Abstract

Lightweight construction is experiencing a significant market implementation with sustained growth both for new buildings and retrofitting purposes. Despite the acknowledged advantages of this type of construction, their reduced thermal inertia can jeopardize indoor thermal comfort levels while leading to higher energy consumption due to high indoor temperature fluctuations and overheating rates. The incorporation of phase change materials (PCMs) into constructive solutions for lightweight buildings is a promising strategy to guarantee adequate thermal comfort conditions. Particularly, the utilization of mortars embedding PCMs as an indoor wall coating for new and existing buildings represents a solution that has not been widely explored in the past and needs further development and validation efforts. This work pursues the analysis of the thermal regulation effects generated by two thermally-enhanced mortars incorporating microencapsulated PCMs with different operating temperature ranges. To that end, an experimental campaign was conducted in Valladolid (Spain) to address the investigation of the proposed solution under a real-scale relevant environment. The proposed mortars were applied as an indoor coating to the envelope of a single-zone lightweight construction that was monitored (under different weather conditions along 1-year monitoring campaign) together with an identical building unit where the mortar was not added to the constructive base layer. The analysis of indoor temperature fluctuations under free-floating operating mode as well as the energy consumption of HVAC equipment under controlled-temperature operation was specifically targeted. Results derived from the continuous monitoring campaign revealed lower temperature fluctuations during summer and shoulder seasons, reducing indoor temperature peaks by 1–2 °C, and producing a time delay of 1–1.5 h into the temperature wave. A clear reduction in energy use due to the incorporation of the PCM-based indoor coating panels is also observed. Thus, this experimental research contributes to proving that the use of innovative mortars incorporating embedded PCMs enables the development of high-end efficient building solutions with innovative materials towards a sustainable built environment.

1. Introduction

Energy efficiency in buildings is one of the key priorities to face the challenges derived from climate change in Europe due to the fact that buildings account for 40% of energy consumption and 36% of CO2 emissions [1]. In this context, it is clear that building renovation efforts are required to increase the energy performance of buildings through the so-called Renovation Wave [2], whose main objective is to double the annual energy renovation rate of the European building stock by 2030, whereas only 0.2% of the buildings are currently being deeply renovated each year [1]. Europe has already established an ambitious plan to reduce 55% of the greenhouse emissions by 2030 [3], as well as to increase the current 3% of the overall building stock that is compliant with the energy performance regulations nowadays in force [4].

In order to reduce the primary energy use and carbon footprint of existing and new buildings, three main strategies can be addressed: (i) reducing their energy demand resourcing to improved passive behavior, (ii) supplying the required energy in the most sustainable manner, from production and distribution up to end users, thanks to local energy harvesting and efficient energy systems, and (iii) increasing the use of clean, renewable energy sources [5].

In this line, the passive exploitation of the thermal inertia in building structures as Thermal Energy Storage (TES) systems, as well as their active management through direct coupling with active energy production technologies (giving rise to the concept of Thermally Activated Building Systems, TABS) [6,7] have demonstrated their high potential for energy savings, since they enable the reduction of peak loads while improving indoor thermal comfort conditions [8]. The application of these technologies supports more sustainable constructions and offers new possibilities to comply with the Climate Action Plan [3,4] objectives by 2030.

Nevertheless, there is an increasing worldwide trend towards lightweight constructions, which are characterized by low thermal capacity values. To overcome those drawbacks derived from this specific characteristic, incorporating innovative functionalized materials, such as phase change materials (PCMs) into building applications is a promising strategy. This would increase the building’s thermal inertia, dampening down the peak indoor temperatures thanks to the passive thermal regulation provided by the additional (latent) energy storage capacity of the incorporated material [9].

In this context, this work aims at demonstrating and verifying the increased performance (both in terms of indoor temperature regulation as well as of energy use reduction) of two innovative mortars with the incorporation of microencapsulated PCMs, which are suitable for application into indoor finishing solutions. Two commercial PCMs were used within the analyzed mortars: CrodaThermTM ME29P [10] and Micronal® DS 5001X [11]. Their characteristics are described in Section 3.

Although the application of PCMs to constructive solutions is attracting more and more interest nowadays, the specific development of PCM-based mortars has not been widely explored, and most of the related literature still focuses on the lab-scale characterization of materials without addressing real-scale applications [12,13,14,15,16,17].

Those mortars hereby proposed have been developed, fully characterized, and demonstrated at real scale in the context of the European SUDOKET project [18] together with a set of other Key Enabling Technologies (KETs) for innovative eco-friendly built environments. They were developed targeting the reduction of overheating while promoting indoor passive thermal regulation and energy efficiency in lightweight constructions under warm southern European climate conditions.

Their experimental characterization in terms of microstructural, mechanical, and thermal properties was first addressed and was presented in a previous research paper by Rebelo et al. [19]. Then, a performance analysis focused on their integration into a real-scale lightweight demonstrator built in Valladolid (Spain) was conducted and is presented in this work.

Thus, the novelty of this research relies on the validation and assessment of the thermal regulation effect of the developed PCM-containing mortars in a relevant real-scale environment. Such thermal regulation specifically tackles overheating problems and how they are translated into energy savings for indoor heating and cooling. This paper describes the proposed solutions and shows the analytical results obtained from continuous monitoring of indoor temperatures and energy consumption.

2. Background

In recent years, lightweight construction has attracted increasing interest, becoming more and more popular, and experienced a rapid market penetration with sustained growth in the construction sector. The main reason for this lies in its inherent advantages in contrast to traditional construction techniques: lower costs, reduced waste (almost 100% recyclable), faster construction timing, reduced use of water, reduced onsite disruption, and high adaptability [9,20]. The major disadvantage of lightweight construction is associated with its lower thermal mass and the consequent lack of thermal inertia, which may jeopardize the indoor thermal comfort conditions due to thermo-regulation difficulties, often leading to an increased overheating risk [21] when facing some specific climatic conditions. Consequently, in some cases, higher energy demands for heating and cooling purposes may be observed in lightweight buildings [9,20,22].

