Experimental Study on the Mechanical Properties of Xinyang Red Clay Improved by Lime and Fly Ash

Abstract

1. Introduction

2. Soil Samples and Experimental Scheme

2.1. Soil Samples

2.2. Modified Material

2.3. Test Setup

3. Test Results and Analysis

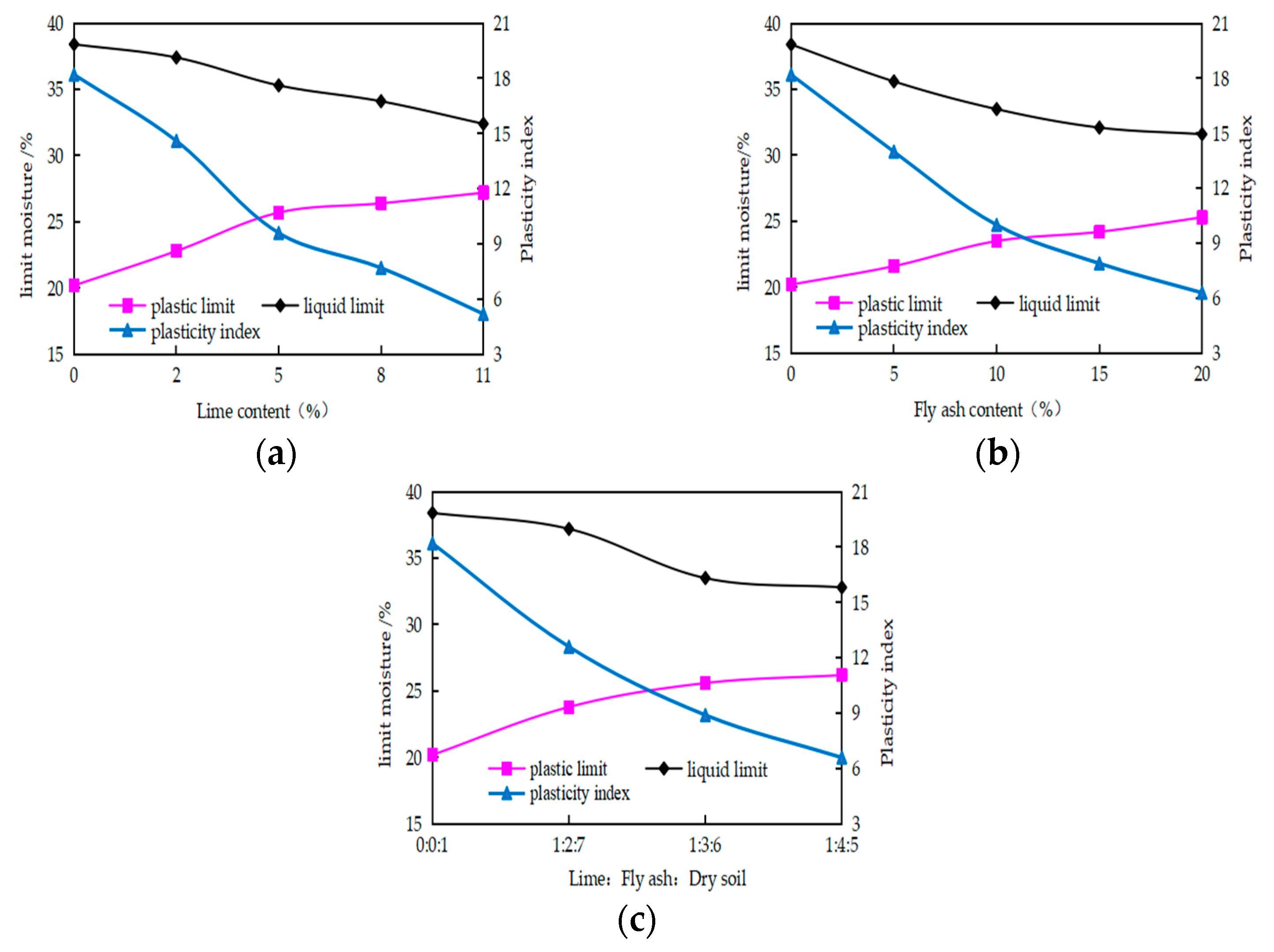

3.1. Limitation Water Content Test

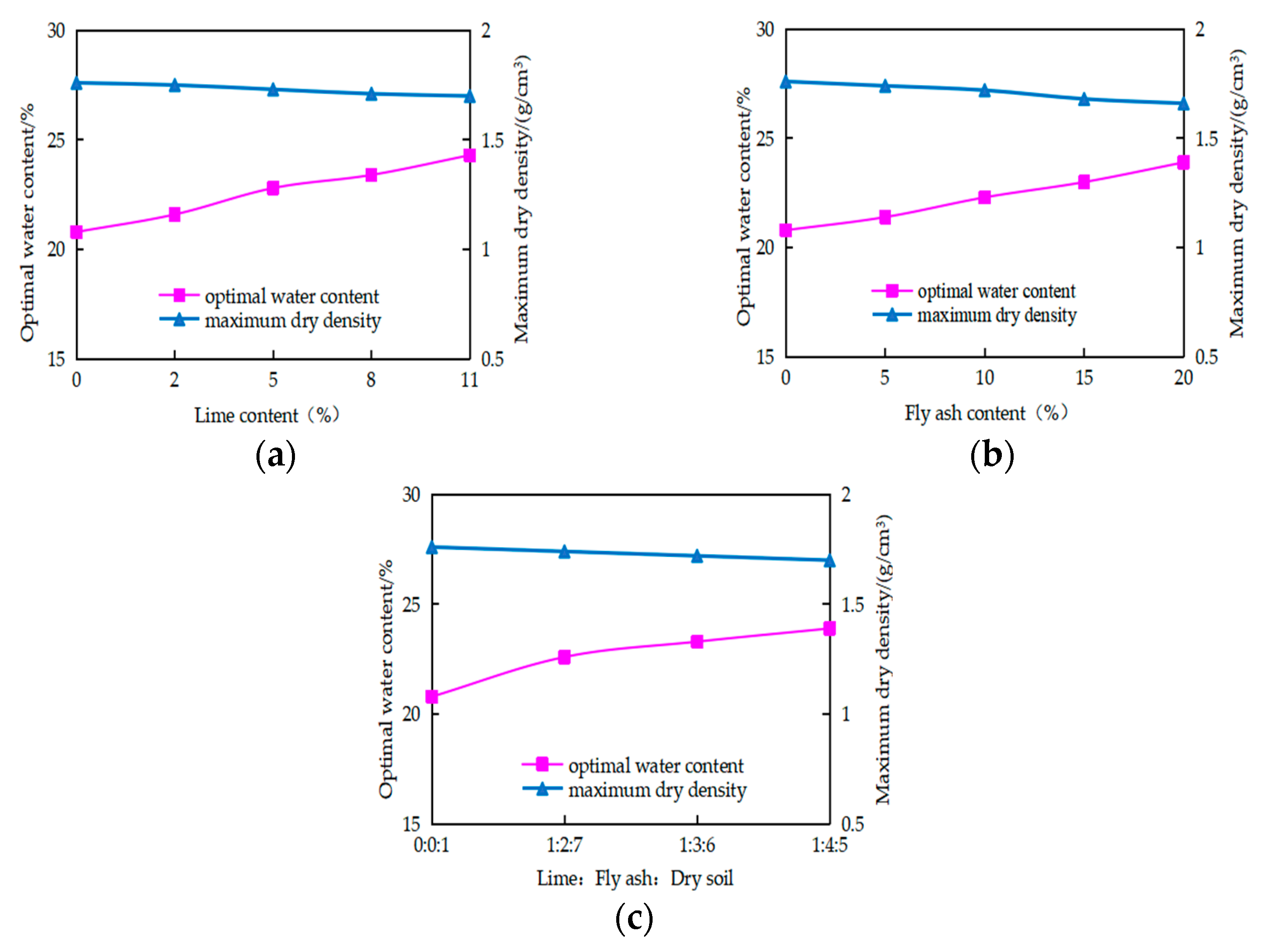

3.2. Compaction Test

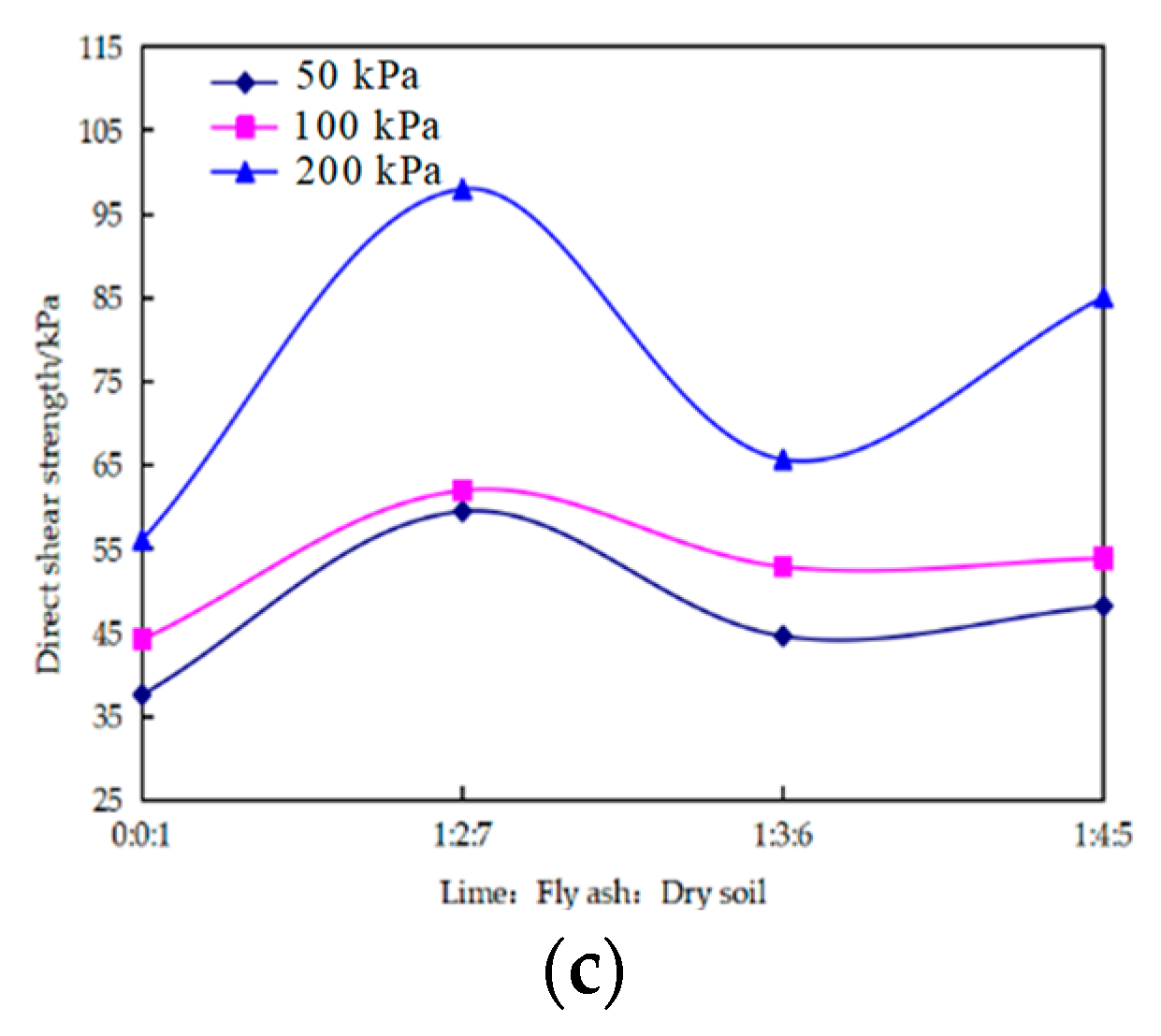

3.3. Direct Shear Test

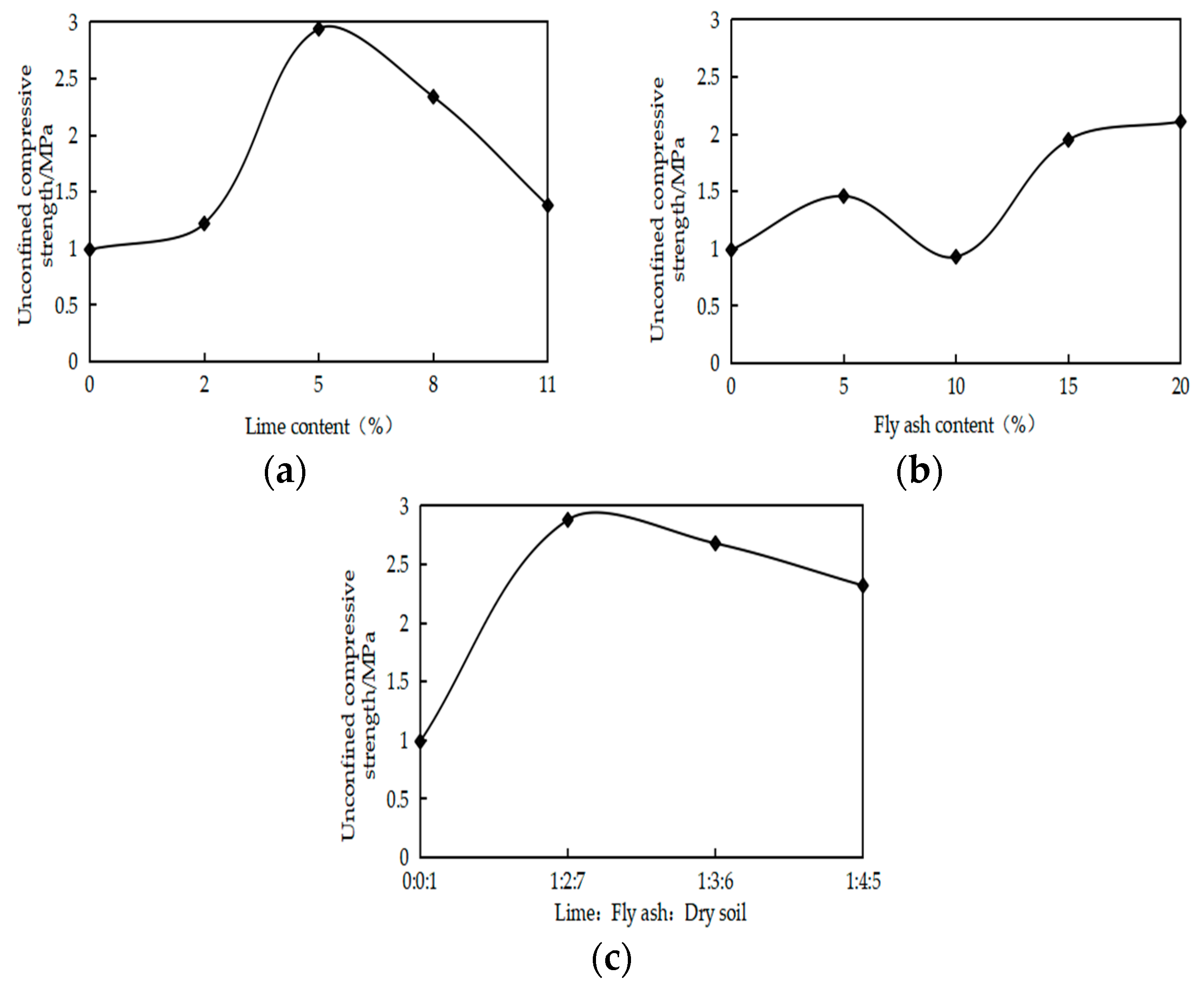

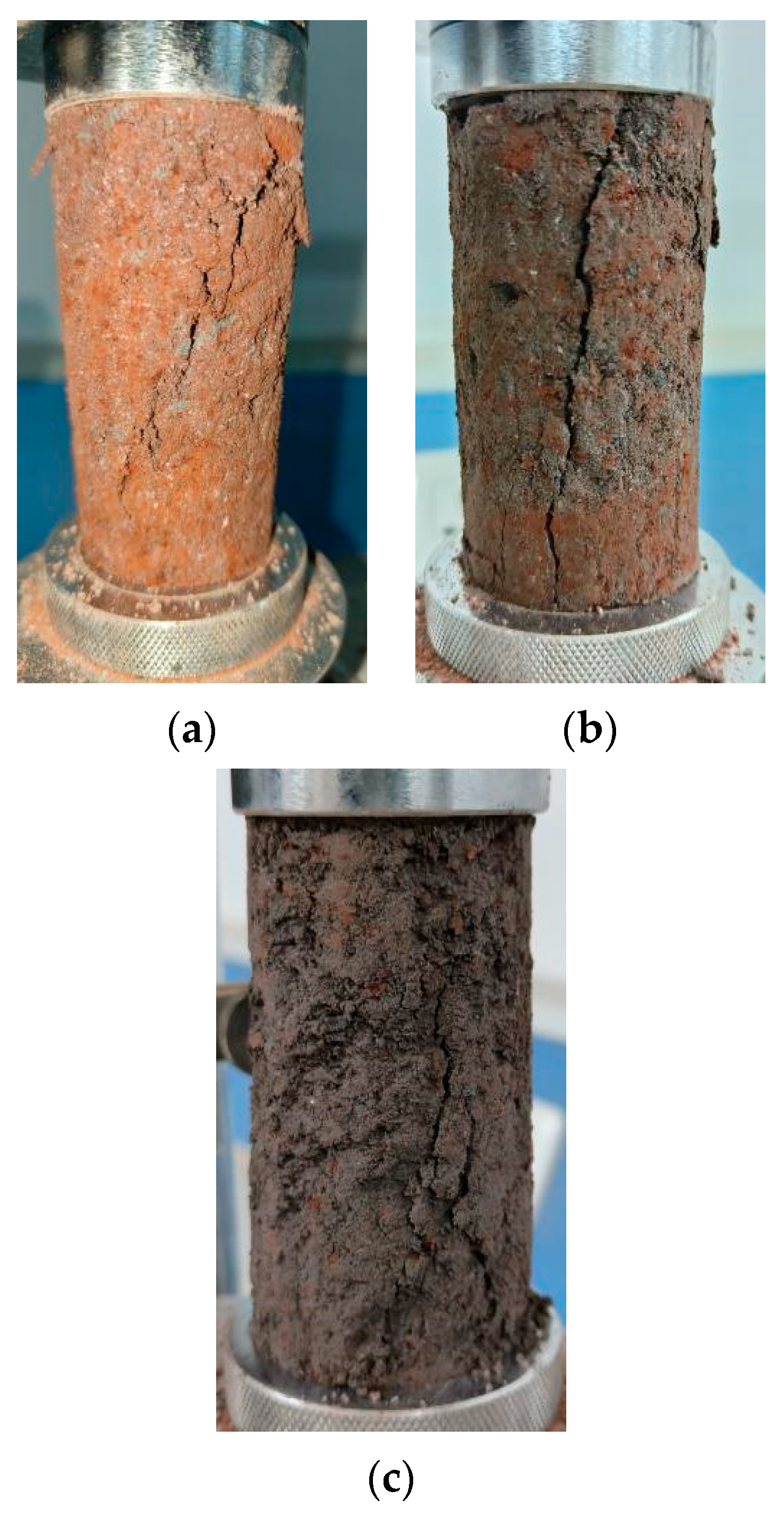

3.4. Unconfined Compressive Strength Test

3.5. Compression Test

