Abstract

Microfluidic screening tools, in vitro, evolve amid varied scientific disciplines. One emergent technique, simultaneously assessing cell toxicity from a primary compound and ensuing cell-generated metabolites (dual-toxicity screening), entails in-line systems having sequentially aligned culture chambers. To explore dual-tox screens, we probe the dissemination of nutrients involving 1-way transport with upstream compound dosing, midstream cascading flows, and downstream cessation. Distribution of flow gives rise to broad concentration ranges of dosing compound (0→ICcompound100) and wide-ranging concentration ranges of generated cell metabolites (0→ICmetabolites100). Innately, single-pass unidirectional flow retains 1st pass informative traits across the network, composed of nine interconnected culture wells, preserving both compound and cell-secreted byproducts as data indicators in each adjacent culture chamber. Thereafter, to assess effective compound hepatotoxicity (0→ECcompound100) and simultaneously classify for cell-metabolite toxicity (0→ECmetabolite100), we reveal utility by analyzing culture viability against ramping exposures of acetaminophen (APAP) and nefazodone (NEF), compounds of hepatic significance. We then discern metabolite generation with an emphasis on amplification across µchannel multiwell sites. Lastly, using conventional cell functions as indicator tools to assess dual toxicity, we investigate a non-drug induced liver injury (non-DILI) compound and DILI compound. The technology is for predictive evaluations of new compound formulations, new chemical entities (NCE), or drugs that have previously failed testing for unresolved reasons.

1. Introduction

New cell culture devices are populating life science and pharmaceutical R&D benches at escalating rates, each with unique features and various functions [1,2,3]. Efforts in development are driven by the need to improve human-relevant experimental systems earlier in the drug evaluation process. New systems could arguably be termed “microfluidic devices” or “benchtop bioreactors” and include characteristics such as kinetic flows, complex cell mixtures, and 2-dimensional (2D) or 3-dimensional (3D) culture spaces [4]. Already, several investigative teams recognize the need for integrating flow with compound exposure and acknowledge this emerging technology may bolster high-content screening and predictive computational modeling [5,6,7,8,9]. In regard to platform physical parameters, µfluidic configurations commonly include a culture chamber, or multiple linked chambers, nutrient flow, and controllers such as pumps, valves, and fluid transport tubes [10]. While such devices can be skillfully prototyped, the refinement into mass manufacturing of product has tangible engineering constraints. Manufacture limitations often cause the platform’s bio-functionality to fall short of what biologists, toxicologists, and drug development researchers find valuable [11,12]. Hence, during µfluidic device creation, early knowledge transfer from end-users and enduring communication with product fabricators are critical evolving interchanges. End-user objectives align with targeted use-model strategies, needs for lab compatible accessories, and design conditions that prompt development constraints. Engineering considerations may include material properties to avoid adsorption of compounds onto fabricated polymers [13,14,15], the process of seeding and removing cells for evaluation [3,16], altered techniques to validate assays [17,18], and device compatibility with lab equipment such as plate readers, imagers, and liquid handling systems.

1.1. A Fluidic Platform for Dual-Toxicity Screening

In this study, a multiwell µfluidic platform is targeted to monitor cellular effects from both primary drug-toxicant and secondary generated cell byproducts (byproducts defined as one or more metabolites). Regarding static culture systems, past literature discloses fundamental limitations of in vitro testing methods that lack fluid flow to indicate no chemical gradients, no metabolite distinctions, and no signaling through interconnected compartments [19]. This no-flow technique can result in data that is less predictive of how a compound will respond, or be responded to, in the in vivo environment. Associatively, even in vivo animal testing can be unpredictable of human physiology due to phenotypic differences in cell types and organ systems [20,21,22]. Strategically, benchtop µfluidic environments that better mimic in vivo flow networks are gaining research and development interests [3,12]. In this context, we stage the SsWaterfall fluidic culture system (Figure 1), an exposure platform having two unique traits, (1) unidirectionality with non-recirculating fluid flows, and (2) the sequential assembly-line of cell cultures. The unidirectional fluid flow is configured as 1-way transport and conceptualized as a waterfall stream (fluidics) trickle flow (time-influential), having riverbeds positioned all along its downstream path (culture spaces). The non-recirculation feature infers that drug distributions and generated cell secretions remain as distinguishable data indicators, unblended across location and time, as sample traits that are critical descriptors for definitive evaluations amid culture spaces. Comparatively, most precedent µfluidic designs innately mix their nutrient elements (recirculating systems) and inherently blend sample distinctions that inhibit definitive cell function analysis amid adjacent culture spaces. The sequential assembly-line of cell cultures can be envisioned as a production line (as in manufacturing) that is arranged so a product (dose of the compound) is moved sequentially along the assembly line (µfluidic channel) and across workspaces (culture wells). Herein, a procedure is performed at each location (cell function/well) prior to moving refined products (cell signals) to the next downstream location (adjacent culture well). Paraphrased, upstream compound dosing and upstream cell responses influence downstream culture wells. Irrespective of flow path or generated cell byproduct, the µfluidic system allows for modular tissue arrangements with passive fluid transport that is regulated by hydrodynamics, capillary action, and a downstream syphon to pull media across culture chambers (i.e., no pumps, no valves, and no tubes [23]). The flow methodology and approach are essential for studying microphysiological system (MPS) arrangements for predictable compound efficacy and toxicity.

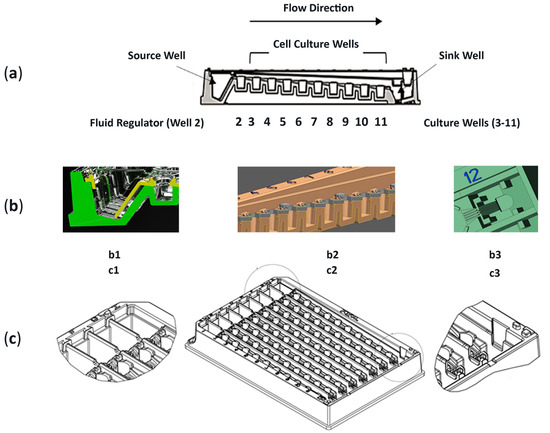

Figure 1.

Characteristics of fluidic culture system. (a) Profile schematic highlighting source well (well 1), 10 connected compartments (wells 2–11), and sink well (well 12). Wells 2–11 having 0.5 mm decrease in height from each well bottom; total 4 mm height difference. (b1) Profile of source well (well 1) and regulator well (well 2; acellular) allowing nutrient media to flow between assembled components (i.e., yellow and green accents). (b2) Profile of wells 3–11 with polystyrene polymer overlay (grey) covering microfluidic channels. (b3) Top view of sink well (well 12) that is covered by syphon wick (wick not shown). (c1) Top CAD view of source well (well 1). (c2) Top CAD view of fluidics platform. (c3) Top CAD view of sink well (well 12).

1.2. The Organ of Investigation Is Liver with Cell Culture Being Hepatoctyes

Drug failure during in vivo clinical trials or the retraction of a drug from an already available commercial compound can be correlated with a lack of effective in vitro model systems; namely, culture platforms that lack integration of flow dynamics and lack complex cell interfacing as naturally observed amid native tissues [24]. It continues to be shown that many clinical failures are due to unpredictable effects and unforeseen hepatotoxicity [25,26,27]. As one model template, DILI is responsible for many post-market drug withdrawals in the European Union [28] and the United States [29,30]. In vivo, certain hepatic toxicities occur as the native liver generates cell metabolites that can cause liver damage [31]. To wit, the advancement of in vitro models that better mimic behaviors of native liver tissue remains an industry challenge, with a focus on improved efficacy and decreased toxicity [32]. To enhance scientific understanding and development, the in vivo organization of cells in the liver implies that in vitro culture systems might benefit from cell–cell communication and intrinsic interactions between a parent compound and generated cell-byproducts. Amid select drug subgroups, literature already discloses that stagnant (i.e., no-flow) hepatic culture systems do have a limited capacity to predict facets of toxicity or efficacy outcomes [33,34,35]. In efforts to broaden the success of predictive studies, a major focus of this research was to demonstrate the ability of a stand-alone and disposable µfluidic platform to simultaneously detect compound toxicity (upstream) and cell-metabolite toxicity (downstream) in one integrated system. To evaluate cell-response modulations, due to perpetual shifts of ascending exposures, two stable but different hepatic cell models were exploited; the human HepaRG cell-line (Biopredic International, Saint Gregoire, France) and freshly isolated rat hepatocytes (Lonza, Basel Switzerland—Durham, NC, USA location).

1.3. Exposure Compounds and Cell Health Readouts

Hepatocyte cultures were exposed to diclofenac, APAP, aspirin (ASA), NEF, and dimethyl sulfoxide (DMSO). Diclofenac is a known cytochrome P450 3A4 (CYP3A4) inducer. APAP is a well-studied standard with known metabolites APAP-glucuronide (APAP-Glu), APAP-sulfate, and APAP-glutathione (APAP-GSH). ASA and NEF are non-DILI or DILI compounds, with DMSO being the compound control vehicle [36]. To appraise cell culture health, cell function readouts include lactate dehydrogenase (LDH) activity, CYP3A4 inducible-fold levels, glutathione (GSH-assay), and live/dead cell image responses (DAPI, calcein AM, CellTox Green, ethidium homodimer). To appraise metabolite generation, liquid chromatography–mass spectrometry (LC/MS) was used to assess supernatant samples.

2. Materials and Methods

2.1. Device, Design, Material, Construction, Culture Surface, and Attributes

2.1.1. Device

Each fluidic culture system consists of 96 wells, 8-row replicate rows (A-H), with wells connected by embedded micro-pathways that link 12 wells across a row (Figure 1). Compound dosing occurs in well 1 (upstream), then the system auto-generates unidirectional flow left-to-right (well 1→12) by hydrodynamics, capillarity, and wicking, i.e., stair-step waterfall design without external pumps. The adjustable flow rate is regulated by removing medium from well 12 (Sink well) and adding medium + drug into well 1 (source or dose well). The frequency and volume of the dosing compound controls the rate by which the drug migrates across the row [23].

Structure and Lab Compatibility

The platform is based on the Society for Biomolecular Screening (SBS) parameters and formatted as a ½ area 96-well plate definition for use in existing scientific infrastructures to include plate readers, imaging systems, and pipettors, i.e., designed lab-compatible, device manageable, with user familiarity, Table 1. The device is considered a medium-throughput system that has reduced cost structures based on decreased cell quantities (½ area 96-well), a reduction in nutrient volumes (100 µL/well), and lower amounts of drug/compound for exposure findings (scaled-down µchannels).

