A Practical Model Study on the Mechanism of Clay Landslide under Static Loads: From the Perspective of Major Crack–Stress–Displacement

Abstract

:1. Introduction

2. Stress Mechanism of Major Crack Initiation and Development

3. Model Experiment

4. Results and Discussion

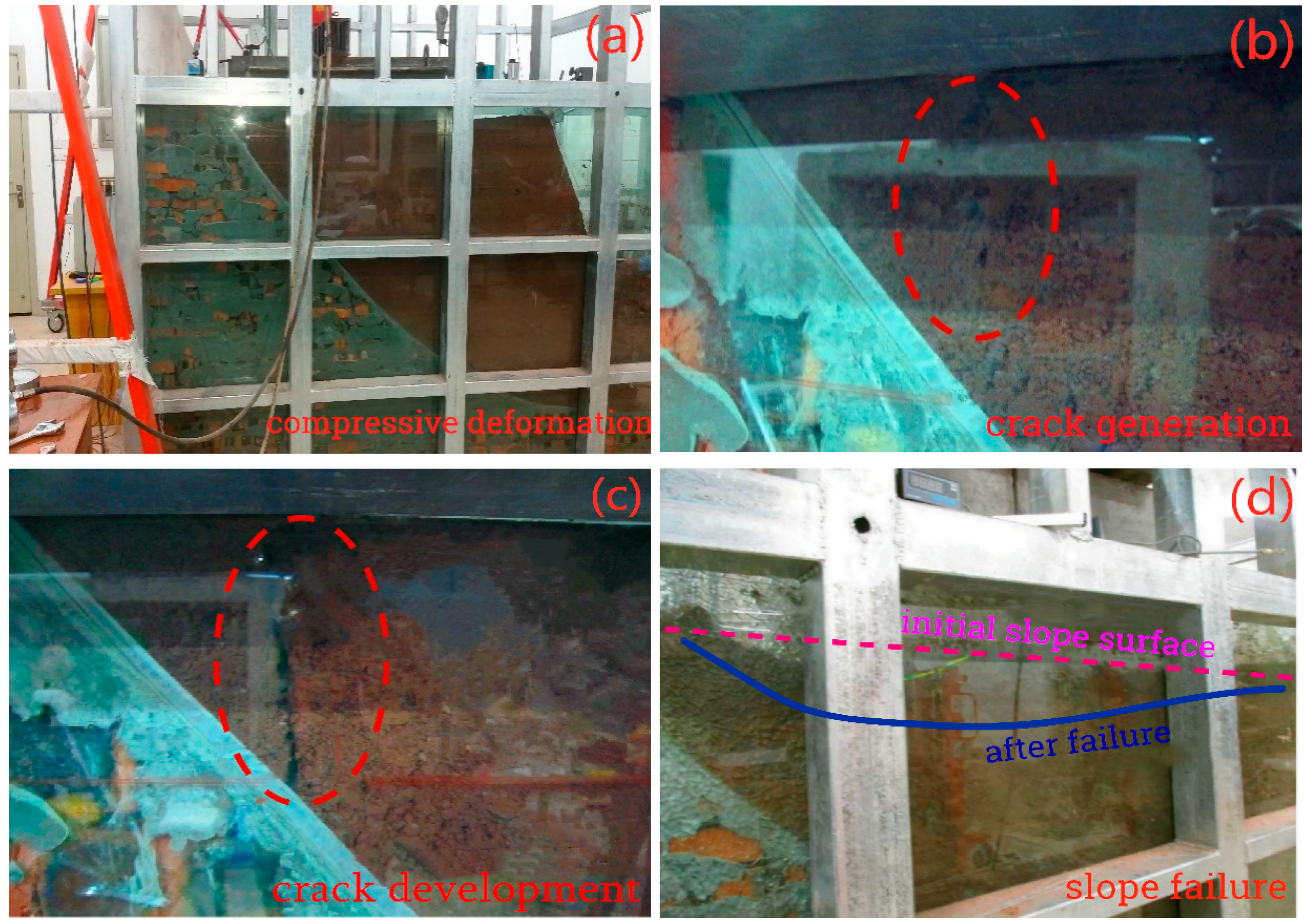

4.1. Major Cracks and Displacement

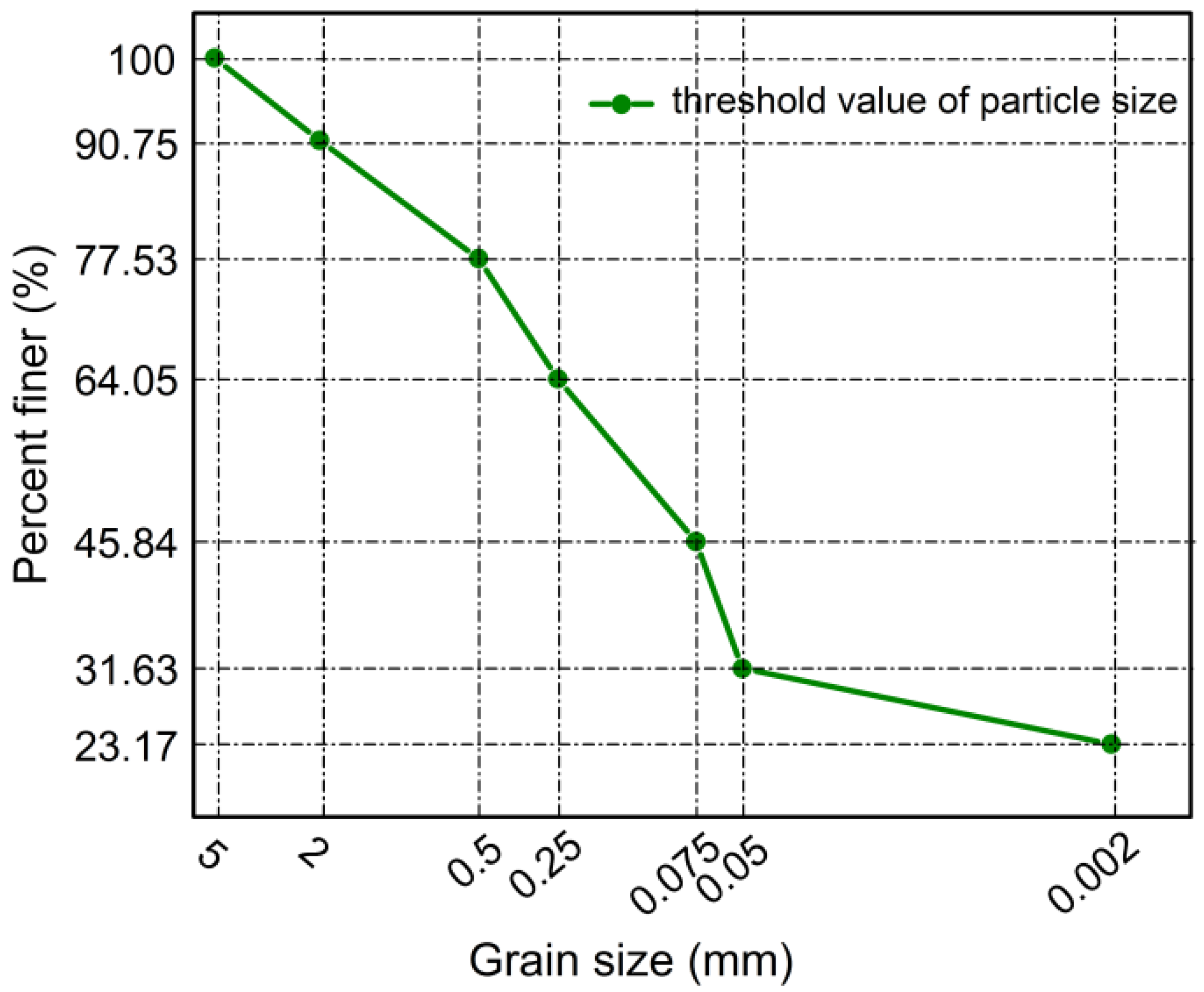

4.1.1. Factors Affecting the Development of Cracks in Clay Slopes

4.1.2. Influence of Preset Slip Surface and Loading Mode

