1. Introduction

The gas turbine system operates at contaminated environment conditions with high temperature and high pressure, which makes the gas path faults occur much more frequently [

1]. The gas path fault includes blade fouling, wearing and corrosion, foreign object damage, etc. These gas path faults contribute to more than 90% of failures of an aero-engine [

2]. Therefore, an effective and reliable gas path fault diagnosis system for a gas turbine has attracted considerable attention. A comprehensive fault diagnosis process consists of two tasks: (1) field data analysis, which extracts fault features from the field data using a gas path analysis (GPA) method; (2) knowledge-based reasoning, which provides diversified fault information and selects a proper maintenance strategy from an expert system. Thus, the final goal of a comprehensive gas path fault diagnosis is to select a correct maintenance activity in task 2 based on the GPA result in task 1 [

3].

During the field data analysis process in task 1, the GPA technology is an effective method to extract the gas path fault feature from the thermodynamic field data, such as temperature, pressure, and flow rate. In the past few decades, many GPA technologies have been developed to estimate the health states of gas turbines and to identify the gas path faults. Different GPA models were built to detect the gas path faults from the field data. Urban [

4] first established a linear GPA model in 1967. In this model, a coefficient matrix is established to diagnose the gas path faults from the field data. In order to improve the diagnosis accuracy, several nonlinear models have been proposed. Larsson [

5] constructed a nonlinear fault diagnosis model based on the extended Kalman filter method. Li et al. [

6] proposed a nonlinear GPA method to quantify the degradation rate of the major gas path components. With the development of big data technologies, many data-driven methods have also been put forward in the GPA models. Vanini et al. [

7] developed multiple GPA models based on the dynamic neural network (DNN) method to detect the health status. Yang et al. [

8] established an optimization GPA model based on the extreme learning machine. Results showed that the optimized extreme learning machine is more reliable than the support vector machine (SVM) and the artificial neural network. Zhong et al. [

9] investigated a transfer learning method based on the convolutional neural network (CNN) and SVM for gas path fault diagnosis. Transfer learning with the CNN is applied to solve the problem of fewer fault samples, and an SVM model is applied to classify the gas path fault modes. Our previous studies also proposed several GPA models to detect the gas path faults, including the nonlinear physical model-based GPA, SVM GPA, and deep learning GPA [

10,

11,

12,

13].

During the knowledge-based reasoning process in task 2, an expert system is necessary to make a correct decision based on the prior knowledge. Applebaum [

14] proposed an expert diagnosis system based on a fuzzy classifier to identify the faults of gas turbine engines. The rules stored in the fuzzy classifier can be modified at any time. Salar et al. [

15] proposed a fuzzy inference system based on a set of knowledge rules to identify the fault locations. Furthermore, the maintenance strategy of washing or repairing is also suggested by the fuzzy inference system. Deng et al. [

16] proposed a rule-based fault diagnosis expert system for a wind turbine. Experts or domain-specific engineers can modify the rules stored in the diagnostic knowledge base. Several fault criteria rules are adopted to identify the gas path faults of a gas turbine. For example, the fault criteria of compressor fouling consists of 7% compressor air flow degradation and 2% compressor efficiency degradation [

17,

18,

19].

The above expert systems are simply developed with the rules from the experiential knowledge of domain experts. These expert systems make it difficult to select a correct maintenance strategy due to their fragile inference ability. According to the theory of reliability-centered maintenance (RCM), selecting a correct maintenance strategy is a complex task due to the numerous components and their complex interconnections. It requires a number of specialized technologies, i.e., fault criteria analysis, physical structure analysis, failure mode, effects, and criticality analysis (FMECA), and the maintenance logic decision tool. A reliable expert system should enable the involvement of more sufficient fault knowledge from different sources. However, with the increasing heterogeneous knowledge for supporting a correct maintenance decision, it is a challenge to efficiently represent the above fault knowledge based on a unified semantic expression, in support of improving the fault inference ability.

In recent years, ontology has been widely applied for knowledge representation and utilization. It enables not only the clear description of knowledge, with explicit specifications, but also the ability to carry out knowledge reasoning using inference engines. Zhou et al. [

20] developed an ontology model to represent the knowledge from the perspective of FMECA for wind turbines. The ontology model can provide more sufficient information for fault diagnosis and maintenance strategy selection. Ebrahimipour et al. [

21] developed an ontology model to support the fault knowledge representation for a typical pneumatic valve. The ontology model effectively converted the fault propagation mechanism into a shareable and accessible knowledge representation. Alkahtani et al. [

22] developed a decision support system to optimize the design parameters for automobile manufacturing. The ontology model was applied to locate the defective components based on the design knowledge from the warranty data. Elhdad et al. [

23] developed an ontology-based reasoning framework to enhance the maintenance decisions for a petroleum plant. Jiménez et al. [

24] built an ontology model to identify the optimal maintenance activities for an air compressor. The concepts of current trends were also considered in the ontology model to trigger the predictive maintenance strategy. Polenghi et al. [

25] proposed a maintenance-related ontology model that includes the concepts of maintenance and production activities. The joint decisions of maintenance and production could be reasoned out by the ontology model. The above studies have proven that the ontology technology is efficient in knowledge representation, sharing, and reasoning for an intelligent expert system.