Table 1.

µFluidics Culture Device—Attributes and Infrastructure.

2.1.2. Material and Cell Compatibility

The device is manufactured from laboratory approved traditional polystyrene, suitable due to its already established quality control and history as a validated cell culture surface material with known assay outcomes. Still, because manufactures of polymers have variant constituent formulas and resin adaptations, non-specific binding should be appraised for quality control validation [23]. Moreover, the optical transparency property of polystyrene enables ease of cell observation and imaging.

Mass Production for Repeatability

The microfluidic biotool is suited to be a cost-effective tissue culture system that can be injection molded for mass production, construction repeatability, and dosing/exposure applicability. The two separate injection molded pieces are ultrasound welded together (Figure 1b); polystyrene welds are preferred as the process avoids extraneous adhesive or diverse material contaminants within the culture areas.

Culture Surface and Treatment

The device’s polystyrene surfaces have been transformed into tissue culture plastic (TCP) by corona plasma treatment. TCP adjusts surface tensions to aid in wetting of a solid by a liquid and is utilized as a surface foundation to support numerous adherent cell types for cell plateability and culture stability [23]. The dyne levels of untreated polystyrene (34 dyne/cm2) and TCP (43 dyne/cm2) were measured to quantify surface tension. EnerDyneTM pens (Enercon; Menomonee Falls, WI, USA) ranging from 30 to 66 provided a means of quantifying the contact angle, θ, which is defined geometrically as the angle formed by a liquid at the three-phase boundary where a liquid, gas, and solid interact.

2.1.3. Assembly of µChannels

The platform has two assembled components. The base unit (96-well fitted plate) has open pathways connecting each well within a row. Atop the base unit are fused row covers over each row, forming a ceiling and two sides of each micro-channel. A computer aid design (CAD) illustration of aligned culture wells shows the intersection between the row-cover, base unit, and the formed fluidic-channel which connects every adjacent well (Figure 1b). Wells in column 1 and 12, i.e., fluid source and sink, are different from well sites in columns 2–11, having discrete functionality described in Table 1.

2.2. Device Preparation for Cell Seeding (Static) and µFluidic Operation (Flow)

2.2.1. Prepare Platform for Cell Seeding Using No Flow Conditions (Static)

Humidify the system by placing it in a humidified incubator for 2 h or longer (overnight). The pre-incubation aids in plate wettability for small-area cell cultures and also diminishes fluid capillary climb along the cell-chamber sidewalls. The inhibition of capillary climb is important to retain disconnected “no-flow” culture traits. Seed the cells in 50 µL of media/well (cell density is cell type dependent). The 50 µL volume is beneath the entrenched micro-channels. Fill the wells from right to left (uphill): column 11, then 10, then 9, 8, 7, 6, 5, 4, and 3; column 2 is normally left acellular as it is in very rapid equilibrium with the source well. Allow cells to settle and attach before initiating fluidics; seed timelines are dependent on cell type.

2.2.2. Connecting Culture Wells and Initiating Fluidic Conditions (Flow)

First, remove the spent media from the cell seeding and acclimation process. Next, add 350 µL of fresh media to the sink well (well 12), 100 µL of fresh media into columns 2–11, filling the wells from right to left (Column 11, 10, 9… 2), and 400 µL of fresh media into the source well. Return the filled platform to a humidified 37 °C incubator, flow begins automatically. The same process is followed regardless of whether it is a cell line, primary cells, or different cell phenotypes seeded in separate multiwell chambers within the device.

2.3. Cell Seeding Conditions in µFluidic Device

HepaRG cells and Rat hepatocytes were cultured in the platform. Cell counts were performed using a hemocytometer and both phenotypes were seeded at 50,000 cells/well in 50 µL of media (no flow conditions); i.e., 312,500 cells/cm2. All cell cultures were maintained in a 37 °C incubator at 5% CO2. All culture material were purchased from GIBCO, Waltham, MA, USA unless otherwise stated.

2.3.1. Human HepaRG Cell Line

The µfluidic platform’s tissue culture surface was suitable for seeding and long-term culture [37,38]. Cells were grown in manufacture recommended media, Williams’ Medium E (Life Technology, Carlsbad, CA, USA) containing supplements for growth (Biopredic). HepaRGs were differentiated before procurement, not passaged, and required a 7-day acclimation/maturity period before treatment. Throughout acclimation, the medium was renewed every 3 days in no-flow static conditions. On day 3, cells reached contact inhibition. On day 8, all media were removed, then the sink well was filled with 350 µL of media, wells 2–11 filled with 100 µL of media, and the source well maximized at 500 µL (400 µL media + 100 µL of treatment compound).

2.3.2. Rat Hepatocytes Freshly Isolated

Prior to cell seeding, rat tail collagen (Sigma-Aldrich, St. Louis, MO, USA) was diluted into cold cell culture medium to 0.05 mg/mL and 30 µL (1.5 μg/well) was applied to each culture well of the device, allowed to attach for 1-h at 37 °C, and washed with rat hepatocyte culture medium containing high-glucose Dulbecco’s modified Eagle’s medium (DMEM) supplemented with 5% fetal bovine serum (FBS), 2 mM Glutamax, 100 U/mL penicillin, and 10 µg/mL streptomycin. For seeding, cells require a 24-h acclimation period before treatment. During seeding/acclimation, medium renewal is not needed during no-flow static conditions. On day 2, all media was removed, then the sink well was filled with 350 µL of media, wells 2–11 filled with 100 µL of media, and the source well maximized at 500 µL (400 µL media + 100 µL of treatment compound).

2.4. Drug Treatment during Cell Culture

In the fluidic platform, compounds were added to the source well (Figure 1a). Daily, 100 µL of media was removed from the last column (well 12), and 100 µL of fresh media containing vehicle (0.1% DMSO) or drug was added to the source well every 24 h. The compounds evaluated for cytotoxicity, in vitro, were assigned to one of 2 categories, non-DILI and DILI, using information extracted from the peer-reviewed scientific literature [39,40] and data contained in product labels. APAP, ASA, and NEF were purchased from Sigma-Aldrich (Burlington, MA, USA). Cells were washed with phosphate-buffered saline (PBS) and exposed to 0.1%DMSO (vehicle-control) medium containing the desired concentration of 1 mM APAP, 25 µM ASA, and 16 µM NEF for 7 days.

2.5. Suitability of FITC Surrogate Drug to Ascertain Compound Concentrations

The fluorescent tracer fluorescein (FITC) was used as a surrogate evaluator (i.e., fluid tracer) for the drug dissemination. FITC, dissolved in the medium at 5× desired concentration (5 × 1 µM), was loaded into the source well adjacent to the actual drug compound row, exactly the same as dosing and in the same volume and frequency as compound re-dosing (100 µL every 24 h), unless otherwise noted. Prior to each dosing/feeding, the fluorescence was measured in each well (CLARIOstar microplate reader, BMG LABTECH USA, Cary, NC, USA) at ex485/em525 including the z-height offsets from Figure 1 and Table 1, with gain optimized for 1 µM FITC. A standard curve of FITC fluorescent was used to determine the shift of FITC concentrations (0–1 µM) across the device. Replicate fluorescent signals across the device, wells 3–11 (n = 9), were averaged and plotted against known concentrations.

2.6. Quantification of APAP Drug Metabolites

Supernatants were collected after 4 h, 24 h, 48 h, and 72 h of incubation and stored at −80 °C until quantification. The addition of acetonitrile precipitated samples for drug metabolite analysis. After centrifugation, the supernatants (containing 90% acetonitrile) were analyzed by LC/MS (OpANS, Research Triangle Park, NC, USA).

2.7. Assays to Evaluate Modulations in Cell Health

2.7.1. Live and Dead Assays (Imaging)

Cells were stained with a mixture of 1 µg/mL of Hoechst stain (Sigma-Aldrich, St. Louis, MO, USA), calcein-AM (2 µM) and ethidium homodimer (EthD)-III (5 µM) purchased from (Thermo Fisher, San Diego, CA, USA), or, with a mixture of 1 µg/mL of Hoechst stain (Sigma-Aldrich, St. Louis, MO, USA) with 1:1000 CellTox Green Stock solution (Promega, Madison, WI, USA), followed by 1× exposure for real-time assay multiplexing. Fluorescently stained cells were auto-imaged with high-content imaging (Cytation 5 Reader/Imager, BioTek, Winooski, VT, USA), using objective software allocating for x, y, and z-height stair-step differences.

2.7.2. LDH Assay

LDH release was measured with a commercially available LDH assay kit (Cytotoxicity Detection Kit, Roche, supplied by Fisher Scientific, Waltman, MA, USA) requiring flow stoppage, incubation period, and generation of discrete data. Briefly, LDH, which becomes released in the cell surrounding environment, causes a reduction in NAD+ to NADH and H+ through the oxidation of lactate to pyruvate. After that, a catalyst (diaphorase) transfers H/H+ from NADH + H+ to a tetrazolium salt (iodonitrotetrazolium, INT) to form a red-colored formazan salt. The amount of color produced is then colorimetrically measured at a wavelength of 490 nm by a spectrophotometer. The colorimetric was measured at room temperature on a BMG CLARIOstar plate reader (BMG Labtech, Cary, NC, USA). LDH content was shown as fold change over vehicle controls.

2.7.3. CYP3A4 Luminescence Assay

CYP3A4 enzyme activity was determined using the P450-Glo CYP3A4 assay (V9001), which contained the substrate luciferin isopropyl acetal (luciferin-IPA) and luciferin detection reagent (Promega, Madison, WI, USA) requiring flow stoppage, incubation period, and generation of discrete data. Briefly, after exposure to compounds, cells were washed with PBS and incubated at 37 °C with luminogenic CYP substrate dissolved in medium without phenol red. After 30 min, the medium was transferred to a 96-well opaque white luminometer plate, and the same volume of luciferin detection reagent was added for 20 min. Luminescence was measured on a BMG CLARIOstar plate reader (BMG Labtech, Cary, NC, USA). CYP3A4 enzyme activity was calculated as fold change over vehicle controls.

