Abstract

The promotion of the SDGs (Sustainable Development Goals) for a sustainable and better society has been actively implemented in all sectors, including the construction industry. In contrast to other industries, however, the construction industry produces a great amount of waste while using a vast amount of resources. The effective utilization of resources is a hot topic of discussion in the construction industry, and sectors remain wherein the effective management of resource utilization is still in progress. Proper disposal of construction-generated soil is one of the issues that needs attention. This type of soil is primarily alkaline and cannot be disposed of without appropriate treatment. The traditional method of treating construction-generated soil before its disposal is the neutralization titration method, where the soil is mixed with a weak acid until the pH value has been lowered to 7. However, this process is performed according to empirical rules, and the exact amount of acid required has yet to be discovered. Therefore, the aim of this study was to derive a theoretical equation to determine the necessary amount of neutralizer. The theoretical equation was successfully derived, and the consistency of the output results was verified for three different neutralizers. Finally, vegetation tests were conducted on each neutralized soil sample to check its suitability as a vegetation substrate.

1. Introduction

In September 2015, the Sustainable Development Goals (SDGs) were established during the United Nations Summit to emphasize the sustainable development of interconnected environmental, social, and economic aspects. As a result, the promotion of SDGs began in the construction industry around the world with an effort to realize a sustainable and better world [1,2,3], and the construction industry started considering the adverse impact of certain types of waste on the environment [2,3]. Construction and demolition waste management has been a hot topic of discussion in the academic world [4]. Many researchers have studied construction waste management in Japan [5,6] and overseas [2,4,7,8,9,10,11]. There is a growing movement to recycle construction resources, such as asphalt and concrete lumps generated at construction sites, as part of the “Responsibility to create” and “Responsibility to use” items set out in SDG 11. According to the survey results [12] on construction by-products, all by-products, except for construction-generated soil, have met the target values, as shown in Table 1. Discussions on the effective use of construction-generated soil are still in progress. Most of it is dumped into a landfill, which might raise concerns about the ecological impact on the surroundings if it is dumped without proper treatment. One of the possible methods for reclaiming construction-generated soil is chemically neutralizing it and using it as a vegetation substrate. Since these soils are construction debris, they might not contain sufficient nutrients for vegetation growth, but it might be possible to use them as a substrate material after proper neutralization. Shi et al. [13], Liu et al. [14], Zhang et al. [15], and Jin et al. [16] studied the neutralization method for soil reclamation, and many other neutralizers have been developed. However, the appropriate amount of neutralizer has not been studied, and the amount required for neutralization is determined according to empirical rules, which cannot be deemed a reliable method. Therefore, a proper methodology for calculating the amount of required neutralizer needs to be developed.

Table 1.

Results of the FY 2018 survey on construction by-products by Ministry of Land, Infrastructure, Transport and Tourism.

The aim of this study was to establish a management system that enables society to easily recycle construction-generated soil. The study focused on deriving a theoretical equation that can calculate the amount of added neutralizer required to completely neutralize construction-generated soil. To validate the consistency of the results using the theoretical equation, separate experiments were conducted to determine the amount of neutralizer required and to compare it with the amount generated by the theoretical equation. In addition, vegetation tests were performed on the treated soil to evaluate its effectiveness as a vegetation substrate.

