Extended Fuzzy-Based Models of Production Data Analysis within AI-Based Industry 4.0 Paradigm

Abstract

Featured Application

Abstract

1. Introduction

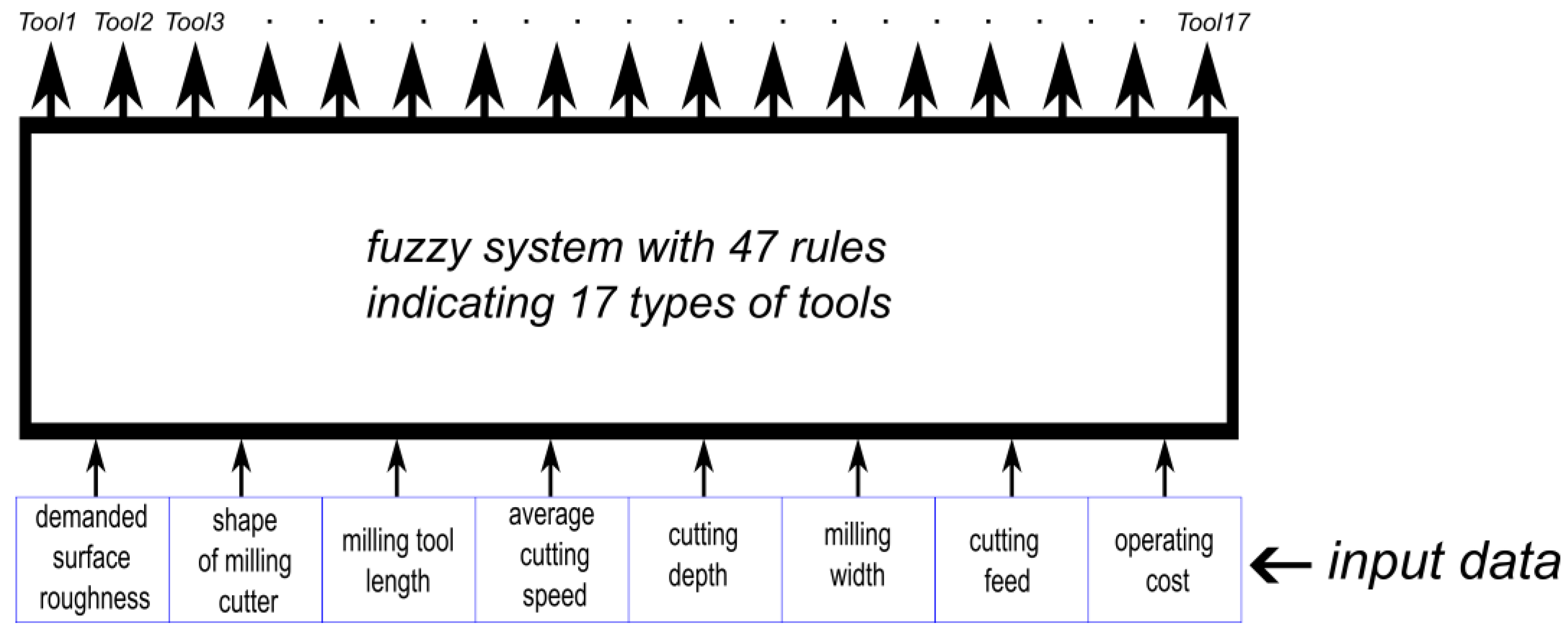

2. Materials and Methods

2.1. Material

2.2. Methods

Identification of the Fuzzy Sets for the Inputs

- The relative increase in the values of a given linguistic variable.

- The total number of occurrences of data representing a given interval of values of that variable.

- If the total number of occurrences in the clusters is less than 25%, and the interval of values of a given space is greater than 50% (of the entire range of this variable), we indicate the entire group as a new fuzzy set (new quality).

- If the number of occurrences is between 25 and 50%, and the value interval is greater than 25% of the entire range of this variable, we transform the clustered data into a fuzzy set.

- If the number of occurrences is above 50% and the value increment in the reference data is 10%, we indicate a new fuzzy set.

- We group the data into larger clusters if the set of basic clusters is small but represents a wide range of values.

- We group the data if the set of basic clusters is medium, and they represent a medium range of values.

- We group the data if the set of basic clusters is large, even if the data they represent has a small range of values.

- We group the data into larger clusters if the set of underlying clusters is at least average.

- Additionally, if another cluster minimally extends the current range of values, we still add it to the group regardless of its size.

- A cumulative increment of at least 25% of occurrences results in a new group (granule)—fuzzy set starting from the next basic cluster;

- Additionally, the increment of values in the variable space must be at least 5% or more.If not, we still add another basic cluster to the previous group.