2.7.4. Glutathione (GSH) Level

GSH activity was measured with a commercially available GSH assay kit according to the manufacturer’s instructions (Promega) requiring flow stoppage, incubation period, and generation of discrete data. Briefly, after treatment with compounds, cells were washed with PBS, and 30 µL of GSH-Glo reagent 1X with luciferin-NT substrate and glutathione S-transferase were added in each well. After 30 min, the lysed cells were transferred in a 96-well opaque white luminometer plate and added the same volume of reconstituted luciferin detection reagent for 20 min. GSH activity was measured using a luminometer. This assay is specific for GSH; other thiols do not cause interference in the assay. Cellular GSH concentration was calculated as fold change over vehicle controls.

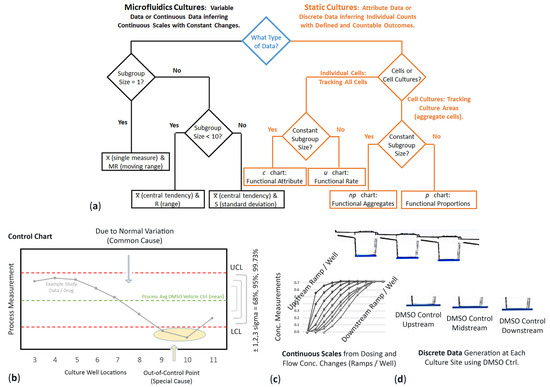

2.8. Statistical Analysis and Tactics for Lean Six Sigma Control Charts

Because different techniques are needed to evaluate the change in platform environments (drug exposure vs. cell assay), statistical relevance is presented in two formats, either continuous variable or discrete variable outcomes [41,42]. Selection is based on a logic tree diagram to indicate appropriate data charts (e.g., X and MR, u or p charts, etc.) that are aligned with lean six-sigma practices (Figure 2a). The tree diagram is adapted from traditional manufacture production lines (originally tracking production line errors) but reformatted into cell-culture features that correlate with µfluidic or static cell-culture schema. Continuous variable is defined as the infinite number of possible measured values as it is impossible to list all scenarios (e.g., variable changes in cell functions). Discrete variable is defined as data that is countable that enables a set number of possible values (e.g., number of cells). Charts are equally valuable.

Figure 2.

(a) Logic tree diagram to select statistical control charts based on data interpretation for microfluidic vs. static cultures. Data types correlate with appropriate statistical analysis. (b) X and MR control chart. Variability is described by Nelson rules and tests for special causes or unusual patterns on a production line. (c) Continuous exposure scales experienced in upstream wells, midstream wells, and downstream wells. (d) DMSO controls are different at each multiwell site along the channel.

2.8.1. Continuous Data for µFluidic Culture

Complex numbers and varying data that are measured over a specific interval (range), such as time or concentration levels. Values are simply not countable but require detailed measurements that can have separate outcomes at any given point, referring to unspecified numbers of possible measurements between two realistic points. The numbers are not always clean and tidy (e.g., curves and skews). Continuous data is about accuracy and typically involves fluctuating numbers between two presumed points. For continuous µfluidics, control charts are used to determine if cell responses are in states of statistical control (predictable) or have become unstable (i.e., variation with unusual outcome such as cell death or generated cell metabolites); Figure 2b. In this study, control charts are used to analyze cell performances across µfluidic culture wells 3–11, conceptualized as a production assembly line, each well with functional responsibility prior moving product (cell signals) to the next location. DMSO vehicle control data is used to signify process average (mean) and significance offsets ±1σ (68%), ±2σ (95%), and ±3σ (99.73%). For normal distribution rules, study data is expected within standard deviation variances [42,43]. If data falls outside of significant offsets, variations imply special or assignable causes, e.g., Nelson rules [44], such as inducible cell functions addressing injury vs. non-injury, compound weed-out, data oscillations, pre-screening before study, and operator interventions. Terminology to define cell modulation traits involving process shifts, special causes, and unusual outcomes are further described in Appendix A.1 and Appendix A.2.

2.8.2. Discrete Data

Numerical data includes whole and concrete numbers with specific fixed data values remaining constant over specific time intervals. Synonyms include disconnected, separate, and distinct. Biological replicates from three separate wells were averaged to obtain the mean and standard error of the mean for each treatment dose. To evaluate if a drug induced cellular changes, the comparisons were made between compounds and vehicle controls. Statistical analysis was performed using a two-way ANOVA test to assess the significance of responses, * p < 0.05, ** p < 0.01, *** p < 0.001, and **** p < 0.0001; ns: not significant. GraphPad Prism software (GraphPad, San Diego, CA, USA) was used to generate all graphs.

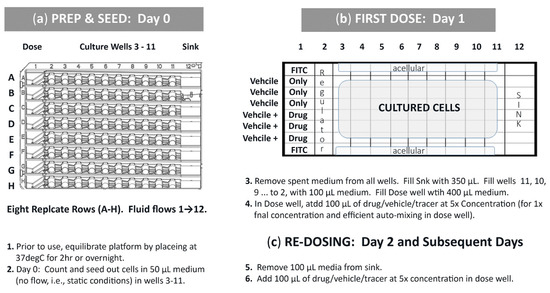

2.9. Standard Operating Procedure (SOP) for One Drug in One Fluidic Culture System

One fluidic device has 8 replicate rows (A-H), Figure 3, affording statistical relevance. For a 1-drug study being assessed using one device (Figure 3b), two rows remain acellular and are used for FITC fluid flow tracers (n = 2; A and H); three cellular rows for DMSO vehicle only control (n = 3; B, C, D) and three cellular rows for DMSO vehicle + study drug (n = 3; E, F, G). A cursory protocol is presented to delineate experiment preparation to convey cell seeding, first compound dose, and compound re-dosing (Figure 2, items 1–6). Briefly, cells are seeded in stagnant conditions and remain in no-flow status while cells acclimate. To begin flow, surplus nutrient media is added to wholly fill culture wells, automatically filling µchannels, and intrinsically connecting well-to-well fluidic pathways such that a nutrient stream is formed across culture wells 1→12. Compound dosing is initiated in well 1 (bolus input; 100 µL). The compound then auto-dilutes while flowing from well 1 and towards well 12. Well 2, being the peak inflection point between uphill nutrient flow energies (wells 1-to-2) and downhill flow forces (wells 2–12), remains acellular and operates as a fluid regulator. The first cellular well, well 3, is exposed to compound concentrations at higher/faster rates than downstream wells. The last cellular well, well 11, experiences the lowest/slowest compound concentrations with delayed exposures. If one entire row is considered as a single unit, i.e., not 12 sequentially linked culture sites, then the bulk flow rate approximates 100 µL/24 h (4.16 µL/h = 0.069 µL/min) and corresponds to hydrodynamic forces (0–1 h), transitional forces (1–3.3 h), and sustained equilibrium forces (3.3–24 h @ re-dose) [23].

Figure 3.

Standard operating procedure (SOP) for 1-drug study (n = 3). (a) Preparation and cell seeding. (b) First dose into well 1. (c) Re-dosing into well 1.

3. Results

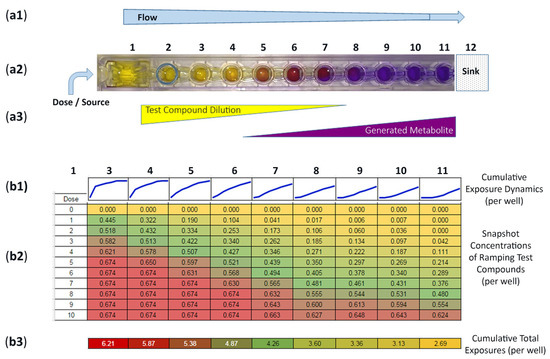

3.1. Operational Insights for Compound Dosing, Quantified Concentration Gradients, Flow Distribution Patterns, and Transforming Well-to-Well Exposures

To quantify fluid flow patterns, we surveyed a single row (1-of-8) over 10 consecutive dosing periods (Figure 4(a1,b2)). Acellular wells are well 1 (source/dose), well 2 (fluid regulator), and well 12 (sink/wick). Cell cultures being wells 3–11. For cell seeding and µchannel flow preparation, the entire row is filled with shared nutrient media (e.g., uncolored and clear). When a bolus drug is placed into well 1, the drug flows toward well 12, creating a dilution gradient of compound flow from high-to-low concentrations (Figure 4(a1–a3), compound dilutions). Then, if cell metabolites are generated in downstream culture chambers, these cell byproducts are pushed towards well 12, hypothetically creating low-to-high concentrations (Figure 4(a2,a3), generated metabolites). To track parent drug exposures and quantify real-time shifts of concentrations, FITC is used as a drug surrogate with FITC concentration gradients monitored/quantified using a microplate reader, ex485/em525 [23]. The Data Table in Figure 4(b2) shows that 1 µM FITC is dosed into the source well (well 1) on 10 chronological iterations. Dose “0” is before FITC dosing (i.e., baseline media) measuring the common and shared nutrient media that is identical across the entire row, wells 3–11, quantified “0.000”. Dose 1 shows well 3 at 0.445 (44.5% of 1 µM FITC dose), well 4 at 0.322 (32.2%), and well 11 at 0.00 (0%), signifying an initial gradient of dose-flow from wells 3–11. A 5th dose displays well 3 at 0.674 (67.4% of 1 µM FITC dose) and well 4 at 0.650 (65.0%) and well 11 at 0.214 (21.4%). A 10th dose displays well 3 at 0.674 (67.4% of 1 µM FITC dose), well 4 at 0.674 (67.4%), and well 11 at 0.624 (62.4%). The distribution of FITC increases after each dose, higher from left-to-right. Quantified data can be assessed across one entire row for wells 3–11 (Figure 4(b2); horizontal display) or within 1 culture well over time periods (Figure 4(b2); vertical display). For individual culture wells (vertical display), time-dependent exposures are portrayed as escalating linescans, i.e., flow timelines/well (Figure 4(b1)). During the 10-dose study, well 3 experiences the quickest/highest exposure (i.e., asymptotic with steepest slope), well 7 depicts an approximate linear exposure pattern, and well 11 foretells a delayed exposure dynamic (i.e., delayed increase). Subsequently, fully developed linescans progress into natural logarithm, linear, and delayed exponential growth [23]. Associatively, cumulative well exposures are depicted in Figure 4(b3). Accrued exposures are similar to a radiation exposure model with area-under-the-curve (AUC) quantifications. Well 3 has the highest AUC at 6.21, wells 7 and 8 with midrange values of 4.26 and 3.60, and well 11 being the lowest at 2.69. From this single-row study, Figure 4(b2), ninety-nine (99) datapoints are generated to establish a trending assessment of non-linear compound concentrations over time and location. From this dosing study, by way of extrapolation, one device equates to 8 rows × 99 = 792 exploitable datapoints.

