Investigation of Microseismic Monitoring of and Precursor Information on Roof Collapse

Abstract

:1. Introduction

2. Cluster Theoretical Bases

3. Engineering Situation and MS System

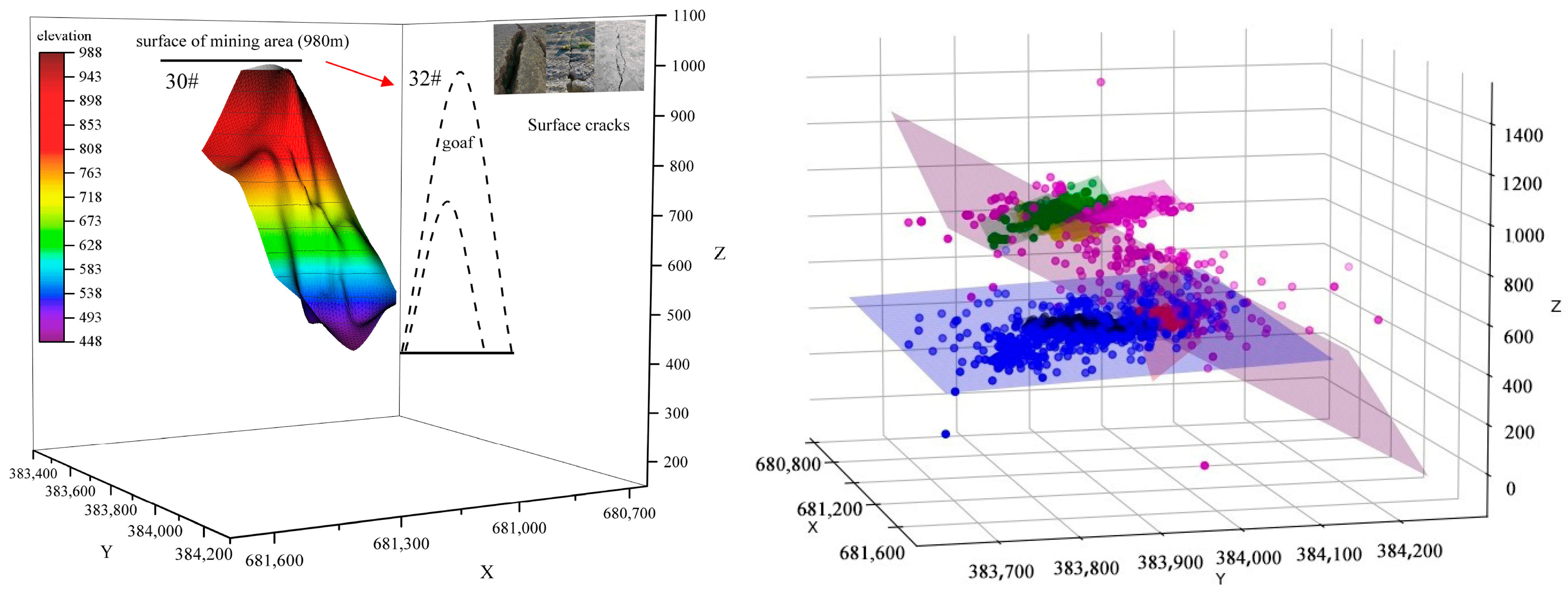

3.1. Geological Conditions

3.2. MS System Profile

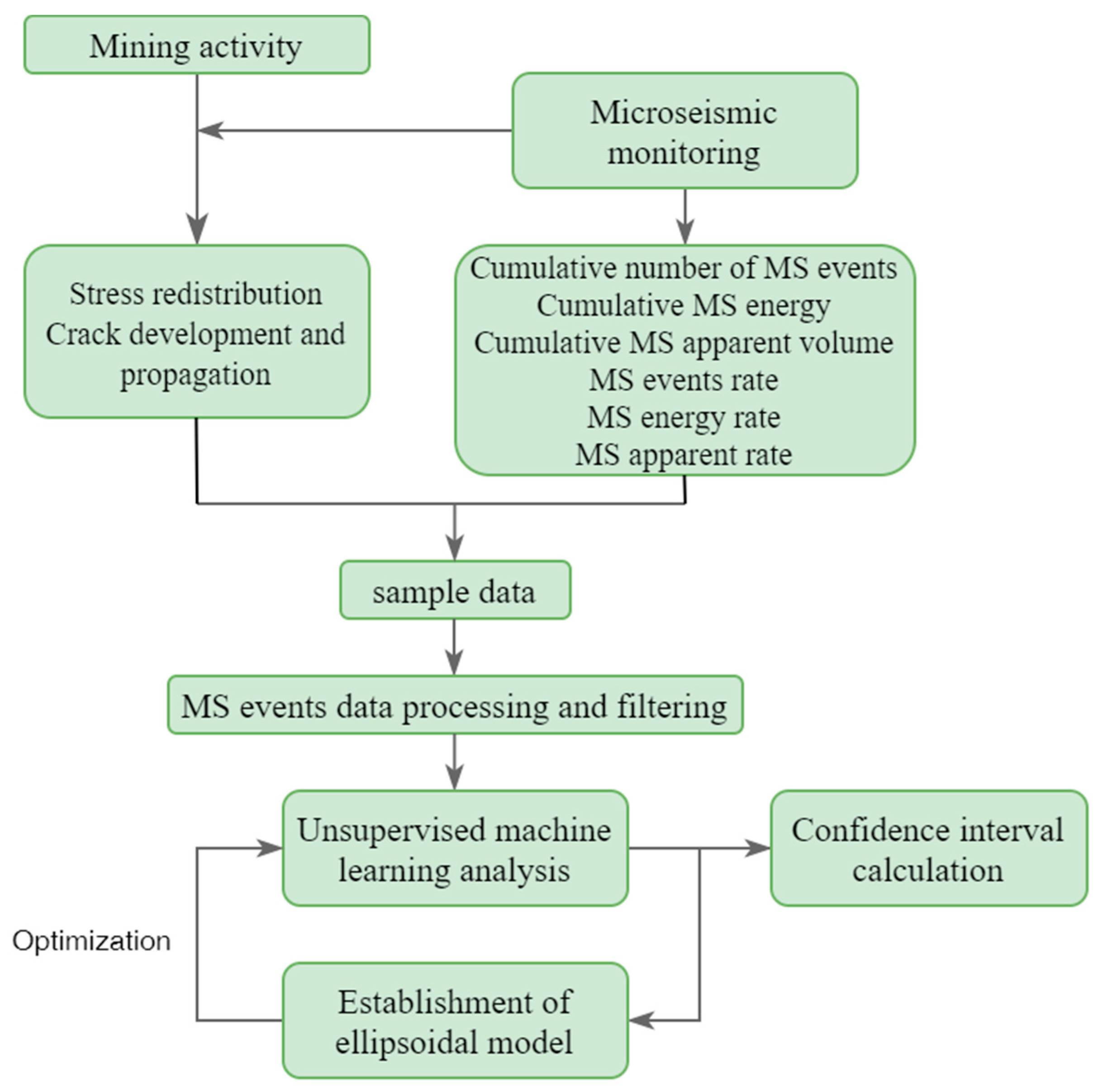

4. Data Analysis and Discussions

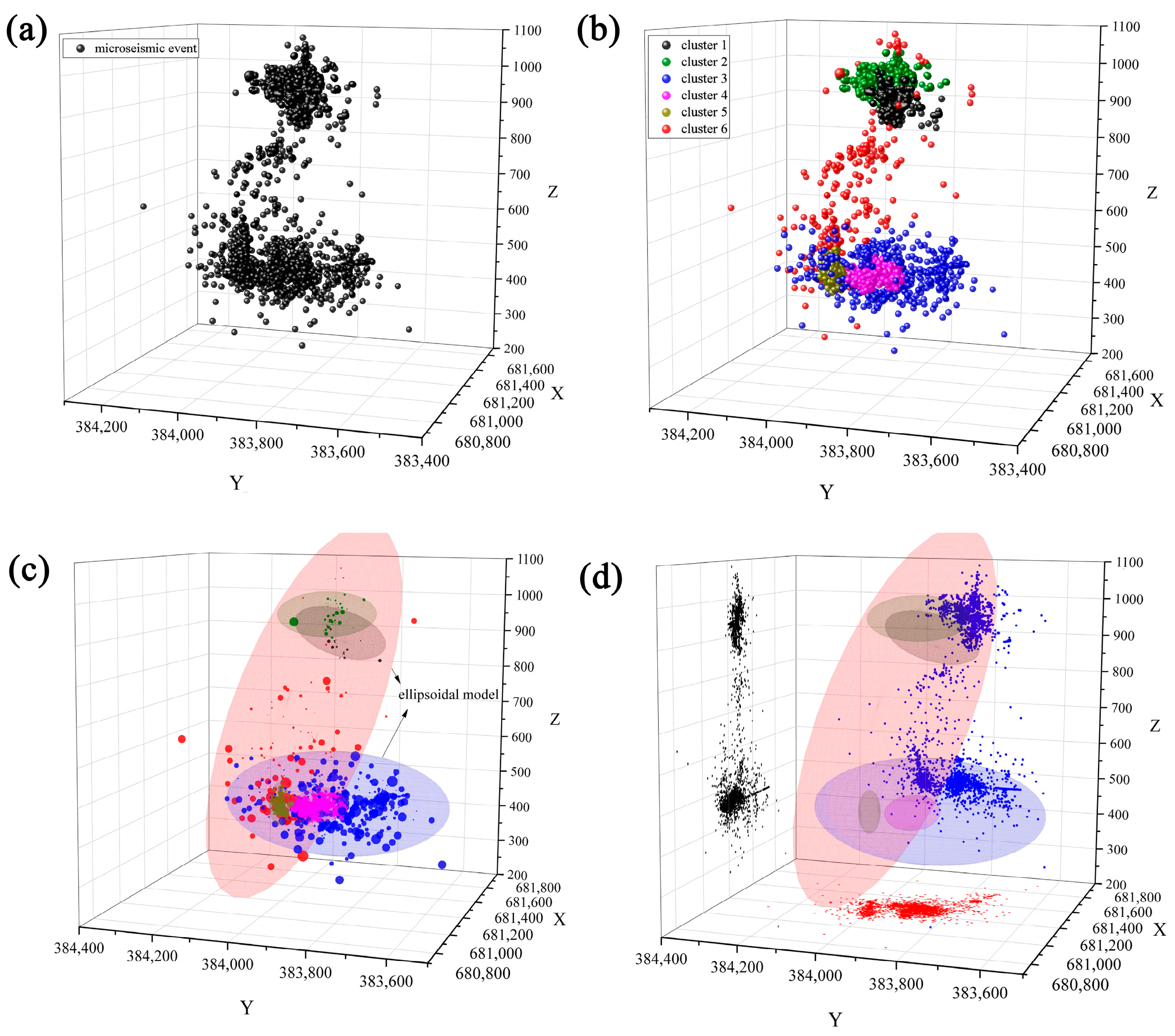

4.1. Machine Learning Clustering Results

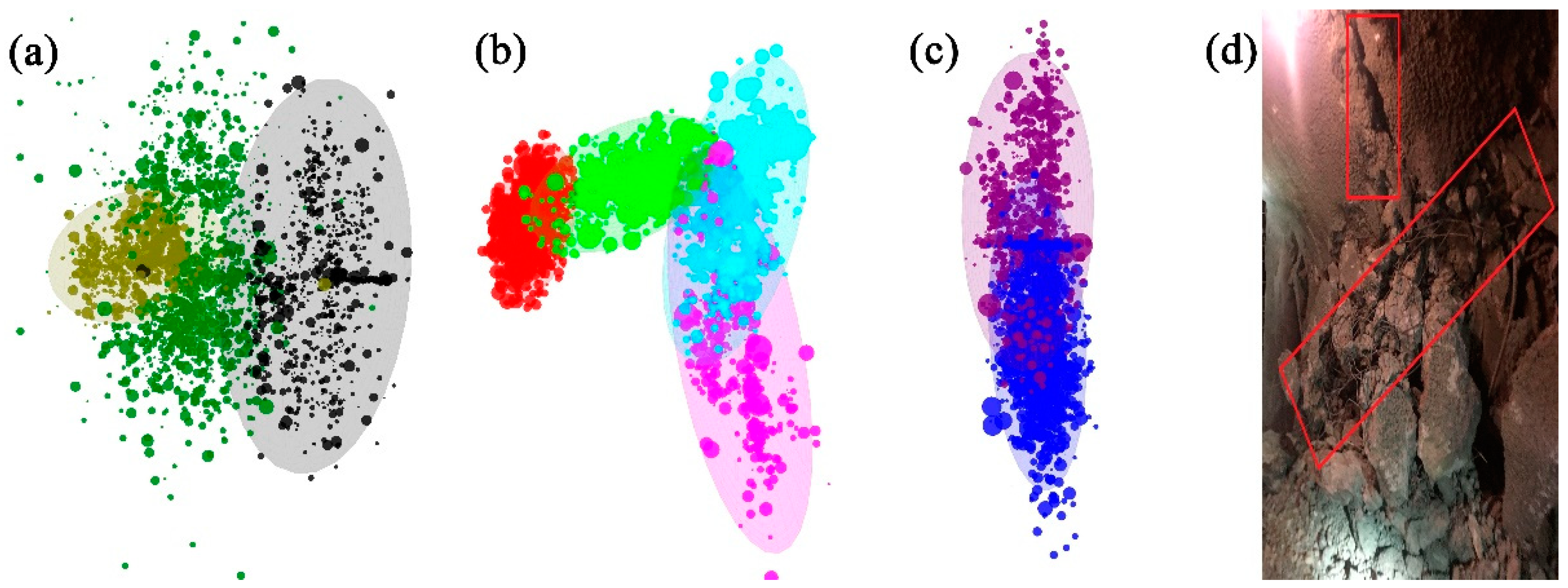

