Stress Analysis and Spalling Failure Simulation on Surrounding Rock of Deep Arch Tunnel

Abstract

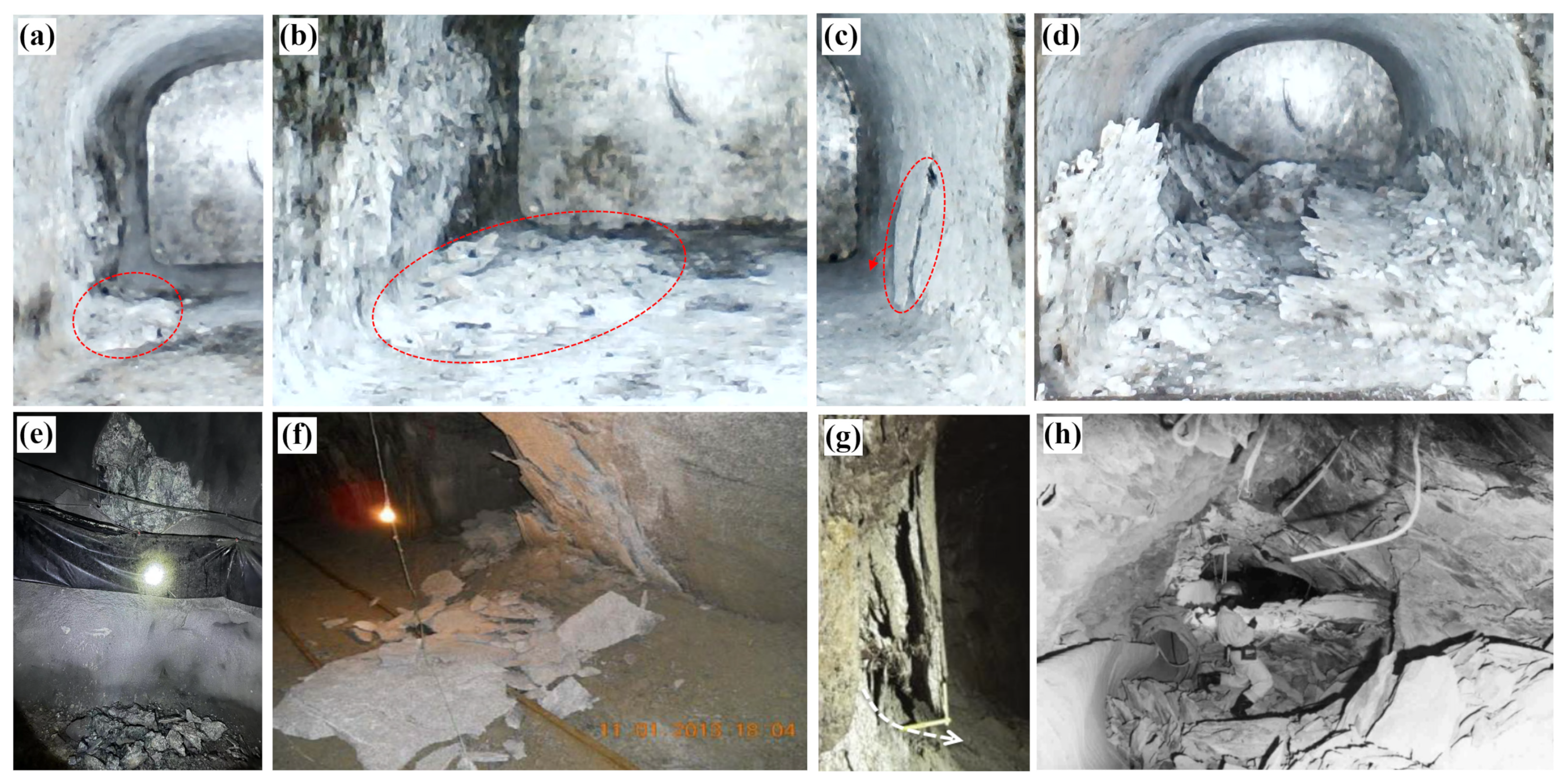

1. Introduction

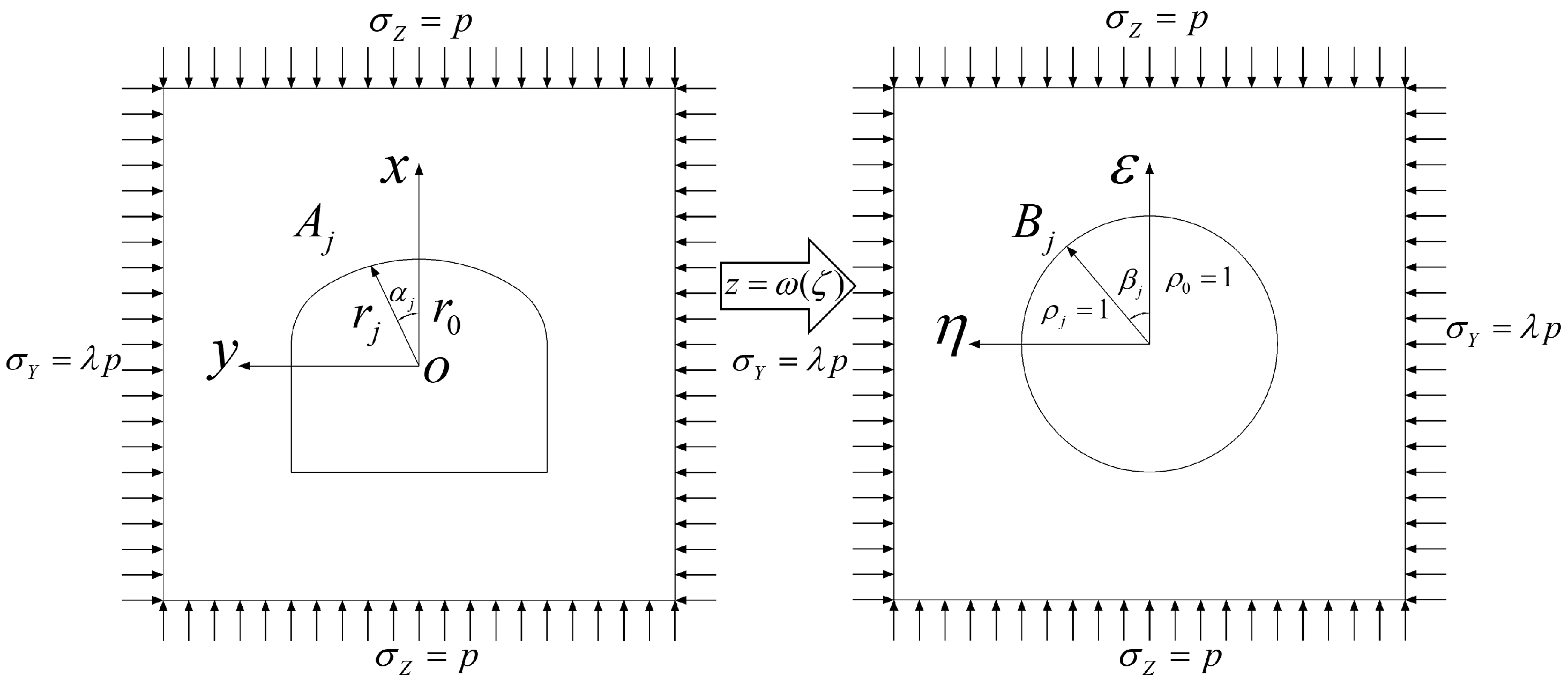

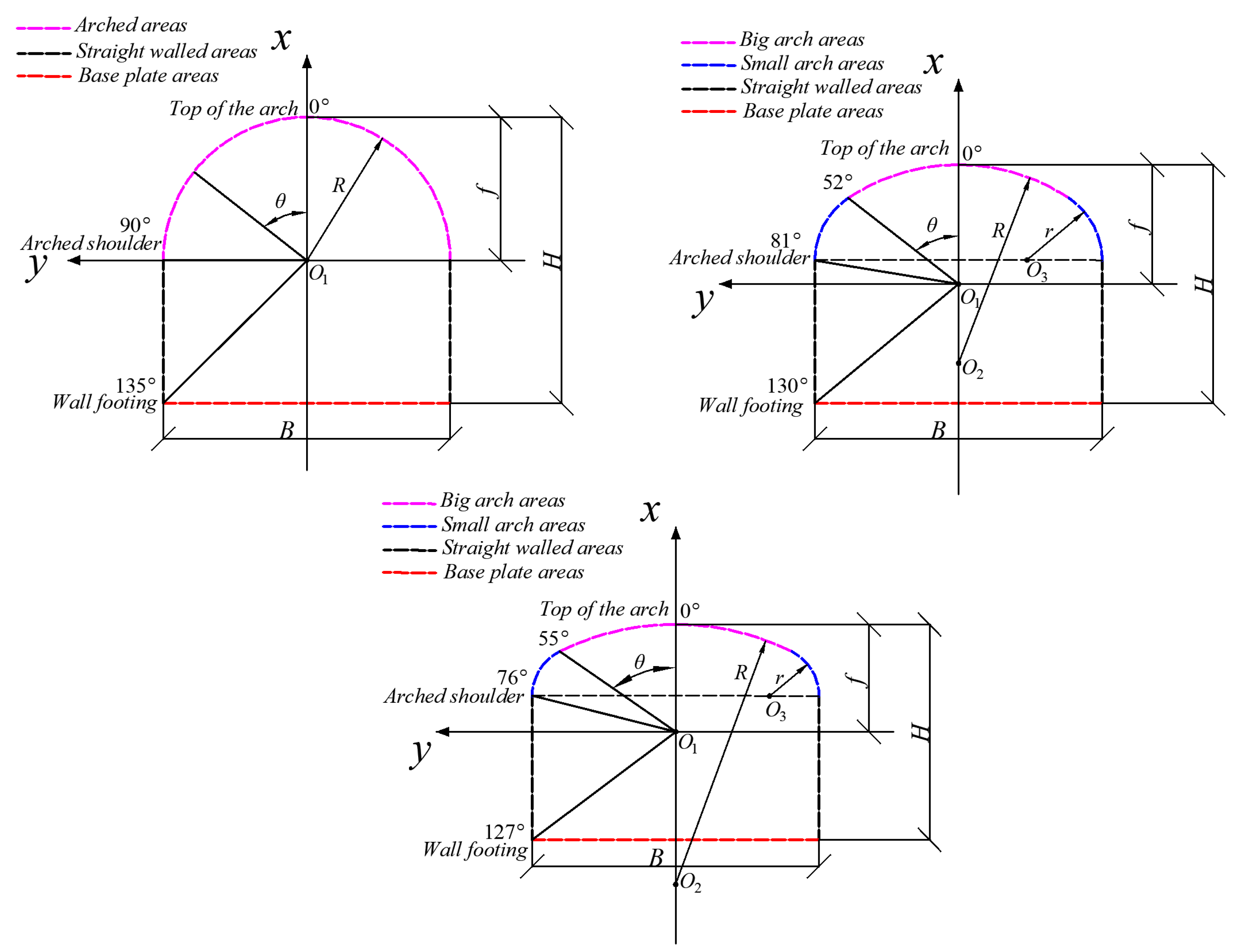

2. Stress Analysis of Surrounding Rock

2.1. Complex Functions for Stress Distribution

2.2. Determination of the Mapping Function

2.3. Stress Solution of the Surrounding Rock

3. Simulation of Spalling Failure

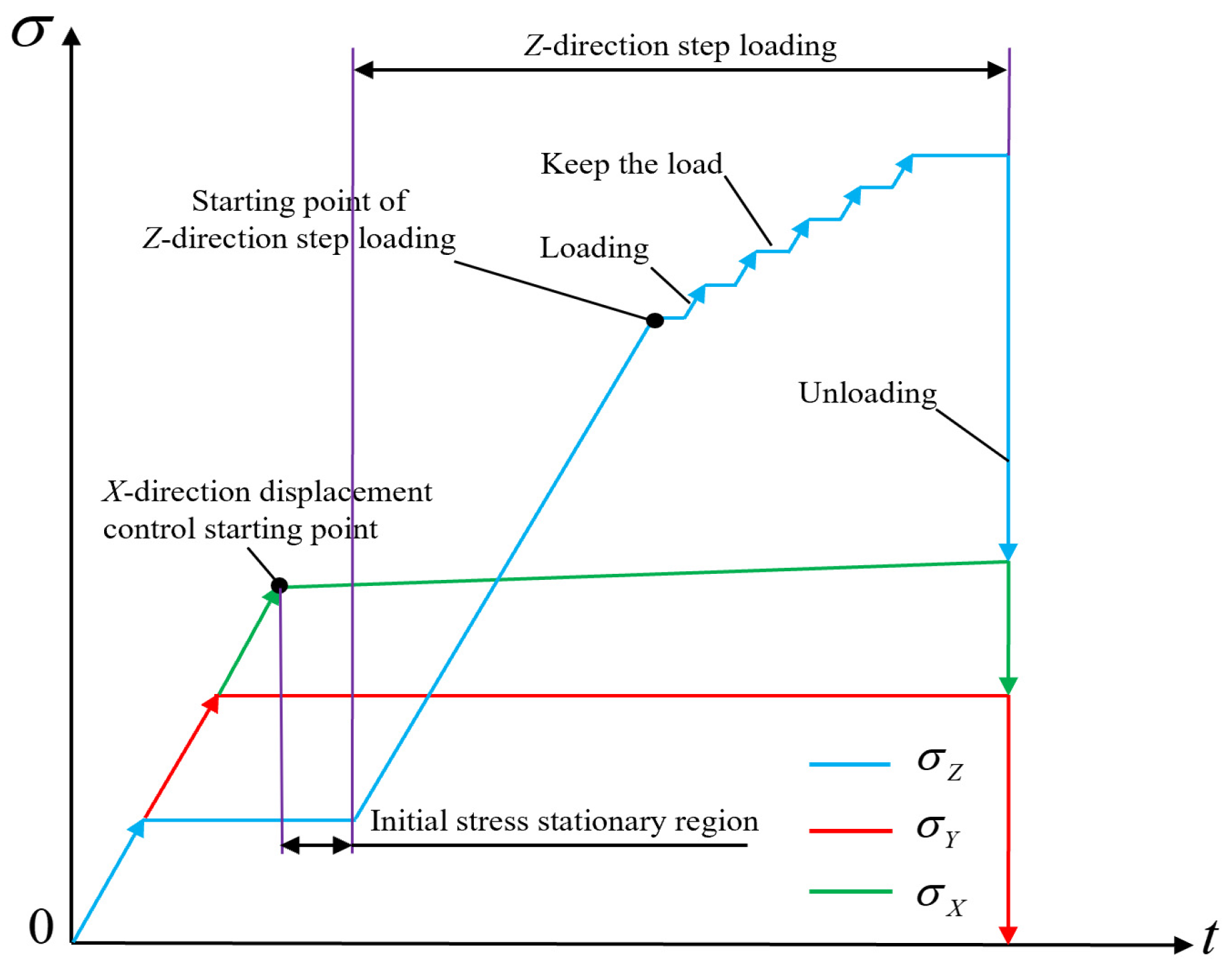

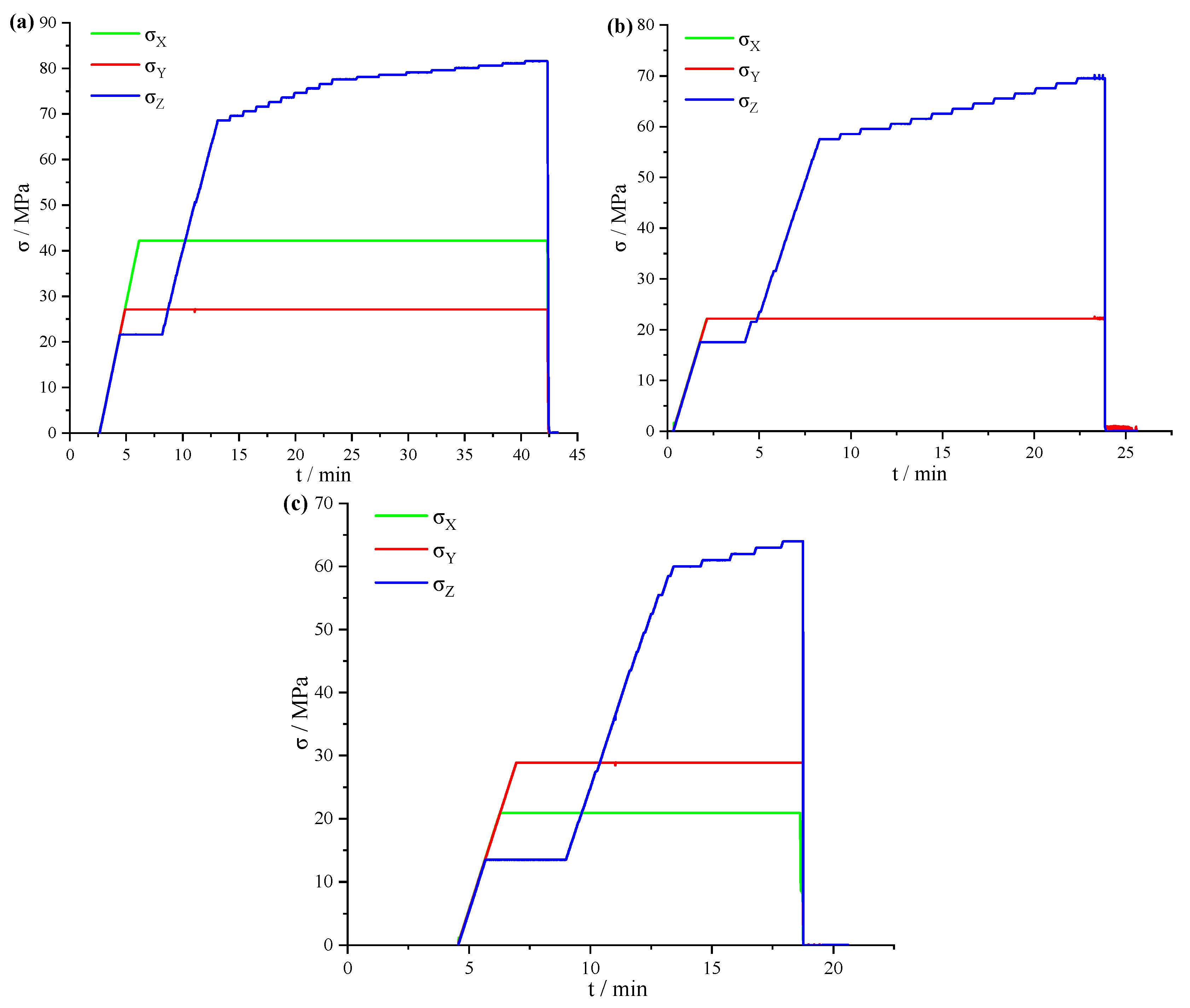

3.1. Test Materials and Methods

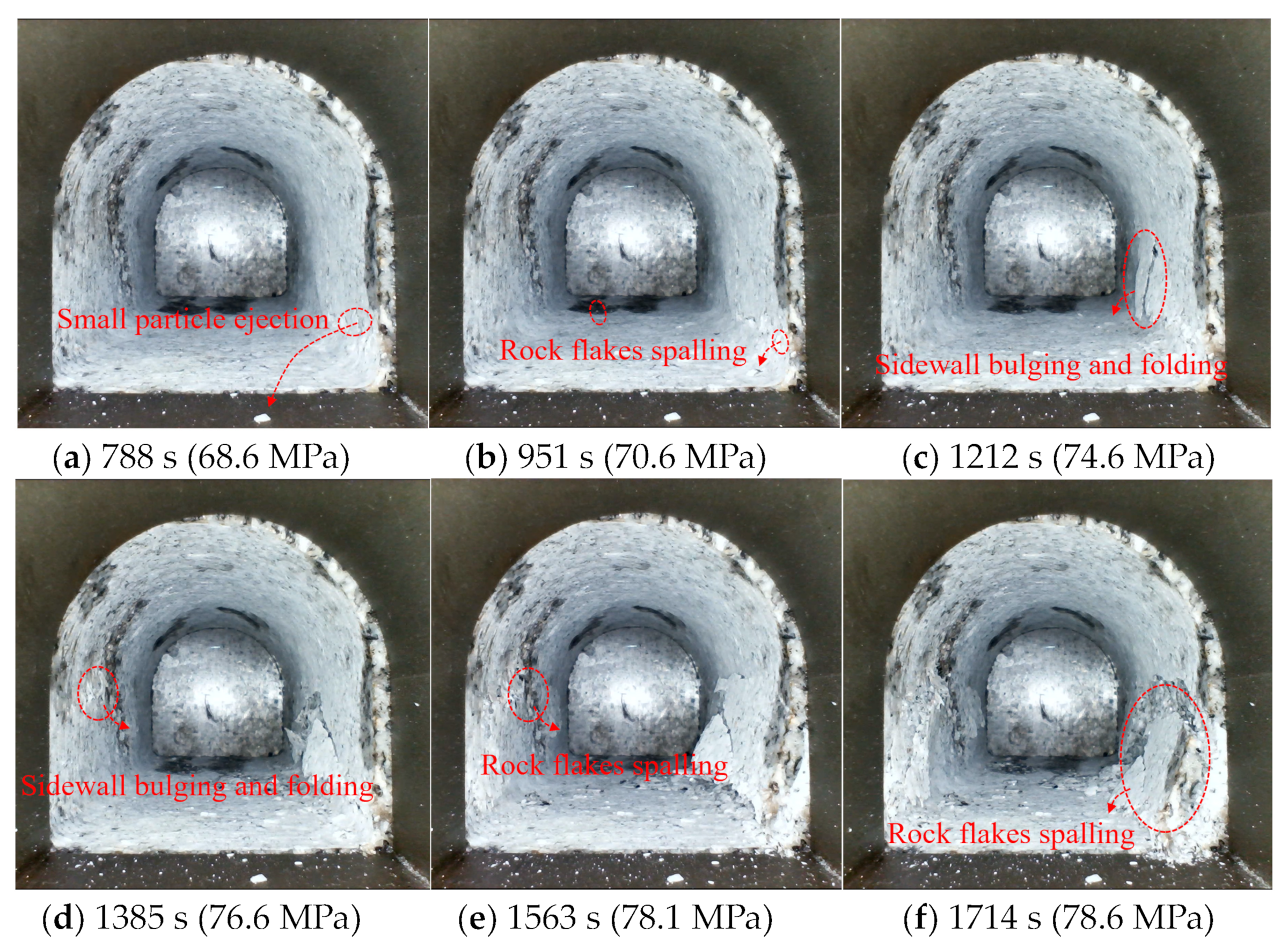

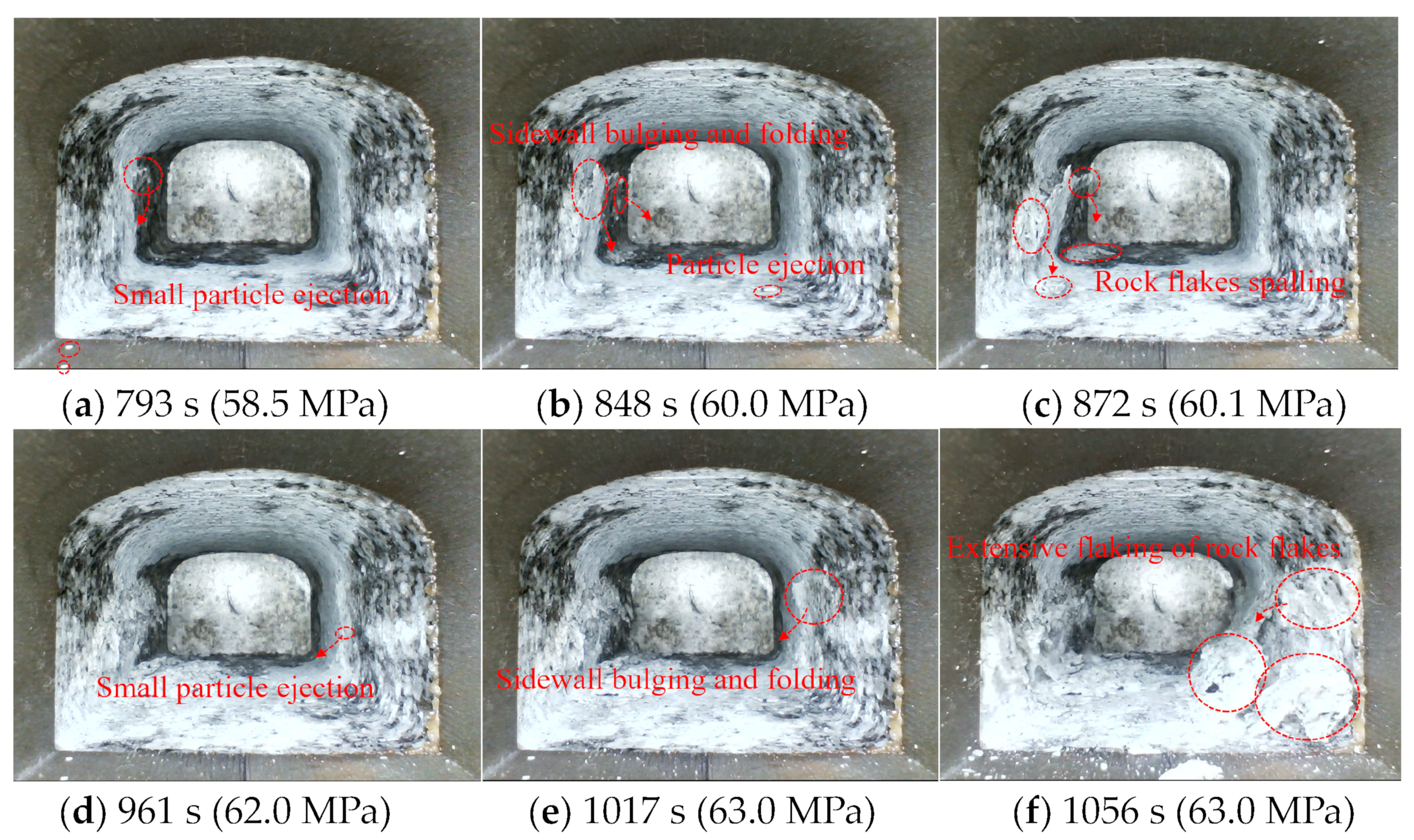

3.2. Test Results

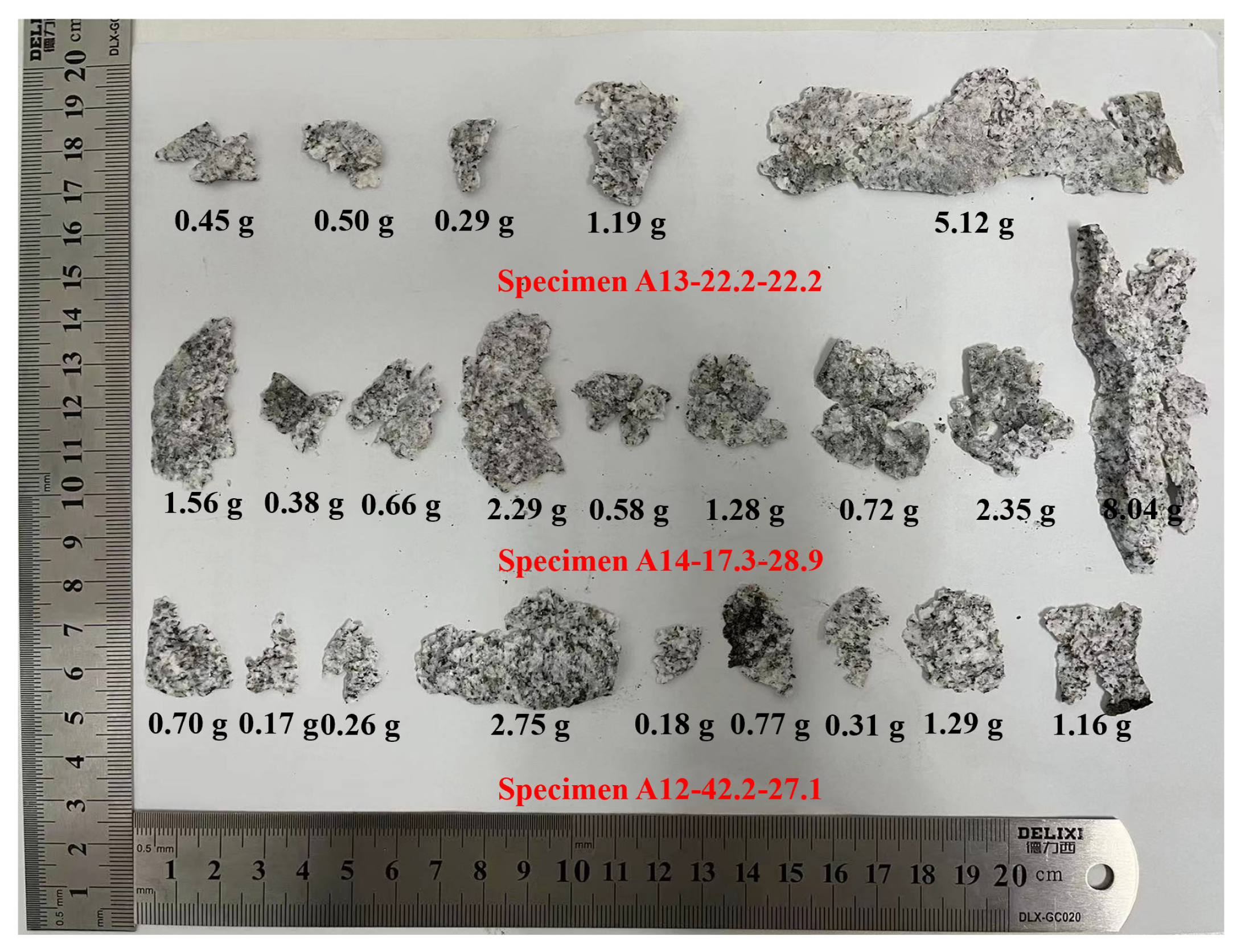

3.3. Characteristics of Sidewall Fragments

4. Discussion

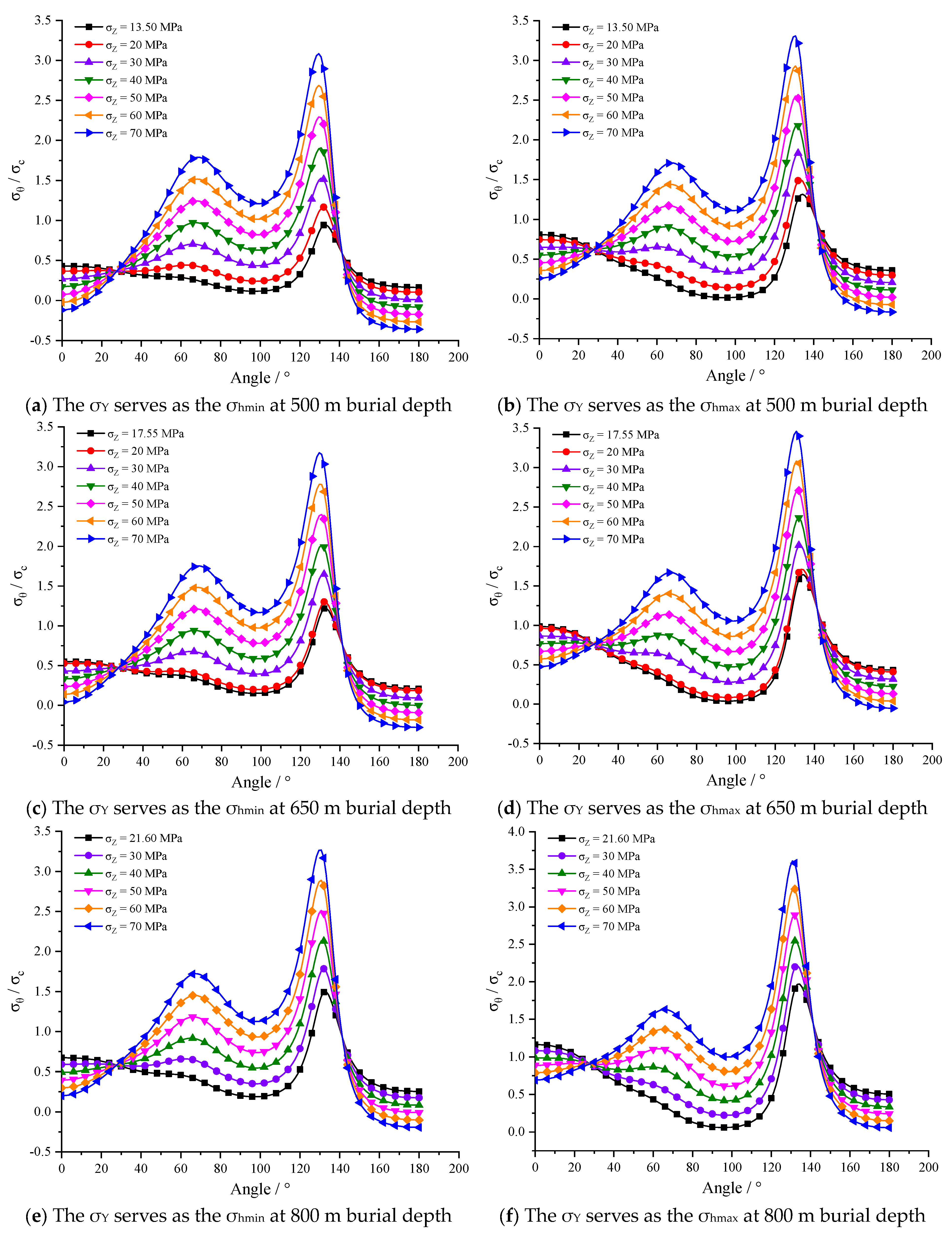

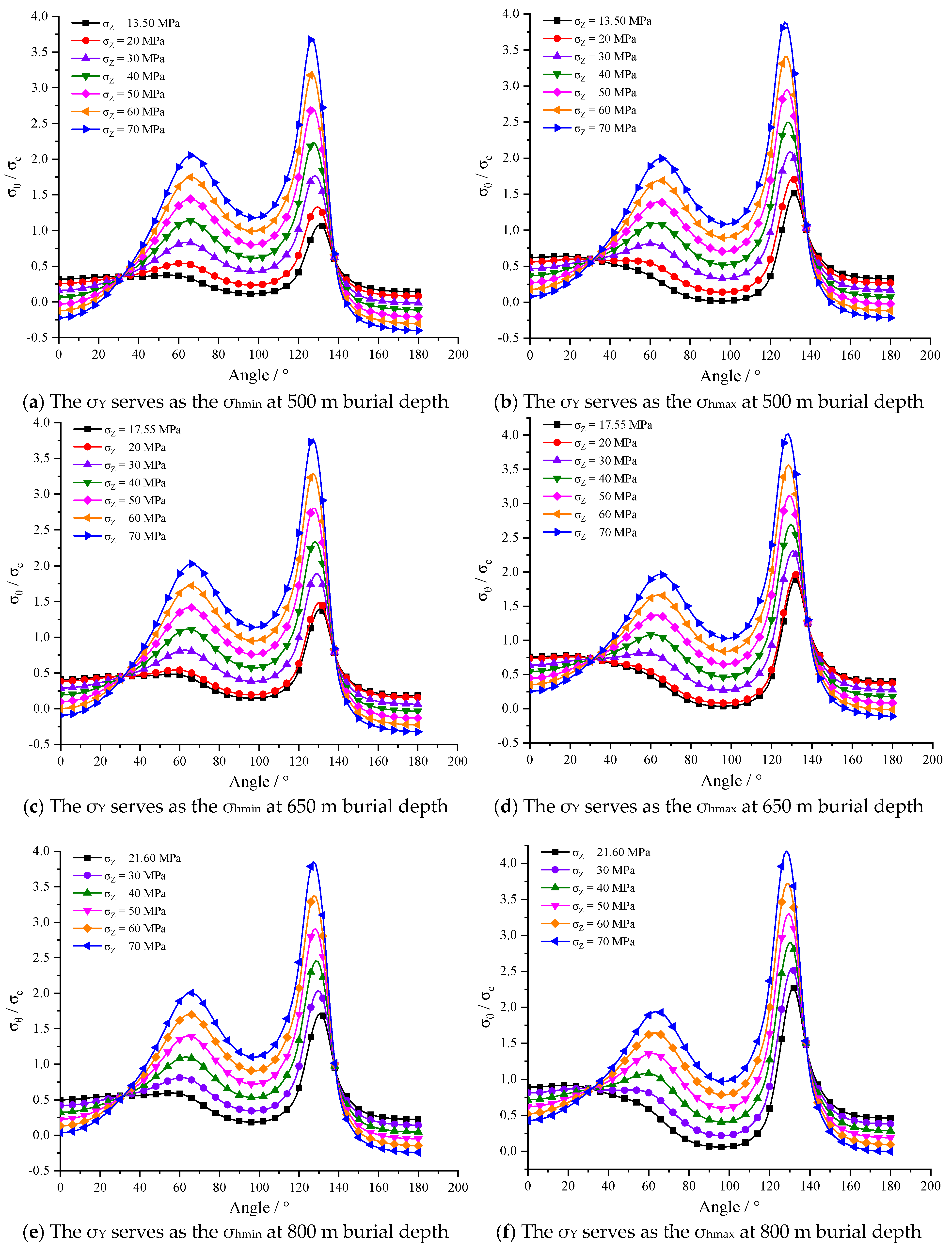

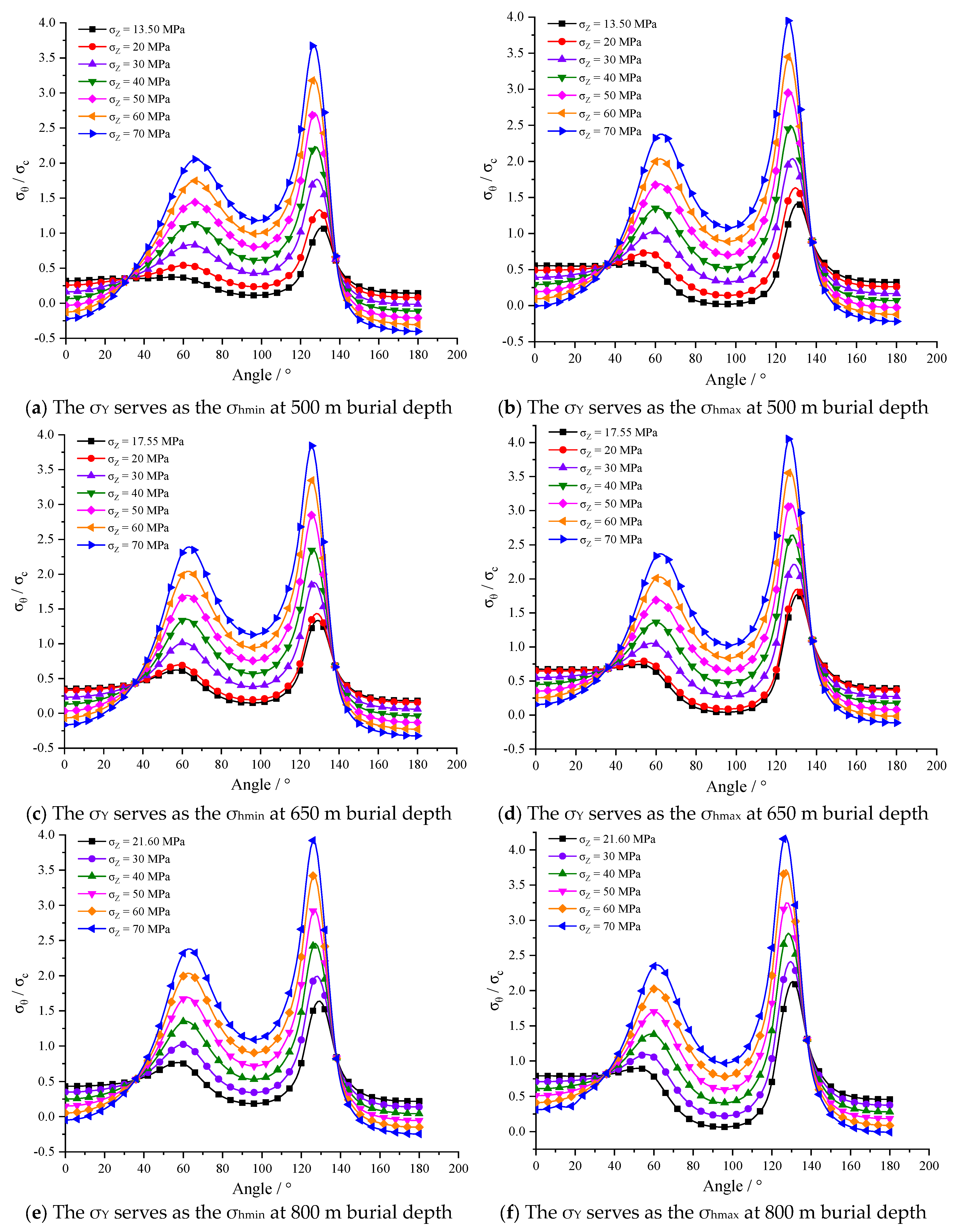

4.1. Stress Distribution Analysis of Surrounding Rock under Different Working Conditions

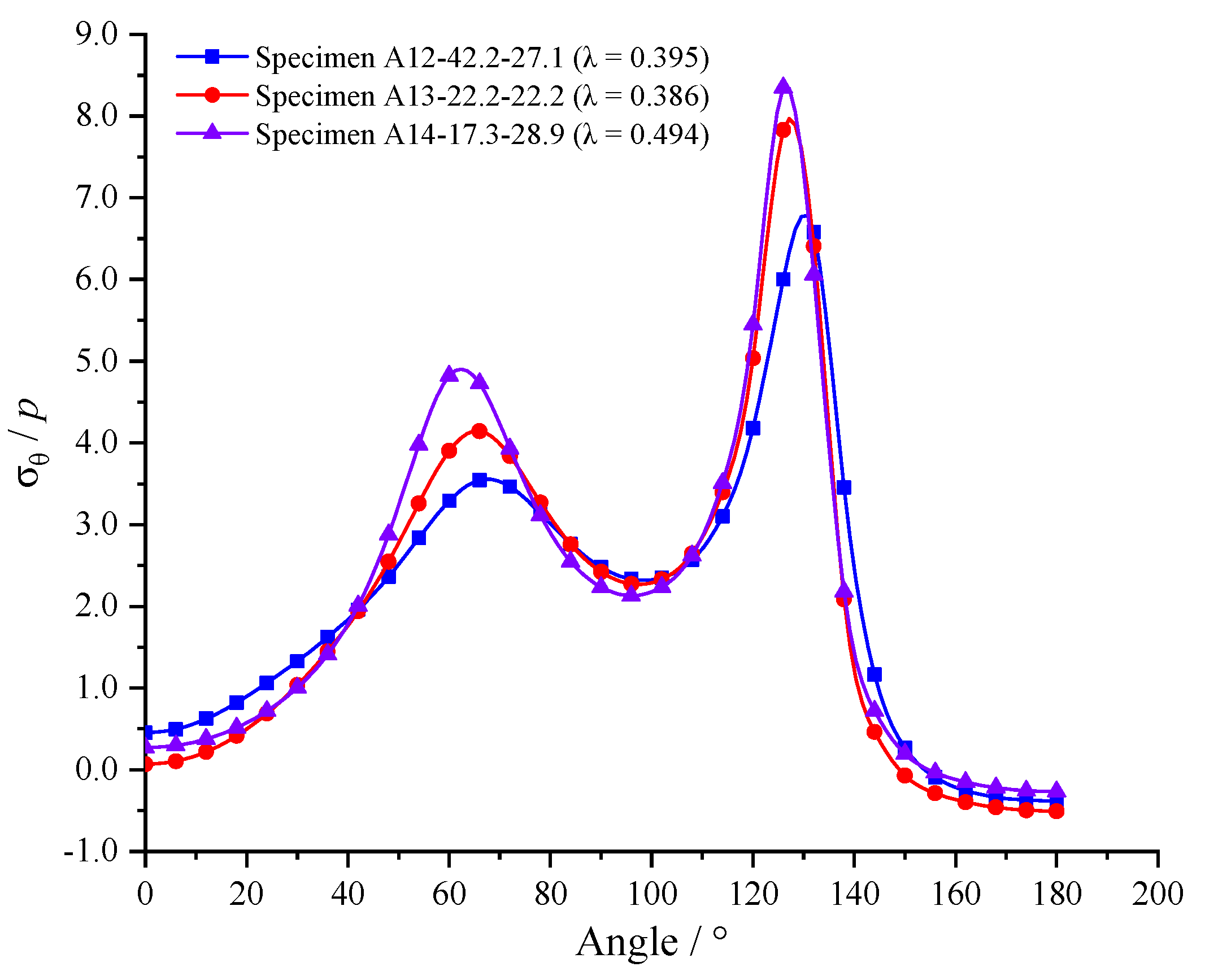

4.2. Characteristics of Initial Failure Stress of Tunnel Sidewall

4.3. Spalling Process

5. Conclusions