Figure 4.

Operational insights. (a) Top view simulation of one microfluidic channel signifying dual exposure gradients of test compound (dosed into well 1) and cell generated metabolite. (b) Modulating experimental exposures of test compound throughout one device row having ten (10) re-doses of 100 µL over 3 days. Values 0→1 equate to 0→100% of dose. Dose “0” is culture media without compound (i.e., no-dose baseline). (b1) Linescans displaying a timeline of aggregate exposure kinetics, per well, with compound exposure traits ranging from asymptotic (wells 3, 4), approximately linear (wells 7, 8), and delayed increase (lag of exposures in wells 10, 11). Subsequently, fully developed linescans progress into natural logarithm, linear, and delayed exponential growth [23]. (b2) Well-specific, data centric, cumulative exposures over time (i.e., area under curve); similar to a radiation model. The final equilibrium drug concentration is very similar across the entire plate (dose 10; wells 3–11; 67.4→62.4%). (b3) Total “Cumulative Exposure” is very different in each well, 6.21→2.69.

3.2. Incentive for Using FITC Surrogate to Track Actual Compound Distributions across Device Wells 3–11

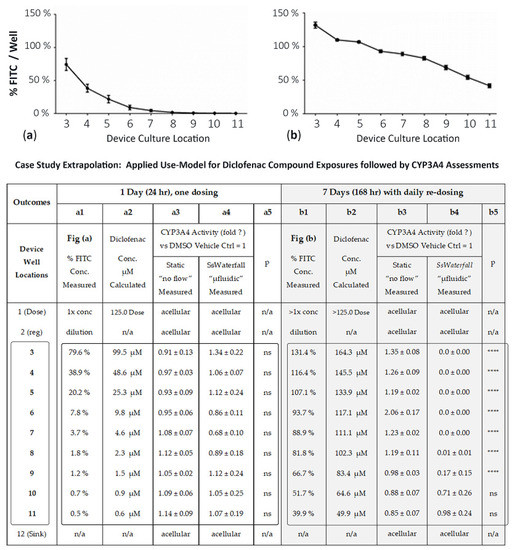

To ascertain actual study compound concentrations across the wells, i.e., spatial and time distributions, 1 μM FITC surrogate was added into a source well in a row parallel to the compound dosing row, simulating an actual compound dose of volume and frequency (drug study). The FITC relative fluorescence units (RFU) are used as a surrogate evaluator in drug dissemination. The fluorescence FITC was measured to estimate drug concentrations after 1 day following a single bolus dose in well 1 (Figure 5a) and after 7 days with daily dosing in well 1 (Figure 5b). In kinetic displays, data curves show the % FITC on the y-axis (i.e., % of 1 µM FITC signal) versus device well-sites on the x-axis. The relationship aligns time-resolved exposure gradients with % FITC surrogate, used to approximate % drug/well [23]. At 1 Day (24 h), culture well 3 approaches 79.6% of initial dose, well 5 (20.2%), well 7 (3.7%), and well 11 (0.5%). Similarly, at 7 days (168 h), well 3 approaches 131.4% of initial dose, well 5 (107.1%), well 7 (88.9%), and well 11 (39.9%). The dose values > 100% (Figure 5b) are a function of repeat dosing and residual FITC in wells that accumulate in value. These data show how the platform can be used to generate trackable and repeatable FITC gradient concentrations across the µfluidic system. In this, it is acknowledged that molecular weight differences between FITC and other drug categories will shift gradients of flowing exposure dynamics; an awareness that trending line-shifts can be calibrated for predictive accuracy [23].

Figure 5.

Percentage and quantification of FITC-flow and drug-concentrations in multiwell device. (a) FITC concentrations after 1 day, i.e., 24 h, and a single FITC bolus dose into well 1. (b) FITC concentrations after 7 days, i.e., 168 h, and daily FITC dosing into well 1. (TABLE: case study using drug diclofenac): Comparison of CYP3A4 activity after diclofenac treatment in HepaRG cells. (a1,b1) % concentrations of FITC surrogate, per well, measured. (a2,b2) µMolar concentrations of diclofenac, per well, calculated from FITC % (i.e., diclofenac dose (well 1) × FITC % (well specific). (a3,b3) CYP3A4 fold-Δ using device in “no flow” static mode. (a4,b4) CYP3A4 fold-Δ from compound dosing in device µfluidics. (a5,b5) Values are mean ± SEM, (n = 10) **** p < 0.00001.

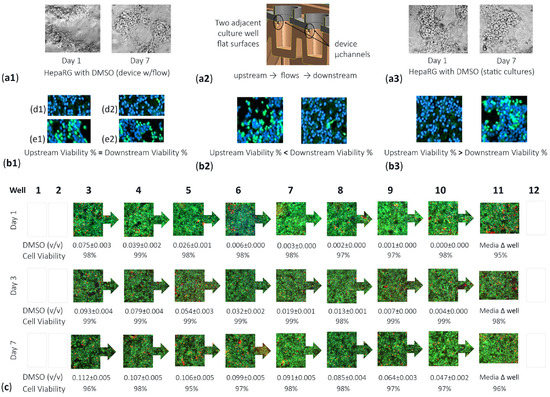

3.3. Validation of Tempered DMSO Compound as an Effective Control Vehicle Using High-Content Cell Imaging across the Sequential Assembly-Line of µFluidic Culture Sites

To investigate effects of the DMSO control vehicle on the viability of cells, HepaRGs were seeded in the µfluidic platform and exposed to the DMSO vehicle for 7 days. HepaRG morphology was evaluated for cells experiencing fluid flow and for cells in no-flow static protocols (Figure 6(a1,a3)). Cell structures were morphologically unchanged with areas of tightly/loosely packed cell densities achieving 100% culture confluency. Yet, given that upstream culture wells feed into downstream well sites, as shown in Figure 6(a2), a variance in cell viability could occur amid adjacent multiwells. Adjacent wells might show cell viability with equivalent high or low measures (Figure 6(b1,d1/d2 or e1/e2)). Adjacent wells might show upstream wells with lower cell viability (Figure 6(b2)). Adjacent wells might show upstream wells having higher cell viability (Figure 6(b3)). To investigate the DMSO control vehicle as a potential cell influencer, DMSO was deemed an actual study compound at 0.1% DMSO (i.e., 0.1 v/v) and dosed daily into device well 1, over 7 days (Figure 6c). At day 1, the DMSO v/v auto-dilutes from 0.075 (well 3) to 0.000 (well 10), with well-to-well cell viability ranges from 98% (well 3) to 97% (well 8) to 98% (well 10). At day 3, after daily re-dosing, the DMSO v/v auto-dilutes from 0.093 (well 3) to 0.004 (well 10), with cell viability scales 98–99%. At day 7, after daily re-dosing, the DMSO v/v auto-dilutes from 0.112 (well 3) to 0.047 (well 10), with cell viability scales 95–98%. As quantified, the DMSO vehicle does not influence cell culture viability across all device wells including upstream (wells 3–5), midstream (wells 6–8), or downstream (wells 9–11) culture sites. In this study, because well 11 undergoes pipette media changes, this site is considered an outlier culture well (Figure 6c well 11). In brief, the data indicates the morphological appearance of cells can be imaged with high content imaging (Cytation 5 Reader/Imager, BioTek, Winooski, VT, USA) using objective positioning software allocating for x, y, and z-height stair-step differences across the µfluidic device. Likewise, quantitative cell viability data indicate that the DMSO control vehicle can be considered a baseline-control comparison for other drug studies.

Figure 6.

Morphology and viability of HepaRG cells in device multiwell culture locations, post 0.1% DMSO vehicle compound treatment. (a2) Profile of device displaying two adjacent wells, two flat culture surfaces, and µchannels entering wells. (a1) Kinetic (fluid flow) cultures with cell images at days 1 and 7, phase contrast brightfield 10×. (a3) Comparative cell images at days 1 and 7 in static (no-flow) cultures, 10×. (b1–b3) Fluorescent image captures of cell nuclei stains (DAPI; blue) and non-viable stains (CellTox Green; green) for adjacent device wells, 4× pictorials. (b1) Equivalent high cell viability (d1,d2), or equivalent lower cell viability (e1,e2). (b2) Upstream device well displaying lower cell viability vs. downstream well. (b3) Upstream device well displaying higher cell viability vs. downstream well. (c) Fluorescent image captures of cell nuclei stains (DAPI; blue), viable cells (Calcein AM; green), and non-viable cells (Ethidium Homodimer; red) to assess variance of cell viability across device wells 3–11. (Day 1) Auto-DMSO concentration gradients after a single 0.1% DMSO bolus dose (0.1 v/v) into well 1. (Day 3) After three 0.1% DMSO re-doses into well 1; daily re-dosing. (Day 7) After seven 0.1% DMSO re-doses into well 1. Overall, cell viability remains effectively unchanged, 95–99%.

3.4. Use-Model, Drug Exposure, and CYP3A4 Comparisons between µFluidic Systems and Static Cultures

3.4.1. DMSO Vehicle as Baseline Control for Cell Functions

We evaluated two cell culture systems, both without flow, one a conventional static culture plate and the second a static protocol in the µfluidic device (i.e., non-active µchannels). In one study, we dosed 125 μM diclofenac compound (+0.1% DMSO) on HepaRGs to evaluate CYP3A4 activity; comparatively, CYP3A4 activities were determined equivalent (data not shown). In a second study, in SsWaterfall, we dosed HepaRGs with DMSO at 24 h, 72 h, and 168 h to evaluate adjacent-well changes related to cell death, CYP3A4, and albumin; in all studies, DMSO-treated cells retained non-significant changes [23]. In subsequent cell function studies, DMSO vehicle treatments were considered as baseline control values.

3.4.2. Extrapolation of Drug Exposures in µFluidic System, Diclofenac (Days 1 and 7)

Day 1: We compared CYP3A4 activities after HepaRG cells were exposed to different concentrations of diclofenac for 24 h (Figure 5 Case Study; a1–a5). The measured FITC concentration per well, column a1, is the % of FITC dispersed across the multiwell system and correlates with Figure 5a. The calculated μM diclofenac concentration, column a2, is column a1 × 125 μM dose (i.e., well 3 is 79.6% × 125 μM = 99.5 μM diclofenac). The actual μM diclofenac drug concentration, not determined, is line-shifted as FITC (389.3 g/mol) and diclofenac (296.1 g/mol) have different molecular weights, but trending flow patterns remain analogous [23]. Column a3 illustrates CYP3A4 outcomes from static culture protocols (no flow) using equivalent drug exposure concentrations. Column a4 shows CYP3A4 outcomes with cultures experiencing kinetic nutrient movements (µfluidic device). At 24 h, we did not observe any significant difference in CYP3A4 activity between the static and µfluidic systems (column a5, statistical “p”, ns).