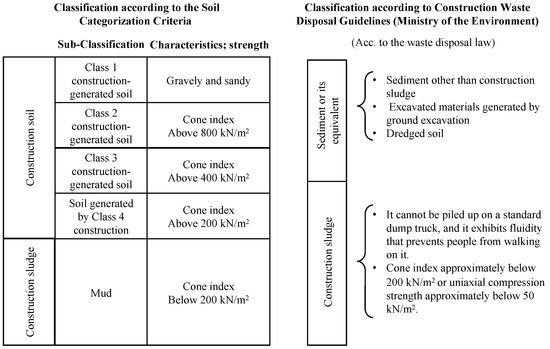

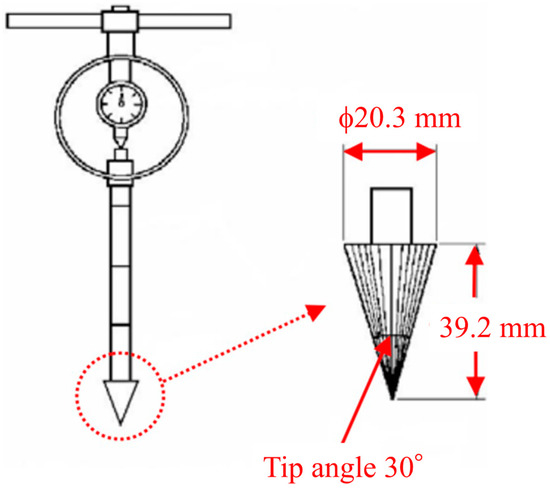

2. Construction-Generated Soil

Construction-generated soil is produced in large quantities at construction sites, such as those for tunnels, embankments, etc. The soil is normally highly alkaline because of the cement content and is not environmentally friendly [10,11,17,18,19,20,21,22]. However, construction-generated soil is not very different from normal soil in terms of its physical properties and appearance, apart from the fact that it contains some cement lumps, as shown in Figure 1. Thus, as long as the soil meets the chemical property standards, it can be recycled and reused. Figure 2 shows the classification of construction-generated soil based on its characteristics and according to the waste disposal law. Construction soil has a cone index value of 200 kN/m2 or more; anything less than that is considered mud. Construction sludge is soil with a cone index value of 200 kN/m2 or less and possesses the ability to flow such that it cannot be piled onto a standard specification dump truck and people cannot walk on it [23]. Figure 3 shows an image of a cone penetrometer, which is used to determine the cone index value. The cone index standardized by “JIS A 1228” refers to the degree of resistance to penetration when a cone penetrometer is pushed into the soil and is an indicator of the soil’s strength.

Figure 1.

Construction-generated soil.

Figure 2.

Definition of construction soil and construction sludge according to the physical properties.

Figure 3.

Details of the cone penetrometer used to determine the cone index.

3. Environmental Conditions of Vegetation Substrate

In this study, the growth condition of vegetation will be used as the decision criterion for verifying the improvement in construction-generated soil quality. The aim was to sufficiently raise the soil quality so that the soil can be used as a vegetation substrate. Potential hydrogen (pH) and electrical conductivity (EC) were adopted as the indices for judgment. pH refers to the exponent of hydrogen ion concentration and is defined as the measure indicating the acidity or alkalinity of the aqueous solution in a logarithmic scale on which 7 is neutral, 1 to 7 indicates acidity, and 7 to 14 indicates alkalinity [24]. Since it is a value consisting of exponents, a decrease in pH of 1 increases the hydrogen ion concentration by a factor of 10; conversely, an increase in pH of 1 decreases the hydrogen ion concentration by a factor of 10. It is extremely difficult for plants to grow under highly acidic or highly alkaline conditions. Electrical conductivity (EC) is a measure of the ionic state of salts in an aqueous solution. Plants need a suitable salt concentration to grow. Both excessive and low salt concentrations result in the failure of plant growth. The environmental conditions for the vegetation base material are a pH value of 4 to 8 and an EC value of 0.1 to 1.5 mS/cm, with the upper limit being the maximum allowed value for the lower level of vegetation base material only [25]. A target pH value of 7 and a target EC value of 1.5 were set for this study. In many cases, when conventional soil improvement methods are used, the EC increases when the pH is lowered and affects vegetation growth. Thus, it is necessary to firstly stabilize the EC value while reducing the pH value.

4. Equation Derivation

Equation (1) shows the general relationship of normality in neutralization titration.

where is the acid mole (mol) number, is the acid valence, is the base mole (mol) number, and is the valence of the base.

To derive the theoretical formula, the following assumptions were made.