- We identify the core (using Variant 1 or Variant 2 on benchmark data) to obtain a set of intervals for a given input space: [kis;kie]—where ks, ke—lower and upper boundary of the i-th interval for given input variable from benchmark data.

- Definition of trapezoidal shape is described by the fourth [l; ks; ke; r], where l is left (down) and r is right (upper) boundary of support of fuzzy membership. That form is popular in many scientific software like Matlab, Octave, Scilab. As was mentioned earlier for the fuzzy edges, the constant parameter spread = 25% was used. Finally, definition of the trapezoid fuzzy set is done as: [ks − 0.25ks; ks; ke; ke + 0.25 × ke].

Yino = (0;0;0;1), Yiyes = (0;1;1;1),

2.3. Specificity of the Rules

3. Results

- Aggregation of premises in the rules: MIN.

- Implication: MIN.

- Aggregation of results from the rules (accumulation): MAX.

- Defuzzification: middle of maxima (MOM).

4. Discussion

- Stochastic uncertainty (based on probability calculus, e.g., dice throw, accident, insurance risk).

- Measurement uncertainty (based on statistical analysis of the problem, e.g., about 2.5 cm or about 10 points).

- Informational uncertainty (based on data mining. e.g., a reliable borrower, a good candidate, i.e., one who collectively meets certain conditions).

- Linguistic uncertainty (based on fuzzy logic, e.g., favorable price, nice weather).

4.1. Limitations of the Proposed Solution

4.2. Directions for Further Research

- Use of directed fuzzy numbers.

- Development of hybrid methods, combining the advantages of different solutions (See, for example, the classification of textile products and fiber-reinforced polymer composites using artificial neural networks, genetic algorithm, and fuzzy logic [56], or aerogels combining enhanced physicochemical properties and structural features with sensory and energetic materials [57].)

- Development of a framework for the development of various models of industrial processes, adapted on site.

- Simultaneous analysis of product/service quality, price, and consumer satisfaction.

- Incorporating this group of solutions into ERP systems.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tepljakov, A. Intelligent Control and Digital Twins for Industry 4.0. Sensors 2023, 23, 4036. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.; Patel, P.; Shah, M. A comprehensive study on Industry 4.0 in the pharmaceutical industry for sustainable. Environ. Sci. Pollut. Res. Int. 2023. [Google Scholar] [CrossRef] [PubMed]

- Werbińska-Wojciechowska, S.; Winiarska, K. Maintenance Performance in the Age of Industry 4.0: A Bibliometric Performance Analysis and a Systematic Literature Review. Sensors 2023, 23, 1409. [Google Scholar] [CrossRef]

- Mazzei, D.; Ramjattan, R. Machine Learning for Industry 4.0: A Systematic Review Using Deep Learning-Based Topic Modelling. Sensors 2022, 22, 8641. [Google Scholar] [CrossRef]

- Tobia, M.J.; Madan, C.R. Tool selection and the ventral-dorsal organization of tool-related knowledge. Physiol. Rep. 2017, 5, e13078. [Google Scholar] [CrossRef] [PubMed]

- Finkel, L.; Hogrefe, K.; Frey, S.H.; Goldenberg, G.; Randerath, J. It takes two to pantomime: Communication meets motor cognition. Neuroimage. Clin. 2018, 19, 1008–1017. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.L.; Huang, H.W.; Federmeier, K.D.; Buxbaum, L.J. Sensory and semantic activations evoked by action attributes of manipulable objects: Evidence from ERPs. Neuroimage 2018, 167, 331–341. [Google Scholar] [CrossRef]

- Rojek, I.; Macko, M.; Mikołajewski, D.; Saga, M.; Burczynski, T. Modern methods in the field of machine modelling and simulation as a research and practical issue related to Industry 4.0. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e136717. [Google Scholar] [CrossRef]

- Chlebus, E. CAx Computer Techniques in Production Engineering; WNT: Warsaw, Poland, 2000. [Google Scholar]

- Prokopowicz, P.; Mikołajewski, D.; Mikołajewska, E.; Kotlarz, P. Fuzzy system as an assessment tool for analysis of the health-related quality of life for the people after stroke. Lect. Notes Comput. Sci. 2017, 10245, 710–721. [Google Scholar]

- Mikołajewska, E.; Prokopowicz, P.; Mikołajewski, D. Computational gait analysis using fuzzy logic for everyday clinical purposes—Preliminary findings. Bio-Algorithms Med.-Syst. 2017, 13, 37–42. [Google Scholar] [CrossRef]

- De Paula Ferreira, W.; Armellini, F.; de Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; Parmentola, A. Smart Manufacturing Systems and Applied Industrial Technologies for a Sustainable Industry: A Systematic Literature Review. Appl. Sci. 2020, 10, 2897. [Google Scholar] [CrossRef]