Day 7: We then compared the effect of different concentrations of diclofenac on CYP3A4 activity after 7 days of exposure (Figure 5 case study; b1–b5), with daily drug re-dosing. Notably, the well-1 dose % (column b1) is listed as >1× concentration and is a function of repeat dosing with rising concentrations above the initial/starting well-1 dilutions to correlate with Figure 5b. Paraphrased, residual compound in well 1 with repeat dosing accumulates values. The % FITC concentrations are increased across all wells ranging from upstream 131.4% (well 3) to downstream 39.9% (well 11), column b1. The calculated diclofenac μM drug concentration, column b2, is column b1 × 125 μM dose (i.e., well 3 is 131.4% × 125 μM = 164.3 μM diclofenac). CYP3A4 activity in HepaRG cells was decreased in the µfluidic device wells 3–9 (column b4) as compared with the static culture (column b3), indicating a significant difference noted in column b5, statistical “p”. These data infer that flow in upstream well (well 3), or cascading flows across µfluidic wells 4–11, create cell-signaling concentration gradients of either dose–compound or endogenous cellular byproducts that factor into cell variances of culture responses.

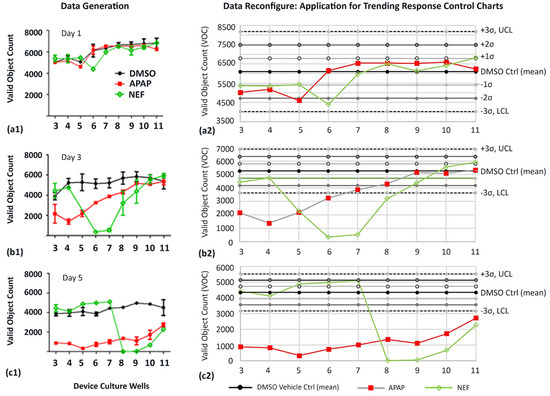

3.5. Trending Effects on Cell Toxicity from DMSO Vehicle Control, APAP, NEF, and Indirect Cell Byproducts in µFluidic Device (Dual Toxicity Trends for Compoud Screening)

High-content cell imaging was used to evaluate valid object counts (VOC: i.e., cell counts) across µfluidic platform locations, referencing device culture wells 3–11, monitoring HepaRGs at days 1, 3, and 5 (Figure 7). The four exposure compounds being DMSO vehicle control, APAP (+DMSO), NEF (+DMSO), and potential indirect exposures coming from inducible cell-generated byproducts.

Figure 7.

High content imaging to evaluate the variance of cell counts to indicate direct-compound or indirect-cell-byproduct toxicity locations; nuclei count (DAPI). Initially, HepaRGs were cultured for 7 days in static conditions prior to activating flow and dosing 1× daily (well 1). (a1,a2) After 1 day and a single bolus dose in well 1. The DMSO control is baseline culture while APAP and NEF are study compounds. (b1,b2) After 3 days and three bolus doses into well 1. (c1,c2) After 5 days and five bolus doses into well 1. Data are expressed as means ± SEM (n = 9). Applied statistics (a2,b2,c2) using six-sigma control charts with DMSO vehicle control signifying process average (mean) and ±1σ (68%), ±2σ (95%), and ±3σ (99.73%) significance offsets. If data fall outside of significant offsets, UCL or LCL, variations in the data imply special or assignable causes, (b2,c2).

3.5.1. Data Generation

Day 1 signifies one day of culture after a single drug dose (Figure 7(a1)). Days 3 and 5 after three and five doses (Figure 7(b1,c1)). ●At Day 1, the DMSO vehicle shows baseline VOCs (cell counts) range between 5000–6300; Figure 7(a1). Similarly, VOCs are quantified for APAP (4400–6300) and NEF (4300–6500). ●At Day 3, the DMSO control has cell counts between 4000–5800; Figure 7(b1). APAP shows fewer cell numbers in upstream wells 3–5 (1200–2100), increasing cell numbers in midstream wells 6–8 (3100–4000), and equivalent DMSO control cell numbers in downstream wells 9–11 (5000–5100). NEF has DMSO equivalent numbers in upstream wells 3–4 (4400–4700), a rapid count decline in midstream wells 5, 6, and 7 (400–2000) with increasing cells numbers in downstream wells 8–11 (3100–5800). ●At Day 5, the DMSO control has sustained cell counts between 3900–4100; Figure 7(c1). APAP displays much lower cell numbers across the entire channel, wells 3–11 (300–2900). NEF has DMSO equivalent numbers in upstream wells 3–7 (4100–5000) and a rapid count decline in midstream wells 8–9 (0–100), with slightly increased cells numbers in downstream wells 10–11 (800–2100).

3.5.2. CV Values for VOC and Fluid-Flow Tracing across the Multiwell Channels

To illustrate intra-plate robustness of the system, coefficient of variation is used to provide a method of performance as overviewed in Table 2.

Table 2.

Coefficient of Variation for Intra-Plate Robustness.

3.5.3. Data Reconfigure for Trending Applications Using X Control Charts Aligned with Statistical Process Control

To expand data relevance, DMSO controls from Figure 7(a1,b1,c2) are reconfigured into lean six-sigma control charts to emphasize data-set process averages (mean) and standard deviation parameters ±1σ (68%), ±2σ (95%), ±3σ (99.73%); Figure 7(a2,b2,c2) and Table 3. Statistical boundaries for the upper control limit (UCL) and the lower control limit (LCL) are defined at DMSO ± 3σ. If study data fall outside UCL or LCL, the variation implies an observable change or unexpected nonstandard outcome (e.g., cell modulation, cell death, or generated metabolite).

Table 3.

Trending VOC outcomes from direct parent compound and indirect cell byproducts.

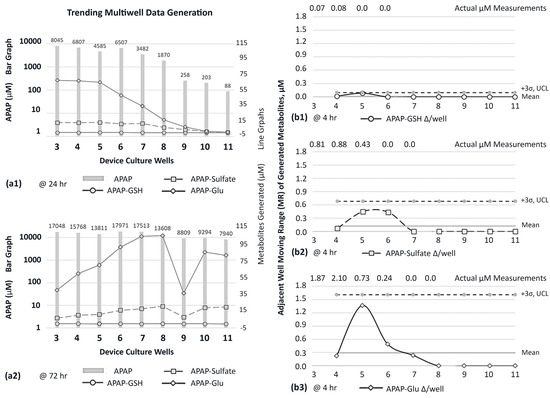

3.6. Metabolite Generation and Dissemination in Multiwell µFluidic Culture System

3.6.1. Targeting APAP Metabolites

Due to the extensive literature history on APAP metabolites [45,46,47], APAP was targeted onto HepaRG culture wells to evaluate metabolite generation across the µfluidic channel, i.e., occurrence trends. APAP was dispensed as a bolus dose (20 mM) into well 1, once daily, and downstream media were collected from each site to measure mutable concentrations of acetaminophen and generated APAP metabolites (Figure 8). LC/MS was used to quantify concentration intensities over a timeline 0→72 h. ▪At 24 h (Figure 8(a1)), gradient concentrations of APAP range from 8.045→0.088 mM (y-axis logarithmic scale) across the µfluidic wells 3–11 (x-axis). The metabolite APAP-glutathione (GSH) displays the lowest magnitude values, ranging 0.23→0.0 µM (y-axis line graph) across the same µfluidic wells 3–11 (x-axis). Metabolite APAP-sulfate has elevated magnitude values ranging 13.26→0.36 µM, while revealing activity in the last culture site, well 11. Metabolite APAP-glucuronide (APAP-Glu) has the highest magnitude values, ranging 67.7→0.8 µM, while displaying a prominent decay curve in downstream wells 6–11. ▪At 72 h (Figure 8(a2)), gradient concentrations of APAP range from 17.048→7.94 mM. The metabolite APAP-GSH retains comparable 24 h displays ranging 0.21→0.0 µM. Both APAP-Sulfate 6.98→20.7 µM and APAP-Glu 39.9→103.3 µM exhibit increased levels across downstream wells 4–11, an indication of ongoing generation of metabolites. Contrastingly, well 1 reveals lower magnitudes (~0.5-fold) with the recognition that well 1 encounters highest APAP exposures. Of note, for trending appraisals, data in well 9 show a reduction in concentrations for APAP-sulfate and APAP-Glu, being possible data outliers or potential special cell-function outcomes.

Figure 8.

Trending channel evaluations for n = 1. (a1,a2) Concentration of APAP and cell-generated metabolites in each multiwell location, post compound dosing in the source well. x-axis is device culture wells 3–11, left vertical axis is APAP (logarithmic scale), right vertical axis is generated metabolites. (a1) After 1 day, i.e., 24 h, and a single bolus dose in well 1. (a2) After 3 days, i.e., 72 h, and daily dosing in well 1. (b1–b3) Origination of APAP metabolites across device multiwell locations 4–11, observed at 4 h after one APAP bolus dose into well 1. MR is the concentration change (∆) between adjacent wells. Well 3 is devoid of an upstream adjoining well (i.e., cellular) and precludes calculation. The APAP metabolite variances (∆/well) are (b1) APAP-GSH, (b2) APAP-sulfate, and (b3) APAP-Glu.

3.6.2. Distribution of APAP Metabolites

Given that APAP metabolites are generated in the device (Figure 8(a1,a2); line graphs), the distribution of each metabolite’s timeline, location, and shifting concentrations becomes significant exposure descriptors across µfluidic culture wells. To chronicle distribution patterns, moving-range (MR) control charts from six-sigma variability processes [41,42,48] are revamped to examine the change in biologic activity amid adjacent culture wells (Figure 8(b1–b3)). The early detection of metabolites, using LCMS, is observed 4 h after a single APAP dose into well 1, measuring for APAP-GSH (Figure 8(b1)), APAP-sulfate (Figure 8(b2)), and APAP-Glu (Figure 8(b3)). Graphically, the horizontal axis is device wells 3–11; the vertical axis is concentration ∆ amid adjoining wells; the mean is the average of aggregate data points; UCL is the upper control limit calculated as 3σ. The MR activity for APAP-GSH is revealed in upstream culture wells 4 and 5, having well–well concentration ∆’s of 0.02 µM and 0.08 µM; thereafter, downstream wells 6–11 register “0” fluctuations. The MR for APAP-sulfate is displayed in upstream culture wells 4–6, with well–well ∆’s being 0.07 µM, 0.45 µM, and 0.43 µM; thereafter, downstream wells 7–11 register “0” fluctuations. The MR for APAP-Glu is displayed in upstream culture wells 4–7 with well–well ∆’s being 0.23 µM, 1.37 µM, 0.49 µM, and 0.24 µM; thereafter, downstream wells 8–11 register “0” fluctuations.

