Reasonable Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry Driving in Inclined Short-Distance Coal Seams

Abstract

1. Introduction

2. Engineering Background

2.1. Engineering Profile

2.2. Originally Adopted Support Scheme and Deformation and Failure Characteristics

3. Calculation of Coal Pillar Width of Gob-Side Entry Driving

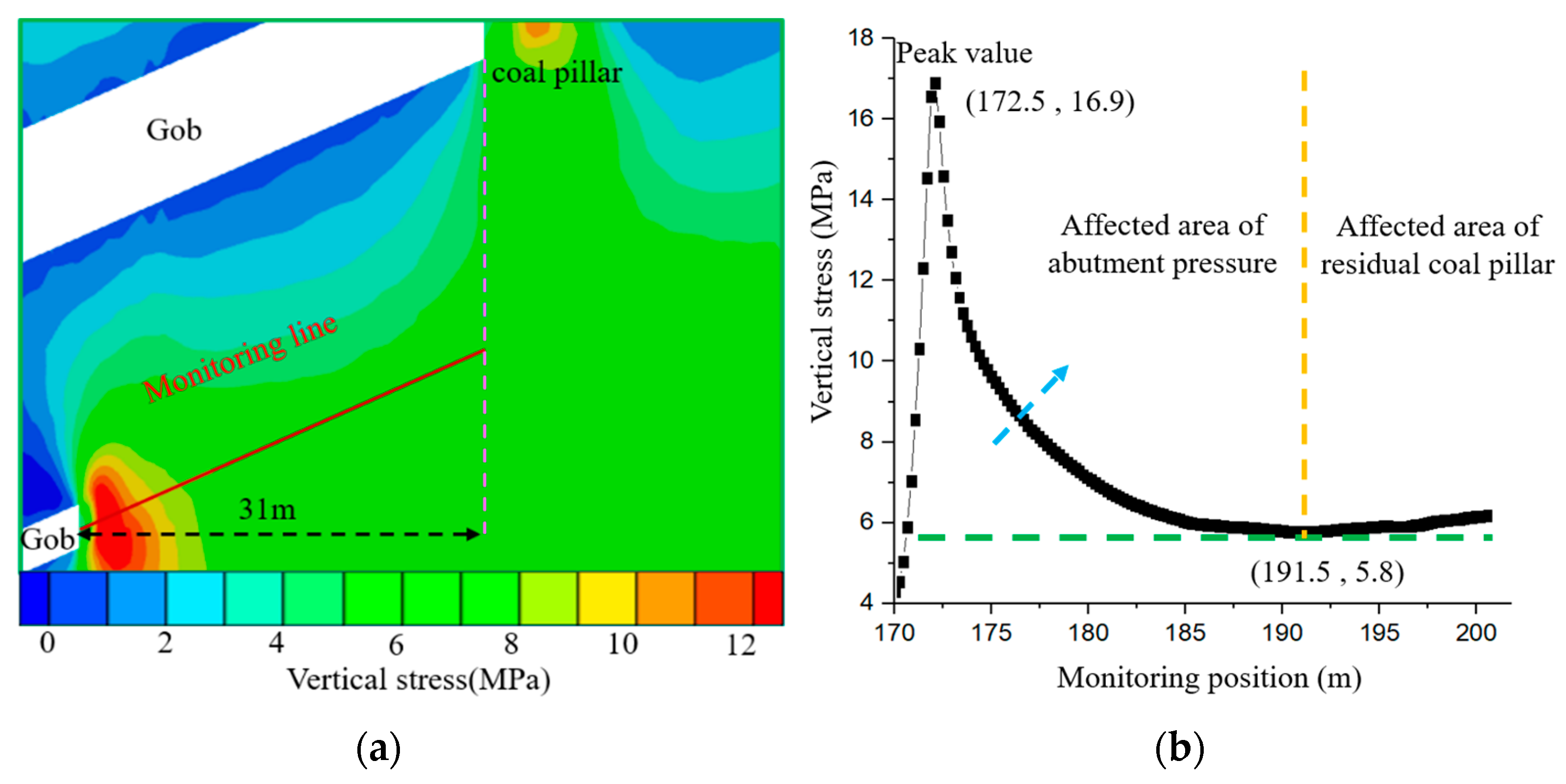

3.1. Study on the Floor Failure Range of Residual Coal Pillars

3.2. Study on the Reasonable Coal Pillar Width

4. Numerical Simulation of Coal Pillar Width of Gob-Side Entry Driving in Inclined Coal Seams

4.1. Establishment of the Numerical Model

4.2. Analysis of the Model Results

- (1)

- At coal pillar widths of 8~14 m, the internal stress of coal pillars presents an asymmetric bimodal distribution with high stress on the gob sides and low stress on the roadway sides. When the width is below 6 m, the internal stress presents a single peak distribution.