On the other hand, Thermal Energy Storage (TES) systems enable the balance between daytime and nighttime energy needs, taking advantage of the large (latent or sensible) heat capacities of certain materials [9]. In this respect, PCMs provide the possibility to store high quantities of energy in the form of latent heat (in addition to their also relevant sensible heat capacity), thus exchanging energy in different moments for predetermined temperature ranges. Thanks to this particular property, PCM-based solutions can buffer the energy demand profile, causing a direct effect on the required power of heating and cooling systems [23,24,25], and thus acting as passive thermo-regulators of the indoor temperature. Indeed, PCMs present specific predetermined phase change temperature ranges, able to store and release high amounts of energy per unit of volume within a small temperature interval, either during the phase change from solid to liquid state (when an endothermic process occurs), as well as during the reverse process wherein the accumulated energy is released due to an exothermic reaction [9,24]. Additionally, PCMs can be incorporated into the envelope’s constructive solutions in numerous ways [8,26]. A wide range of PCM applications in buildings and its use for enhanced solutions into constructive systems can be found in the literature [8], including gypsum boards and plasters [27,28], mortars [7,29], concrete [24,30,31], bricks [32,33], geopolymers [34], metallic roof panels [35], insulation materials [36], glazing, and shading solutions [37]. These studies reveal that the heat capacity and thermal conductivity of PCM-enhanced materials and constructive solutions portray a significant role in the development of efficient thermal activation of building structural components.

Marin et al. [9] performed a numerical study in which it was observed the reduction of energy consumption and extreme indoor temperature fluctuations due to the use of PCM in lightweight buildings subjected to different weather conditions. Results revealed significant reductions of energy consumption for heating and cooling. The authors highlight the importance of the PCM temperature melting point selection for maximizing its performance, thus emphasizing PCM impact in extremely lightweight buildings. Cabeza et al. [31] studied the effect on the building thermal performance due to the incorporation of microencapsulated PCM into the concrete walls, observing indoor temperature reductions of the PCM-containing building around 1 °C, with a maximum temperature shift of 2 h. Soares et al. [21] observed through numerical simulation analysis that the use of PCM in lightweight buildings can lead to the improvement of the energy efficiency up to 60%, depending on the climate zone. Cunha et al. [38,39] performed experimental research to evaluate the thermal behavior of small-scale test cells incorporating PCM-enhanced mortars with different binders, observing a reduction of extreme temperatures ranging from 2 to 5 °C, coupled with a significant time lag delay when subjected to different Portuguese climate conditions. Salgueiro et al. [29] investigated the mechanical and thermal properties of different formulations of expanded clay mortar with the incorporation of PCM, attaining a reduction of about 20% of mechanical strength (flexural and compressive), an increase of 17% in the specific heat capacity and a reduction of 24% in the thermal conductivity for the resulting PCM-containing mortars.

Embedding PCM into a mortar matrix must guarantee that the resulting PCM-containing mortar is suitable for construction applications and behaves within satisfactory levels of performance regarding mechanical strength and workability [40]. Additionally, it is paramount to avoid chemical incompatibilities between the PCM and the mortar matrix, as well as leakage issues during the material’s liquid state [8]. Lucas et al. [41] studied different mortar compositions with various binders and different quantities of embedded PCM, thus concluding that a good compromise between thermal and mechanical performance of the resulting mortar is achieved for an amount of 20 wt.% of incorporated microencapsulated PCM. Kheradmand et al. reached a similar ratio of mass fraction for incorporated PCM of 20 wt.% of the mortar’s global mass [40,42]. Higher amounts of incorporated PCM into the mortar matrix do not necessarily imply an increase in latent heat transfer due to the role of internal porosity since nanopores significantly reduce the heat transfer capability, even for increased contents of embedded PCM [40].

Since incorporating PCM into mortars for indoor wall finishing in lightweight buildings (new constructions and retrofit scenarios) is a stimulating strategy for passive thermal regulation and reduction of energy demand for heating and cooling purposes, two thermally-enhanced mortars with incorporated microencapsulated PCMs were developed and characterized in previous research stages. The developed mortars are intended to tackle overheating risk through the reduction of indoor thermal fluctuations. An experimental campaign for monitoring the thermal behavior and energy consumption profile of a real-scale application comprising two lightweight test cells located in Valladolid (Spain) is presented in this work. Thus, previous knowledge from laboratory tests and materials research is used to take a step forward towards real-scale demonstration of the PCM-containing mortars applied to indoor wall coatings at the targeted test cells.

3. Materials and Methods

In order to demonstrate and validate the effects on the indoor temperature regulation capabilities of 2 PCM-containing mortar solutions applied to lightweight constructions, as well as on the corresponding energy demand for space conditioning, a methodology consisting of 4 main phases was followed:

- Design and fundamental research of the PCM solutions, including selection of PCM temperature ranges, lab testing of microstructural, mechanical, and thermal characteristics, as well as preliminary numerical studies. The specific activities and results derived from this phase were reported by the authors in previous research papers [19,43].

- PCM incorporation in 1 real-scale test cell out of the 2 depicted in Figure 1. The second test cell was taken as a reference for benchmarking.

Figure 1. Test cells used for the demonstration of the PCM solutions: (a) South-West view; (b) North-East view.

Figure 1. Test cells used for the demonstration of the PCM solutions: (a) South-West view; (b) North-East view. - Monitoring campaign where 2 PCMs (i.e., CrodaTherm [10] and Micronal [11]) embedded into mortar solutions were alternatively studied considering both a free-floating temperature mode (i.e., no space conditioning system activated) and a conditioned mode (i.e., PCM supporting the active operation of the space conditioning system). Winter, summer, and mid-seasons were covered by the monitoring phase.

- Analysis of the monitoring results and evaluation.

3.1. Description of the Lightweight Test Cells

Two test cells with the same constructive characteristics were used, as presented in Figure 1. These cells are used for research purposes concerning different energy solutions for buildings and are characterized by lightweight construction with low thermal inertia and high thermal insulation values. The constructive features of the cells’ envelopes are the following:

- Façades: sandwich panel with 8 cm of thermal insulation (polyurethane foam) with U-value = 0.287 W/(m2·K);

- Roof: metallic roof with 16 cm of thermal insulation (mineral wool) in the internal surface presenting a U-value = 0.242 W/(m2·K);

- Floor: vinyl-based without thermal insulation and ventilated underneath.

- Openings: both test-cells have a sliding double-glazed window (U-value = 3.137 W/(m2·K) and Solar Heat Gain Coefficient (SHCG) = 0.762) and an opaque door (U-value = 0.747 W/(m2·K)), both facing South.