3.7. Metabolite Variance across Multiwell Fluidic System to Ascertain Sites of Generated Cell Byproducts

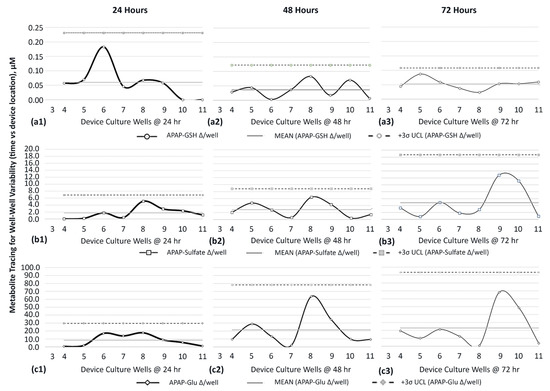

The detailed surveillance in metabolite variance, on HepaRG cells experiencing APAP exposures after 24, 48, and 72 h timelines, are presented using MR control charts to chronicle distribution patterns across device wells 3–11, Figure 9. Moving ranges are itemized by APAP-GSH-24/48/72 h (Figure 9(a1–a3)), APAP-Sulfate-24/48/72 h (Figure 9(b1–b3)), and APAP-Glu-24/48/72 h (Figure 9(c1–c3)). Graphically, accompanying descriptors include the data aggregate mean (mean) and UCL (3σ). By way of itemization, Table 4 is portioned to compare/contrast metabolite generation and dissemination. The APAP-metabolite data indicate the platform is able to allot for evaluations of cell-generated metabolites as cellular byproducts disperse across the device in compound-exposure patterns and time-distribution dynamics, allowing for trending evaluations in cell metabolite kinetics, i.e., a statistical process survey.

Figure 9.

Surveillance of metabolite variability amid device multiwell locations 4–11 (n = 1), observed at 24 h, 48 h, and 72 h. MR is the concentration moving range (∆) between adjacent wells. Well 3 is devoid of an upstream adjoining well and precludes MR calculation. Metabolites are (a1–a3) APAP-GSH. (b1–b3) APAP-sulfate. (c1–c3) APAP-Glu.

Table 4.

Summary of APAP-Metabolite variance from HepaRGs—generation and dissemination.

3.8. Cell Function Variance across Multiwell Fluidic System to Assess Bio-Activity Trends Affiliated with Direct Drug Exposure and Predictive Recognition for Indirect Cell-Byproduct Stimuli (Dual Assessment Screens)

Conventional cell function assays LDH, CYP3A4, and GSH are re-purposed as µfluidic device biomarkers and utilized as cell function indicators (sensors) across the platform’s changing well–well environments, i.e., monitoring worksites across an assembly line. Assays are used to track mutable cell-health kinetics, throughout µchannel wells 3–11, corresponding to real-time ramps in drug concentrations, accruing exposure times, and for gaging the incidence of cell-generated byproducts. To initiate surveys, an exposure compound is dosed into the upstream source well 1, daily for 7 days. Compounds in this study are DMSO control vehicle (0.1%), ASA (25 µM; non-DILI drug), and NEF (16 µM; DILI drug). With flow, compounds auto-disperse along the µchannel, catalyzing adaptive bioactivity amid aligned device culture site locations, i.e., wells 3–11. To reveal if gradients of drug, time, or cellular byproducts have influence on cell functions, we assessed both system-trends and adjacent-well responses, i.e., six sigma control charts, from two hepatic sources: human HepaRG cells and rat hepatocytes.

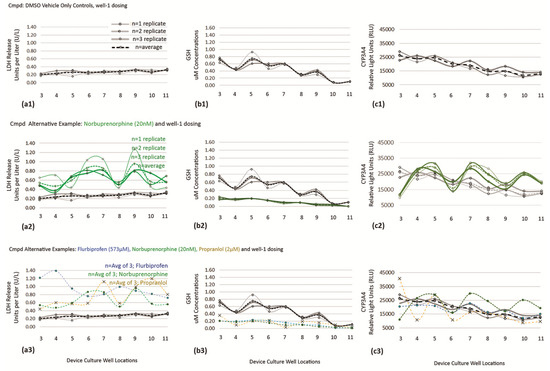

3.8.1. Trending Relevance

Study outcomes of discrete, continuous, and trending models are displayed in Figure 10, Figure 11 and Figure 12; LDH (Figure 10), CYP3A4 (Figure 11), and GSH (Figure 12). In figures, vertical columns are categorized (a1–a3) HepaRGs exposed to ASA, (b1–b3) rat hepatocytes exposed to ASA, (c1–c3) HepaRGs exposed to NEF, and (d1–d3) rat hepatocytes exposed to NEF. Within figures, horizontal rows are demarcated by a1→d1, a2→d2, and a3→d3 as defined in Table 5. From the same SOP, trending effects of DMSO vehicle, additional exposure compounds, and additional assays are corroborated in Appendix B with Figure A1 and in the supplemental section as illustrated in supplemental Figure S1.

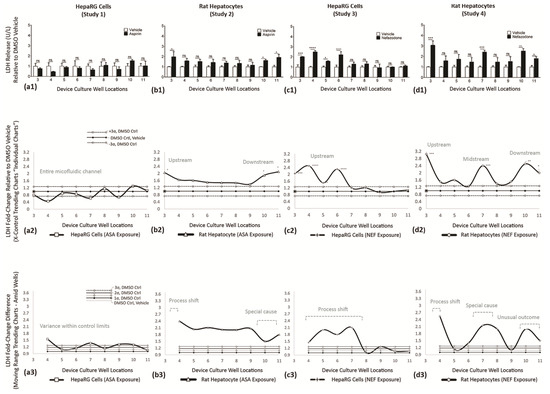

Figure 10.

LDH release across multiwell cultures on Day 7. LDH activity shown as fold change (vertical axis) vs. DMSO vehicle controls; vehicle normalized at 1. (a1,b1) Effect of aspirin exposure in HepaRG cells and rat hepatocytes. (c1,d1) Effect of NEF exposure in HepaRG cells and rat hepatocytes. (a2,b2,c2,d2) Re-expression of data using individual trending charts (i.e., X control charts) to convey DMSO controls with drug study outcomes. (a2—HepaRG line graph) ASA does not induce LDH. (b2—rat hepatocyte line graph) ASA stimulates LDH across all wells, 3–11, with increased relevance at upstream well 3 (*) and downstream wells 10 (*) and 11 (*). (c2—HepaRG line graph) NEF stimulates LDH at upstream wells 3 (***), 4 (****), 5 (*), and 6 (****). (d2—rat hepatocyte line graph) NEF stimulates LDH across all device wells, with increased relevance at upstream well 3 (***), midstream well 7 (***), downstream wells 10 (**) and 11 (*). (a3,b3,c3,d3) Variability charts (i.e., MR control charts) to display functional fold-changes amid adjacent wells. (a3—HepaRG line graph) ASA does not induce a trending variation. (b3—rat hepatocyte line graph) ASA stimulates a process shift at upstream well 3 and special cause in downstream wells 10 and 11. (c3—HepaRG line graph) NEF induces a trending process shift at upstream wells 4–7. (d3—rat hepatocyte line graph) NEF stimulates a process shift at upstream well 3, a special cause at wells 7–8, and an unusual outcome in downstream wells 10 and 11. Values a1-d1 represented as the mean ± SEM (n = 9). * p < 0.05, ** p < 0.01, *** p < 0.001, and **** p < 0.0001.

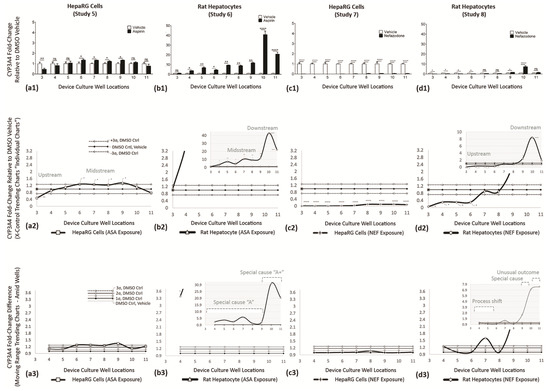

Figure 11.

CYP3A4 enzyme activities across multiwell culture locations at Day 7. Activity shown as fold changes (vertical axis) vs. DMSO vehicle control; vehicle normalized at 1. (a1,b1) Effect of ASA exposure in HepaRG cells and rat hepatocytes. (c1,d1) Effect of NEF exposure in HepaRG cells and rat hepatocytes. (a2,b2,c2,d2) Re-expression of data using individual trending charts (i.e., X control charts) to convey DMSO controls with drug study outcomes. (a2—HepaRG line graph) ASA impedes CYP3A4 at upstream wells 3 (**) then shows upregulated stimulation in midstream wells 6 (*), 7 (*), 8 (*), and 9 (*). (b2—rat hepatocyte line graph) ASA has no effect on upstream well 3, then stimulates CYP3A4 across all remaining downstream wells 4 (*)–9 (*) and 10 (****)–11 (****). (c2—HepaRG line graph) NEF inhibits CYP3A4 activity across the entire µfluidic channel, inclusive of wells 3–11. (d2—rat hepatocyte line graph) NEF inhibits CYP3A4 activity in upstream wells 3–6 (*), regains normal function in wells 7–8, has functional increases in wells 9 (*) and 10 (****), and returns to near normal activity in downstream well 11. (a3,b3,c3,d3) Variability charts (i.e., MR control charts) to display functional fold changes amid adjacent-wells. (a3—HepaRG line graph) ASA induces a trending process shift of upstream inhibition (well 3) followed by midstream recovery (wells 6–9). (b3—rat hepatocyte line graph) ASA is inconsequential at upstream well 3, stimulates a special cause “A” in wells 4–9, then an upregulation special cause (A+) in downstream wells 10 and 11. (c3—HepaRG line graph) NEF induces a negative trending process shift across the entire µchannel. (d3—rat hepatocyte line graph) NEF creates a negative process shift, wells 3–6, normal functions wells 7–8, special cause wells 9–10, and unusual decline outcome in well 11. Values a1-d1 are represented as the mean ± SEM (n = 9). * p < 0.05, ** p < 0.01, and **** p < 0.0001.

