Systematic Literature Review of MBSE Tool-Chains

Abstract

:1. Introduction

- The tools in the workflow support system formalisms in the activities of product development, such as system requirements, design, analysis, and V&V.

- The tools in the workflow support the formalisms of system functional and non-functional aspects, such as process management and dependability.

- The tools are required to support heterogeneous model integration for system-level verification.

- The tools are required to support data, knowledge, and information exchange, and to execute model transformations within the system development process.

- While constructing the MBSE tool-chains, a unified ontology is defined to support the entire formalism of systems engineering workflows.

- The tool-chain enables the integration of existing engineering tools and system development platforms for project management and process management.

2. Research Methodology

2.1. Research Questions

- RQ 1: What is the intensity of the research on MBSE tool-chains? This research question was designed to identify the scope of research topics associated with MBSE tool-chains. The investigated views are summarized in Table 1.

- RQ 2: What are the most frequently investigated research areas related to MBSE tool-chains? Furthermore, what application areas have they been used in? This research question was used to analyze how MBSE tool-chains support researchers’ work in systems engineering and to capture which domains they are in. It was analyzed by the given information about application domains and functionalities of MBSE tool-chains, as illustrated in Table 1.

- RQ 3: What are the most frequently applied research types and research methods? This question was used to understand which techniques can be used to construct MBSE tool-chains. Four aspects were considered: social perspective, process, information, and technical perspective based on the SPIT framework for tool-chain development [3]:

- The social perspective refers to an explicit network of stakeholders related to system development as well as environmental constraints and policies regarding MBSE tool-chain development and implementation. We focused on identifying stakeholders, referring to authors and their relevant studies.

- The process aspect refers to development processes of the target systems developed using MBSE tool-chains. For this survey, we focused on the development phases in which the tool-chains are implemented.

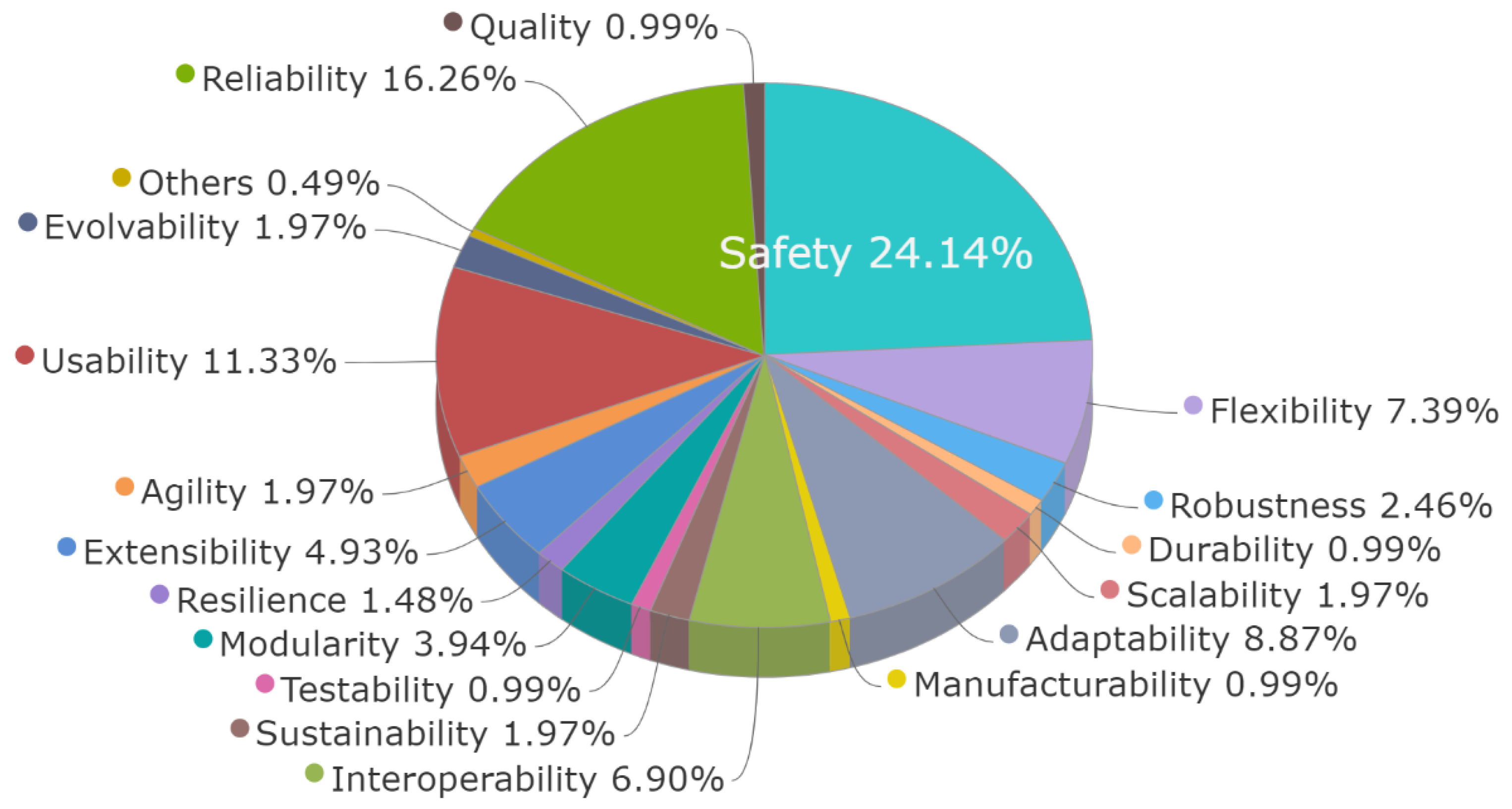

- The information refers to system artifacts of complex systems. We focused on understanding the life properties from a system engineering perspective, which the MBSE tool-chains aim at. The life properties were selected based on Olivier’s definitions [16], including: (1) quality; (2) reliability; (3) safety; (4) flexibility; (5) robustness; (6) durability; (7) scalability; (8) adaptability; (9) usability; (10) interoperability; (11) sustainability; (12) testability; (13) modularity; (14) resilience; (15) extensibility; (16) agility; (17) manufacturability; (18) repairability; and (19) evolvability.

- The technical perspective refers to the related technologies for constructing MBSE tool-chains. We expected to understand the contents related to: (1) modeling purposes; (2) modeling languages; (3) modeling methods; (4) simulation methods; (5) modeling tools; (6) solutions for integrated verification; (7) tool integration; (8) testing; (9) process modeling; (10) process control and management; (11) model checking; and (12) optimization [17].