- The stress distributions of the surrounding rock of the tunnel with three arch heights are consistent. With the adjustment of vertical stress, when σZ > 30 MPa, the tensile stress appears on rise-span ratios of f/B = 1/4, f/B = 1/3, f/B = 1/2 arch tunnel in order at the floor middle, while tensile stress appears at the arch top after σZ rises about 20 MPa. As σY doubles, the σZ value of tensile stress at the arch top and the floor middle increases by 20 MPa correspondingly. With the increase in σZ or σY, the same maximum tangential stress value is first reached at the foot of the straight wall, which is f/B = 1/4 first, f/B = 1/3 second, f/B = 1/2 last, and all of them are compressive stress;

- Indoor tests were performed to simulate the spalling process of deep hard rock tunnels with different arch heights using a true triaxial test machine. The initial failure stress of the holes with different arch heights is 0.39–0.48 times the UCS of the rock. The initial failure occurs at the arch foot, where the tangential stress is the maximum. When the lateral pressure coefficient is in the range of 0.38–0.50, the tangential stress is 3.2–3.5 times the UCS. By comparison, it was found that the semi-circular arch tunnel has a better pressure-bearing capacity than the three-centered arch tunnel. The maximum tangential stress increases as the arch height decreases or the burial depth increases;

- The four spalling periods of surrounding rock of hard rock tunnels with different arch heights were clarified. In the calm period of internal crack expansion, the internal pores were compressed, and microfractures were initiated in the rock sample. The ejection period of fine particles at the foot or shoulder of the arch represents a stage of crack expansion along the arch foot and sidewalls after an initial failure of the arch or shoulder. In the macrocrack penetration and spalling stage, macrocracks expanded after the internal microfractures. In the V- or arc-shaped groove formation period, macrocracks developed deeper in rock spalling parallel to the sidewalls continuously occurred.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fairhurst, C.; Cook, N.G.W. The of Maximum Phenomenon of Rock Splitting Parallel to the Direction Compression in the Neighbourhood of a Surface. In Proceedings of the 1st ISRM Congress, Lisbon, Portugal, 25 September–1 October 1966. [Google Scholar]

- Cai, M.; Kaiser, P. Rockburst Support Reference Book—Volume I: Rockburst Phenomenon and Support Characteristics; Laurentian University: Sudbury, ON, Canada, 2018. [Google Scholar]

