Modeling the Effects of Horizontal Transverse Vibrations on the Thermal Behavior and the Ampacity of Rectangular Bus Bars

Abstract

1. Introduction

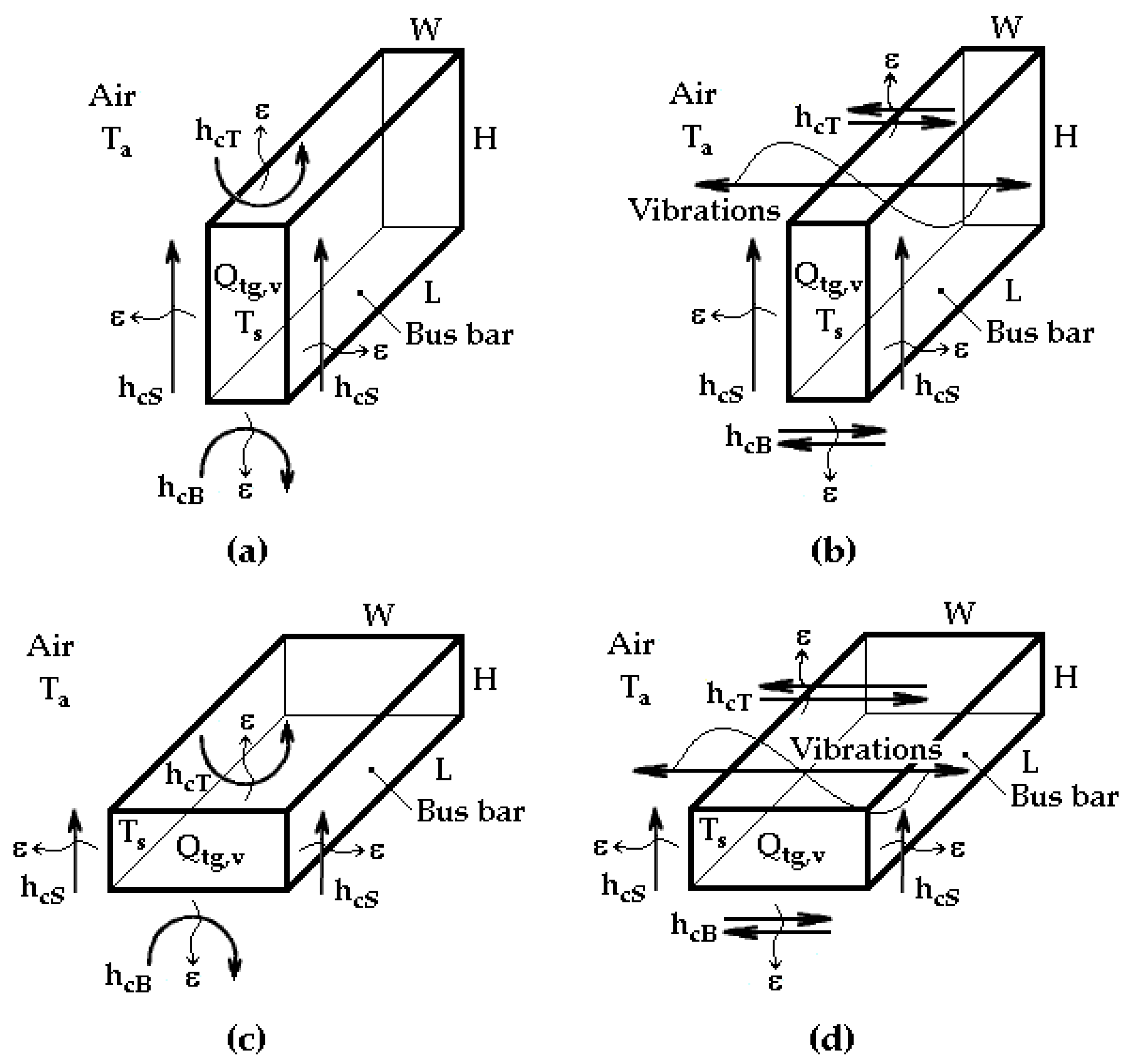

2. Geometry, Material Properties, and Assumptions

3. Mathematical Modeling

3.1. Analytical Steady-State Thermal Model

- -

- in the case of the two side surfaces;

- -

- in the case of the top surface; and

- -

- in the case of the bottom surface; where is the characteristic length of the side, top, or bottom bus bar surface in m, and is the Grashof number that refers to the side, top or bottom bus bar surface and that is defined by the corresponding characteristic length . Equations (30)–(34) represent simplified correlations for the free convection heat transfer coefficient from different flat surfaces to air at atmospheric pressure [28]. According to [29], a 5 mm long flat zone can be regarded as the zone where a boundary layer has enough space to form. Based on this, for each bus bar surface whose vertical or horizontal dimension is equal to or less than 5 mm, the characteristic length is set to mm. In particular, the proposed non-adiabatic assumption is used for each such surface instead of the adiabatic one.