- (1)

- All alkaline components in construction soil come from calcium hydroxide ( = 2). Calcium carbonate (CaCO3) from cement is the only major compound found in construction-generated soil. Only a negligible presence of other chemicals exists, such that their influence can be ignored. When water is added to CaCO3, it undergoes a hardening phase while ionizing into ions, which combine with the water to form calcium hydroxide [26]. Equation (2) describes the process of calcium hydroxide generation in cement. However, there are still many unresolved aspects of this process, since the assumed reactions are complicated by the fineness of the cement, the amount of water, and temperature, but their influence is assumed to be negligible in this study.

- (2)

- The ionization degree of the neutralizer and the calcium hydroxide shall be 1, and all acids and bases shall be ionized. Under normal circumstances, acids and bases are ionized when dissolved in an aqueous solution, and their degree of ionization varies depending on several factors. To be precise, weak acids and weak bases ionize only partially in an aqueous solution, while strong acids and strong bases show an ionization degree of 1. However, as it is difficult to estimate the degree of ionization, it is assumed to be 1 in this study.

- (3)

- The neutralization reaction occurring in construction-generated soil with a neutralizer is assumed to be the same as that occurring in an aqueous solution, where the neutralization reaction occurs in all directions. In the case of a neutralization reaction in an aqueous solution, the reaction takes place in all directions because of the fluidity of the solution. However, in the case of neutralization reactions occurring in soil, fluidity is not ensured because the soil is granular and neutralization from all directions is impossible.

Since there are no instruments that can easily measure the total amount of alkali present in construction soil, the amount of alkali material in construction soil is estimated from the pH of the construction soil. When calculating the amount of base substance in construction soil from the pH, water is added so that the mass ratio of water to furnace dry mass of the construction soil becomes 5. The Japanese Geotechnical Society prescribed this pH measurement method as “JGS 0211-2000”. Firstly, the molar concentration of the base is calculated using Equation (3) [26,27]:

where is the molar concentration of the base (mol/L) and pH is the pH value of the construction-generated soil.

The volume of the aqueous solution is calculated using Equation (4).

where is the volume of the aqueous solution (L), is the wet mass of the construction soil (g), w is the water content ratio of the construction soil (%), and is the density of water (=998 g/L).

The amount of base material, shown in Equation (5), can be derived using Equations (3) and (4).

The theoretical equation for the amount of neutralizer required for the neutralization titration reaction, shown in Equation (6), can be derived using Equations (1) and (5).

where is the mass of the neutralizer added for neutralization (g) and is the molar mass of the acid (g/mol).

5. Verification Test

5.1. Neutralization Titration Test

To evaluate the theoretical equation, experimental tests were conducted to determine the amount of acidic neutralizer required to neutralize the sample construction-generated soil. Two different samples were prepared based on the mixing method. One was prepared by mixing 200 g of the soil by hand, and the other was prepared by mixing 20 kg of the soil with a mixer. The physical and chemical properties of the soil used in the tests are shown in Table 2.

Table 2.

Properties of construction-generated soil used in neutralization titration test.

In this study, three different neutralizers were used, namely, citric acid, succinic acid, and malic acid. They are all weak acids that can be purchased commercially and are easy to handle. Citric acid is an organic compound contained in citrus fruits. It is one of the hydroxy acids, being widely used as a food additive because of its refreshing sour taste. It is a colorless solid at room temperature and is available as hydrated and anhydrous crystals. Succinic acid is an organic compound used as a food additive. It is a clear, colorless solid at room temperature. Malic acid is one of the hydroxy acids; it was first discovered in unripe apples. It is an organic compound used as a food additive and is a colorless solid at room temperature. The chemical properties of the three neutralizers used in this study are shown in Table 3.

Table 3.

Chemical properties of each neutralizing agent used in the neutralization titration test.

The test procedure is as follows:

- (1)

- Place the construction-generated sample soil in the container.

- (2)

- Add 0.5% neutralizer to the mass of the sample soil.

- (3)

- After the addition of the neutralizer, mix the sample for one minute. For the manually mixed sample, cover the container containing the soil sample and shake it upside down for one minute. For the mechanically mixed sample, mix the soil for 30 s in the clockwise direction and in the anti-clockwise direction for the next 30 s using a Pellegaia mixer, as shown in Figure 4.