- (2)

- After the roadway excavation, the vertical stress is re-distributed. At a small coal pillar width, stress is concentrated on the right side of the roadway. As the width increases, the position of the stress concentration gradually shifts to the gob side.

- (3)

- At widths of 4 m and 6 m, fractures develop in the coal pillars, leading to serious damage and poor bearing capacity, which fails to form stress concentration. However, as the width continuously increases to 8 m, the mechanical properties of the coal and rock mass improve, and the peak value of the stress nucleus rises. When the width reaches 10 m, the maximum stress peak value is 11.30 MPa. When the width exceeds a certain value and reaches 12 m, the abutment pressure increases and surpasses the ultimate strength of the coal body. In this case, the stress in the coal pillar is relieved, and the peak value of the stress nucleus decreases. The peak stress value rises first and then decreases in turn in the following order: 1.67 MPa, 7.22 MPa, 10.67 MPa, 11.30 MPa, 10.27 MPa, and 10.25 MPa.

- (4)

- When the width of the coal pillar reaches 8 m, the coal pillar boasts an overall good bearing capacity. An increase in the width improves the integrity of the coal pillar, but this will cause a significant waste of coal resources. However, a width below 8 m corresponds to poor integrity and difficult maintenance; at the same time, it is easy to cause air leakage in the coal pillar, which is not conducive to fire prevention management in the goaf. Therefore, a width of 8 m can ensure the stability of coal pillars through appropriate measures and maximize the recovery of coal resources.

5. Determination of the 4602 Head Roadway Support Scheme

5.1. Bolt Support System

5.2. Auxiliary Support System

6. Engineering Experiment

6.1. Roadway Deformation Data and Analysis

6.2. Observed Data of Bolt Stress and Analysis

6.3. Observed Data of Anchor Stress and Analysis

6.4. Potential Future Research

7. Conclusions

- (1)

- A theoretical model of short-distance coal seam floor failure and a mechanical model of inclined gob-side roadway were established. The influence depth of the residual coal pillars in the upper coal seam on the floor is 27 m, and the influence ranges of the stress concentration in coal pillars and the low-stress area of the inclined coal seam are 11 m and 12.6 m, respectively. With reference to the on-site production geological condition, the coal pillar width is preliminarily determined to be in the range of 6~8 m.

- (2)

- Numerical simulation analysis reveals that when the width of coal pillars is smaller than 6 m, the internal stress of coal pillars is distributed in a single-peak shape, and stress is concentrated near the roadway. When the width is 8~14 m, the internal stress concentration position of coal pillars moves to the gob side, showing an asymmetric bimodal distribution of high stress on the gob side and low stress on the roadway side.

- (3)

- Through numerical simulation calculation, the residual coal pillar has a certain impact on the mining of the #1 coal seam, and the influence range of the stress concentration is 10.5 m, which is almost consistent with the theoretical calculation of the concentrated influence range of the remaining coal pillar of the coal seam, which is 11 m, verifying the accuracy of the theoretical calculation. As the coal pillar width rises, the overall peak stress increases first and then decreases. When the coal pillar width reaches 8 m, the coal pillars have an overall strong bearing capacity.

- (4)

- The gob-side entry driving in inclined short-distance coal seams should adopt the technology of pressure-yield anchor net cable support. The technology boasts good overall support, realizes the safety and stability of roadway support and provides a reference for mine roadway support under similar conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuyuk, A.F.; Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F. Designing a Large-Scale Lake Cooling System for an Ultra-Deep Mine: A Canadian Case Study. Energies 2019, 12, 811. [Google Scholar] [CrossRef]

- Palei, S.K.; Das, S.K. Logistic regression model for prediction of roof fall risks in bord and pillar workings in coal mines: An approach. Saf. Sci. 2009, 47, 88–96. [Google Scholar] [CrossRef]

- Yan, H.; Weng, M.Y.; Feng, R.M.; Li, W.K. Layout and support design of a coal roadway in ultra-close multiple-seams. J. Cent. South Univ. 2015, 22, 114385–114395. [Google Scholar] [CrossRef]

- Yavuz, H. An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int. J. Rock Mech. Min. Sci. 2004, 41, 193–205. [Google Scholar] [CrossRef]

- Mo, S.; Tutuk, K.; Saydam, S. Management of floor heave at Bulga Underground Operations—A case study. Int. J. Min. Sci. Technol. 2019, 29, 73–78. [Google Scholar] [CrossRef]