3.2. FEM-Based Steady-State Thermal Model

- -

- radiation boundary condition; and

- -

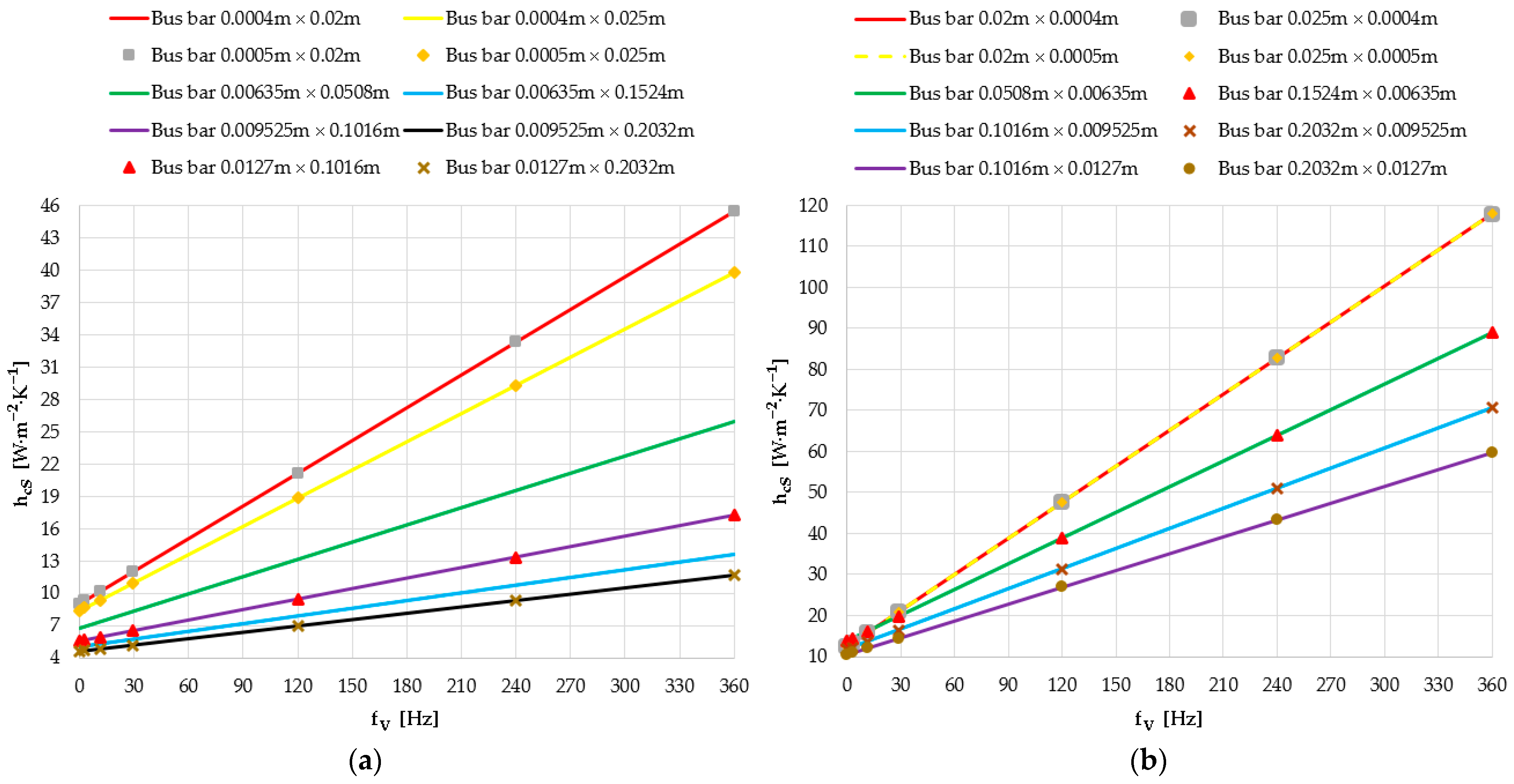

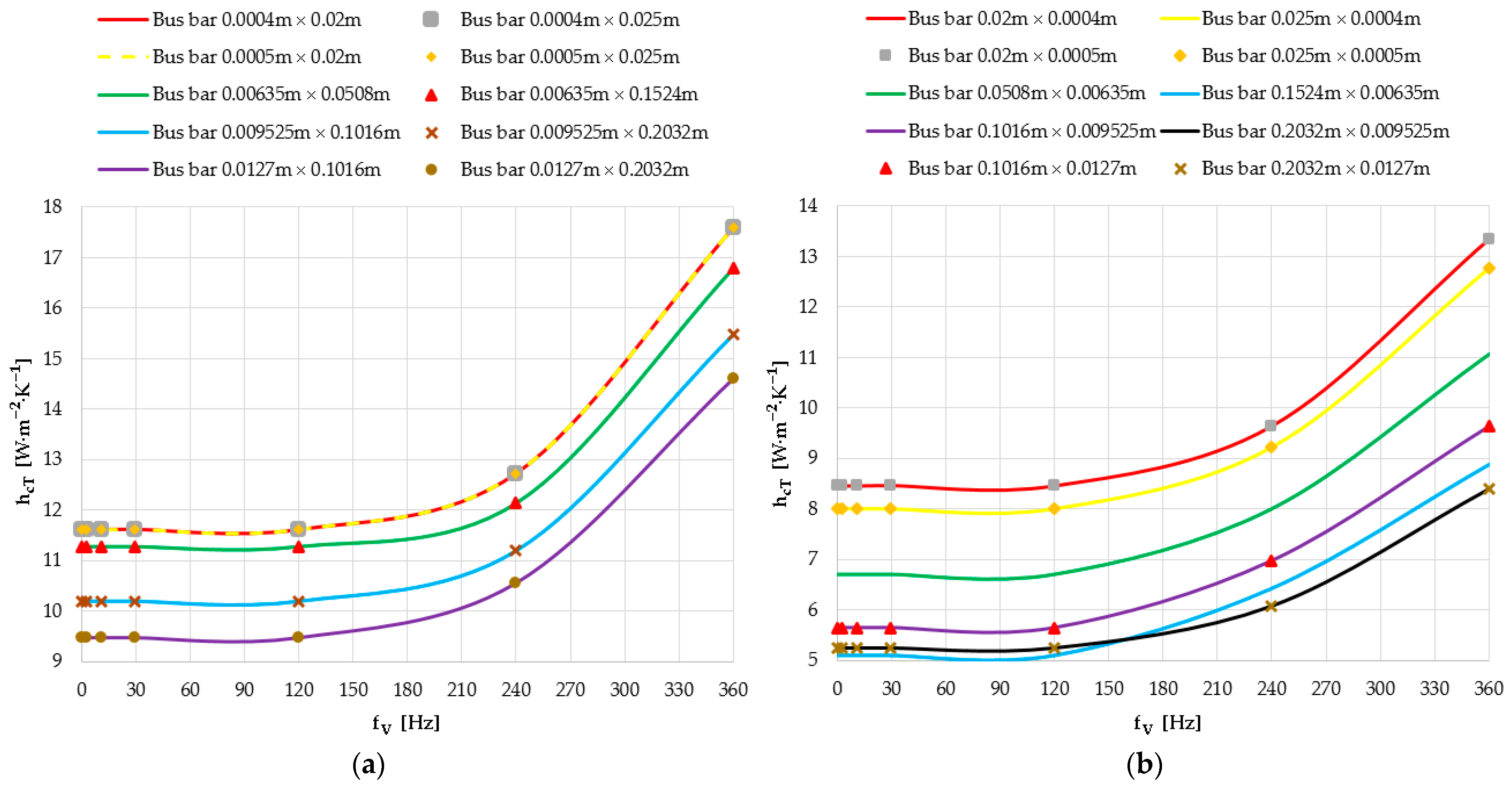

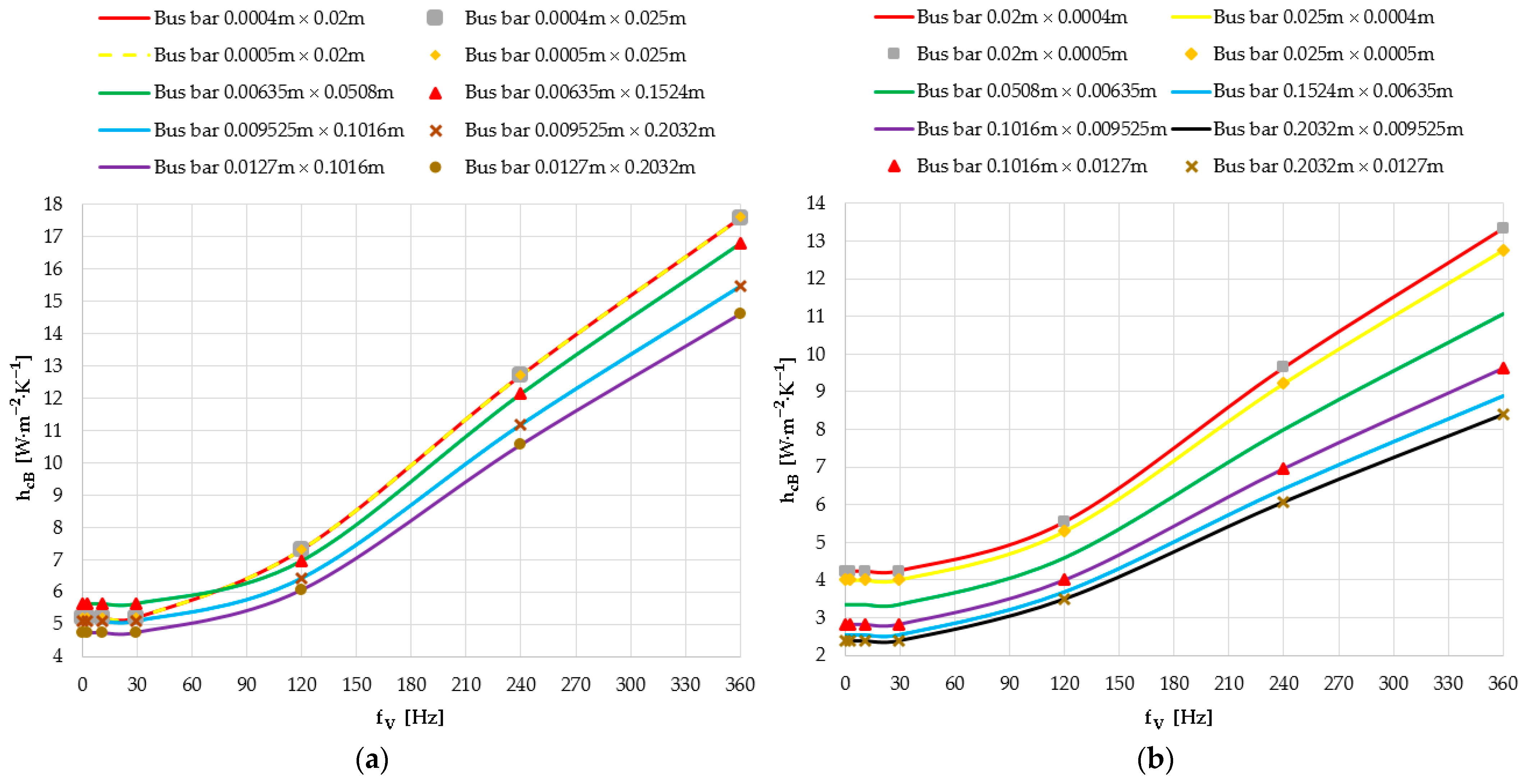

- convection boundary condition [23,30]. In Equations (36) and (37), is the normal vector oriented outwards in relation to the side, top, or bottom surface of the bus bar; is the unknown temperature of the side, top, or bottom surface of the bus bar in K; is the heat transfer coefficient due to radiation from the bus bar surfaces defined by Equation (4) in W·m−2·K−1; is the heat transfer coefficient due to free or vibration-assisted convection from the side, top, or bottom surface of the bus bar in W·m−2·K−1; and is the temperature of the ambient air contacting the bus bar surfaces in K. The radiation boundary condition in each of the FEM-based models can be specified either by the thermal emissivity or by the radiation heat transfer coefficient . The effect of horizontal transverse vibrations on free convection from any rectangular bus bar is included in the corresponding FEM-based model using the convection heat transfer coefficient in the following manner: —for its side surfaces, —for its top surface, and —for its bottom surface. In addition, the combination of radiation and convection boundary conditions ensures that Equation (35) is non-linear, regardless of the fact that here the temperature difference should be constant and equal to 30 K.