4.2. Distribution Characteristics of Crack Clusters

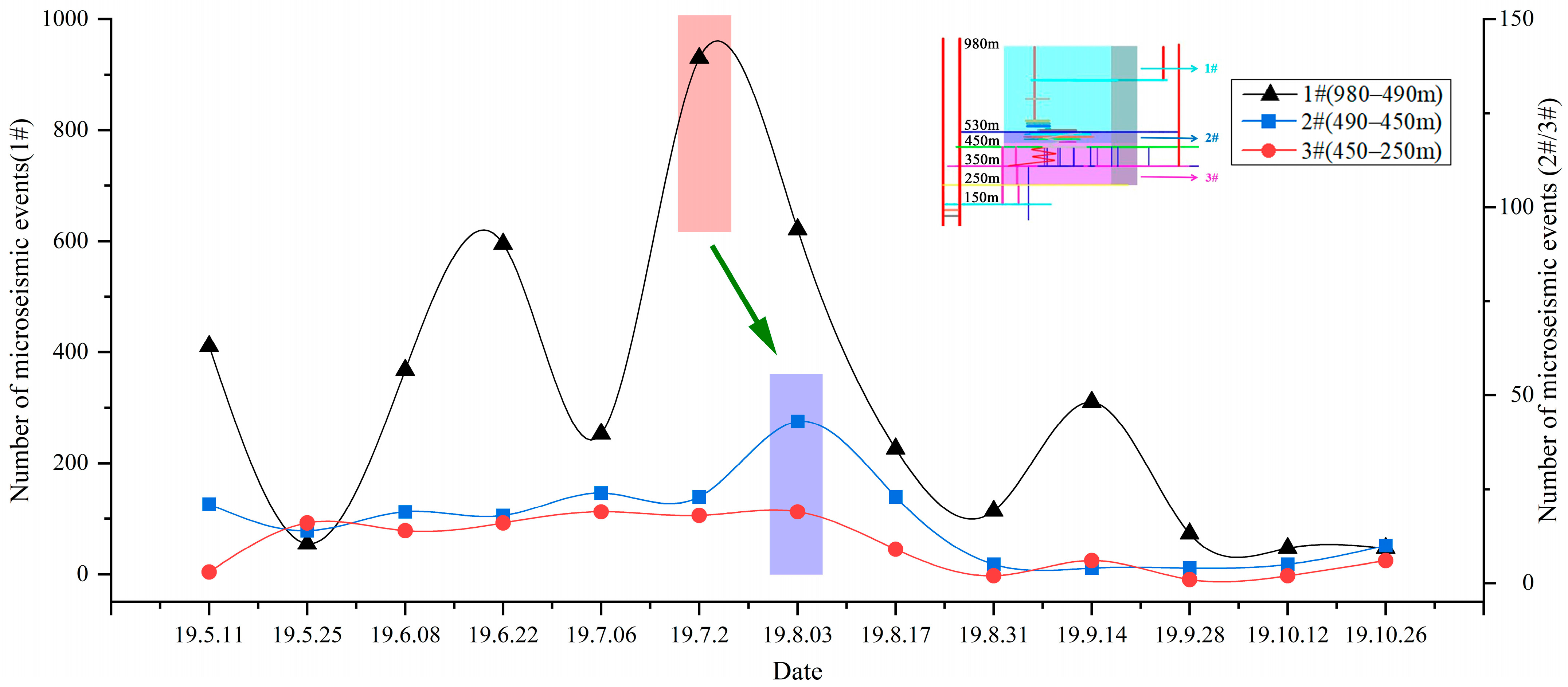

4.3. Case Study

5. Discussion

5.1. Cluster Analysis of Roof Collapse MS Events

5.2. Crack Spatiotemporal Evolution Features

6. Conclusions

- Microseismic equipment proves to be an effective tool for monitoring the crack evolution of rock masses. By utilizing machine learning methods, it becomes possible to classify and characterize individual cracks. Furthermore, when microseismic events are located on a