Several investigations have been carried out for implementing task 1 or task 2 of the gas path fault diagnosis process. In task 1, the GPA method has proved its effectiveness in field data analysis. In task 2, the ontology model is a powerful alternative to developing an intelligent expert system for knowledge-based reasoning. However, most of the previous studies assumed that task 1 and task 2 are isolated and are not integrated to cover the whole gas path diagnosis process. In practice, the gas path diagnosis is difficult to implement if the expert system cannot work with the domain-specific data analysis.

The purpose of this work is to propose a data-knowledge hybrid driven method for an intelligent gas path diagnosis system. The contribution is that the hybrid driven method supports the whole gas path diagnosis process, which includes field data analysis (task 1) and knowledge-based reasoning (task 2). Firstly, a physical model-based GPA method is used to extract the fault feature from the field data in task 1. Moreover, an ontology-based model is applied to represent the massive fault knowledge from different sources. With the defined reasoning rules, the fault information and correct maintenance strategy can be obtained with the input of the identified fault feature criteria individual in task 2. Secondly, a virtual mapping algorithm is developed to map the GPA result from task 1 to a specific feature criteria individual described in the ontology model. Finally, a case study of a real gas turbine driven natural gas compressor unit is carried out to verify the effectiveness of the proposed hybrid driven method.

The remainder of this paper is organized as follows:

Section 2 describes the framework of the proposed data-knowledge hybrid driven method for gas path fault diagnosis. In

Section 3, the methodologies of the physical model-based GPA method, ontology based model, and virtual distance mapping algorithm are described. In

Section 4, a case study of a real General Electric (GE) LM2500 PLUS gas turbine driven natural gas compressor unit is carried out to discuss the feasibility of the proposed hybrid driven method. The conclusions are summarized in the final section.