4. Microscopic Test

4.1. Sample Preparation

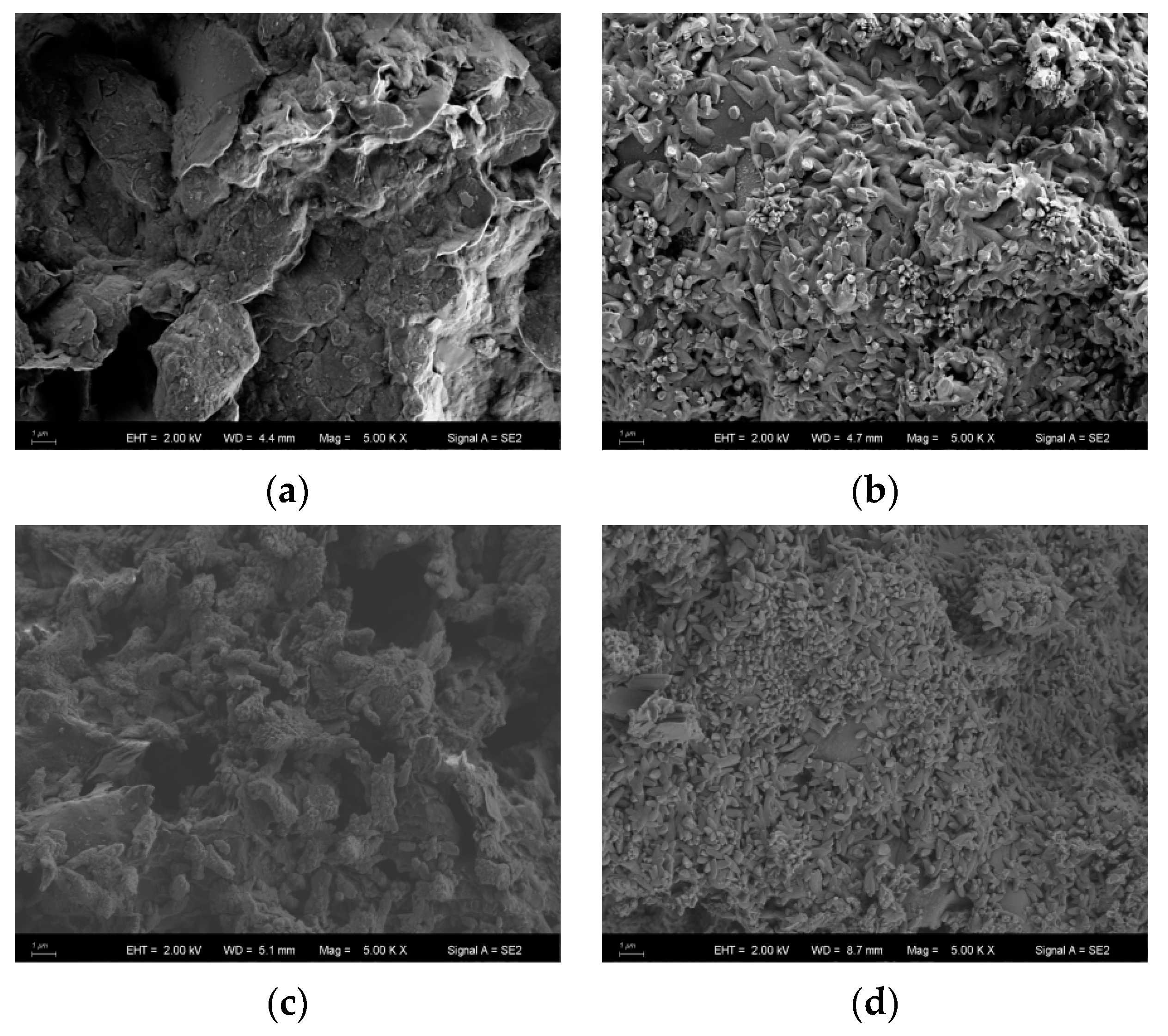

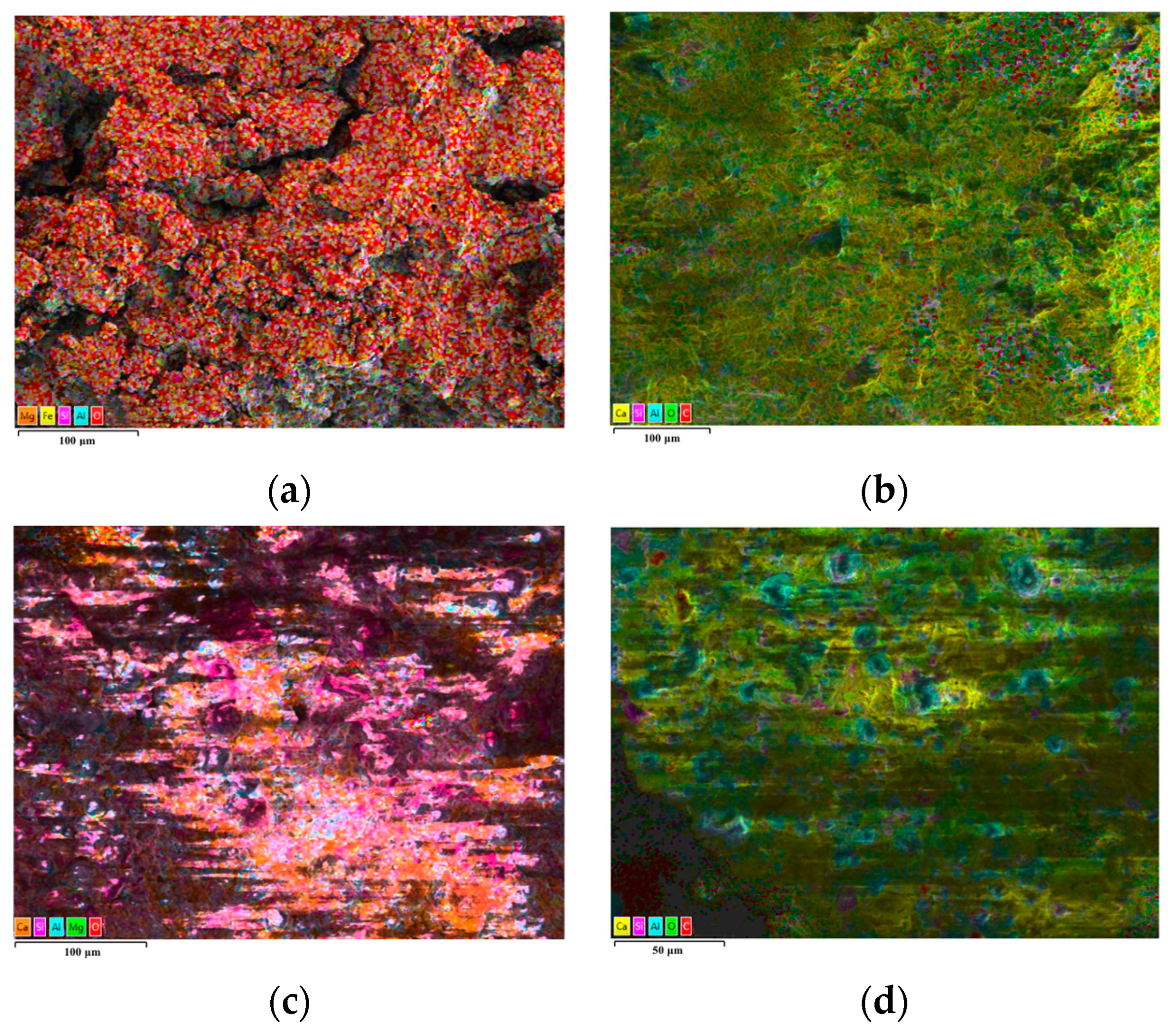

4.2. Microstructure Analysis of Improved Soil

5. Conclusions

- (1)

- The liquid limit, plastic index, and maximum dry density of red clay decrease with the increase of the proportion of lime and fly ash, while the plastic limit and optimal water content increase with the increase of lime and fly ash content. This suggests that adding lime and fly ash reduces the plasticity and increases the compaction characteristics of the red clay.

- (2)