Figure 4. Pellegaia mixer.

Figure 4. Pellegaia mixer. - (4)

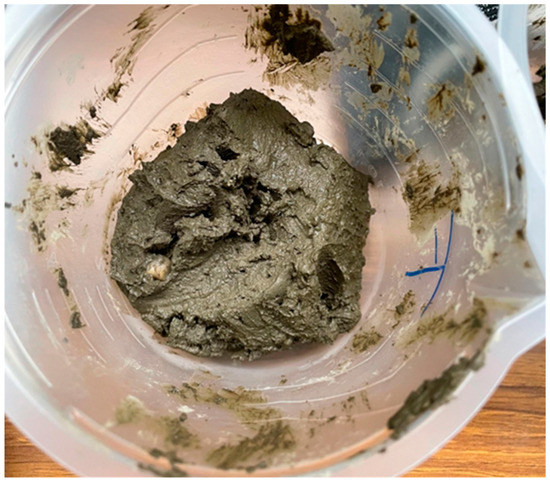

- After mixing, allow the mixture to settle for one minute, and then measure the pH and EC values. Measure the values at three different places and take the average of the three values. Figure 5 shows the condition of the construction-generated soil during the test.

Figure 5. Soil after neutralization titration test.

Figure 5. Soil after neutralization titration test. - (5)

- Repeat Steps (2)–(4) until the average pH value is less than 7.

5.2. Vegetation Test

In this study, garden radish (Raphanus sativus var. sativus) was selected to observe the germination status in the neutralized and non-neutralized soil samples to check whether the germination succeeded or not. It belongs to the family Brassicaceae. It can be harvested within 20 days, and the germination status can be easily observed within five days.

The test procedure conducted in this study is described below:

- (1)

- Place 100 g of the construction-generated soil sample in four different containers.

- (2)

- To prepare the neutralized soil samples, follow the neutralization titration test procedure using the manual mixing method with different neutralizers, as described in Section 5.1.

- (3)

- Measure the pH and EC value of the soil sample at three different points. Take the average value.

- (4)

- After the sample vegetation substrate preparation is complete, plant three seeds of garden radish at equal distance in all neutralized and non-neutralized soil samples.

- (5)

- Place the samples in a location with sufficient sunlight.

- (6)

- Water the plants once every day at the designated time with the help of a misting sprayer (about 30 mL of water) and observe them for about a week.

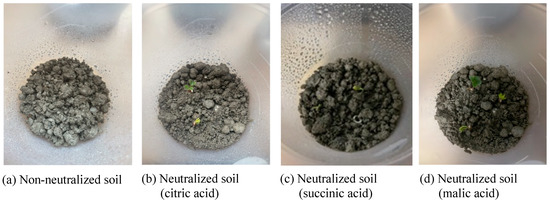

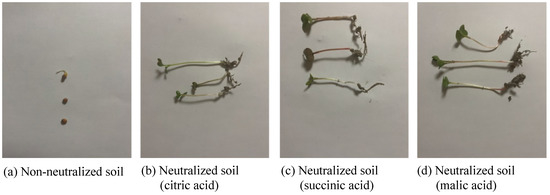

- (7)

- The germination condition can be confirmed after 5 days, so, after 7 days of observation, remove the seed/germination from the sample vegetation substrate and compare the germination status. Figure 6 and Figure 7 show the vegetation substrate samples and their germination status, respectively.

Figure 6. Germination condition of garden radish in each sample vegetation substrate after 3 days.

Figure 6. Germination condition of garden radish in each sample vegetation substrate after 3 days. Figure 7. Germination condition of garden radish in each sample vegetation substrate after 7 days.

Figure 7. Germination condition of garden radish in each sample vegetation substrate after 7 days.

