Infrared Nanosecond Laser Texturing of Cu-Doped Bioresorbable Calcium Phosphate Glasses

Abstract

:1. Introduction

2. Materials and Methods

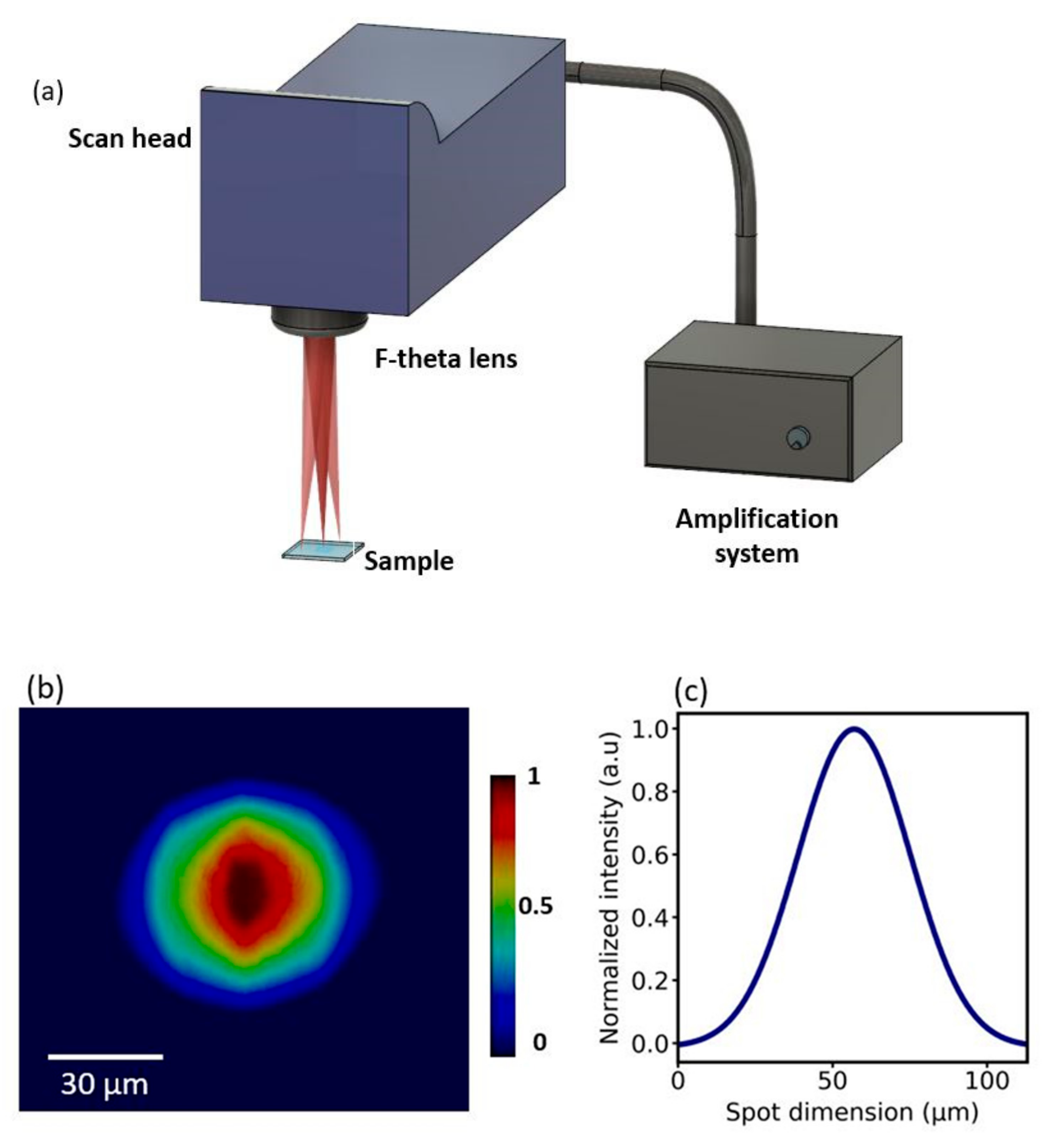

2.1. Glass Preparation and Laser Modification

2.2. Surface Characterization

3. Results and Discussion

3.1. Absorption Characteristics of Calcium Phosphate Glass

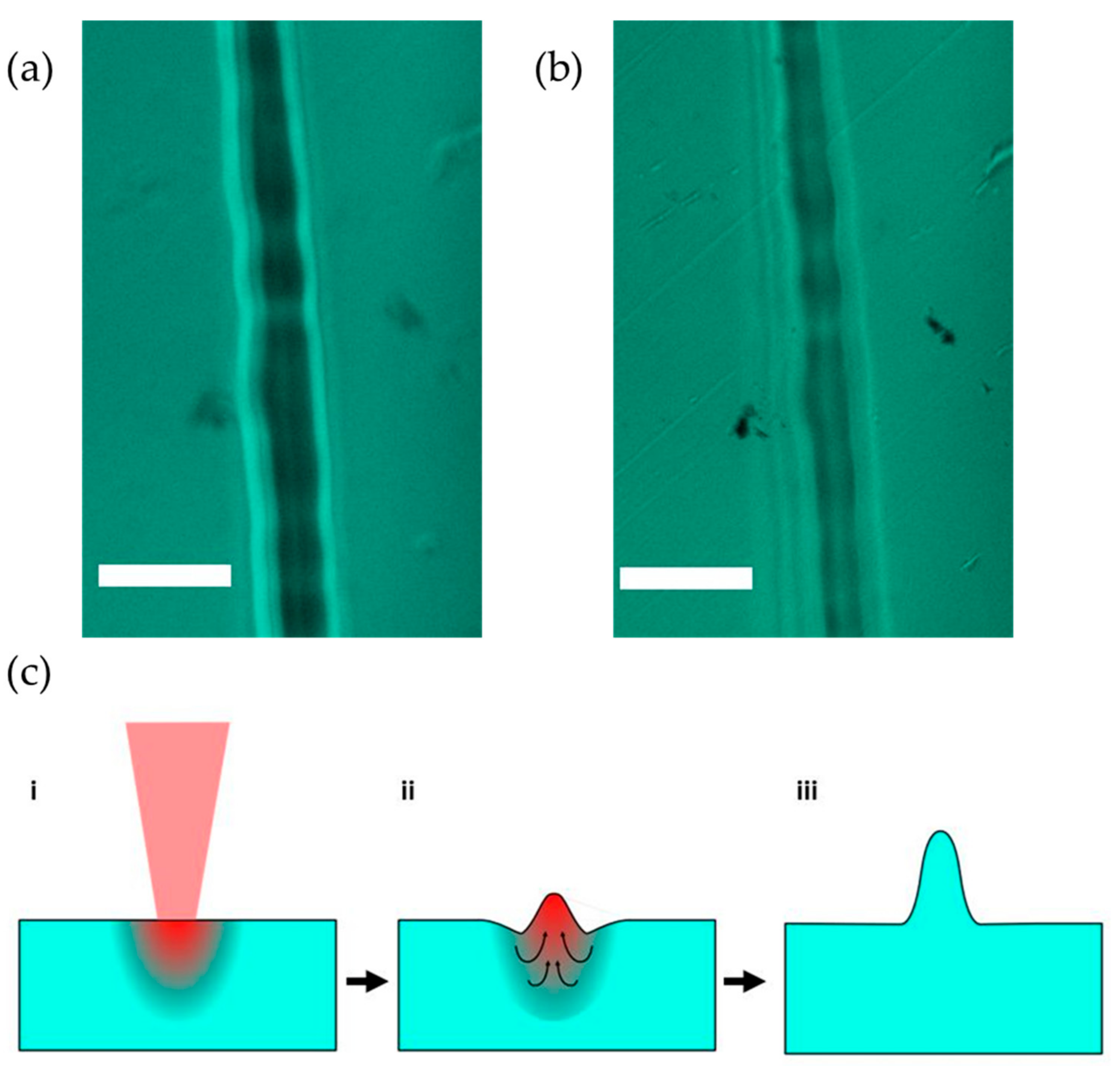

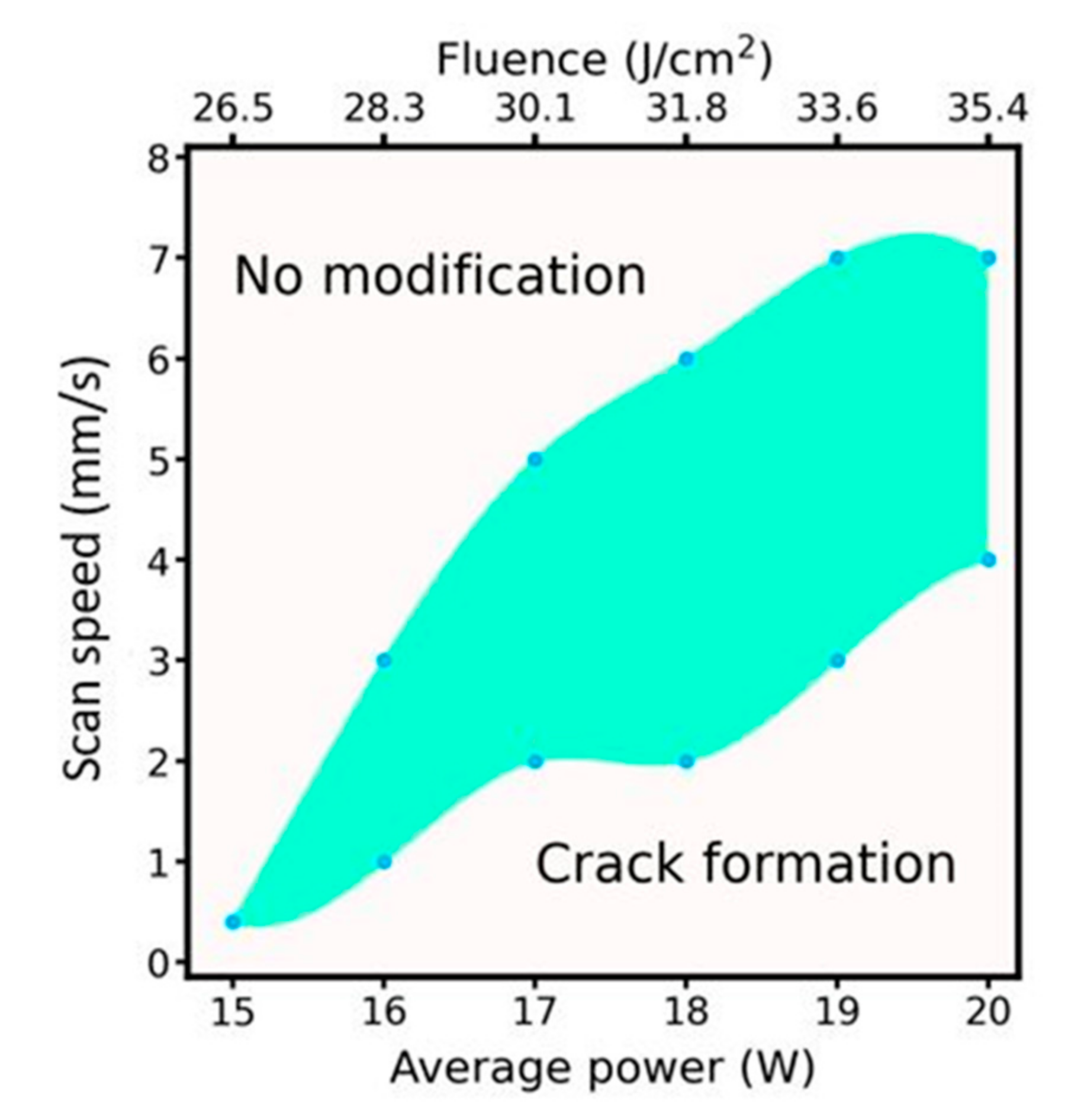