- Zhao, X.-G.; Wang, J.; Cai, M.; Cheng, C.; Ma, L.-K.; Su, R.; Zhao, F.; Li, D.-J. Influence of Unloading Rate on the Strainburst Characteristics of Beishan Granite Under True-Triaxial Unloading Conditions. Rock Mech. Rock Eng. 2014, 47, 467–483. [Google Scholar] [CrossRef]

- Zhou, H.; Lu, J.-J.; Hu, S.-C.; Zhang, C.-Q.; Xu, R.-C.; Meng, F.-Z. Influence of curvature radius of tunnels excavation section on slabbing of hard brittle rockmass under high stress. Rock Soil Mech. 2016, 37, 140. [Google Scholar] [CrossRef]

- Feng, X.-T.; Xu, H.; Qiu, S.-L.; Li, S.-J.; Yang, C.-X.; Guo, H.-S.; Cheng, Y.; Gao, Y.-H. In Situ Observation of Rock Spalling in the Deep Tunnels of the China Jinping Underground Laboratory (2400 m Depth). Rock Mech. Rock Eng. 2018, 51, 1193–1213. [Google Scholar] [CrossRef]

- Song, Z.-Y.; Konietzky, H.; Wu, Y.-F.; Du, K.; Cai, X. Mechanical Behaviour of Medium-Grained Sandstones Exposed to Differential Cyclic Loading with Distinct Loading and Unloading Rates. J. Rock Mech. Geotech. Eng. 2022, 14, 1849–1871. [Google Scholar] [CrossRef]

- Wang, Y.-M.; Wang, Y.-Q.; Luo, S.; Liu, H.; Yi, G.-S.; Peng, K. Influence of the Crack Angle on the Deformation and Failure Characteristics of Sandstone under Stepped Cyclic Uniaxial Compression with a Constant Lower Limit. Mathematics 2023, 11, 2187. [Google Scholar] [CrossRef]

