Shear Behavior of Superposed Perfobond Connectors Considering Lateral Constraints

Abstract

:1. Introduction

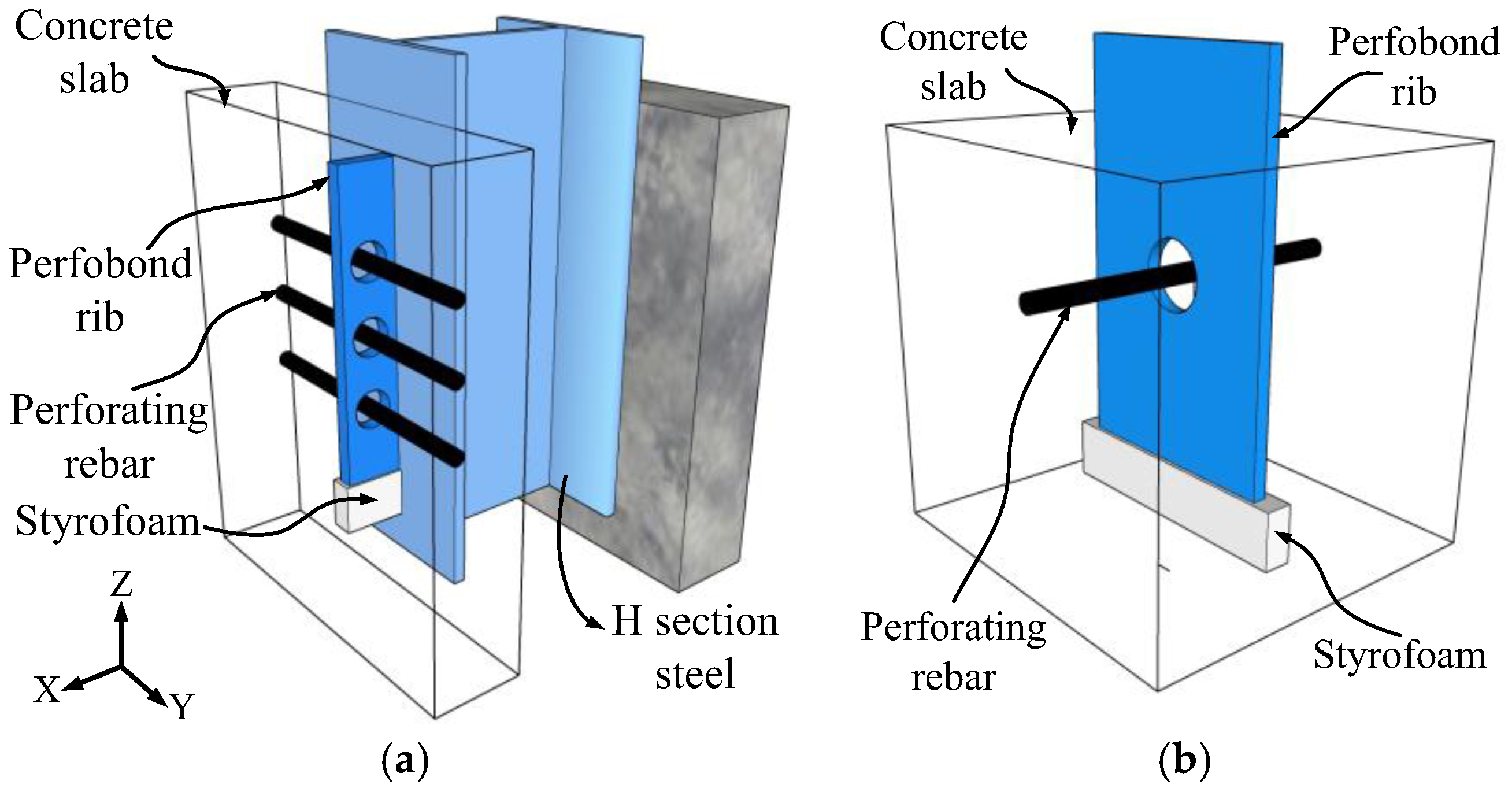

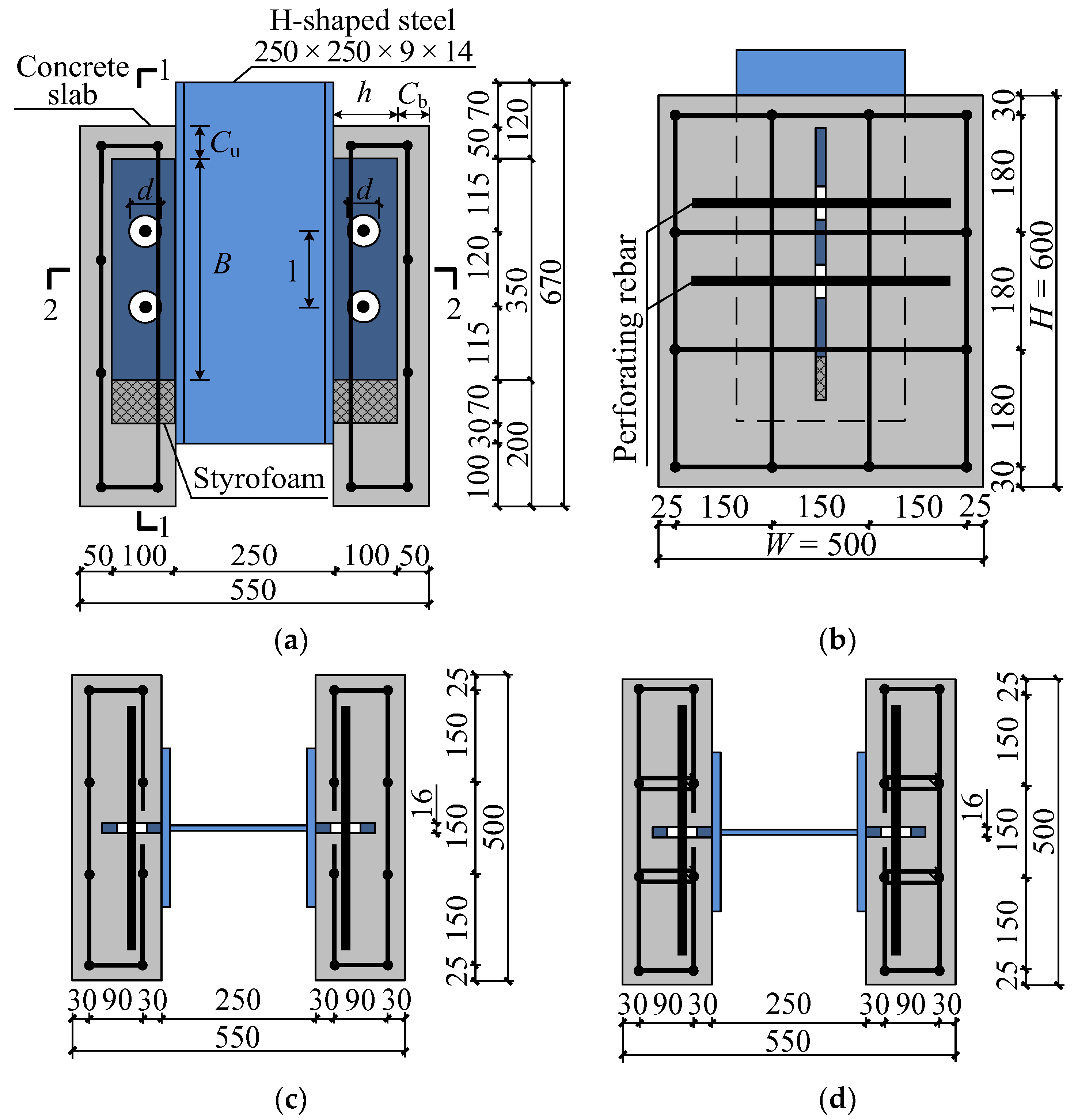

2. Experimental Program

2.1. Push-Out Specimens

2.2. Materials

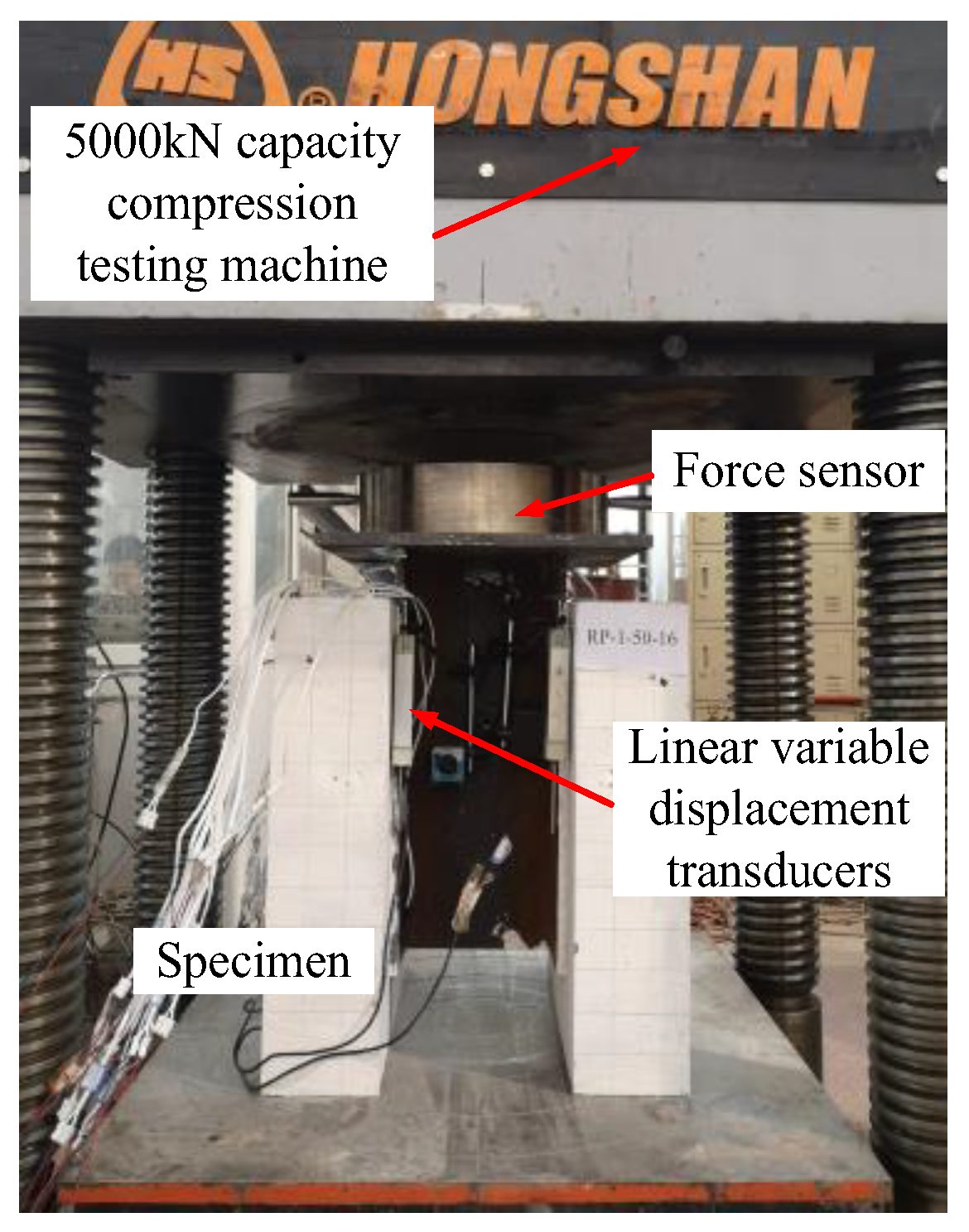

2.3. Test Setup and Instrumentation

3. Experimental Results

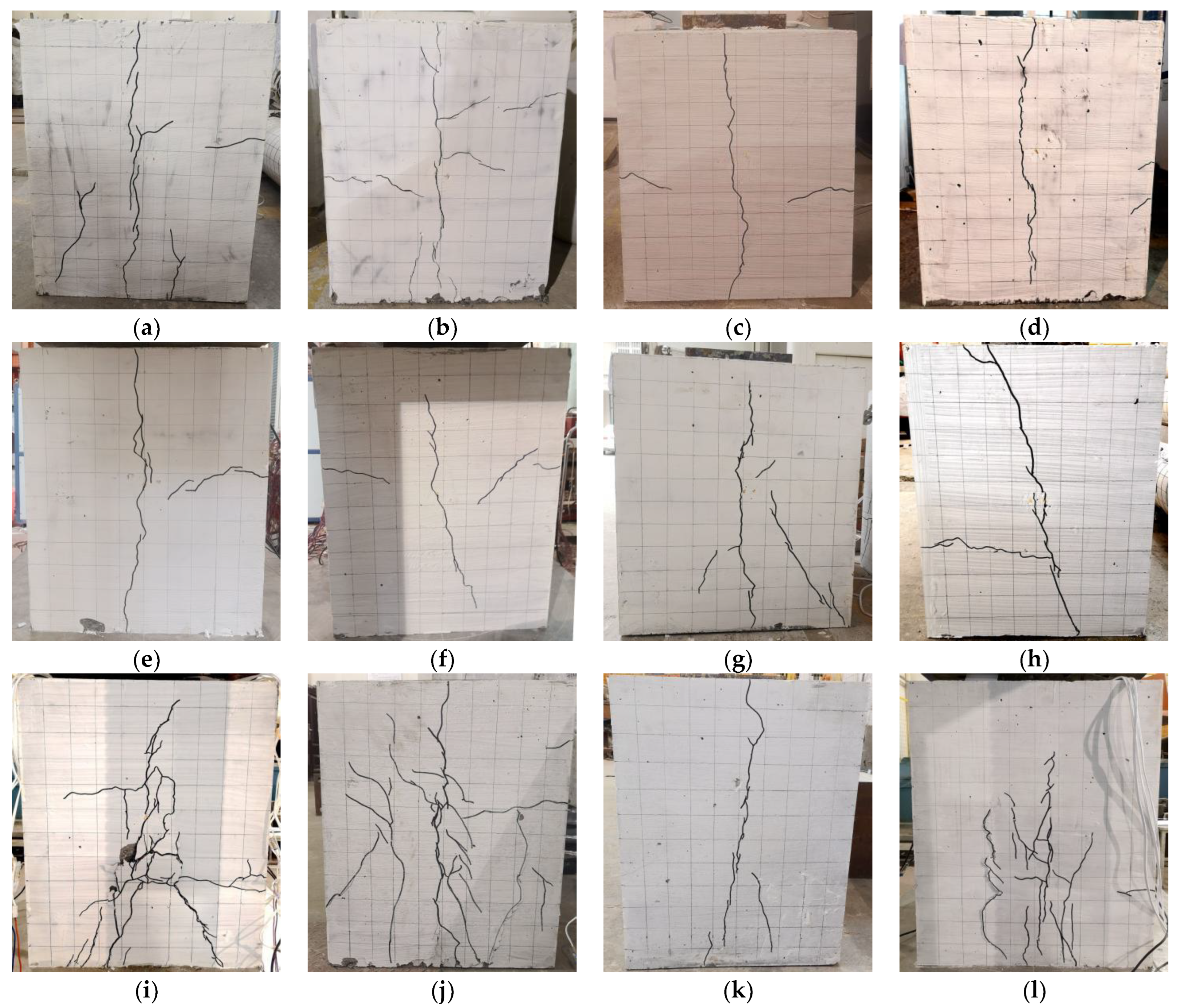

3.1. Failure Modes

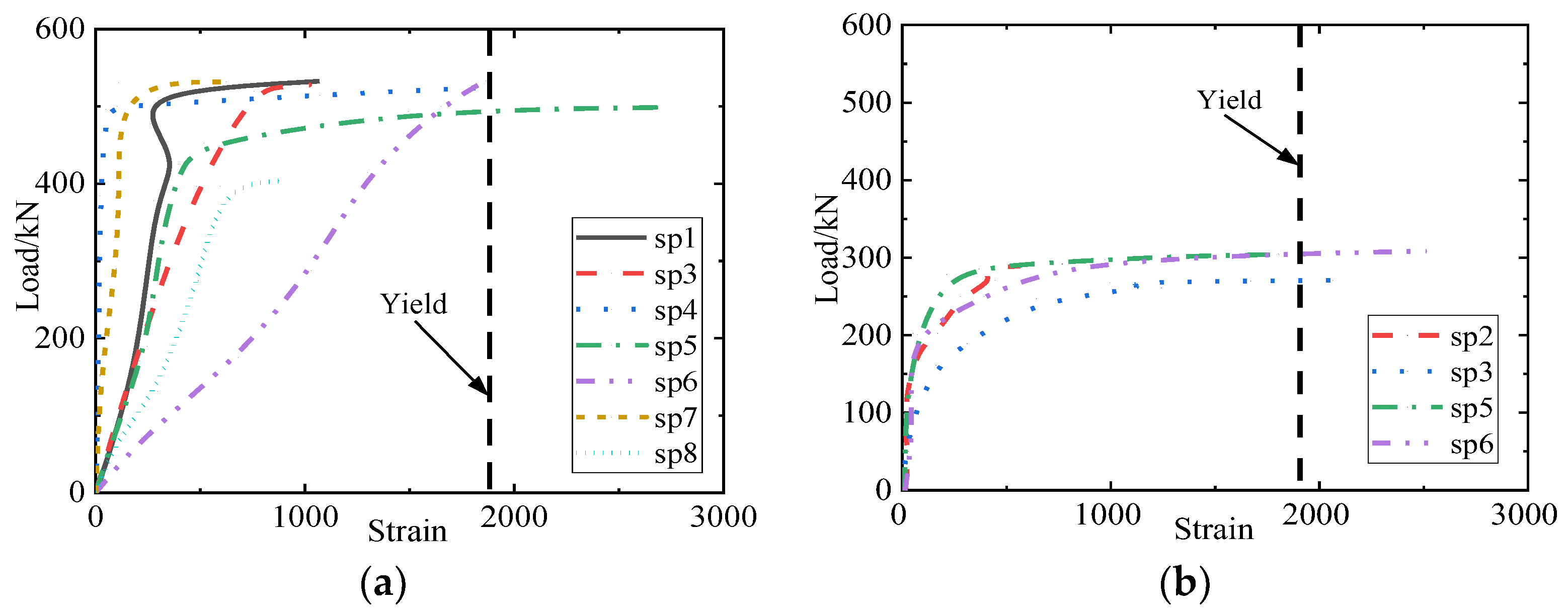

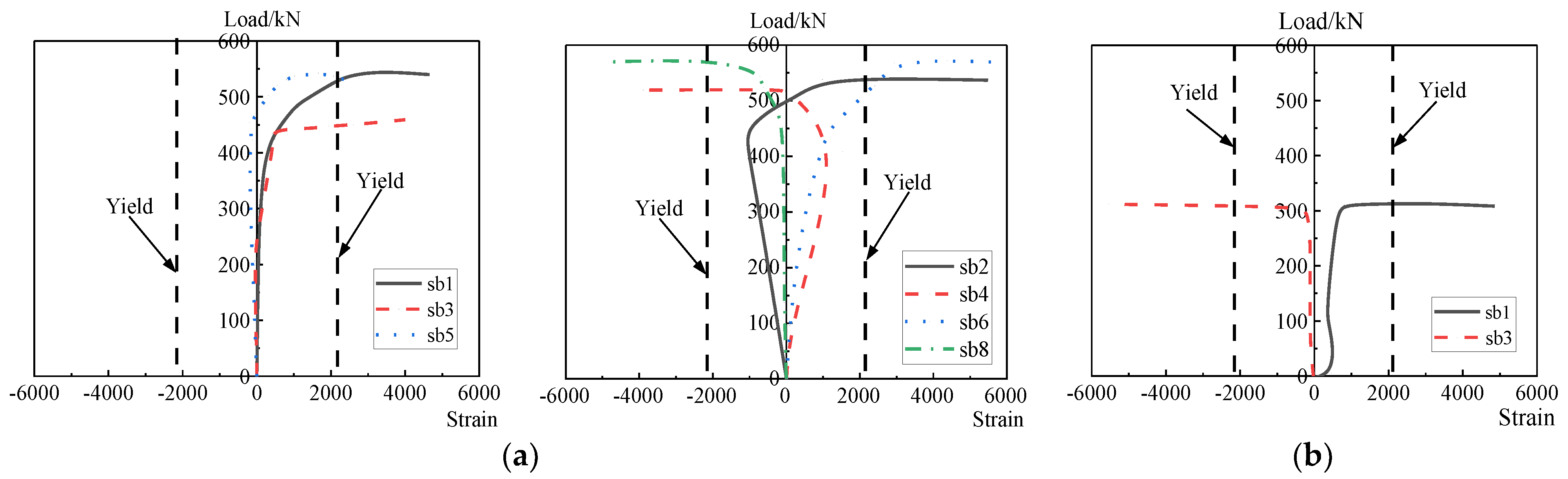

3.2. Strain Analysis of Perfobond Rib and Perforating Rebar

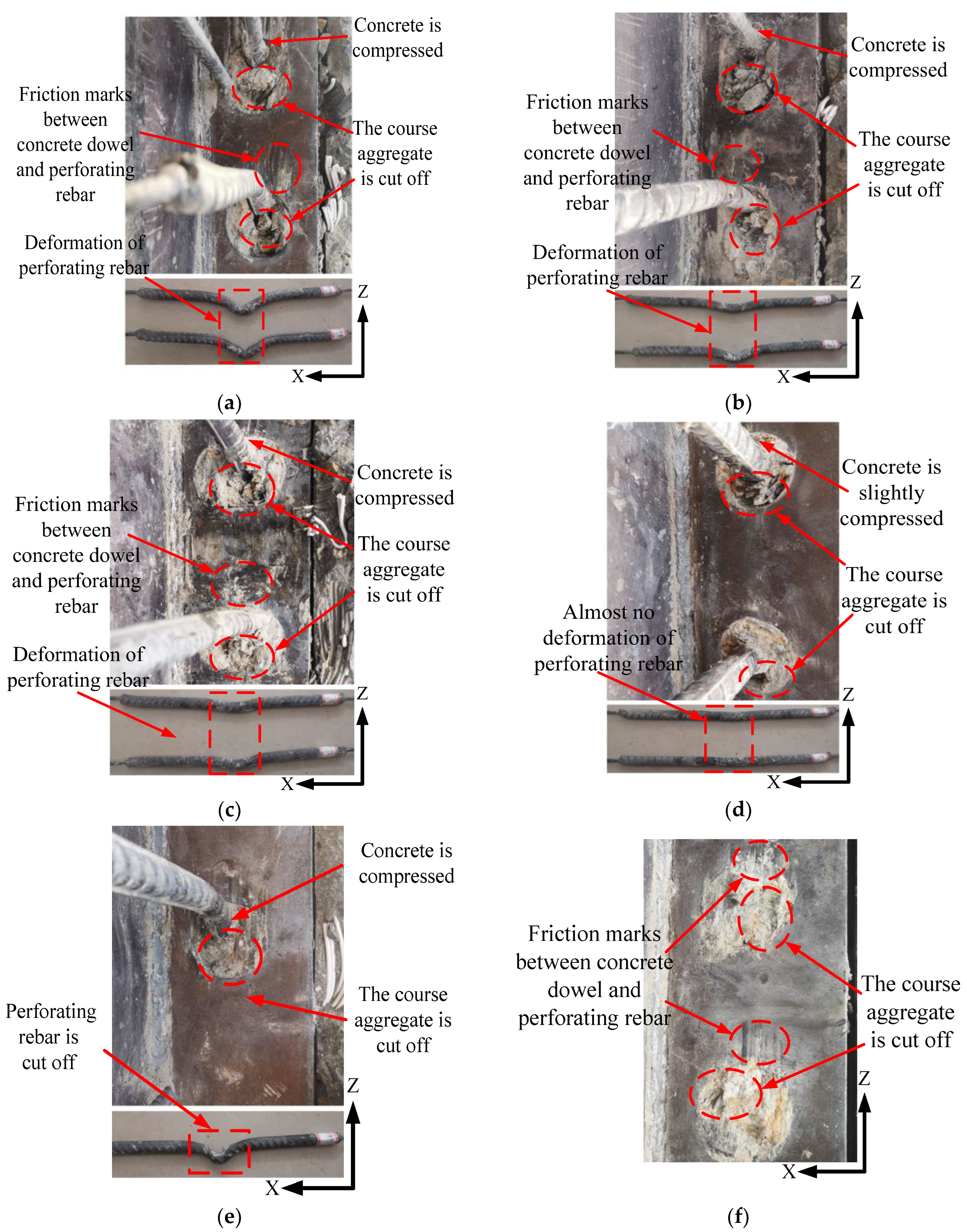

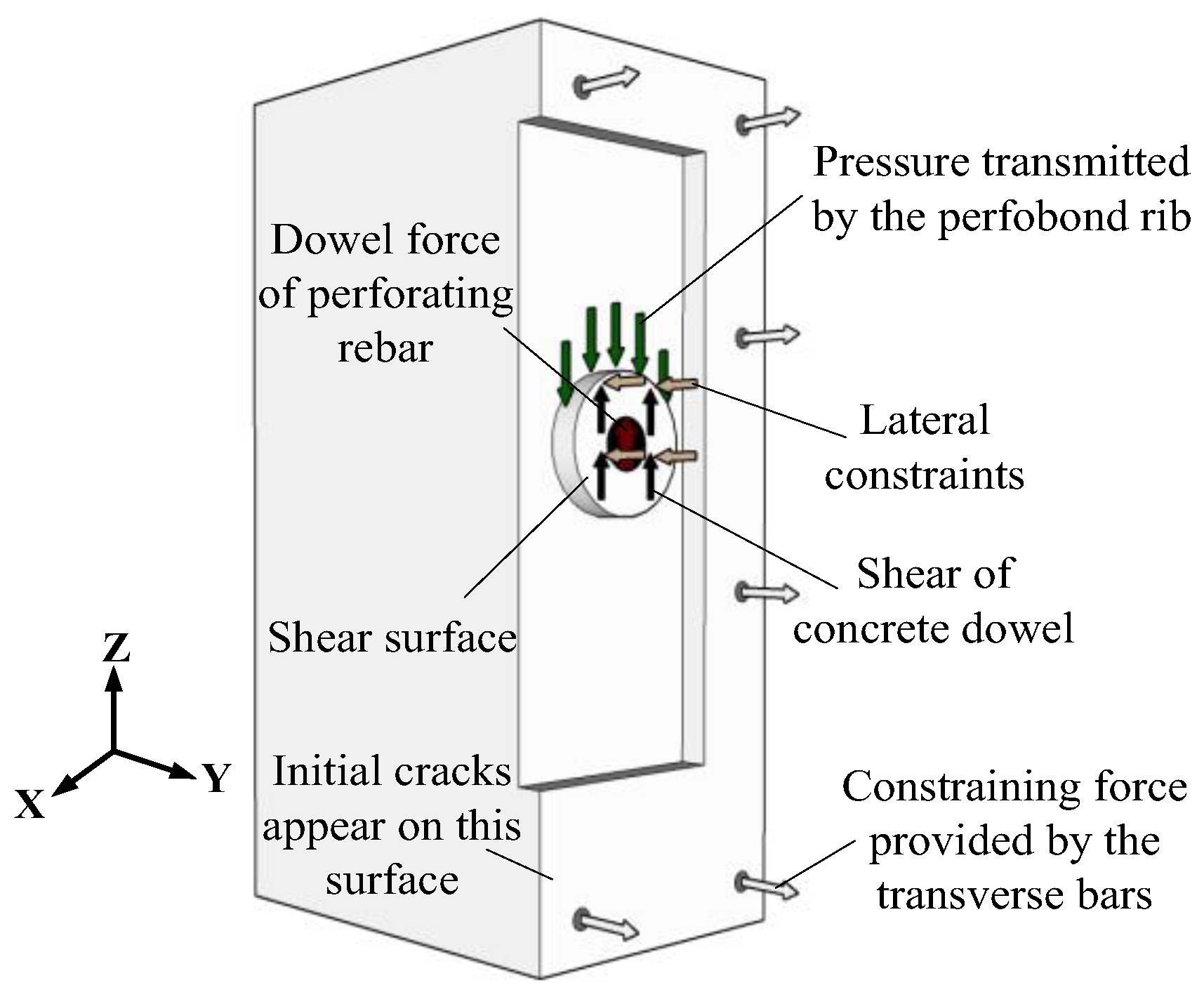

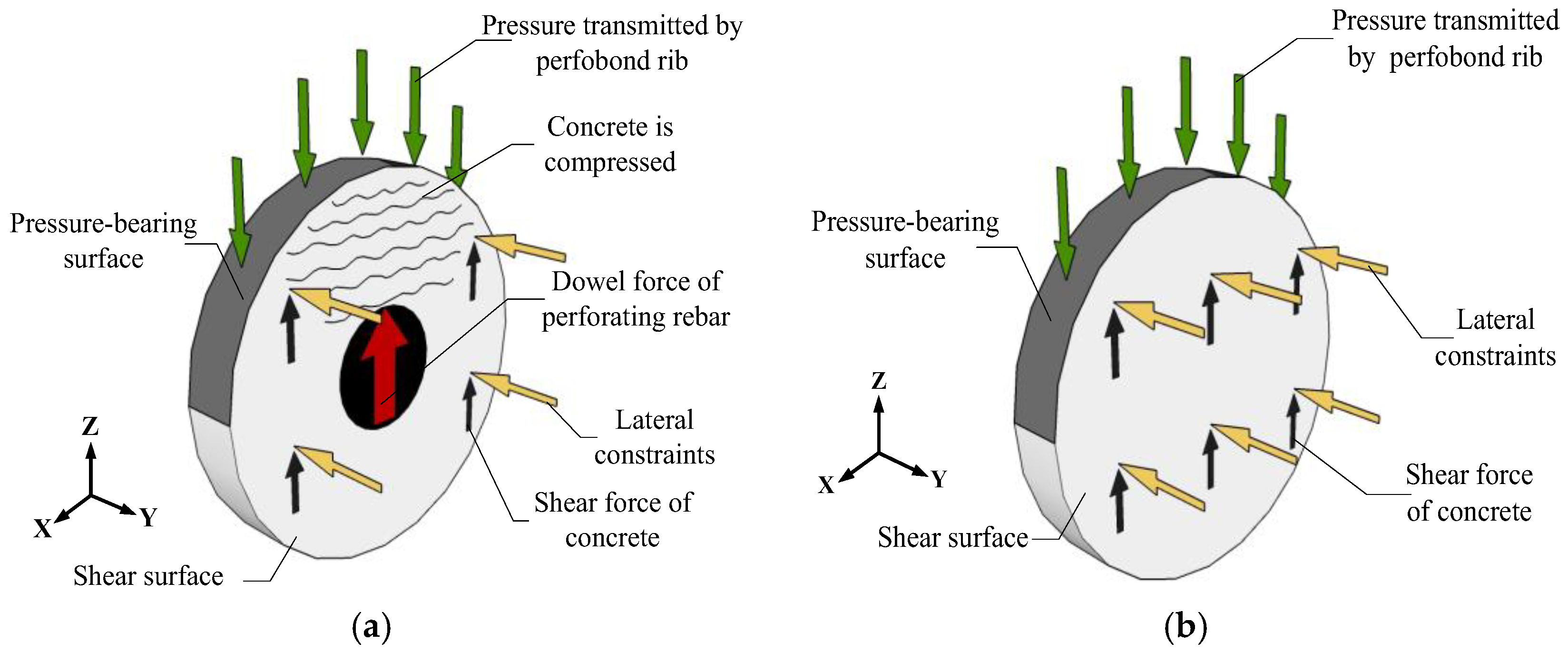

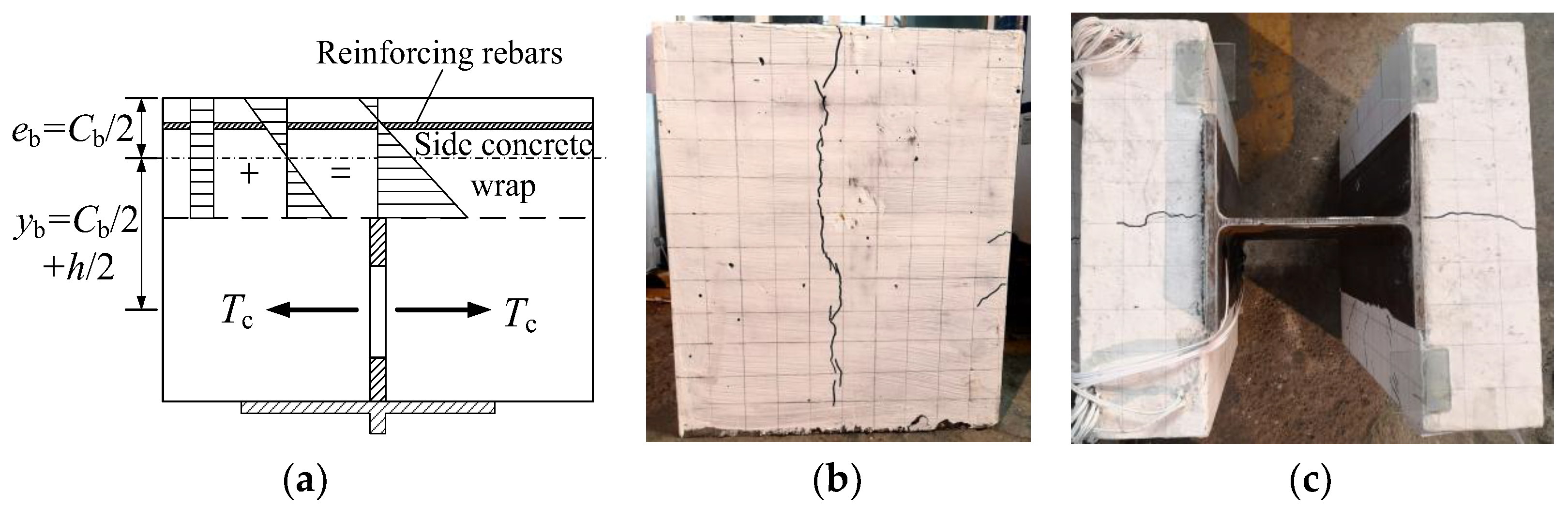

3.3. Shear Failure Mechanism of Connectors

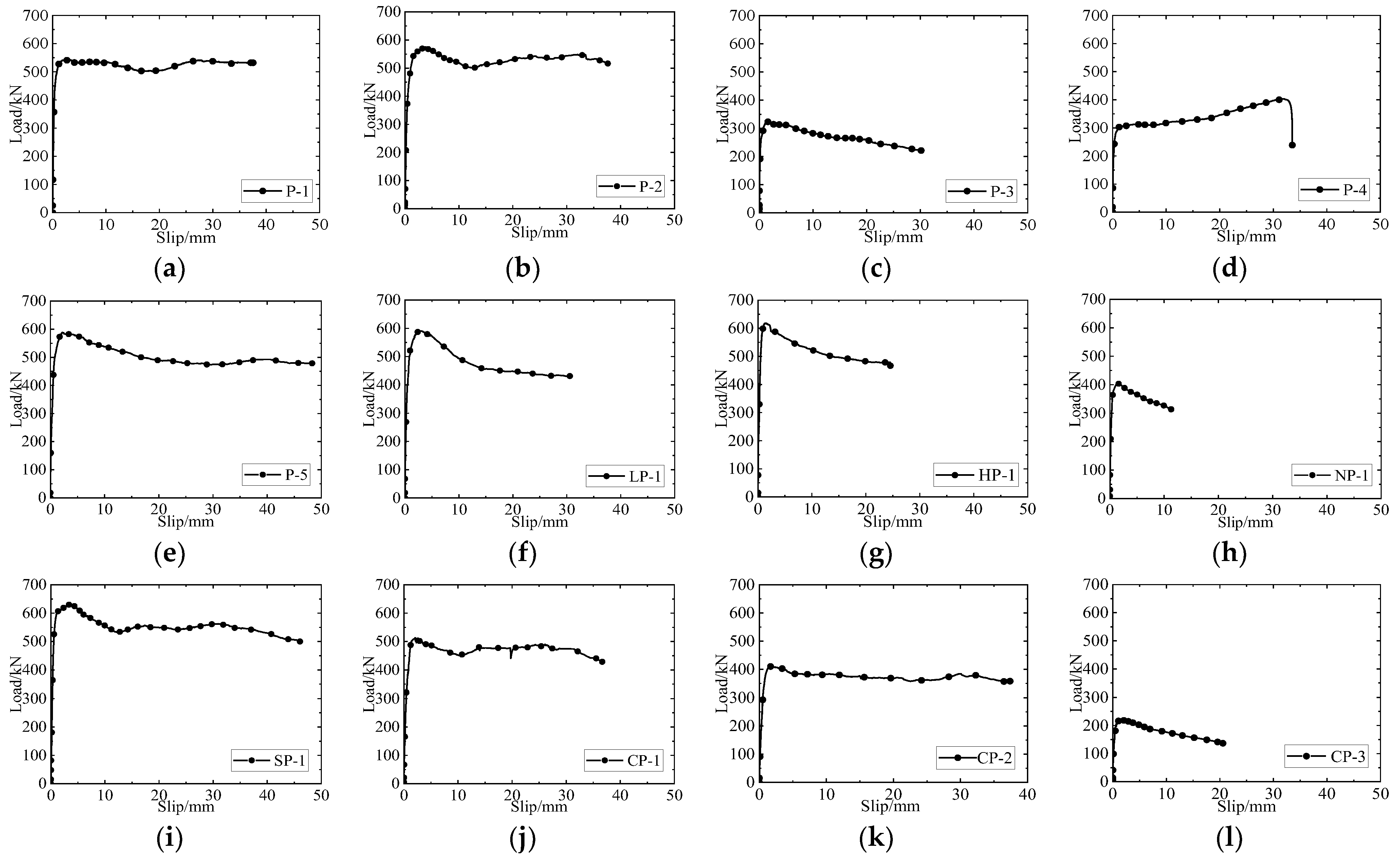

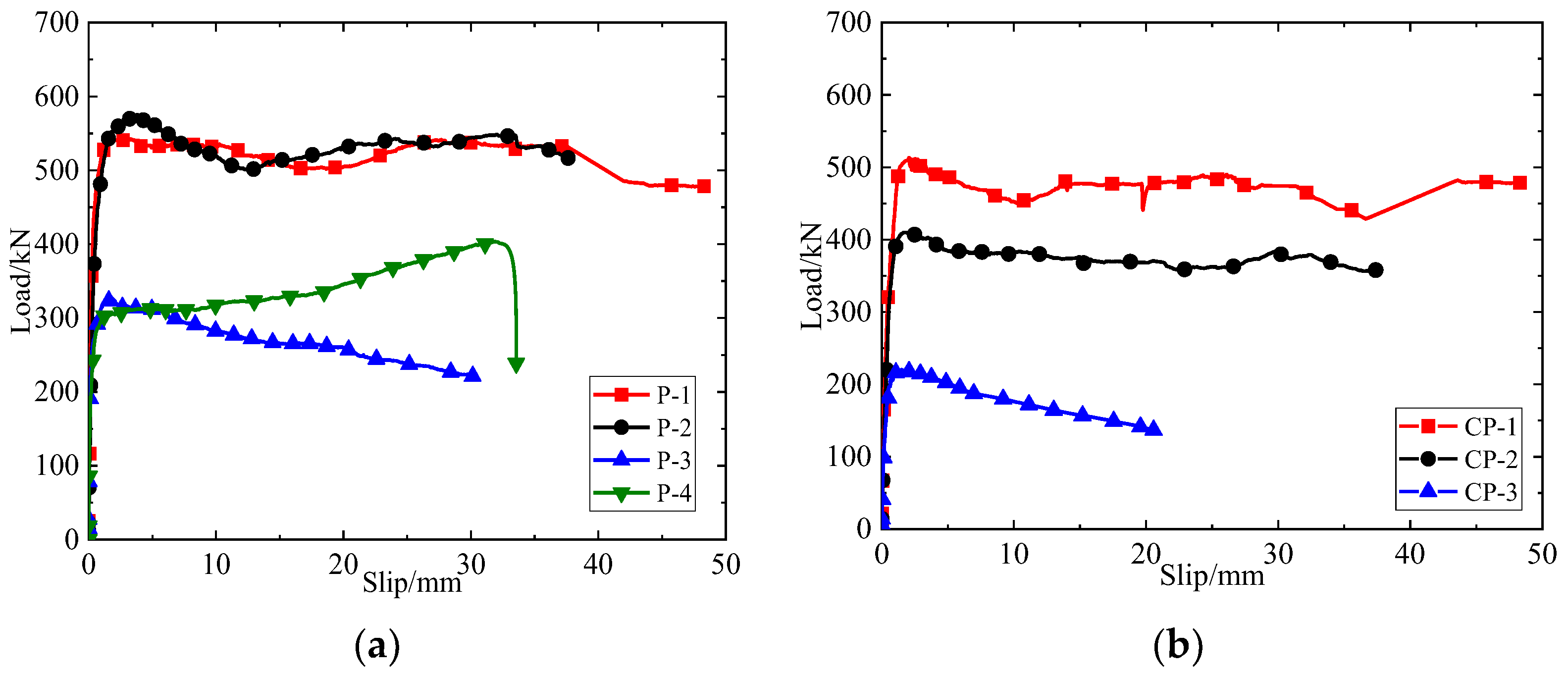

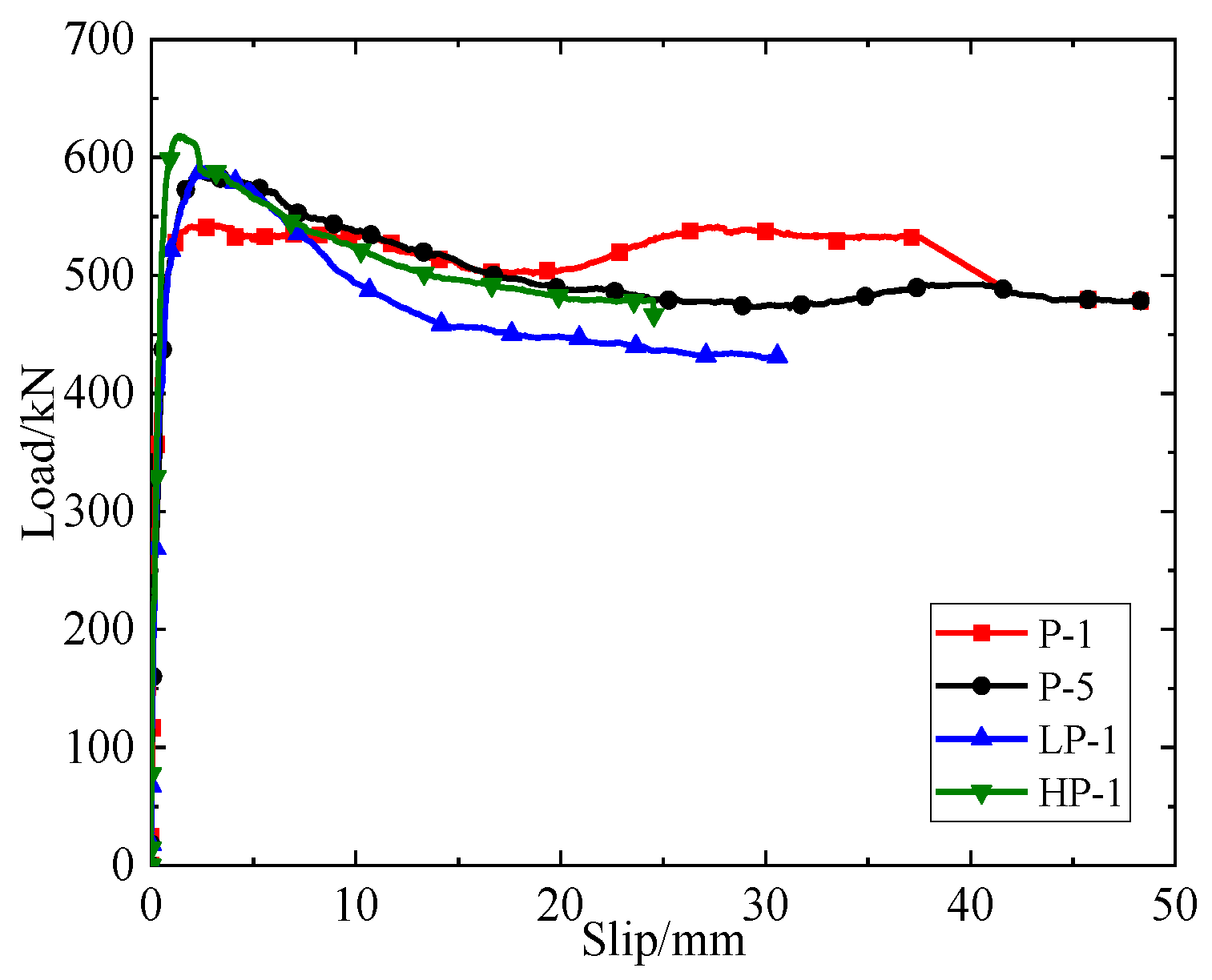

3.4. Load–Slip Curve

3.5. Test Parameter Analysis

3.5.1. Shear Capacity

3.5.2. Load-Holding Capacity

3.5.3. Shear Stiffness

3.5.4. Ductility

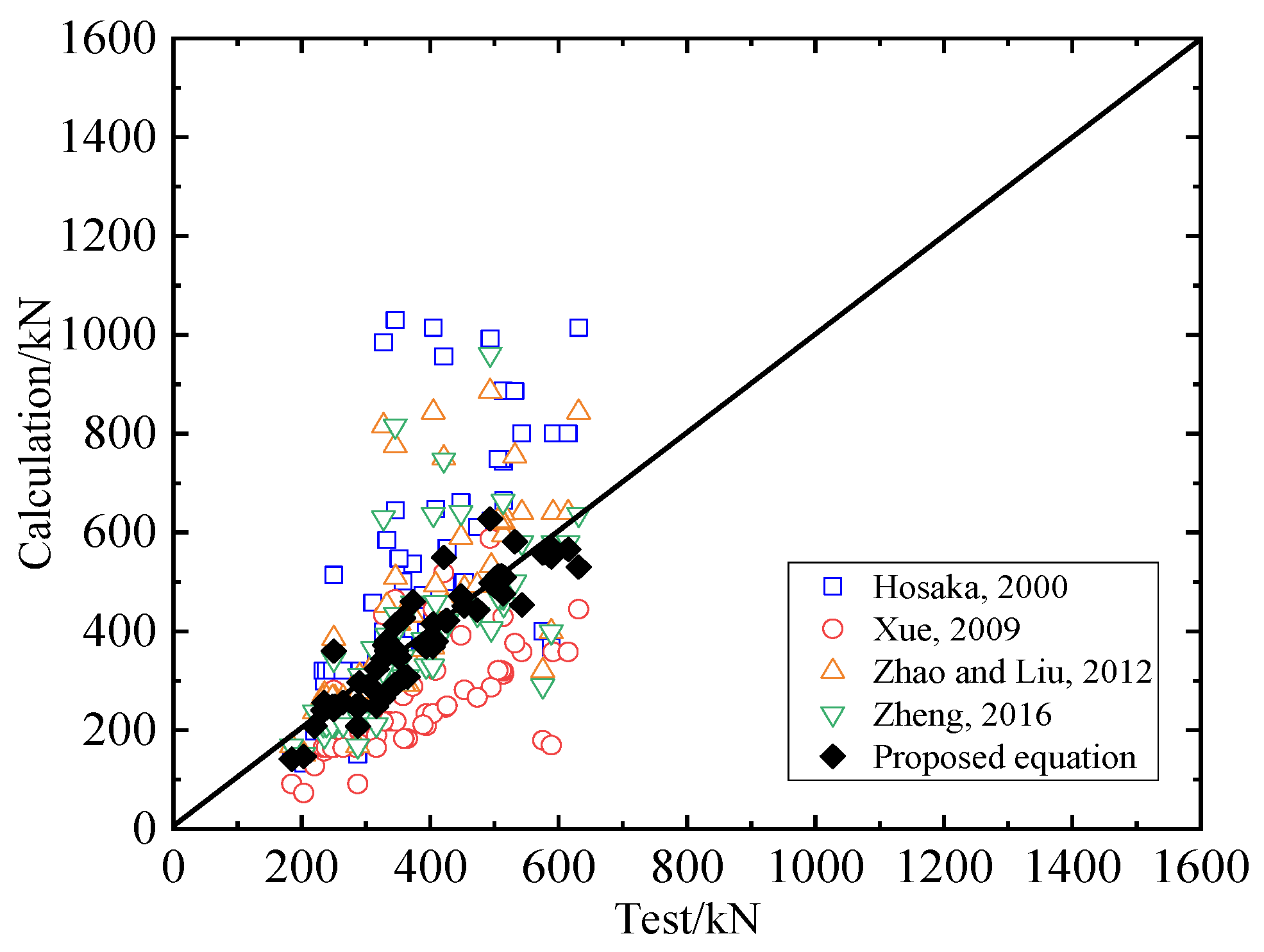

4. Equation for Calculating Shear Capacity