4. Results and Discussion

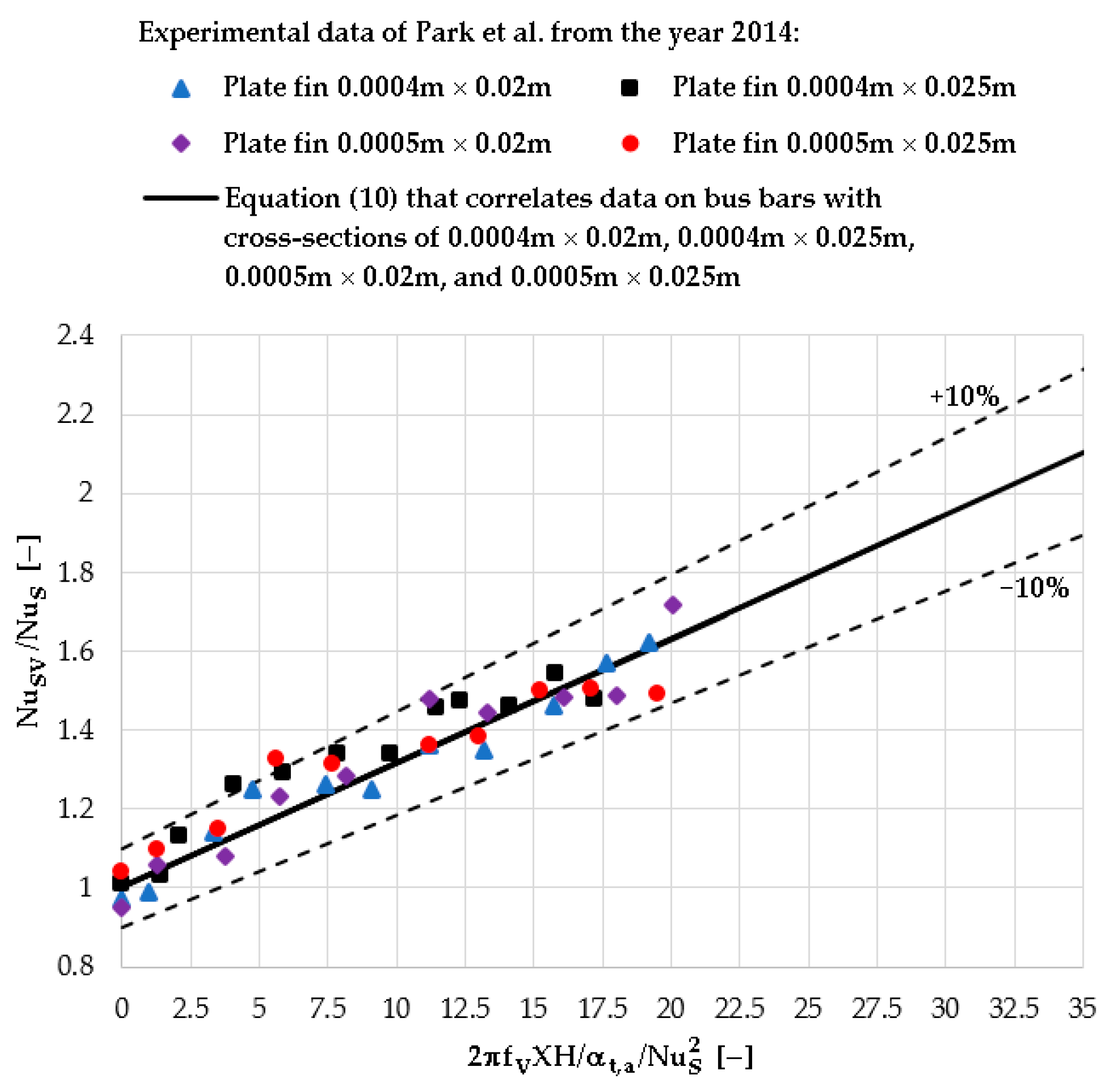

4.1. Experimental Validation of the Proposed Analytical Model

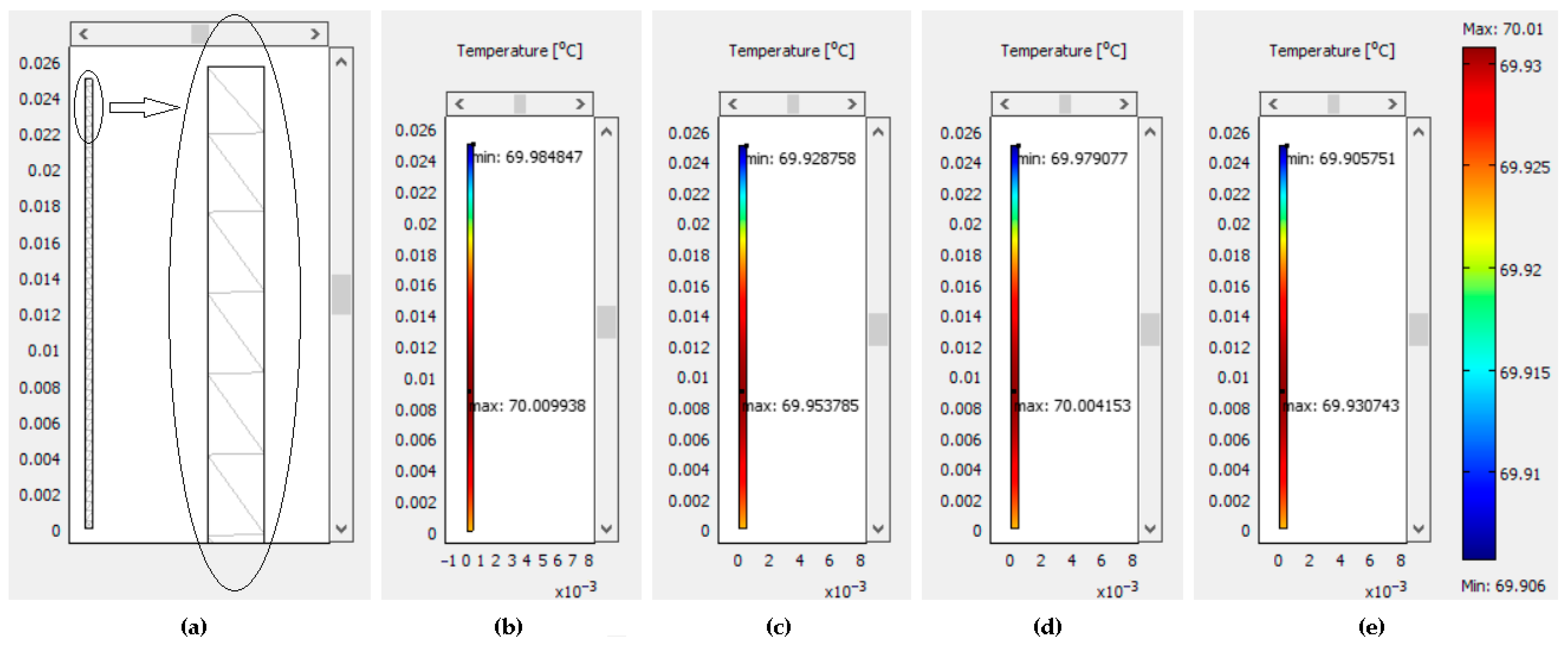

4.2. FEM-Based Verification of the Proposed Analytical Model

- (i)

- W·m−3, W·m−2·K−1, W·m−2·K−1, and W·m−2·K−1—for the case of free convection.

- (ii)

- W·m−3, W·m−2·K−1, W·m−2·K−1, and W·m−2·K−1—for the case of vibration class A.

