1. Introduction

With the advances in infrastructure construction in China, the number of tunnels constructed is increasing year by year [

1,

2,

3,

4,

5]. The shield method has gradually become the mainstream method of tunnel construction, due to advantages which include a high degree of mechanization, high construction efficiency, and the possibility of performing construction with water, and it is widely used for the construction of highways, railways, electric power, urban rail transit, etc. [

6,

7,

8]. Disc cutters, as a direct tool used by the shield machine to break up rock and soil, has a crucial impact on the efficiency and safety of the construction of the shield tunnel. The use of an appropriate design for the disc cutter is extremely important in the construction of shield tunnels. There are many factors affecting the rock-breaking efficiency of disc cutters, including the size of the disc cutter, blade width, blade angle, blade fillet, the properties of the rock and soil, etc. [

9]. Therefore, to improve the rock-breaking efficiency of the disc cutter, it is necessary to optimize the design according to the factors influencing the rock breaking.

Many researchers have studied rock properties and the performance of disc cutters in recent years. In the numerical simulation of rock breaking with disc cutters, the most commonly used rock dynamic computational constitutive model is the HJC (Holmquist–Johnson–Cook) model [

10,

11,

12]. The HJC model was originally a constitutive model for simulating concrete taking into consideration the strain rate effects, damage effects, confining pressure effects, crushing effects and compaction effects when subjected to large strains, high strain rates, and high pressure [

13,

14]. Since the crushing process of rock is highly consistent with that of concrete, it can also be used to simulate the breaking behaviour of rock. In recent years, many scholars have studied methods for determining the HJC model parameters. Based on the concrete strength calculation formula proposed by the American Concrete Association, Zhang and Li [

15] gave a simple method for deriving other basic mechanical parameters in the HJC model from the uniaxial compressive strength, but the limitation of this method is that it does not include the limit surface parameters of the HJC model. Polanco-Loria et al. [

16,

17] enhanced the pressure-shear behaviour of the HJC model and changed the modelling of strain rate sensitivity so that the enhancement factor of strain rate goes to unity for a strain rate of zero. Based on the yield surface theory, Xiong et al. [

18,

19] established the relationship between the cohesion strength and the parameters of the Mohr–Coulomb criterion and proposed a method for obtaining the limit surface parameters of the HJC model. Zhang et al. [

20] proposed a method for determining the failure strength parameters and obtained the value of the failure strength parameters. Fang et al. [

21] derived the relationship between the cohesion parameter and the cap model parameters based on the plastic yield surface theory. Sun et al. [

22] analysed the failure type parameter in the parameters of the HJC model, studied the influence of this parameter on concrete compaction failure, and determined its value range. Su et al. [

23] investigated the previous studies and was able to obtain the strength parameters, state parameters, rate effect parameters, and damage parameters of the HJC model through the analysis and fitting of existing experimental data. In addition, the relevant parameters were revised according to the results of the shield cutting tool cutting concrete test. Since the HJC model was originally used to describe the failure behaviour of concrete, most of the initial parameters are not suitable for rock materials. Therefore, to accurately describe the failure behaviour of rocks, scholars have carried out many studies regarding the determination of the parameters of the HJC model for rocks. At present, a series of HJC model parameters of rocks or rock-like media have been determined, including limestone, granite porphyry, granite, sandstone, marble, and coal [

24,

25,

26,

27,

28].

Scholars have performed research analysing the structural design and rock-breaking efficiency, and simulating the rock-breaking process of shield disc cutters. Regarding the structural design of disc cutters, Frenzel et al. [

29] found that changes in blade width had less effect on disc cutter wear. Zhao et al. [

30] designed a parametric model of the variable cross-section (VCS) cutter ring and used FEM to simulate rolling behaviour, and the results showed that the VCS cutter ring applied a periodic force to the rocks during the rolling process. With regard to rock-breaking efficiency, Teale [

31] proposed the concept of specific energy, which is defined as the energy required to excavate a unit volume of rock. Gertsch et al. [