4.1. Existing Shear Capacity Equations for the Superposed Perfobond Connectors

4.2. Proposed Shear Capacity Equation

4.2.1. Concrete Dowel and Perforating Rebar

4.2.2. Lateral Constraint Composition

- (1)

- Concrete wrapping

- (2)

- Perforating rebar

- (3)

- Transverse reinforcement

4.3. Determining the Shear Capacity Equation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, P.G.; Shim, C.S.; Chang, S.P. Static and fatigue behavior of large stud shear connectors for steel-concrete composite bridges. J. Constr. Steel Res. 2005, 61, 1270–1285. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Kim, S.E. Finite element modeling of push-out tests for large stud shear connectors. J. Constr. Steel Res. 2009, 65, 1909–1920. [Google Scholar] [CrossRef]

- Leonhardt, F.; Andra, W.; Andra, H.P.; Harre, W. New, improved bonding means for composite load-bearing structures with high fatigue strength. Int. J. Fatigue 1987, 82, 325–331. [Google Scholar]

- Kraus, D.; Wurzer, O. Nonlinear finite-element analysis of concrete dowels. Comput. Struct. 1997, 64, 1271–1279. [Google Scholar] [CrossRef]

- Valente, I.; Cruz, P.J. Experimental analysis of Perfobond shear connection between steel and lightweight concrete. J. Constr. Steel Res. 2004, 60, 465–479. [Google Scholar] [CrossRef] [Green Version]

- Hosaka, T.; Mitsuki, K.; Hiragi, H.; Ushijima, Y.; Watanabe, H. An experimental study on shear characteristics of perfobond strip and it’s rational strength equations. J. Struct. Eng. 2000, 46, 1593–1604. [Google Scholar]

- Xiao, L.; Qiang, S.Z.; Li, X.Z.; Wei, X. Research on mechanical performance of PBL shear connectors considering the perforated plate’s thickness. Eng. Mech. 2012, 29, 282–288. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Q.H.; Li, Q.; Tang, L. Fracture mechanism and ultimate carrying capacity of shear connectors applied for steel-concrete joint segment of bridge pylon. China J. Highw. Transp. 2007, 1, 85–90. (In Chinese) [Google Scholar]

- He, S.; Fang, Z.; Fang, Y.; Liu, M.; Liu, L.; Mosallam, A.S. Experimental study on perfobond strip connector in steel–concrete joints of hybrid bridges. J. Constr. Steel Res. 2016, 118, 169–179. [Google Scholar] [CrossRef]

- He, S.; Fang, Z.; Mosallam, A.S. Push-out tests for perfobond strip connectors with UHPC grout in the joints of steel-concrete hybrid bridge girders. Eng. Struct. 2017, 135, 177–190. [Google Scholar] [CrossRef]