4.2. Major Cracks and Stress Variations

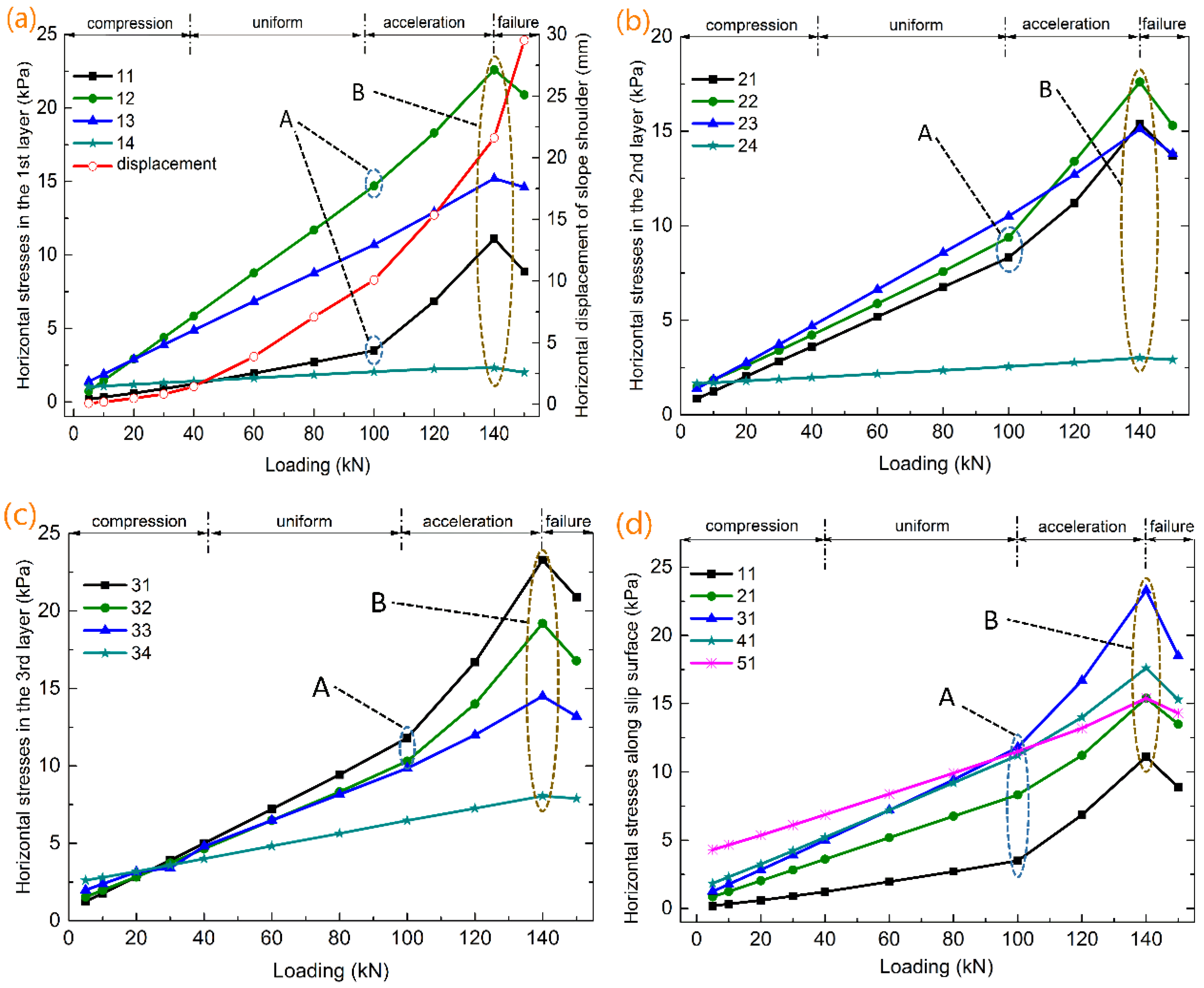

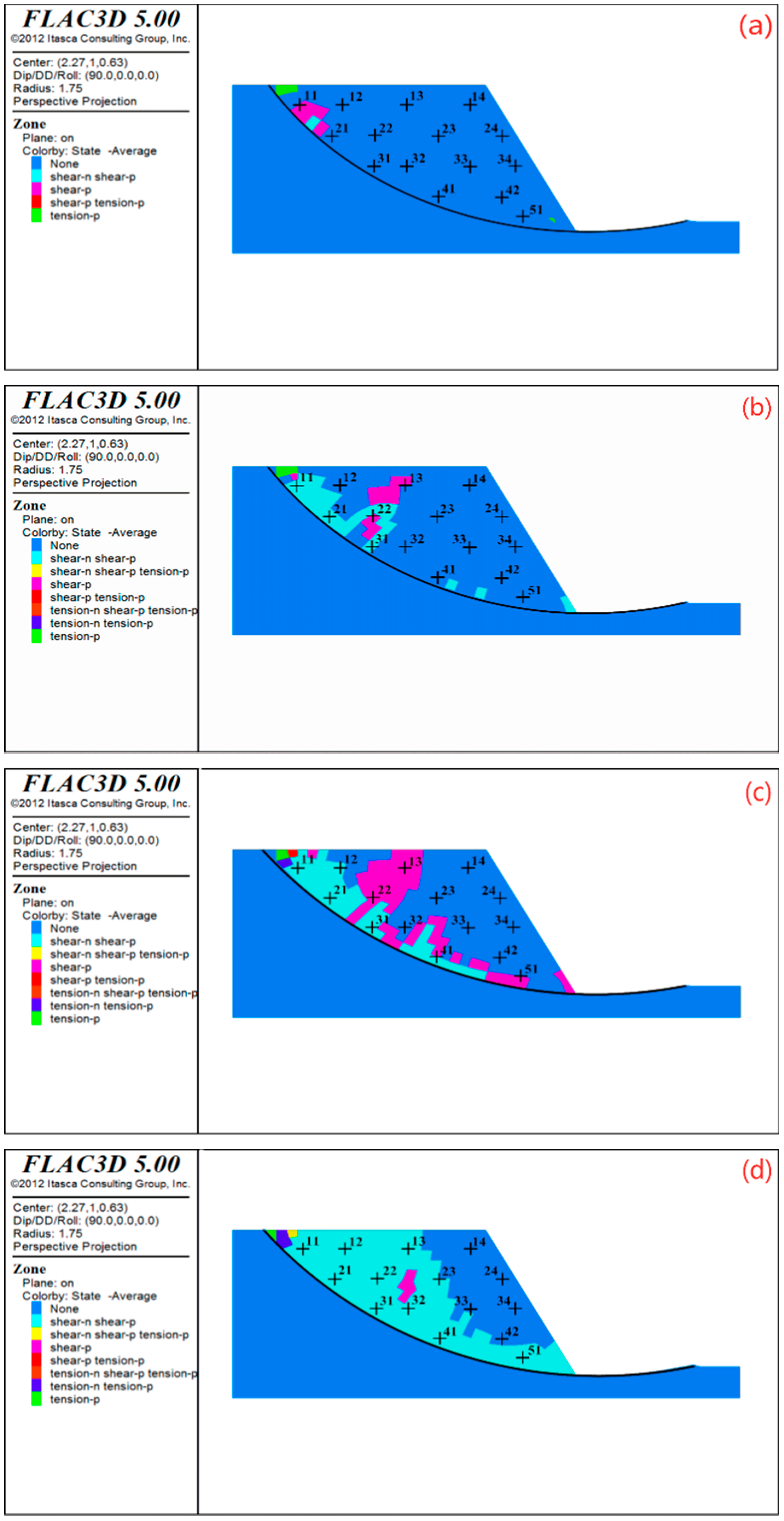

4.2.1. Evolution of Major Cracks with Horizontal and Vertical Stresses

4.2.2. Locations and Depths of the Major Cracks

4.2.3. Rationality and Correctness of the Test Method to Monitor the Evolution of the Major Cracks

4.3. Intrinsic Consistency of the Evolution of Major Cracks, Displacements, and Horizontal Stresses

5. Conclusions and Suggestions

- The development process of major cracks is inherently consistent with the variation processes of horizontal stresses near the major cracks and slope shoulder displacements. In addition, the limit loads of horizontal stresses and displacements are consistent. When no cracks appear, the displacements increase slowly or uniformly, while the horizontal stresses increase uniformly. When a trailing edge crack occurs, the development of horizontal stresses and slope shoulder displacements begin to accelerate in general. The occurrence of the front edge crack causes the horizontal stresses of the nearby measuring points to appear as inflection points. At the same time, the slope shoulder displacements develop rapidly.

- In the process of stress transfer and redistribution under loading, the horizontal stresses near the major cracks appear as inflection points and accelerated growth. The locations and depths of the major cracks could be determined by analyzing the horizontal stress differences between adjacent measuring points. It is recommended that horizontal stresses be used to reflect the development process of major cracks.

