Modeling and Simulation Process via Incremental Methods of a Production-Aimed Upper Limb Prosthesis

Abstract

Featured Application

Abstract

1. Introduction

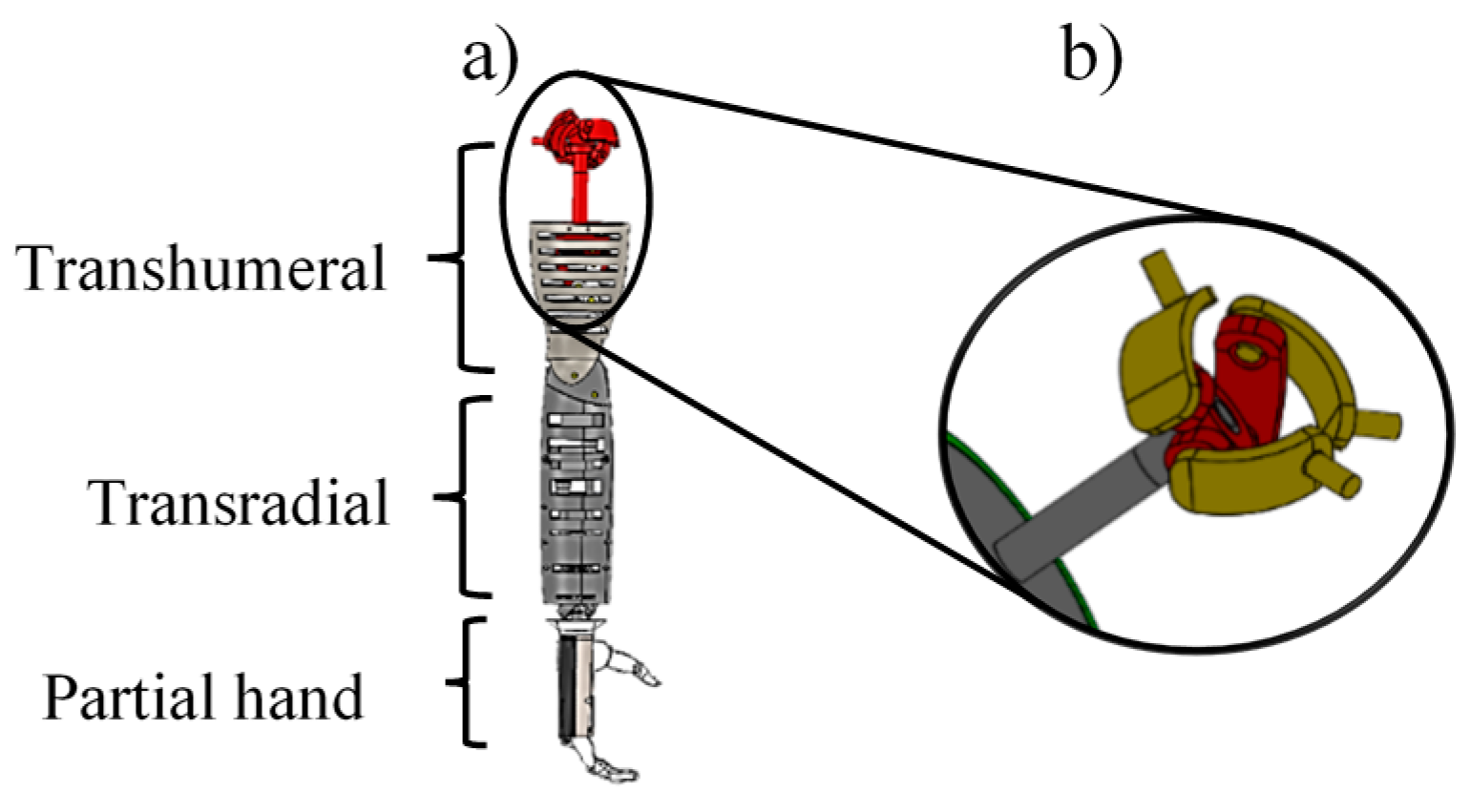

2. Backgrounds and Manufacture Requirements

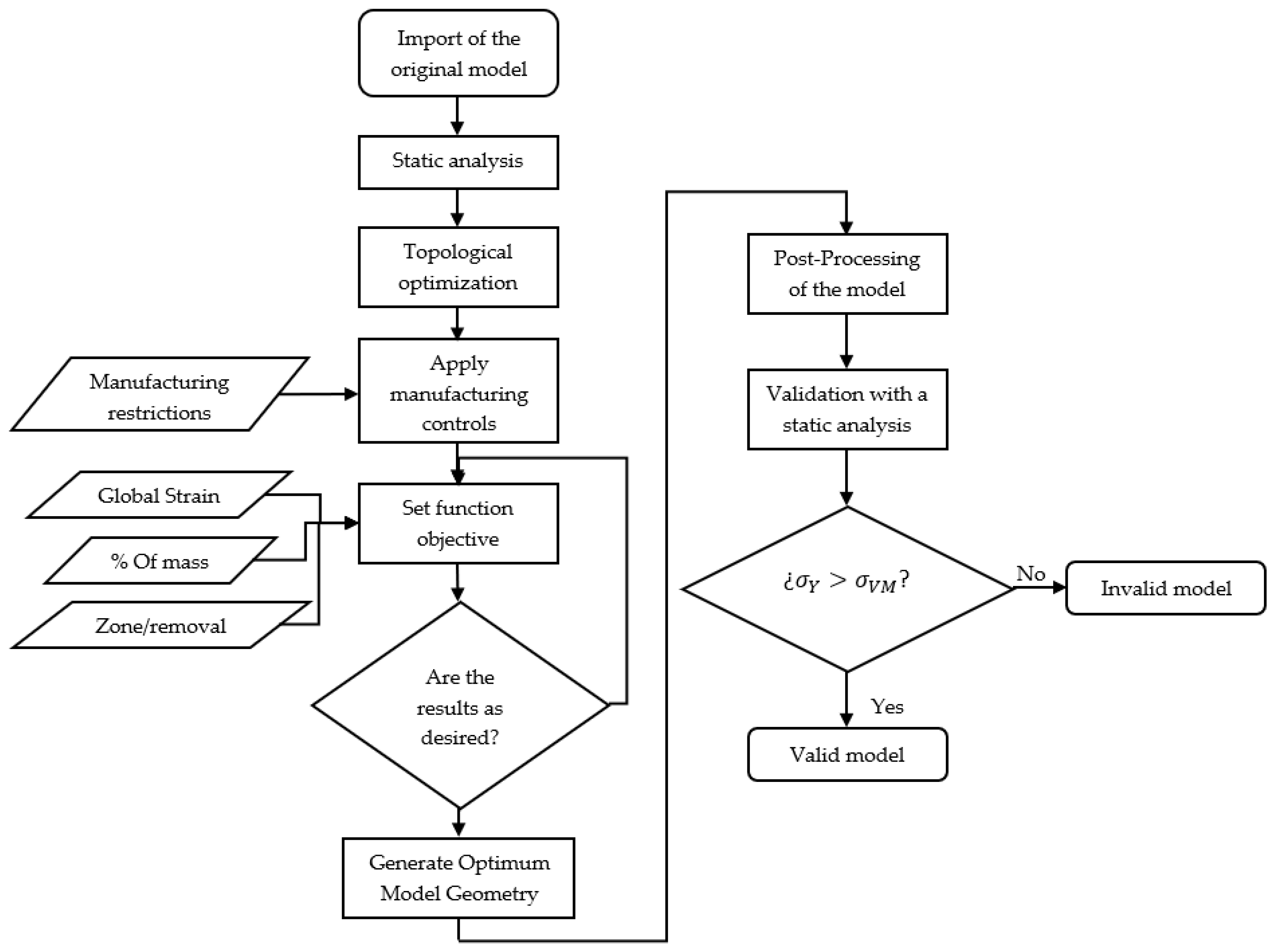

3. Topological Optimization

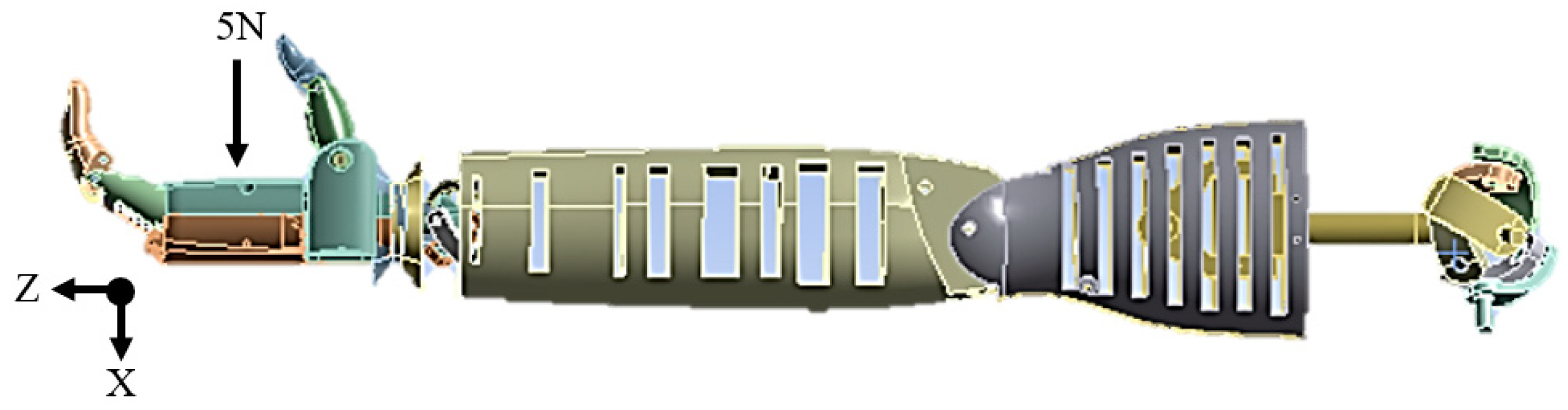