- Li, G.; Yang, S.; Xu, Z.; Wang, J.; Ren, Z.; Li, G. Resource allocation methodology based on object-oriented discrete event simulation: A production logistics system case study. CIRP J. Manuf. Sci. Technol. 2020, 31, 394–405. [Google Scholar] [CrossRef]

- Davis, R.; Vochozka, M.; Vrbka, J.; Neguriţă, O. Industrial Artificial Intelligence, Smart Connected Sensors, and Big Data-driven Decision-Making Processes in Internet of Things-based Real-Time Production Logistics. Econ. Manag. Financ. Mark. 2020, 15, 9–15. [Google Scholar] [CrossRef]

- Santos, C.H.D.; de Queiroz, J.A.; Leal, F.; Montevechi, J.A.B. Use of simulation in the industry 4.0 context: Creation of a Digital Twin to optimise decision making on non-automated process. J. Simul. 2022, 16, 284–297. [Google Scholar] [CrossRef]

- Sun, H.; Pedrielli, G.; Zhao, G.; Zhou, C.; Xu, W.; Pan, R. Cyber coordinated simulation for distributed multi-stage additive manufacturing systems. J. Manuf. Syst. 2020, 57, 61–71. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, G.Q.; Ngai, B.K.K.; Chen, X. Case-based polishing process planning with Fuzzy Set Theory. J. Intell. Manuf. 2010, 21, 831–842. [Google Scholar] [CrossRef]

- Tan, C.F.; Kher, V.K.; Ismail, N. An expert system carbide cutting tools selection system for CNC lathe machine. Int. Rev. Mech. Eng. 2012, 6, 1402–1405. [Google Scholar]

- Igari, S.; Tanaka, F.; Onosato, M. Customization of a Micro Process Planning System for an Actual Machine Tool based on Updating a Machining Database and Generating a Database-Oriented Planning Algorithm. J. Control. 2013, 26, 87–94. [Google Scholar] [CrossRef]

- Yan, H.S.; Wang, Y.F. Matching decision method for knowledgeable manufacturing system and its production environment. J. IntellManuf. 2019, 30, 771–782. [Google Scholar] [CrossRef]

- Saranya, K.; John RozarioJegaraj, J.; Ramesh Kumar, K.; Rao, G.V. Artificial Intelligence Based Selection of Optimal Cutting Tool and Process Parameters for Effective Turning and Milling Operations. J. Inst. Eng. India. Ser. C 2018, 99, 381–392. [Google Scholar] [CrossRef]

- Shetty, R.; Kumar, C.R.S.; Ravindra, M.R. RSM based expert system development for cutting force prediction during machining of Ti–6Al–4V under minimum quantity lubrication. Int. J. Syst. Assur. Eng. Manag. 2021. [Google Scholar] [CrossRef]

- Orazbayev, B.; Zhumadillayeva, A.; Orazbayeva, K.; Iskakova, S.; Utenova, B.; Gazizov, F.; Ilyashenko, S.; Afanaseva, O. The System of Models and Optimization of Operating Modes of a Catalytic Reforming Unit Using Initial Fuzzy Information. Energies 2022, 15, 1573. [Google Scholar] [CrossRef]

- Orazbayev, B.B.; Orazbayeva, K.N.; Utenova, B.E. Development of mathematical models and modeling of chemical engineering systems under uncertainty. Theor. Found. Chem. Eng. 2014, 48, 138–147. [Google Scholar] [CrossRef]

- Fichtner, D.; Nestler, A.; Dang, T.N.; Schulze, A.; Carlsen, U.; Schreiber, S.; Lee, S.W. Use of agents and neural networks for acquisition and preparation of distributed NC information to support NC planning. Int. J. Comput. Inte.-Grated. Manuf. 2006, 19, 581–592. [Google Scholar] [CrossRef]

- Nassehi, A.; Newman, S.T.; Allen, R.D. The application of multi-agent systems for STEP-NC computer aided process planning of prismatic components. Inter.-Natl. J. Mach. Tools Manuf. 2006, 46, 559–574. [Google Scholar] [CrossRef]

- Agraval, R.; Shukla, S.K.; Kumar, S.; Tiwari, M.K. Multi-agent system for distributed computer-aided process planning problem in e-manufacturing environment. Int. J. Adv. Manuf. Technol. 2009, 44, 579–594. [Google Scholar] [CrossRef]

- Xie, S.Q.; Tu, Y. An Agent-based Sheet Metal Process Planning System. In Rapid One-of-a-kind Product Development: Strategies, Algorithms and Tools; Springer: Berlin/Heidelberg, Germany, 2011; pp. 125–148. [Google Scholar] [CrossRef]