32] found that the spacing between disc cutters had a greater impact on specific energy than penetration, and a spacing of 76 mm was close to optimum in hard and brittle crystalline rock. Ning et al. [

33] carried out a full-scale cutting test for a 432 mm disc cutter with three different blade widths, and found that the specific energy and optimal spacing were positively related to blade width. Scholars have also performed a lot of work on the numerical simulation of rock-breaking using shield disc cutters. Cho et al. [

34] used AUTODYN-3D to simulate the three-dimensional dynamic failure observed in LCM tests and determined the optimum cutter spacing by calculating the specific energy. Li et al. [

35] built a model of a disc cutter by Pro/E and carried out a numerical simulation of rock-breaking using the disc cutter. The results showed that the disc cutter was able to cut hard rock, and the contact force was in agreement with the common prediction formula for disc cutter forces, which showed that the modelling method was correct and feasible. Zhang et al. [

36] established five rock-breaking models for disc cutters with different diameters and penetrations, and found that with increasing disc cutter diameter and penetration, the contact force increased as well. Choi et al. [

37] implemented a numerical simulation of the optimum cutter spacing and failure aspects of Korean tuff, and the results were compared with those of the LCM test, showing that the numerical method was correct. Labra et al. [

38] created a numerical model that combined the advantages of DEM and FEM to more accurately simulate the rock-breaking process of a disc cutter. Zhou et al. [

39] developed a general particle dynamics code to simulate the rock-breaking process of a disc cutter in the mixed-face ground, and a novel algorithm of the contacts at the boundary between the two different media was proposed.

By investigating existing studies, it can be found that the existing research on the structural design and numerical simulation of disc cutters is not specific enough, and only describes the general influence of geometric configuration on the rock-breaking behaviour of the disc cutter, without further considering the influence of geometric configuration.

This paper aims to explore the influence of the geometric configuration of the disc cutter on the rock-breaking process and to provide guidance for the design and selection of the geometric configuration of the disc cutter.

Section 1 introduces the currently existing research and provides a brief introduction to the work carried out in this paper. In

Section 2, a comprehensive introduction to the HJC model is provided, including the strength equation, state equation, and damage equation. To ensure the accuracy of the numerical simulation,

Section 3 introduces a method for determining the parameters of the diorite HJC model in the Jinan area, and uses the uniaxial compression test, triaxial compression test, Brazilian splitting test and split Hopkinson compression bar test to determine the parameters of the HJC model in the Jinan area.

Section 4 describes the numerical simulation of the rock-breaking process of the disc cutter, including the establishment of the model and the results of the simulation, and identifies the geometric configuration that influences the rock-breaking behaviour, including aspects such as blade width and blade fillet, and reveals the influence of geometric configuration of the disc cutter on the rock-breaking process, including rock-breaking force and the impact range.

Section 5 summarizes the conclusions of this study.

2. An Overview of the HJC Model

The HJC (Holmquist–Johnson–Cook) constitutive model comprehensively considers the effects of high strain, high strain rate, and high pressure. This model is divided into three parts: the strength equation, the damage equation and the state equation.

2.1. Strength Equation

The strength equation in the HJC model is shown in

Figure 1, and its strength function is as follows:

The normalized dimensionless equivalent stress is expressed as a function of damage, pressure and strain rate. In this equation, σ* is defined as σ* = σ/fc′ (σ is the actual equivalent stress, fc′ is quasi-static uniaxial compressive strength); P* is defined as P* = P/fc′ (P is actual pressure); defined as ( is actual strain rate, is reference strain rate, ); A is the normalized cohesive strength; B is the normalized pressure hardening coefficient; C is the strain rate coefficient; and N is the pressure hardening exponent. Since σ* increases as P* increases, there is a limit value for σ*, defined as Smax, which is the normalized maximum intensity.