plane, they are considered to be potential precursors to cracks and rock mass instability.

- Different morphologies of crack clusters reflect the complexity of crack development in the analyzed region. The identified crack development can be categorized into three distinct types, illustrating the dynamic evolution process of the rock mass. This process involves independent development at nucleation positions, mutual influence between adjacent locations, and subsequent crack growth and propagation.

- The proposed model is demonstrated to effectively predict the direction and angle of crack propagation. Its successful engineering application provides valuable guidance for studying rock mass stability and informing related research efforts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fischer, T.; Kühn, D.; Roth, M. Microseismic events on the Åknes rockslide in Norway located by a back-projection approach. J. Seismol. 2020, 24, 55–74. [Google Scholar] [CrossRef]

- Barla, G.; Antolini, F.; Barla, M.; Mensi, E.; Piovano, G. Monitoring of the Beauregard landslide (Aosta Valley, Italy) using advanced and conventional techniques. Eng. Geol. 2010, 116, 218–235. [Google Scholar] [CrossRef]

- Wang, C.L.; Chen, Z.; Liao, Z.F.; Hou, X.L.; Li, H.T.; Wang, A.W.; Li, C.F.; Qian, P.F.; Li, G.Y.; Lu, H. Experimental investigation on predicting precursory changes in entropy for dominant frequency of rockburst. J. Cent. South Univ. 2021, 28, 981. [Google Scholar] [CrossRef]