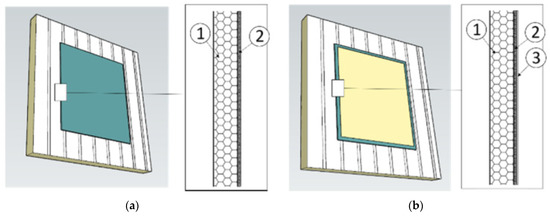

In addition to the base envelope layers listed above, one of the cells was used as reference (DEMO1) and incorporated commercial insulation panels (WEDI® panels) mounted on the internal face of the façade walls. The specific location of the panels placed on 2 of the vertical walls is shown in Figure 2a. The same distribution was applied to the remaining vertical internal surfaces (without covering the window opening area). The insulation panels were fixed to the base layer using adhesive magnetic stripes.

Figure 2.

Indoor view of the test cells with the thermal insulation panels (WEDI®): (a) DEMO1: without PCM; (b) DEMO2: with PCM.

The second cell (DEMO2) was used to test the effects of the PCM-containing mortars applied as indoor wall coating and incorporated test boards composed of the same type of WEDI® panels with an additional 4 mm-layer of the corresponding mortar. The specific location of these boards is shown in Figure 2b. In this case, they were mounted on the walls reinforcing the adhesive magnetic fixing with additional stripes of Velcro tape.

A detailed schematic diagram of the 2 indoor coating solutions (with and without the 4 mm PCM-based mortar layer) is shown in Figure 3 and was presented and explained in further detail in [19].

Figure 3.

Schematic diagram of the indoor coating solutions applied to the 2 test cells. (a) DEMO1; reference cell with only WEDI® panels (2) added to the base layer (1); (b) DEMO2; test cell with WEDI® panels (1) + PCM-based mortar layer (3) added to the base layer (1). Source: [19].

Test boards with the 2 aforementioned PCM solutions (i.e., CrodaThermTM ME29P and Micronal® DS 5001X) were prepared. The characterization of the thermophysical and mechanical properties of the PCM-containing mortars in terms of latent heat capacity and phase change behavior, as well as the thermal conductivity of the external envelope walls (composed by sandwich panels with the different mortars), were also reported in detail in Rebelo et al. [19]. The main results from [19] regarding hardened density value for the mortar containing the Micronal PCM resulted in a reduction of 36.4% in comparison with the reference mortar, and for the mortar incorporating CrodaTherm PCM, a density reduction of 18.7% was observed. The results obtained for the mechanical strength regarding the PCM-containing mortar with Micronal revealed a decrease of 68% and 76%, and for the CrodaTherm PCM incorporation, a reduction of 57% and 72% in flexural and compressive strengths was attained, respectively.

The selected microencapsulated PCM materials were incorporated into the mortar, which has a density of 1600 kg/m3. The mixture in a 20 wt% into the solid material modifies the density as well as melting and crystallization temperatures in comparison with the pure mortar and PCM characteristics. The resulting thermal values obtained from the characterization of the mixtures are presented in Table 1.

Table 1.

Thermo-physical properties of the two PCMs used into the applied mortars.

Moreover, in order to analyze the effect of the PCM solutions in the conditioned mode (i.e., when supporting the operation of space conditioning equipment), both cells were equipped with reversible, split, direct expansion (DX) air conditioning systems capable of controlling the indoor room temperature in heating and cooling modes. These units use R32 as a refrigerant and have nominal heating/cooling capacities of 2.7 kW/2.6 kW, respectively.

3.2. Monitoring Equipment

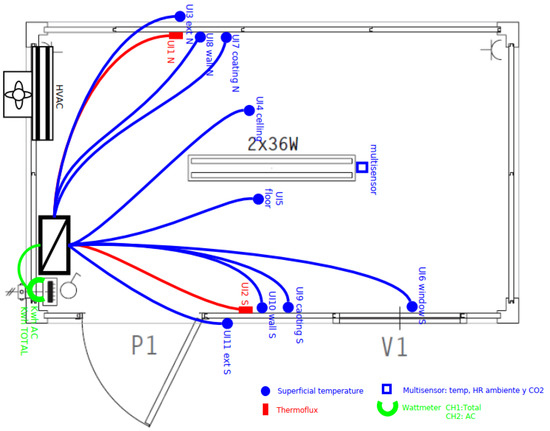

Both test cells were fully monitored to characterize the indoor thermal conditions and the energy profiling. Figure 4 presents the schematic location of the different sensors used into the test cells. Superficial temperature both in the envelope walls and openings (i.e., windows), heat flux values through the façades, and indoor temperatures were continuously recorded. The energy use of the space conditioning units was also monitored. Table 2 presents a summary list with all the monitored variables, for which data were recorded with a sampling rate of 5 min.

Figure 4.

Scheme of the location of the monitoring sensors into the test cells. (Both were equipped with the same number and type of sensors).

Table 2.

Summary list of the monitored variables (both at the reference and test constructions).

In addition, the monitoring infrastructure was based on the standard Lonworks communication protocol. It was used for data storage and created a communication network between both cells.

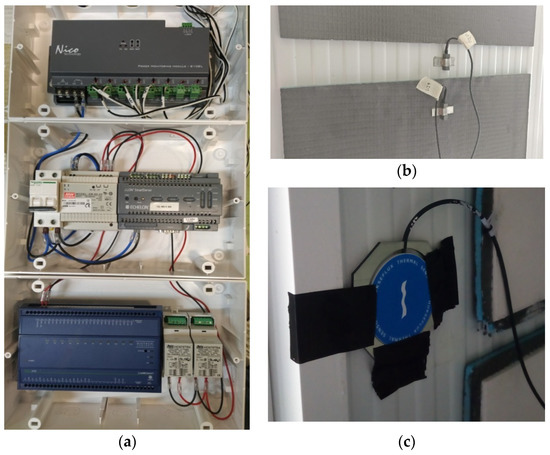

Each test cell was equipped with an electrical cabinet for monitoring purposes (see Figure 5). Apart from the thermomagnetic protections corresponding to each panel, the cabinets included the following equipment:

Figure 5.

Example views of the main components of the monitoring infrastructure placed inside the test cells: (a) electrical cabinet with datalogger, PLC and auxiliary monitoring devices, (b) surface temperature probes, (c) heat flux meter on an internal wall.

- Head Equipment—iLON SmartServer: it acts as a central data logger as well as a communication gateway between Lonworks and TCP/IP.

- Wattmeter for electrical energy use measurement. NICO 8108 LON: This equipment has a total of 8 measurement channels, of which only 2 of them are occupied for measuring the electrical energy use of the HVAC units and the total electrical energy use of the corresponding test cell.