6. Results and Discussion

6.1. Neutralization Titration Test Results

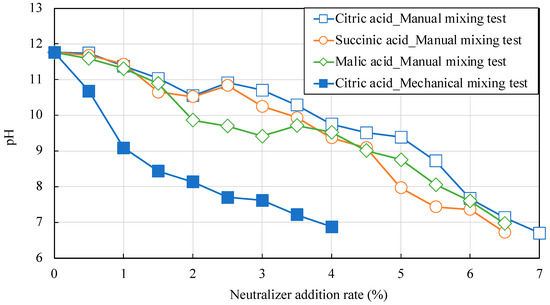

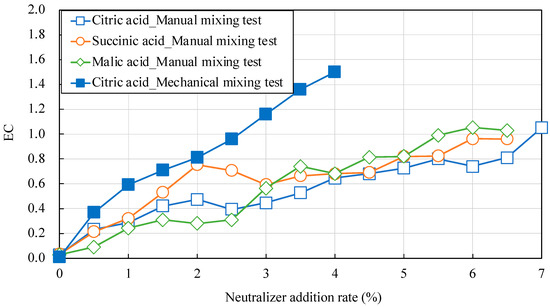

Figure 8 and Figure 9 show the results for the changes in pH and EC values, respectively, after the neutralization titration tests using different neutralizers in the constructed-generated soil. When the neutralizer was added, theoretically the pH should have changed exponentially. However, it was observed to have changed linearly in this study. The reason for this is the pH buffering in the soil, which mitigated the pH change [28]. In addition, the presence of dissolved minerals, organic matter, and microorganisms in the soil delayed the reduction in the pH value. The amount of neutralizer required for the mechanical mixing test was less than that required for the manual mixing test. The probable reason for this might be the uneven spreading of the neutralizer in the manual mixing test, which resulted in an incomplete neutralization reaction. Therefore, it is believed that the mixing process has a great influence on the amount of neutralizer required.

Figure 8.

Changes in pH values for each neutralizer addition rate in neutralization titration tests.

Figure 9.

Changes in EC values for each neutralizer addition rate in neutralization titration tests.

The initial EC value of the soil was 0.03, but it increased to 1.0–1.5 when the pH was 7. The only explanation for this is that the neutralization reaction of the construction-generated soil generated salt. However, the reason the EC value remained within the target range is because of the usage of a weak acid. Compared to strong acids, the reactions are milder, and the salt formation is limited while the pH is reduced, thus limiting the rise in EC. Since the value is within the acceptable target range of the environmental conditions for vegetation substrates, it will probably not hinder vegetation growth. At a pH value of 7, the EC value was 1.0 after the manual mixing, but it was 1.5 after the mechanical mixing. Still, environmentally speaking, it falls within an acceptable range. The reason a higher EC value was obtained with mechanical mixing is that the sample was uniformly mixed, and thus, a complete neutralization reaction was achieved throughout the sample. Besides these observations, the formation of water molecules during the neutralization reaction was observed, as seen in Figure 5, and thus the sample gradually became muddy. The only explanation for this is that the reaction of the H+ ions caused the formation of H2O molecules from the neutralizer and OH− ions from Ca(OH)2. Therefore, it is necessary to pay attention to the net amount of water used when conducting neutralization tests. In this study, the physical criteria were of less concern. The environmental conditions specified by the Parks and Landscape Division of the Urban Planning Bureau of the Ministry of Land, Infrastructure, Transport and Tourism, i.e., soil hardness and effective moisture retention, were given higher priority. Therefore, a discussion on the amount of water generated may be required in the future.

6.2. Comparison of Neutralization Titration Test Results with Theoretical Values

The theoretical values at neutralization (pH = 7) were calculated and compared with the results of the neutralization titration tests given in Table 4. Upon comparison, it is seen that the test values at neutralization were 27.5 times, 28.2 times, and 25.6 times higher than the theoretical values for citric acid, succinic acid, and malic acid, respectively, after manual mixing. The values were 15.8 times higher for the citric acid after mechanical mixing. The reason for the discrepancy is probably that the theoretical equations did not take the pH buffering effect into account and that the neutralization reaction in the soil was different from that in the aqueous solution. Unlike the aqueous solution, only a very small amount of the alkaline substance from the soil leached into the pore water, thus creating a vast difference in the neutralization procedure. Therefore, it is necessary to reconstruct the theoretical equation considering the above limitations and to multiply it by a certain factor of safety. As derived from the results, the value should be 27 for manual mixing and 15 for mechanical mixing.