- Wang, Y.C.; Tang, C.A.; Cai, M.; Tang, L.X.; Ma, T.H.; Zhang, S.C.; Li, L.M.; Li, Y.B. Microseismicity evolution related to two extremely intense rockbursts in a water diversion tunnel. Int. J. Rock Mech. Min. 2023, 164, 105359. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, D.; Zuo, C.; Wang, P.; Liu, Q.; Shi, F. Investigation of the microseismic response characteristics of a bottom structure’s ground pressure activity under the influence of faults. Appl. Sci. 2023, 13, 3796. [Google Scholar] [CrossRef]

- Ma, T.H.; Tang, C.A.; Liu, F.; Zhang, S.C.; Feng, Z.Q. Microseismic monitoring, analysis and early warning of rockburst. Geomat. Nat. Haz. Risk. 2021, 12, 2956–2983. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, Z.; Zhang, D.; Chen, Z. Investigation of microseismic characteristics of rock burst based on fractal theory. Appl. Sci. 2023, 13, 4613. [Google Scholar] [CrossRef]

- Young, R.P.; Maxwell, S.C.; Urbancic, T.I.; Feignier, B. Mining-induced microseismicity: Monitoring and applications of imaging and source mechanism techniques. Pure Appl. Geophys. 1992, 139, 697–719. [Google Scholar] [CrossRef]

- Srinivasan, C.; Arora, S.K.; Benady, S. Precursory monitoring of impending rockbursts in Kolar gold mines from microseismic emissions at deeper levels. Int. J. Rock Mech. Min. Sci. 1999, 36, 941–948. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, G.H.; Liu, C.; Li, S.G.; Xue, J.H.; Cheng, R.H.; Wang, X.L.; Zeng, X.Z. Prediction of rockbursts in a typical island working face of a coal mine through microseismic monitoring technology. Tunn. Undergr. Sp. Tech. 2021, 113, 103972. [Google Scholar] [CrossRef]

- Zhang, H.; Zeng, J.; Ma, J.; Fang, Y.; Chen, Z. Time series prediction of microseismic multi-parameter related to rockburst based on deep learning. Rock Mech. Rock Eng. 2021, 54, 6299–6321. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.M.; Si, G.Y.; Cao, A.Y. A new seismic-based strain energy methodology for coal burst forecasting in underground coal mines. Int. J. Rock Mech. Min. Sci. 2019, 123, 104086. [Google Scholar] [CrossRef]

- Shen, B.T.; Duan, Y.; Luo, X. Monitoring and modelling stress state near major geological structures in an underground coal mine for coal burst assessment. Int. J. Rock Mech. Min. Sci. 2020, 129, 104294. [Google Scholar] [CrossRef]

- Feng, G.L.; Feng, X.T.; Xiao, Y.X.; Yao, Z.B.; Hu, L. Characteristic microseismicity during the development process of intermittent rockburst in a deep railway tunnel. Int. J. Rock Mech. Min. Sci. 2019, 124, 104135. [Google Scholar] [CrossRef]

- Li, P.X.; Feng, X.T.; Feng, G.L.; Xiao, Y.X.; Chen, B.R. Rockburst and microseismic characteristics around lithological interfaces under different excavation directions in deep tunnels. Eng. Geol. 2019, 260, 105209. [Google Scholar] [CrossRef]

- Liu, Q.S.; Wu, J.; Zhang, X.P. Microseismic monitoring to characterize structuretype rockbursts: A case study of a TBM-excavated tunnel. Rock Mech. Rock Eng. 2020, 53, 2995–3013. [Google Scholar] [CrossRef]

- Srinivasan, C.; Arora, S.K.; Yaji, R.K. Use of mining and seismological parameters as premonitors of rockbursts. Int. J. Rock Mech. Min. Sci. 1997, 34, 1001–1008. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K. Assessment of excavation damaged zone using a micromechanics model. Tunn. Undergr. Sp. Tech. 2005, 20, 301–310. [Google Scholar] [CrossRef]