2.2. Damage Equation

The damage equation in the HJC model is shown in

Figure 2; its damage function is as follows, where

D is the damage factor (

):

In this equation, Δεp and Δμp are the equivalent plastic strain increment and plastic volumetric strain increment, respectively; D1(P* + T*) D2 is the fracture plastic strain under a constant pressure P, where D1 and D2 are both constants; T* = T/fc′, T is maximum tensile hydrostatic strength. Since the rock material cannot bear any plastic strain when P* = −T*, and the damage factor increases with increasing P*, the third damage constant, namely the minimum damage constant εfmin, is added; EFmin is the minimum plastic strain when the material is fractured, which is used to control the brittle cracking of the material caused by the tensile stress.

2.3. State Equation

The state equation in the HJC model can be divided into three regions: the linear elastic region, the transition region, and the fully dense region.

(1) Linear elastic region (0 ≤ μ ≤ μcrush)

The pressure in the linear elastic region is expressed as follows:

In this equation, P is pressure; μ is volumetric strain, μ = (ρ/ρ0) − 1; ρ and ρ0 are the current density and initial density, respectively; Kelastic is the elastic bulk modulus, Kelastic = Pcrush/μcrush, Pcrush and μcrush are pressure and volumetric strain under the elastic compression limit.

(2) Transition region (μcrush < μ ≤ μlock)

In this region, the air is gradually compressed out of the holes of the rock material, and there will be a plastic volumetric strain in the rock material. At this time, the pressure of the material during loading and unloading is expressed as follows:

In this equation,

μlock and

Plock are volumetric strain and pressure, respectively, in the transition region;

F is the unloading coefficient, which is expressed as follows:

(3) Fully dense region (μlock < μ)

In this region, the air is fully removed from the rock mass. At this time, the pressure of the material during loading and unloading is expressed as follows:

In this equation, is the modified volumetric strain; μlock is the volumetric strain of the rock material compaction point; and K1, K2 and K3 are rock material constants.

3. Determination of HJC Model Parameters of Diorite in the Jinan Region

The diorite specimen used in this paper was taken from a shield tunnel project on Jinan metro line 2. The specimen was of uniform material, and fine and dense in particle composition. The diameter of the specimen was 50 mm, and the length was divided into three types. A specimen with a length of 100 mm was used for uniaxial compression and triaxial compression experiments, a specimen with a length of 50 mm was used for SHPB (split Hopkinson pressure bar) dynamic impact tests, and a specimen with a length of 25 mm was used for Split tensile tests. The specimens were finely ground at both ends of the test, and the non-parallelism was within 0.02 mm.

3.1. Determination of Basic Physical and Mechanical Parameters

The basic physical and mechanical parameters in the HJC model include density

ρ, uniaxial compressive strength

fc, elastic modulus

E, Poisson’s ratio

ν, shear modulus

G, and bulk modulus

K. Among these parameters, the density is determined using the wax seal method. Uniaxial static compressive strength, maximum tensile hydrostatic pressure and corresponding strain were determined by uniaxial compression experiments, and other basic mechanical parameters were obtained using Formulas (10)–(14). The basic physical and mechanical parameters of diorite in the Jinan region are shown in

Table 1.