- (iii)

- W·m−3, ·m−2·K−1, W·m−2·K−1, and W·m−2·K−1—for the case of vibration class B.

- (iv)

- W·m−3, ·m−2·K−1, W·m−2·K−1, and W·m−2·K−1—for the case of vibration class C.

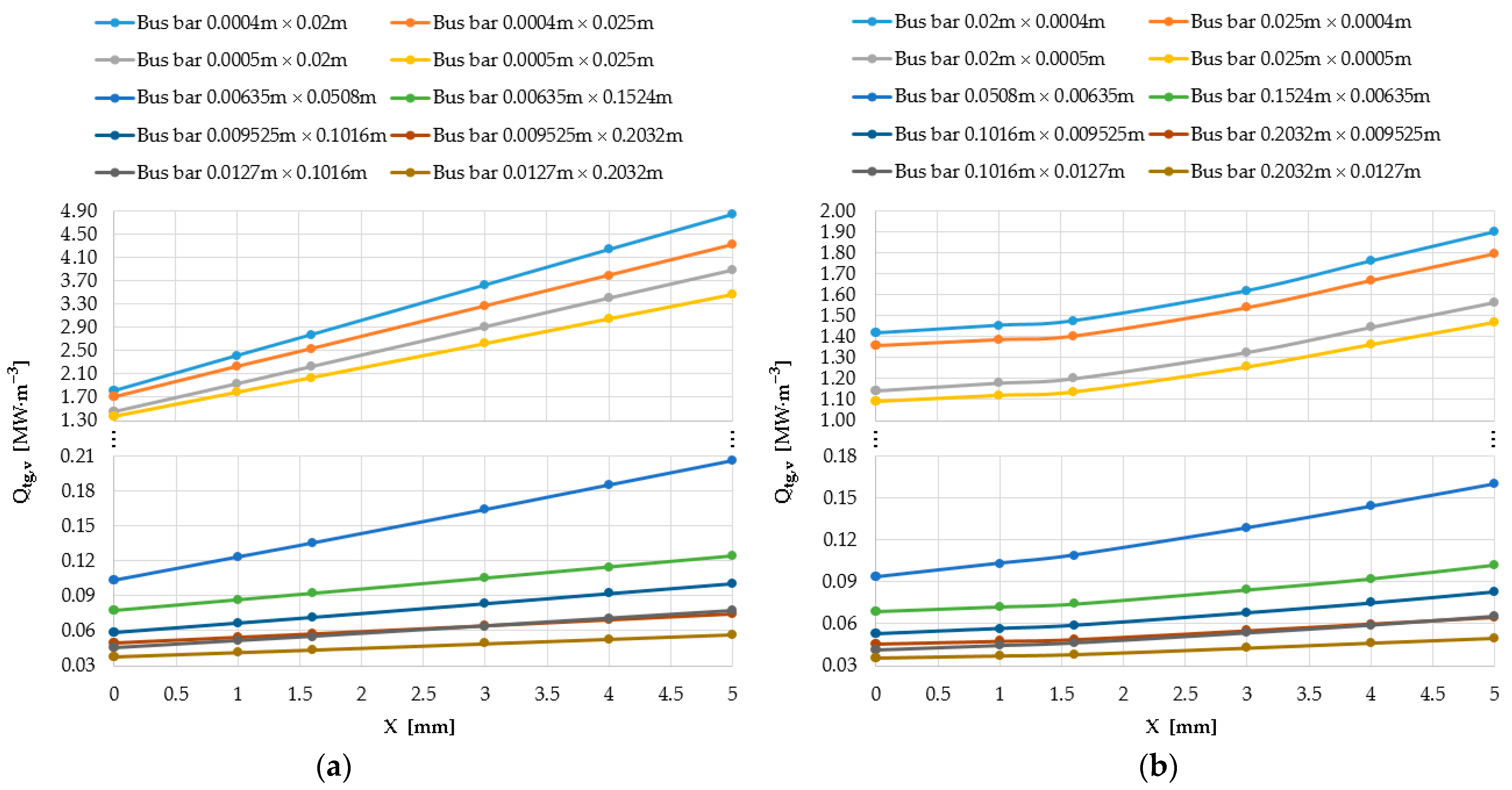

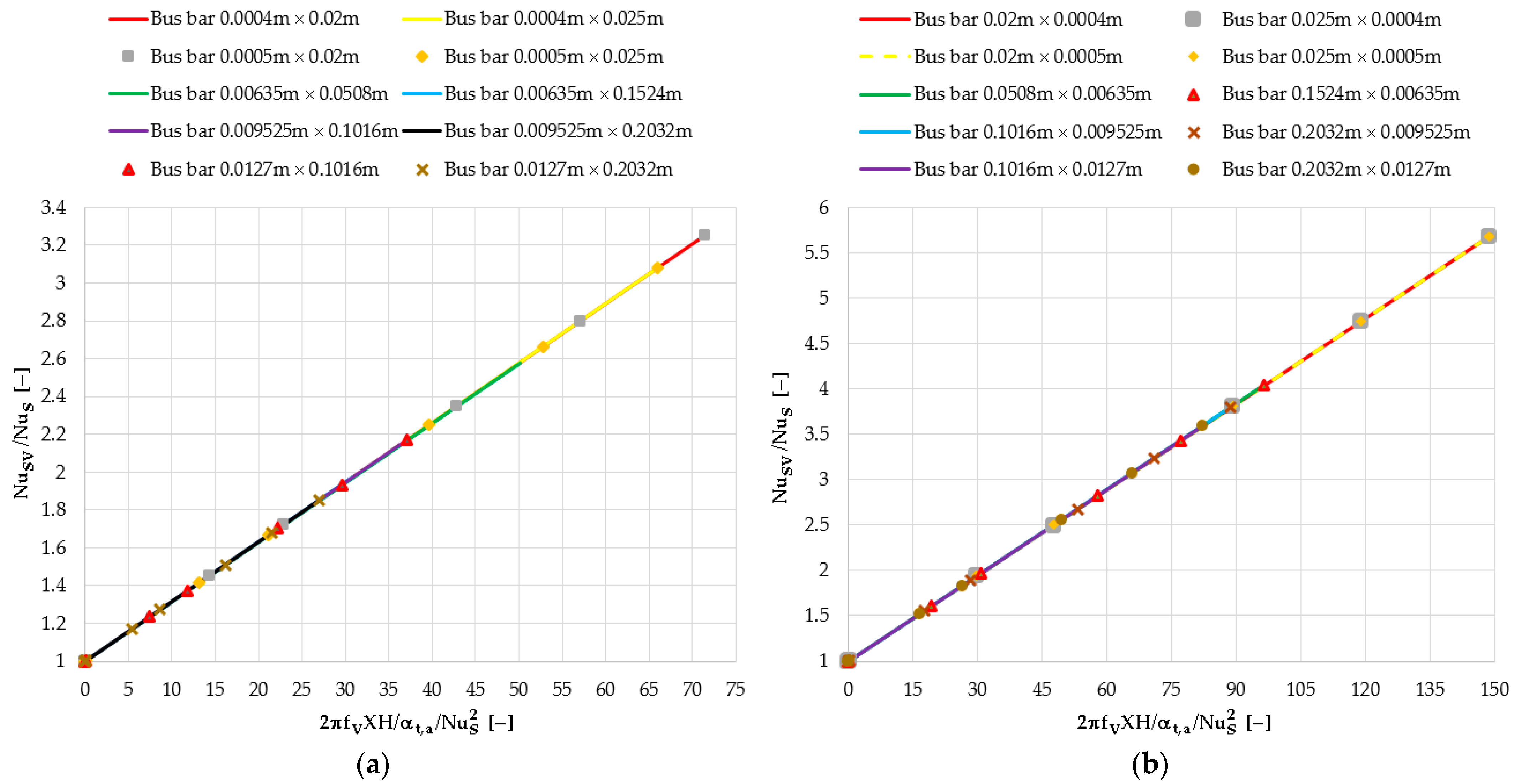

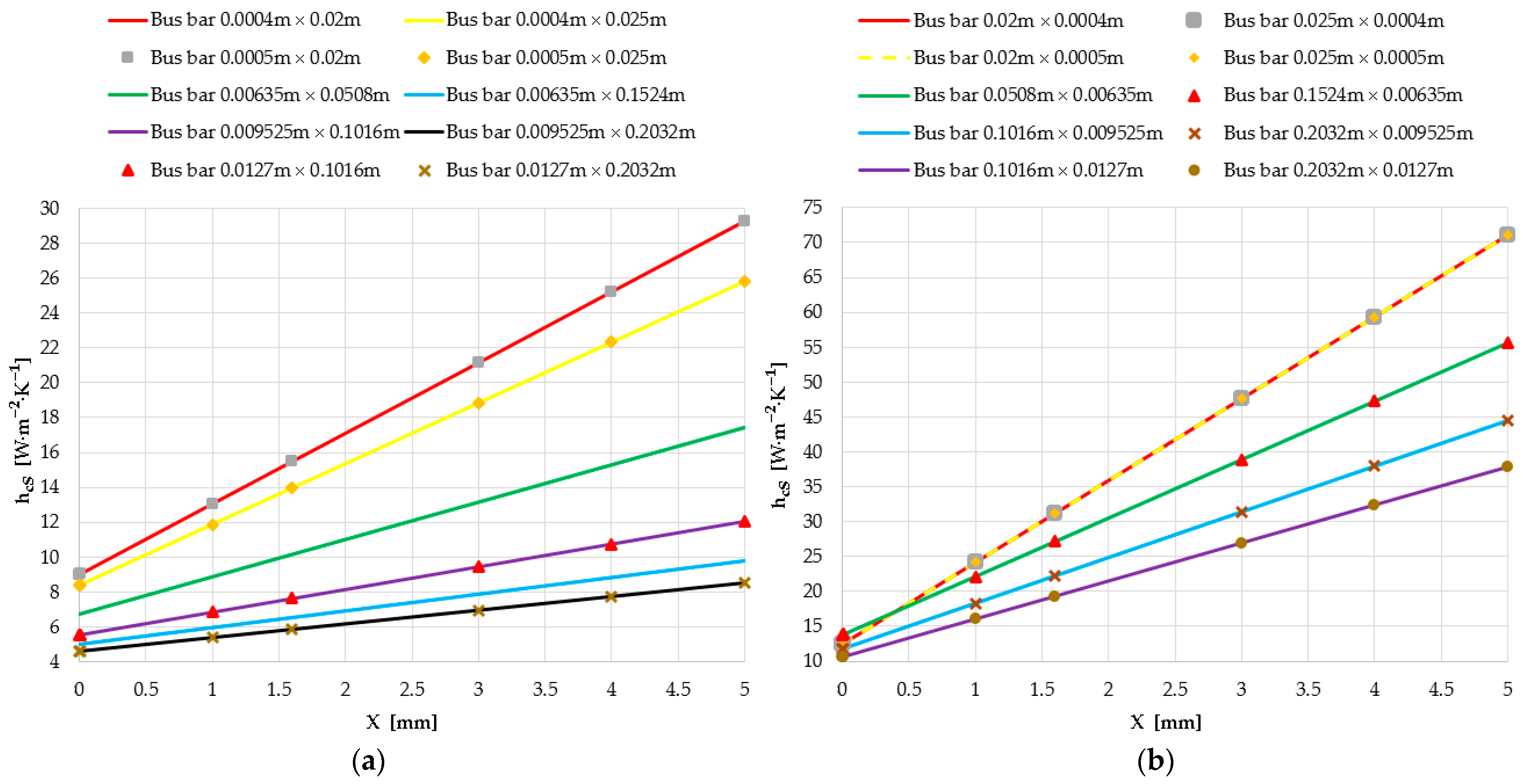

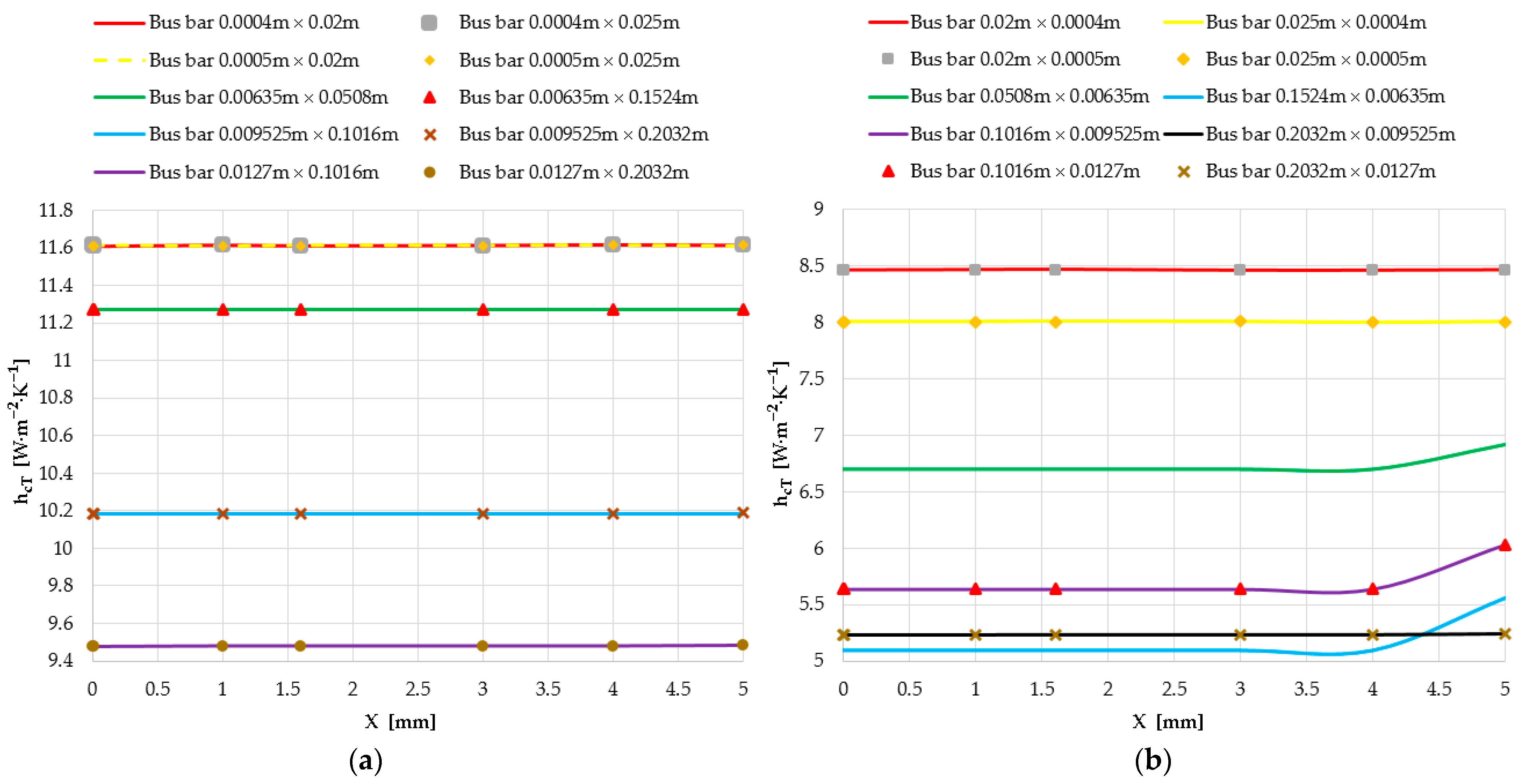

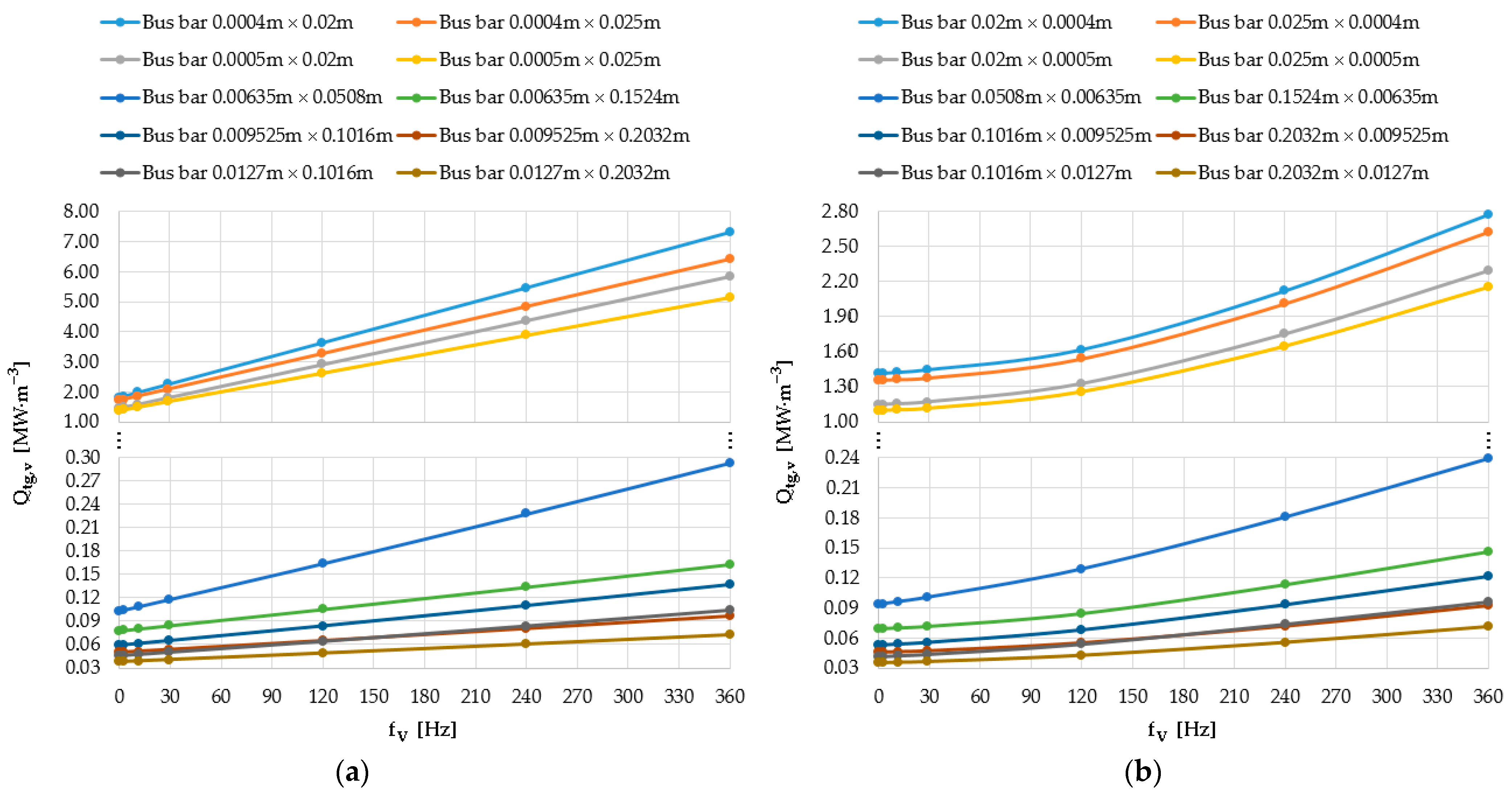

4.3. Results of Analytical Thermal Modeling

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |||

| A | constant, – | area of one side surface of a rectangular bus bar, m2 | |

| specific heat of air at constant pressure, J·kg−1·K−1 | |||

| area of the top surface of a rectangular bus bar, m2 | |||

| frequency of the power system, 60 Hz | |||

| vibration frequency, Hz | T | unknown nodal temperature, or unknown temperature of the side, top, or bottom surface of a rectangular bus bar, K | |

| Gr | Grashof number, – | ||

| H | height of a rectangular bus bar, m | ||

| heat transfer coefficient due to free or vibration-assisted convection, W·m−2·K−1 | ambient air temperature, °C or K | ||

| continuously permissible temperature of bus bars, °C or K | |||

| heat transfer coefficient due to radiation, W·m−2·K−1 | |||

| film temperature, K | |||

| RMS current of a rectangular bus bar, A | , | bus bar temperature, °C or K | |

| ampacity of a rectangular bus bar, A | V | volume of a rectangular bus bar, m3 | |

| thermal conductivity of the bus bar material, W·m−1·K−1 | vibration velocity, m·s−1 | ||

| W | width of a rectangular bus bar, m | ||

| thermal conductivity of air, W·m−1·K−1 | X | vibration amplitude, m, mm or μm | |

| extra loss coefficient for the proximity effect, – | x, y | Cartesian spatial coordinates, m | |

| extra loss coefficient for the skin effect, – | solar absorptivity, – | ||