3.2. Glass Modification Threshold Test

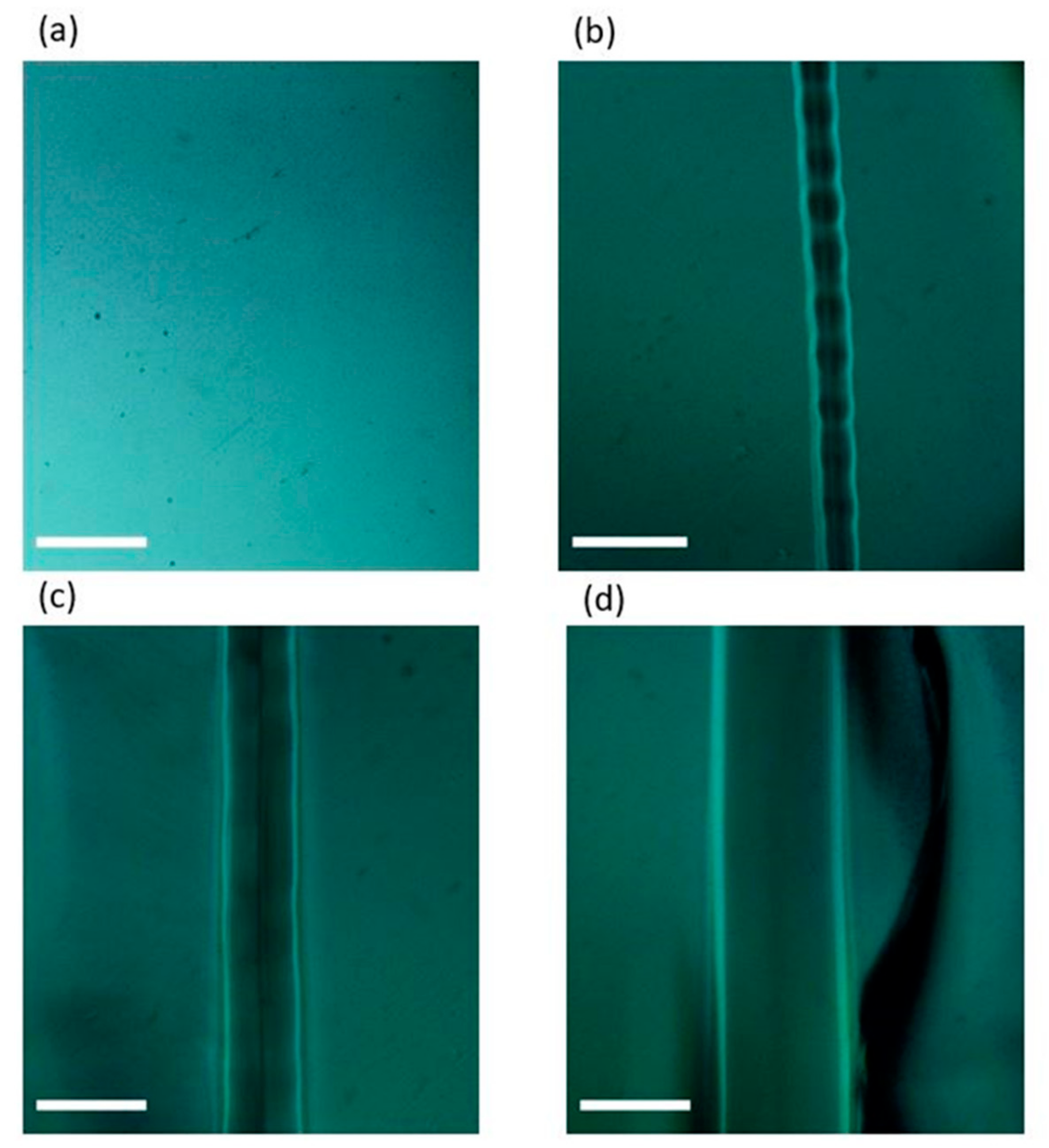

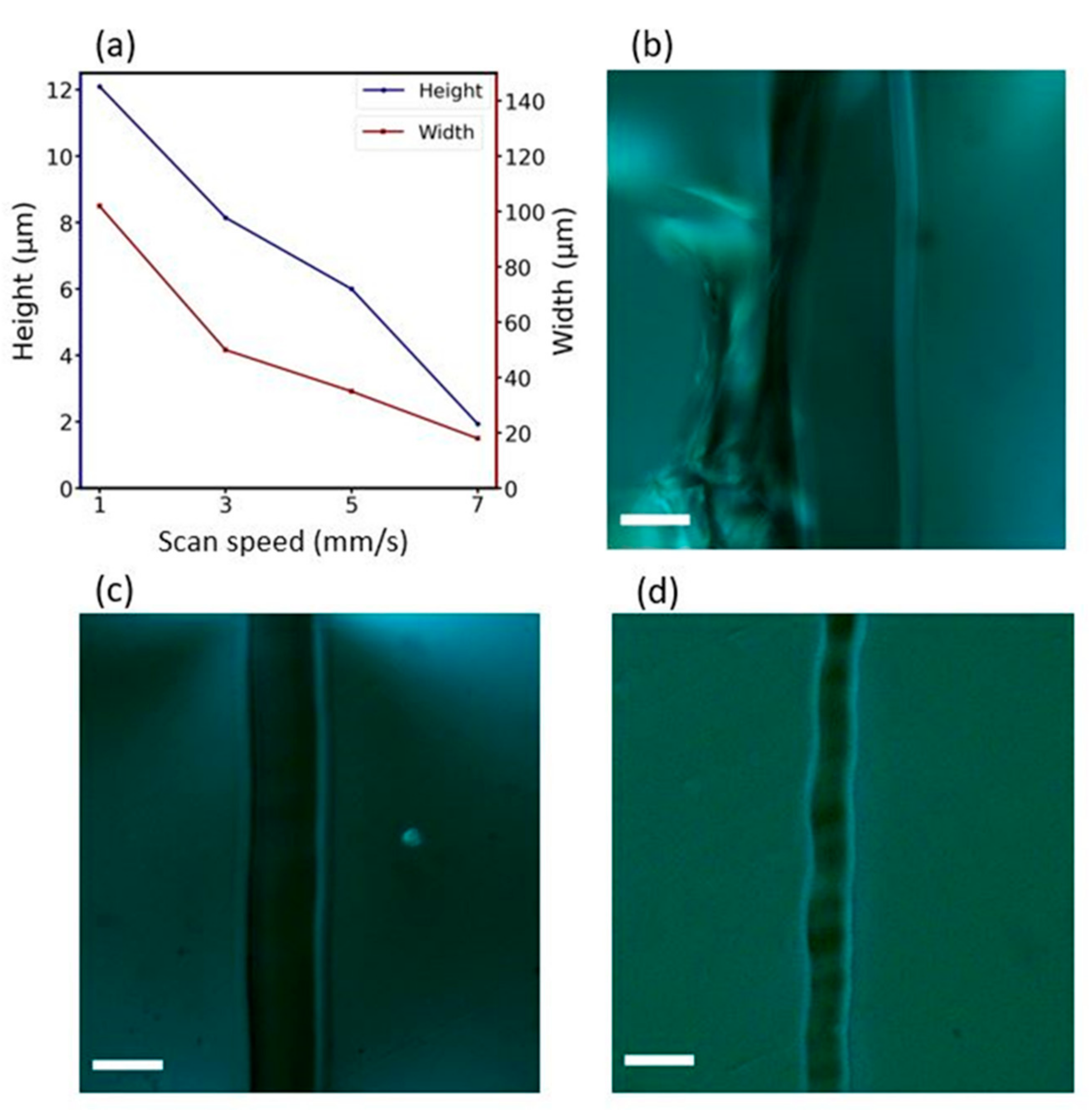

3.3. Scan Speed Effect on Morphology

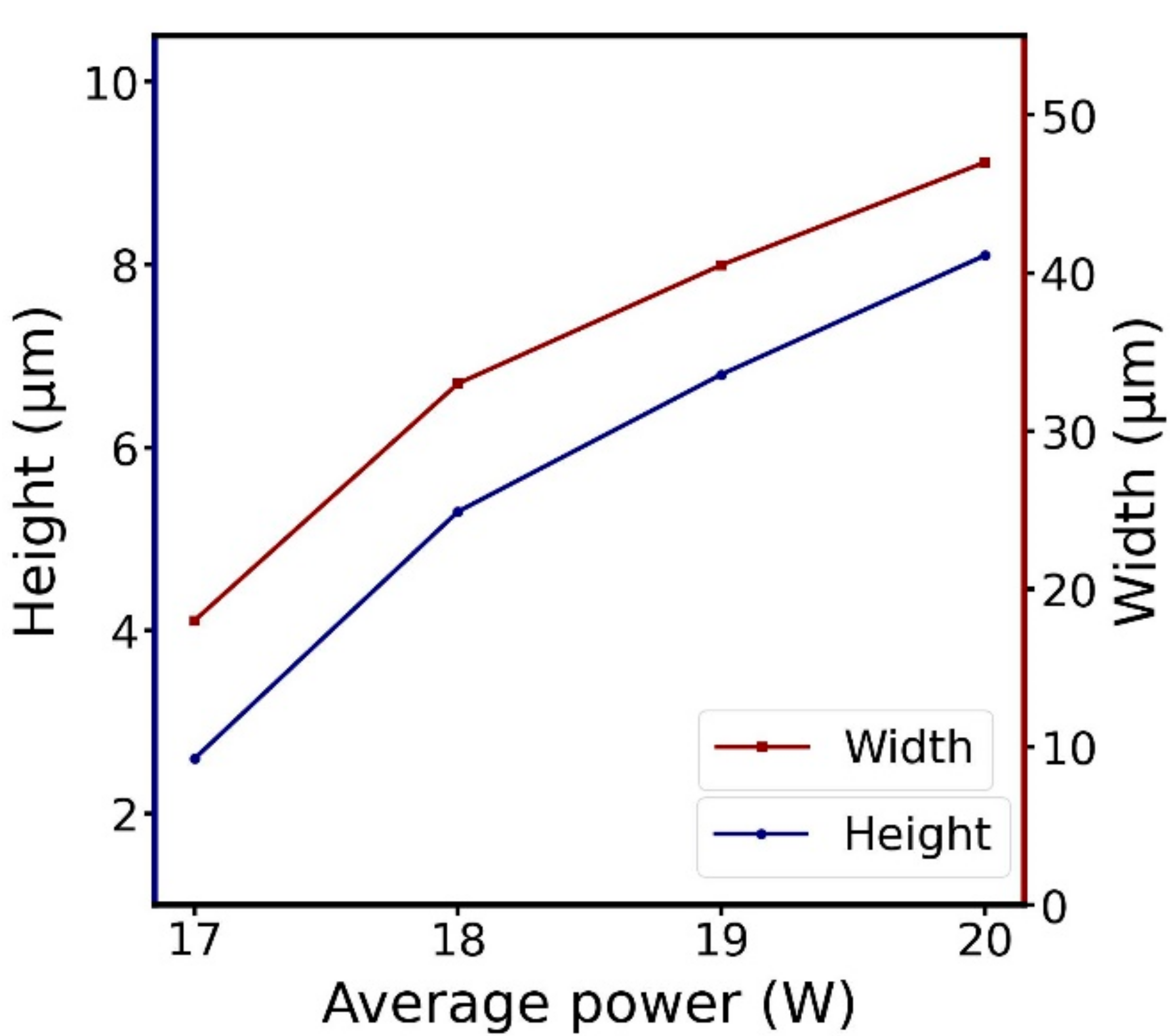

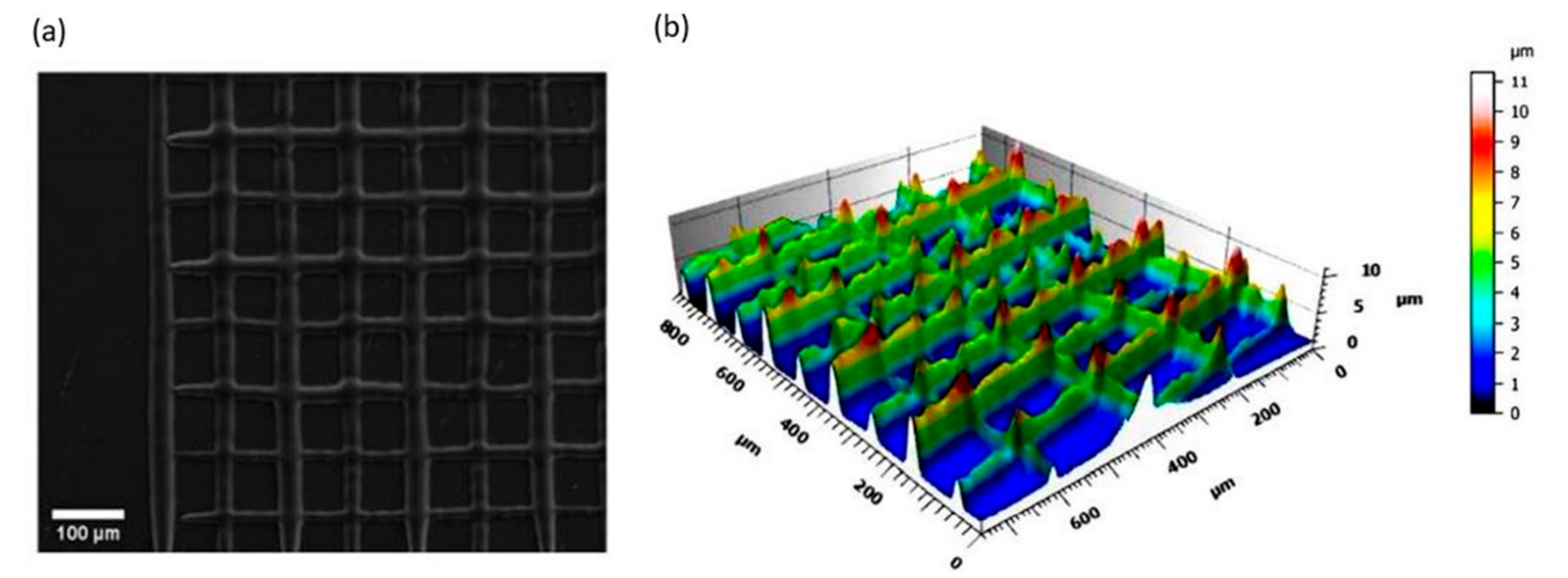

3.4. Optimal Parameters for Surface Processing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, T.; Yuan, Y.; Yalikun, Y.; Hosokawa, Y.; Li, M.; Tanaka, Y. Glass based micro total analysis systems: Materials, fabrication