- Luo, Y.; Gong, F.-Q.; Li, X.-B.; Wang, S.-Y. Experimental Simulation Investigation of Influence of Depth on Spalling Characteristics in Circular Hard Rock Tunnel. J. Cent. South Univ. 2020, 27, 891–910. [Google Scholar] [CrossRef]

- Wang, C.-L.; Wu, A.-X.; Lu, H.; Bao, T.-C.; Liu, X.-H. Predicting Rockburst Tendency Based on Fuzzy Matter–Element Model. Int. J. Rock Mech. Min. Sci. 2015, 75, 224–232. [Google Scholar] [CrossRef]

- Wang, C.-L.; Chen, Z.; Liao, Z.-F.; Hou, X.-L.; Li, H.-T.; Wang, A.-W.; Li, C.-F.; Qian, P.-F.; Li, G.-Y.; Lu, H. Experimental Investigation on Predicting Precursory Changes in Entropy for Dominant Frequency of Rockburst. J. Cent. South Univ. 2020, 27, 2834–2848. [Google Scholar] [CrossRef]

- Wang, C.-L.; Cao, C.; Li, C.-F.; Chuai, X.-S.; Zhao, G.-M.; Lu, H. Experimental Investigation on Synergetic Prediction of Granite Rockburst Using Rock Failure Time and Acoustic Emission Energy. J. Cent. South Univ. 2022, 29, 1262–1273. [Google Scholar] [CrossRef]

- Gong, F.-Q.; Zhang, P.-L.; Du, K. A Novel Staged Cyclic Damage Constitutive Model for Brittle Rock Based on Linear Energy Dissipation Law: Modelling and Validation. Rock Mech. Rock Eng. 2022, 55, 6249–6262. [Google Scholar] [CrossRef]