| L | length of a rectangular bus bar, m | thermal diffusivity of air, m2·s−1 | |

| normal vector oriented outwards in relation to the side, top, or bottom surface of a rectangular bus bar, – | temperature coefficient of resistivity, K−1 | ||

| thermal expansion coefficient of air, K−1 | |||

| thermal emissivity, – | |||

| Nu | Nusselt number, – | dynamic viscosity, kg·m−1·s−1 | |

| Pr | Prandtl number, – | kinematic viscosity of air, m2·s−1 | |

| volume power of heat sources, W·m−3 | π | Pi number, 3.14159265 | |

| Re | Reynolds number, – | density of air, kg·m−3 | |

| S | geometric cross-sectional area of a rectangular bus bar, m2 | d.c. resistivity of the bus bar material, Ω·m | |

| d.c. resistivity of the bus bar material at 20 °C or 293.157 K, Ω·m | |||

| area of the bottom surface of a rectangular bus bar, m2 | |||

| Stefan–Boltzmann constant, 5.67·10−8 W·m−2·K−4 | |||

| surface area of a rectangular bus bar, m2 | |||

| Subscripts | |||

| B | bottom surface of a rectangular bus bar | T | top surface of a rectangular bus bar |

| cr | critical value | V | vibration, or vibrating bus bar |

| S | side surface of a rectangular bus bar | ||

| Abbreviations | |||

| d.c. | direct current | FEM | finite element method |

| FE | finite element | RMS | Root-Mean Square |

References

- Chapman, D.; Norris, T. Copper for Busbars—Guidance for Design and Installation, 15th ed.; Copper Development Association Inc.: New York, NY, USA; European Copper Institute Ltd.: Brussels, Belgium, 2014; pp. 1–107. [Google Scholar]

- Thierry, J.-P.; Kilindjian, C. Electrodymanic Forces on Busbars in LV Systems; No. 162; Cahier Technique Merlin Gerin: Grenoble, France, 1996; pp. 1–20. [Google Scholar]

- Maheswara Rao, N.; Vasudevamurthy, B.R.; Girija, G.; Das, S.K. Significance of support structure for short circuit withstand strength of bus-bar assembly panels—Experiences with testing. Power Res. A J. CPRI 2013, 9, 197–204. [Google Scholar]