- Joo, J.; Park, S.; Cho, H. Adaptive and dynamic process planning using neural networks. Int. J. Prod. Res. 2010, 39, 2923–2946. [Google Scholar] [CrossRef]

- Salehi, M.; Tavakkoli-Moghaddam, R. Application of genetic algorithm to computer-aided process planning in preliminary and detailed planning. Eng. Appl. Artif. Intell. 2009, 22, 1179–1187. [Google Scholar] [CrossRef]

- Rojek, I. MLP Neural Nets in Design of Technological Process. Adv. Manuf. Sci. Technol. 2015, 39, 87–95. [Google Scholar]

- Kacalak, W.; Majewski, M. Inteligentne, interaktywne, zautomatyzowane systemy projektowania elementówi zespołów maszyn na podstawie ich cech opisywanych w języku naturalnym. Pomiary Autom. Kontrola 2012, 58, 471–474. [Google Scholar]

- Kacalak, W.; Majewski, M.; Stuart, K.D.; Budniak, Z. Interactive systems for designing machine elements and assemblies. Manag. Prod. Eng. Rev. 2015, 6, 10–20. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Alexopoulos, K.; Arkouli, Z. Artificial Intelligence in Manufacturing Equipment, Automation, and Robots. In A Perspective on Artificial Intelligence in Manufacturing. Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2023; Volume 436. [Google Scholar] [CrossRef]

- Turban, E.; Aronson, J.E.; Liang, T.-P.; McCarthy, R.V. Decision Support Systems and Intelligent Systems, 7th ed.; Prentice Hall: Hoboken, NJ, USA, 2004. [Google Scholar]

- Sharda, R.; Delen, D.; Turban, E. Analytics, Data Science & Artificial Intelligence: Systems for Decision Support, 11th ed.; Pearson: London, UK, 2019. [Google Scholar]

- Kosiński, W.; Prokopowicz, P.; Rosa, A. Defuzzification Functionals of Ordered Fuzzy Numbers. IEEE Trans. FuzzySyst. 2013, 21, 1163–1169. [Google Scholar] [CrossRef]

- Ahmadi, H.; Gholamzadeh, M.; Shahmoradi, L.; Nilashi, M.; Rashvand, P. Diseases diagnosis using fuzzy logic methods: A systematic and meta-analysis review. Comput. Methods Programs Biomed. 2018, 161, 145–172. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Julio, Y.F.; Prieto-Guevara, M.J.; Nieto-Bernal, W.; Meriño-Fuentes, I.; Guerrero-Avendaño, A. Framework for the Development of Data-Driven Mamdani-Type Fuzzy Clinical Decision Support Systems. Diagnostics 2019, 9, 52. [Google Scholar] [CrossRef]

- Farzandipour, M.; Nabovati, E.; Saeedi, S.; Fakharian, E. Fuzzy decision support systems to diagnose musculoskeletal disorders: A systematic literature review. Comput. Methods Programs Biomed. 2018, 163, 101–109. [Google Scholar] [CrossRef] [PubMed]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital twins in product lifecycle for sustainability in manufacturing and maintenance. Appl. Sci. 2021, 11, 31. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-optimized technological aspects of the material used in 3D printing processes for selected medical applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef]

- Rojek, I.; Burduk, R.; Heda, P. Ensemble selection in one-versus-one scheme—Case study for cutting tools classification. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e136044. [Google Scholar] [CrossRef]

- Cruz, R.M.; Sabourin, R.; Cavalcanti, G.D. Dynamic classifier selection: Recent advances and perspectives. Inf. Fusion. 2018, 41, 195–216. [Google Scholar] [CrossRef]

- Arji, G.; Ahmadi, H.; Nilashi, M.; Rashid, T.A.; Hassan Ahmed, O.; Aljojo, N.; Zainol, A. Fuzzy logic approach for infectious disease diagnosis: A methodical evaluation, literature and classification. Biocybern. Biomed. Eng. 2019, 39, 937–955. [Google Scholar] [CrossRef]

- Al-Dmour, J.A.; Sagahyroon, A.; Al-Ali, A.R.; Abusnana, S. A fuzzy logic-based warning system for patients classification. Health Inform. J. 2019, 25, 1004–1024. [Google Scholar] [CrossRef] [PubMed]

- Alcan, V.; Canal, M.R.; Zinnuroğlu, M. Using fuzzy logic for diagnosis and classification of spasticity. Turk. J. Med. Sci. 2017, 47, 148–160. [Google Scholar] [CrossRef] [PubMed]

- Ghorbani, S.; Barari, M.; Hoseini, M. Presenting a new method to improve the detection of micro-seismic events. Environ. Monit. Assess. 2018, 190, 464. [Google Scholar] [CrossRef] [PubMed]