- PLC—Distech ECL 400: it is used as an analog input module for the heat flux meters and the temperature probes. This PLC equipment has the advantage of being programmable for the most suitable monitoring strategy to the study intended.

- Amplifier (mV-V), which measures the signal from the heat flux meters and adapts it to allow the PLC equipment to read it.

- Power Source (24Vcc) required for power supply to the PLC and the multi-sensor (indoor temperature, relative humidity, and CO2 concentration) device.

The following sensors were integrated into the monitoring network:

- Surface temperature probes: Distech PDCSY-TT-351-A-5M. They are NTC 10K thermistors with an operating range between −10 °C and 100 °C.

- Multisensor probes: WRF04 CO2 RH LON. They are composed of an internal temperature sensor, a relative humidity (RH) sensor, and a CO2 sensor. The ranges of each sensor are as follows: Measuring range: Temperature: 0–50 °C; RH: 0–100% RH non-condensing; CO2: 0–2000 ppm.

- Heat flux meters: HUKEFLUX HFP01. They were connected to the analog inputs of the PLC, which must be previously programmed to be able to adjust the precision, the measurement tolerance, as well as the voltage reading range. In order for the PLC to interpret the voltage signal introduced by the heat flux meter, the connection of an amplifier was required thus as to increase the voltage of the signal.

- Power meter: a 60 A clamp was connected to a NICO 8108L power meter in order to measure the electricity consumption of the HVAC units. The meter accuracy reported by the manufacturer is: ±1% fs (50/60 Hz) for voltage and current measurements; ±1.5% fs for active power.

CO2 and relative humidity values were monitored by multi-sensors placed inside both test cells. However, the corresponding data collected by these sensors (as well as heat flux measurements) were not used for the thermal and energy analyses within the scope of this work.

All the sensors used during the monitoring campaign were calibrated according to the calibration curves provided by the manufacturers. Regarding the temperature probes, preliminary analyses were performed comparing those temperature values measured by the different sensors inside the target operating range. Maximum temperature differences reached 0.2 °C, in line with the accuracy value referred in the technical datasheet.

3.3. Experimental Test Setups

The experimental campaign comprised periods of continuous monitoring (alternatively using each of the PCM solutions) under different operating modes:

- Free-floating temperature mode: in these periods the air conditioning units of both test cells were turned off, thus the corresponding surface and room air temperatures evolved freely as a result of the cell energy balance accounting for wall transmission loads, infiltrations, solar irradiation through the windows and the specific thermal inertia of the constructions. No upper or lower bounds in the evolution of the indoor air temperatures were imposed.

- Conditioned mode: in these periods the indoor environment at each test cell was controlled by the air conditinioning units. Particularly, a setpoint of 25 °C was fixed to control the indoor room temperature, thus imposing an upper bound to its evolution during cooling operation, while modifying the natural energy balance with the additional heat supply to reach the setpoint during heating operation. The electricity use of the conditioning equipment was monitored continuously in order to detect differences between the reference cell and the target cell (with PCM-based mortar applied).

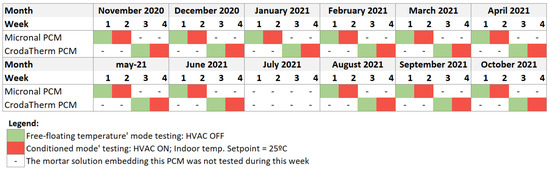

One year (from November 2020 to October 2021) was used as the overall monitoring period, thus covering winter, summer, and mid-seasons (Autumn and Spring), in which different boundary conditions in terms of outdoor temperature and subsequent energy demand had an influence on the thermal behavior of the test cells and the PCM solutions. It should be noted that no data are shown in the following sections for July 2021, since the tests were stopped during some weeks due to the vacation period and the impossibility to follow the pre-defined testing calendar (see further explanations below).

As previously mentioned, the 2 PCM solutions were mounted alternatively on the internal walls of the test cell (while the WEDI® panels, without PCM, remained in the reference cell during the whole monitoring campaign). The specific periods for the application of each PCM solution were selected following an annual calendar designed a priori before starting the monitoring campaign (see Figure 6). In particular, every 2 weeks the panels with the PCM-containing mortar were changed, while, alternatively, every week the operating mode was modified from free-floating temperature to conditioned mode and vice versa. In this way, every month of the year each PCM solution was tested in the 2 operating modes enabling to observe the effects of the enhanced thermal inertia into the passive thermal behavior of the building as well as on the energy consumption of the conditioning systems.

Figure 6.

Annual calendar designed for the monitoring campaign alternatively testing both PCM-based mortars (with Micronal and CrodaTherm materials) under ‘Free-floating temperature mode’ and ‘Conditioned mode’.

4. Results

This section aims to present the results derived from the experimental campaign as well as to remark the most relevant observations affecting temperature evolutions and energy consumption.

4.1. Thermal Response under Free-Floating Temperature Conditions

As a result of the monitoring period under free-floating temperature conditions, a positive effect on the temperature regulation capacity of the test cell was observed thanks to the incorporation of PCM-based mortars into internal coating elements. This effect was observed for both the PCMs utilized in this work: Micronal® DS 5001 X (‘Micronal’ in the following) and CrodaThermTM ME 29P (‘CrodaTherm’ in the following). However, some quantitative differences can be described as derived from the monitored data.

Next, the results obtained for the two different materials are presented, including a statistical overview per month of the room air temperature values along with the whole monitoring campaign, as well as a specific zoom on the thermal behavior observed during three consecutive, representative days on free-floating temperature mode operation. In both cases, a comparison between the reference cell, DEMO1 (only using WEDI panels without PCM), and the test cell equipped with the PCM-based mortar, DEMO2, is discussed.

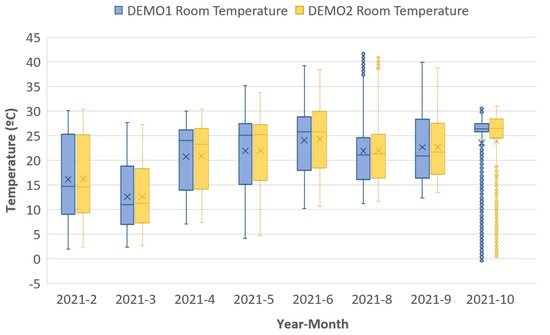

Figure 7.

Statistical analysis per month for the comparison of indoor room temperature values monitored at DEMO1 (reference) and DEMO2 (test cell) during free-floating temperature mode periods with indoor coating elements based on Micronal® DS 5001X.