- Due to the proximity to the slip surface, the appearance and development of the tension–shear vertical crack at the trailing edge have a more significant impact on the displacement of the slope shoulder and the horizontal stresses. Compared to the front edge shear diagonal crack, the trailing edge crack has a greater impact on the landslide.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keller, T.; Lamand, M.; Peth, S.; Berli, M.; Delenne, J.Y.; Baumgarten, W.; Rabbel, W.; Radja, F.; Rajchenbach, J.; Selvadurai, A.P.S.; et al. An interdisciplinary approach towards improved understanding of soil deformation during compaction. Soil Tillage Res. 2013, 128, 61–80. [Google Scholar] [CrossRef] [Green Version]

- Viswanadham, B.; Rajesh, S. Centrifuge model tests on clay based engineered barriers subjected to differential settlements. Appl. Clay Sci. 2009, 42, 460–472. [Google Scholar] [CrossRef]

- Tang, C.S.; Wang, D.Y.; Zhu, C.; Zhou, Q.Y.; Xu, S.K.; Shi, B. Characterizing drying-induced clayey soil desiccation cracking process using electrical resistivity method. Appl. Clay Sci. 2018, 152, 101–112. [Google Scholar] [CrossRef]

- Hu, F.; Li, Z.; Tian, Y.; Hu, R. Failure patterns and morphological soil–rock interface characteristics of frozen soil–rock mixtures under compression and tension. Appl. Sci. 2021, 11, 461. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.S.; Xu, D.; Zeng, H.; Shi, B. Water infiltration in a cracked soil considering effect of drying-wetting cycles. J. Hydrol. 2021, 593, 125640. [Google Scholar] [CrossRef]

- Sima, J.; Jiang, M.; Zhou, C. Numerical simulation of desiccation cracking in a thin clay layer using 3D discrete element modeling. Comput. Geotech. 2014, 56, 168–180. [Google Scholar] [CrossRef]

- Ren, J.H.; Li, X.J.; Zhao, K. Quantitative analysis of relationships between crack characteristics and properties of soda-saline soils in Songnen Plain, China. Chin. Geogr. Sci. 2015, 25, 591–601. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.S.; Chen, Z.G.; El-Maarry, M.R.; Zeng, H.; Shi, B. Tensile behavior of clayey soils during desiccation cracking process. Eng. Geol. 2020, 279, 105909. [Google Scholar] [CrossRef]

- Li, J.H.; Lu, Z.; Guo, L.B.; Zhang, L.M. Experimental study on soil-water characteristic curve for silty clay with desiccation cracks. Eng. Geol. 2017, 218, 70–76. [Google Scholar] [CrossRef]

- Feng, L.C.; Lang, X.Q. Experimental study on the mechanism of landslip crevices. J. Lanzhou Univ. 1980, 1, 120–130. [Google Scholar]

- Yu, J. Selection of parameters and method to determine forecasting standards for landslide. Chin. J. Geol. Hazard Control 1992, 3, 39–47. [Google Scholar]

- Chen, T.L.; Zhou, C.; Shen, Z.J. Analysis of deformation characteristics of clay. Rock Soil Mech. 2004, 25, 522–528. [Google Scholar]

- Lakshmikantha, M.R.; Prat, P.C.; Ledesma, A. Experimental evidence of size effect in soil cracking. Can. Geotech. J. 2012, 49, 264–284. [Google Scholar] [CrossRef]

- Levatti, H.U.; Prat, P.C.; Ledesma, A. Numerical and experimental study of initiation and propagation of desiccation cracks in clayey soils. Comput. Geotech. 2019, 105, 155–167. [Google Scholar] [CrossRef]

- Konrad, J.M.; Ayad, R. An idealized framework for the analysis of cohesive soils undergoing desiccation. Can. Geotech. J. 1997, 34, 477–488. [Google Scholar] [CrossRef]

- Yan, S.; Guo, B.; Chu, J.; Sun, L. Mechanism study and model tests on soft clay cracking. In Proceedings of the Geo-Shanghai 2014, Shanghai, China, 26–28 May 2014; ASCE Press: Reston, VA, USA, 2014; pp. 184–193. [Google Scholar]

- Trabelsi, H.; Jamei, M.; Zenzri, H.; Olivella, S. Crack patterns in clayey soils: Experiments and modeling. Int. J. Numer. Anal. Methods Geomech. 2012, 36, 1410–1433. [Google Scholar] [CrossRef]

- Lee, F.H.; Lo, K.W.; Lee, S.L. Tension crack development in soils. J. Geotech. Eng. 1988, 114, 915–929. [Google Scholar] [CrossRef]

- Vogel, H.J.; Hoffmann, H.; Leopold, A.; Roth, K. Studies of crack dynamics in clay soil II. A physically based model for crack formation. Geoderma 2005, 125, 213–223. [Google Scholar] [CrossRef]