- Di, J.; Zou, Y.; Zhou, X.; Qin, F.; Peng, X. Push-out test of large perfobond connectors in steel–concrete joints of hybrid bridges. J. Constr. Steel Res. 2018, 150, 415–429. [Google Scholar] [CrossRef]

- Zou, Y.; Di, J.; Zhou, J.; Zhang, Z.; Li, X.; Zhang, H.; Qin, F. Shear behavior of perfobond connectors in the steel-concrete joints of hybrid bridges. J. Constr. Steel Res. 2020, 172, 106217. [Google Scholar] [CrossRef]

- Veldanda, M.R.; Hosain, M.U. Behaviour of perfobond rib shear connectors: Push-out tests. Can. J. Civ. Eng. 1992, 19, 1–10. [Google Scholar] [CrossRef]

- Hosain, E. A parametric study of perfobond rib shear connectors. Can. J. Civ. Eng. 1994, 21, 614–625. [Google Scholar] [CrossRef]

- Oguejiofor, E.C.; Hosain, M.U. Numerical analysis of push-out specimens with perfobond rib connectors. Comput. Struct. 1997, 62, 617–624. [Google Scholar] [CrossRef]

- Veríssimo, G.S.; Paes, J.R.; Valente, I.; Cruz, P.J.; Fakury, R.H. Design and experimental analysis of a new shear connector for steel and concrete composite structures. In Proceedings of the Third International Conference on Bridge Maintenance, Safety and Management, Porto, Portugal, 16–19 July 2006. [Google Scholar]