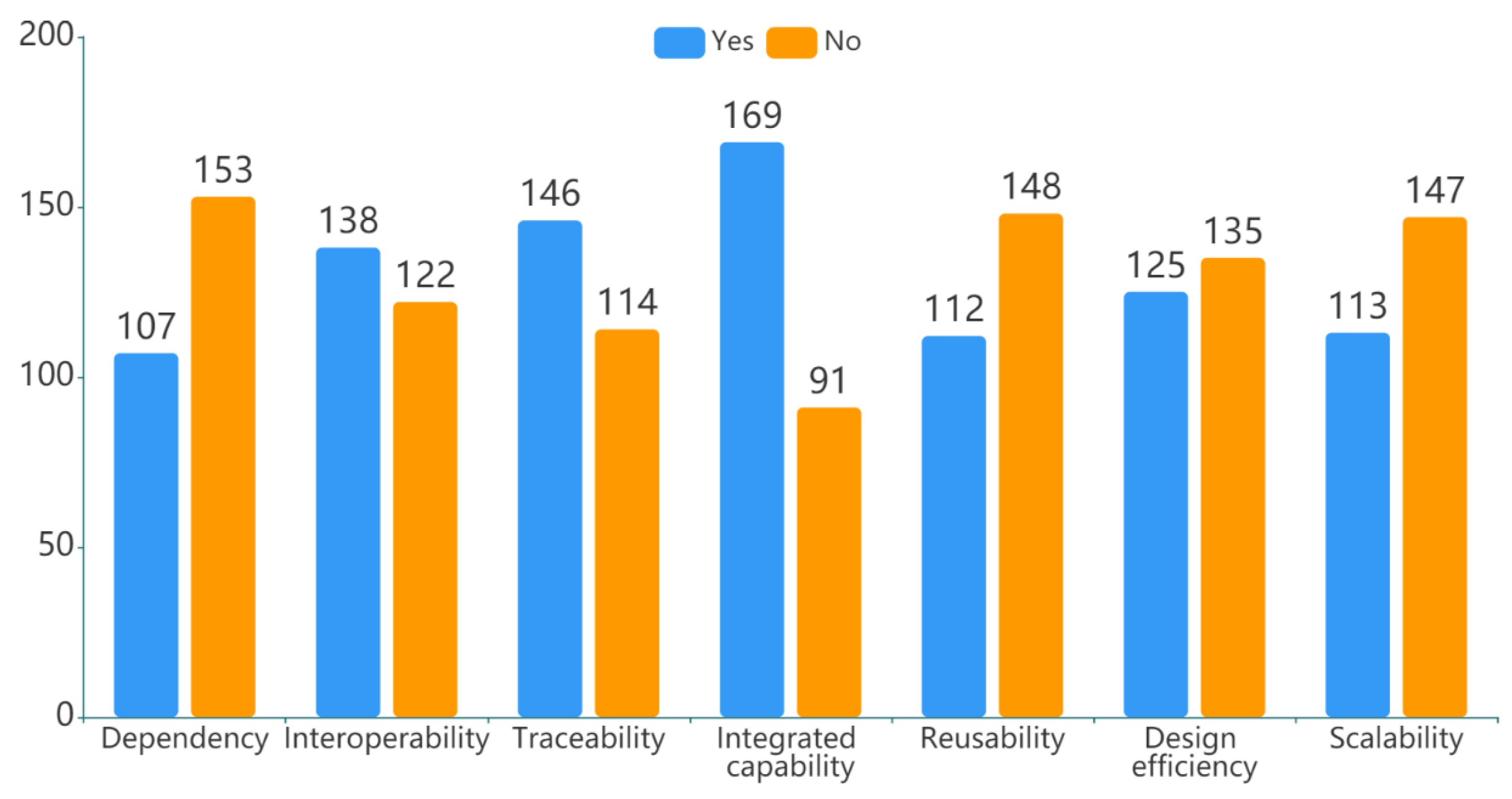

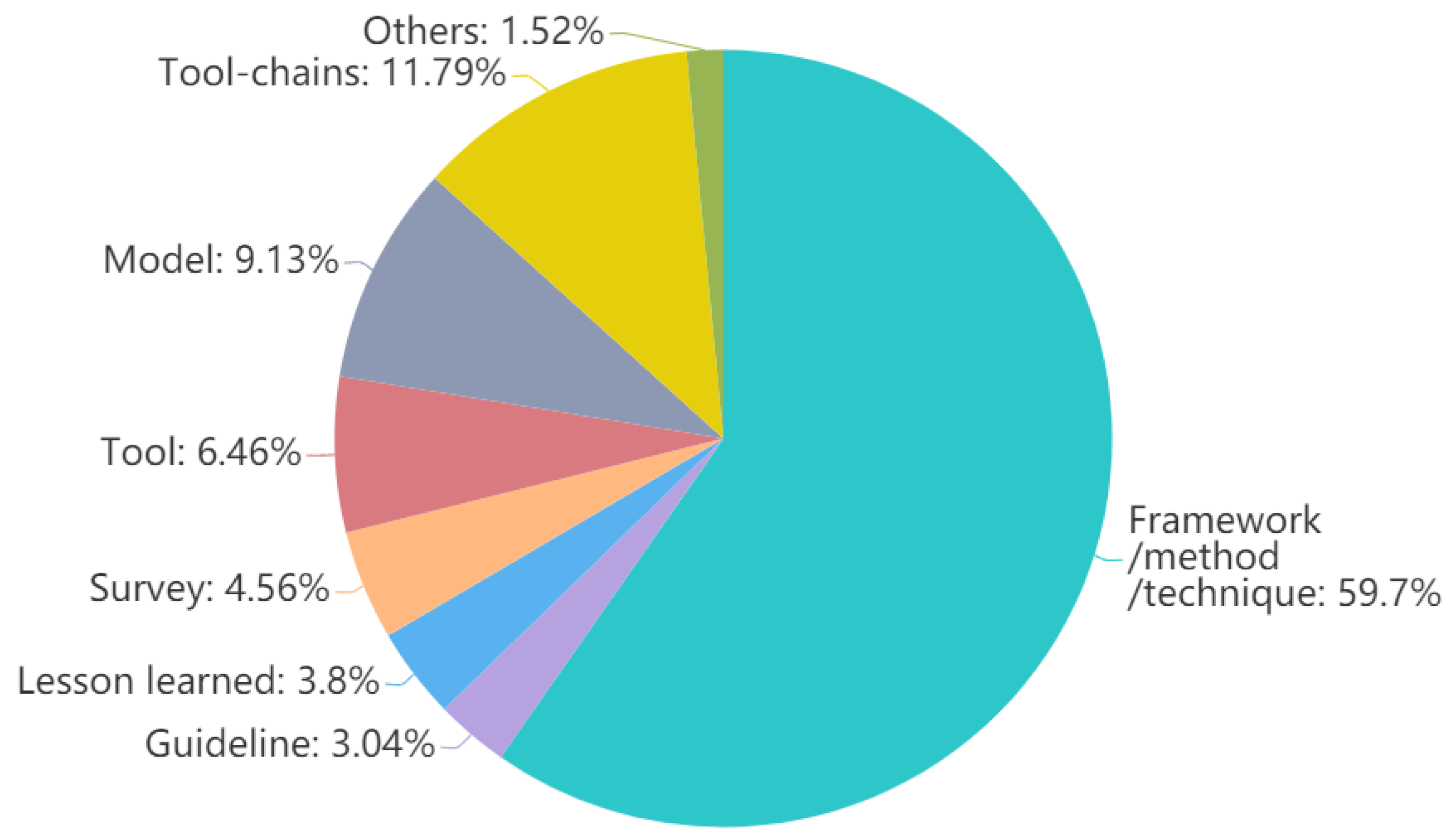

- RQ 4: What contributions are provided by research related to MBSE tool-chains? This question was used to clarify the authors’ contributions. We summarized the authors’ contributions from the papers, including: (1) framework/method/technique; (2) guidelines; (3) lessons learned; (4) models; (5) tools; (6) surveys; and (7) tool-chain architectures. Moreover, metrics accessing MBSE tool-chains were surveyed from the literature reviews, which included: (1) dependency; (2) interoperability; (3) traceability; (4) integrated capability; (5) reusability; (6) design efficiency; and (7) scalability.

2.2. Search Process

- Initial literature review: the aerospace and aircraft industries were first investigated as two leading domains for MBSE practices. Therefore, they were selected for searching papers for the initial literature review, including databases, research groups, journals, conferences, and online websites. Our previous article surveyed papers from 28 journals and 26 conferences of the American Institute of Aeronautics and Astronautics (AIAA) [3]. The results were analyzed to provide some initial topics for the collection and analysis of the MBSE tool-chains literature.

- Exploratory literature review: After identifying several topics based on the initial literature review, the strategy when selecting literature was to start with a systematic search through Google Scholar using “MBSE”, “model-based systems engineering” in combination with “tool-chain” as keywords. Finally, papers were collected and analyzed for this exploratory literature review.

2.3. Inclusion Criteria and Exclusion Criteria

2.3.1. Inclusion Criteria

2.3.2. Exclusion Criteria

2.4. Quality Assessment

- Data valuation of an MBSE tool-chain was based on concrete facts and a theoretical perceptive without any vagueness.

- Research was implemented using methods verified by other researchers.

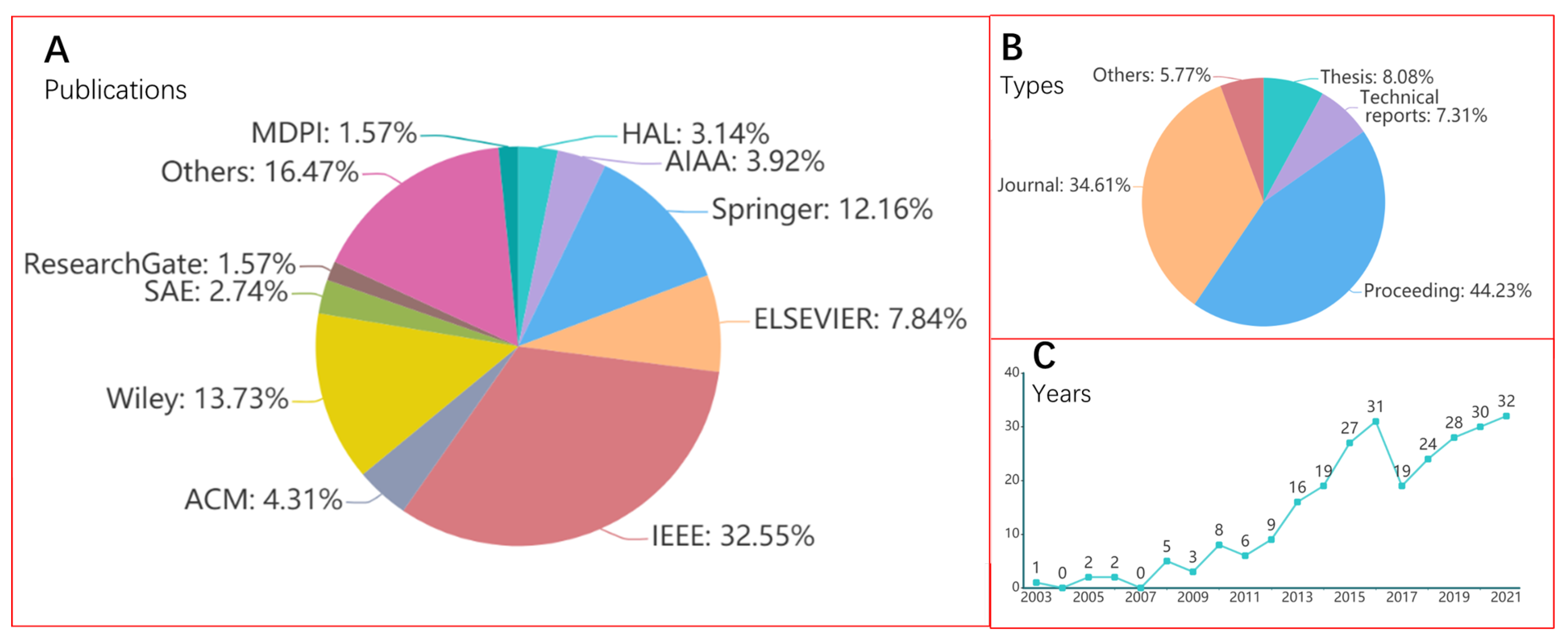

- More comprehensive papers were acquired, if available. We collected papers from 2003 to 2021; approximately 73% of the papers were from 2015 to 2021.

- To ensure the intensity of the research, more than five renowned scientific databases were included.