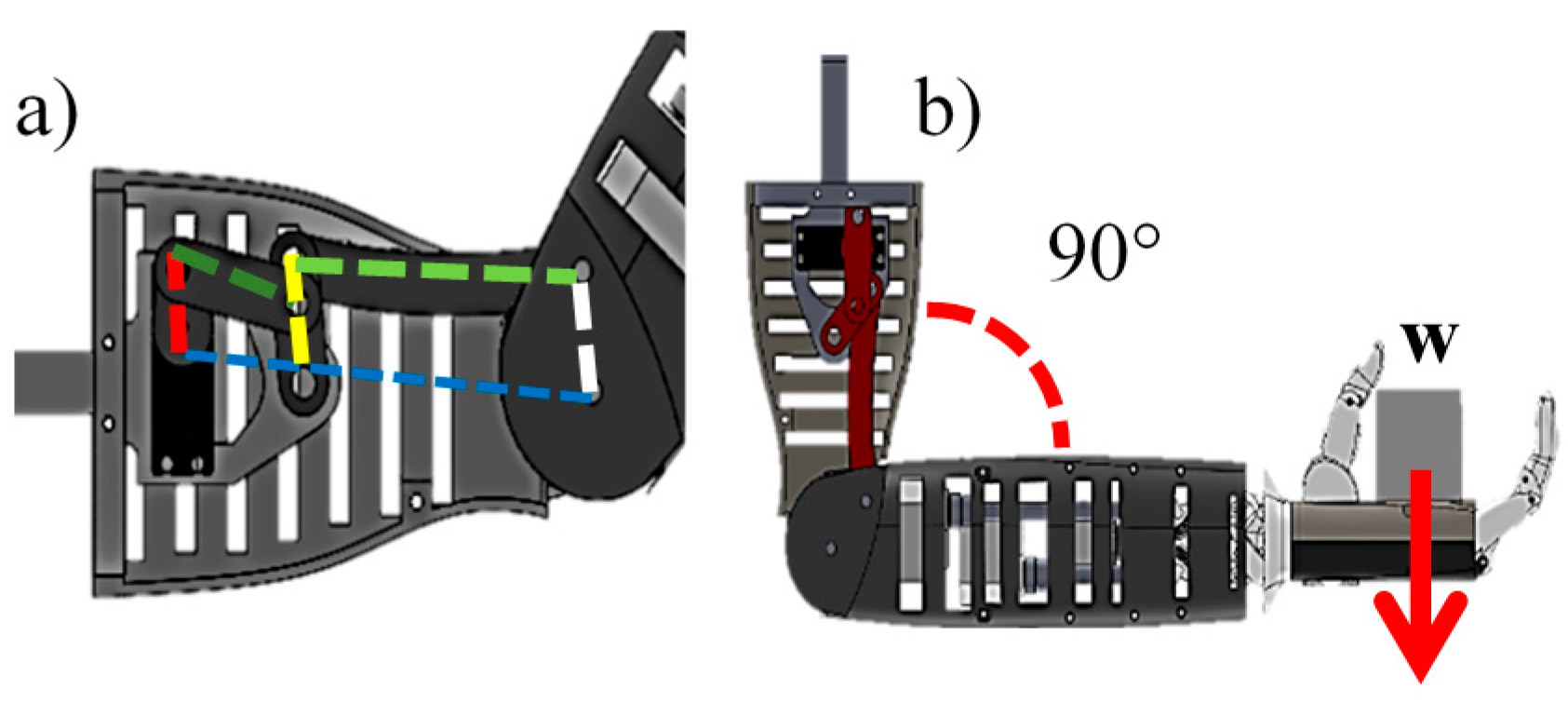

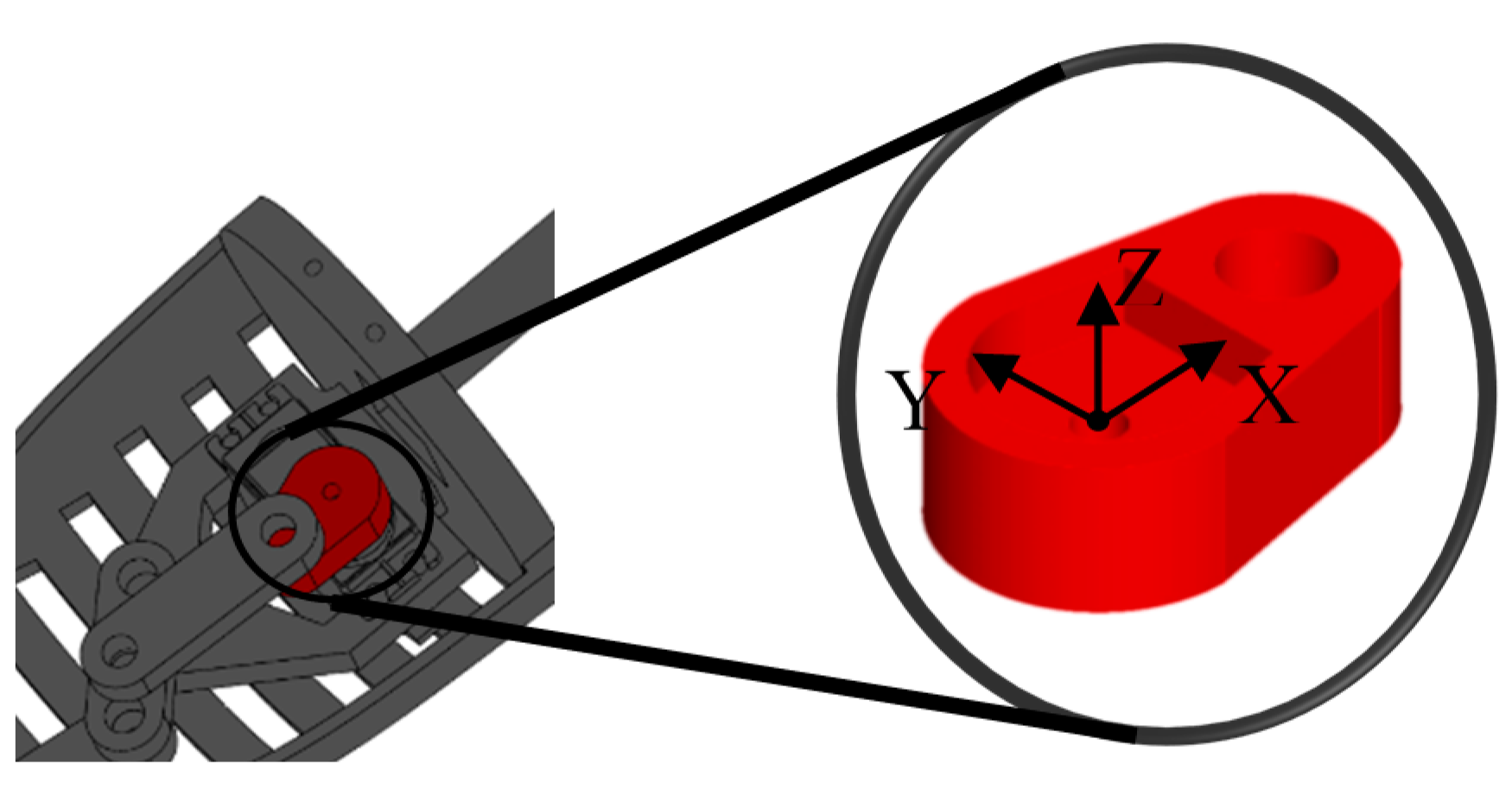

3.1. Six-Bar Mechanism

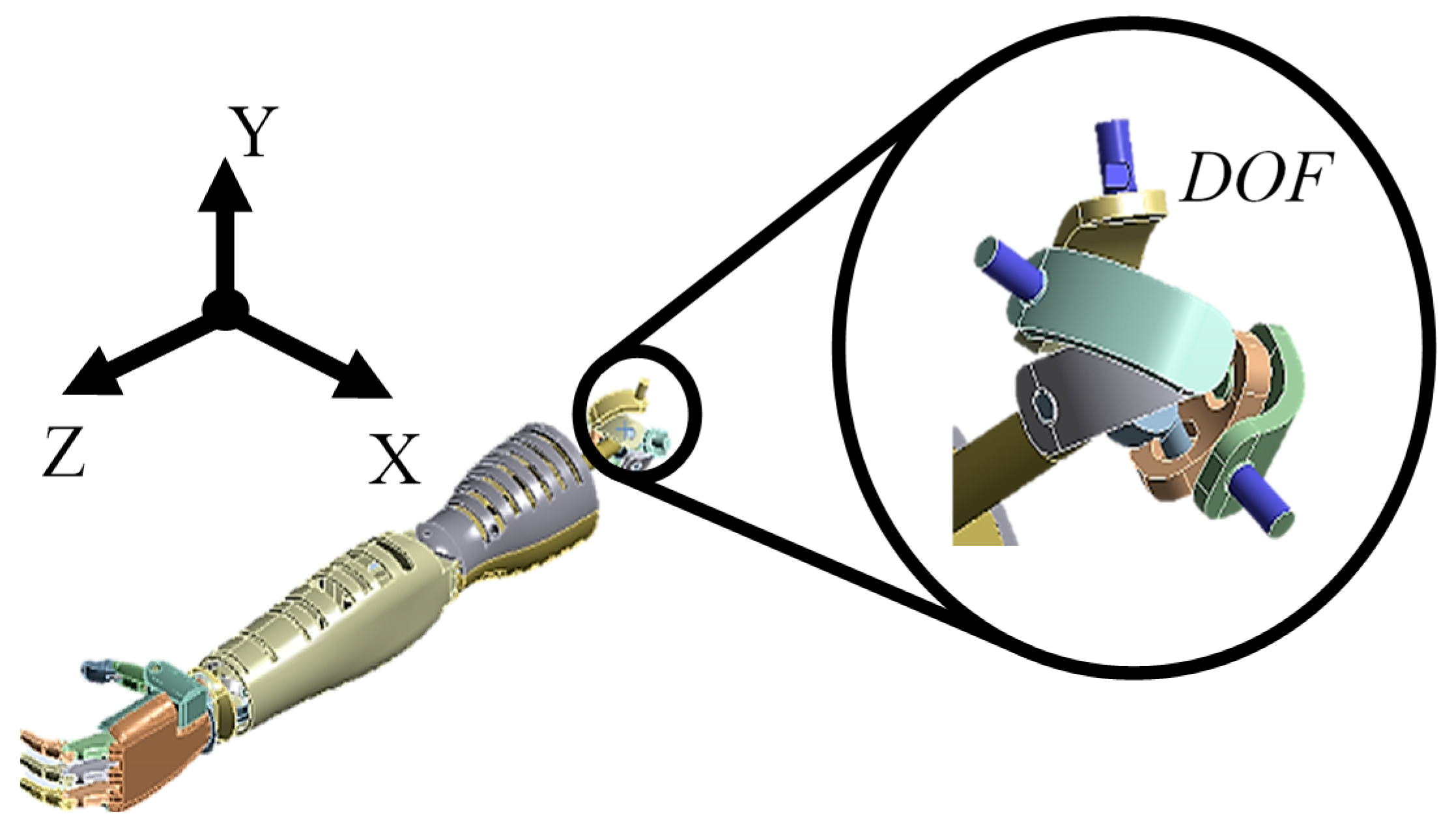

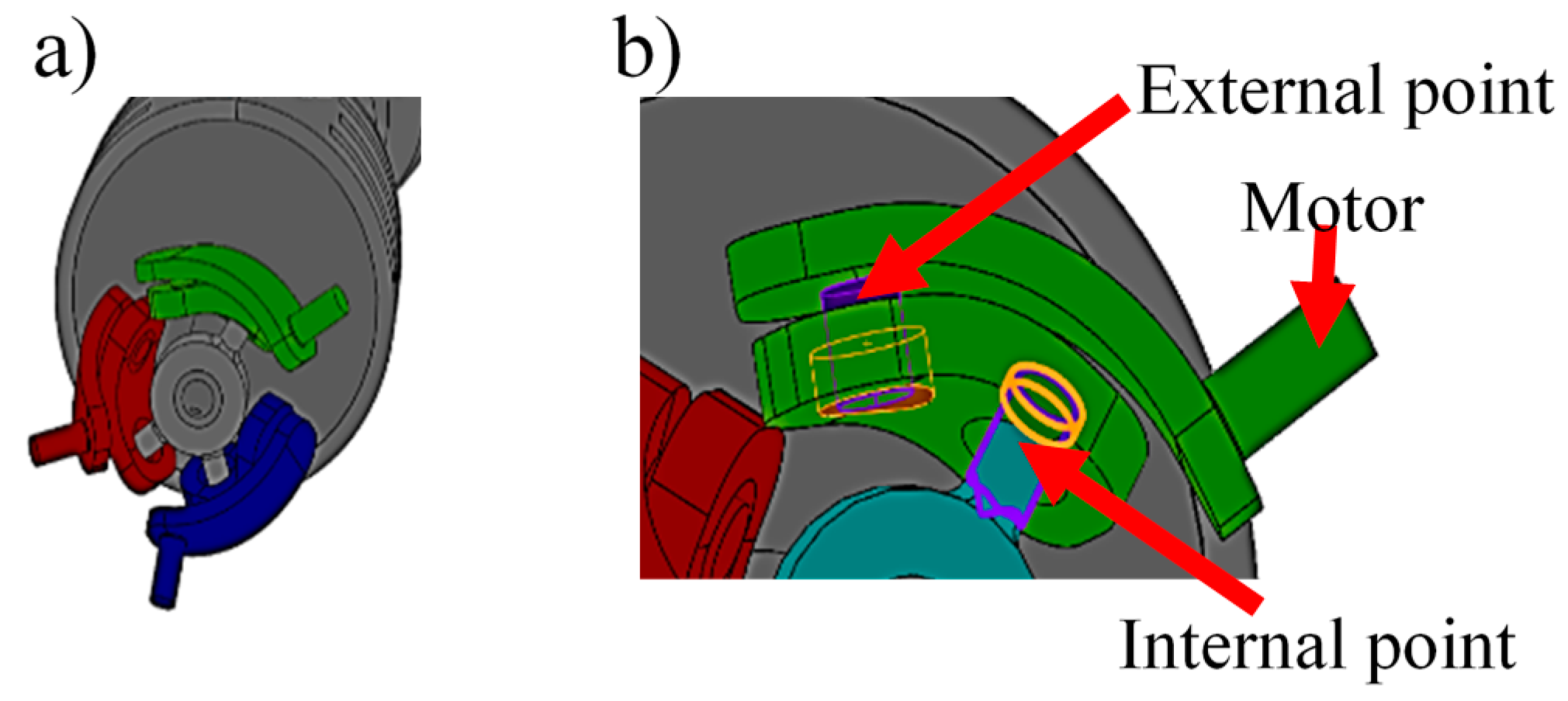

3.2. Spheric Mechanism

4. Manufacture Process

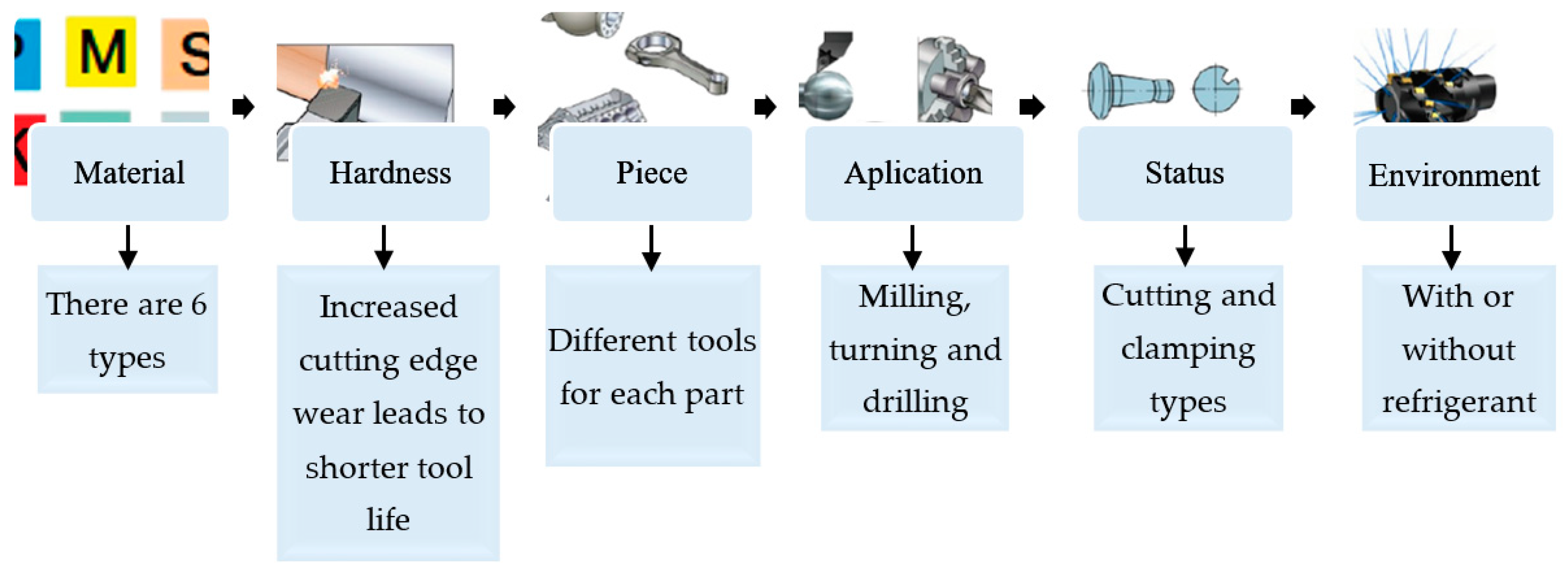

4.1. Progress Sheet

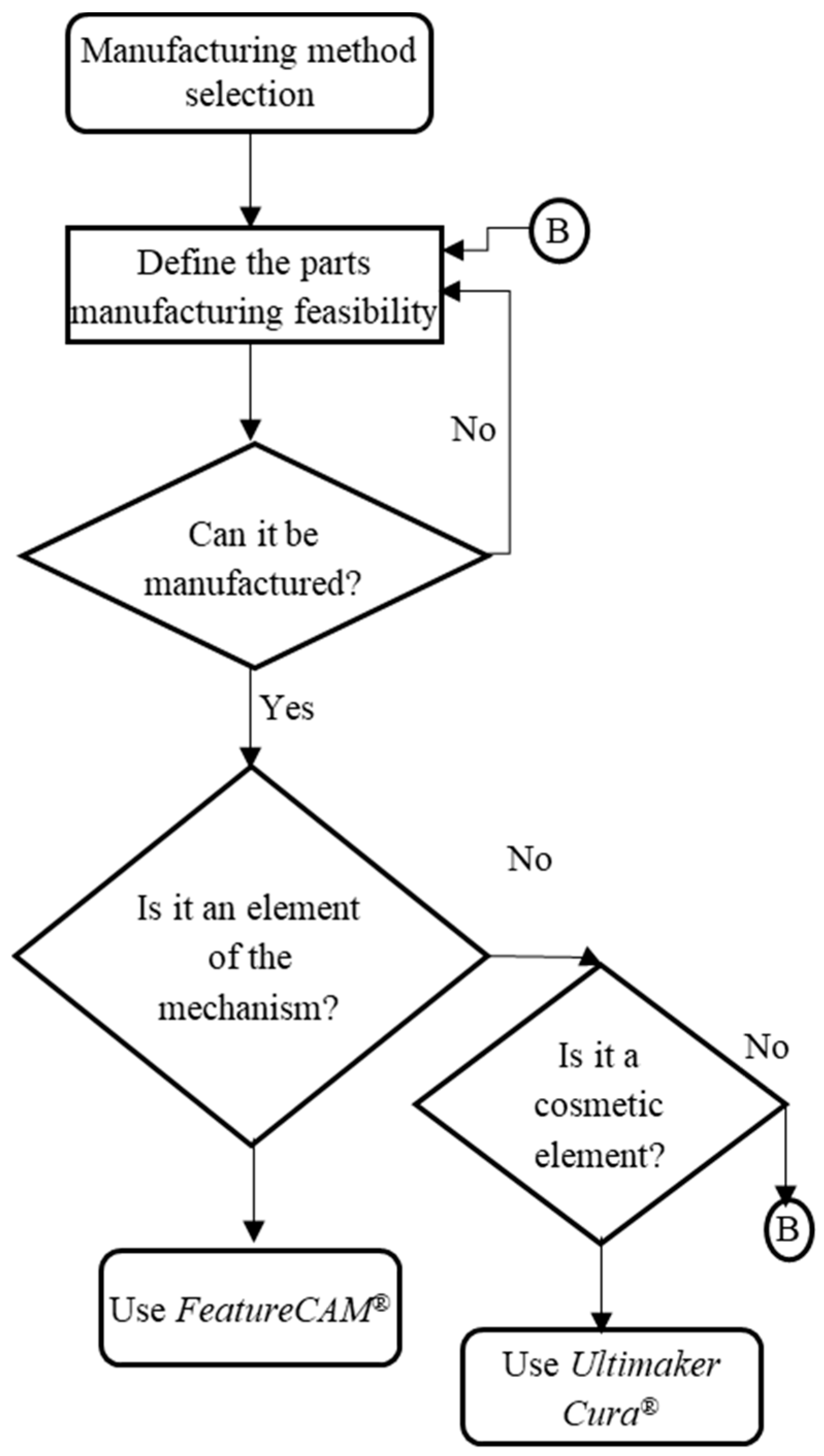

4.2. FeatureCAM® and Ultimaker Cura®

