High-Q TeO2–Si Hybrid Microring Resonators

Abstract

:1. Introduction

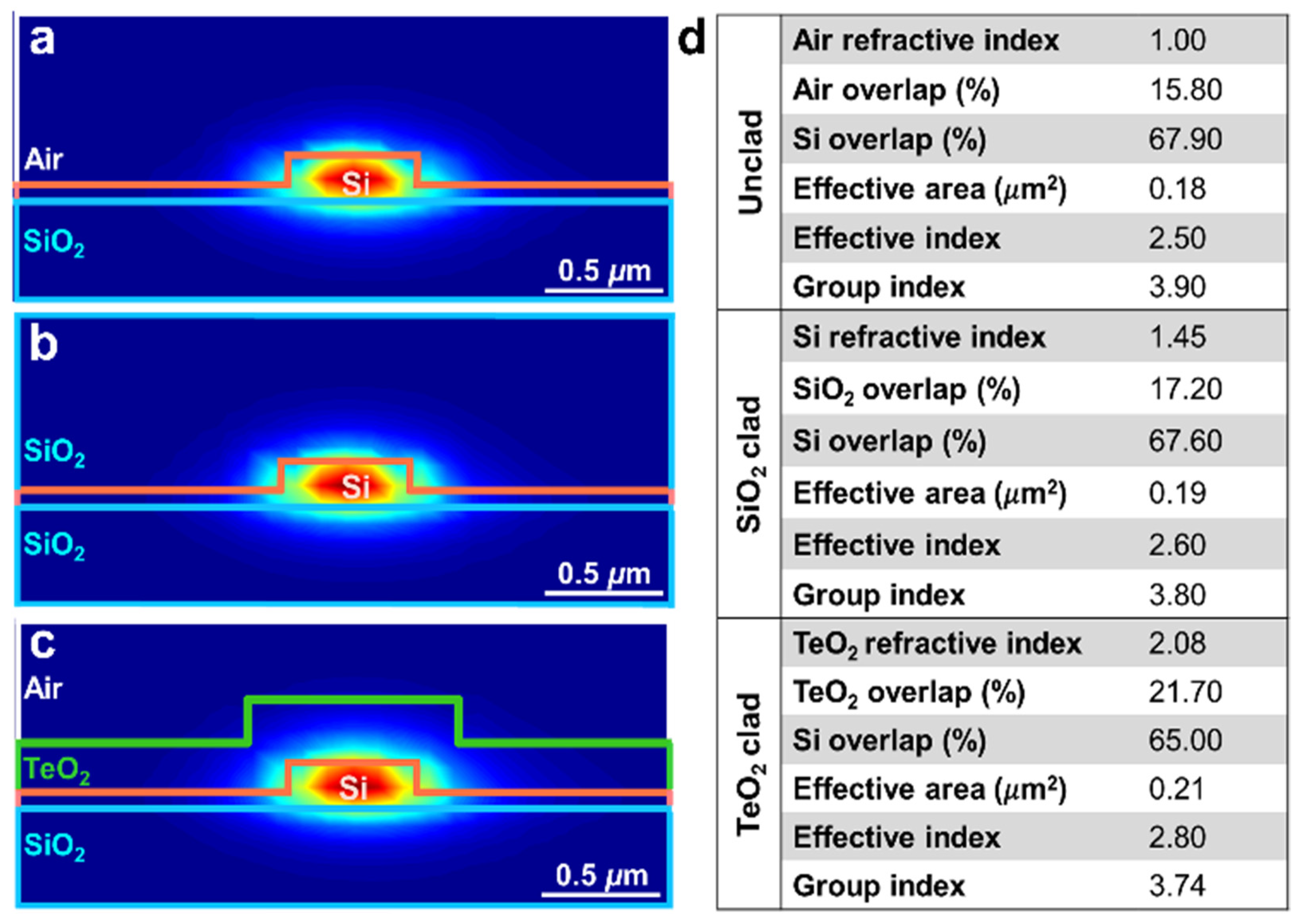

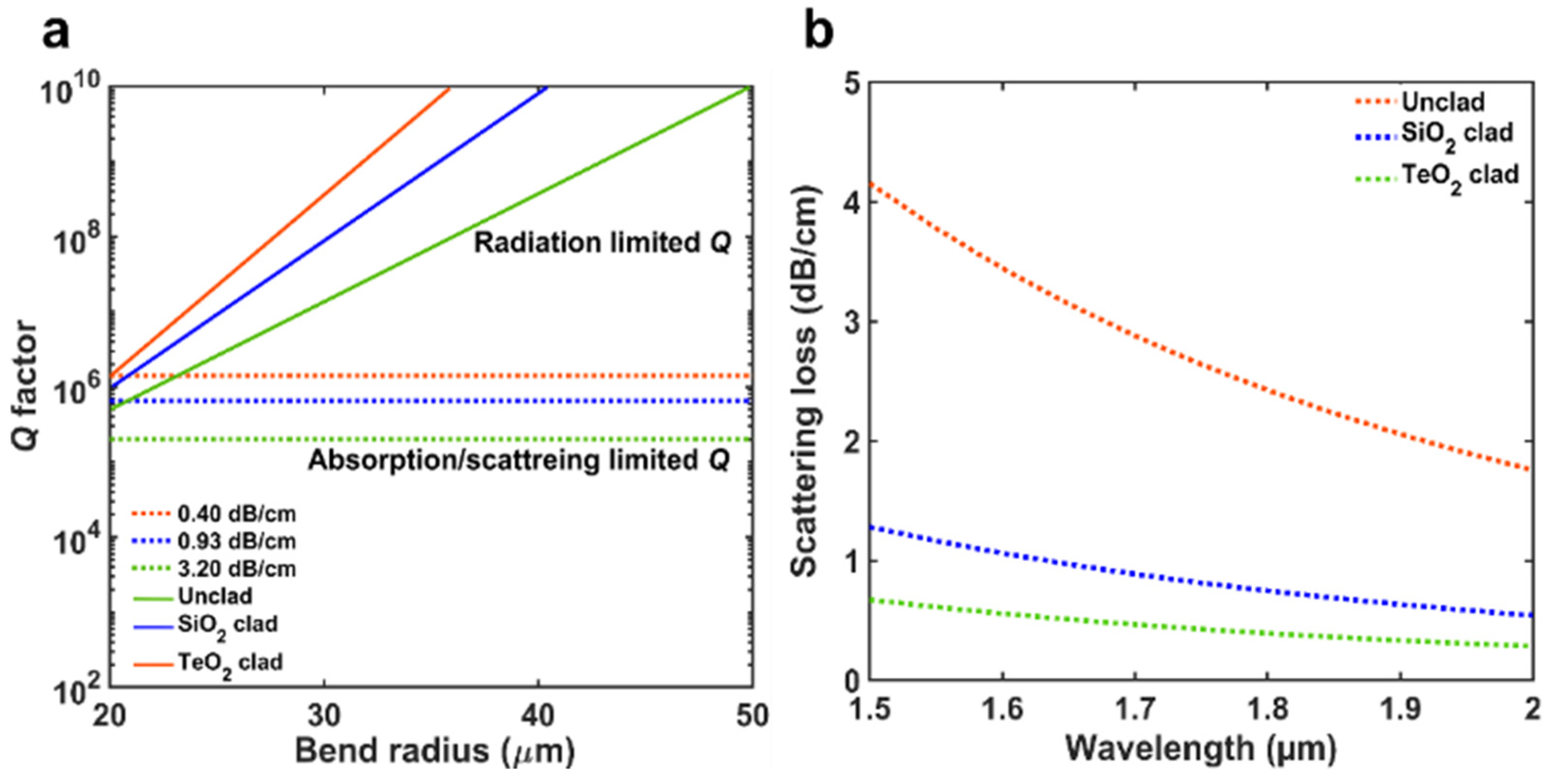

2. Microring Resonator Fabrication and Design

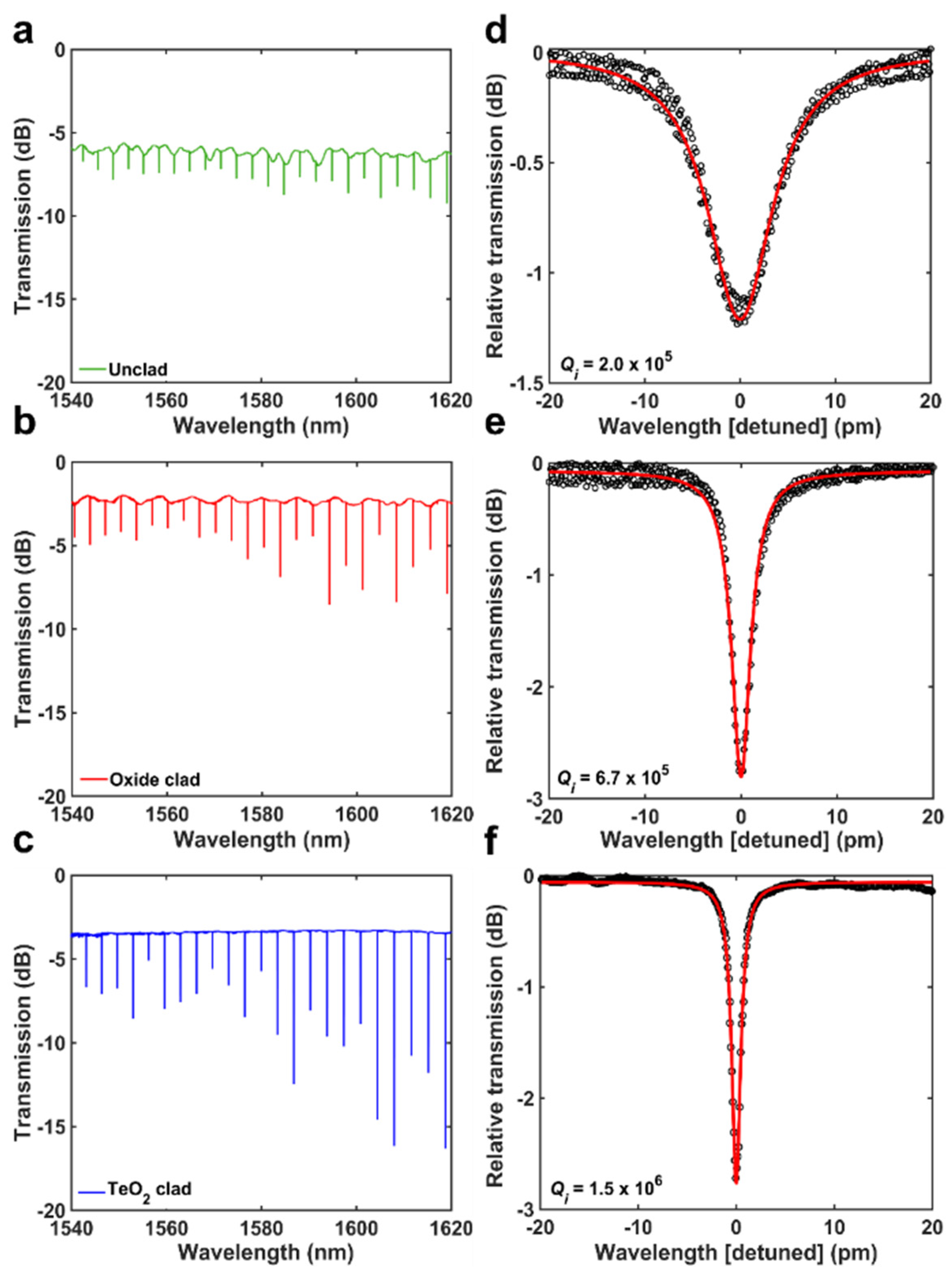

3. Microring Resonator Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomson, D.; Zilkie, A.; Bowers, J.E.; Komljenovic, T.; Reed, G.T.; Vivien, L.; Marris-Morini, D.; Cassan, E.; Virot, L.; Fédéli, J.-M.; et al. Roadmap on silicon photonics. J. Opt. 2016, 18, 073003. [Google Scholar] [CrossRef]

- Baets, R.; Subramanian, A.Z.; Clemmen, S.; Kuyken, B.; Bienstman, P.; Le Thomas, N.; Roelkens, G.N.; Van Thourhout, D.; Helin, P.; Severi, S. Silicon Photonics: Silicon nitride versus silicon-on-insulator. In Proceedings of the Optical Fiber Communications Conference and Exhibition, Anaheim, CA, USA, 20–22 March 2016. [Google Scholar]