- Azarafza, M.; Akgün, H.; Feizi-Derakhshi, M.R.; Azarafza, M.; Rahnamarad, J.; Derakhshani, R. Discontinuous rock slope stability analysis under blocky structural sliding by fuzzy key-block analysis method. Heliyon 2020, 6, e03907. [Google Scholar] [CrossRef]

- Keramitsoglou, I.; Kiranoudis, C.T.; Maiheu, B.; De Ridder, K.; Daglis, I.A.; Manunta, P.; Paganini, M. Heat wave hazard classification and risk assessment using artificial intelligence fuzzy logic. Environ. Monit. Assess. 2013, 185, 8239–8258. [Google Scholar] [CrossRef]

- Sathyendranath, S.; Brewin, R.J.W.; Brockmann, C.; Brotas, V.; Calton, B.; Chuprin, A.; Cipollini, P.; Couto, A.B.; Dingle, J.; Doerffer, R.; et al. An Ocean-Colour Time Series for Use in Climate Studies: The Experience of the Ocean-Colour Climate Change Initiative (OC-CCI). Sensors 2019, 19, 4285. [Google Scholar] [CrossRef]

- Ordoñez-Avila, R.; Salgado Reyes, N.; Meza, J.; Ventura, S. Data mining techniques for predicting teacher evaluation in higher education: A systematic literature review. Heliyon 2023, 9, e13939. [Google Scholar] [CrossRef]

- Khumaidi, A.; Purwanto, Y.A.; Sukoco, H.; Wijaya, S.H. Using Fuzzy Logic to Increase Accuracy in Mango Maturity Index Classification: Approach for Developing a Portable Near-Infrared Spectroscopy Device. Sensors 2022, 22, 9704. [Google Scholar] [CrossRef]

- Duch, W. Concept Representation and the Geometric Model of Mind. Stud. Log. Gramm. Rhetor. 2022, 67, 151–167. [Google Scholar] [CrossRef]

- Amor, N.; Noman, M.T.; Petru, M. Classification of Textile Polymer Composites: Recent Trends and Challenges. Polymers 2021, 13, 2592. [Google Scholar] [CrossRef] [PubMed]

- Noman, M.T.; Amor, N.; Ali, A.; Petrik, S.; Coufal, R.; Adach, K.; Fijalkowski, M. Aerogels for Biomedical, Energy and Sensing Applications. Gels 2021, 7, 264. [Google Scholar] [CrossRef] [PubMed]

- Pinto, A.; Ribeiro, R.A.; Nunes, I.L. Fuzzy approach for reducing subjectivity in estimating occupational accident severity. Accid. Anal. Prev. 2012, 45, 281–290. [Google Scholar] [CrossRef]

- Broekhuizen, H.; Groothuis-Oudshoorn, C.G.; van Til, J.A.; Hummel, J.M.; IJzerman, M.J. A review and classification of approaches for dealing with uncertainty in multi-criteria decision analysis for healthcare decisions. Pharmacoeconomics 2015, 33, 445–455. [Google Scholar] [CrossRef] [PubMed]

- Prokopowicz, P. Adaptation of Rules in the Fuzzy Control System Using the Arithmetic of Ordered Fuzzy Numbers. In Artificial Intelligence and Soft Computing—ICAISC 2008. ICAISC 2008, Lecture Notes in Computer Science; Rutkowski, L., Tadeusiewicz, R., Zadeh, L.A., Zurada, J.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; p. 5097. [Google Scholar] [CrossRef]

- Prokopowicz, P. Analysis of the changes in processes using the kosinski’s fuzzy numbers. In Proceedings of the 2016 Federated Conference on Computer Science and Information Systems, FedCSIS 20916, Gdansk, Poland, 11–14 September2016; pp. 121–128. [Google Scholar]

- Price, A.R. The marine food chain in relation to biodiversity. Sci. World J. 2001, 1, 579–587. [Google Scholar] [CrossRef] [PubMed]

- Park, E.Y. Recent progress in microbial cultivation techniques. Adv. Biochem. Eng. Biotechnol. 2004, 90, 1–33. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets as a basis for a theory of possibility. Fuzzy. Sets Syst. 1978, 1, 3–28. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef]

| Input No. | Input Description | Values and Their Occurrences Form the Initial Clusters | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