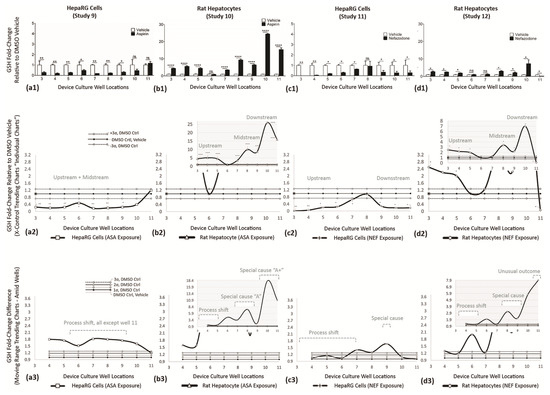

Figure 12.

GSH levels across multiwell culture locations at Day 7. GSH synthesis shown as fold changes (vertical axis) vs. DMSO vehicle control; vehicle normalized at 1. (a1,b1) Effect of aspirin exposure in HepaRG cells and rat hepatocytes. (c1,d1) Effect of nefazodone exposure in HepaRG cells and rat hepatocytes. (a2,b2,c2,d2) Re-expression of data using individual trending charts (i.e., X control charts) to convey DMSO controls with drug study outcomes. (a2—HepaRG line graph) ASA inhibits GSH activity across wells 3 (**)–9 (*). (b2—rat hepatocyte line graph) ASA promotes GSH synthesis in upstream wells 3 (****)–5 (****), displays normal function in well 6, then stimulates GSH functions in wells 7 (****)–11 (****). (c2—HepaRG line graph) NEF inhibits GSH activity across wells 3 (*)–7 (*) and wells 9 (*)–11 (*). (d2—rat hepatocyte line graph) NEF promotes GSH synthesis in upstream wells 3 (*)–5 (*), displays normal function in wells 6–7, again stimulates GSH functions in wells 7 (*)–10 (*). (a3,b3,c3,d3). Variability charts (i.e., MR control charts) to display functional fold changes amid adjacent wells. (a3—HepaRG line graph) ASA induces a trending process shift across most of the µchannel, wells 3–10. (b3—rat Hepatocyte Line Graph) ASA stimulates a process shift in wells 3–5, has normal function at well 6, stimulates a special cause “A” in wells 7–9, then enhanced special cause “A+” in wells 10–11. (c3—HepaRG line graph) NEF induces a trending process shift in wells 3–7, normal function at well 8, then a negative special cause in wells 9–11. (d3—rat hepatocyte line graph) NEF stimulates a process shift in wells 3–5, has normal function in wells 6–7, stimulates a special cause in wells 8–10, then unusual outcome in well 11. Values (a1–d1) are represented as the mean ± SEM (n = 9). * p < 0.05, ** p < 0.01, and **** p < 0.0001.

LDH ASSAY—Functional Indicator (Studies 1–4)

LDH is found in cells. LDH discharge is used as a biomarker of cell cytotoxicity as release can increase mitochondrial damage [19]. ASA exposure on HepaRG cells (Study 1) is displayed in Figure 10(a1). LDH outcomes, for DMSO vs. ASA, are non-significant (ns) as revealed in wells 3–11. ASA exposure on rat hepatocytes (Study 2) is displayed in Figure 10(b1). ASA induces LDH release in upstream well 3 (*) and downstream wells 10 (*) and 11 (*). NEF exposure on HepaRG cells (Study 3) is displayed in Figure 10(c1). NEF stimulates LDH in upstream wells 3 (***), 4 (****), 5 (*), and 6 (****); thereafter, wells 7–11 register as non-significant cell function activities. NEF exposure on rat hepatocytes (Study 4) is displayed in Figure 10(d1). NEF stimulates LDH in upstream well 3 (***), midstream well 7 (***), and downstream wells 10 (**) and 11 (*). Interior wells 4–6 and 8–9 register as non-significant. For Studies 1–4, LDH trending responses are further summarized in Table 6.

Table 6.

Summary of LDH indicator responses.

CYP3A4 ASSAY—Functional Indicator (Studies 5–8)

Cytochrome P450 3A4 activity is found in the liver and has a significant role in the biotransformation of compounds [49]. ASA exposure on HepaRG cells (Study 5) is displayed in Figure 11(a1). ASA impedes CYP3A4 activity in well 3 (**) with slightly upregulated activities in wells 6 (*), 7 (*), 8 (*), and 9 (*); remaining wells 4, 5, 10, and 11 register as non-significant. ASA exposure in rat hepatocytes (Study 6) is displayed in Figure 11(b1). In data presentation, the scale of the vertical axis increased 10-fold to accommodate for intensified CYP3A4 outputs, i.e., range 0–5 adjusted to 0–50. ASA exposure is non-significant in well 3, CYP3A4 upregulates in wells 4 (*)–9 (**) to denote 3-to-10-fold increases over DMSO controls, then maximized in wells 10 (****) and 11 (****) at 40-fold and 20-fold levels. NEF exposure in HepaRG cells (Study 7) is displayed in Figure 11(c1). NEF exposure shows no CYP3A4 activity in wells 3–6 and marginal 0.1-fold functions in wells 7–11. Throughout, DMSO vehicle controls have higher CYP3A4 over NEF datasets, wells 3 (****)–11 (****). NEF exposure in rat hepatocytes (Study 8) is displayed in Figure 11(d1). In data generation, the scale of the vertical axis is increased 10-fold to accommodate intensified CYP3A4 outputs, i.e., range 0–5 adjusted 0–50. The NEF datasets show impeded CYP3A4, below DMSO vehicle controls in wells 3 (*)–6 (*), data being non-significant in wells 7–8, then NEF has higher CYP3A4 activity in wells 9 (*)–10 (****), concluding with non-significant cell reactions in well 11. For Studies 5–8, CYP3A4 trending responses are further summarized in Table 7.

Table 7.

Summary of CYP3A4 indicator responses.

GLUTATHIONE (GSH) ASSAY—Functional Indicator (Studies 9–12)

Glutathione (GSH), a tripeptide present in most tissues, is highly concentrated in the liver [50]. GSH protects against oxidative stress and regulates important events such as growth and apoptosis. ASA exposure in HepaRG cells (Study 9) is displayed in Figure 12(a1). ASA impedes GSH activity in wells 3 (**), 4 (**), 5 (**), 6 (*), 7 (**), 8 (**), and 9 (*); wells 10–11 register as non-significant. ASA exposure in rat hepatocytes (Study 10) is displayed in Figure 12(b1). The scale of the vertical axis is increased 6-fold to accommodate for intensified GSH outputs, i.e., range 0–5 adjusted 0–30. ASA stimulates GSH response in wells 3 (****)–5 (****) with activity approaching 5.8-fold, then non-significant at well 6, then inducible again in wells 7 (****)–11(****) with activity 26.5-fold above DMSO controls. NEF exposure in HepaRG cells (Study 11) is displayed in Figure 12(c1). NEF impedes GSH activity in wells 3 (**), 4 (**), 5 (*), 6 (*), and 7 (*) having 0 to 0.25-fold ranges, is non-significant in well 8, then impedes activity in wells 9 (*), 10 (*), and 11 (*), having 0.2 to 0.3-fold ranges. NEF exposure in rat hepatocytes (Study 12) is displayed in Figure 12(d1). The scale of the vertical axis is increased 6-fold to accommodate for intensified GSH outputs, i.e., range 0–5 adjusted 0–30. NEF stimulates GSH activity in wells 3 (*), 4 (*), 5 and (*), is non-significant in wells 6–7, induces again in wells 8 (*), 9 (*), and 10 (*), then falls below DMSO control in well 11 (*). For Studies 9–12, GSH trending responses are summarized in Table 8.

Table 8.

Summary of GSH indicator responses.

3.8.2. Vetting Trends in Cell Modulation by Drug or Cell Byproduct Stimuli (Studies 1–12)

LDH, CYP3A4, and GSH cell indicator data are coalesced to ascertain if exposure compound or endogenous cell byproducts induce cell function variance across device worksites (Table 9). In Table 9, the twelve aforementioned studies are itemized with odd study numbers being HepaRGs (1, 3, 5, 7, 9, and 11) and even study numbers featuring rat hepatocytes (2, 4, 6, 8, 10, and 12). The table’s vertical columns are cataloged into cell phenotype, exposure drug, cell function, and device culture well sites for upstream (wells 3–5), midstream (wells 6–8), and downstream (wells 9–11) workspaces. Subcategorized are statistical classifications using six-sigma nomenclature, for cell function activities, to indicate a process shift (direct drug influence; light grey backdrop), w/i normal limits (not significant; white backdrop), and special cause or unusual outcome (cell byproduct/metabolite influence; dark grey backdrop). As demarcated, all HepaRG studies initiate with a process shift, i.e., direct drug influence, except Study 1. Study 1 is the LDH response from aspirin exposure (HepaRG/ASA/LDH; Figure 10(a1–a3)) displaying no significant change when compared against the baseline DMSO control (i.e., w/i normal limits). Comparatively, distinct studies show cell functions remain under direct drug influence (HepaRG/NEF/CYP3A4; Figure 11(d1–d3)) while other studies rebound to achieve normal cell functions aligned with baseline DMSO controls (HepaRG/ASA/GSH; Figure 12(a1–a3)). Probingly, Study 5 (HepaRG/ASA/CYP3A4; Figure 11(a1–a3)) and Study 11 (HepaRG/NEF/GSH; Figure 12(c1–c3)) allude to midstream normal functions, i.e., w/i control limits, with reduced downstream cell activities to indicate marginal levels of special cause effects (i.e., cell byproducts). In comparison, assessing rat hepatocytes, all studies initiate with a process shift, i.e., direct drug influence, except Study 6. Study 6 is the CYP3A4 response from aspirin exposure that remains within DMSO baseline controls (rat Hep/ASA/CYP3A4; Figure 11(b1–b3)). For other companion studies (Table 9; Studies 2, 4, 8, 10, 12), cell activities rebound into normal cell function levels, i.e., w/i control limits. Thereafter, all downstream cell functions modulate again to indicate a special cause (i.e., cell byproduct) or unusual or tertiary outcome (i.e., 2nd cell byproduct), inclusive of LDH, CYP3A4, and GSH compound appraisals. Studies having both special and tertiary variances are Study 4 (Rat Hep/LDH/NEF; Figure 10(d1–d3)) and Study 12 (rat Hep/GSH/NEF; Figure 12(d1–d3)). By proportion, HepaRG studies experience 33.3% special cause outcomes, albeit displaying minimal effects, while rat hepatocyte studies experienced 100% special cause outcomes and reveal significantly high magnitude differences for CYP3A4 (Figure 11b,d) and GSH (Figure 12b,d), 7.9-fold to 40-fold, respectively. The high-magnitude responses inferring rat hepatocytes have elevated sensitivity outputs related to cell indicator functions. In brief, the variance of cell functions across device culture wells can reveal if an exposure compound has no influence (i.e., w/i normal limits), has direct drug influence (i.e., process shift), or has indirect drug influence (i.e., special cause from cell byproducts/metabolites). In this manner, when variance trends are detected (i.e., special cause or tertiary), follow-up studies using LC/MS (discovery mode) could be resourcefully applied, via compound targeting, so previously unspecified cell byproducts are identified into metabolite inducers. That is, efficiently, logically, and resourcefully finding the unknowns.