- Al-Darzi, S.Y.K.; Chen, A.R.; Liu, Y.Q. Finite element simulation and parametric studies of perfobond rib connector. Am. J. Appl. Sci. 2007, 4, 122–127. [Google Scholar] [CrossRef] [Green Version]

- Ahn, J.H.; Lee, C.G.; Won, J.H.; Kim, S.H. Shear resistance of the perfobond-rib shear connector depending on concrete strength and rib arrangement. J. Constr. Steel Res. 2010, 66, 1295–1307. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Cai, J.W. Experiment on Static Behavior of Perfobond Shear Connectors. China J. Highw. Transp. 2017, 30, 255–263. (In Chinese) [Google Scholar]

- Yang, Y.; Chen, Y. Experimental study on the shear capacity of PBL shear connectors. Eng. Mech. 2018, 35, 89–96. (In Chinese) [Google Scholar] [CrossRef]

- Medberry, S.B.; Shahrooz, B.M. Perfobond Shear Connector for Composite Construction. Eng. J. 2002, 39, 2–12. [Google Scholar]

- Xue, W.C.; Dai, Y.; Zhou, L.; Lu, Y.C. Experimental studies on shear behavior of perfobond connectors. J. Build. Struct. 2009, 30, 103–111. (In Chinese) [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; Liu, Y.Q. Experimental study of shear capacity of perfobond connector. Eng. Mech. 2012, 29, 349–354. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, S.J.; Liu, Y.Q.; Yoda, T.; Lin, W.W. Parametric study on shear capacity of circular-hole and long-hole perfobond shear connector. J. Constr. Steel Res. 2016, 117, 64–80. [Google Scholar] [CrossRef]

- Su, Q.T.; Wang, W.; Luan, H.W.; Yang, G.T. Experimental research on bearing mechanism of perfobond rib shear connectors. J. Constr. Steel Res. 2014, 95, 22–31. [Google Scholar] [CrossRef]

- Su, Q.T.; Yang, G.T.; Bradford, M.A. Bearing capacity of perfobond rib shear connectors in composite girder bridges. J. Bridge Eng. 2016, 21, 06015009. [Google Scholar] [CrossRef]

- Fujii, K.; Dokan, Y.; Iwasaki, H.; Himukai, M.; Yamaguchi, S. Ultimate shear strength of perfobond strip. J. Jpn. Soc. Civ. Eng. Ser A1 2014, 70, 53–68. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Eurocode 4: Design of Composite Steel and Concrete Structures; European Committee for Standardization: Brussels, Belgium, 2004.

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture and Building Press: Beijing, China, 2010.