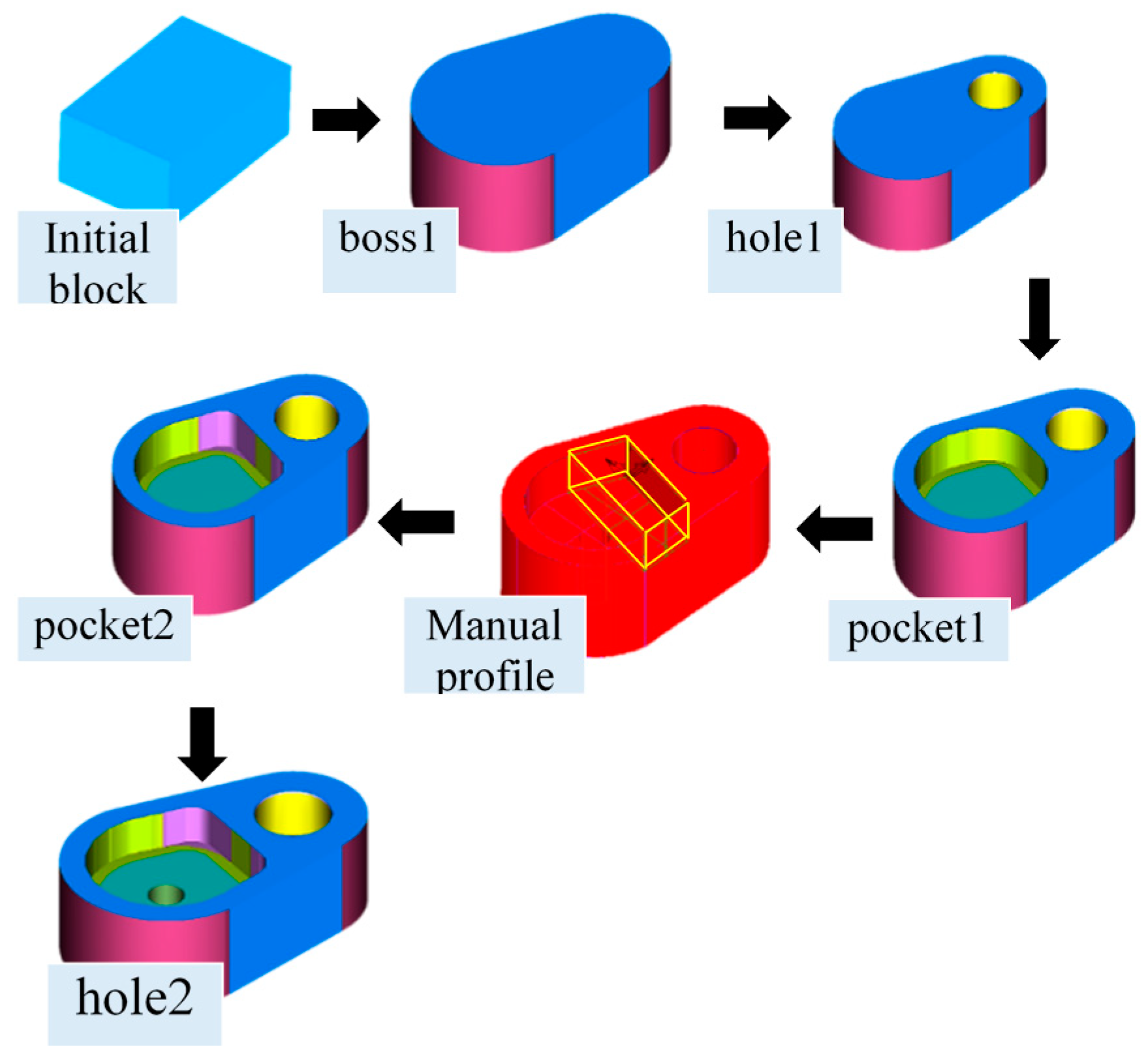

4.3. Manufacturing with Feature CAM®

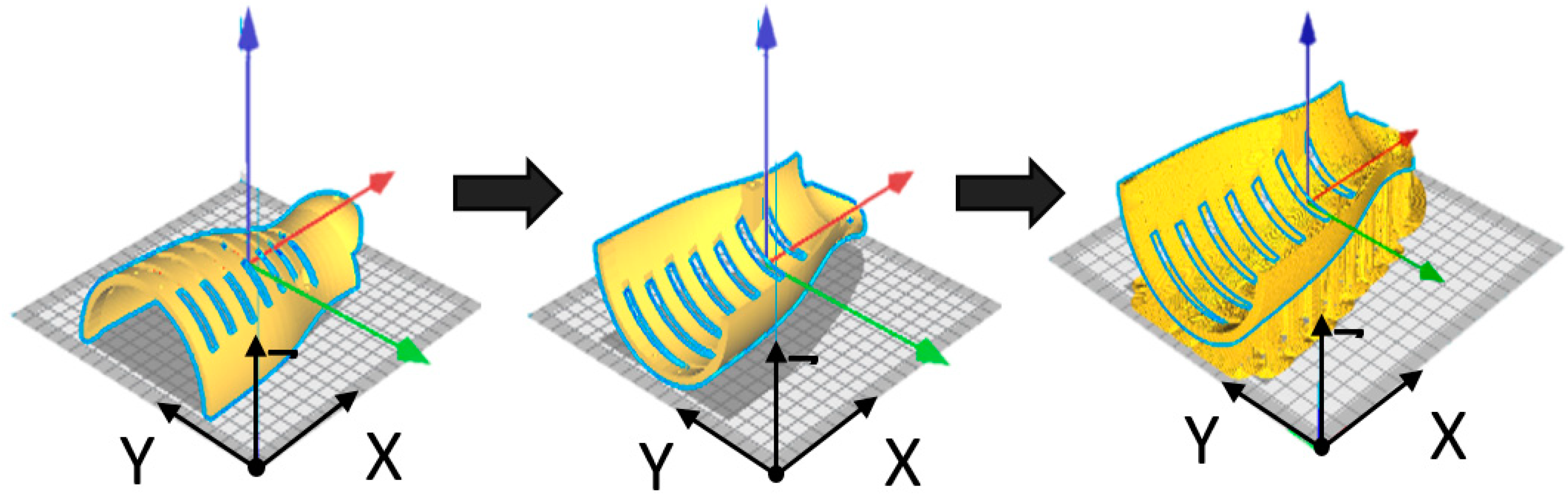

4.4. Manufacture with Ultimaker Cura®

5. Discussion

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- INEGI, Disabilities in Mexico, Percentage of Population with Disabilities According to Difficulty in Activity, Población. Discapacidad. 2020. Available online: Inegi.org.mx (accessed on 31 January 2022).

- Villadot-Pericé, R.; Cochí-Riambau, O.; Clavell-Paloma, S. Upper Extremity of Orthosis and Prosthesis of the Locomotor System; Masson: Barcelona, Spain, 2005; p. 280. [Google Scholar]

- Johnson, S.S.; Mansfield, E. Prosthetic training: Upper limb. Phys. Med. Rehabil. Clin. N. Am. 2014, 25, 133–151. [Google Scholar] [CrossRef] [PubMed]

- Kistenberg, R.S. Prosthetic choices for people with leg and arm amputations. Phys. Med. Rehabil. Clin. N. Am. 2014, 25, 93–115. [Google Scholar] [CrossRef] [PubMed]

- Advanced Arm Dynamics, Prosthetic Options. 2018. Available online: https://www.armdynamics.com/ (accessed on 31 January 2022).

