6758. https://doi.org/10.3390/app13116758

Chicago/Turabian StylePoveda-Giraldo, Jhonny Alejandro, and Carlos Ariel Cardona Alzate. 2023. "Analysis of Sequential Pretreatments to Enhance the Early-Stage Biorefinery Designs" Applied Sciences 13, no. 11: 6758. https://doi.org/10.3390/app13116758

APA StylePoveda-Giraldo, J. A., & Cardona Alzate, C. A. (2023). Analysis of Sequential Pretreatments to Enhance the Early-Stage Biorefinery Designs. Applied Sciences, 13(11), 6758. https://doi.org/10.3390/app13116758