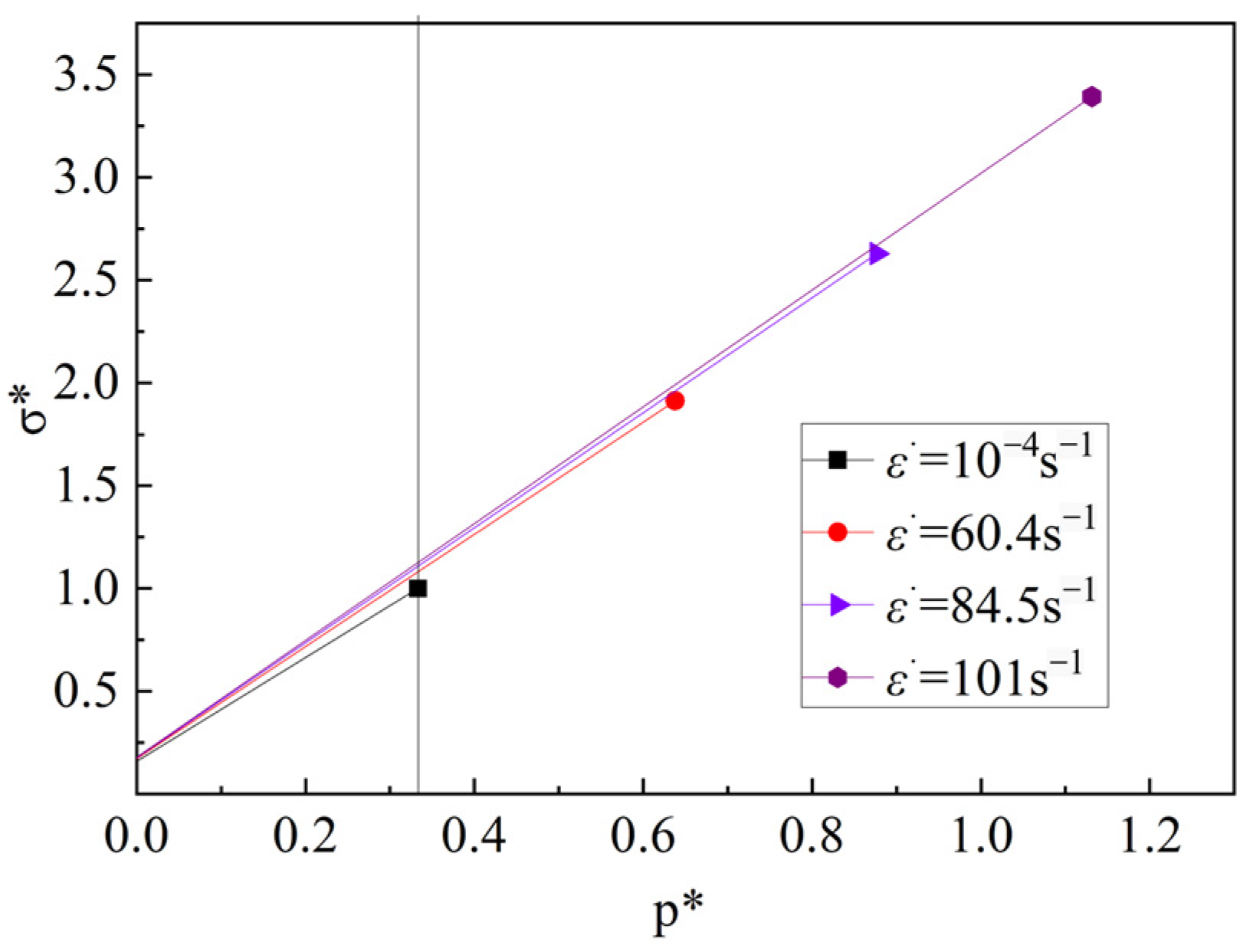

3.2. Determination of Strain Rate Constant

The strain rate constant

C was determined using the SHPB test. To obtain the strain rate effect alone, the pressure effect must be removed.

Figure 1 presents the technique used to remove the pressure effect and obtain the strain rate constant. Firstly, starting from the maximum hydrostatic pressure

T*(

T* =

T/fc = 0.063), a straight line was drawn through each test date. Moreover, the slope of the straight line represented the strain A measure of the rate effect. Secondly, by making a straight line parallel to the vertical axis corresponding to the constant normalized pressure,

p* = 1/3, and intersecting the straight lines with different slopes. The characteristic strength under the same constant normalized pressure with different strain rates can be obtained, and the pressure effect was removed. The strain rate constant

C is obtained by fitting the data points from the characterized stress at different strain rates,

C = 0.00103, as shown in

Figure 2.

3.3. Determination of Limit Surface Parameters

(1) Determination of strength constant A

If the effects of damage and strain rate are not considered, the limit surface equation of HJC model can be expressed as follows:

Since Equation (15) does not consider the influence of the Rohde angle, the projection of the limit surface on the partial plane is the Mises circle. According to the plastic theory, when the Rhodes angle is 60°, the compression meridian of the Mises criterion on the deviated plane is connected to the compression meridian of the M-C criterion. The expression of the M-C criterion is expressed as shown in Formula (16).