- Rico-Mandujano, C.D. Structural Analysis of a Bionic Arm Prosthesis for an Upper Limb. Master’s Thesis, Instituto Politécnico Nacional, Mexico City, Mexico, 2011. [Google Scholar]

- Leal-Naranjo, J.A.; Ceccarelli, M.; Torres-San-Miguel, C.R.; Aguilar-Perez, L.A.; Urriolagoitia-Sosa, G.; Urriolagoitia-Calderón, G. Multi-Objective Optimisation of a Paraller Manipulator for the Design of a Prosthetic Arm Using Genetic Algorithms. Lat. Am. J. Solids Struct. 2018, 15, 2–7. [Google Scholar]

- Leal-Naranjo, J.A.; Miguel, C.R.T.S.; Ceccarelli, M.; Rostro-Gonzalez, H. Mechanical Design and Assessment of a Low-Cost 7-DOF Prosthetic Arm for Shoulder Disaticulation. Appl. Bionics Biomech. 2018, 2018, 4357602. [Google Scholar] [CrossRef] [PubMed]

- Dhiraj-Hussain, A.; Radhakrishnan, N.; Sarfas, M.; Francis, V. Design Considerations for Body-Powered 3D Printed Prostheses with String Mechanism for Upper Limb Disarticulation. In Proceedings of the International Conference on Industrial and Manufacturing Systems, (CIMS-2020), Jalandhar, India, 26–28 June 2020; pp. 283–299. [Google Scholar]

- Diment, L.; Thompson, M.; Bergmann, J. Three-dimensional printed upper-limb prostheses lack randomised controlled trials: A systematic review. Prosthet. Orthot. Int. 2018, 42, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Bastarrechea, A.; Estrada, Q.; Zubrzycki, J.; Torres-Argüelles, V.; Reynoso, E.; Rodríguez-Mendez, A.; Coutiño, E. Mechanical design of a low-cost ABS hand prosthesis using the finite element method. J. Phys. Conf. Ser. 2021, 1736, 012039. [Google Scholar] [CrossRef]

- Kayrıcı, M.; Uzun, Y.; Gök, O.; Arikan, H. Mathematical modeling and production of semi-active hand prosthesis from clear resin. Int. Adv. Res. Eng. J. 2021, 5, 171–180. [Google Scholar]

- Chen, R.K.; Jin, Y.A.; Wensm, J.; Shih, A. Additive manufacturing of custom orthoses and prostheses—A review. Addit. Manufacturing 2016, 12, 77–89. [Google Scholar] [CrossRef]

- Agudelo-Ardila, C.; Prada-Botía, G.; Rodrigues, P. Orthotic prototype for upper limb printed in 3D: A efficient solution. J. Phys. Conf. Ser. 2019, 1388, 012016. [Google Scholar] [CrossRef]

- Olsen, J.; Day, S.; Dupan, S.; Nazarpour, K.; Dyson, M. 3D-Printing and Upper-Limb Prosthetic Sockets: Promises and Pitfalls. IEEE Trans. Neural Syst. Rehabil. Eng. 2021, 29, 527–535. [Google Scholar] [CrossRef]

- Kate, J.; Smit, G.; Breedveld, P. 3D-printed upper limb prostheses: A review. Disabil. Rehabil. Assist. Technol. 2016, 12, 300–314. [Google Scholar] [CrossRef]

- Silva, L.A.D.; Medola, F.O.; Rodrigues, O.V.; Rodrigues, A.C.T.; Sandnes, F.E. Inrterdisciplinary-based Development of User-Friendly Customized 3D Printed Upper Limb Prosthesis. In Proceedings of the International Conference on Applied Human Factors and Ergonomics AHFE: Advances in Usability, User Experience and Assistive Technology, Orlando, FL, USA, 21–25 July 2018; Volume 794, pp. 899–908. [Google Scholar]

- Fajardo, J.; Ferman, V.; Cardona, D.; Maldonado, G.; Lemus, A.; Rohmer, E. Galileo Hand: An Anthropomorphic andAffordable Upper-Limb Prosthesis. IEEE Access 2020, 8, 81365–81377. [Google Scholar] [CrossRef]

- King, M.; Phillips, B.; Shively, M.; Raman, V.; Fleishman, A.; Ritter, S.; Mehta, K. Optimization of Prosthetic Hand Manufacturing. In Proceedings of the IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 8–11 October 2015; Volume 15648748, pp. 59–66. [Google Scholar]

- Radosh, A.; Kuczko, W.; Wichniarek, E.; Górski, F. Prototyping of cosmetic Prosthesis of upper limb using additive manufacturing technologies. Adv. Sci. Technol. Res. J. 2017, 11, 102–108. [Google Scholar] [CrossRef][Green Version]

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodriguez Salgado, D. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials 2020, 13, 295. [Google Scholar] [CrossRef] [PubMed]

- Leal-Naranjo, J.A. Design and Experimental Evaluation of a New Prosthetic Arm. Ph.D. Thesis, Instituto Politécnico Nacional, Mexico City, Mexico, 2017; pp. 10–15. [Google Scholar]

- Angana, S.; Sushmi, M.; Nitin, S.; Sudip, P.; Dinesh, B.; Suresh, V.; Putin-Kumar, R. Recent Advancements in Prosthetic Hand Technology. J. Med. Eng. Y Technol. 2016, 40, 255–264. [Google Scholar]

- Data Vis. DataVis Material Properties, Ed. Mc Graw Hill. 2018. Available online: https://www.accessengineeringlibrary.com/datavis/material-properties#/ (accessed on 31 January 2022).

- Dassult Systemes. Motion Analysis Redundancy Tutorial, SolidWorks Help. 2018. Available online: https://help.solidworks.com/2018/english/SolidWorks/motionstudies/c_Redundant_Mates_SWMotion.htm (accessed on 31 January 2022).

- Correal-Franco, S.; Palacio-Delgado, L.J.; Salazar-Gómez, I.C. FEA Analysis of Polycentric Knee Prosthesis. Adv. Syst. Inf. Mag. 2006, 3, 35–38. [Google Scholar]

- ISO 513. Classification and Application of Hard Cutting Materials for Metal Removal with Defined Cutting Edges–Designation of the Main Groups and Groups of Application; ISO International: Geneva, Switzerland, 2012. [Google Scholar]

- Sanvik Conromant. Metal Machining Technology Manual Training; Sanvick Coromant Publications: Sandviken, Sweden, 2019; pp. 4–8. [Google Scholar]

- FeatureCam. Make Parts Faster with Automated CAM; Autodesk Inc.: Mill Valley, CA, USA, 2019. [Google Scholar]

- Ultimaker, B.V. Ultimaker, Professional 3D Printing Made Accesible. 2019. Available online: https://ultimaker.com/ (accessed on 31 January 2022).

- Roșu, M.M.; Matei, L.; Ungureanu, L.M.; Iliescu, M. Concept, Design, Initial Tests and Prototype of Customized Upper Limb Prosthesis. Appl. Sci. 2021, 11, 3077. [Google Scholar]