2.5. Data Collection and Analysis

3. Findings

3.1. Basic Information

3.2. Extent of MBSE Tool-Chains

3.3. Techniques of MBSE Tool-Chains

- Integrated capability, means the degree of combining software components, hardware components, or both into an overall system to constitute a tool-chain.

- Interoperability, means the degree of two or more systems or components to exchange information and use the information that has been exchanged in tool-chains.

- Traceability, means the degree to which a relationship can be established between technical recourse, system information, system development processes, and social networks.

- Dependency, means the capability of disposing of the determinant of technical recourse, system information, system development processes, and social networks.

- Reusability, means the capability of reusing technical resources (e.g., models, data, tools) by other modules or work products.

- Design efficiency, means the degree to which the system developers implement their design jobs with minimum consumption of resources by developed tool-chains.

- Scalability, means the degree to which the tool-chain handles a growing amount of engineering work or its potential to be enlarged to accommodate such growth.

3.4. Contributions

4. Discussion

4.1. Overview of Findings

4.2. Detailed Analysis from Findings

4.2.1. Basic Analysis

4.2.2. Extent Analysis of MBSE Tool-Chains

4.2.3. Techniques Analysis of MBSE Tool-Chains

Life-Cycle Properties

- Safety refers to the application of safety engineering in MBSE tool-chains, identifying potential dangers in the system through risk model definition and simulation analysis for taking effective control measures to minimize the dangers. For example, Timo and Seppo extended the scope of UML AP to also cover the development and design of safety systems. The work was targeted to the requirement concepts of the profile but also to documenting the results of risk and hazard analysis, which aided in the discovery of the information when the developers needed it [23]. Lena et al. presented a functional safety analysis approach in the process of system modeling, and the analysis of the resulting model was performed through a stochastic Bayesian model. This approach strove to both bypass the necessity for costly hardware testing and integrate the functional safety analysis into an intuitive component development process [24].

- Reliability is defined as the ability of a functional unit to perform a required function under given conditions for a given time interval [25]. For example, Zhao Huang et al. explored the integration of failure mode and effects analysis (FMEA) and MBSE by generating FMEA models from MBSE models to support system reliability design [26]. Furthermore, David et al. generated FMEA models from structural and behavioral diagrams in SysML models and used the AltaRica language to compute the reliability indicators [27]. Moreover, the reliability of the code generator has been identified as a key concern in automatic code generation. In order to investigate the model-based design approach for control system software development, Matias Soini et al. constructed the traceability between Simulink models and the generated program code by developing reliable code generators [28]. The result implies that safety and reliability are two important life-cycle properties in aerospace and vehicles, because most of the papers we collected were from these two domains, as shown in Figure 4.

Technical Aspects

4.2.4. Assessment of MBSE Tool-Chains

4.2.5. Contributions

- Framework/method/technique indicates that the contribution of the article is about the framework of the tool-chain, the methods used by the tool-chain, and the technology involved in the tool-chains.

- Guideline indicates that the contribution of the papers is to provide guidance for building the MBSE tool-chains.

- Lesson learned emphasizes the experience summary of the tool-chain construction process.

- Model indicates that the contribution is about the modeling.

- Tool indicates that the contribution of the paper is about the use of the tool itself.

- Survey indicates that the contribution of the paper is about a survey.

- Tool-chain architecture indicates that the contribution of the paper is about tool-chain architecture.

4.3. Answers to the Questions

4.4. Limitations

- We used the appropriate keywords “MBSE” or “model-based systems engineering” or “tool-chain”, and thoroughly scanned the search results. However, we missed some papers which, with keywords such as “model driven”, “PDM”, and “Integration”, are also related to MBSE tool-chains.

- The paper collection and data analysis was completed in October 2020, so that any papers after that date did not appear in our research, which may have resulted in the data results not being up-to-date.

- In order to answer the questions, we needed to analyze the paper content, because it was not obvious how to capture some of them. For instance, a large number of papers belong to two application areas of tool-chains, but we only considered one. This may have caused data deviations, but may not have affected the overall analysis of the data.

5. Conclusions

- The related technologies of SysML are the most mature. In the field of system design, tools such as requirements management, system modeling, and simulation can be integrated based on the SysML language specification.

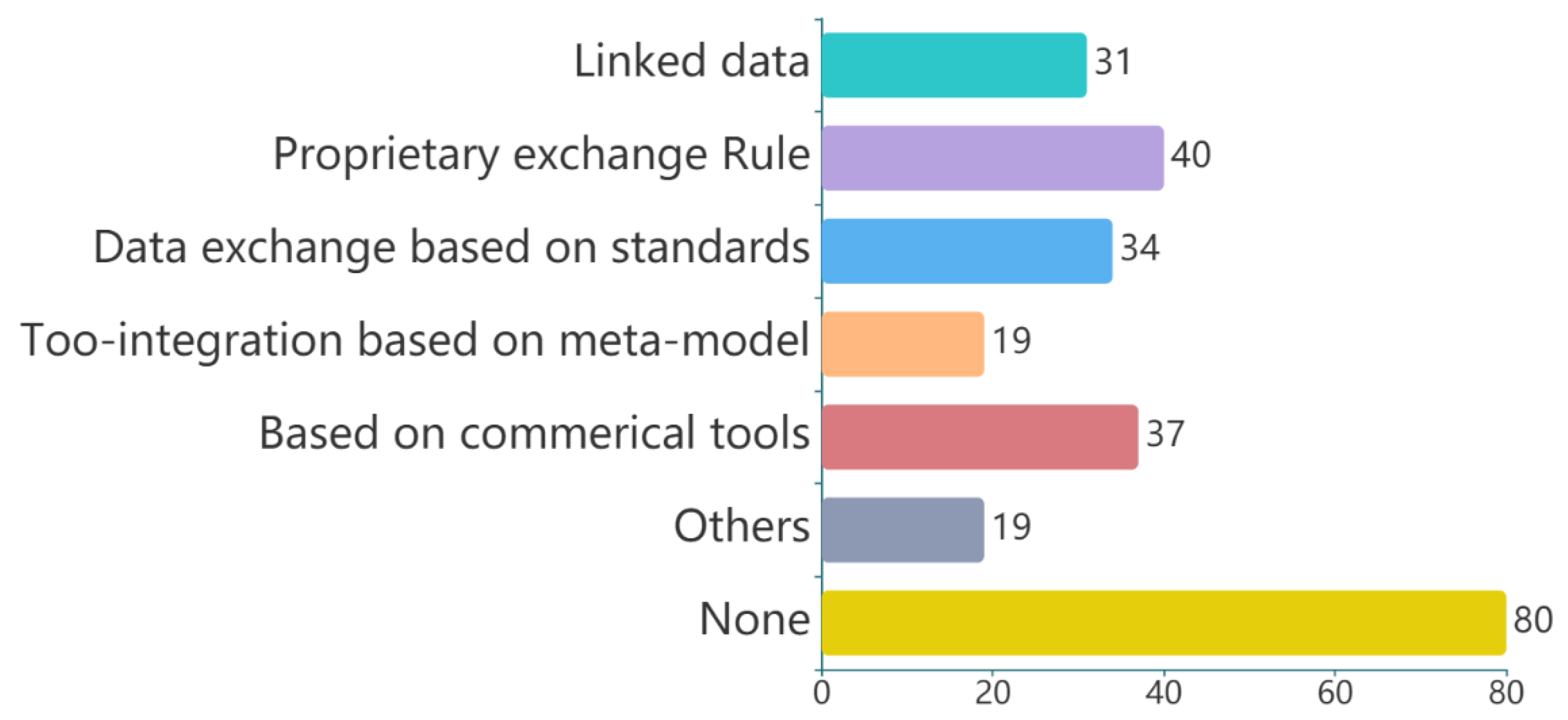

- Data exchange based on standards has become an important solution for tool integration. In the future, we should pay attention to the unified formulation of standards.

- We suggest that, with the steady development of tool-chain research, it is necessary not only to concentrate on research in the R&D phase, but also to focus on the whole life-cycle of real product development.

- When assessing tool-chains, we expect integrated capability, interoperability, and traceability to become more effective indicators.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haskins, C.; Forsberg, K.; Krueger, M.; Walden, D.; Hamelin, D. Systems engineering handbook. INCOSE 2006, 9, 185. [Google Scholar]

- Wiki. Hello. 2005. Available online: https://en.wikipedia.org/wiki/Toolchain (accessed on 2 November 2021).