- Det Norske Veritas (DNV). Environmental Test Specification for Instrumentation and Automation Equipment; Standard for Certification No. 2.4; DNV: Oslo, Norway, 2015. [Google Scholar]

- Abdu-Razak, A.E.; Abbas, E.F.; Tahseen, T.A. The effect of vibration on the heat transfer from a vertical plate: A review. SSRG Int. J. Therm. Eng. 2020, 6, 1–5. [Google Scholar] [CrossRef]

- Rahman, A.; Tafti, D. Characterization of heat transfer enhancement for an oscillating flat plate-fin. Int. J. Heat Mass Transf. 2020, 147, 119001. [Google Scholar] [CrossRef]

- Krishna Prasad, K.; Ramanathan, V. Heat transfer by free convection from a longitudinally vibrating vertical plate. Int. J. Heat Mass Transf. 1972, 15, 1213–1223. [Google Scholar] [CrossRef]

- An, B.H.; Kim, H.J.; Kim, D.-K. Nusselt number correlation for natural convection from vertical cylinders with vertically oriented plate fins. Exp. Therm. Fluid Sci. 2012, 41, 59–66. [Google Scholar] [CrossRef]

- Kadkhodaei, G.; Sheshyekani, K.; Hamzeh, M.; Tavakoli, S.D. Multiphysics analysis of busbars with various arrangements under short-circuit conditions. IET Electr. Syst. Transp. 2016, 6, 237–245. [Google Scholar] [CrossRef]

- Plesca, A. Thermal analysis of busbars from a high current power supply system. Energies 2019, 12, 2288. [Google Scholar] [CrossRef]

- Kolimas, Ł.; Łapczyński, S.; Szulborski, M. Simulations of electrical parameters in high current busbars. Prz. Elektrotech. 2020, 11, 178–181. [Google Scholar] [CrossRef]

- Szulborski, M.; Łapczyński, S.; Kolimas, Ł.; Kozarek, Ł.; Rasolomampionona, D.D. Calculations of electrodynamic forces in three-phase asymmetric busbar system with the use of FEM. Energies 2020, 13, 5477. [Google Scholar] [CrossRef]