| Material | ρ | ν | E | $ | Machinability | Density (kg/m3) | Mass (kg) |

|---|---|---|---|---|---|---|---|

| Aluminum 7075-O | 2800 | 0.36 | 72 | 19 | Perfect | 2810 | 1.686 |

| Stainless Steel SAE 304 | 8000 | 0.29 | 193 | 12.5 | Regular | 8000 | 4.8 |

| Titanium Ti-6Al-4V | 4430 | 0.34 | 114 | 118 | Bad | 4430 | 2.658 |

| Steel AISI 1040-Normalized | 7850 | 0.29 | 200 | 4.20 | Good | 7850 | 4.71 |

| Original ABS | 1060 | 0.33 | 2.30 | 5.18 | N/A | 1060 | 0.630 |

| Variable | Description |

|---|---|

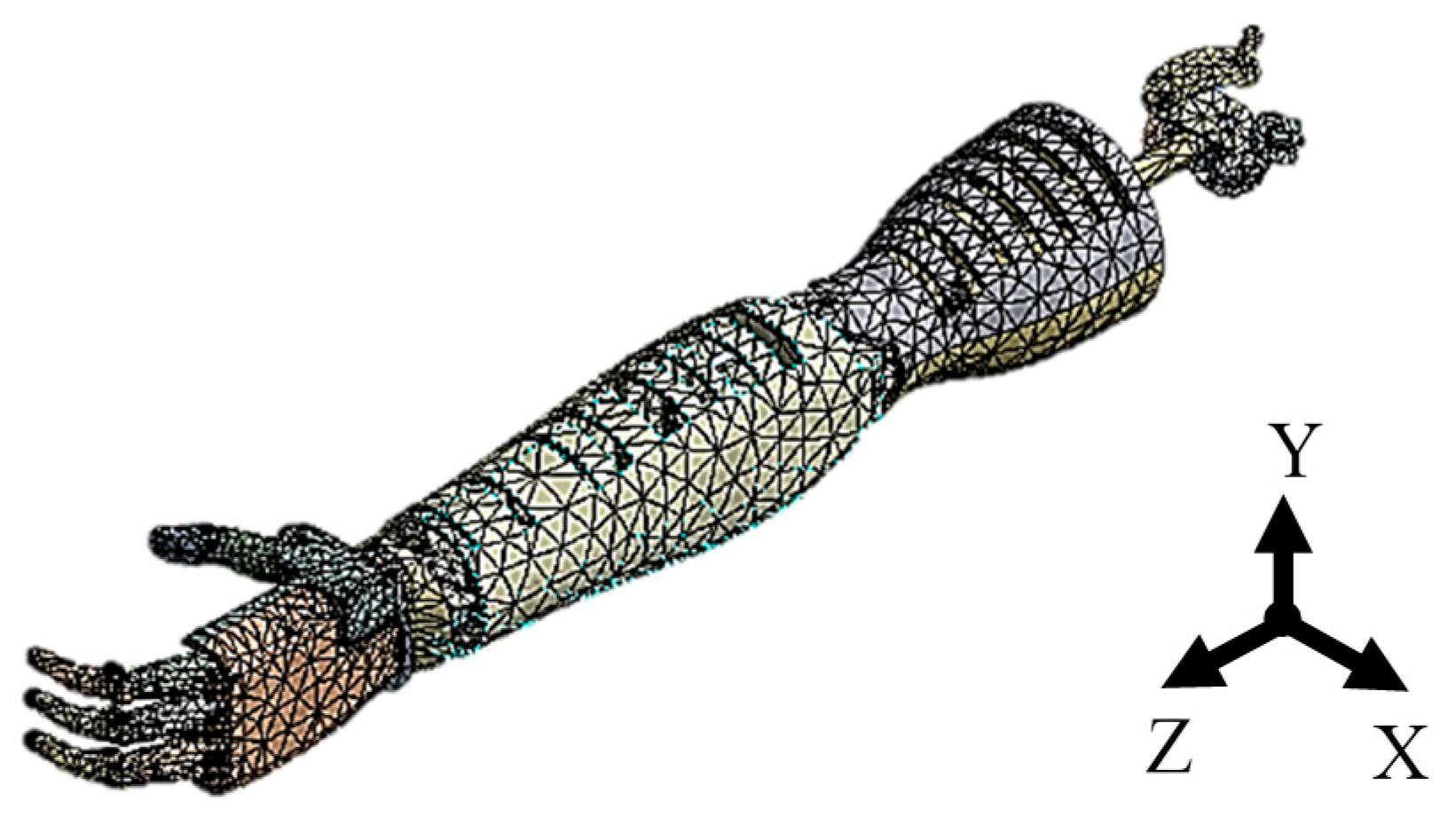

| Type of analysis | Isotropic linear static |

| Model view | 3D |

| Degrees of freedom | Ux, Uy and Uz |

| Iteration algorithm | Newton–Raphson |

| Mesh type | Mesh with adaptive size function |

| Element type | Solid-186/187 |

| Nodes | 137,630 |

| Contacts | 28,329 |

| Solid elements | 55,076 |

| Total elements | 83,405 |

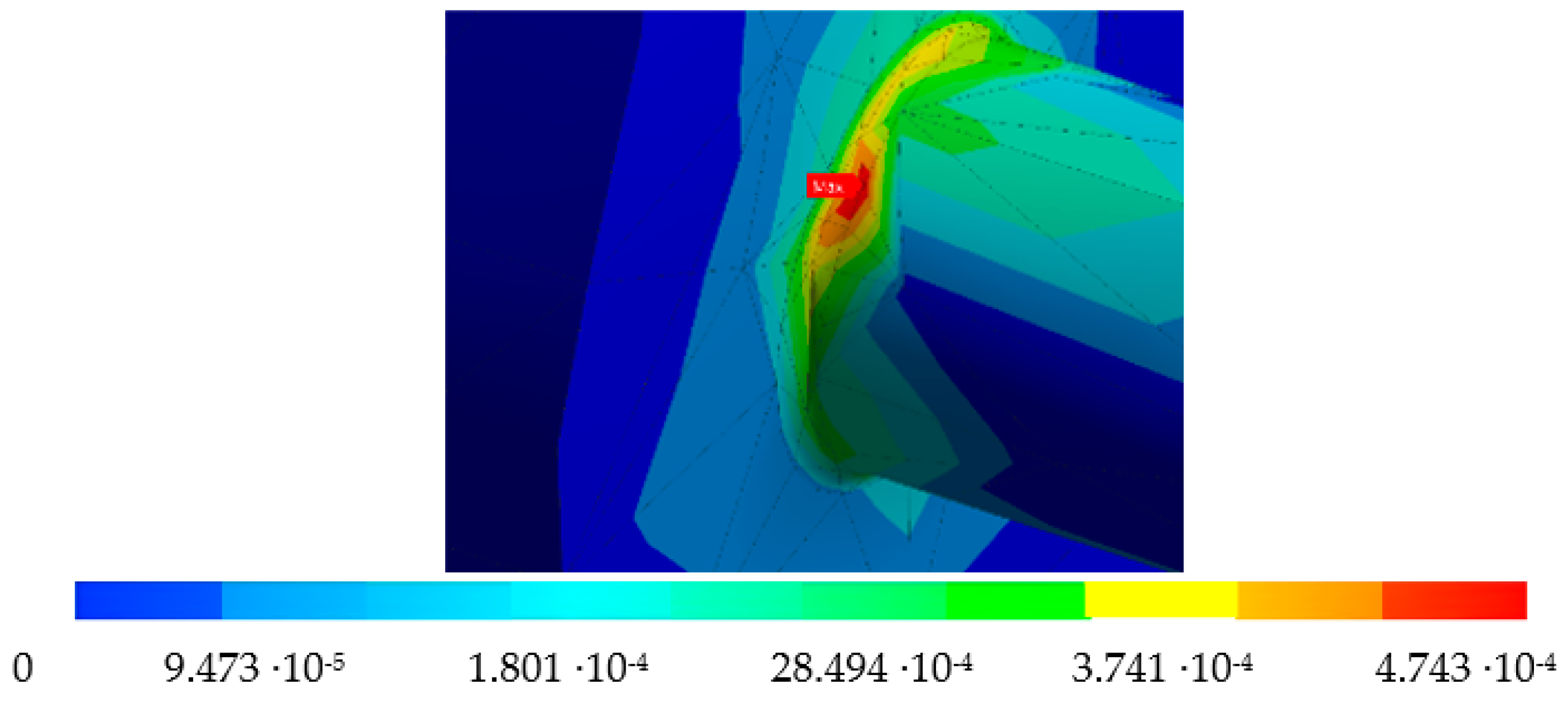

| Material | Total Displacement (mm) | Maximum Shear Stress (MPa) | Total Deformation |