In this equation, c and φ are cohesive strength and internal friction angle, respectively. According to the data of triaxial experimental under different confining pressures, an envelope of this group of Mohr circles was obtained, and the cohesive strength c is 49.12 MPa.

It can be seen from the above analysis that if the Mohr–Coulomb criterion satisfies the linear relationship, the strength constant A is equal to c/fc, and the quasi-static cohesive strength (when ) can be obtained at the same time, A = 0.251. When normalized strain rates , A = 0.251/(1 + Cln10−4) = 0.254 were obtained.

(2) Determination of strength constants B and N

Triaxial compression tests were performed using a triaxial compression apparatus. Under different confining pressure conditions, according to Formulas (17) and (18), the different hydrostatic pressures

p and the corresponding maximum differential pressure Δ

σ are measured. Normalizing maximum differential pressure Δ

σ as shown in Formula (19), a series of points (

,

) was obtained. Then, to obtain the values of the strength constants

B and

N, the data points were fitted as shown in Formula (20).

Figure 3 shows the test data and fitting results. The strength constants

B and

N are 1.695 and 0.742, respectively.

3.4. Determination of State Equation Parameters

The pressure constants of diorite are as follows:

where

ρg and

ρ0 are grain density and real density respectively.

The values of

K1,

K2, and

K3 can be obtained from the Hugoniot test for diorite. The parameters are derived from the existing research results and obtained by fitting, as shown in

Figure 4. Based on the fitting results,

K1 = 94.7 GPa,

K2 = 632.4 GPa,

K3 = 938.1 GPa.

= 2.2 GPa is the pressure at which all the air voids are removed from the rock.

is determined by providing the best fit to the data.

3.5. Determination of Damage Model Constants

Figure 5 shows the stress–strain results for a cylinder subjected to SHPB cyclic compression loading test. An assumed failure surface is defined on the basis of the test results. The tangent line from the failure surface intersects with the x-axis, and the intersection point is

EFmin. The value of

EFmin is 0.00977, as shown in

Figure 5.

Previous studies have shown that D2 has little effect on the results. Therefore, following the previous calculation method, first assume that D2 = 1.0, then determine the value of D1 according to Formula (3), D1 = 0.0312.

5. Discussion

It can be seen in

Figure 16a,b that, among the three types of disc cutter with different blade fillets and a blade width of 22 mm, the contact force of the disc cutter with a blade fillet of 0 mm was smaller than that of the disc cutter with a blade fillet of 5 mm and larger than that of the disc cutter with a blade fillet of 9 mm when the penetration was 5 mm. Its growth rate was faster, and its contact force was obviously greater than that of the other two kinds of disc cutter when the penetration exceeded 10 mm. When the penetration was 5 mm, the contact force of the disc cutter with a blade fillet of 5 mm was greater than that of the others, but with increasing penetration, the increment in the contact force was smaller, and the growth rate was relatively stable. The contact force of the disc cutter with a blade fillet of 9 mm was smaller than that of the others under all penetration conditions, and with increasing penetration, its increment was relatively stable and approximately linear.

It can be seen in

Figure 16c,d that the range and standard deviation of the contact force of the disc cutter with a blade fillet of 0 mm was significantly greater than that of the other two kinds of disc cutter with different blade fillets. The range of the contact force of the disc cutter with a blade fillet of 5 mm increased slightly when the penetration was increased from 5 mm to 15 mm, and then increased rapidly. In addition, its standard deviation changed slightly with increasing penetration. The growth trend of the range and standard deviation of the contact force of the disc cutter with a blade fillet of 9 mm were similar to those of the disc cutter with a blade fillet of 5 mm, but the values were lower.