2. Framework of Data-Knowledge Hybrid Driven Method

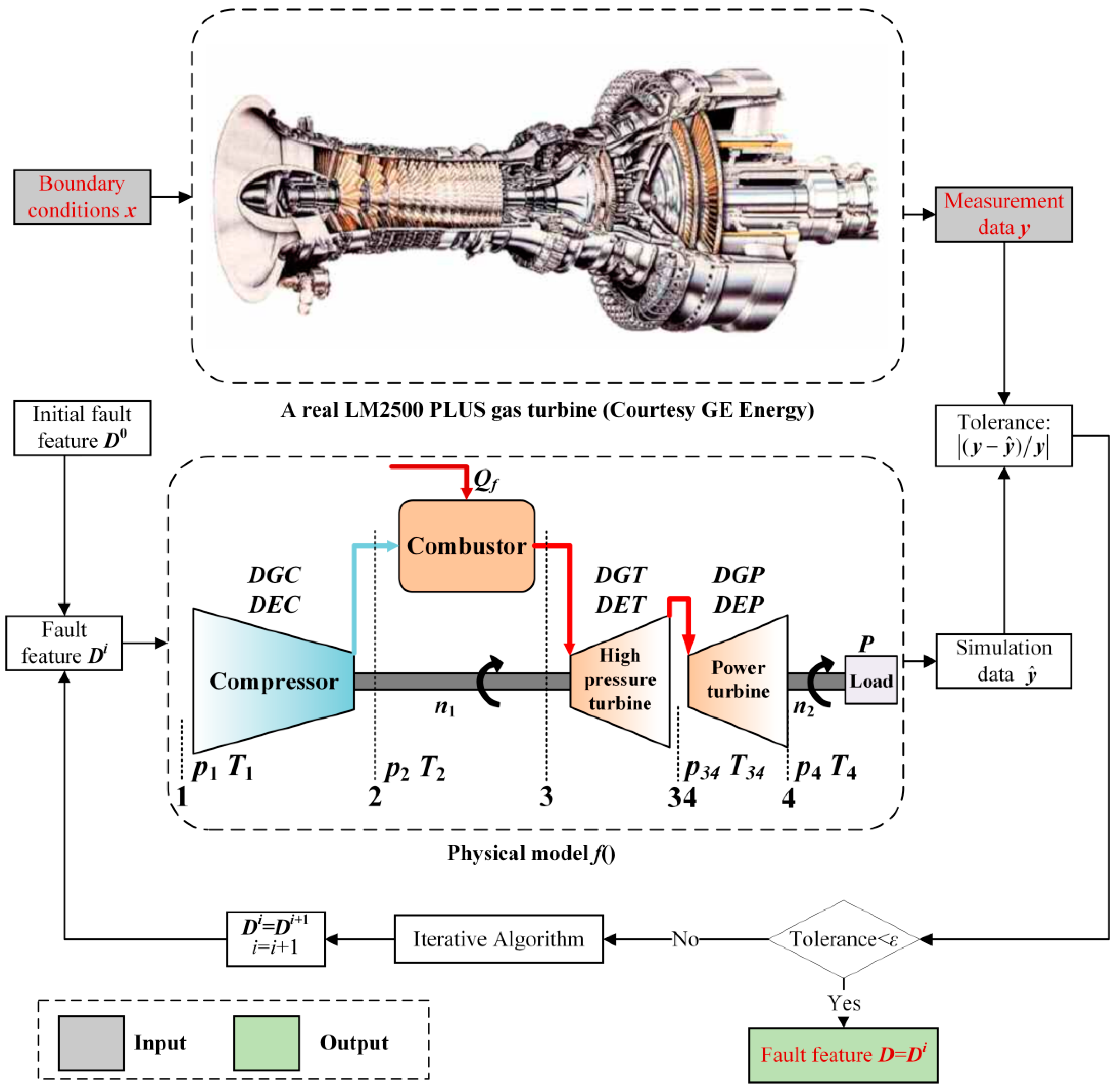

In order to support the whole gas path diagnosis process with task 1 and task 2, a data-knowledge hybrid driven method is proposed. The framework of the hybrid driven method is divided into three parts: the physical model-based GPA method, the ontology based model, and the virtual distance mapping algorithm, as shown in

Figure 1.

The physical model-based GPA method is used to extract the gas path fault features from the field data. The gas path fault mainly affects the aerodynamic characteristics of the compressor and turbine components. Correspondingly, the efficiency degradation and flow rate degradation in the compressor and turbine are selected as the gas path fault features. As shown in

Figure 1, the physical model-based GPA method takes the field data

x and

y as the inputs, and takes the fault feature

D as the output. For a two-shaft gas turbine, the fault feature

D includes the flow degradation and efficiency degradation in the three components: compressor, high pressure turbine, and power turbine. The detailed description of the physical model-based GPA method can be seen in

Section 3.1.

The ontology based model effectively represents the heterogeneous fault knowledge based on a unified semantic expression. The gas path fault diagnosis ontologies are constructed with the knowledge from fault criteria analysis, physical structure analysis, FMECA, and the maintenance logic decision tool. The ontologies are encoded by the Web Ontology Language (OWL), which is recommended by W3C [

26]. With the reasoning engine, the fault information (including fault mode, fault effect, fault criticality, etc.) is reasoned out quickly with the input of the identified feature criteria individual, and a proper maintenance strategy is finally selected. The fault information is ruled by Semantic Web Rule Language (SWRL) stored in the reasoning engine.

The virtual distance mapping algorithm is used to connect the GPA model and the ontology model. The GPA result is mapped to the likelihood of the feature criteria individual. The reference fault features (FFref) are stored in the data property of the feature criteria individual. Firstly, the virtual distance mapping algorithm calculates the probability of each feature criteria individual according to the difference between GPA result and FFref. The more similarity between the GPA result and the FFref, the greater the probability. Then, the GPA result is mapped to a specific feature criteria individual, whose probability exceeds the threshold of 90%. Finally, the script of a mapping rule is generated according to the data property of the mapped feature criteria individual, and the subsequent fault reasoning is performed in the developed fault diagnosis ontology model.

3. Methodology

According to the framework of the proposed data-knowledge hybrid driven method for the gas path fault diagnosis, the methodologies of the physical model-based GPA method, the ontology based model, and the virtual distance mapping algorithm are described in this section.

3.1. Physical Model-Based GPA Method

The schematic of the physical model-based GPA method is shown in

Figure 2. The inputs of the GPA model are boundary conditions

x and measurement data

y, and its output is the fault feature

D. As shown in

Figure 2, the whole solving process of the GPA model is an iterative process. In the

i-th iterative process, the iterative process

Di and boundary condition

x are inputted into the gas turbine physical model

f( ) to obtain the simulation data

of the measurement parameters. The iterative process ends when the simulation data

and actual measurement data

y satisfy the tolerance condition.

The GPA solving process is the reverse of the simulation process of the physical model. Therefore, the gas turbine physical model

f( ) can simulate the measurement parameters based on the boundary condition

x and the fault feature

D. It is a steady-state model which is developed by the energy and mass balance equations. The simulation model can be expressed as follows.

The gas turbine used in this study is a GE LM 2500 PLUS gas turbine engine [

27], shown in

Figure 2. It is a two-shaft gas turbine, which consists of a compressor, a combustor, a high pressure turbine, and a power turbine.

The gas path fault affects the aerodynamic performance in the compressor and turbines. In other word, the characteristic maps derivate from the healthy maps when the gas path fault occurs. The gas path fault feature of each component is defined as follows:

where

DG is the component flow rate degradation,

G is the reduced flow rate in the component characteristic map,

DE is the component efficiency degradation, and

is the efficiency in the component characteristic map. Subscript

f denotes the fault state;

h denotes the healthy state.

Three components (including compressor, high pressure turbine, and power turbine) are analyzed in the GPA method. Consequently, six gas path fault features of the above three components are applied to evaluate the degradation degree of the three components. The gas path fault feature

D = {

DGC,

DEC,

DGT,

DET,

DGP,

DEP} is summarized in

Table 1. The boundary condition

x = {

p1,

T1,

P,

n2} includes ambient pressure

p1 and temperature

T1, output power

P, and power turbine rotational speed

n2. The measurement parameter is

y = {

p2,

T2,

p34,

T34,

p4,

T4,

Qf,

n1}. The

T and

p indicate the temperature and pressure. Subscript 2 indicates compressor outlet, 34 indicates high pressure turbine outlet, and 4 indicates power turbine outlet.

Qf is the fuel flow rate;

n1 is the high pressure rotational speed.