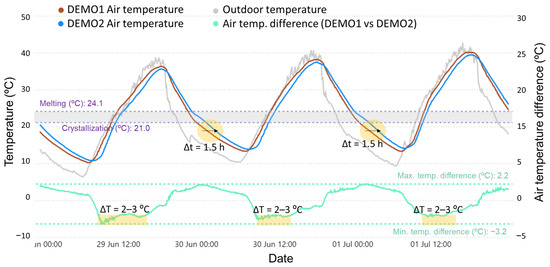

Figure 8.

Comparison of room air temperature values at DEMO1 (reference cell without PCM) and DEMO 2 (test cell incorporating Micronal-based panels). Zoom on three consecutive days on the last week of June 2021. In light green, the room temperature difference between both cells is shown.

Figure 7 reveals that the use of PCM-based mortar incorporating Micronal material led to a reduction of the indoor temperature fluctuations with maximum achieved temperature levels that are around 1 °C lower during summer and shoulder seasons (from May to September). During colder months representing winter conditions, due to the PCM operating temperature range (selected to reduce overheating), indoor room temperatures are not able to activate the PCM, and, therefore, the effect of the thermally-enhanced mortar was not noticed (i.e., the PCM did not charge nor discharge).

This impact is more evident when observing the detailed evolution of room temperatures along the day. For this purpose, three days of the last week of June 2021 (typical summer conditions) were selected and are shown in Figure 8. Hereby, it is evidenced that the monitored indoor temperatures in DEMO2 were between 2–3 °C lower on average than those in DEMO1 during the first part of the day when outdoor temperatures and cooling loads were rising, and they were up to 2.2 °C higher than those in DEMO 1 in the second part of the day, thus preventing fast temperature reduction in the evening. In this sense, the room temperature wave in DEMO2 revealed a time delay of 1.5 h during the cooling period of the day, related to the PCM energy discharge.

In addition, it can be observed that the separation of the reference and the PCM-related room temperature curves occurred at thermal levels very close to the phase change range of the material (21–24.1 °C). Slight differences were reasonable since the room air temperature (monitored variable) and the mortar temperature (actually driving the phase change process) were not expected to coincide due to indoor-outdoor temperature differences and the corresponding thermal resistance.

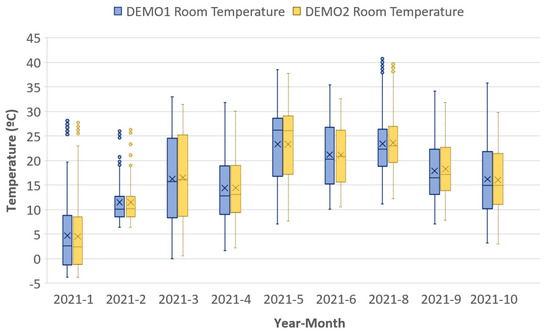

Figure 9.

Statistical analysis per month for the comparison of indoor room temperature values monitored at DEMO1 (reference) and DEMO2 (test cell) during free-floating temperature mode periods with indoor coating elements based on CrodaThermTM ME29P.

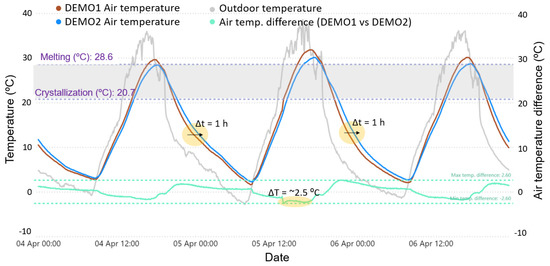

Figure 10.

Comparison of room air temperature values at DEMO1 (reference cell without PCM) and DEMO 2 (test cell incorporating CrodaTherm-based panels). Zoom on three consecutive days on the 2nd week of April 2021. In light green, the room temperature difference between both cells is shown.

From the statistical analysis of room temperature measurements for the reference cell (DEMO1) and the test cell with CrodaTherm-based internal coating (DEMO2) along with the whole monitoring campaign (Figure 9), a clear reduction of the indoor temperature fluctuations during summer and shoulder seasons (from March to October) was observed. Maximum indoor temperatures in DEMO2 were in general 1–2 °C lower than those in DEMO1. Similar to previous observations for Micronal PCM, due to the operating temperature range of the CrodaTherm PCM, during the winter season (e.g., January and February), no indoor temperature benefits from the PCM-containing mortar were noticed.

In addition, the impact of using the PCM-based mortar with CrodaTherm as indoor wall coating of DEMO2 on the passive thermal regulation of indoor temperature is highlighted when zooming into those weeks with extreme indoor temperatures. For this purpose, three days of the second week of April in which such conditions occurred were selected and are shown in Figure 10. DEMO2 revealed a reduction of indoor temperatures up to 2.6 °C in comparison to the reference cell (DEMO1), which takes place close to the central hours of the day with the highest outdoor temperatures and corresponding cooling loads. Additionally, a time delay of 1 h was observed during the cooling period of the day as the incorporated PCM was discharged.

Finally, it can be observed that the separation of the reference and the PCM-related room temperature curves occurred at thermal levels very close to the phase change range of the material. It is particularly evident during the melting process close to 28.5 °C.

4.2. Impacts on the Energy Use of the Conditioning Equipment

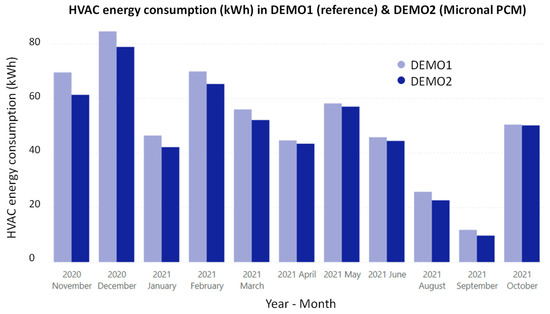

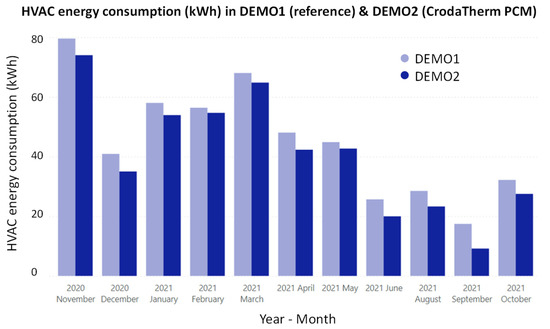

From the energy perspective, the analysis of results is focused on the energy consumption of the HVAC systems installed in the test cells. Figure 11 and Figure 12 represent the impact of each specific PCM utilized in this work in terms of the energy use of the air conditioning units for the reference cell (DEMO1) and the test cell incorporating the PCM-based mortar into internal wall coating elements (DEMO2). Both graphs show the aggregated monthly energy consumption (in kWh) directly registered in the two lightweight constructions during the corresponding periods selected for testing of the ‘Conditioned mode’ according to the pre-defined testing calendar (see Section 3.3). It should be noticed that July 2021 is not included in the analysis since the monitoring campaign had to be stopped for some weeks due to the annual vacation period. Nevertheless, June, August, and September provided relevant results for the summer conditions.