- Xue, R.; Liang, Z.; Xu, N. Rockburst prediction and analysis of activity characteristics within surrounding rock based on microseismic monitoring and numerical simulation. Int. J. Rock Mech. Min. Sci. 2021, 142, 104750. [Google Scholar] [CrossRef]

- Zhang, B.; Tian, X.P.; Ji, B.X.; Zhao, J.Z.; Zhu, Z.M.; Yin, S. Study on microseismic mechanism of hydro-fracture propagation in shale. J. Petrol. Sci. Eng. 2019, 178, 711–722. [Google Scholar] [CrossRef]

- Enoki, M.; Kishi, T. Theory and analysis of deformation moment tensor due to microcracking. Int. J. Fract. 1988, 38, 295–310. [Google Scholar] [CrossRef]

- Vera, R.I.; Stanchits, S.; Burghardt, J. Data-driven, in situ, relative sensor calibration based on waveform fitting moment tensor inversion. Rock Mech. Rock Eng. 2017, 50, 891–911. [Google Scholar] [CrossRef]

- Wei, S.; Wu, S.C. A study of crack initiation and source mechanism in the Brazilian test based on moment tensor. Eng. Fract. Mech. 2021, 246, 107622. [Google Scholar] [CrossRef]

- Corral, A. Long-term clustering, scaling, and universality in the temporal occurrence of earthquakes. Phys. Rev. Lett. 2004, 92, 108501. [Google Scholar] [CrossRef]

- Li, Y.H.; Liu, J.P.; Zhao, X.D.; Yang, Y.J. Experimental studies of the change of spatial correlation length of acoustic emission events during rock fracture process. Int. J. Rock Mech. Min. Sci. 2010, 47, 1254–1262. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Zhang, Y.H.; Qin, X.Y.; Khan, M. Comparative study on fracture characteristics of coal and rock samples based on acoustic emission technology. Theor. Appl. Fract. Mec. 2020, 111, 102851. [Google Scholar] [CrossRef]

- Gerd, M. Application of the cluster analysis and time statistic of acoustic emission events from tensile test of a cylindrical rock salt specimen. Eng. Fract. Mech. 2018, 210, 84–94. [Google Scholar] [CrossRef]

- Duxbury, P.M.; Leath, P.L. Failure probability and average strength of disordered systems. Phys. Rev. Lett. 1994, 72, 2805–2808. [Google Scholar] [CrossRef]

- Mouret, F.; Hippert-Ferrer, A.; Pascal, F.; Tourneret, J.Y. A Robust and Flexible EM Algorithm for Mixtures of Elliptical Distributions with Missing Data. IEEE Trans. Signal Process. 2023, 7, 1669–1682. [Google Scholar] [CrossRef]

- Pernkopf, F.; Bouchaffra, D. Genetic-based EM algorithm for learning Gaussian mixture models. IEEE Trans. Pattern Anal. 2005, 27, 1344–1348. [Google Scholar] [CrossRef]

- Feng, G.; Lin, M.; Yu, Y.; Fu, Y.A. Microseismicity-Based Method of Rockburst Intensity Warning in Deep Tunnels in the Initial Period of Microseismic Monitoring. Energies 2020, 13, 2698. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, Q.; Feng, G.; Chen, D.; Chen, B.; Zhao, Z. Microseismicity-based method for the dynamic estimation of the potential rockburst scale during tunnel excavation. Bull. Eng. Geol. Environ. 2021, 80, 3605–3628. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Wei, D.; Li, F.; Shi, H.; Si, Y. Quantitative risk assessment for deep tunnel failure based on clustering and logistic regression at the Ashele copper mine, China. Int. J. Min. Reclam. Env. 2022, 36, 688–709. [Google Scholar] [CrossRef]