3.2. Ontology Based Model for Gas Path Fault Reasoning

3.2.1. Development of the Fault Diagnosis Ontology Model

Ontology is a powerful technology for organizing massive heterogeneous knowledge and logical relations [

28]. On the one hand, ontology provides the unified formalizing vocabularies to explicitly represent the heterogeneous fault knowledge, avoiding the divergence and misunderstanding between different domain engineers. On the other hand, ontology guarantees the fault reasoning ability by comprehensively analyzing the knowledge relations [

29].

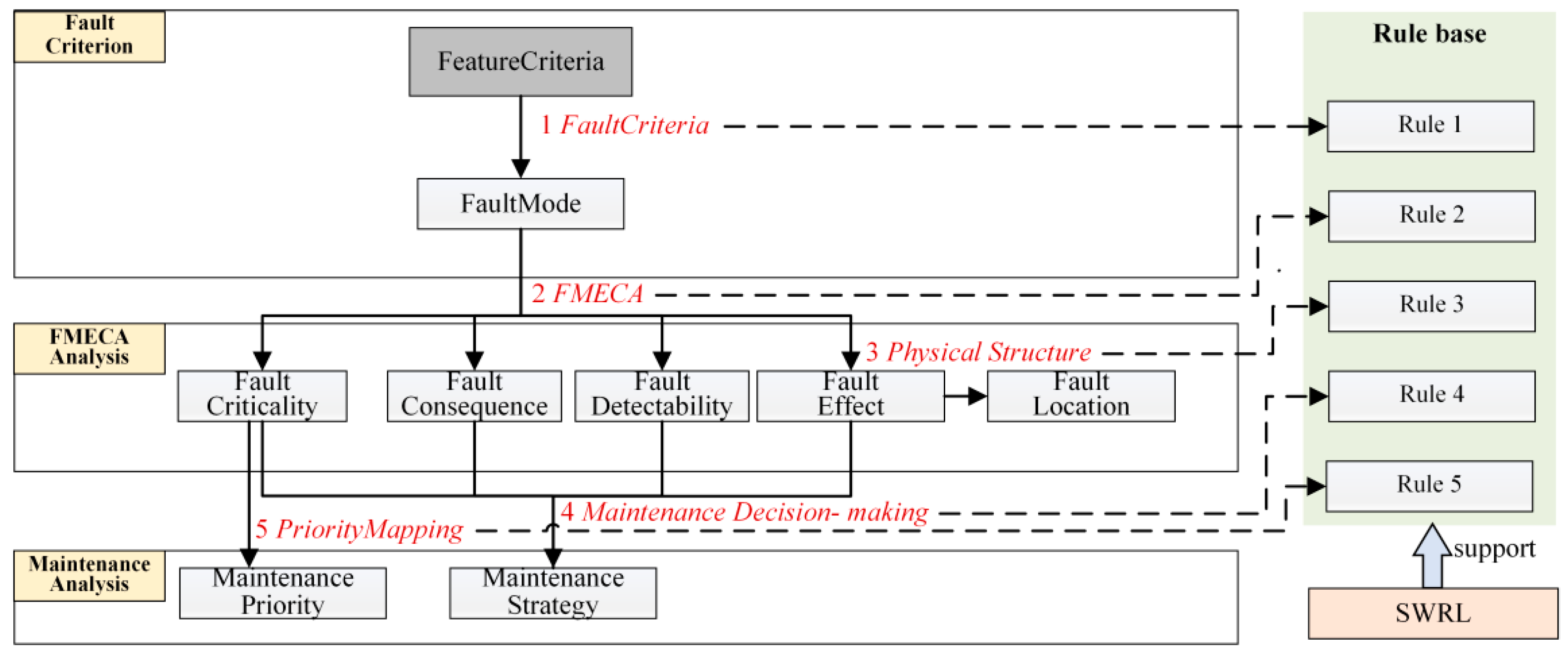

There are several domains of technologies to provide the knowledge for fault reasoning, such as fault criteria analysis, physical structure analysis, FMECA, and the maintenance logic decision tool. The heterogeneous fault knowledge involves massive numbers of terminologies. Consequently, a unified ontology with a hierarchical structure for gas path fault diagnosis is constructed to address the problem of heterogeneous terminologies. Moreover, the ontology can be updated and extended flexibly with the hierarchical architecture, as shown in

Figure 3. In the unified ontology, three classes (including

FaultCriteria,

FMECA, and

MaintenanceAnalysis) are applied to provide a standard fault diagnosis process. The details of the classes are described as follows.

FaultCriteria represents the knowledge from the fault criteria analysis of each gas path fault mode. It has the sub-classes of FeatureCriteria and FaultMode. The FeatureCriteria sub-class represents the reference fault feature of each gas path fault mode. The FaultMode sub-class represents the typical gas path fault modes of a gas turbine.

FMECA represents the knowledge from physical structure analysis and FMECA. It has the sub-classes of FaultLocation, FaultEffect, FaultCriticality, FaultConsequence, FaultDetectablity. The fault information is stored and reasoned in the above sub-classes.