- Morris, P.H.; Graham, J.; Williams, D.J. Cracking in drying soils. Can. Geotech. J. 1992, 29, 263–277. [Google Scholar] [CrossRef]

- Kodikara, J.K.; Choi, X. A simplified analytical model for desiccation cracking of clay layers in laboratory tests. In Proceedings of the Fourth International Conference on Unsaturated Soils, Carefree, AZ, USA, 2–6 April 2006; ASCE Press: Reston, VA, USA, 2006; pp. 2558–2569. [Google Scholar]

- Ma, J.; Chen, S.X.; Yu, F.; Feng, M.G. Experimental research on crack evolution process in fissured clay. Rock Soil Mech. 2007, 28, 2203–2208. [Google Scholar]

- Deng, G.; Shen, Z.J.; Yang, D.Q. Numerical simulation of crack formation due to desiccation in clay surface. Chin. J. Geotech. Eng. 2006, 28, 241–248. [Google Scholar]

- He, K.; Song, C.; Fell, R. Numerical modelling of transverse cracking in embankment dams. Comput. Geotech. 2021, 132, 104028. [Google Scholar] [CrossRef]

- Kitsunezaki, S. Crack growth and plastic relaxation in a drying paste layer. J. Phys. Soc. Jpn. 2010, 79, 124802. [Google Scholar] [CrossRef]

- Utili, S.; Abd, A.H. On the stability of fissured slopes subject to seismic action. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 785–806. [Google Scholar] [CrossRef]

- Utili, S. Investigation by limit analysis on the stability of slopes with cracks. Géotechnique 2013, 63, 140–154. [Google Scholar] [CrossRef]

- Michalowski, R.L. Stability assessment of slopes with cracks using limit analysis. Can. Geotech. J. 2013, 50, 1011–1021. [Google Scholar] [CrossRef]

- Gao, Y.F.; Song, W.Z.; Zhang, F.; Qin, H.Y. Limit analysis of slopes with cracks: Comparisons of results. Eng. Geol. 2015, 188, 97–100. [Google Scholar] [CrossRef]

- Stockton, E.; Leshchinsky, B.A.; Olsen, M.J.; Evans, T.M. Influence of both anisotropic friction and cohesion on the formation of tension cracks and stability of slopes. Eng. Geol. 2019, 249, 31–44. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X. Stability analysis of crack slope considering nonlinearity and water pressure. KSCE J. Civ. Eng. 2015, 20, 2289–2296. [Google Scholar] [CrossRef]

- Zhao, L.H.; Cheng, X.; Dan, H.C.; Tang, Z.P.; Zhang, Y. Effect of the vertical earthquake component on permanent seismic displacement of soil slopes based on the nonlinear Mohr–Coulomb failure criterion. Soils Found. 2017, 57, 237–251. [Google Scholar] [CrossRef]

- Zhao, L.H.; Cheng, X.; Li, L.; Chen, J.Q.; Zhang, Y.B. Seismic displacement along a log-spiral failure surface with crack using rock Hoek–Brown failure criterion. Soil Dyn. Earthq. Eng. 2017, 99, 74–85. [Google Scholar] [CrossRef]

- Li, Z.W.; Yang, X.L.; Li, T.Z. Static and seismic stability assessment of 3D slopes with cracks. Eng. Geol. 2020, 265, 105450. [Google Scholar] [CrossRef]

- Zheng, Y.R.; Kong, L. Geotechnical Plastic Mechanics; China Architecture and Building Press: Beijing, China, 2010. [Google Scholar]

- Michalowski, R.L. Reply to the discussion by Utili on “Stability assessment of slopes with cracks using limit analysis”. Can. Geotech. J. 2014, 51, 826–827. [Google Scholar] [CrossRef]

- Hu, X.W.; Li, Q.F.; Zhao, Z.S.; Kong, D.F. Mechanical properties of fissured clay. Chin. J. Geotech. Eng. 1994, 16, 81–88. [Google Scholar]

- Ma, H.S.; Hu, X.W. Numerical simulation research on fissure effect of clay masses. J. Mineral. Petrol. 1998, 18, 182–184. [Google Scholar]

- Abd, A.H.; Utili, S. Design of geosynthetic-reinforced slopes in cohesive backfills. Geotext. Geomembr. 2017, 45, 627–641. [Google Scholar] [CrossRef]