- Si, X.-F.; Luo, S.; Luo, Y. A Review of Mechanical Properties and Rockburst Investigation of Transversely Isotropic Rocks by Experimental Technique. Materials 2023, 16, 3183. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Gong, F.-Q.; Liu, Z.-X. Experiments on Rockburst Proneness of Pre-Heated Granite at Different Temperatures: Insights from Energy Storage, Dissipation and Surplus. J. Rock Mech. Geotech. Eng. 2022, 14, 1343–1355. [Google Scholar] [CrossRef]

- Luo, S.; Gong, F.-Q. Evaluation of Energy Storage and Release Potentials of Highly Stressed Rock Pillar from Rockburst Control Perspectives. Int. J. Rock Mech. Min. Sci. 2023, 163, 105324. [Google Scholar] [CrossRef]

- Gong, F.-Q.; Zhang, P.-L.; Xu, L. Damage Constitutive Model of Brittle Rock under Uniaxial Compression Based on Linear Energy Dissipation Law. Int. J. Rock Mech. Min. Sci. 2022, 160, 105273. [Google Scholar] [CrossRef]

- Gong, F.-Q.; Shi, R.-H.; Xu, L. Linear Energy Storage and Dissipation Laws of Concrete under Uniaxial Compression at Different Ages. Constr. Build. Mater. 2022, 318, 125963. [Google Scholar] [CrossRef]

- Si, X.-F.; Li, X.-B.; Gong, F.-Q.; Huang, L.-Q.; Ma, C.-D. Experimental Investigation on Rockburst Process and Characteristics of a Circular Opening in Layered Rock under Three-Dimensional Stress Conditions. Tunn. Undergr. Space Technol. 2022, 127, 104603. [Google Scholar] [CrossRef]