- Lu, J.; Chen, D.J.; Gürdür, D.; Törngren, M. An Investigation of Functionalities of Future Tool-chain for Aerospace Industry. In INCOSE International Symposium; Wiley Online Library: Hoboken, NJ, USA, 2017; Volume 27, pp. 1408–1422. [Google Scholar]

- Binder, C.; Fischinger, M.; Neureiter, C.; Lastro, G.; Polanec, K.; Gross, J.A. Towards a Tool-Based Approach for Dynamically Generating Co-Simulation Scenarios based on complex Smart Grid System Architectures. In Proceedings of the 2020 IEEE 15th International Conference of System of Systems Engineering (SoSE), Budapest, Hungary, 2–4 June 2020; pp. 199–204. [Google Scholar]

- König, C.; Mengist, A.; Gamble, C.; Höll, J.; Lausdahl, K.; Bokhove, T.; Brosse, E.; Möller, O.; Pop, A. Traceability in the Model-Based Design of Cyber-Physical Systems. In Proceedings of the American Modelica Conference 2020, Boulder, CO, USA, 23–25 March 2020. [Google Scholar]

- Lu, J.; Chen, D.; Wang, G.; Kiritsis, D.; Törngren, M. Model-based systems engineering tool-chain for automated parameter value selection. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 2333–2347. [Google Scholar] [CrossRef]

- Estefan, J.A. Survey of Model-Based Systems Engineering ( MBSE ) Methodologies. Environment 2008, 25, 1–12. [Google Scholar]

- Motamedian, B. MBSE applicability Analysis. Int. J. Sci. Eng. Res. 2013, 4, 7. [Google Scholar]

- Lu, J.; Wen, Y.; Liu, Q.; Gürdür, D.; Törngren, M. MBSE Applicability Analysis in Chinese Industry. INCOSE Int. Symp. 2018, 28, 1037–1051. [Google Scholar] [CrossRef] [Green Version]

- Huldt, T.; Stenius, I. State-of-practice survey of model-based systems engineering. Syst. Eng. 2019, 22, 134–145. [Google Scholar] [CrossRef]

- Rashid, M.; Anwar, M.W.; Khan, A.M. Toward the tools selection in model based system engineering for embedded systems—A systematic literature review. J. Syst. Softw. 2015, 106, 150–163. [Google Scholar] [CrossRef]

- Hutchinson, J.; Rouncefield, M.; Whittle, J. Model-driven engineering practices in industry. In Proceeding of the 33rd International Conference on Software Engineering, Honolulu, HI, USA, 21–28 May 2011; ACM Press: New York, NY, USA, 2011; p. 633. [Google Scholar] [CrossRef]

- Gomes, C.; Thule, C.; Broman, D.; Larsen, P.G.; Vangheluwe, H. Co-simulation: State of the art. arXiv 2017, arXiv:1702.00686. [Google Scholar]

- Asplund, F.; Biehl, M.; El-Khoury, J.; Törngren, M. Tool integration beyond Wasserman. In Proceedings of the International Conference on Advanced Information Systems Engineering, London, UK, 20–24 June 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 270–281. [Google Scholar]

- Kitchenham, B.; Pretorius, R.; Budgen, D.; Pearl Brereton, O.; Turner, M.; Niazi, M.; Linkman, S. Systematic literature reviews in software engineering—A tertiary study. Inf. Softw. Technol. 2010, 52, 792–805. [Google Scholar] [CrossRef]

- De Weck, O.L.; Ross, A.M.; Rhodes, D.H. Investigating Relationships and Semantic Sets amongst System Lifecycle Properties (Ilities). In Proceedings of the Third International Engineering Systems Symposium CESUN, Delft, The Netherlands, 18–20 June 2012; pp. 18–20. [Google Scholar]

- Lu, J. Research Survey on Model-Based Systems Engineering Tool-Chain; Technical Report; KTH: Stockholm, Sweden, 2019. [Google Scholar]

- Torraco, R.J. Writing Integrative Literature Reviews: Guidelines and Examples. Hum. Resour. Dev. Rev. 2005, 4, 356–367. [Google Scholar] [CrossRef]

- Lu, J.; Gürdür, D.; Chen, D.J.; Wang, J.; Törngren, M. Empirical-evolution of frameworks supporting co-simulation tool-chain development. In Proceedings of the World Conference on Information Systems and Technologies, Naples, Italy, 27–29 March 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 813–828. [Google Scholar]

- Lu, J.; Wang, G.; Tao, X.; Wang, J.; Törngren, M. A domain-specific modeling approach supporting tool-chain development with Bayesian network models. Integr. Comput.-Aided Eng. 2020, 27, 153–171. [Google Scholar] [CrossRef] [Green Version]

- Geraci, A.; Katki, F.; McMonegal, L.; Meyer, B.; Porteous, H. IEEE Standard Computer Dictionary: A Compilation of IEEE Standard Computer Glossaries; Technical Report; IEEE Press: Piscataway, NJ, USA, 1991. [Google Scholar] [CrossRef]

- Biggs, G.; Juknevicius, T.; Armonas, A.; Post, K. Integrating Safety and Reliability Analysis into MBSE: Overview of the new proposed OMG standard. INCOSE Int. Symp. 2018, 28, 1322–1336. [Google Scholar] [CrossRef]

- Vepsäläinen, T.; Kuikka, S. Simulation-based development of safety related interlocks. In Simulation and Modeling Methodologies, Technologies and Applications; Springer: Berlin/Heidelberg, Germany, 2013; pp. 165–182. [Google Scholar]

- Rogovchenko-Buffoni, L.; Tundis, A.; Hossain, M.Z.; Nyberg, M.; Fritzson, P. An integrated toolchain for model based functional safety analysis. J. Comput. Sci. 2014, 5, 408–414. [Google Scholar] [CrossRef]

- Joglar, F. Reliability, availability, and maintainability. In SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2016; pp. 2875–2940. [Google Scholar]

- Huang, Z.; Swalgen, S.; Davidz, H.; Murray, J. MBSE-assisted FMEA approach—Challenges and opportunities. In Proceedings of the 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017; pp. 1–8. [Google Scholar]

- David, P.; Idasiak, V.; Kratz, F. Reliability study of complex physical systems using SysML. Reliab. Eng. Syst. Saf. 2010, 95, 431–450. [Google Scholar] [CrossRef]

- Soini, M. Modeling and Simulation Practices in Control System Software Development. Master’s Thesis, Tampere University of Technology, Tampere, Finland, 2014. [Google Scholar]

- Chen, R.; Chen, C.H.; Liu, Y.; Ye, X. Ontology-based requirement verification for complex systems. Adv. Eng. Inform. 2020, 46, 101148. [Google Scholar] [CrossRef]

- Willich, F.; Wolff, C.; Sutorma, A.; Jahn, U.; Stampa, M. Model-based Systems Engineering of an Active, Oleo-Pneumatic Damper for a CS-23 General Aviation Aircraft Landing Gear. In Proceedings of the 2021 IEEE European Technology and Engineering Management Summit (E-TEMS), Dortmund, Germany, 18–20 March 2021; pp. 166–172. [Google Scholar]

- Bilic, D. Managing Variability in SysML Models of Automotive Systems. Ph.D. Thesis, Mälardalen University, Westeros, Sweden, 2020. [Google Scholar]

- Myron, H.; Elisabeth, N.; Aaron, C.; Pinchak, J. Automated generation of failure modes and effects analysis for a medical device. In Proceedings of the IEEE International Symposium on Software Reliability Engineering Workshops (ISSREW), Gaithersburg, MD, USA, 2–5 November 2015; pp. 29–32. [Google Scholar]

- Lankhorst, M.M. Enterprise architecture modelling—The issue of integration. Adv. Eng. Informatics 2004, 18, 205–216. [Google Scholar] [CrossRef]

- Hu, Z.; Lu, J.; Chen, J.; Zheng, X.; Kyritsis, D.; Zhang, H. A complexity analysis approach for model-based system engineering. In Proceedings of the 2020 IEEE 15th International Conference of System of Systems Engineering (SoSE), Budapest, Hungary, 2–4 June 2020; pp. 000501–000506. [Google Scholar]

- Vepsäläinen, T.; Kuikka, S. Integrating model-in-the-loop simulations to model-driven development in industrial control. Simulation 2014, 90, 1295–1311. [Google Scholar] [CrossRef]

- Riccobene, E.; Scandurra, P. Integrating the SysML and the SystemC-UML profiles in a model-driven embedded system design flow. Des. Autom. Embed. Syst. 2012, 16, 53–91. [Google Scholar] [CrossRef]

- Shani, U.; Franke, M.; Hribernik, K.A.; Thoben, K.D. Ontology mediation to rule them all: Managing the plurality in product service systems. In Proceedings of the 11th Annual IEEE International Systems Conference, Montreal, QC, Canada, 24–27 April 2017; pp. 1–7. [Google Scholar] [CrossRef] [Green Version]

- Adam, K.; Holldobler, K.; Rumpe, B.; Wortmann, A. Engineering Robotics Software Architectures with Exchangeable Model Transformations. In Proceedings of the 2017 First IEEE International Conference on Robotic Computing (IRC), Taichung, Taiwan, 10–12 April 2017; pp. 172–179. [Google Scholar] [CrossRef]

- Pavalkis, S. Towards Industrial Integration of MBSE into PLM for Mission-Critical Systems. INCOSE Int. Symp. 2016, 26, 2462–2477. [Google Scholar] [CrossRef]

- Jackson, M.; Wilkerson, M. MBSE-driven visualization of requirements allocation and traceability. In Proceedings of the 2016 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2016; pp. 1–17. [Google Scholar] [CrossRef]

- Lu, J.; Chen, D.; Jinzhi, L.; Lu, J.; Chen, D.; Törngren, M.; Loiret, F.; Martin, T.; Lu, J.; Chen, D.; et al. A Model-driven and Tool-integration Framework for Whole Vehicle Co-simulation Environments. In Proceedings of the 8th European Congress on Embedded Real Time Software and Systems, Toulouse, France, 27–29 January 2016. [Google Scholar]

- Baras, J.S.; Austin, M.A.; Baras, S. Development of a Framework for CPS Open Standards and Platforms; Technical Report; The Institute for Systems Research, University of Maryland: College Park, MD, USA, 2014. [Google Scholar]