Table 4.

Comparison of theoretical values and test results during neutralization.

6.3. Vegetation Test Results

The measured pH and EC values of the construction-generated soil used for the vegetation tests are presented in Table 5. The growth condition of the garden radish after seven days is shown in Figure 7. No germination was observed in the untreated soil even after the seven days. The only explanation for this is that the pH and EC values did not meet the standard values, and hence, were not suitable for the growth of garden radish. The germination was confirmed in all the neutralized soils after about three days. Additionally, within seven days, sufficient growth was confirmed. If bringing the pH and EC values within the acceptable ranges, in terms of the environmental conditions, is the only criterion required for judging the suitability of construction-generated soil as a vegetation substrate, and from the observation of successful germination made in this study, it can be concluded that construction-generated soil can satisfactorily function as a substrate for vegetation after complete neutralization titration.

Table 5.

Measured pH and EC values of construction-generated soil used for vegetation tests.

7. Conclusions

The following major conclusions can be drawn from this study:

- (1)

- The equation derivation was successful, but there was a deviation in the amount of neutralizer required to neutralize the samples compared to the test results. The reason for the deviation was the pH buffering effect in the soil, which was not taken into consideration during the derivation of the formula, and the neutralization reaction itself did not take place in the aqueous solution. To correct this, the theoretical value should be multiplied by a certain factor of safety.

- (2)

- In addition, the amount of neutralizer required for the complete neutralization differed depending on the mixing method. The neutralizer did not spread throughout the soil and might have prevented the neutralization reaction. To reduce the amount necessary for complete neutralization, it is suggested that a proper mixing system be introduced.

- (3)

- Since the germination of the new vegetation was confirmed, it is thought that the pH and EC values were successfully brought into the acceptable ranges for vegetation substrate material. Moreover, it can be concluded that construction-generated soil can be recycled as a substrate for vegetation.

During the verification of the theoretical equation derived in this study, a large deviation from the actual phenomenon was revealed. Thus, the equation needs to be updated while taking into account the pH buffering in the soil. It is also necessary to consider the pH rebound phenomenon, which is a soil-specific phenomenon.

Author Contributions

Conceptualization, S.I.; Methodology, S.I.; Formal analysis, K.N.; Investigation, K.N. and T.N.; Writing—original draft, S.S.; Writing—review & editing, S.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Amrutha, V.N.; Geetha, S.N. A systematic review on green human resource management: Implications for social sustainability. J. Clean. Prod. 2020, 247, 119131. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H.P. A framework of understanding waste management studies in construction. Waste Manag. 2011, 31, 1252–1260. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Tam, V.W.Y. Construction waste management policies and their effectiveness in Hong Kong: A longitudinal review. Renew. Sustain. Energy Rev. 2013, 23, 214–223. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L. Trend of the research on construction and demolition waste management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Yamamura, K. Current status of waste management in Japan. Waste Manag. Res. 1983, 1, 1–15. [Google Scholar] [CrossRef]

- Gotoh, S. Waste management and recycling trends in Japan. Resour. Conserv. 1987, 14, 15–28. [Google Scholar] [CrossRef]

- Gao, M.A. Construction & Demolition Waste Management: From Japan to Hong Kong. Griffin’s View on International and Comparative Law. 2008, pp. 1–29. Available online: https://ssrn.com/abstract=1131984 (accessed on 1 March 2023).