methods, and applications. Sens. Actuators B 2021, 339, 129859. [Google Scholar] [CrossRef]

- Ferraris, S.; Yamaguchi, S.; Barbani, N.; Cristallini, C.; Gautier di Confiengo, G.; Barberi, J.; Cazzola, M.; Miola, M.; Vernè, E.; Spriano, S. The mechanical and chemical stability of the interfaces in bioactive materials: The substrate-bioactive surface layer and hydroxyapatite-bioactive surface layer interfaces. Mater. Sci. Eng. C 2020, 116, 111238. [Google Scholar] [CrossRef] [PubMed]

- Al-Hadeethi, Y.; Sayyed, M.I.; Barasheed, A.Z.; Ahmed, M.; Jagannath, G. Nanosecond nonlinear optical, optical limiting and structural properties of Eu3+ activated antimony sodium borate glasses embedded with silver nanoparticles: Effect of heat treatment. Opt. Mater. 2022, 125, 112106. [Google Scholar] [CrossRef]

- Italia, V.; Giakoumaki, A.N.; Bonfadini, S.; Bharadwaj, V.; Le Phu, T.; Eaton, S.M.; Ramponi, R.; Bergamini, G.; Lanzani, G.; Criante, L. Laser-inscribed glass microfluidic device for non-mixing flow of miscible solvents. Micromachines 2019, 10, 23. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, J.M.F.; Rebelo, A. The key features expected from a perfect bioactive glass—How far we still are from an optimal composition? Biomed. J. Sci. Tech. Res. 2017, 1, 4–7. [Google Scholar]

- Kaur, G.; Kumar, V.; Baino, F.; Mauro, J.C.; Pickrell, G.; Evans, I.; Bretcanu, O. Mechanical properties of bioactive glasses, ceramics, glass-ceramics and composites: State-of-the-art review and future challenges. Mater. Sci. Eng. C 2019, 104, 109895. [Google Scholar] [CrossRef]

- Massera, J.; Mayran, M.; Rocherullé, J.; Hupa, L. Crystallization behavior of phosphate glasses and its impact on the glasses’ bioactivity. J. Mater. Sci. 2015, 50, 3091–3102. [Google Scholar] [CrossRef]