- Schneider, J.P.; Champeau, J.; Lagadec, L.; Senn, E. Role Framework to Support Collaborative Virtual Prototyping of System of Systems. In Proceedings of the 2015 IEEE 24th International Conference on Enabling Technologies: Infrastructure for Collaborative Enterprises, Larnaca, Cyprus, 15–17 June 2015; pp. 144–149. [Google Scholar] [CrossRef]

| Id | Title | Cardinality 1 | RQ | Description |

|---|---|---|---|---|

| 1 | Publication Year | 1:1 | RQ 1 | The publication time. |

| 2 | Publisher | 1:1 | RQ 1 | The publisher’s name, such as IEEE. |

| 3 | Publication Type | 1:1 | RQ 1 | The types of publications, such as conference or journal. |

| 4 | Roles contributed by papers | 1:n | RQ 2 | The stakeholders’ roles to which the papers contribute. |

| 5 | Development phases contributed by papers | 1:1 | RQ 2 | The development phases that papers focus on. |

| 6 | Application domain | 1:n | RQ 2 | The domain that papers focus on. |

| 7 | Functionalities of MBSE tool-chains | 1:n | RQ 2 | Characteristic purpose of the MBSE tool-chains. |

| No. | Description | Details |

|---|---|---|

| 1 | Bibliographic information | Title, publishers, publication types, publication year |

| 2 | Application areas | Aerospace, aircraft, vehicle, machine, CPS, etc. |

| 3 | Stakeholders | System engineer, domain engineer, team leader, etc. |

| 4 | Process | R&D project, the whole life-cycle of real product development, pilot project, etc. |

| 5 | Life properties | Quality, reliability, safety, flexibility, robustness, durability, scalability, etc. |

| 6 | Technical aspect | Modeling purposes, modeling languages, modeling methods, simulation methods, modeling tools, etc. |

| 7 | Contributions | Clarifying the contributions of authors with guidelines, models, tools, surveys, etc. |

| RQ | Content | Result |

|---|---|---|

| RQ1 | What is the intensity of the research on MBSE tool-chains? | 1. Research articles are typically published in IEEE, Wiley, and Springer, as shown in Figure 2. 2. Since 2012, researchers have shown increasing interest in tool-chains, as shown in Figure 2. |

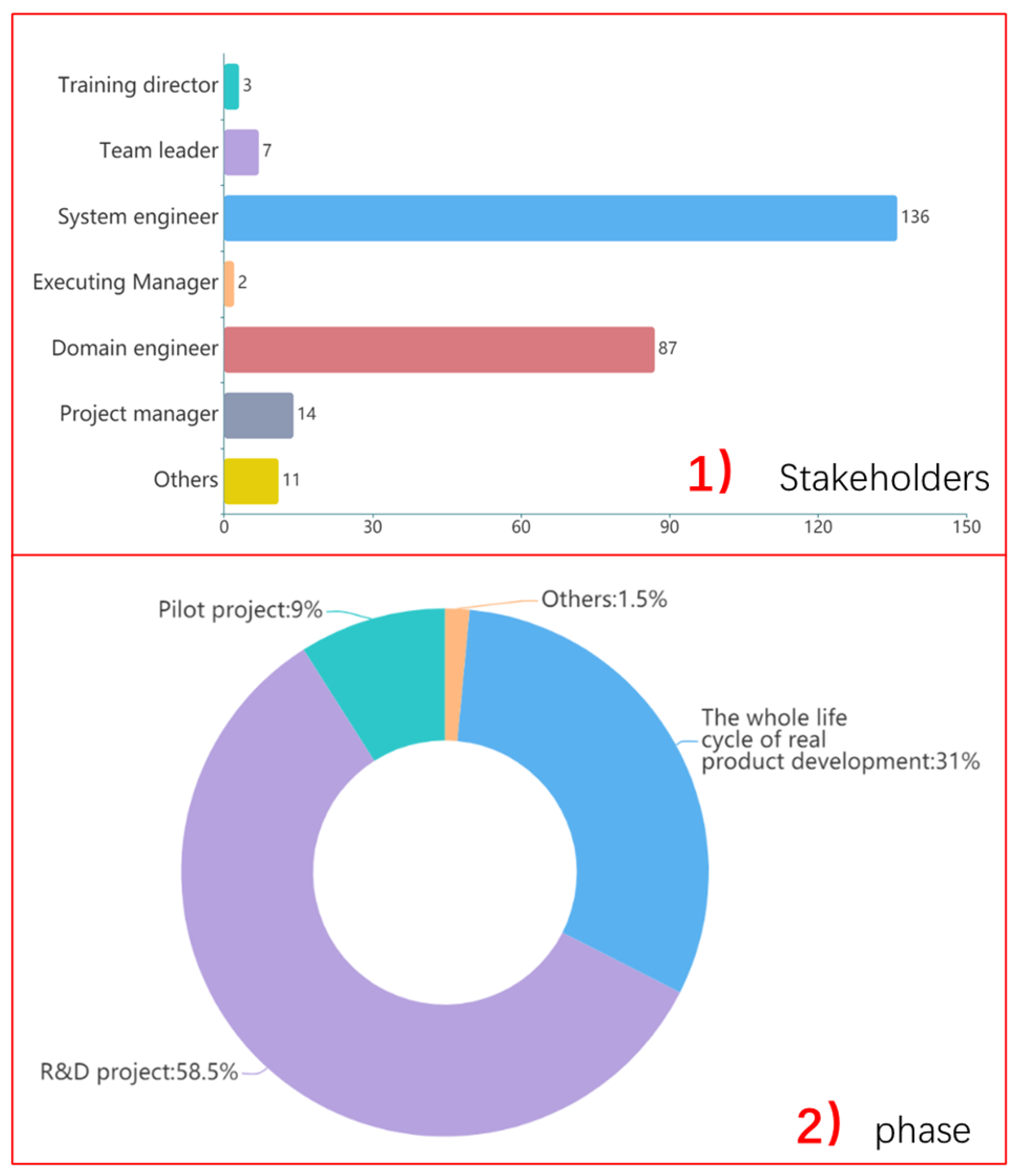

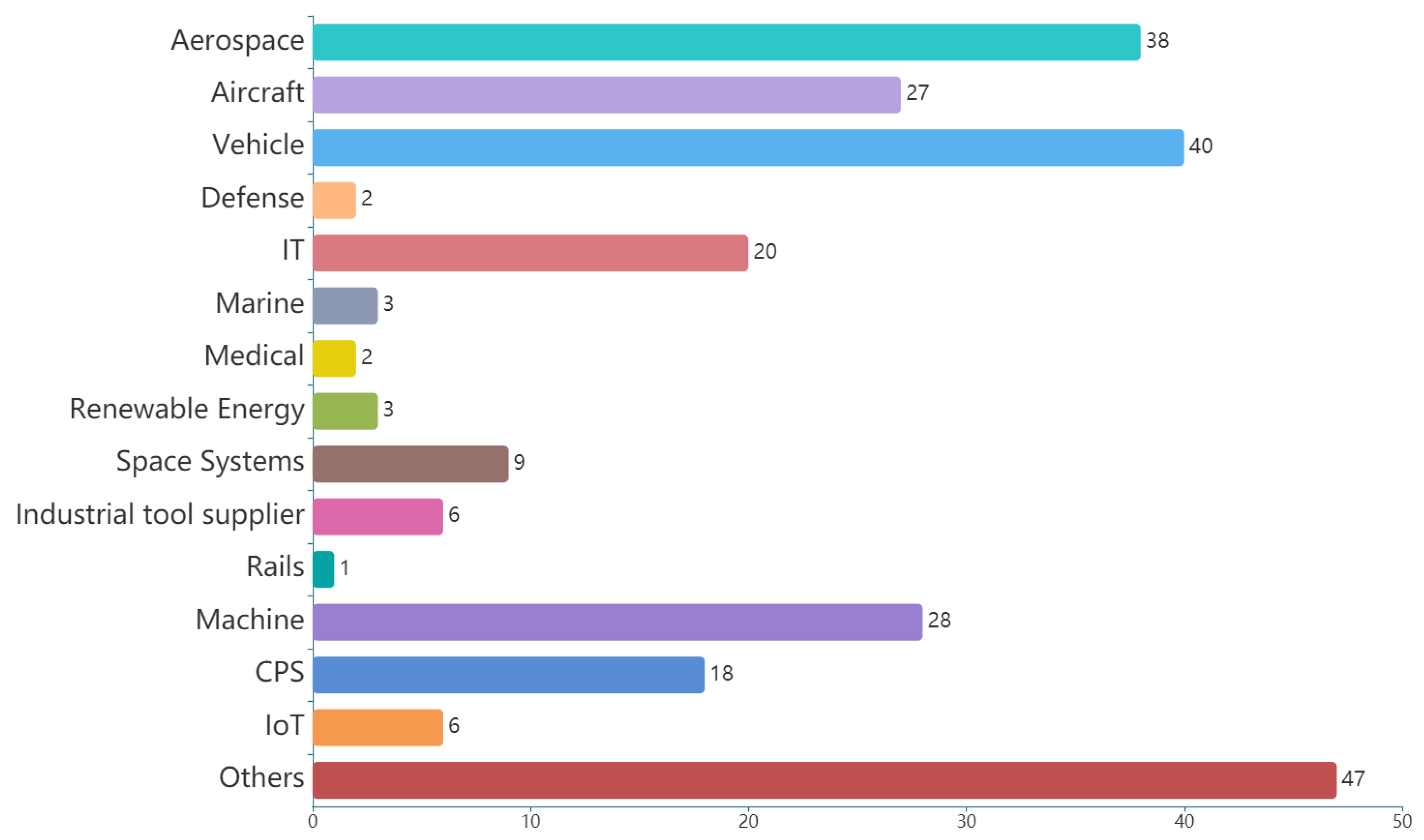

| RQ2 | What are the most frequently investigated research areas related to MBSE tool-chains? | 1. System engineers contribute the most to tool-chain development. Most of the papers focus on R&D projects, as shown in Figure 3. 2. The tool-chains are most widely used in the domains of aerospace and vehicles, as shown in Figure 4. 3. System design is the field which is the most supported via developed tool-chains, as shown in Figure 5. |