- Ma, C.; Jiang, Y.; Li, T. Gravitational Search Algorithm for Microseismic Source Location in Tunneling: Performance Analysis and Engineering Case Study. Rock Mech. Rock Eng. 2019, 52, 3999–4016. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Q.; Pan, Y.; Huang, X. A novel tree-based algorithm for real-time prediction of rockburst risk using field microseismic monitoring. Environ. Earth Sci. 2021, 80, 504. [Google Scholar] [CrossRef]

| Cluster | a | b | c | Ellipsoidal Volume/m3 | Number of MS Events | MS Event Density Logarithm |

|---|---|---|---|---|---|---|

| 1 | 157.51 | 150.49 | 95.61 | 9,488,279.657 | 1006 | −3.97 |

| 2 | 220.87 | 181.01 | 160.11 | 26,799,466.08 | 1616 | −4.22 |

| 3 | 48.27 | 30.72 | 22.19 | 137,760.3372 | 1062 | −2.11 |

| 4 | 82.5 | 27.4 | 21.45 | 203,001.942 | 2310 | −1.94 |

| 5 | 74.54 | 41.91 | 16.32 | 213,449.7195 | 937 | −2.36 |

| 6 | 228.04 | 137.01 | 44.86 | 5,868,011.45 | 458 | −4.11 |

| 7 | 96.21 | 49.29 | 24.89 | 494,165.3772 | 1891 | −2.42 |

| 8 | 88.65 | 60.35 | 19.76 | 442,599.9284 | 980 | −2.65 |

| 9 | 87.89 | 34.45 | 34.45 | 436,703.127 | 1761 | −2.39 |

| 10 | 68 | 57 | 12.13 | 196,839.8176 | 1401 | −2.15 |

| Comparison | t-Statistic | p-Value | Significant Difference |

|---|---|---|---|

| cluster1 and cluster 2 | −40.8732 | 0 | Yes |

| cluster 1 and cluster 3 | −16.0652 | 0 | Yes |

| cluster 1 and cluster 4 | 18.4766 | 0 | Yes |

| cluster 1 and cluster 5 | 32.0344 | 0 | Yes |

| cluster 1 and cluster 6 | −13.2928 | 0 | Yes |

| cluster 2 and cluster 3 | −4.9693 | 0 | Yes |

| cluster 2 and cluster 4 | −59.092 | 0 | Yes |

| cluster 2 and cluster 5 | 76.7093 | 0 | Yes |

| cluster 2 and cluster 6 | 1.2132 | 0.2252 | No |

| cluster 3 and cluster 4 | −15.863 | 0 | Yes |

| cluster 3 and cluster 5 | 16.9806 | 0 | Yes |

| cluster 3 and cluster 6 | 1.9937 | 0.0465 | Yes |

| cluster 4 and cluster 5 | 15.1011 | 0 | Yes |

| cluster 4 and cluster 6 | −19.3877 | 0 | Yes |

| cluster 5 and cluster 6 | 25.1445 | 0 | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Chen, Z.; Li, Z.; Wang, P. Investigation of Microseismic Monitoring of and Precursor Information on Roof Collapse. Appl. Sci. 2023, 13, 11307. https://doi.org/10.3390/app132011307

Chen Y, Chen Z, Li Z, Wang P. Investigation of Microseismic Monitoring of and Precursor Information on Roof Collapse. Applied Sciences. 2023; 13(20):11307. https://doi.org/10.3390/app132011307

Chicago/Turabian StyleChen, Yin, Zeng Chen, Zijun Li, and Ping Wang. 2023. "Investigation of Microseismic Monitoring of and Precursor Information on Roof Collapse" Applied Sciences 13, no. 20: 11307. https://doi.org/10.3390/app132011307

APA StyleChen, Y., Chen, Z., Li, Z., & Wang, P. (2023). Investigation of Microseismic Monitoring of and Precursor Information on Roof Collapse. Applied Sciences, 13(20), 11307. https://doi.org/10.3390/app132011307