MaintenanceAnalysis represents the knowledge from the maintenance logic decision tool. It has a sub-class of MaintenanceStrategy and MaintenancePriority. The correct maintenance strategy of a fault mode is selected and stored in the MaintenanceStrategy sub-class. The implementation priority of the selected maintenance strategy is stored in the MaintenancePriority sub-class.

In this work, the fault diagnosis ontology model for task 2 is established according to the unified ontology with hierarchical structure (shown in

Figure 3). The OWL is applied to encode the fault diagnosis ontology model. Four components are selected based on the constitution of the OWL ontology [

30], which can be defined as follows.

where

denotes the collection of entities in the ontology. The detailed descriptions of the four components are listed as follows.

Classes: types of objects, or kinds of things.

Individuals: instances of different Classes.

Attributes: aspects, properties, features, and characteristics of Classes.

Relations: relations between different Classes or individuals.

The ontology model can be expressed as follows.

The classes of

FaultCriteria,

FMECA, and

MaintenanceAnalysis can be described as follows.

In summary, nine sub-classes are provided to refine the above three classes.

Figure 4 shows the sub-classes, data properties, and relations of the developed fault diagnosis ontology model. The relations between the classes are described by the

Object Properties and

Data Properties, which are used to reason out the fault information and maintenance from a given

FeatureCriteria. The detailed definitions of the main

Object Properties (shown by the solid lines with arrows in

Figure 4) in the developed ontology model are illustrated in

Table 2. For example, the object property

FC_has_FMd describes the relation between

FeatureCritera and

FaultMode according to the fault criteria knowledge.

3.2.2. Development of Reasoning Rules in the Ontology Model

Task 2 of the diagnosis process is to provide diversified fault information and to select a correct maintenance strategy from the mapped fault criteria individual. Therefore, the querying and reasoning functions should be supported to enable in-depth knowledge reasoning for gas path fault diagnosis. Here, SWRL is used to establish an enhanced reasoning engine for the gas path diagnosis.

According to the predicate logic, the SWRL rules are written to assign the subject, predicate, and object [

31]. The implicit fault knowledge can be discovered with the SWRL rules, realizing in-depth fault knowledge reasoning. The designed gas path fault reasoning engine based on the SWRL rules is shown in

Figure 5.

As shown in

Figure 5, the mapped specific

FeatureCriteria individual is considered as the input of the fault diagnosis reasoning process in task 2. There are five reasoning scenarios to determine the fault information and the correct maintenance strategy.

Rule 1 is used to identify the corresponding fault mode, with the input of the mapped FeatureCriteria individual reasoned out by the mapping rule, which can be express as follows.

hasHappened(?FCta,true)^FeatureCriteria(?FCta)^FaultMode(?FMd)^FCta_has_FMd (?FCta,?FMd)->hasHappened(?FMd,true)

Rule 2 reasons out the fault information (such as fault criticality, fault consequence, fault detectability, fault effect, etc.) with the input of the identified FaultMode individual from Rule 1, which can be express as follows.

hasHappened(?FMd,true)^FMd_has_FCri(?FMd,?FCri)^FMd_has_FCon(?FMd,?FCon)

^FMd_has_FDet(?FMd,?FDet)^FMd_has_FE(?FMd,?FE)->hasHappened(?FCri,true)^hasHappened(?FCon,true)^hasHappened(?FDet,true)^hasHappened(?FE,true)

Rule 3 captures the fault location information, with the input of identified FaultEffect individual from Rule 2, which can be express as follows.

hasHappened(?FE,true)^FaultLocation(?FL)^FaultEffect(?FE)^FE_has_FL(?FE,?FL)

->hasHappened(?FL,true)

Rule 4 selects a proper maintenance strategy with the inputs of FaultDetectability, FaultCriticality, and FaultConsequence individuals from Rule 2, which can be express as follows.

hasHappened(?FCri,true)^hasHappened(?FCon,true)^hasHappened(?FDet,true)

^MaintenanceStrategy(?FMs1)^MaintenanceStrategy(?FMs2)^MaintenanceStrategy(?FMs3)^FCri_has_FMs(?FCri,?FMs)^FCon_has_FMs(?FCon,?FMs)^FDet_has_FMs(?FDet,?FMs->hasHappened(?FMs,true)

Rule 5 determines the maintenance priority, with the inputs of the identified FaultCriticality individual from Rule 2, which can be express as follows.

hasHappened(?FCri,true)^FaultCriticality(?FCri)^MaintenancePriority(?Mp)^ FCri_has_FMp(?FCri,?Mp)->hasHappened(?Mp,true)

Where the bolded elements in Rules 1–5 represent the inputs of each reasoning scenario.

3.3. Virtual Distance Mapping Algorithm

The GPA method is a mathematical model that extracts the fault feature from the field data of a gas turbine. On the other hand, the fault diagnosis ontology model represents the heterogeneous knowledge with a unified semantics. A mapping method is needed to relate the GPA result to a specific

FeatureCriteria individual in the developed ontology model. The reference fault feature (

FFref) from the fault criteria analysis is stored in the data property of the

FeatureCriteria individuals. According to the fault criteria analysis knowledge from previous works [

32,

33,

34], the reference fault features corresponding to several typical gas path fault modes are summarized in

Table 3.