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Blengini, G.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Yuan, H.; Chini, A.R.; Lu, Y.; Shen, L. A dynamic model for assessing the effects of management strategies on the reduction of construction and demolition waste. Waste Manag. 2012, 32, 521–531. [Google Scholar] [CrossRef]

- Coelho, A.; Brito, J. Influence of construction and demolition waste management on the environmental impact of buildings. Waste Manag. 2012, 32, 532–541. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure, Transport and Tourism (MLIT). Results of the FY 2018 Survey on Actual Conditions of Construction By-Products, 1st ed.; Public Works Planning and Coordination Division, General Policy Bureau: Tokyo, Japan, 2018; pp. 1–5.

- Shi, J.; Long, T.; Zheng, L.; Gao, S.; Wang, L. Neutralization of industrial alkali-contaminated soil by different agents: Effects and environmental impact. Sustainability 2022, 14, 5850. [Google Scholar] [CrossRef]

- Liu, M.; Tan, X.; Zheng, M.; Yu, D.; Lin, A.; Liu, J.; Wang, C.; Gao, Z.; Cui, J. Modified biochar/humic substance/fertiliser compound soil conditioner for highly efficient improvement of soil fertility and heavy metals remediation in acidic soils. J. Environ. Manag. 2023, 325, 116614. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Xue, B.; Jiao, L.; Meng, X.; Zhang, L.; Li, B.; Sun, H. Preparation of ball-milled phosphorus-loaded biochar and its highly effective remediation for Cd- and Pb-contaminated alkaline soil. Sci. Total Environ. 2022, 813, 152648. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Huang, X.; Wu, J.; Zhao, W.; Fu, W. A 10-year field experiment proves the neutralization of soil pH in Chinese hickory plantation of southeastern China. J. Soils Sediments 2022, 22, 2995–3005. [Google Scholar] [CrossRef]

- Ofori, G. The environment: The fourth construction project objective? Constr. Manag. Econ. 1992, 10, 369–395. [Google Scholar] [CrossRef]

- United Nations Centre for Human Settlements. Development of National Capacity for Environmental Sound Construction; United Nations Centre for Human Settlements: Nairobi, Kenya, 1993. [Google Scholar]

- Boiral, O.; Henri, J.F. Modelling the impact of ISO 14001 on environmental performance: A comparative approach. J. Environ. Manag. 2012, 99, 84–97. [Google Scholar] [CrossRef]

- Simion, I.M.; Fortuna, M.E.; Bonoli, A.; Gavrilescu, M. Comparing environmental impacts of natural inert and recycled construction and demolition waste processing using LCA. J. Environ. Eng. Landsc. Manag. 2013, 21, 273–287. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Predicting on-site environmental impacts of municipal engineering works. Environ. Impact Assess. Rev. 2014, 44, 43–57. [Google Scholar] [CrossRef]

- Toller, S.; Wadeskog, A.; Finnveden, G.; Malmqvist, T.; Carlsson, A. Energy use and environmental impacts of the Swedish building and real estate management sector. J. Ind. Ecol. 2011, 15, 394–404. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure, Transport and Tourism (MLIT). Standard for Utilization of Generated Soil, 1st ed.; Committee for the Revision of Standard for Utilization of Generated Soil: Tokyo, Japan, 2007; pp. 2–3.

- Inazumi, S.; Sekitani, M.; Hashida, H.; Okamoto, I.; Chuman, T. Potential of high alkaline construction generated soil as planting base layer by mixing neutralize. J. Soc. Mater. Sci. Jpn. 2018, 67, 59–62. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure, Transport and Tourism (MLIT). Procedures for the Development of Planting Bases/Parks, 1st ed.; Greenery and Landscape Division, Urban Affairs Bureau: Tokyo, Japan, 2015; p. 10.

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Frassetto, L.; Banerjee, T.; Powe, N.; Sebastian, A. Acid Balance, Dietary Acid Load, and Bone Effects -A Controversial Subject. Nutrients 2018, 10, 517. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Herrboldt, E.C.B.; Gu, B.; Wullschleger, S.D.; Graham, D.E. Quantifying pH buffering capacity in acidic, organic-rich Arctic soils: Measurable proxies and implications for soil carbon degradation. Geoderma 2022, 424, 116003. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).