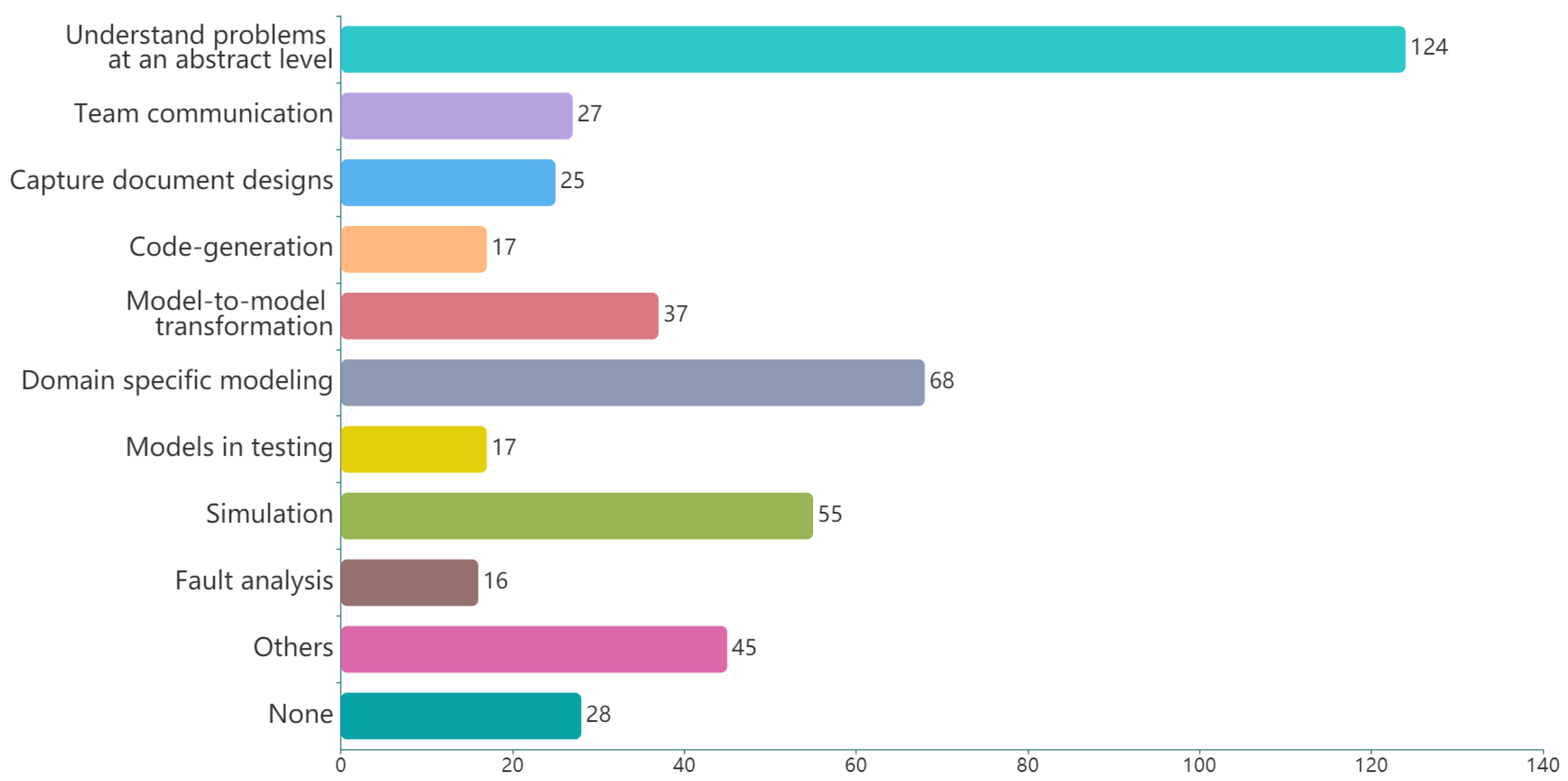

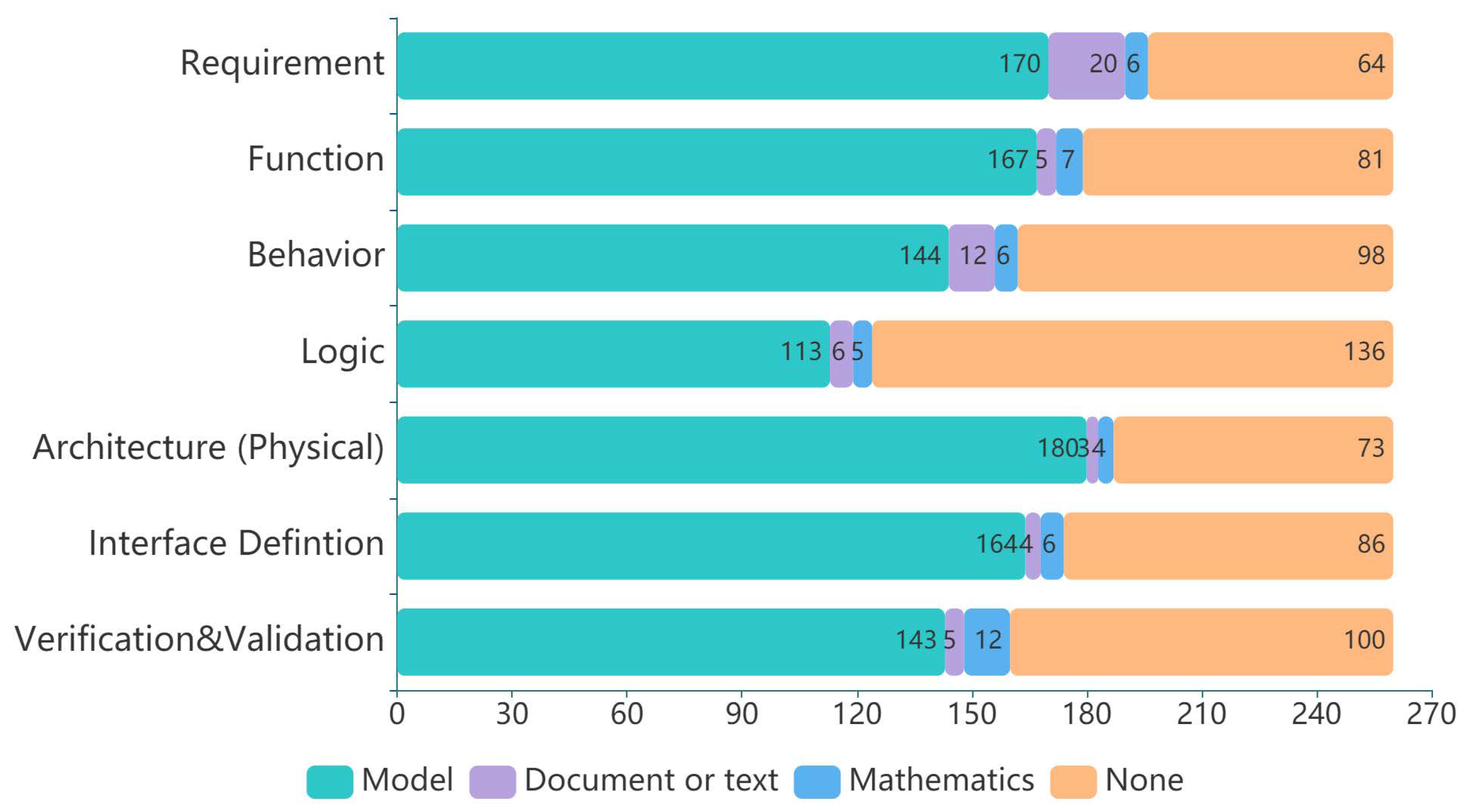

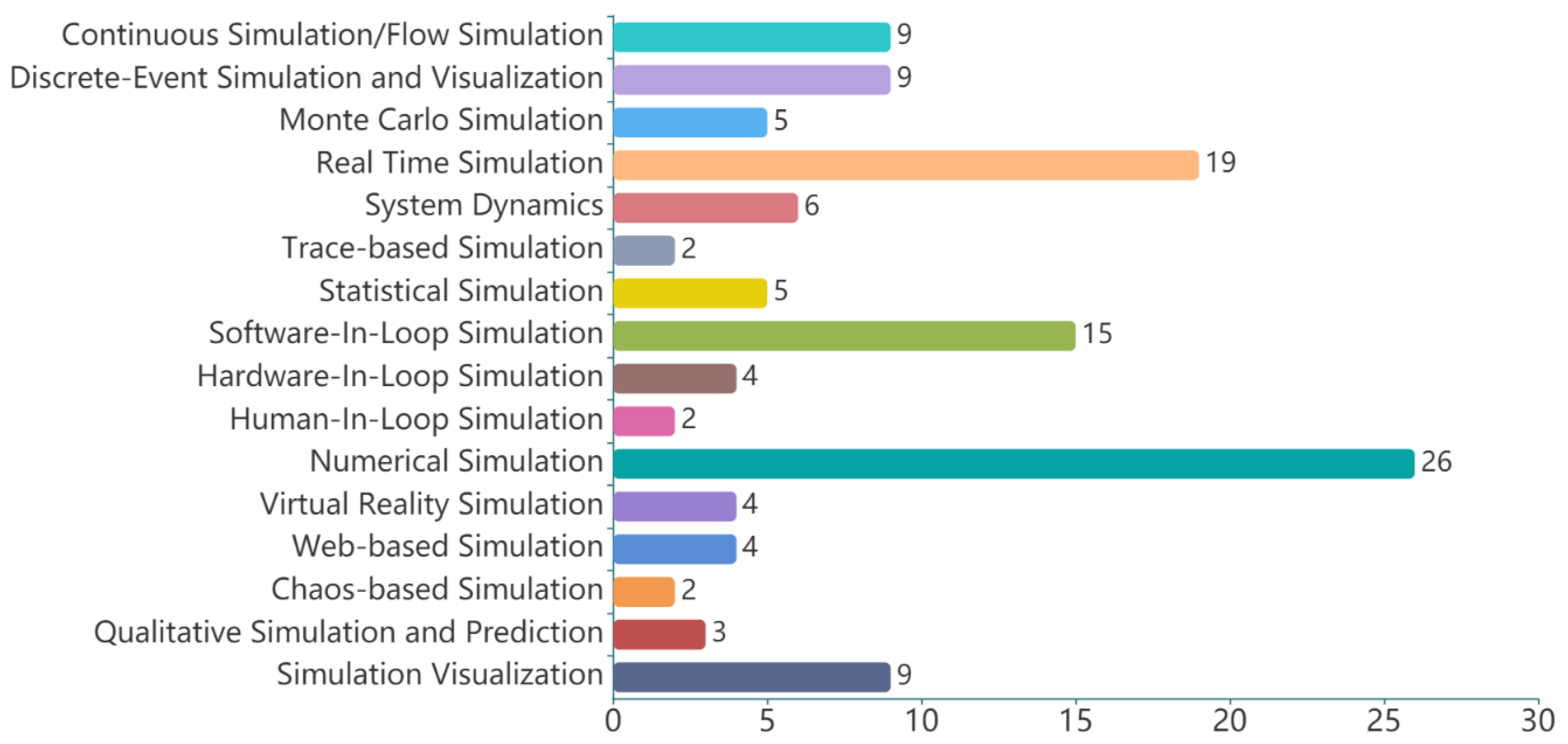

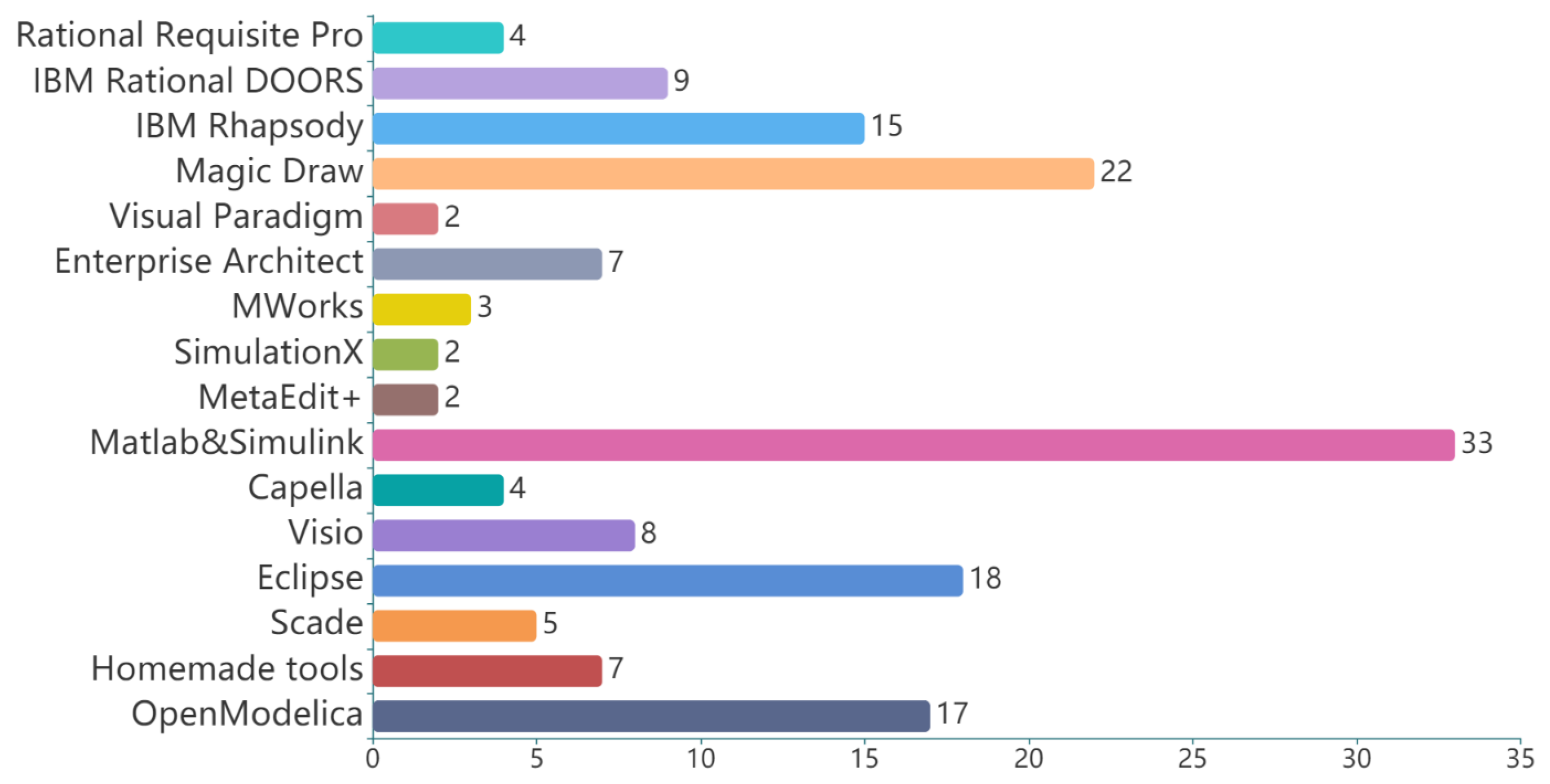

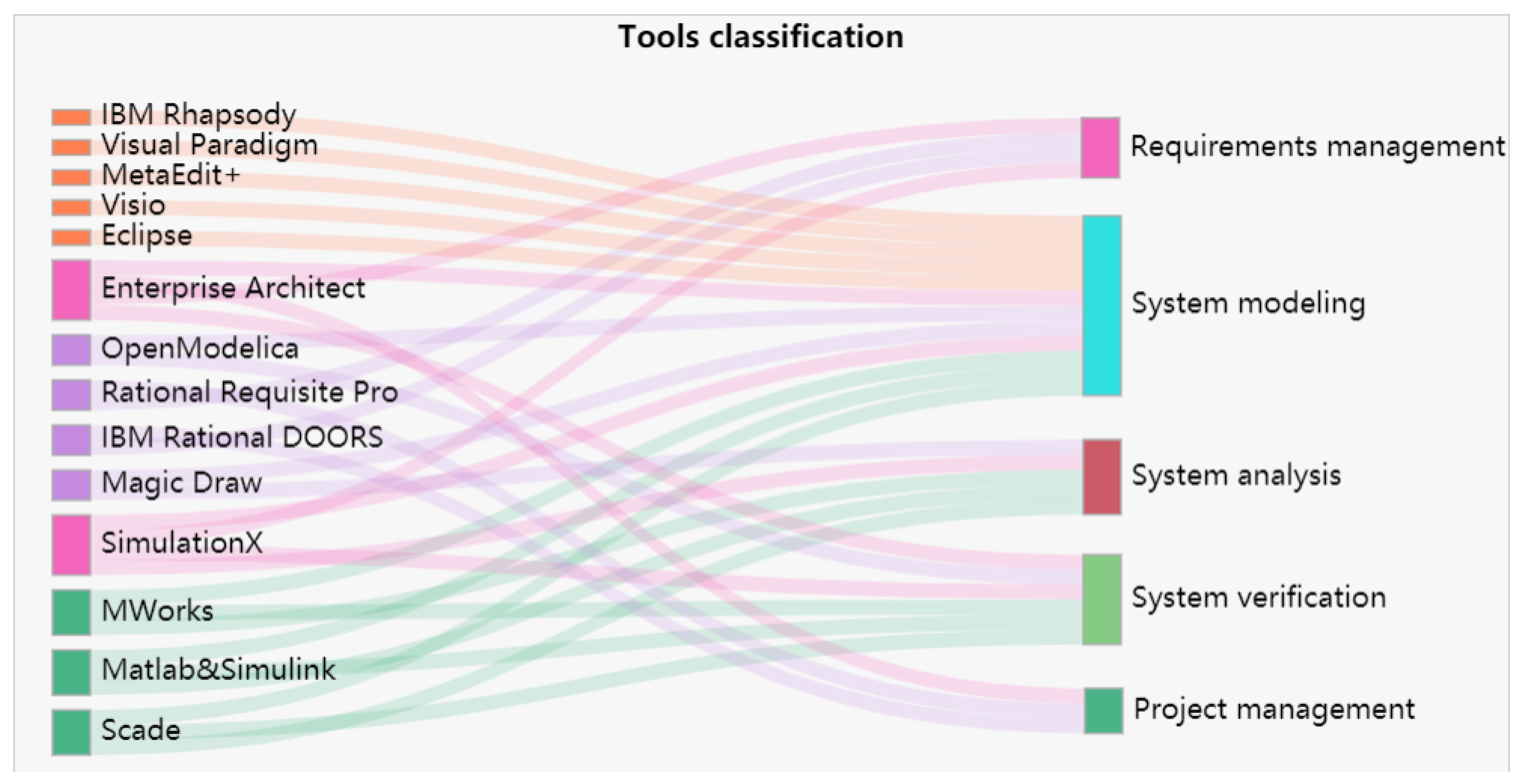

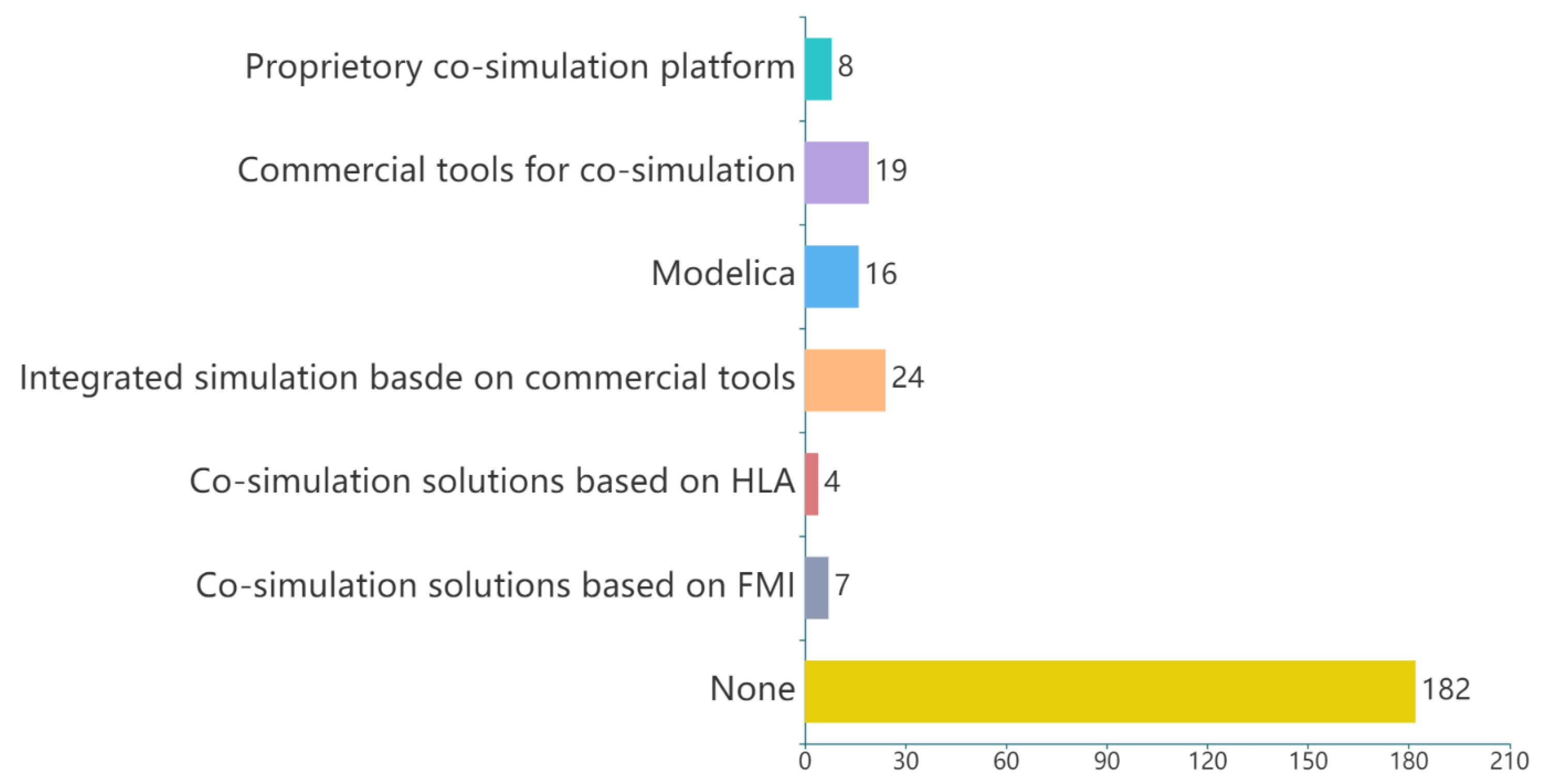

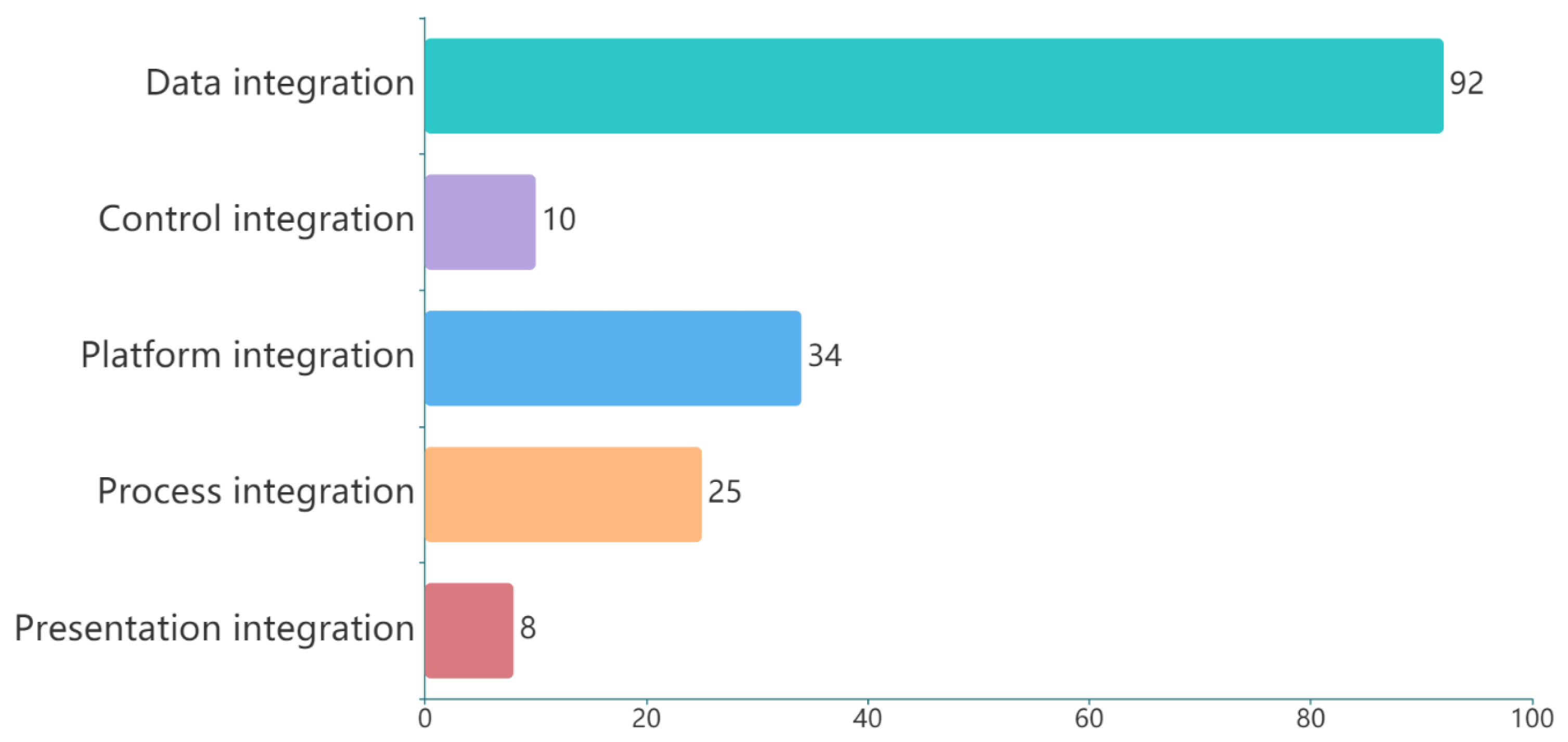

| RQ3 | What are the most frequently applied research types and research methods? (Mainly to identify the technology of the MBSE tool-chains.) | 1. The life-cycle properties of safety and reliability are of interest to researchers, as shown in Figure 6. 2. Understanding problems at an abstract level is the most important modeling purpose, as shown in Figure 7. 3. The model formalism is mostly mentioned, among which the requirement model is the most frequently mentioned perspective, as shown in Figure 8. 4. SysML is the most widely used modeling language in the context of tool-chains, as shown in Figure 9. 