The mapping process consists of three steps. Firstly, the virtual distance is calculated by measuring the Euclidean distance between the GPA result and each FFref. Secondly, a fault probability algorithm based on the virtual distance is presented to identify the most likely FeatureCriteria individual. Finally, the mapping rule script is generated based on the data property of the identified FeatureCriteria individual.

It is noted that there are two turbine components in a two-shaft gas turbine system. The high pressure turbine and power turbine should both consider the turbine fault modes 5, 6, and 7. In summary, ten fault mode individuals are included to analyze the two-shaft gas turbine. For the ten defined FeatureCriteria individuals, the reference fault features stored in the i-th FeatureCriteria individual are (i = 1, 2, 3, …, 10). The first four reference fault features (i = 1, 2, 3, 4) belong to the compressor component, and the next three reference fault features (i = 5, 6, 7) belong to the high pressure turbine component. The last three reference fault features (i = 8, 9, 10) belong to the power turbine component.

As shown in

Table 1, the GPA results are the fault features of the compressor (

DGC,

DEC), high pressure turbine (

DGT,

DET), and power turbine (

DGP,

DEP).

In the compressor component, the virtual distance between the compressor fault features, and the

i-th compressor

(

i = 1, 2, 3, 4) in Euclidean space is defined as follows.

where

di is the virtual distance.

and

are values of the

.

In the high pressure turbine and power turbine components, the virtual distance is defined as follows:

Finally, the virtual distance set is as follows:

The next step is to estimate the probability based on the virtual distance set. Here, the Gaussian distribution function is applied to estimate the fault probability.

where

Pj is the probability of the

i-th

FeatureCriteria individual;

is the standard deviation.

With the smaller value of di, the probability of the i-th FeatureCriteria individual is higher. Here, the probability threshold of 90% is selected to judge whether the corresponding gas path fault occurs. If the probability Pi is more than the threshold, the GPA result would be mapped to the i-th FeatureCriteria individual.

After the specific FeatureCriteria individual is identified by the virtual distance mapping algorithm, the mapping rule script is triggered to modify the data property of hasHappened. Next, the identified FeatureCriteria individual is inputted to trigger Rules 1–5. The mapping rule is as follows.

FeatureCriteria(?FCta)^FlowrateDegradation(?FCta,DG)^EfficiencyDegradation(?FCta, DE)->hasHappened(?FCta,true)

Where DG and DE indicate the values of FlowrateDegradation and EfficiencyDegradation data properties in the mapped FeatureCriteria individual.

4. Case Study

4.1. Problem Statement

A case study for a real GE LM2500 PLUS gas turbine is applied to verify the proposed data-knowledge hybrid driven method. The LM2500 PLUS gas turbine, evolving from the LM2500 gas turbine, is manufactured by the General Electric Company, Shawmut Peninsula, MA, USA. It rolled off the production line in December 1996 [

27]. In this study, the GE LM2500 PLUS gas turbine offers a two-stage high speed power turbine to drive the natural gas compressor unit in the Chinese West–East Gas Pipeline. The GE LM2500 PLUS gas turbine consists of the following components:

17-stage axial compressor

Annular combustion chamber

Two-stage high pressure turbine

Two-stage power turbine

The main parameters at standard ambient conditions (15 °C temperature, 1.013 bar pressure, and 60% relative humidity), defined by the International Standards Organization (ISO), are shown in

Table 4.

A gas turbine shutdown occurred in May 2019, due to the overhigh fluctuations of the vibration parameters. Through borehole inspection, it was found that four stage 11 compressor rotor blades had fallen off the ring groove. Subsequently, the fallen blades caused serious secondary damage to the stage 12–17 compressor blades. In summary, the shut-down of the gas turbine system originated from the foreign objects damage of the compressor blades, and the objects resulted from the fallen pieces of the compressor blade itself. One of the damaged compressor blades is shown in

Figure 6.

4.2. Field Data Analysis Based on GPA Model

Firstly, the physical-model GPA method, described in

Section 3.1, is applied to extract the fault features from the field data. As an example, four parameters (

T1,

p1,

n1, and

n2) of the field data

x and

y collected from the GE LM2500 PLUS gas turbine are displayed in

Figure 7. The gas turbine experienced a sudden shutdown at the moment of 128 s. Before the shutdown, the range of the four parameters was

T1 [26.2 °C, 26.8 °C],

p1 [0.911 bar, 0.927 bar],

n1 [9545 rpm, 9714 rpm], and

n2 [5589 rpm, 5930 rpm].

Secondly, the collected field data are inputted into the GPA model to obtain the six fault features of the compressor (

DGC,

DEC), high pressure turbine (

DGT,

DET), and power turbine (

DGP,

DEP). In this study, the gas path fault occurs in the compressor. Correspondingly, the extracted compressor fault features of

DGC and

DEC are selected to analyze the compressor fault mode. The variations of

DGC and

DEC are shown in

Figure 8. The

DGC varies within a range of 1% before the sudden shutdown. However, the

DEC shows an exception (reaching about 5%) at the moment of about 110 s. This

DEC exception indicates that the gas path fault would already occur at the moment of about 110 s. The results show that the GPA method can detect the gas path fault 18 s in advance, compared with the vibration monitoring system.