- Szulborski, M.; Łapczyński, S.; Kolimas, Ł. Thermal analysis of heat distribution in busbars during rated current flow in low-voltage industrial switchgear. Energies 2021, 14, 2427. [Google Scholar] [CrossRef]

- Yang, D.; Li, Y.; Han, Y.; Ding, B.; Li, L.; Wu, J. Vibration analysis and experimental study of GIS busbar enclosure under electric field. Shock. Vib. 2022, 2022, 3055139. [Google Scholar]

- Aberuee, M.J.; Ahmadikia, H.; Ziaei-Rad, M. The effect of internal plate vibration on the rate of heat transfer in a glass recycling process dryer. Int. J. Therm. Sci. 2020, 156, 106424. [Google Scholar] [CrossRef]

- Ono, J.; Unno, N.; Yuki, K.; Taniguchi, J.; Satake, S.-I. Visualization and sound measurements of vibration plate in a boiling bubble resonator. Fluids 2021, 6, 443. [Google Scholar] [CrossRef]

- Akcay, S.; Akdag, U. Mixed convection heat transfer from a vertical flat plate subjected to periodic oscillations. J. Ther. Eng. 2021, 7, 1377–1391. [Google Scholar] [CrossRef]

- Hou, S.; Zhang, X.; Liu, J.; Fan, S.; Zhang, Y.; Li, M. Impact of vibration on heat transfer and flow properties of heat exchange surfaces. Numer. Heat Transf. A Appl. 2022, 1–21. [Google Scholar] [CrossRef]

- Rasangika, A.H.D.K.; Nasif, M.S.; Pao, W.; Al-Waked, R. Numerical investigation of the effect of square and sinusoidal waves vibration parameters on heat sink forced convective heat transfer enhancement. Appl. Sci. 2022, 12, 4911. [Google Scholar] [CrossRef]

- Hu, J.; Min, C.; Yang, X.; Wang, K.; Xie, L. Numerical and experimental study on heat transfer characteristics of single vibrating blade in a channel flow. J. Therm. Sci. 2023, 32, 982–992. [Google Scholar] [CrossRef]

- Park, K.T.; Lee, J.W.; Lee, M.G.; Kim, H.J.; Kim, D.-K. Nusselt number correlation for vibration-assisted convection from vertically oriented plate fins. Int. J. Heat Mass Transf. 2014, 78, 522–526. [Google Scholar] [CrossRef]

- Klimenta, D.O.; Perović, B.D.; Jevtić, M.D.; Radosavljević, J.N. An analytical algorithm to determine allowable ampacities of horizontally installed rectangular bus bars. Therm. Sci. 2016, 20, 717–730. [Google Scholar] [CrossRef]

- COMSOL AB. Heat Transfer Module User’s Guide, Version 4.3; COMSOL AB: Stockholm, Sweden, 2012. [Google Scholar]

- NDT Supply. com. Conductivity and Resistivity Values for Aluminum & Alloys; NDT Supply.com, Inc.: Lenexa, KS, USA, 2002. [Google Scholar]

- IEEE Std 605TM-2008; IEEE Guide for Bus Design in Air Insulated Substations. (Revision of IEEE Std 605-1998/Incorporates IEEE Std 605-2010/Amendment 1); IEEE: New York, NY, USA, 2010.

- Incropera, F.P.; Dewitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 401–484. [Google Scholar]

- Lienhard, J.H., IV; Lienhard, J.H., V. A Heat Transfer Handbook, 5th ed.; Phlogiston Press: Cambridge, MA, USA, 2020; pp. 269–535. [Google Scholar]

- Holman, J.P. Heat Transfer, 8th ed.; McGraw-Hill Book Co: Singapore, 1999; pp. 336–393. [Google Scholar]

- Salort, J.; Liot, O.; Rusaouen, E.; Seychelles, F.; Tisserand, J.-C.; Creyssels, M.; Castaing, B.; Chillà, F. Thermal boundary layer near roughnesses in turbulent Rayleigh-Bénard convection: Flow structure and multistability. Phys. Fluids 2014, 26, 015112. [Google Scholar] [CrossRef]

- Šućurović, M.; Klimenta, D.; Raičević, N.; Perović, B. The Effect of Aging of Surface Non-Metallic Coatings on the Ampacity of Medium Voltage Rectangular Bus Bars. In Proceedings of the 7th Virtual International Conference on Science, Technology and Management in Energy–eNergetics 2021, Belgrade, Serbia, 16–17 December 2021. [Google Scholar]

- Klimenta, D.; Minić, D.; Pantić-Ranđelović, L.; Radonjić-Mitić, I.; Premović-Zečević, M. Modeling of steady-state heat transfer through various photovoltaic floor laminates. Appl. Therm. Eng. 2023, 229, 120589. [Google Scholar] [CrossRef]

- Eid, E.I.; Gomaa, M.E. Influence of vibration in enhancement of heat transfer rates from thin plannar fins. Heat Mass Transf. 2009, 45, 713–726. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions, and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

| Aluminum Alloy | (W·m−1·K−1) | (Ω·m) | (K−1) |

|---|---|---|---|

| 5052-O | 138.0 | 4.930 ×·10−8 | 0.00383 |

| 6101-T61 | 218.5 | 2.998 × 10−8 | 0.00383 |

| W | H | for X = 0 m | for X = 8.541 μm | for X = 1 mm | for X = 1.6 mm | for X = 3 mm | for X = 4 mm | for X = 5 mm | |

|---|---|---|---|---|---|---|---|---|---|

| BUSBAR b | BUSBAR b | BUSBAR b | BUSBAR b | BUSBAR b | BUSBAR b | BUSBAR b | |||

| m | m | Hz | A | A | A | A | A | A | A |

| Bus bars installed horizontally with a vertical major axis and adiabatic top and bottom surfaces | |||||||||

| 0.0004 | 0.02 | 50 | 44.0 | 44.1 | 47.1 | 48.8 | 52.6 | 55.2 | 57.6 |

| 0.0004 | 0.025 | 29 | 53.5 | 53.5 | 55.5 | 56.7 | 59.2 | 61.0 | 62.8 |

| 0.0005 | 0.02 | 59 | 49.3 | 49.3 | 53.2 | 55.5 | 60.4 | 63.7 | 66.8 |

| 0.0005 | 0.025 | 40 | 59.9 | 59.9 | 62.9 | 64.6 | 68.5 | 71.2 | 73.7 |

| Bus bars installed horizontally with a vertical major axis and non-adiabatic top and bottom surfaces | |||||||||

| 0.0004 | 0.02 | 50 | 44.3 | 44.4 | 47.4 | 49.1 | 52.9 | 55.4 | 57.8 |

| 0.0004 | 0.025 | 29 | 53.9 | 53.9 | 55.8 | 57.0 | 59.5 | 61.3 | 63.0 |

| 0.0005 | 0.02 | 59 | 49.7 | 49.7 | 53.6 | 55.9 | 60.7 | 64.0 | 67.1 |

| 0.0005 | 0.025 | 40 | 60.3 | 60.3 | 63.3 | 65.0 | 68.9 | 71.6 | 74.1 |

| FE Mesh | Number of Nodes | Number of Elements | () (°C) a | () (°C) b | () (°C) c |

|---|---|---|---|---|---|

| Automatically generated (Figure 3a) | 93 | 92 | 30.004153 | 30.0 | 0.004153 |

| Generated after the first refinement | 277 | 368 | 30.004164 | 30.0 | 0.004164 |

| Generated after the second refinement | 921 | 1472 | 30.004164 | 30.0 | 0.004164 |

| W | H | at 70 °C | for X = 0 m | for X = 8.541 μm | for X = 1 mm | for X = 1.6 mm | for X = 3 mm | for X = 4 mm | for X = 5 mm |

|---|---|---|---|---|---|---|---|---|---|

| BUSBAR c | BUSBAR d | BUSBAR d | BUSBAR d | BUSBAR d | BUSBAR d | BUSBAR d | |||

| m | m | – | A | A | A | A | A | A | A |

| Bus bars installed horizontally with a vertical major axis | |||||||||

| 0.0004 a | 0.02 | 1.000 | 44.3 | 44.4 | 51.3 | 55.0 | 62.9 | 68.0 | 72.7 |

| 0.0004 a | 0.025 | 1.000 | 53.9 | 53.9 | 61.6 | 65.7 | 74.6 | 80.4 | 85.8 |

| 0.0005 a | 0.02 | 1.000 | 49.7 | 49.8 | 57.4 | 61.6 | 70.4 | 76.1 | 81.3 |

| 0.0005 a | 0.025 | 1.000 | 60.3 | 60.4 | 68.9 | 73.6 | 83.5 | 90.0 | 96.0 |

| 0.00635 b | 0.0508 | 1.014 | 544.9 | 545.4 | 595.5 | 623.8 | 687.1 | 730.0 | 770.3 |