- Luo, S.; Gong, F.-Q. Linear Energy Storage and Dissipation Laws during Rock Fracture under Three-Point Flexural Loading. Eng. Fract. Mech. 2020, 234, 107102. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Martin, C.D. A Tensile Model for the Interpretation of Microseismic Events near Underground Openings. Pure Appl. Geophys. 1998, 153, 67–92. [Google Scholar] [CrossRef]

- Cai, M. Influence of Intermediate Principal Stress on Rock Fracturing and Strength near Excavation Boundaries—Insight from Numerical Modeling. Int. J. Rock Mech. Min. Sci. 2008, 45, 763–772. [Google Scholar] [CrossRef]

- Jia, P.; Yang, T.-H.; Yu, Q.-L. Mechanism of Parallel Fractures around Deep Underground Excavations. Theor. Appl. Fract. Mech. 2012, 61, 57–65. [Google Scholar] [CrossRef]

- Zhang, C.-Q.; Feng, X.-T.; Zhou, H. Estimation of in Situ Stress along Deep Tunnels Buried in Complex Geological Conditions. Int. J. Rock Mech. Min. Sci. 2012, 52, 139–162. [Google Scholar] [CrossRef]

- Ukadgaonker, V.G.; Awasare, P.J. A Novel Method of Stress Analysis of an Infinite Plate with Rounded Corners of a Rectangular Hole under Uniform Edge Loading. Indian J. Eng. Mater. Sci. 1994, 1, 17–25. [Google Scholar]

- Ukadgaonker, V.G.; Rao, D.K.N. Stress Distribution around Triangular Holes in Anisotropic Plates. Compos. Struct. 1999, 45, 171–183. [Google Scholar] [CrossRef]

- Exadaktylos, G.E.; Stavropoulou, M.C. A Closed-Form Elastic Solution for Stresses and Displacements around Tunnels. Int. J. Rock Mech. Min. Sci. 2002, 39, 905–916. [Google Scholar] [CrossRef]

- Zhao, G.-P.; Yang, S.-L. Analytical Solutions for Rock Stress around Square Tunnels Using Complex Variable Theory. Int. J. Rock Mech. Min. Sci. 2015, 80, 302–307. [Google Scholar] [CrossRef]

- Soni, S.; Saindane, U. Stress Analysis of Infinite Plate with Elliptical Hole. In Advances in Engineering Design; Prasad, A., Gupta, S.S., Tyagi, R.K., Eds.; Springer: Singapore, 2019; pp. 535–545. [Google Scholar]

- Fan, X.; Yang, Z.-J.; Hong, M.; Yu, H.; Xie, Y.-L. Mechanism of Stress Distribution and Failure around Two Different Shapes of Openings within Fractured Rock-like Materials. J. Cent. South Univ. 2022, 29, 1916–1932. [Google Scholar] [CrossRef]

- Chen, S.-J.; Zhao, Z.-H.; Feng, F.; Zhang, M.-Z. Stress Evolution of Deep Surrounding Rock under Characteristics of Bi-Modulus and Strength Drop. J. Cent. South Univ. 2022, 29, 680–692. [Google Scholar] [CrossRef]

- Wu, S.; Li, K.-G.; Wu, S.-C.; Wang, H.-L.; Qin, Q.-L.; Li, M.-L.; He, F.-Y. Analysis of Geometric Parameters of Straight Wall Three-Centered Arch and Stress of Surrounding Rock Based on Conformal Mapping. Rock Soil Mech. 2020, 41, 1–11. [Google Scholar] [CrossRef]

- Wu, H.; Kulatilake, P.H.S.W.; Zhao, G.-Y.; Liang, W.-Z.; Wang, E.-J. A Comprehensive Study of Fracture Evolution of Brittle Rock Containing an Inverted U-Shaped Cavity under Uniaxial Compression. Comput. Geotech. 2019, 116, 103219. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, G.-Y.; Ma, S.-W. Failure Behavior of Horseshoe-Shaped Tunnel in Hard Rock under High Stress: Phenomenon and Mechanisms. Trans. Nonferrous Met. Soc. China 2022, 32, 639–656. [Google Scholar] [CrossRef]

- Tan, L.-H.; Ren, T.; Dou, L.-M.; Yang, X.-H.; Qiao, M.; Peng, H.-D. Analytical Stress Solution and Mechanical Properties for Rock Mass Containing a Hole with Complex Shape. Theor. Appl. Fract. Mech. 2021, 114, 103002. [Google Scholar] [CrossRef]

- Martin, C.D. Seventeenth Canadian Geotechnical Colloquium: The Effect of Cohesion Loss and Stress Path on Brittle Rock Strength. Can. Geotech. J. 1997, 34, 698–725. [Google Scholar] [CrossRef]

- Carter, B.J. Size and Stress Gradient Effects on Fracture around Cavities. Rock Mech. Rock Eng. 1992, 25, 167–186. [Google Scholar] [CrossRef]

- Wang, Y.; He, M.-C.; Liu, D.-Q.; Gao, Y.-B. Rockburst in Sandstone Containing Elliptic Holes with Varying Axial Ratios. Adv. Mater. Sci. Eng. 2019, 2019, 5169618. [Google Scholar] [CrossRef]

- Liu, X.-X.; Liang, Z.-Z.; Zhang, Y.-B.; Yao, X.-L.; Li, H.-Y. Unloading test for rockburst mechanism in tunnel model. J. Eng. Geol. 2016, 24, 967–975. [Google Scholar] [CrossRef]

- Zhao, H.-G.; Liu, C.; Huang, G.; Yu, B.-C.; Liu, Y.-B.; Song, Z.-L. Experimental Investigation on Rockburst Process and Failure Characteristics in Trapezoidal Tunnel under Different Lateral Stresses. Constr. Build. Mater. 2020, 259, 119530. [Google Scholar] [CrossRef]

- Zhao, H.-G.; Song, Z.-L.; Zhang, D.-M.; Liu, C.; Yu, B.-C. True Triaxial Experimental Study on Mechanical Characteristics and Energy Evolution of Sandstone under Various Loading and Unloading Rates. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 22. [Google Scholar] [CrossRef]

- Liu, C.-Y.; Zhao, G.-M.; Xu, W.-S.; Meng, X.-R.; Huang, S.-J.; Zhou, J.; Wang, Y.-K. Experimental Investigation on Failure Process and Spatio-Temporal Evolution of Rockburst in Granite with a Prefabricated Circular Hole. J. Cent. South Univ. 2020, 27, 2930–2944. [Google Scholar] [CrossRef]

- Lee, M.; Haimson, B. Laboratory Study of Borehole Breakouts in Lac Du Bonnet Granite: A Case of Extensile Failure Mechanism. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 1039–1045. [Google Scholar] [CrossRef]

- Si, X.-F.; Li, X.-B.; Gong, F.-Q.; Huang, L.-Q.; Liu, X.-L. Experimental Investigation of Failure Process and Characteristics in Circular Tunnels under Different Stress States and Internal Unloading Conditions. Int. J. Rock Mech. Min. Sci. 2022, 154, 105116. [Google Scholar] [CrossRef]

- Wu, W.-X.; Gong, F.-Q.; Yang, W.-M. Experimental Simulation Study of Spalling in Deep Rectangular Tunnel with Plastic Fine Grain Marble. Tunn. Undergr. Space Technol. 2020, 98, 103319. [Google Scholar] [CrossRef]

- Li, P.; Cai, M.-F.; Gao, Y.-B.; Wang, P.-T.; Miao, S.-J.; Wang, Y.; Xi, X. Dynamic Mechanical Behavior and Cracking Mechanism of Cross-Jointed Granite Containing a Hole. J. Mater. Res. Technol. 2023, 22, 1572–1594. [Google Scholar] [CrossRef]

- Zhang, X.-J.; Wang, D.; Xiao, C.; Zheng, H.-C. Test of rockburst in straight-wall-top-arch tunnels(tunnels) and its splitting and shearing failure analysis. Rock Soil Mech. 2013, 34, 35–40. [Google Scholar] [CrossRef]

- Zhu, G.-Q.; Feng, X.-T.; Zhou, Y.-Y.; Li, Z.-W.; Fu, L.-J.; Xiong, Y.-R. Physical Model Experimental Study on Spalling Failure Around a Tunnel in Synthetic Marble. Rock Mech. Rock Eng. 2020, 53, 909–926. [Google Scholar] [CrossRef]

- Gong, F.-Q.; Luo, Y.; Liu, D.-Q. Simulation tests on spalling failure in deep straight-wall-top-arch tunnels. Chin. J. Geotech. Eng. 2019, 41, 1091. [Google Scholar] [CrossRef]