|---|---|---|---|

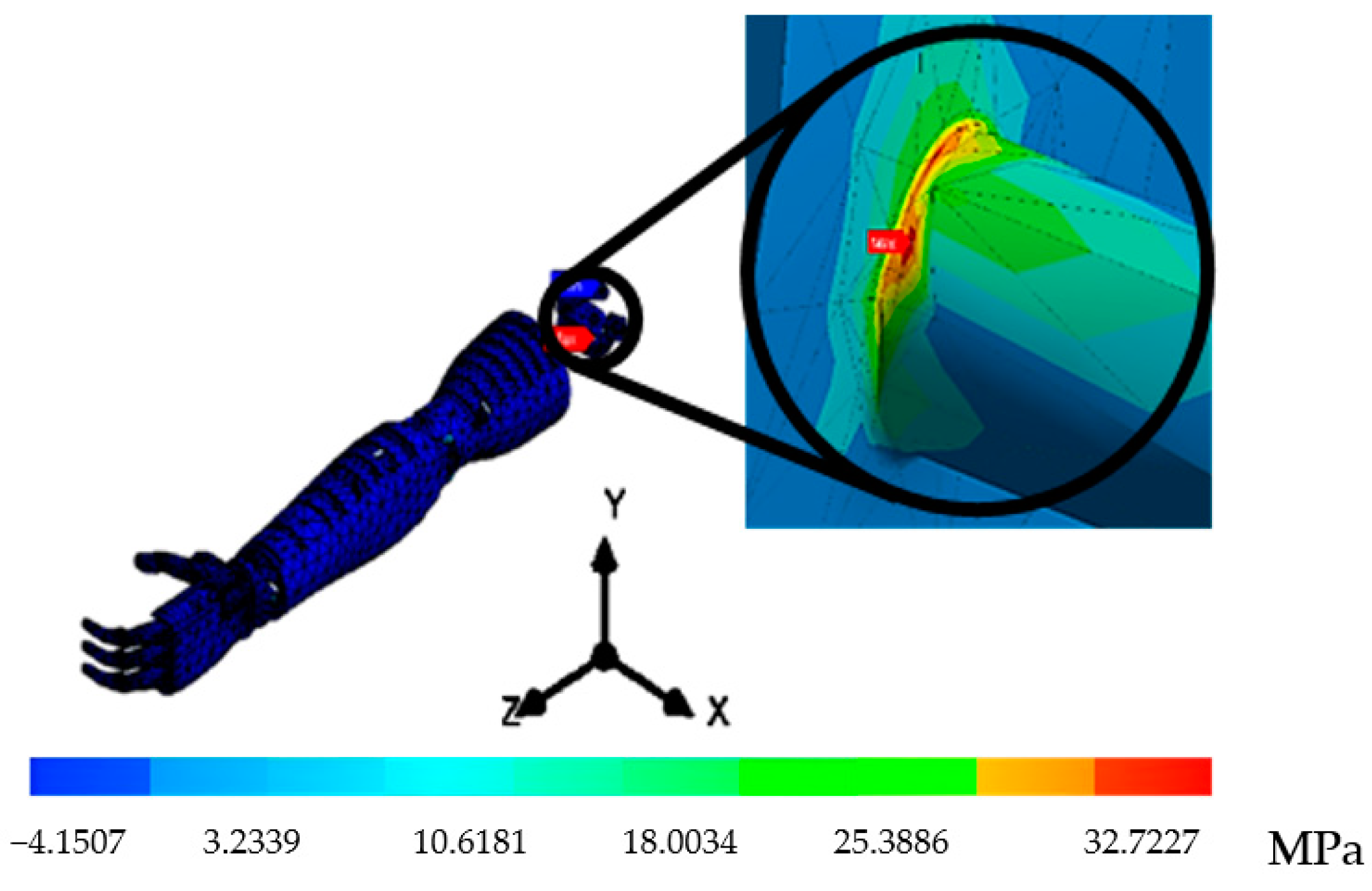

| Aluminum; 7075-O | 1.0207 | 32.772 | 0.00042631 |

| Stainless Steel; SAE 304 | 0.37987 | 32.299 | 0.0001781 |

| Titanium; Ti-6Al-4V | 0.64199 | 32.94 | 0.00026773 |

| Stainless; AISI 1040- Standardized | 0.36631 | 32.329 | 0.0001721 |

| ABS | 31.814 | N/A | 0.014786 |

| Point of Interest | Results (N) |

|---|---|

| Fx = 199 |

| Fy = 1 | |

| Size = 199 | |

| Fx = 1 |

| Fy = 199 | |

| Size = 199 | |

| Fx = 56 |

| Fy = 122 | |

| Size = 134.2 | |

| Fx = 32 |

| Fy = 55 | |

| Size = 64 | |

| Fx = 133 |

| Fy = 17 | |

| Size = 134 |

| Property | Value |

|---|---|

| Poisson’s coefficient | 0.36 |

| Modulus of elasticity | 72,000 MPa |

| Maximum strain | 572 MPa |

| Density | 2800 kg/m3 |

| Yielding strain | 503 MPa |

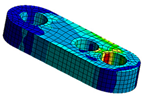

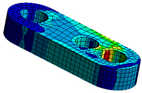

| Original Piece | Post-Processing | Optimized Piece |

|---|---|---|

σVM = 10.70 MPa |  |  σVM = 351.48 MPa |

σVM = 37.41 MPa |  |  σVM = 232.55 MPa |

σVM = 7.68 MPa |  |  σVM = 110.64 MPa |

σVM = 9.50 MPa |  |  σVM = 247.66 MPa |

σVM = 4.79 MPa |  |  σVM = 89.13 MPa |

| Point of Interest | Results (N) |

|---|---|

| External |

| Fx = 1, Fy = −1 | |

| Fz = 4 | |

| Size = 4 | |

| Internal | |

| Fx = 1, Fy = −1 | |

| Fz = 4 | |

| Size = 4 | |

| External |

| Fx = 1, Fy = −19 | |

| Fz = −26 | |

| Size = 32 | |

| Internal | |

| Fx = 1, Fy = −19 | |

| Fz = −26 | |

| Size = 32 | |

| External |

| Fx = 9, Fy = 27 | |

| Fz = 17 | |

| Size = 33 | |

| Internal | |

| Fx = 9, Fy = 27 | |

| Fz = 17 | |

| Size = 33 |

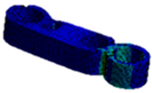

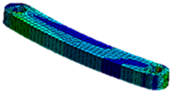

| Original Piece | Post-Processing | Optimized Piece |

|---|---|---|

External green σVM = 0.85 MPa |  |  σVM = 308.55 MPa |

Internal green σVM = 1.63 MPa |  |  σVM = 68.09 MPa |

External blue σVM = 11.543 MPa |  |  σVM = 165.66 MPa |

Internal blue σVM = 19.04 MPa |  |  σVM = 94.48 MPa |

External red σVM = 8.56 MPa |  |  σVM = 137.45 MPa |

Internal red σVM = 9.50 MPa |  |  σVM = 69.91 MPa |

| Parameter | Description | Value |

|---|---|---|

| Quality | Sets the layer height that affects the resolution of the final piece. | 0.1 mm |

| Shell | Sets the wall thickness, the number of walls generated, the thickness of the first and last layers. | Wall thickness = 0.8 mm Number of walls = 2 The thickness of the first/last layer = 0.8 mm |

| Infill | Sets the density of the part and the type of structural pattern. | Density = 40% Pattern= Triangular |

| Material | The temperature at which the material melts, the heat bed temperature, and the option to activate material shrinkage are given. | PLA = 200 °C Bed = 60 °C Retraction=Active |

| Print speed | Sets the speed of the stepping motor when inducing the material into the extruder tip. | 60 mm/s |

| Cooling | Activates the printer ventilator and the percentage speed at which the print cooling fans rotate. | Ventilator = active Speed= 100% |

| Support | It activates the support material that can be placed on the entire model where it is required or only on the parts that are in contact with the surface and the protruding angle of the support. | Support = active Position = All Angle = 50° |

| Build plate adhesion | Provides three options for the material adhesion of the surface. | Type = Brim |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres-SanMiguel, C.R. Modeling and Simulation Process via Incremental Methods of a Production-Aimed Upper Limb Prosthesis. Appl. Sci. 2022, 12, 2788. https://doi.org/10.3390/app12062788

Torres-SanMiguel CR. Modeling and Simulation Process via Incremental Methods of a Production-Aimed Upper Limb Prosthesis. Applied Sciences. 2022; 12(6):2788. https://doi.org/10.3390/app12062788

Chicago/Turabian StyleTorres-SanMiguel, Christopher René. 2022. "Modeling and Simulation Process via Incremental Methods of a Production-Aimed Upper Limb Prosthesis" Applied Sciences 12, no. 6: 2788. https://doi.org/10.3390/app12062788

APA StyleTorres-SanMiguel, C. R. (2022). Modeling and Simulation Process via Incremental Methods of a Production-Aimed Upper Limb Prosthesis. Applied Sciences, 12(6), 2788. https://doi.org/10.3390/app12062788