Figure 11.

HVAC system energy use during Micronal testing under ‘Conditioned mode’.

Figure 12.

HVAC system energy use during CrodaTherm tests under ‘Conditioned mode’.

Figure 11 reveals that the energy use of the air conditioning unit was reduced when incorporating the Micronal-based internal panels, either working in heating or cooling modes. The effect of reduced temperature fluctuations observed under free-floating temperature mode was consistent with the fact that less energy was required to maintain the indoor environment within the comfort limits (i.e., to meet the heating/cooling setpoints of the conditioning equipment).

Table 3 complements the graphical results with quantified values of the monitored energy use per month for each test cell during Micronal tests. In September 2021, the maximum percentage of energy savings was reached, accounting for up to 18% of energy savings. During the entire period, the energy use for the DEMO1 was 562.05 kWh, while the conditioning of DEMO2 required 526.16 kWh. This led to a 6.39% of energy savings.

Table 3.

Energy use in each test cell during the testing period with Micronal-based panels.

On the other hand, Figure 12 illustrates the evolution of the monitored energy use corresponding to the air conditioning units of both DEMO1 and DEMO2 during the testing of CrodaTherm-based panels. The annual profile and the absolute values of the monitored consumptions were different from the ones for Micronal since measurements obviously corresponded to different weeks within the corresponding month in which the outdoor climate was different as well. However, the same trend was observed, thus revealing a clear reduction in energy use due to the incorporation of the PCM-based indoor coating panels.

Table 4 presents the quantitative results per month along with the whole monitoring campaign. It can be observed that the energy use for the DEMO1 was 499.82 kWh, while the conditioning of DEMO2 required 447.52 kWh. This led to a 10.46% of energy savings.

Table 4.

Energy use in each test cell during the testing period with CrodaTherm-based panels.

5. Discussion of Main Findings and Implications

The results presented above (Section 4) provide relevant proof of the good performance of PCM-based mortars to limit overheating situations and reduce the energy consumption of air-conditioning equipment in lightweight constructions. This has been proven at a real-scale relevant environment, thus stepping over previous studies which strictly relied on lab-scale characterizations or numerical simulations.

The main findings derived from this work have revealed peak temperature reductions by 1–2 °C and air-conditioning energy savings by 5–10% as a result of the application of two specific PCM-containing mortars as indoor coating solutions at a real-scale lightweight demonstrator. These represent the first promising results that spearhead a step forward from laboratory to field research on this topic and promote advances in the technology readiness of PCM-based solutions integrated into sustainable built environments.

At the same time, these promising findings pave the way for further studies, which are required to extend the conclusions to other materials and constructive assemblies, address cost-benefit aspects, and consolidate the above-mentioned positive impacts under different building contexts and climate conditions.

From a long-term perspective, PCM-containing mortars are expected to enable a relevant impact on lightweight prefabricated constructions, which will become increasingly frequent in the construction sector over the coming years. Indeed, according to recent market studies [44,45], the prefabricated building market in Europe is expected to sustainably grow at a Compound Annual Growth Rate (CAGR) of approximately 4–5.5% up to 2026.

This will bring important challenges to ensure high-quality indoor comfort and reduced energy consumption since the low thermal inertia of lightweight buildings may lead to higher temperature fluctuations and thermal demands. Overheating is a major risk in Southern Europe, while increased heating and cooling energy use would also affect colder climates where the prefabricated housing market is particularly rising [46].

However, based on the findings presented in this work, it has been demonstrated that PCM-containing mortars can successfully be applied to this kind of constructions with clear benefits to face the above-mentioned challenges in the next future.

6. Conclusions and Future Work

The present work has addressed the implementation and monitoring, at a real-scale relevant environment, of indoor wall coating elements for lightweight constructions based on two thermally-enhanced mortars with incorporation of PCMs with different operating temperature ranges.

The conducted research enabled the validation of the passive thermal regulation effects provided by these solutions, reducing the indoor thermal fluctuations as well as the energy use of related conditioning equipment. The following conclusions can be derived from this work:

- The monitoring results revealed a reduction in indoor thermal fluctuations with significant expression during summer and shoulder seasons. The selected PCM configurations contribute to reducing indoor temperature peaks by 1–2 °C in such periods.

- Due to the selected PCM phase change temperatures (close to the higher limit of the thermal comfort zone), the impact of the two PCM-containing mortars on the indoor thermal behavior under free-floating mode operation remained unnoticed during the winter season.

- A 5–10% reduction on the energy consumption of the air-conditioning equipment was observed during the monitoring campaign.

- This trend was observed both during winter and summer months under controlled-temperature (conditioned mode) operation because the targeted indoor comfort conditions intersected the phase change range of the selected PCMs and triggered their partial activation (which did not happen under free-floating temperature mode).

Therefore, based on the results of the conducted monitoring campaign, it can be stated that the incorporation of the selected PCMs (with phase change ranges close to the indoor comfort zone) in thermally-enhanced mortars for internal wall coating solutions is a promising strategy capable of reducing temperature fluctuations and triggering 5–10% energy savings for conditioning systems in lightweight constructions.

Future research is nevertheless needed in order to extrapolate these results to other materials (i.e., mixtures of construction mortars and microencapsulated PCMs) and constructive solutions, thus also addressing the design optimization for different building environments. In this sense, further studies with different quantities of PCMs must be faced to understand the potential for multiplying those impacts hereby demonstrated and elaborate cost-benefit analyses that will contribute to the referred design optimization. Moreover, studies on durability and ageing of the proposed PCM-based boards, as well as further investigation of alternative constructive assemblies for the application of the PCM-containing mortars are relevant topics for future research work.