- Luo, Y.; Gong, F.-Q.; Liu, D.-Q.; Wang, S.-Y.; Si, X.-F. Experimental Simulation Analysis of the Process and Failure Characteristics of Spalling in D-Shaped Tunnels under True-Triaxial Loading Conditions. Tunn. Undergr. Space Technol. 2019, 90, 42–61. [Google Scholar] [CrossRef]

- Si, X.-F.; Huang, L.-Q.; Li, X.-B.; Ma, C.-D.; Gong, F.-Q. Experimental Investigation of Spalling Failure of D-Shaped Tunnel Under Three-Dimensional High-Stress Conditions in Hard Rock. Rock Mech. Rock Eng. 2021, 54, 3017–3038. [Google Scholar] [CrossRef]

- Chen, S.-J.; Du, Z.-W.; Zhang, Z.; Zhang, H.-W.; Xia, Z.-G.; Feng, F. Effects of Chloride on the Early Mechanical Properties and Microstructure of Gangue-Cemented Paste Backfill. Constr. Build. Mater. 2020, 235, 117504. [Google Scholar] [CrossRef]

- Chen, S.-J.; Du, Z.-W.; Zhang, Z.; Yin, D.-W.; Feng, F.; Ma, J.-B. Effects of Red Mud Additions on Gangue-Cemented Paste Backfill Properties. Powder Technol. 2020, 367, 833–840. [Google Scholar] [CrossRef]

- An, X.-X.; Hu, Z.-P.; Su, Y.; Cao, S.-L.; Tao, L.; Zhang, Y.-H. Initial Support Distance of a Non-Circular Tunnel Based on Convergence Constraint Method and Integral Failure Criteria of Rock. J. Cent. South Univ. 2022, 29, 3732–3744. [Google Scholar] [CrossRef]

- Li, P.-F.; Chen, K.-Y.; Wang, F.; Li, Z. An Upper-Bound Analytical Model of Blow-out for a Shallow Tunnel in Sand Considering the Partial Failure within the Face. Tunn. Undergr. Space Technol. 2019, 91, 102989. [Google Scholar] [CrossRef]

- Li, P.-F.; Wang, F.; Fang, Q. Undrained Analysis of Ground Reaction Curves for Deep Tunnels in Saturated Ground Considering the Effect of Ground Reinforcement. Tunn. Undergr. Space Technol. 2018, 71, 579–590. [Google Scholar] [CrossRef]

- Fan, X.; Yang, Z.-J.; Li, K.-H. Effects of the Lining Structure on Mechanical and Fracturing Behaviors of Four-Arc Shaped Tunnels in a Jointed Rock Mass under Uniaxial Compression. Theor. Appl. Fract. Mech. 2021, 112, 102887. [Google Scholar] [CrossRef]

- Chen, H.; Lai, H.-P.; Qiu, Y.-L.; Chen, R. Reinforcing Distressed Lining Structure of Highway Tunnel with Bonded Steel Plates: Case Study. J. Perform. Constr. Facil. 2020, 34, 04019082. [Google Scholar] [CrossRef]

- Chen, H.; Lai, H.-P.; Huang, M.; Wang, G.; Tang, Q. Failure Mechanism and Treatment Measures of Supporting Structures at the Portal for a Shallow Buried and Asymmetrically Loaded Tunnel with Small Clear-Distance. Nat. Hazards 2022, 114, 2283–2310. [Google Scholar] [CrossRef]

- Muskhelishvili, N.I. Some Basic Problems of the Mathematical Theory of Elasticity; Noordhoff Groningen: Groningen, The Netherlands, 1953; Volume 15. [Google Scholar]

- Sharma, D.S. Stress Distribution around Polygonal Holes. Int. J. Mech. Sci. 2012, 65, 115–124. [Google Scholar] [CrossRef]

- Hromadka, T.V.; Lai, C. The Complex Variable Boundary Element Method in Engineering Analysis; Springer Science & Business Media: New York, NY, USA, 2012; ISBN 1-4612-4660-1. [Google Scholar]

- Chen, Z.-Y. Analytical Solution of Surrounding Rock Stress Distribution; China Coal Industry Publishing House: Beijing, China, 1994. [Google Scholar]

- Lv, A.-Z.; Wang, Q.-W. New method of determination for the mapping function of tunnel with arbitrary boundary using optimization techniques. Chin. J. Rock. Mech. Eng. 1995, 14, 269–274. [Google Scholar]

- Gong, F.-Q.; Luo, Y.; Li, X.-B.; Si, X.-F.; Tao, M. Experimental Simulation Investigation on Rockburst Induced by Spalling Failure in Deep Circular Tunnels. Tunn. Undergr. Space Technol. 2018, 81, 413–427. [Google Scholar] [CrossRef]

- Brown, E.T.; Hoek, E. Trends in Relationships between Measured In-Situ Stresses and Depth. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 211–215. [Google Scholar] [CrossRef]

- Stephansson, O.; Särkkä, P.; Myrvang, A. State of Stress in Fennoscandia. In Proceedings of the ISRM International Symposium, Stockholm, Sweden, 31 August–3 September 1986. ISRM-IS-1986-002. [Google Scholar]

- Ortlepp, W.D. The Behaviour of Tunnels at Great Depth under Large Static and Dynamic Pressures. Tunn. Undergr. Space Technol. 2001, 16, 41–48. [Google Scholar] [CrossRef]

- Zhang, C.-Q.; Feng, X.-T.; Zhou, H.; Zhang, C.-S.; Wu, S.-Y. Brittle Failure of Surrounding Rock Mass in Deep Test Tunnels and Its Numerical Simulation. Chin. J. Rock Mech. Eng. 2010, 29, 2063–2068. [Google Scholar]

- Si, X.-F.; Gong, F.-Q.; Luo, Y.; Li, X.-B. Experimental Simulation on Rockburst Process of Deep Three-Dimensional Circular Cavern. Rock Soil Mech. 2018, 39, 621. [Google Scholar] [CrossRef]

- Ortlepp, W.D.; O’Ferrall, R.M.; Wilson, J.W. Support Methods in Tunnels. In Association of Mines Managers of South Africa Paper Discussion; Association of Mines Managers of South Africa: Johannesburg, South Africa, 1976. [Google Scholar]

- Gong, F.-Q.; Luo, Y.; Si, X.-F.; Li, X.-B. Experimental Modelling on Rockburst in Deep Hard Rock Circular Tunnels. Chin. J. Rock Mech. Eng. 2017, 36, 1634–1648. [Google Scholar]

- Gong, F.-Q.; Wu, W.-X.; Li, T.-B.; Si, X.-F. Experimental Simulation and Investigation of Spalling Failure of Rectangular Tunnel under Different Three-Dimensional Stress States. Int. J. Rock Mech. Min. Sci. 2019, 122, 104081. [Google Scholar] [CrossRef]

| k | h Value | C0 | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|---|---|

| 6 | 0.6193 | −0.1089 | −0.0067 | 0.0845 | −0.0796 | 0.0333 | 0.0075 | −0.0083 |

| 0.6419 | −0.0915 | −0.0947 | 0.0749 | −0.0963 | 0.0285 | 0.0135 | −0.0109 | |

| 0.4767 | −0.0717 | −0.1468 | 0.0543 | −0.1043 | 0.0265 | 0.0192 | −0.0088 |

| Depth (m) | σhmax (MPa) | σhmin (MPa) | σv (MPa) |

|---|---|---|---|

| 500 | 28.90 | 17.25 | 13.50 |

| 650 | 35.56 | 22.19 | 17.55 |

| 800 | 42.22 | 27.12 | 21.60 |

| Specimen | σX/(MPa) | σY/(MPa) | σZ/(MPa) | σZi/(MPa) | σZj/(MPa) |

|---|---|---|---|---|---|

| A12-42.2-27.1 | 42.2 | 27.1 | 21.6 | 68.6 | 68.6 |

| A13-22.2-22.2 | 22.2 | 22.2 | 17.6 | 57.5 | 65.6 |

| A14-17.3-28.9 | 17.3 | 28.9 | 13.5 | 58.5 | 60.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, K.; Yi, G.; Luo, S.; Si, X. Stress Analysis and Spalling Failure Simulation on Surrounding Rock of Deep Arch Tunnel. Appl. Sci. 2023, 13, 6474. https://doi.org/10.3390/app13116474

Peng K, Yi G, Luo S, Si X. Stress Analysis and Spalling Failure Simulation on Surrounding Rock of Deep Arch Tunnel. Applied Sciences. 2023; 13(11):6474. https://doi.org/10.3390/app13116474

Chicago/Turabian StylePeng, Kang, Guansheng Yi, Song Luo, and Xuefeng Si. 2023. "Stress Analysis and Spalling Failure Simulation on Surrounding Rock of Deep Arch Tunnel" Applied Sciences 13, no. 11: 6474. https://doi.org/10.3390/app13116474

APA StylePeng, K., Yi, G., Luo, S., & Si, X. (2023). Stress Analysis and Spalling Failure Simulation on Surrounding Rock of Deep Arch Tunnel. Applied Sciences, 13(11), 6474. https://doi.org/10.3390/app13116474