According to the analysis of the contact force of the three kinds of disc cutter with different blade fillets and a blade width of 22 mm under different penetration depths, it can be seen that the contact force of the disc cutter with a blade fillet of 0 mm was relatively large during the rock breaking process. Moreover, the contact force fluctuated more violently than in the other cases. Although the influence range of the disc cutter during rock breaking was larger than that of the other two types of disc cutter, it was easy for damage to be caused to the cutter due to the more violent cyclic loading in the actual use process. The contact force of the disc cutter with a blade fillet of 5 mm was greater than that of the disc cutter with a blade fillet of 9 mm at all penetration depths, and their growth trends were similar. The range of contact force and standard deviation both increased with increasing penetration, and were both larger than those of the disc cutter with a blade fillet of 9 mm. However, the increment in standard deviation was relatively small, and the growth rate was relatively stable. The contact force, range and standard deviation of the disc cutter with a blade fillet of 9 mm were smaller than those of the other two kinds of disc cutter under different penetration depths. The contact force range increased with increasing penetration. In addition, the standard deviation of contact force remained basically unchanged with increasing penetration, so the fluctuation in the contact force of this kind of disc cutter was the smallest among these disc cutters under different penetration depths, but the influence range of the disc cutter during rock breaking was also relatively small.

It can be seen from

Figure 19 that, among the four types of disc cutters with 5 mm blade fillets and different blade widths, the disc with a blade width of 19 mm showed a small increase in contact force with penetration within the range of 5–15 mm. The increase in the contact force of the three other kinds of disc cutter was relatively consistent, but it can be clearly seen that the contact force increases with increasing blade width. In addition, the range and standard deviation of the contact force of the disc with a blade width of 19 mm were smaller than those of the other three kinds of disc cutter. Although the range of the contact force increased in a fluctuating manner with increasing penetration depth, the overall growth rate was low. The contact force range of the disc cutter with a blade width of 22 mm increased approximately linearly with increasing penetration, with a relatively stable growth trend, and the standard deviation of the contact force was closer to that of the disc cutter with a blade width of 19 mm. The contact force range of the disc cutters with blade widths of 25 mm and 28 mm generally showed a near-linear growth trend, and the standard deviation of their growth trend was relatively stable. However, the overall values of range and standard deviation were obviously greater than those of the disc cutters with blade widths of 19 mm and 22 mm. In terms of the influence range of the disc cutter during rock breaking, it can be clearly seen that the influence range increased with increasing blade width, but the shape remained basically unchanged.

At present, most of the research on shield disc cutters is focused on the influence of the shield tunnelling parameters on the rock-breaking behaviour of the disc cutter. In this paper, the influence of the geometric configuration of a single disc cutter on rock-breaking behaviour was analysed in detail, in order to be able to provide certain guidelines for the selection of disc cutters during shield tunnel construction. Although founded on a study of a single disc cutter, this is only a small part of the total rock-breaking behaviour of the shield machine, and therefore the rock-breaking behaviour of the group of disc cutters present in the cutter-head should be further explored. In follow-up research, in order to validate the rock-breaking behaviour of a single disc cutter, a more detailed and systematic study of the rock-breaking behaviour of groups of disc cutters will be carried out.

In the current rock-breaking simulation of a shield disc cutter, the HJC model was used as the constitutive model for the rock. However, previous studies have seldom determined the parameters of the HJC model of the targeted rock, rather mainly opting to use existing HJC models. In addition, most of the parameters are taken from the concrete HJC model. In this paper, the parameters of the HJC constitutive model were determined for the diorite in the Jinan area, so the simulation results are more accurate and closer to the actual situation in engineering practice.

The HJC model is used for the simulation of rock and concrete under large deformation and high strain rates. In the early stage, it was mainly used in high-speed interactions such as bullet–concrete penetration. For the rock-breaking behaviour of the disc cutter, the speed of the disc cutter is relatively slow (the running speed of the disc cutter is generally ≤2 m/s), so the HJC model has certain limitations when simulating rock-breaking behaviour in the cutter–rock interaction, and is different from the actual situation. Therefore, in follow-up research, a new constitutive model should be developed according to the characteristics of the rock-breaking behaviour of the disc cutter to ensure a better match between the simulation and the actual construction.