Author Contributions

Conceptualization, M.A., V.M.F., L.A.B.; methodology, R.V., L.A.B., F.M., J.S.; software, J.L.H., Á.C.; validation, M.A., L.A.B.; formal analysis, J.L.H., L.A.B.; investigation, Á.C., J.S., F.M.; resources, F.R., A.F.; data curation, J.L.H.; writing—original draft preparation, M.A., J.L.H., L.A.B.; writing—review and editing, V.M.F., R.V., F.R., A.F.; visualization, J.L.H.; supervision, V.M.F., L.A.B., M.A.; project administration, L.A.B.; funding acquisition, M.A., L.A.B., V.M.F., R.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been funded by the European Commission through European Regional Development Funds (ERDF) granted by the competent authority of the INTERREG V SUDOE programme for the development of the SUDOKET project (“Mapping, consolidation and dissemination of Key Enabling Technologies (KETs) for the construction sector in the Sudoe space”) [ref. SOE2/P1/E0677]. Additionally, this work was also partially supported by the Foundation for Science and Technology (FCT)—Aveiro Research Centre for Risks and Sustainability in Construction (RISCO), Universidade de Aveiro, Portugal [FCT/UIDB/ECI/04450/2020], as well as by the Spanish Ministry of Science and Innovation together with the Centre for Technological and Industrial Development (CDTI) within the framework of CERVERA programme for the excellence in research centres under the work record CER20191019 (HySGRID+).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

| % fs | Sensor accuracy expressed as a % of full scale |

| CAGR | Compound Annual Growth Rate |

| DX | Direct Expansion |

| HVAC | Heating, Ventilation and Air Conditioning |

| KET | Key Enabling Technology |

| PCM | Phase Change Material |

| RH | Relative Humidity |

| SHGC | Solar Heat Gain Coefficient |

| TABS | Thermally Activated Building Systems |

References

- Building Performance Institute of Europe (BPIE). Underpinning the Role of One-Stop Shops in the EU Renovation Wave: First Lessons Learned from the Turnkey Retrofit Replication. Available online: https://www.bpie.eu/wp-content/uploads/2021/11/Turnkey-Retrofit-report_OneStopShops_RenovationWave_Final.pdf (accessed on 2 December 2021).

- Building Performance Institute of Europe (BPIE). Deep Renovation: Shifting from Exception to Standard Practice in EU Policy. Available online: https://www.bpie.eu/wp-content/uploads/2021/11/BPIE_Deep-Renovation-Briefing_Final.pdf (accessed on 2 December 2021).

- COM (2020) 562 Final—Stepping Up Europe’s 2030 Climate Ambition Communication. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0562from=EN (accessed on 2 December 2021).

- COM (2020) 662 Final—A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0662from=EN (accessed on 2 December 2021).

- Martínez, F.J.R.; Velasco Gómez, E. Eficiencia Energética en Edificios. Certificación y Auditorías Energéticas: Certificación y Auditorías Energéticas; Editorial Paraninfo: Madrid, Spain, 2006; pp. 1–234. [Google Scholar]

- Arce, P.; Medrano, M.; Gil, A.; Oró, E.; Cabeza, L.F. Overview of thermal energy storage (TES) potential energy savings and climate change mitigation in Spain and Europe. Appl. Energy 2011, 88, 2764–2774. [Google Scholar] [CrossRef]

- Olivieri, L.; Tenorio, J.A.; Revuelta, D.; Navarro, L.; Cabeza, L.F. Developing a PCM-enhanced mortar for thermally active precast walls. Constr. Build. Mater. 2018, 181, 638–649. [Google Scholar] [CrossRef]

- Da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; Gracia, A.; Zhu, X.; Farid, M.; Cabeza, L.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef] [Green Version]

- CrodaThermTM ME29P Microencapsulated Ambient Temperature Phase Change Material. Material Specification. Available online: https://www.crodaenergytechnologies.com/en-gb/product-finder/product/981-Crodatherm_1_29 (accessed on 6 December 2021).

- BASF. Micronal® PCM. Intelligent Temperature Management for Buildings. Material Specification. Available online: https://www.microteklabs.com/product-data-sheets (accessed on 6 December 2021).

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-mortar based construction materials for energy efficient buildings: A review on research trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Haurie, L.; Serrano, S.; Bosch, M.; Fernández, A.I.; Cabeza, L.F. Addition of microencapsulated PCM into single layer mortar: Physical and thermal properties and fire resistance. In Proceedings of the Eurotherm Seminar, University of Lleida, Lleida, Spain, 28–30 May 2014; Volume 99, pp. 1–9. [Google Scholar]

- Guardia, C.; Barluenga, G.; Palomar, I.; Diarce, G. Thermal enhanced cement-lime mortars with phase change materials (PCM), lightweight aggregate and cellulose fibers. Constr. Build. Mater. 2019, 221, 586–594. [Google Scholar] [CrossRef]

- Guardia, C.; Barluenga, G.; Palomar, I. PCM Cement-Lime Mortars for Enhanced Energy Efficiency of Multilayered Building Enclosures under Different Climatic Conditions. Materials 2020, 13, 4043. [Google Scholar] [CrossRef]

- Yeon, J.H. Thermal behavior of cement mortar embedded with low-phase transition temperature PCM. Constr. Build. Mater. 2020, 252, 119168. [Google Scholar] [CrossRef]

- Djamai, Z.I.; Salvatore, F.; Larbi, A.S.; Cai, G.; el Mankibi, M. Multiphysics analysis of effects of encapsulated phase change materials (PCMs) in cement mortars. Cem. Concr. Res. 2019, 119, 51–63. [Google Scholar] [CrossRef]

- SUDOKET Project. Available online: http://sudoket.com/ (accessed on 2 December 2021).