| 0.00635 b | 0.1524 | 1.092 | 1365.8 | 1366.5 | 1443.5 | 1488.2 | 1589.5 | 1659.3 | 1726.2 |

| 0.009525 b | 0.1016 | 1.100 | 1182.3 | 1183.0 | 1261.7 | 1307.0 | 1410.4 | 1481.6 | 1549.2 |

| 0.009525 b | 0.2032 | 1.210 | 2073.7 | 2074.6 | 2173.9 | 2231.8 | 2365.1 | 2457.7 | 2546.8 |

| 0.0127 b | 0.1016 | 1.140 | 1359.6 | 1360.3 | 1448.5 | 1499.3 | 1616.6 | 1697.6 | 1774.7 |

| 0.0127 b | 0.2032 | 1.259 | 2366.7 | 2367.7 | 2479.2 | 2544.3 | 2695.5 | 2800.9 | 2902.2 |

| Bus bars installed horizontally with a horizontal major axis | |||||||||

| 0.02 a | 0.0004 | 1.000 | 39.3 | 39.3 | 39.8 | 40.1 | 42.0 | 43.8 | 45.5 |

| 0.025 a | 0.0004 | 1.000 | 48.1 | 48.1 | 48.6 | 48.9 | 51.2 | 53.3 | 55.3 |

| 0.02 a | 0.0005 | 1.000 | 44.1 | 44.1 | 44.8 | 45.2 | 47.5 | 49.6 | 51.6 |

| 0.025 a | 0.0005 | 1.000 | 53.9 | 53.9 | 54.6 | 55.0 | 57.8 | 60.2 | 62.5 |

| 0.0508 b | 0.00635 | 1.014 | 517.8 | 518.1 | 544.5 | 559.8 | 608.2 | 643.7 | 678.8 |

| 0.1524 b | 0.00635 | 1.092 | 1286.6 | 1286.8 | 1316.9 | 1334.7 | 1421.7 | 1485.9 | 1562.5 |

| 0.1016 b | 0.009525 | 1.100 | 1121.1 | 1121.5 | 1161.4 | 1184.9 | 1273.3 | 1338.2 | 1409.0 |

| 0.2032 b | 0.009525 | 1.210 | 1992.1 | 1992.5 | 2033.7 | 2058.2 | 2184.8 | 2277.3 | 2364.0 |

| 0.1016 b | 0.0127 | 1.140 | 1294.7 | 1295.1 | 1344.5 | 1373.5 | 1478.1 | 1554.3 | 1636.9 |

| 0.2032 b | 0.0127 | 1.259 | 2278.7 | 2279.1 | 2330.4 | 2360.8 | 2509.1 | 2616.9 | 2718.1 |

| W | H | at 70 °C | for = 0 Hz | for = 2.75 Hz | for = 11.09 Hz | for = 29 Hz | for = 120 Hz | for = 240 Hz | for = 360 Hz |

|---|---|---|---|---|---|---|---|---|---|

| BUSBAR c | BUSBAR d | BUSBAR d | BUSBAR d | BUSBAR d | BUSBAR d | BUSBAR d | |||

| m | m | – | A | A | A | A | A | A | A |

| Bus bars installed horizontally with a vertical major axis | |||||||||

| 0.0004 a | 0.02 | 1.000 | 44.3 | 44.9 | 46.4 | 49.5 | 62.9 | 77.1 | 89.2 |

| 0.0004 a | 0.025 | 1.000 | 53.9 | 54.4 | 56.1 | 59.5 | 74.6 | 90.8 | 104.6 |

| 0.0005 a | 0.02 | 1.000 | 49.7 | 50.3 | 51.9 | 55.4 | 70.4 | 86.3 | 99.8 |

| 0.0005 a | 0.025 | 1.000 | 60.3 | 60.9 | 62.8 | 66.7 | 83.5 | 101.6 | 117.0 |

| 0.00635 b | 0.0508 | 1.014 | 544.9 | 548.5 | 559.4 | 582.0 | 687.1 | 809.5 | 918.7 |

| 0.00635 b | 0.1524 | 1.092 | 1365.8 | 1371.3 | 1387.8 | 1422.6 | 1589.5 | 1791.6 | 1977.0 |

| 0.009525 b | 0.1016 | 1.100 | 1182.3 | 1187.9 | 1204.8 | 1240.4 | 1410.4 | 1616.1 | 1803.9 |

| 0.009525 b | 0.2032 | 1.210 | 2073.7 | 2080.8 | 2102.0 | 2146.8 | 2365.1 | 2635.1 | 2886.1 |

| 0.0127 b | 0.1016 | 1.140 | 1359.6 | 1365.9 | 1384.8 | 1424.6 | 1616.6 | 1851.9 | 2067.8 |

| 0.0127 b | 0.2032 | 1.259 | 2366.7 | 2374.6 | 2398.4 | 2448.8 | 2695.5 | 3003.8 | 3291.7 |

| Bus bars installed horizontally with a horizontal major axis | |||||||||

| 0.02 a | 0.0004 | 1.000 | 39.3 | 39.3 | 39.4 | 39.7 | 42.0 | 48.1 | 55.0 |

| 0.025 a | 0.0004 | 1.000 | 48.1 | 48.1 | 48.2 | 48.4 | 51.2 | 58.5 | 66.8 |

| 0.02 a | 0.0005 | 1.000 | 44.1 | 44.2 | 44.3 | 44.6 | 47.5 | 54.6 | 62.5 |

| 0.025 a | 0.0005 | 1.000 | 53.9 | 54.0 | 54.1 | 54.4 | 57.8 | 66.2 | 75.7 |

| 0.0508 b | 0.00635 | 1.014 | 517.8 | 519.7 | 525.3 | 537.3 | 608.2 | 720.1 | 828.5 |

| 0.1524 b | 0.00635 | 1.092 | 1286.6 | 1288.7 | 1295.1 | 1308.6 | 1421.7 | 1648.5 | 1873.7 |

| 0.1016 b | 0.009525 | 1.100 | 1121.1 | 1124.0 | 1132.5 | 1150.5 | 1273.3 | 1489.6 | 1701.2 |

| 0.2032 b | 0.009525 | 1.210 | 1992.1 | 1995.0 | 2003.7 | 2022.3 | 2184.8 | 2490.7 | 2823.2 |

| 0.1016 b | 0.0127 | 1.140 | 1294.7 | 1298.1 | 1308.7 | 1331.0 | 1478.1 | 1730.1 | 1975.3 |

| 0.2032 b | 0.0127 | 1.259 | 2278.7 | 2282.3 | 2293.1 | 2316.3 | 2509.1 | 2863.6 | 3245.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garić, L.; Klimenta, D.; Andriukaitis, D.; Jovanović, S. Modeling the Effects of Horizontal Transverse Vibrations on the Thermal Behavior and the Ampacity of Rectangular Bus Bars. Appl. Sci. 2023, 13, 6745. https://doi.org/10.3390/app13116745

Garić L, Klimenta D, Andriukaitis D, Jovanović S. Modeling the Effects of Horizontal Transverse Vibrations on the Thermal Behavior and the Ampacity of Rectangular Bus Bars. Applied Sciences. 2023; 13(11):6745. https://doi.org/10.3390/app13116745

Chicago/Turabian StyleGarić, Ljubiša, Dardan Klimenta, Darius Andriukaitis, and Saša Jovanović. 2023. "Modeling the Effects of Horizontal Transverse Vibrations on the Thermal Behavior and the Ampacity of Rectangular Bus Bars" Applied Sciences 13, no. 11: 6745. https://doi.org/10.3390/app13116745

APA StyleGarić, L., Klimenta, D., Andriukaitis, D., & Jovanović, S. (2023). Modeling the Effects of Horizontal Transverse Vibrations on the Thermal Behavior and the Ampacity of Rectangular Bus Bars. Applied Sciences, 13(11), 6745. https://doi.org/10.3390/app13116745