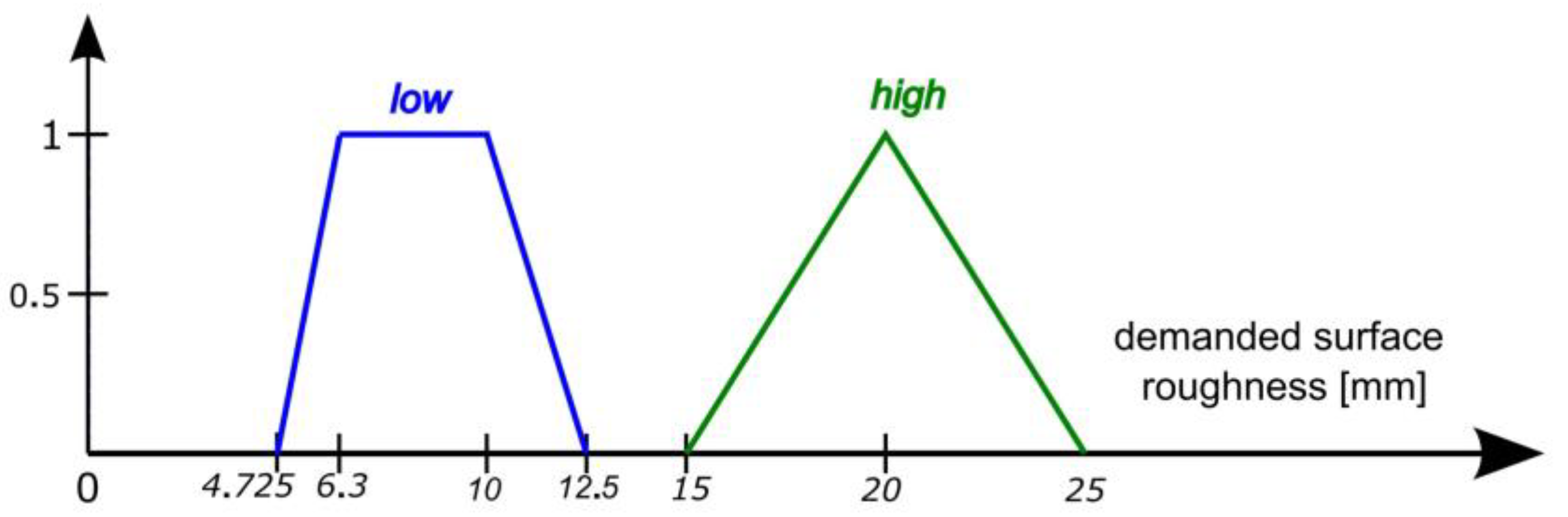

| 1 | Surface roughness | Values | 6.3 | 10 | 20 | |||||||||||||||||||||||||

| No. of occur. | 1 | 23 | 23 | |||||||||||||||||||||||||||

| 2 | Shape of milling cutter | Values | 10 | 16 | 20 | 25 | 40 | 63 | 80 | 100 | 125 | 250 | ||||||||||||||||||

| No. of occur. | 4 | 5 | 10 | 6 | 2 | 2 | 4 | 6 | 4 | 4 | ||||||||||||||||||||

| 3 | Milling tool length | Values | 32 | 35 | 40 | 50 | 55 | 63 | 92 | 100 | 104 | 125 | 165 | 175 | ||||||||||||||||

| No. of occur. | 1 | 2 | 2 | 8 | 2 | 8 | 6 | 4 | 4 | 4 | 2 | 4 | ||||||||||||||||||

| 4 | Average cutting speed | Values | 60 | 67.5 | 74 | 75 | 82 | 119 | 120 | 127.5 | 148 | 156 | 180 | 210 | 222 | 254 | 270 | 318 | 328 | 375 | ||||||||||

| No. of occur. | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 2 | 4 | 2 | 2 | 5 | 2 | 5 | 4 | 2 | 2 | 1 | ||||||||||||

| 5 | Cutting depth | Values | 2.5 | 4 | 5 | 6 | 6.25 | 8 | 9 | 9.5 | 10 | 12 | 12.5 | 15 | 16 | 19 | 20 | 25 | 30 | 37.5 | 75 | |||||||||

| No. of occur. | 1 | 1 | 4 | 1 | 3 | 2 | 1 | 1 | 6 | 1 | 2 | 7 | 1 | 1 | 3 | 1 | 7 | 2 | 2 | |||||||||||

| 6 | Milling width | Values | 0.15 | 0.25 | 0.3 | 0.5 | 1 | |||||||||||||||||||||||

| No. of occur. | 11 | 7 | 11 | 11 | 7 | |||||||||||||||||||||||||

| 7 | Cutting feed | Values | 178 | 187 | 198 | 216 | 225 | 229 | 240 | 249 | 270 | 285 | 286 | 289 | 300 | 318 | 321 | 326 | 338 | 361 | 372 | 385 | 414 | 445 | 509 | 596 | 722 | 795 | 796 | 1032 |

| No. of occur. | 2 | 6 | 2 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 2 | 1 | 1 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 1 | 2 | ||

| 8 | Operating cost | Values | 75 | 120 | 196 | 250 | 260 | 315 | 350 | 410 | 455 | 486 | 595 | 730 | 760 | 765 | 1700 | |||||||||||||