- Rebelo, F.; Figueiredo, A.; Vicente, R.; Ferreira, V.M. Study of a thermally enhanced mortar incorporating phase change materials for overheating reduction in buildings. J. Energy Storage 2022, 6, 103876. [Google Scholar] [CrossRef]

- Soares, N.; Santos, P.; Gervásio, H.; Costa, J.J.; da Silva, L.S. Energy efficiency and thermal performance of lightweight steel-framed (LSF) construction: A review. Renew. Sustain. Energy Rev. 2017, 78, 194–209. [Google Scholar] [CrossRef]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Multi-dimensional optimization of the incorporation of PCM-drywalls in lighweight steel-framed residential buildings in different climates. Energy Build. 2014, 70, 411–421. [Google Scholar] [CrossRef]

- Roque, E.; Vicente, R.; Almeida, R.M.S.F. Opportunities of Light Steel Framing towards thermal comfort in southern European climates: Long-term monitoring and comparison with the heavyweight construction. Build. Environ. 2021, 200, 107937. [Google Scholar] [CrossRef]

- Amaral, C.; Vicente, R.; Ferreira, V.M.; Silva, T. Polyurethane foams with microencapsulated phase change material: Comparative analysis of thermal conductivity characterization approaches. Energy Build. 2017, 153, 392–402. [Google Scholar] [CrossRef]

- Figueiredo, A.; Lapa, J.; Vicente, R.; Cardoso, C. Mechanical and thermal characterization of concrete with incorporation of microencapsulated PCM for applications in thermally activated slabs. Constr. Build. Mater. 2016, 112, 639–647. [Google Scholar] [CrossRef]

- Frazzica, A.; Brancato, V.; Palomba, V.; la Rosa, D.; Grungo, F.; Calabrese, L.; Proverbio, E. Thermal performance of hybrid cement mortar-PCMs for warm climates application. Sol. Energy Mater. Sol. Cells 2019, 193, 270–280. [Google Scholar] [CrossRef]

- Gracia, A.; Cabeza, L.F. Phase change materials and thermal energy storage for buildings. Energy Build. 2015, 103, 414–419. [Google Scholar] [CrossRef] [Green Version]

- Shilei, L.; Neng, Z.; Guohui, F. Impact of phase change wall room on indoor thermal environment in winter. Energy Build. 2006, 38, 18–24. [Google Scholar] [CrossRef]

- Oliver, A. Thermal characterization of gypsum boards with PCM included: Thermal energy storage in buildings through latent heat. Energy Build. 2012, 48, 1–7. [Google Scholar] [CrossRef]

- Salgueiro, T.; Samagaio, A.; Gonçalves, M.; Figueiredo, A.; Labrincha, J.; Silva, L. Incorporation of phase change materials in an expanded clay containing mortar for indoor thermal regulation of buildings. J. Energy Storage 2021, 36, 102385. [Google Scholar] [CrossRef]

- Navarro, L.; de Gracia, A.; Castell, A.; Álvarez, S.; Cabeza, L.F. PCM incorporation in a concrete core slab as a thermal storage and supply system: Proof of concept. Energy Build. 2015, 103, 70–82. [Google Scholar] [CrossRef] [Green Version]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113–119. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Soares, N.; Ferreira, V. Experimental testing and numerical modelling of masonry wall solution with PCM incorporation: A passive construction solution. Energy Build. 2012, 49, 235–245. [Google Scholar] [CrossRef]

- Vicente, R.; Silva, T. Brick masonry walls with PCM macrocapsules: An experimental approach. Appl. Therm. Eng. 2014, 67, 24–34. [Google Scholar] [CrossRef]

- Muraleedharan, M.; Nadir, Y. Geopolymer mortar integrated with phase change materials for improvement of thermal efficiency in buildings: A review. Mater. Today Proc. 2020, 44, 878–885. [Google Scholar] [CrossRef]

- Chou, H.-M.; Chen, C.-R.; Nguyen, V.-L. A new design of metal-sheet cool roof using PCM. Energy Build. 2013, 57, 42–50. [Google Scholar] [CrossRef]

- Amaral, C.; Pinto, S.C.; Silva, T.; Mohseni, F.; Amaral, J.S.; Amaral, V.S.; Marques, P.A.A.P.; Barros-Timmons, A.; Vicente, R. Development of polyurethane foam incorporating phase change material for thermal energy storage. J. Energy Storage 2020, 28, 101177. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F. Literature review on the use of phase change materials in glazing and shading solutions. Renew. Sustain. Energy Rev. 2016, 53, 515–535. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.B.; Tadeu, A. Thermal performance and cost analysis of mortars made with PCM and different binders. Constr. Build. Mater. 2016, 122, 637–648. [Google Scholar] [CrossRef]

- Cunha, S.; Leite, P.; Aguiar, J. Characterization of innovative mortars with direct incorporation of phase change materials. J. Energy Storage 2020, 30, 101439. [Google Scholar] [CrossRef]

- Kheradmand, M.; Azenha, M.; de Aguiar, J.L.B.; Castro-Gomes, J. Experimental and numerical studies of hybrid PCM embedded in plastering mortar for enhanced thermal behaviour of buildings. Energy 2016, 94, 250–261. [Google Scholar] [CrossRef] [Green Version]

- Lucas, S.S.; Ferreira, V.M.; de Aguiar, J.L.B. Latent heat storage in PCM containing mortars—Study of microstructural modifications. Energy Build. 2013, 66, 724–731. [Google Scholar] [CrossRef] [Green Version]

- Kheradmand, M.; Azenha, M.; de Aguiar, J.L.B.; Krakowiak, K.J. Thermal behavior of cement based plastering mortar containing hybrid microencapsulated phase change materials. Energy Build. 2014, 84, 526–536. [Google Scholar] [CrossRef]

- Rebelo, F.; Corredera, A.; Andrés, M.; Vicente, R.; Morentin, F.; Ferreira, V.M.; Bujedo, L.A. Análisis del efecto de materiales de cambio de fase sobre la demanda de calefacción en una casa fotovoltaica. In CIES2020-XVII Congresso Ibérico e XIII Congresso Ibero-Americano de Energia Solar; LNEG-Laboratório Nacional de Energia e Geología: Lisbon, Portugal, 2020; pp. 761–768. [Google Scholar]

- Mordor Intelligence. European Prefabricated Buildings Market—Growth, Trends, COVID-19 Impact, and Forecasts (2022–2027). Available online: https://www.mordorintelligence.com/industry-reports/european-prefabricated-buildings-industry-study (accessed on 12 December 2021).

- ReportLinker. Prefabricated Building Market in Europe—Industry Outlook and Forecast (2021–2026). Available online: https://www.reportlinker.com/p06063356/Prefabricated-Building-Market-in-Europe-Industry-Outlook-and-Forecast.html?utm_source=GNW (accessed on 12 December 2021).

- Roland Berger. Prefabricated Housing Market in Central and Northern Europe—Overview of Market Trends and Development. Available online: https://www.rolandberger.com/en/Insights/Publications/Prefabricated-housing-market.html (accessed on 12 December 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).