- The addition of lime and fly ash has a significant influence on the cohesion (c) of the shear strength index, but has no significant influence on the internal friction angle (φ). This indicates that lime and fly ash primarily affect the cohesive properties of the red clay.

- (3)

- When the content of lime is 5%, fly ash is 10%, and the ratio of lime to fly ash is 1:2:7, the shear strength index and unconfined compressive strength of the soil are improved, and the compressibility of the soil is reduced. This suggests that a specific combination of lime and fly ash, with appropriate proportions, yields the best results in terms of improving the mechanical properties of the red clay.

- (4)

- When the red clay is improved by adding lime–fly ash, the improved soil may become brittle to some extent when the fly ash content is high. Therefore, it is important to control the fly ash content appropriately, to avoid detrimental effects on the mechanical properties of the soil.

- (5)

- Scanning electron microscope and X-ray diffraction analysis revealed that the modified red clay particles, with a ratio of 1:2:7 of lime to fly ash, were coated with Ca(OH)2, calcium silicate hydrate (C–S–H), calcium aluminate hydrate (C–A–H), and other gel substances. These substances cemented the particles together, increasing the bonding force between the particles, and improving the overall structure of the red clay.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, X.; Guo, J.; Yang, H.; Bao, S.; Wen, C.; Chen, J. Study on Stress–Strain Relationship of Coir Fiber-Reinforced Red Clay Based on Duncan–Chang Model. Appl. Sci. 2023, 13, 556. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, S.; Li, R.Y.M.; Mo, Y.; Yang, G.; Zhang, M. Experimental study on the mechanical properties of Guiyang red clay considering the meso micro damage mechanism and stress path. Sci. Rep. 2020, 10, 17449. [Google Scholar] [CrossRef] [PubMed]

- Xiang, P.; Wei, G.; Zhang, S.; Cui, Y.; Guo, H. Model Test on the Influence of Surcharge, Unloading and Excavation of Soft Clay Soils on Shield Tunnels. Symmetry 2021, 13, 2020. [Google Scholar] [CrossRef]

- Song, Y.; Geng, Y.; Dong, S.; Ding, S.; Xu, K.; Yan, R.; Liu, F. Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability 2023, 15, 4411. [Google Scholar] [CrossRef]

- Dhar, S.; Hussain, M. The strength and microstructural behavior of lime stabilized subgrade soil in road construction. Int. J. Geotech. Eng. 2021, 15, 471–483. [Google Scholar] [CrossRef]