4.3. Virtual Distance Mapping Analysis

After extracting the fault features (shown in

Figure 8) using the GPA model, the similar probability of the four compressor reference fault features

(

i = 1, 2, 3, 4) are calculated using the virtual distance mapping algorithm. The calculated probabilities of the compressor reference fault features are shown in

Figure 9. The similar probability of the

FeatureCriteria individual (

DGref = 1% and

DEref = 5%) reaches the threshold of 90% at 112 s. The maximum probabilities of the other three compressor

FeatureCriteria individuals are only 33.81% (

DGref = 7%,

DEref = 2%), 34.32% (

DGref = 4%,

DEref = 0), and 21.02% (

DGref = 0,

DEref = 2%). According to the mapping rule, the most likely

FeatureCriteria individual has the data property of

DGref = 1% and

DEref = 5%. Consequently, the mapping rule can be written and triggered, as follows:

FeatureCriteria(?FCta)^FlowrateDegradation(?FCta,0.01)^EfficiencyDegradation(?FCta, 0.05)->hasHappened(?FCta,true)

4.4. Extraction of Fault Diagnosis Knowledge

According to the method shown in

Section 3.2, the fault diagnosis ontology model is developed based on the heterogeneous knowledge sources, including fault criteria analysis, physical structure analysis, FMECA, and the maintenance logic decision tool. The fault criteria analysis of the seven typical gas path fault modes has been summarized in

Table 3. The other knowledge sources in this case study will be described as follows.

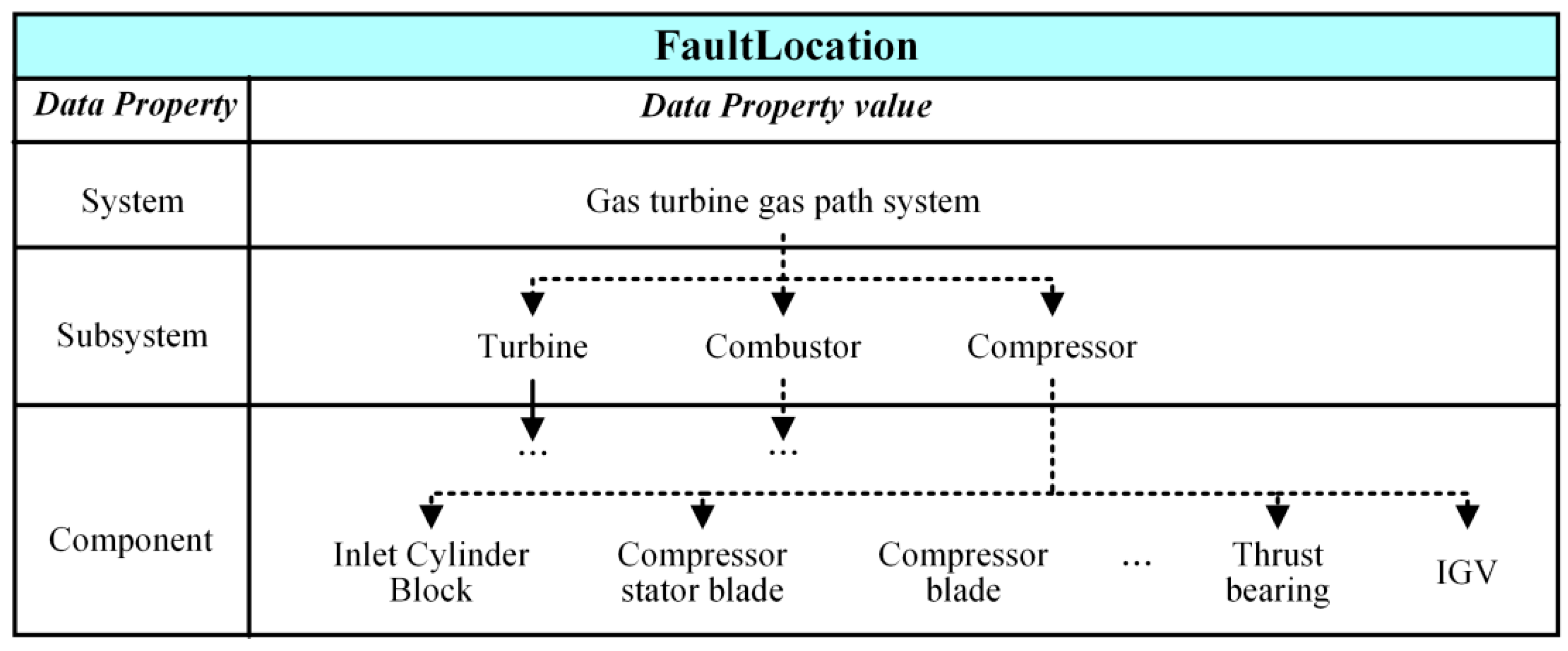

As a reliability analysis method, RCM aims to determine the maintenance strategy and fault information in a structured way. The RCM process is completed by two analysis tools: FMECA and the maintenance logic decision tool [

35]. The first step is to analyze the fault modes, effects, criticality, and consequences using the FMECA tool. The second step is to select a correct maintenance strategy using the maintenance logic decision tool. In the FMECA process, the fault effects on different levels are analyzed based on the knowledge of physical structure analysis. In this work, three level effects (local effect, higher level effect, and system effect) correspond to three levels of physical structures. As shown in

Figure 10, the gas turbine gas path system is divided into three levels of physical structures (system, subsystem, and component) to locate the fault effects. Consequently, the above three level structures are considered as the data properties of the

FaultLocation individual.