| No. of occur. | 4 | 1 | 2 | 4 | 4 | 4 | 4 | 2 | 2 | 4 | 4 | 2 | 4 | 2 | 4 | |||||||||||||||

| Input No. | Input Description | Numeric Values and Corresponding Linguistic Values | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | Surface roughness | 6.3 | 10 | 20 | |||||

| Fuzzy sets—cores | low | low | high | ||||||

| 2 | Shape of milling cutter | 10 | 20 | 25 | 80 | 100 | 250 | ||

| Fuzzy set | low | low | medium | medium | high | high | |||

| 3 | Milling tool length | 32 | 50 | 55 | 92 | 100 | 125 | 165 | 175 |

| Fuzzy sets—cores | low | low | medium | medium | high | high | very high | very high | |

| 4 | Average cutting speed | 60 | 120 | 127.5 | 210 | 222 | 270 | 318 | 375 |

| Fuzzy sets—cores | low | low | medium | medium | high | high | very high | very high | |

| 5 | Cutting depth | 2.5 | 8 | 9 | 12.5 | 15 | 20 | 25 | 75 |

| Fuzzy sets—cores | low | low | medium | medium | high | high | very high | very high | |

| 6 | Milling width | 0.15 | 0.25 | 0.3 | 0.5 | 1 | |||

| Fuzzy sets—cores | low | low | medium | medium | high | ||||

| 7 | Cutting feed | 178 | 249 | 270 | 338 | 361 | 722 | 795 | 1032 |

| Fuzzy sets—cores | low | low | medium | medium | high | high | very high | very high | |

| 8 | Operating cost | 75 | 260 | 315 | 455 | 486 | 765 | 1700 | |

| Fuzzy sets—cores | low | low | medium | medium | high | high | very high | ||

| Tool 1 | Tool 2 | Tool 3 | Tool 4 | Tool 5 | Tool 6 | Tool 7 | Tool 8 | Tool 9 | Tool 10 | Tool 11 | Tool 12 | Tool 13 | Tool 14 | Tool 15 | Tool 16 | Tool 17 | Expected Recognition | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of input data | 1 | 0.99 | 0.705 | 0.645 | N | 0.675 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 1 |

| 2 | 0.99 | 0.99 | 0.645 | N | 0.675 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 1 | |

| 3 | 0.99 | 0.705 | 0.645 | N | 0.705 | 0.705 | N | N | N | N | N | N | N | N | N | N | N | Tool 1 | |

| 4 | 0.99 | 0.99 | 0.645 | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 1 | |

| 5 | N | 0.99 | 0.58 | 0.51 | 0.675 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 6 | 0.99 | 0.99 | 0.58 | 0.51 | 0.675 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 7 | 0.99 | 0.99 | 0.58 | 0.51 | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 8 | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 9 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 10 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 11 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 12 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 13 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 14 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 15 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 16 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 17 | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 18 | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 19 | 0.99 | 0.99 | N | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 20 | 0.99 | 0.99 | N | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 21 | 0.99 | 0.99 | N | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 6 | |

| 22 | 0.99 | 0.99 | N | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 6 | |

| 23 | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | Tool 7 | |

| 24 | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | N | N | N | N | N | Tool 8 | |

| 25 | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | Tool 9 | |

| 26 | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | N | N | Tool 10 | |

| 27 | N | N | N | N | N | N | N | N | N | 0.525 | 0.525 | N | N | N | N | N | N | Tool 11 | |

| 28 | N | N | N | N | N | N | N | N | N | N | 0.525 | N | N | N | N | N | N | Tool 11 | |

| 29 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | 0.545 | 0.545 | N | Tool 12 | |

| 30 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | 0.545 | 0.545 | N | Tool 12 | |

| 31 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | 0.545 | N | Tool 12 | |

| 32 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | 0.545 | N | Tool 12 | |

| 33 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | Tool 13 | |

| 34 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | Tool 13 | |

| 35 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | Tool 13 | |

| 36 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | N | N | N | Tool 13 | |

| 37 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 38 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 39 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 40 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 41 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.99 | N | Tool 15 | |

| 42 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.515 | N | Tool 15 | |

| 43 | N | N | N | N | N | N | N | N | N | N | N | 0.63 | 0.63 | N | 0.99 | 0.99 | N | Tool 16 | |

| 44 | N | N | N | N | N | N | N | N | N | N | N | 0.63 | 0.63 | N | 0.99 | 0.99 | N | Tool 16 | |

| 45 | N | N | N | N | N | N | N | N | N | N | N | 0.63 | 0.63 | N | N | 0.99 | N | Tool 16 | |

| 46 | N | N | N | N | N | N | N | N | N | N | N | 0.63 | 0.63 | N | N | 0.99 | N | Tool 16 | |

| 47 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | Tool 17 | |

| Tool 1 | Tool 2 | Tool 3 | Tool 4 | Tool 5 | Tool 6 | Tool 7 | Tool 8 | Tool 9 | Tool 10 | Tool 11 | Tool 12 | Tool 13 | Tool 14 | Tool 15 | Tool 16 | Tool 17 |