- Shang, H.F.; Ning, J.G.; Hu, S.C.; Yang, S.; Qiu, P.Q. Field and numerical investigations of gateroad system failure under an irregular residual coal pillar in close-distance coal seams. Energy Sci. Eng. 2019, 7, 2720–2740. [Google Scholar] [CrossRef]

- Yue, X.Z.; Tu, M.; Li, Y.F.; Zhang, J.S.; Gao, L. Calculation of subsidiary mining stress in floor roadway under the remaining boundary pillar of close coal seam mining. J. Min. Saf. Eng. 2021, 38, 246–252,259. [Google Scholar]

- Das, A.J.; Mandal, P.K.; Sahu, S.P.; Kushwaha, A.; Bhattacharjee, R.; Tewari, S. Evaluation of the Effect of Fault on the Stability of Underground Workings of Coal Mine through DEM and Statistical Analysis. J. Geol. Soc. India 2018, 92, 732–742. [Google Scholar] [CrossRef]

- Islam, M.R.; Shinjo, R. Mining-induced fault reactivation associated with the main conveyor belt roadway and safety of the Barapukuria coal mine in Bangladesh: Constraints from BEM simulations. Int. J. Coal Geol. 2009, 79, 115–130. [Google Scholar] [CrossRef]

- Vu, T.T. Solutions to prevent face spall and roof falling in fully mechanized longwall at underground mines, Vietnam. Min. Miner. Depos. 2022, 16, 127–134. [Google Scholar] [CrossRef]

- Xu, B.; Dong, S.N.; Xu, Y.L. Waterproof pillar size design in steep coal seam. J. Min. Sci. Technol. 2017, 2, 301–315. [Google Scholar]

- Murphy, M.M.; Ellenberger, J.L.; Esterhuizen, G.S.; Miller, T. Analysis of roof and pillar failure associated with weak floor at a limestone mine. Int. J. Min. Sci. Technol. 2016, 26, 471–476. [Google Scholar] [CrossRef] [PubMed]

- Ram, S.; Singh, A.K.; Kumar, R.; Kumar, A.; Kumar, N.; Waclawik, P.; Gautam, A.; Raja, M. Design of rock bolt-based goaf edge support for conventional depillaring with stowing. Arab. J. Geosci. 2021, 14, 2164. [Google Scholar] [CrossRef]

- Yadav, A.; Behera, B.; Sahoo, S.K.; Singh, G.S.P.; Sharma, S.K. An Approach for Numerical Modeling of Gob Compaction Process in Longwall Mining. Min. Metall. Explor. 2020, 37, 631–649. [Google Scholar]

- Wang, K.; Huang, Y.L.; Gao, H.D.; Zhai, W.; Qiao, Y.F.; Li, J.M.; Ouyang, S.Y.; Li, W. Recovery technology of bottom coal in the gob-side entry of thick coal seam based on floor heave induced by narrow coal pillar. Energies 2020, 13, 3368. [Google Scholar] [CrossRef]

- Peng, S.S.; Chandra, U. Getting the most from multiple seam reserves. Coal Min. Process. 1980, 17, 78–84. [Google Scholar]

- Quang, P.L.; Zubov, V.; Duc, T.P. Design a reasonable width of coal pillar using a numerical model a case study of khe cham basin, vietnam. In Proceedings of the Vth International Innovative Mining Symposium, Kemerovo, Russia, 19–21 October 2020; Volume 174, p. 01043. [Google Scholar]

- Gao, M.Z. Similarity model test of strata movement with steep seam. Chin. J. Rock Mech. Eng. 2004, 23, 441–445. [Google Scholar]

- Ghasemi, E.; Ataei, M.; Shahriar, K. An intelligent approach to predict pillar sizing in designing room and pillar coal mines. Int. J. Rock Mech. Min. Sci. 2014, 65, 86–95. [Google Scholar] [CrossRef]

- Hu, B.; Kang, H.P.; Lin, J. Comparison and application of high prestress and intensive support system in close, soft and cracked roadway support. Adv. Mater. Res. 2012, 524–527, 29–35. [Google Scholar] [CrossRef]

- He, F.L.; Gao, S.; Zhang, G.C.; Jiang, B.Y. Ground response of a gob-side gateroad suffering mining-induced stress in an extra thick coal seam. Geomech. Eng. 2020, 22, 1–9. [Google Scholar]