- Huang, R.Q. Geodynamical process and stability control of high rock slope development. Chin. J. Rock Mech. Eng. 2008, 27, 1525–1544. [Google Scholar]

- Leung, A.K.; Ng, C.W.W. Field investigation of deformation characteristics and stress mobilisation of a soil slope. Landslides 2016, 13, 229–240. [Google Scholar] [CrossRef] [Green Version]

- Vesga, L.F.; Vallejo, L.E.; Lobo-Guerrero, S. DEM analysis of the crack propagation in brittle clays under uniaxial compression tests. Int. J. Numer. Anal. Methods 2008, 32, 1405–1415. [Google Scholar] [CrossRef]

- Yalcin, A. The effects of clay on landslides: A case study. Appl. Clay Sci. 2007, 38, 77–85. [Google Scholar] [CrossRef]

- Gui, Y.L.; Zhao, Z.Y.; Kodikara, J.; Bui, H.H.; Yang, S.Q. Numerical modelling of laboratory soil desiccation cracking using UDEC with a mix-mode cohesive fracture model. Eng. Geol. 2016, 202, 14–23. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.R. Influence of structure on the behavior of a saturated clayey loess. Can. Geotech. J. 2016, 53, 1026–1037. [Google Scholar] [CrossRef]

- Lu, N.; Likos, W.J. Unsaturated Soil Mechanics; John Wiley and Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Baker, R. Sufficient conditions for existence of physically significant solutions in limiting equilibrium slope stability analysis. Int. J. Solids Struct. 2003, 40, 3717–3735. [Google Scholar] [CrossRef]

- Baker, R. Tensile strength, tension cracks, and stability of slopes. Soils Found. 1981, 21, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Vitone, C.; Cotecchia, F.; Desruse, J.; Viggiani, G. An approach to the interpretation of the mechanical behaviour of intensely fissured clays. Soils Found. 2009, 49, 355–368. [Google Scholar] [CrossRef] [Green Version]

- Vitone, C.; Viggiani, G.; Cotecchia, F.; Hall, S.A. Localized deformation in intensely fissured clays studied by 2D digital image correlation. Acta Geotech. 2013, 8, 247–263. [Google Scholar] [CrossRef]

- Zhang, G.; Hu, Y.; Wang, L.P. Behaviour and mechanism of failure process of soil slopes. Environ. Earth Sci. 2015, 73, 1701–1713. [Google Scholar] [CrossRef]

- Liu, C.N.; Wu, C.C. Integrating GIS and stress transfer mechanism in mapping rainfall-triggered landslide susceptibility. Eng. Geol. 2008, 101, 60–74. [Google Scholar] [CrossRef]

- Zhang, G.; Hu, Y. Numerical modeling of failure process of soil slopes. Int. J. Geomech. 2017, 17, 6016031. [Google Scholar] [CrossRef]

- Sun, J.C.; Wang, G.Q.; Sun, Q.C. Crack spacing of unsaturated soils in the critical state. Chin. Sci. Bull. 2009, 54, 2008–2012. [Google Scholar] [CrossRef] [Green Version]

- Lachenbruch, A.H. Depth and spacing of tension cracks. J. Geophys. Res. 1961, 66, 4273–4292. [Google Scholar] [CrossRef]

- Ayad, R.; Konrad, J.M.; Soulié, M. Desiccation of a sensitive clay: Application of the model CRACK. Can. Geotech. J. 1997, 34, 943–951. [Google Scholar] [CrossRef]

- Michalowski, R.L. Stability of intact slopes with tensile strength cut-off. Géotechnique 2017, 67, 720–727. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Utili, S. Stability of intact slopes with tensile strength cut-off: Discussion. Géotechnique 2019, 69, 1123–1126. [Google Scholar] [CrossRef]

- Hou, H.J.; Wang, B.; Deng, Q.X.; Zhu, Z.W.; Xiao, F. Model experimental study on stress transfer and redistribution in a clay landslide under surcharge Load. Adv. Mater. Sci. Eng. 2020, 2020, 4269043. [Google Scholar] [CrossRef]

- Vallejo, L.E. Fracture criteria for fissured clays under mixed-mode loading. In Proceedings of the Geo-Frontiers Congress 2011, Dallas, TX, USA, 13–16 March 2011; ASCE Press: Reston, VA, USA, 2011; pp. 3858–3867. [Google Scholar]