- Mohamed, A.A.M.S.; Yuan, J.; Al-Ajamee, M.; Dong, Y.; Ren, Y.; Hakuzweyezu, T. Improvement of expansive soil characteristics stabilized with sawdust ash, high calcium fly ash and cement. Case Stud. Constr. Mater. 2023, 18, e01894. [Google Scholar] [CrossRef]

- Barman, D.; Dash, S.K. Stabilization of expansive soils using chemical additives: A review. J. Rock Mech. Geotech. Eng. 2022, 14, 1319–1342. [Google Scholar] [CrossRef]

- Abdullah, H.H.; Shahin, M.A.; Walske, M.L. Review of Fly-Ash-Based Geopolymers for Soil Stabilisation with Special Reference to Clay. Geosciences 2020, 10, 249. [Google Scholar] [CrossRef]

- Tajaddini, A.; Saberian, M.; Kamalzadeh Sirchi, V.; Li, J.; Maqsood, T. Improvement of mechanical strength of low-plasticity clay soil using geopolymer-based materials synthesized from glass powder and copper slag. Case Stud. Constr. Mater. 2023, 18, e01820. [Google Scholar] [CrossRef]

- Ho, L.S.; Nakarai, K.; Duc, M.; Kouby, A.L.; Maachi, A.; Sasaki, T. Analysis of strength development in cement-treated soils under different curing conditions through microstructural and chemical investigations. Constr. Build. Mater. 2018, 166, 634–646. [Google Scholar] [CrossRef]

- Hosseini, S.; Brake, N.A.; Nikookar, M.; Günaydın-Şen, Ö.; Snyder, H.A. Enhanced strength and microstructure of dredged clay sediment-fly ash geopolymer by mechanochemical activation. Constr. Build. Mater. 2021, 301, 123984. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, A.; Jaksa, M. Enhancing mechanical behavior of micaceous soil with jute fibers and lime additives. J. Rock Mech. Geotech. Eng. 2021, 13, 1093–1100. [Google Scholar] [CrossRef]

- Moreira, E.B.; Baldovino, J.d.J.A.; Luis dos Santos Izzo, R.; Rose, J.L. Impact of Sustainable Granular Materials on the Behavior Sedimentary Silt for Road Application. Geotech. Geol. Eng. 2020, 38, 917–933. [Google Scholar] [CrossRef]

- Banzibaganye, G.; Twagirimana, E.; Kumaran, G.S. Strength Enhancement of Silty Sand Soil Subgrade of Highway Pavement Using Lime and Fines from Demolished Concrete Wastes. Int. J. Eng. Res. Afr. 2018, 36, 74–84. [Google Scholar] [CrossRef]

- Baldovino Jair, A.; Moreira Eclesielter, B.; Izzo, R.L.D.S.; Rose Juliana, L. Empirical Relationships with Unconfined Compressive Strength and Split Tensile Strength for the Long Term of a Lime-Treated Silty Soil. J. Mater. Civ. Eng. 2018, 30, 06018008. [Google Scholar] [CrossRef]

- Jamsawang, P.; Charoensil, S.; Namjan, T.; Jongpradist, P.; Likitlersuang, S. Mechanical and microstructural properties of dredged sediments treated with cement and fly ash for use as road materials. Road Mater. Pavement Des. 2021, 22, 2498–2522. [Google Scholar] [CrossRef]

- Atahu, M.K.; Saathoff, F.; Gebissa, A. Strength and compressibility behaviors of expansive soil treated with coffee husk ash. J. Rock Mech. Geotech. Eng. 2019, 11, 337–348. [Google Scholar] [CrossRef]

- Sukmak, P.; Sukmak, G.; Horpibulsuk, S.; Setkit, M.; Kassawat, S.; Arulrajah, A. Palm oil fuel ash-soft soil geopolymer for subgrade applications: Strength and microstructural evaluation. Road Mater. Pavement Des. 2019, 20, 110–131. [Google Scholar] [CrossRef]

- Sukprasert, S.; Hoy, M.; Horpibulsuk, S.; Arulrajah, A.; Rashid, A.S.A.; Nazir, R. Fly ash based geopolymer stabilisation of silty clay/blast furnace slag for subgrade applications. Road Mater. Pavement Des. 2021, 22, 357–371. [Google Scholar] [CrossRef]

- Panich, V.; Suksun, H.; Chairat, T. Bagasse ash–fly ash-geopolymer-treated soft Bangkok clay as subgrade material. Environ. Geotech. 2019, 40, 1–8. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Bo, M.W.; Darmawan, S. Effects of industrial by-product based geopolymers on the strength development of a soft soil. Soils Found. 2018, 58, 716–728. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Arulrajah, A.; Horpibulsuk, S. Engineering Behaviour of a Geopolymer-stabilised High-water Content Soft Clay. Int. J. Geosynth. Ground Eng. 2022, 8, 45. [Google Scholar] [CrossRef]

- Eslami, A.; Akbarimehr, D. Failure analysis of clay soil-rubber waste mixture as a sustainable construction material. Constr. Build. Mater. 2021, 310, 125274. [Google Scholar] [CrossRef]