5. Meta-modeling is the most widely used modeling method, as shown in Figure 10. 6. Numerical simulation is the most widely used simulation method, as shown in Figure 11. 7. MATLAB and Simulink are the most frequently used tools, as shown in Figure 12. 8. Integrated simulation based on commercial tools, Modelica, and commercial tools for co-simulation are the three main solutions employed by the tool-chains for supporting integrated verification, as shown in Figure 14. 9. Data integration is the most frequent process for tool integration, as shown in Figure 15. Data exchange based on standards has been used for integration in most tools in recent years, as shown in Figure 16. 10. Integrated capability is most frequently considered tool-chain assessment metric, as shown in Figure 17. |

| RQ4 | What contributions are provided by research related to MBSE tool-chains? | 1. The item of the framework/method/technique is the most frequent contribution, as shown in Figure 18. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Wang, G.; Lu, J.; Vangheluwe, H.; Kiritsis, D.; Yan, Y. Systematic Literature Review of MBSE Tool-Chains. Appl. Sci. 2022, 12, 3431. https://doi.org/10.3390/app12073431

Ma J, Wang G, Lu J, Vangheluwe H, Kiritsis D, Yan Y. Systematic Literature Review of MBSE Tool-Chains. Applied Sciences. 2022; 12(7):3431. https://doi.org/10.3390/app12073431

Chicago/Turabian StyleMa, Junda, Guoxin Wang, Jinzhi Lu, Hans Vangheluwe, Dimitris Kiritsis, and Yan Yan. 2022. "Systematic Literature Review of MBSE Tool-Chains" Applied Sciences 12, no. 7: 3431. https://doi.org/10.3390/app12073431

APA StyleMa, J., Wang, G., Lu, J., Vangheluwe, H., Kiritsis, D., & Yan, Y. (2022). Systematic Literature Review of MBSE Tool-Chains. Applied Sciences, 12(7), 3431. https://doi.org/10.3390/app12073431