- Nisiumi, K.; Okimoto, M. Shear strength of perfobond rib shear connector under the confinement. Proc. JSCE 1999, 633, 193–203. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Xiao, L. Mechanical Behaviour and Failure Mechanism of Perfobond Shear Connectors in Steel-Concrete Hybrid Structure. IABSE Symp. Rep. 2013, 99, 463–468. [Google Scholar]

- Furukawa, Y.; Fujii, K.; Doukan, Y.; Yamaguchi, S. On pushes tests slip strength of PBL under dimensional parameters. In Proceedings of the 9th Symposium on Research and Application of Hybrid and Composite Structures, Tokyo Metropolis, Japan Society of Civil Engineers, Tokyo, Japan, November 2011; pp. 58–65. (In Japanese). [Google Scholar]

- Xiao, L.; Wei, X.; Qiang, S.Z. Comparative study on two kinds of push-out tests of PBL shear connectors. China Civ. Eng. J. 2013, 46, 70–80. (In Chinese) [Google Scholar]

- Zheng, S.J.; Liu, Y.Q. Experiment of initial shear stiffness of perfobond connector. China J. Highw. Transp. 2014, 27, 69–75. (In Chinese) [Google Scholar]

- Fujii, K.; Iwasaki, H.; Fukada, K.; Toyota, T.; Fujimura, N. Crack restraint factors in ultimate slip behavior of perfobond strip. Doboku Gakkai Ronbunshuu A 2008, 64, 502–512, In Japanese. [Google Scholar] [CrossRef]

- Guo, Z.H. Reinforced Concrete Theory; Tsinghua University Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

| Specimen | Hole Shape | Number of Holes n | d (mm) | dl (mm) | dh mm | A (mm2) | l (mm) | ds (mm) | Concrete Grade | Stirrups Form |

|---|---|---|---|---|---|---|---|---|---|---|

| P-1 | Circular hole | 2 | 50 | 50 | 50 | 1963.5 | 120 | 16 | C60 | Conventional stirrups |

| P-2 | 2 | 50 | 50 | 50 | 1963.5 | 120 | 20 | C60 | ||

| P-3 | 2 | 50 | 50 | 50 | 1963.5 | 120 | 0 | C60 | ||

| P-4 | 1 | 50 | 50 | 50 | 1963.5 | 0 | 16 | C60 | ||

| P-5 | 2 | 60 | 60 | 60 | 2827.4 | 120 | 16 | C60 | ||

| CP-1 | 2 | 50 | 50 | 50 | 1963.5 | 120 | 20 | C40 | ||

| CP-2 | 2 | 50 | 50 | 50 | 1963.5 | 120 | 16 | C40 | ||

| CP-3 | 2 | 50 | 50 | 50 | 1963.5 | 120 | 0 | C40 | ||

| LP-1 | Long hole | 2 | 50 | 70 | 50 | 2963.5 | 120 | 16 | C60 | |

| HP-1 | High hole | 2 | 50 | 50 | 70 | 2963.5 | 120 | 16 | C60 | |

| NP-1 | Circular hole | 2 | 50 | 50 | 50 | 1963.5 | 120 | 16 | C60 | None |

| SP-1 | 2 | 50 | 50 | 50 | 1963.5 | 120 | 16 | C60 | Segmented stirrups |

| Materials | Concrete Cube Compressive Strength fcu (MPa) | Young’s Modulus of Concrete Ec (MPa) |

|---|---|---|

| C40 | 42.8 | 33,662.5 |

| C60 | 72.2 | 37,635.5 |

| Materials | Diameter of Rebars (mm) | Thickness of Steel Plate (mm) | Yield Strength of Steel fy (MPa) | Ultimate Tensile of Steel fu (MPa) | Young’s Modulus of Steel Es (105 MPa) |

|---|---|---|---|---|---|

| Q355 | − | 16 | 378.6 | 513.4 | 2.05 |

| HRB400 | 10 | − | 508.2 | 670.5 | 2.06 |

| 16 | − | 443.7 | 640.8 | 2.06 | |

| 20 | − | 443.2 | 628.3 | 2.06 |

| Specimen | Pu/kN | PRk/kN | PRd/kN | K/(kN/mm) | δd/mm | δu/mm | D |

|---|---|---|---|---|---|---|---|

| P-1 | 542.9 | 488.6 | 390.9 | 1215.2 | 0.30 | 20.00 | 67.8 |

| P-2 | 575.5 | 518.0 | 414.4 | 1205.4 | 0.57 | 10.10 | 17.9 |

| P-3 | 327.3 | 294.6 | 235.7 | 1005.8 | 0.21 | 7.38 | 35.5 |

| P-4 | 345.6 | 311.0 | 248.8 | 1020.5 | 0.24 | 20.00 | 84.4 |

| P-5 | 588.5 | 529.6 | 423.7 | 1320.2 | 0.54 | 11.38 | 21.2 |

| LP-1 | 591.5 | 532.4 | 425.9 | 1271.4 | 0.57 | 7.40 | 13.1 |

| HP-1 | 615.5 | 554.0 | 443.2 | 1358.9 | 0.41 | 6.17 | 15.1 |

| NP-1 | 404.8 | 364.3 | 291.5 | 1212.5 | 0.29 | 5.01 | 17.1 |

| SP-1 | 631.2 | 568.1 | 454.5 | 1217.5 | 0.45 | 8.64 | 19.3 |

| CP-1 | 513.5 | 462.1 | 369.7 | 929.3 | 0.64 | 8.21 | 12.9 |

| CP-2 | 410.0 | 369.0 | 295.2 | 714.9 | 0.54 | 20.0 | 37.2 |

| CP-3 | 220.7 | 198.6 | 158.9 | 594.3 | 0.35 | 5.43 | 15.7 |

| Specimens | n | A0/mm2 | fcu/MPa | B/mm | h/mm | Cb/mm | Cu/mm | As/mm2 | fy/ MPa | nst | Ast/ mm | fyt/ MPa | Qu,Exp/ kN | Qu.Pre/Qu,Exp | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Equation (2) | Equation (3) | Equation (4) | Equation (5) | Equation (19) | |||||||||||||||

| Specimens in this study | P-1 | 2 | 2863.0 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 542.9 | 1.48 | 0.66 | 1.18 | 1.07 | 0.84 |

| P-2 | 2 | 3368.9 | 72.2 | 350 | 100 | 50 | 50 | 314.2 | 443.7 | 1 | 78.5 | 508.2 | 575.5 | 1.79 | 0.81 | 1.35 | 1.42 | 0.97 | |

| P-3 | 2 | 1963.5 | 72.2 | 350 | 100 | 50 | 50 | 0.0 | 0.0 | 1 | 78.5 | 508.2 | 327.3 | 1.12 | 0.52 | 1.22 | 1.22 | 0.82 | |

| P-4 | 1 | 2863.0 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 345.6 | 1.16 | 0.52 | 0.93 | 0.84 | 0.85 | |

| P-5 | 2 | 3726.9 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 588.5 | 1.67 | 0.74 | 1.39 | 1.07 | 0.94 | |

| LP-1 | 2 | 3863.0 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 591.5 | 1.72 | 0.75 | 1.43 | 1.08 | 0.96 | |

| HP-1 | 2 | 3863.0 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 615.0 | 1.65 | 0.72 | 1.37 | 1.04 | 0.92 | |

| NP-1 | 2 | 2863.0 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 0 | 0.0 | 0.0 | 404.8 | 1.98 | 0.89 | 1.58 | 1.43 | 1.03 | |

| SP-1 | 2 | 2863.0 | 72.2 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 3 | 78.5 | 508.2 | 631.2 | 1.27 | 0.57 | 1.01 | 0.92 | 0.84 | |

| CP-1 | 2 | 3571.9 | 42.8 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 513.5 | 1.73 | 0.84 | 1.25 | 1.29 | 0.93 | |

| CP-2 | 2 | 2992.8 | 42.8 | 350 | 100 | 50 | 50 | 201.1 | 443.7 | 1 | 78.5 | 508.2 | 408.6 | 1.58 | 0.78 | 1.21 | 1.12 | 0.93 | |

| CP-3 | 2 | 1963.5 | 42.8 | 350 | 100 | 50 | 50 | 0.0 | 0.0 | 1 | 78.5 | 508.2 | 220.7 | 0.89 | 0.58 | 1.08 | 1.08 | 0.95 | |

| Xue [22] | I | 2 | 3338.8 | 50.6 | 350 | 100 | 50 | 100 | 201.1 | 361.7 | 1 | 78.5 | 383.3 | 346.0 | 1.86 | 0.99 | 1.47 | 1.26 | 1.19 |

| II | 2 | 3328.7 | 41.9 | 350 | 100 | 50 | 100 | 201.1 | 361.7 | 1 | 78.5 | 383.3 | 332.6 | 1.76 | 0.95 | 1.36 | 1.18 | 1.14 | |

| III | 2 | 3547.5 | 32.9 | 350 | 100 | 50 | 100 | 201.1 | 361.7 | 1 | 78.5 | 383.3 | 249.9 | 2.06 | 1.13 | 1.54 | 1.38 | 1.44 | |

| IV | 2 | 2520.3 | 54.1 | 350 | 100 | 50 | 100 | 201.1 | 361.7 | 1 | 78.5 | 383.3 | 351.5 | 1.56 | 0.85 | 1.19 | 1.16 | 0.99 | |

| V | 2 | 1866.9 | 53.3 | 350 | 100 | 50 | 100 | 201.1 | 361.7 | 1 | 78.5 | 383.3 | 310.4 | 1.47 | 0.77 | 1.07 | 1.18 | 0.91 | |

| VI | 2 | 2375.8 | 48.7 | 350 | 100 | 50 | 100 | 0.0 | 0.0 | 1 | 78.5 | 383.3 | 290.3 | 0.94 | 0.68 | 1.07 | 1.07 | 0.86 | |

| VII | 2 | 4103.7 | 48.0 | 350 | 100 | 50 | 100 | 314.2 | 488.9 | 1 | 78.5 | 383.3 | 421.3 | 2.27 | 1.23 | 1.78 | 1.77 | 1.30 | |