In the actual shield construction, the disc cutter can easily maintain a penetration of about 10 mm in soft and medium-hardness rock formations (strength less than 30 MPa). In hard rock formations (strength greater than 50–100 MPa), penetration is generally 5–10 mm. However, it is difficult for the disc cutter to penetrate the rock, and the penetration is difficult to maintain. In extremely hard rock formations (strength greater than 120 MPa) and soft–hard mixed formations, it is difficult to penetrate the rock and the damage to the disc cutter will be more serious. At the same time, in order to reduce the amount of cutter damage, the penetration degree is generally maintained below 5 mm, and in most cases even less than 3 mm. Combined with the actual construction situation and the relevant research content in this paper, we give several basic suggestions for the configuration of disc cutters in different strata:

In soft and medium-hardness rock formations, the cutter penetrates easily, so the rock-breaking efficiency of the disc cutter should be improved as much as possible. This means that the rock-breaking influence range of the disc cutter should be increased. Therefore, it is recommended to use a disc cutter with a large blade width (25–28 mm) and a small blade fillet (0–5 mm);

In hard rock formations, it is difficult for the disc cutter to penetrate, so the ability of the disc cutter to penetrate the rock should be ensured. This will result in a reduction in the penetration force. Therefore, a disc cutter with a medium or small blade width (19–22 mm) and a medium blade fillet (9–10 mm) should be selected;

In extremely hard rock formations and soft–hard mixed formations, it is hard to penetrate the rock and the damage to the cutter is serious, so a balance between the life of the disc cutter and penetration ability should be found. Therefore, it is appropriate to use a disc cutter with a large blade width (28 mm) and a large blade fillet (15 mm).

6. Conclusions

This study mainly focuses on two aspects. First, to ensure the accuracy and validity of the numerical simulation, the parameters of the diorite HJC model in the Jinan area were determined. Secondly, the numerical simulation of a disc cutter with different blade widths and blade fillets was carried out using the parameters of the diorite HJC model in the Jinan area. The main conclusions of this study are enumerated below.

(1) The basic physical and mechanical parameters, the strain rate constant, the limit surface parameters, state equation parameters and damage model constants of diorite in the Jinan region were obtained by means of a series of experiments. Compared with previous numerical simulation studies on rock-breaking using disc cutters, this study obtained simulation results closer to the actual situation by measuring the rock parameters encountered in the actual project.

(2) The influence of the penetration degree on the contact force of the disc cutter and its range and standard deviation were investigated. With increasing penetration, the contact force of the disc cutter gradually increases, and the range of contact force fluctuates slightly and increases, but the standard deviation of the contact force remains stable.

(3) The influence of blade fillet and blade width on the rock-breaking behaviour of the disc cutter was analysed. When the penetration was the same, the larger the blade fillet, the smaller the contact force, as well as the range and the standard deviation of contact force. The influence range of the disc cutter during rock breaking decreases with increasing blade fillet. At the same penetration depth, the wider the blade width, the greater the contact force, range of contact force and standard deviation of contact force. Moreover, the influence range of the disc cutter during rock breaking increases with increasing blade width.

(4) The influence law of each factor described in this paper on the rock-breaking behaviour of the disc cutter provides a certain reference for the selection of disc cutters in future shield projects.

It is hoped that the research on the influencing factors of rock-breaking by disc cutters in this paper will be able to provide a certain reference for engineering in the construction of shield tunnels. The current research is mainly limited to the rock-breaking simulation of a single disc cutter, with the simulated cutter being an 18-inch disc cutter, and the research results were not further verified by laboratory experiments. In future research, the rock-breaking behaviour of 17–20 inch disc cutters should be explored extensively and in detail, in order to provide more effective and specific guidance for practical engineering. At the same time, research on the rock-breaking behaviour of groups of disc cutters should be carried out, and the overall rock-breaking ability and rock-breaking effect of the shield should be further discussed in a more macro and specific manner.