The system data property has the value of “Gas turbine gas path system”. The subsystem data property has the value of “Turbine”, “Combustor”, and “Compressor”. The component data property has the value of “stator blade”, “rotor blade”, “thrust bearing”, etc.

The FMECA knowledge of the typical gas path fault modes is summarized in

Table 5. The fault effect, fault criticality, fault consequence, and detectability of seven gas path fault modes are analyzed and stored in the

FaultEffect,

FaultCriticality,

FaultConsequence, and

FaultDeteability sub-classes.

The fault criticality indicates the risk of the fault mode according to the fault severity and fault frequency. The fault criticality is divided into three levels, including low, medium, and high.

Generally, there are four kinds of fault consequences, including hidden consequence, safety consequence, operational consequence, and non-operational consequence. The explanations of the four fault consequences are as follows:

Hidden consequence, which cannot be detected by a monitoring system and can be found by periodic testing. Therefore, the fault modes with hidden consequence are undetectable.

Safety consequence, which involve the casualty of human beings.

Operational consequence, which cause economic loss due to the adverse effect on operational capability.

Non-operational consequence, which only involves the economic loss in repair costs.

In order to eliminate the subjectivity involved in selecting a proper maintenance strategy, a maintenance logic decision diagram is applied to build the relationship between fault characteristics and fault maintenance. The maintenance logic decision knowledge stored in the ontology model is shown in

Figure 11. The maintenance strategy is logically reasoned out based on the fault characteristics from FMECA, including the fault consequence, fault criticality, and detectability. In summary, there are four types of maintenance strategies: corrective maintenance, condition-based maintenance, time-based maintenance (inspect, replace, and test), and maintenance after shutdown. Each fault mode can be dealt with using a proper maintenance strategy based on the logic decision diagram.

4.5. Development of Ontology Model and Diagnosis Reasoning

In this section, the ontology model is developed based on the extracted fault diagnosis knowledge. The fault diagnosis ontology model is constructed using Protégé 5.5 software. As an excellent ontology model construction tool, Protégé 5.5 has both application types of GUI and API interface and can construct

Class,

Property,

Individual, and

Rule [

36].

Figure 12 demonstrates the fault diagnosis ontology model and the reasoning rules in Protégé 5.5.

Figure 12A shows the developed fault diagnosis ontology model. The classes of

FaultCriteria,

FMECA, and

MaintenanceAnalysis are built first. Then, the corresponding sub-classes are constructed to formalize the basic concepts of the fault diagnosis knowledge. Furthermore, the individuals and object properties are created in sequence to represent the fault knowledge.

Figure 12B shows the hierarchical structure of the developed classes and sub-classes using the

OntoGraf plug-in [

37]. As shown in

Figure 12B, the

FaultCriteria class has the sub-classes of

FeatureCriteria and

FaultMode. Finally, the mapping rule and five diagnosis reasoning rules are also encoded in the Protégé 5.5, as shown in

Figure 12C.

Figure 13 demonstrates the reasoning process of the fault diagnosis ontology model. Firstly, the mapping rule with

DGref = 1% and

DEref = 5% (generated in

Section 4.3) is triggered to identify the corresponding

FeatureCriteria individual. As a result, the

FCta_comp_003 is identified, and its data property

hasHappened is modified to “

true”.

Next, the FaultMode individual of FMd_comp_003 (compressor foreign object damage) is reasoned out by rule 1, with the object property of FCta_has_FMd in the FeatureCriteria individual. The data property of hasHappened in FMd_comp_003 is also set to “true” by rule 1.

After identifying the FMd_comp_003, rule 2 is trigged to reason out the fault information, such as FE_comp_003 (FaultEffect), FCri_comp_003 (FaultCriticality: “High”), FDet_comp_003 (FaultDetectability: “YES”), FCon_comp_003 (FaultConsequence: “Operational”). The reasoning results show that the local effect corresponding to FMd_comp_003 is “Reducing compressor efficiency sharply,” the higher-level effect is “Causing damage on compressor, combustor, and turbine, Reducing compressor power consumption”, and the system effect is “Reducing system economy and lifetime”. The reasoning results are consistence with the FMECA knowledge in

Table 5, which proves that the developed fault diagnosis ontology model is effective to represent the FMECA knowledge.

Rule 3 is triggered with the input of FE_comp_003. The fault location FL_comp_001 is reasoned out to locate the fault effects on different physical structure levels. The data properties (Component: “compressor blades”, Subsystem: “compressor”, System: “Gas turbine gas path system”) of FL_comp_001 are reasoned out.

Rule 4 reasons out the maintenance strategy FMs_comp_001 (“condition-based maintenance”) with the input of FDet_comp_003, FCri_comp_003, and FCon_comp_003.

Rule 5 reasons out the maintenance priority FMp_comp_001 (“high”) with the input of FCri_comp_003. Therefore, the maintenance priority of the “compressor foreign object damage” fault mode is “high”.