- Massera, J.; Petit, L.; Cardinal, T.; Videau, J.J.; Hupa, M.; Hupa, L. Thermal properties and surface reactivity in simulated body fluid of new strontium ion-containing phosphate glasses. J. Mater. Sci. Mater. Med. 2013, 24, 1407–1416. [Google Scholar] [CrossRef]

- Cannio, M.; Bellucci, D.; Roether, J.A.; Boccaccini, D.N.; Cannillo, V. Bioactive glass applications: A literature review of human clinical trials. Materials 2021, 14, 5440. [Google Scholar] [CrossRef]

- Islam, M.T.; Felfel, R.M.; Abou Neel, E.A.; Grant, D.M.; Ahmed, I.; Hossain, K.M.Z. Bioactive calcium phosphate–based glasses and ceramics and their biomedical applications: A review. J. Tissue Eng. 2017, 8, 1–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hyunh, N.B.; Palma, C.S.D.; Rahikainen, R.; Mishra, A.; Azizi, L.; Vernè, E.; Ferraris, S.; Hytönen, V.P.; Sanches Ribeiro, A.; Massera, J. Surface modification of bioresorbable phosphate glasses for controlled protein adsorption. ACS Biomater. Sci. Eng. 2021, 7, 4483–4493. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.; Noppari, P.; Boussard-Plédel, C.; Petit, L.; Massera, J. Changes in the mechanical properties of bioactive borophosphate fiber when immersed in aqueous solutions. Int. J. Appl. Glass Sci. 2020, 11, 622–631. [Google Scholar] [CrossRef]

- Farano, V.; Cresswell, M.; Gritsch, K.; Jackson, P.; Attik, N.; Grosgogeat, B.; Maurin, J.-C. Bioactivity evaluation of collagen-based scaffolds containing a series of Sr-doped melt-quench derived phosphate-based glasses. J. Mater. Sci. Mater. Med. 2018, 29, 101. [Google Scholar] [CrossRef]

- Gallichi-Nottiani, D.; Pugliese, D.; Boetti, N.G.; Milanese, D.; Janner, D. Toward the fabrication of extruded microstructured bioresorbable phosphate glass optical fibers. Int. J. Appl. Glass Sci. 2020, 11, 632–640. [Google Scholar] [CrossRef]

- Ceci-Ginistrelli, E.; Pontremoli, C.; Pugliese, D.; Barbero, N.; Boetti, N.G.; Barolo, C.; Visentin, S.; Milanese, D. Drug release kinetics from biodegradable UV-transparent hollow calcium-phosphate glass fibers. Mater. Lett. 2017, 191, 116–118. [Google Scholar] [CrossRef]

- Boetti, N.G.; Pugliese, D.; Ceci-Ginistrelli, E.; Lousteau, J.; Janner, D.; Milanese, D. Highly doped phosphate glass fibers for compact lasers and amplifiers: A review. Appl. Sci. 2017, 7, 1295. [Google Scholar] [CrossRef] [Green Version]

- Deb, P.; Deoghare, A.B.; Borah, A.; Barua, E.; Das Lala, S. Scaffold development using biomaterials: A review. Mater. Today Proc. 2018, 5, 12909–12919. [Google Scholar] [CrossRef]

- Jacobs, A.; Renaudin, G.; Forestier, C.; Nedelec, J.-M.; Descamps, S. Biological properties of copper-doped biomaterials for orthopedic applications: A review of antibacterial, angiogenic and osteogenic aspects. Acta Biomater. 2020, 117, 21–39. [Google Scholar] [CrossRef]

- Shaikh, S.; Singh, D.; Subramanian, M.; Kedia, S.; Singh, A.K.; Singh, K.; Gupta, N.; Sinha, S. Femtosecond laser induced surface modification for prevention of bacterial adhesion on 45S5 bioactive glass. J. Non-Cryst. Solids 2018, 482, 63–72. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.; Zhang, B.; Liu, Y.; Suo, X.; Li, H. Influence of surface topography on bacterial adhesion: A review (Review). Biointerphases 2018, 13, 060801. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Podrazký, O.; Peterka, P.; Kašík, I.; Vytykáčová, S.; Proboštová, J.; Mrázek, J.; Kuneš, M.; Závalová, V.; Radochová, V.; Lyutakov, O.; et al. In vivo testing of a bioresorbable phosphate-based optical fiber. J. Biophotonics 2019, 12, e201800397. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, H.; Shen, Y.; Xiong, Y.; Dong, L.; Zheng, J.; Zhao, S. Fabrication of porous β-TCP/58S bioglass scaffolds via top-down DLP printing with high solid loading ceramic-resin slurry. Mater. Chem. Phys. 2021, 267, 124587. [Google Scholar] [CrossRef]

- Accioni, F.; Vázquez, J.; Merinero, M.; Begines, B.; Alcudia, A. Latest trends in surface modification for dental implantology: Innovative developments and analytical applications. Pharmaceutics 2022, 14, 455. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Bala, N. Characterization, electrochemical behavior and in vitro hemocompatibility of hydroxyapatite-bioglass-iron oxide-chitosan composite coating by electrophoretic deposition. Surf. Coat. Technol. 2021, 405, 126564. [Google Scholar] [CrossRef]