| Zhao and Liu [23] | PS-3 | 1 | 3511.0 | 43.3 | 250 | 150 | 250 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 316.4 | 1.09 | 0.60 | 0.90 | 0.94 | 1.02 |

| PS-4 | 1 | 4375.0 | 43.3 | 250 | 150 | 250 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 332.1 | 1.20 | 0.66 | 1.02 | 0.96 | 1.08 | |

| PS-5 | 1 | 5965.4 | 43.3 | 250 | 150 | 250 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 357.8 | 1.40 | 0.75 | 1.22 | 0.97 | 1.19 | |

| PS-6 | 1 | 3326.8 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 381.7 | 1 | 78.5 | 382.0 | 394.1 | 1.04 | 0.53 | 0.90 | 0.94 | 0.95 | |

| PS-7 | 1 | 4190.7 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 381.7 | 1 | 78.5 | 382.0 | 424.0 | 1.18 | 0.58 | 1.03 | 0.96 | 0.99 | |

| PS-8 | 1 | 5781.2 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 381.7 | 1 | 78.5 | 382.0 | 514.4 | 1.29 | 0.61 | 1.16 | 0.88 | 0.99 | |

| PS-9 | 1 | 3817.9 | 43.3 | 250 | 150 | 250 | 80 | 201.1 | 373.6 | 1 | 78.5 | 382.0 | 289.5 | 1.08 | 0.60 | 0.96 | 0.77 | 1.02 | |

| PS-10 | 1 | 5245.5 | 43.3 | 250 | 150 | 250 | 80 | 490.9 | 373.6 | 1 | 78.5 | 382.0 | 372.8 | 1.44 | 0.77 | 1.16 | 1.23 | 1.23 | |

| PS-11 | 1 | 4190.7 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 480.0 | 1 | 78.5 | 382.0 | 453.3 | 1.10 | 0.62 | 1.07 | 1.01 | 1.00 | |

| PS-12 | 1 | 4375.0 | 43.3 | 250 | 100 | 300 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 329.6 | 1.21 | 0.66 | 1.03 | 0.97 | 1.13 | |

| PS-13 | 1 | 4375.0 | 43.3 | 250 | 150 | 250 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 338.9 | 1.18 | 0.64 | 1.00 | 0.94 | 1.06 | |

| PS-14 | 1 | 4375.0 | 43.3 | 250 | 150 | 250 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 346.6 | 1.15 | 0.63 | 0.98 | 0.92 | 1.04 | |

| PS-15 | 1 | 4865.9 | 43.3 | 250 | 210 | 190 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 393.7 | 1.09 | 0.59 | 0.94 | 0.84 | 0.94 | |

| PS-16 | 1 | 4865.9 | 43.3 | 250 | 210 | 190 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 404.0 | 1.07 | 0.58 | 0.91 | 0.82 | 0.91 | |

| PS-17 | 1 | 4375.0 | 43.3 | 250 | 150 | 150 | 80 | 314.2 | 373.6 | 1 | 78.5 | 382.0 | 326.7 | 1.22 | 0.67 | 1.04 | 0.98 | 1.05 | |

| PS-18 | 1 | 5813.2 | 63.4 | 250 | 150 | 350 | 80 | 314.2 | 335.0 | 1 | 78.5 | 382.0 | 495.0 | 1.26 | 0.58 | 1.08 | 0.82 | 1.01 | |

| PS-19 | 1 | 3411.2 | 54.6 | 250 | 100 | 100 | 80 | 314.2 | 335.0 | 1 | 78.5 | 382.0 | 364.9 | 1.02 | 0.50 | 0.80 | 0.85 | 0.84 | |

| PS-20 | 1 | 3411.2 | 54.6 | 250 | 100 | 100 | 80 | 314.2 | 335.0 | 1 | 78.5 | 382.0 | 359.3 | 1.03 | 0.51 | 0.82 | 0.86 | 0.86 | |

| PS-21 | 1 | 3411.2 | 54.6 | 250 | 100 | 100 | 80 | 314.2 | 335.0 | 1 | 78.5 | 382.0 | 358.7 | 1.04 | 0.51 | 0.82 | 0.86 | 0.86 | |

| PS-22 | 1 | 1963.5 | 54.6 | 250 | 100 | 100 | 80 | 0.0 | 0.0 | 1 | 78.5 | 382.0 | 203.0 | 0.65 | 0.36 | 0.74 | 0.74 | 0.72 | |

| Zheng [24] | CP-1 | 1 | 3326.6 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 388.8 | 1.22 | 0.54 | 0.93 | 0.99 | 0.96 |

| CP-2 | 1 | 4190.5 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 426.2 | 1.33 | 0.58 | 1.06 | 0.99 | 0.99 | |

| CP-3 | 1 | 5780.9 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 514.2 | 1.45 | 0.62 | 1.21 | 0.91 | 0.99 | |

| LP-1 | 1 | 4576.6 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 473.5 | 1.29 | 0.56 | 1.04 | 0.92 | 0.94 | |

| LP-2 | 1 | 5826.6 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 511.1 | 1.47 | 0.63 | 1.22 | 0.92 | 1.00 | |

| LP-3 | 1 | 7076.6 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 531.9 | 1.67 | 0.71 | 1.42 | 0.94 | 1.09 | |

| HP-1 | 1 | 5826.6 | 70.3 | 250 | 150 | 250 | 80 | 314.2 | 382.0 | 1 | 78.5 | 382.0 | 505.7 | 1.48 | 0.63 | 1.23 | 0.93 | 1.01 | |

| Yang [19,20] | P-1-45-14# | 1 | 3746.9 | 49.4 | 375 | 80 | 45 | 50 | 153.9 | 357.0 | 1 | 78.5 | 357.0 | 235.0 | 1.27 | 0.67 | 1.16 | 0.80 | 1.09 |

| P-3-50-45-20# | 3 | 3466.8 | 49.0 | 375 | 80 | 45 | 50 | 314.2 | 417.0 | 1 | 78.5 | 357.0 | 493.2 | 2.01 | 1.19 | 1.80 | 1.95 | 1.27 | |

| P-2-50-45-20# | 2 | 3466.8 | 49.0 | 375 | 80 | 45 | 50 | 314.1 | 417.0 | 1 | 78.5 | 357.0 | 448.1 | 1.48 | 0.88 | 1.32 | 1.43 | 1.05 | |

| Fujii [35] | PS-30-R1 | 1 | 4037.3 | 42.3 | 280 | 150 | 30 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 233.4 | 1.37 | 0.71 | 1.14 | 0.91 | 1.03 |

| PS-50-R1 | 1 | 4037.3 | 42.3 | 280 | 150 | 50 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 249.8 | 1.28 | 0.66 | 1.06 | 0.85 | 0.97 | |

| PS-75-R1 | 1 | 4037.3 | 42.3 | 280 | 150 | 75 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 238.3 | 1.34 | 0.69 | 1.12 | 0.89 | 1.03 | |

| PS-100-N | 1 | 2827.4 | 42.3 | 280 | 150 | 100 | 120 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 184.2 | 0.82 | 0.49 | 0.91 | 0.91 | 0.77 | |

| PS-100-N-FR | 1 | 2827.4 | 42.3 | 280 | 150 | 100 | 120 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 287.2 | 0.53 | 0.32 | 0.59 | 0.59 | 0.72 | |

| PS-100-R1L-M | 1 | 4037.3 | 42.3 | 280 | 150 | 100 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 284.3 | 1.13 | 0.58 | 0.94 | 0.74 | 0.87 | |

| PS-100-R1M-M | 1 | 4037.3 | 42.3 | 280 | 150 | 100 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 251.5 | 1.27 | 0.66 | 1.06 | 0.84 | 0.99 | |

| PS-100-R1M-U | 1 | 4037.3 | 42.3 | 280 | 150 | 100 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 247.6 | 1.29 | 0.67 | 1.07 | 0.85 | 1.00 | |

| PS-100-R1M-L | 1 | 4037.3 | 42.3 | 280 | 150 | 100 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 316.2 | 1.01 | 0.52 | 0.84 | 0.67 | 0.79 | |

| PS-150-R1 | 1 | 4037.3 | 42.3 | 280 | 150 | 150 | 120 | 201.1 | 345.0 | 0 | 0.0 | 0.0 | 264.2 | 1.21 | 0.62 | 1.01 | 0.80 | 0.97 | |

| Average | 1.33 | 0.68 | 1.12 | 1.01 | 0.99 | ||||||||||||||

| Standard deviation coefficient | 0.36 | 0.17 | 0.23 | 0.24 | 0.14 | ||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Shi, Q.; Ma, G.; Li, T. Shear Behavior of Superposed Perfobond Connectors Considering Lateral Constraints. Appl. Sci. 2022, 12, 3162. https://doi.org/10.3390/app12063162

Guo J, Shi Q, Ma G, Li T. Shear Behavior of Superposed Perfobond Connectors Considering Lateral Constraints. Applied Sciences. 2022; 12(6):3162. https://doi.org/10.3390/app12063162

Chicago/Turabian StyleGuo, Jiangran, Qingxuan Shi, Ge Ma, and Tengfei Li. 2022. "Shear Behavior of Superposed Perfobond Connectors Considering Lateral Constraints" Applied Sciences 12, no. 6: 3162. https://doi.org/10.3390/app12063162

APA StyleGuo, J., Shi, Q., Ma, G., & Li, T. (2022). Shear Behavior of Superposed Perfobond Connectors Considering Lateral Constraints. Applied Sciences, 12(6), 3162. https://doi.org/10.3390/app12063162