- Lu, Y.F.; Huang, X.B.; Liu, D.F. Distribution characteristics of force and stability analysis of slope. Chin. J. Geotech. Eng. 2017, 39, 1321–1329. [Google Scholar]

- Yong, R.; Hu, X.L.; Tang, H.M.; Li, C.D.; Ma, J.W.; Song, Y.J. Model testing and numerical simulation study of evolutionary process of thrust load caused landslide. Rock Soil Mech. 2013, 34, 3018–3027. [Google Scholar]

- Cotecchia, F.; Vitone, C.; Santaloia, F.; Pedone, G.; Bottiglieri, O. Slope instability processes in intensely fissured clays: Case histories in the Southern Apennines. Landslides 2015, 12, 877–893. [Google Scholar] [CrossRef]

- Skempton, A.W. First-time slides in over-consolidated clays. Géotechnique 1970, 20, 320–324. [Google Scholar] [CrossRef]

| Name | Unit Weight | Effective Cohesion | Effective Friction Angle | Young’s Modulus | Poisson’s Ratio |

|---|---|---|---|---|---|

| (kN/m3) | (kPa) | (°) | (MPa) | ||

| Slip Mass | 19.88 | 16.00 | 21.00 | 1.00 × 109 | 0.30 |

| Slide Bed | 30.00 | 5.00 × 103 | 35.00 | 1.00 × 109 | 0.30 |

| Sliding Surface | Cohesion | Friction Angle | Normal Stiffness | Tangential Stiffness | Dilation Angle |

| (kPa) | (°) | (MPa) | (MPa) | (°) | |

| 0.80 | 18.00 | 2.00 | 20.00 | 18.00 |

| Monitoring Point | Distance from Loading Center/m | Slope of Stress Curve (Mean Value) | Vertical Stress Slope (0–140 kN) | ||

|---|---|---|---|---|---|

| 0–100 kN | 100–140 kN | 140–150 kN | |||

| 11 | 0.5 | 0.033 | 0.190 | −0.223 | 0.222 |

| 12 | 0.1 | 0.147 | 0.198 | −0.171 | 0.494 |

| 13 | 0.5 | 0.099 | 0.113 | −0.060 | 0.264 |

| 14 | 1.1 | 0.011 | 0.007 | −0.031 | 0.004 |

| 21 | 0.2 | 0.079 | 0.177 | −0.170 | 0.422 |

| 22 | 0.2 | 0.082 | 0.206 | −0.230 | 0.400 |

| 23 | 0.8 | 0.095 | 0.115 | −0.130 | 0.070 |

| 24 | 1.4 | 0.009 | 0.012 | −0.010 | 0.009 |

| 31 | 0.2 | 0.108 | 0.288 | −0.241 | 0.302 |

| 32 | 0.5 | 0.091 | 0.223 | −0.242 | 0.179 |

| 33 | 1.1 | 0.082 | 0.116 | −0.130 | 0.051 |

| 34 | 1.5 | 0.040 | 0.039 | −0.015 | 0.037 |

| 41 | 0.8 | 0.098 | 0.160 | −0.230 | 0.117 |

| 51 | 1.6 | 0.075 | 0.098 | −0.110 | 0.058 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, H.; Zhu, Z.; Wang, B.; Zhou, W. A Practical Model Study on the Mechanism of Clay Landslide under Static Loads: From the Perspective of Major Crack–Stress–Displacement. Appl. Sci. 2022, 12, 3224. https://doi.org/10.3390/app12073224

Hou H, Zhu Z, Wang B, Zhou W. A Practical Model Study on the Mechanism of Clay Landslide under Static Loads: From the Perspective of Major Crack–Stress–Displacement. Applied Sciences. 2022; 12(7):3224. https://doi.org/10.3390/app12073224

Chicago/Turabian StyleHou, Hengjun, Zhengwei Zhu, Bo Wang, and Wenhao Zhou. 2022. "A Practical Model Study on the Mechanism of Clay Landslide under Static Loads: From the Perspective of Major Crack–Stress–Displacement" Applied Sciences 12, no. 7: 3224. https://doi.org/10.3390/app12073224

APA StyleHou, H., Zhu, Z., Wang, B., & Zhou, W. (2022). A Practical Model Study on the Mechanism of Clay Landslide under Static Loads: From the Perspective of Major Crack–Stress–Displacement. Applied Sciences, 12(7), 3224. https://doi.org/10.3390/app12073224