- Moreira, E.B.; Baldovino, J.A.; Rose, J.L.; Luis dos Santos Izzo, R. Effects of porosity, dry unit weight, cement content and void/cement ratio on unconfined compressive strength of roof tile waste-silty soil mixtures. J. Rock Mech. Geotech. Eng. 2019, 11, 369–378. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Nwonu, D.C. Resilient Modulus of Lime-Bamboo Ash Stabilized Subgrade Soil with Different Compactive Energy. Geotech. Geol. Eng. 2019, 37, 3557–3565. [Google Scholar] [CrossRef]

- Kumar Sharma, N. Utilization of fly ash, lime sludge and polypropylene fiber as stabilizers to enhance soil properties. Mater. Today Proc. 2022, 65, 988–994. [Google Scholar] [CrossRef]

- Ural, N. The significance of scanning electron microscopy (SEM) analysis on the microstructure of improved clay: An overview. Open Geosci. 2021, 13, 197–218. [Google Scholar] [CrossRef]

- Ramezani Seyed, J.; Toufigh Mohammad, M.; Toufigh, V. Utilization of Glass Powder and Silica Fume in Sugarcane Bagasse Ash-Based Geopolymer for Soil Stabilization. J. Mater. Civ. Eng. 2023, 35, 04023042. [Google Scholar] [CrossRef]

- Rajabi, A.M.; Hamrahi, Z. An experimental study on the influence of metakaolin on mechanical properties of a clayey sand. Bull. Eng. Geol. Environ. 2021, 80, 7921–7932. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, Y.; Liu, S.; Liu, Q.; Chen, Y.; Zha, F. Strength and micro-structure evolution of compacted soils modified by admixtures of cement and metakaolin. Appl. Clay Sci. 2016, 127, 44–51. [Google Scholar] [CrossRef]

- Nwonu, D.C.; Mama, C.N. Delineating the Aptness of Improved Geomaterial Strength for Ground Improvement Through Microstructure and Cluster Analysis. Indian Geotech. J. 2021, 51, 1151–1165. [Google Scholar] [CrossRef]

- Murmu, A.L.; Jain, A.; Patel, A. Mechanical Properties of Alkali Activated Fly Ash Geopolymer Stabilized Expansive Clay. KSCE J. Civ. Eng. 2019, 23, 3875–3888. [Google Scholar] [CrossRef]

| Mineral Composition | SiO2 | Al2O3 | Fe2O3 | K2O | Others |

|---|---|---|---|---|---|

| Mass fraction (%) | 44.64 | 28.32 | 20.67 | 1.87 | 4.5 |

| Mineral Composition | SiO2 | Al2O3 | Fe2O3 | GaO | Others |

|---|---|---|---|---|---|

| Mass fraction (%) | 43.21 | 33.86 | 6.43 | 9.63 | 6.87 |

| Experimental Items | Experimental Instruments | Testing Parameters |

|---|---|---|

| Limit water content experiment | Liquid–plastic combined tester | Plastic limit Liquid limit |

| Compaction experiment | Standard portable compaction instrument | Optimal water content Maximum dry density |

| Direct shear experiment | Strain-controlled direct shear apparatus | Cohesion Friction angle |

| Unconfined compression experiment | Strain-controlled unconfined pressure gauge | Unconfined compressive strength |

| Consolidation experiment | Fully automatic consolidation instrument | Compression coefficient |

| Lime Content (%) | Cohesion (kPa) | Friction Angle (°) | Fly Ash Content (%) | Cohesion (kPa) | Friction Angle (°) | Lime: Fly Ash: Dry Soil | Cohesion (kPa) | Friction Angle (°) |

|---|---|---|---|---|---|---|---|---|

| 2 | 18 | 14 | 5 | 26 | 11 | 0:0:1 | 30 | 12.5 |

| 5 | 43 | 14 | 10 | 30 | 13 | 1:2:7 | 46 | 12.8 |

| 8 | 38 | 15 | 15 | 36 | 12 | 1:3:6 | 32 | 10.2 |

| 11 | 34 | 17 | 20 | 34 | 10 | 1:4:5 | 38 | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Yang, Z.; Zhu, H.; Dong, H. Experimental Study on the Mechanical Properties of Xinyang Red Clay Improved by Lime and Fly Ash. Appl. Sci. 2023, 13, 6271. https://doi.org/10.3390/app13106271

Tang H, Yang Z, Zhu H, Dong H. Experimental Study on the Mechanical Properties of Xinyang Red Clay Improved by Lime and Fly Ash. Applied Sciences. 2023; 13(10):6271. https://doi.org/10.3390/app13106271

Chicago/Turabian StyleTang, Hui, Ziquan Yang, Hongtao Zhu, and Haoqiang Dong. 2023. "Experimental Study on the Mechanical Properties of Xinyang Red Clay Improved by Lime and Fly Ash" Applied Sciences 13, no. 10: 6271. https://doi.org/10.3390/app13106271

APA StyleTang, H., Yang, Z., Zhu, H., & Dong, H. (2023). Experimental Study on the Mechanical Properties of Xinyang Red Clay Improved by Lime and Fly Ash. Applied Sciences, 13(10), 6271. https://doi.org/10.3390/app13106271