4. Discussion

4.1. Drug Development Is a Very Long and Expensive Process

A pharmaceutical compound can take 10–15 years to progress through the development process before FDA clearance. Depending on the type of drug being developed, the total cost per compound can run USD 1.8B–5.0B [51,52,53,54]. The process is plagued by late-stage clinical failures, which could be circumvented to some degree by implementing innovative tissue engineering in vitro testing earlier in the development pipeline. A goal being “fail fast” in early research stages to avoid expended time, squandered resources, and depleted finances. Many companies attempt to improve efficiency in drug development by employing a battery of front-end in vitro assays, these being efforts to distinguish lead compounds for toxicity and efficacy. Still, the evolution of predictive science continues to result in false-negative (missing potentially unsafe compounds) and false-positive (falsely identifying potentially efficacious compounds as toxic) outcomes. Similarly, the use of in vivo animal models has become more questionable as they often fail to identify safety liabilities that ultimately arise in human trials. One in vivo study, comparing drug toxicities between human and animals, indicated that only 43% of animal models can predict human toxicity [55]. Correspondingly, many political and societal pressures are driving the effort to reduce or eliminate the use of animal studies in toxicological research [56,57]. Overall, a critical unmet need persists for innovative in vitro physiologically tools that can improve predictive potentials for evaluation of new drug candidates.

4.2. Natural 3D Organs with Instrinsic Fluid Flows

Native organ systems, human or animal, innately have in vivo fluid movements from velocity and diffusion, i.e., dispersion, together being flow vigors to help facilitate exposures of compounds, nutrients, and metabolites [58]. In contradiction, in vitro drug research historically employs static cultures for evaluating compounds [59]. These no-flow schemes are absent of delivery velocity, are limited in transport diffusion, and lack dynamic exposure conditions intrinsic to 3D natural organ systems. As such, traditional “no-flow” classifications are disadvantaged in schemes to predict efficacy and toxicity of compounds, are inefficient in monitoring gradient ramps of drug concentrations (e.g., nonlinearity and redosing), and are perceived incomplete for evaluating cell byproducts for metabolite interfacing. Accordingly, contemporary tissue engineering processes are impelled to provide in vitro, multifarious, and complex models having rapid, accurate, and focused predictions for compound evaluations [60,61,62].

4.2.1. µFluidic Contemporary Technologies for In Vitro Cell Simulations

Already, rival µfluidic culture systems provide use-model benefits having dissimilar microenvironments with discrete applications and distinct advantages [63,64]. For evolving technologies, Kirkstall’s Quasi Vivo allows Lego-like building systems. Hurel’s Hurelflow allows co-cultures and reactive metabolites. BellBrook’s IUVO allows cell invasion analysis. BioIVT’s HepatoPac allows cell-patterned modules. Various commercial systems having fit-for-purpose functions include Millipore’s CellAsic with flow gradients, CNBio having transwells and basal flow, Emulate with microchannel scaffolds, TissUse with systemic organics, Mimetas with vascular Phaseguides, and inSphero with 3D hepatic co-cultures. A synopsis of simulations includes drug screening, cell signaling, proliferation, and differentiation, as overviewed in Table 10.

Table 10.

µFluidic contemporary technologies with fit-for-purpose application.

4.2.2. Unmasking the Cell-Byproduct Mechanism Using 1-Way In Vitro µFluidics

Static systems have limits in identifying drug toxicity due to a lack of separation between parent-compound and cell-metabolite, i.e., masking cell-byproduct mechanisms. Depending upon the rate of metabolism, toxicity may be missed in a static system or a drug’s safety may be grossly overestimated. In static systems, slowly metabolized compounds appear to be much safer because the standard protocol involves complete media changeover every 24–48 h. Total media changes remove all cell byproducts from the static system and replenish the parent compound; thus, creating a need to dose at exceedingly high parent compound concentrations to accumulate enough metabolites to detect any toxicity—a limitation of short incubation times provided in static techniques.

Recirculating µfluidic systems have limits in identifying metabolite toxicity as cell secretions are blended into the common nutrient media and this mixture is repeatedly transmitted back onto the same culture spaces, i.e., masking individual cell-byproduct mechanisms.

Unidirectional µfluidic systems, i.e., 1-way flows, are able to preserve cell byproducts to allow for enhanced detection of metabolite-mediated toxicity of slowly metabolized compounds as conserved cell secretions are used to evaluate de-risking of toxicity profiles by way of concurrent mechanistic evaluations of both ascending primary compound (i.e., drug) and perpetually generating secondary metabolite exposures (i.e., cell byproducts).

4.2.3. Trending Variations to Observe Different Types of Cell Toxicity

The SsWaterfall platform is a screening tool with the potential to evaluate wide-ranging compound exposures and concurrently observe indirect cell byproduct influencing amid stable, upregulated, or downregulated cell functions. The outcomes are non-specific by design, such that all-inclusive datasets are utilized as additional information categories (i.e., cell responses previously unviable) to be co-analyzed with traditional culture techniques. From an analogous viewpoint, nuclear magnetic resonance (NMR) metabolite snapshots are all-inclusive, non-specific, and powerful datasets that provide generalized bulk information (e.g., inclusive cell byproducts), whereas liquid chromotography mass spectrometry (LCMS) is specific to one deliverable such as one evaluated metabolite. In this NMR–LCMS scenario, NMR can be utilized to evaluate all-inclusivity that affords information to guide effective and efficient LCMS studies; that is, bulk analysis as resourceful tailoring into specific details. In this regard, the SsWaterfall platform’s aim is to recognize unforeseen cell-modulation trends early in research and development in vitro stages, as generalized non-specific data snapshots. For a study, if data trends of primary compound and indirect cell byproducts remain stable, e.g., do not modulate, the implication is that the compound is not detrimental to cell health. However, if culture modulations are recognized, then additional and precise evaluations of the compound are needed as drug developers better understand unanticipated incidences to include inducible cell byproducts. Herein, drug developers may quickly weed-out the compound to avoid lost time, lost effort, and lost money corresponding to the fail-fast mantra.

4.3. DILI Is One Reason That New Compounds Are Removed from Late-Stage Clinical Trials

In the framework of precision medicine, DILI is a subgroup of liver injury and is one reason that new drug compounds are removed from late-stage clinical trials and after market entry [65,66,67]. Typically, static cultures or animal studies are deemed unreliable because DILI can be induced by parental drugs or subsequent cell-generated metabolites [55], indicating DILI as a longer-term chronic hepatotoxicity injury model with explicit cell signaling implications, whereas short-term in vitro cultures of hepatocytes, in static setups, are limited due to omitted cell signaling dynamics. Meanwhile, longer-term in vivo animal studies can be limited by species-specific cell metabolite generation of contradictory complexities. In consequence, in vitro methods to predict DILI with high accuracy continue to be sought-after attributes. Suitably, fluid-flow systems are evolving to replicate, as accurately as practical, in vivo exposure schemes. Given that hepatocytes are the performing biologic participants, and distinct cell phenotypes have unique functional responses, both the adequately studied human HepaRG cell line [37,68] and historically analyzed primary rat hepatocytes are considered stable reproducible contributors needed for these exposure investigations. Relatedly, isolated primary human hepatocytes were excluded from initial studies due to their inherent cell function variability [69], but primary human cells could be available for accommodating evaluations.

4.4. Perpetually Adapating Cell Responses for Complementary Knowledge

With flow, the operational use of hepatocytes in culture facilitates extended culture timelines, retains cell function efficacy, and maintains activities of metabolizing enzymes [70]. Collectively, by emulating a radiation AUC exposure model, the device supports atypical cell responses to create complementary data outcomes, i.e., not replicate or replacement data. Each µchannel workspace experiences quantifiable-centric contacts, compound-centric exposures, and accumulation-centric encounters (Figure 4(b1–b3)). Herein, the multiwell µfluidics device is designated a biologic process assembly line for both compound-exposure and cell-generated byproducts, where real-time trending variations are used to evaluate bio-transformations. Analogous trending charts are successfully employed in conventional manufacture assembly-line processes, i.e., six-sigma engineering analysis, to track, sustain, or re-align production processes within boundary limits (e.g., UCL and LCL).

4.4.1. Focused Modeling with Enhanced Tissue Engineering

Traditionally, in efforts to predict the bioactivity responses of new compounds, drug development companies have devoted enormous in vitro research efforts for predictive efficacy and foretelling toxicity, by employing high-throughput cell culture systems. Still, the abundance of front-end testings utilized, i.e., extensively searching for validations, continues to generate findings that do not fully recapitulate in vivo effects and results in late-stage clinical failures at significantly high costs. Many shortfalls could be overcome through enhanced tissue engineered models that more robustly mimic natural in vivo organ structures. Focused modeling could have explicit and tangible deliverables contrary to the voluminous routine of implicit studies, i.e., evaluating subgroups in high accuracy formats. By evolving complex organ structures, in vitro assemblies might exist as viable and non-viable influencers to include nutrient mass transport, cell communication, and cell generated byproducts. In this framework, multiwell and µfluidic platforms are expected to enrich supplemental datasets to help select/deselect compounds of interest.

4.4.2. LDH Release Is a Biomarker to Evaluate Liver Damage