- Malashkevych, D.; Petlovanyi, M.; Sai, K.; Zubko, S. Research into the coal quality with a new selective mining technology of the waste rock accumulation in the mined-out area. Min. Miner. Depos. 2022, 16, 103–114. [Google Scholar] [CrossRef]

- Smoliński, A.; Malashkevych, D.; Petlovanyi, M.; Rysbekov, K.; Lozynskyi, V.; Sai, K. Research into Impact of Leaving Waste Rocks in the Mined-Out Space on the Geomechanical State of the Rock Mass Surrounding the Longwall Face. Energies 2022, 15, 9522. [Google Scholar] [CrossRef]

- Xu, X.H.; He, F.L.; Li, X.B.; Lv, K.; He, C.X.; Li, L. Roadway impact mechanism and optimization design under coal pillar disturbance in large mining height working face. J. Min. Saf. Eng. 2021, 38, 547–555,564. [Google Scholar]

- Song, Z.Q. Mining Pressure and Strata Control; China University of Mining and Technology Press: Xuzhou, China, 1986. [Google Scholar]

- Zhang, G.C.; He, F.L.; Lai, Y.H.; Song, J.W.; Xiao, P. Reasonable width and control technique of segment coal pillar with high-intensity fully-mechanized caving mining. J. China Coal Soc. 2016, 41, 2188–2194. [Google Scholar]

- Chen, J.H.; Liu, L.; Zeng, B.Q.; Tao, K.M.; Zhang, C.; Zhao, H.B.; Li, D.Q.; Zhang, J.W. A constitutive model to reveal the anchorage mechanism of fully bonded bolts. Rock Mech. Rock Eng. 2023, 56, 1739–1757. [Google Scholar] [CrossRef]

- Dyczko, A.; Kamiński, P.; Jarosz, J.; Rak, Z.; Jasiulek, D.; Sinka, T. Monitoring of Roof Bolting as an Element of the Project of the Introduction of Roof Bolting in Polish Coal Mines—Case Study. Energies 2021, 15, 95. [Google Scholar] [CrossRef]

- Krykovskyi, O.; Krykovska, V.; Skipochka, S. Interaction of rock-bolt supports while weak rock reinforcing by means of injection rock bolts. Min. Miner. Depos. 2021, 15, 8–14. [Google Scholar] [CrossRef]

- Wang, J.; Apel, D.B.; Xu, H.W.; Wei, C.; Skrzypkowski, K. Evaluation of the Effects of Yielding Rockbolts on Controlling Self-Initiated Strainbursts: A Numerical Study. Energies 2022, 15, 2574. [Google Scholar] [CrossRef]

- Zuo, J.P.; Liu, J.H.; Liu, D.J.; Wu, L.L.; Sun, Y.J. Control theory of uniform strength support in deep roadway. J. Min. Sci. Technol. 2021, 6, 148–159. [Google Scholar]

| Lithology | ||||||

|---|---|---|---|---|---|---|

| Coarse sandstone | 2556 | 10.25 | 7.64 | 29.31 | 1.86 | 0.20 |

| No.1 coal seam | 1335 | 2.46 | 2.91 | 23.59 | 1.35 | 0.25 |

| Siltstone | 2548 | 7.25 | 4.59 | 28.42 | 1.62 | 0.18 |

| Fine sandstone | 2552 | 10.63 | 6.90 | 31.74 | 1.72 | 0.19 |

| Mudstone | 1220 | 3.58 | 1.50 | 15.53 | 0.80 | 0.27 |

| No.2 coal seam | 1329 | 2.97 | 2.35 | 21.86 | 1.10 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, F.; Zhai, W.; Song, J.; Xu, X.; Wang, D.; Wu, Y. Reasonable Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry Driving in Inclined Short-Distance Coal Seams. Appl. Sci. 2023, 13, 6578. https://doi.org/10.3390/app13116578

He F, Zhai W, Song J, Xu X, Wang D, Wu Y. Reasonable Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry Driving in Inclined Short-Distance Coal Seams. Applied Sciences. 2023; 13(11):6578. https://doi.org/10.3390/app13116578

Chicago/Turabian StyleHe, Fulian, Wenli Zhai, Jiayu Song, Xuhui Xu, Deqiu Wang, and Yanhao Wu. 2023. "Reasonable Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry Driving in Inclined Short-Distance Coal Seams" Applied Sciences 13, no. 11: 6578. https://doi.org/10.3390/app13116578

APA StyleHe, F., Zhai, W., Song, J., Xu, X., Wang, D., & Wu, Y. (2023). Reasonable Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry Driving in Inclined Short-Distance Coal Seams. Applied Sciences, 13(11), 6578. https://doi.org/10.3390/app13116578