| Tool 1 | Tool 2 | Tool 3 | Tool 4 | Tool 5 | Tool 6 | Tool 7 | Tool 8 | Tool 9 | Tool 10 | Tool 11 | Tool 12 | Tool 13 | Tool 14 | Tool 15 | Tool 16 | Tool 17 | Expected Recognition | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of input data | 1 | 0.99 | N | 0.645 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 1 |

| 2 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 1 | |

| 3 | 0.99 | N | N | N | N | 0.735 | N | N | N | N | N | N | N | N | N | N | N | Tool 1 | |

| 4 | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 1 | |

| 5 | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 6 | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 7 | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 8 | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 2 | |

| 9 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 10 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 11 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 12 | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 3 | |

| 13 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 14 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 15 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 16 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | N | Tool 4 | |

| 17 | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 18 | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 19 | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 20 | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | N | Tool 5 | |

| 21 | 0.835 | 0.545 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 6 | |

| 22 | 0.755 | 0.595 | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | N | Tool 6 | |

| 23 | N | N | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | N | N | Tool 7 | |

| 24 | N | N | N | N | N | N | 0.795 | 0.99 | N | N | N | N | N | N | N | N | N | Tool 8 | |

| 25 | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | N | N | N | N | Tool 9 | |

| 26 | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | N | N | N | Tool 10 | |

| 27 | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | N | N | Tool 11 | |

| 28 | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | N | N | Tool 11 | |

| 29 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.815 | N | N | N | N | Tool 12 | |

| 30 | N | N | N | N | N | N | N | N | N | 0.595 | N | 0.99 | 0.815 | N | N | N | N | Tool 12 | |

| 31 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.815 | N | N | N | N | Tool 12 | |

| 32 | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.815 | N | N | N | N | Tool 12 | |

| 33 | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | Tool 13 | |

| 34 | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | Tool 13 | |

| 35 | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | Tool 13 | |

| 36 | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | N | Tool 13 | |

| 37 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 38 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 39 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 40 | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | N | Tool 14 | |

| 41 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | N | N | Tool 15 | |

| 42 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | 0.515 | N | Tool 15 | |

| 43 | N | N | N | N | N | N | N | N | N | N | N | 0.595 | 0.595 | N | 0.595 | 0.99 | N | Tool 16 | |

| 44 | N | N | N | N | N | N | N | N | N | 0.595 | N | 0.595 | 0.595 | N | N | 0.99 | N | Tool 16 | |

| 45 | N | N | N | N | N | N | N | N | N | N | N | 0.595 | 0.595 | N | N | 0.99 | N | Tool 16 | |

| 46 | N | N | N | N | N | N | N | N | N | N | N | 0.585 | 0.585 | N | N | 0.99 | N | Tool 16 | |

| 47 | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | N | 0.99 | Tool 17 | |

| Tool 1 | Tool 2 | Tool 3 | Tool 4 | Tool 5 | Tool 6 | Tool 7 | Tool 8 | Tool 9 | Tool 10 | Tool 11 | Tool 12 | Tool 13 | Tool 14 | Tool 15 | Tool 16 | Tool 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojek, I.; Prokopowicz, P.; Kotlarz, P.; Mikołajewski, D. Extended Fuzzy-Based Models of Production Data Analysis within AI-Based Industry 4.0 Paradigm. Appl. Sci. 2023, 13, 6396. https://doi.org/10.3390/app13116396

Rojek I, Prokopowicz P, Kotlarz P, Mikołajewski D. Extended Fuzzy-Based Models of Production Data Analysis within AI-Based Industry 4.0 Paradigm. Applied Sciences. 2023; 13(11):6396. https://doi.org/10.3390/app13116396

Chicago/Turabian StyleRojek, Izabela, Piotr Prokopowicz, Piotr Kotlarz, and Dariusz Mikołajewski. 2023. "Extended Fuzzy-Based Models of Production Data Analysis within AI-Based Industry 4.0 Paradigm" Applied Sciences 13, no. 11: 6396. https://doi.org/10.3390/app13116396

APA StyleRojek, I., Prokopowicz, P., Kotlarz, P., & Mikołajewski, D. (2023). Extended Fuzzy-Based Models of Production Data Analysis within AI-Based Industry 4.0 Paradigm. Applied Sciences, 13(11), 6396. https://doi.org/10.3390/app13116396