- Baino, F.; Fiume, E.; Miola, M.; Verné, E. Bioactive sol-gel glasses: Processing, properties, and applications. Int. J. Appl. Ceram. Technol. 2018, 15, 841–860. [Google Scholar] [CrossRef]

- Butkutė, A.; Jonušauskas, L. 3D manufacturing of glass microstructures using femtosecond laser. Micromachines 2021, 12, 499. [Google Scholar] [CrossRef] [PubMed]

- Bushunov, A.A.; Tarabrin, M.K.; Lazarev, V.A. Review of surface modification technologies for mid-infrared antireflection microstructures fabrication. Laser Photonics Rev. 2021, 15, 2000202. [Google Scholar] [CrossRef]

- Foroutan, F.; McGuire, J.; Gupta, P.; Nikolaou, A.; Kyffin, B.A.; Kelly, N.L.; Hanna, J.V.; Gutierrez-Merino, J.; Knowles, J.C.; Baek, S.-Y.; et al. Antibacterial copper-doped calcium phosphate glasses for bone tissue regeneration. ACS Biomater. Sci. Eng. 2019, 5, 6054–6062. [Google Scholar] [CrossRef]

- Attallah, M.; Farouk, M.; El-Korashy, A.; ElOkr, M. Copper doped phosphate glass as an optical bandpass filter. Silicon 2018, 10, 547–554. [Google Scholar] [CrossRef]

- Jiménez, J.A.; Hansen, D. Insights into the composition-structure-property relationship in P2O5–CaO–Na2O–CuO bio-relevant glasses. Chem. Phys. Impact 2021, 3, 100029. [Google Scholar] [CrossRef]

- Paulose, P.I.; Jose, G.; Thomas, V.; Jose, G.; Unnikrishnan, N.V.; Warrier, M.K.R. Spectroscopic studies of Cu2+ ions in sol-gel derived silica matrix. Bull. Mater. Sci. 2002, 25, 69–74. [Google Scholar] [CrossRef]

- Shin, J.; Nam, K. Groove formation in glass substrate by a UV nanosecond laser. Appl. Sci. 2020, 10, 987. [Google Scholar] [CrossRef] [Green Version]

- Fujino, S.; Hwang, C.; Morinaga, K. Surface tension of PbO-B2O3 and Bi2O3-B2O3 glass melts. J. Mater. Sci. 2005, 40, 2207–2212. [Google Scholar] [CrossRef]

- Tsang, S.; Sun, C.-L. Utilizing the inverse Marangoni convection to facilitate extremely-low-flow-rate intermittent spray cooling for large-area systems. Appl. Therm. Eng. 2020, 166, 114725. [Google Scholar] [CrossRef]

- Grzybowski, R.; Logunov, S.; Streltsov, A.; Sutherland, J. Extraordinary laser-induced swelling of oxide glasses. Opt. Express 2009, 17, 5058–5068. [Google Scholar] [CrossRef] [PubMed]

- Qian, Y.; Jiang, M.; Zhang, Z.; Huang, H.; Yan, J. On the transformation between micro-concave and micro-convex in nanosecond laser ablation of a Zr-based metallic glass. J. Manuf. Processes 2021, 68, 1114–1122. [Google Scholar] [CrossRef]

- Zahn, D.; Seiler, H.; Windsor, Y.W.; Ernstorfer, R. Ultrafast lattice dynamics and electron–phonon coupling in platinum ex-tracted with a global fitting approach for time-resolved polycrystalline diffraction data. Struct. Dyn. 2021, 8, 064301. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menon, D.M.N.; Pugliese, D.; Janner, D. Infrared Nanosecond Laser Texturing of Cu-Doped Bioresorbable Calcium Phosphate Glasses. Appl. Sci. 2022, 12, 3516. https://doi.org/10.3390/app12073516

Menon DMN, Pugliese D, Janner D. Infrared Nanosecond Laser Texturing of Cu-Doped Bioresorbable Calcium Phosphate Glasses. Applied Sciences. 2022; 12(7):3516. https://doi.org/10.3390/app12073516

Chicago/Turabian StyleMenon, Devanarayanan Meena Narayana, Diego Pugliese, and Davide Janner. 2022. "Infrared Nanosecond Laser Texturing of Cu-Doped Bioresorbable Calcium Phosphate Glasses" Applied Sciences 12, no. 7: 3516. https://doi.org/10.3390/app12073516

APA StyleMenon, D. M. N., Pugliese, D., & Janner, D. (2022). Infrared Nanosecond Laser Texturing of Cu-Doped Bioresorbable Calcium Phosphate Glasses. Applied Sciences, 12(7), 3516. https://doi.org/10.3390/app12073516