- Watts, M.R.; Shaw, M.J.; Nielson, G.N. Optical Resonators: Microphotonic Thermal Imaging. Nat. Photonics 2007, 1, 632. [Google Scholar] [CrossRef]

- Tran, M.A.; Huang, D.; Komljenovic, T.; Peters, J.; Malik, A.; Bowers, J.E. Ultra-Low-Loss Silicon Waveguides for Heterogeneously Integrated Silicon/III-V Photonics. Appl. Sci. 2018, 8, 1139. [Google Scholar] [CrossRef] [Green Version]

- Xiang, C.; Jin, W.; Guo, J.; Williams, C.; Netherton, A.M.; Chang, L.; Morton, P.A.; Bowers, J.E. Effects of nonlinear loss in high-Q Si ring resonators for narrow-linewidth III-V/Si heterogeneously integrated tunable lasers. Opt. Express 2020, 28, 19926–19936. [Google Scholar] [CrossRef] [PubMed]

- Biberman, A.; Bergman, K. Optical interconnection networks for high performance computing system. Rep. Prog. Phys. 2012, 75, 046402. [Google Scholar] [CrossRef]

- Xiao, S.; Khan, M.H.; Shen, H.; Qi, M. Multiple-channel silicon micro-resonator-based filters for WDM applications. Opt. Express 2007, 15, 7489–7498. [Google Scholar] [CrossRef] [PubMed]

- Salih Magden, E.; Li, N.; Purnawirman; Bradley, J.D.B.; Singh, N.; Ruocco, A.; Petrich, G.S.; Leake, G.; Coolbaugh, D.D.; Ippen, E.P.; et al. Monolithically-integrated distributed feedback laser compatible with CMOS processing. Opt. Express 2017, 25, 18058–18065. [Google Scholar] [CrossRef] [PubMed]

- Stern, B.; Ji, X.; Dutt, A.; Lipson, M. Compact narrow-linewidth integrated laser based on a low-loss silicon nitride ring resonator. Opt. Lett. 2017, 42, 4541–4544. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Fan, X. Optical ring resonators for biochemical and chemical sensing. Analytical and Bioanalytical Chemistry. Anal. Bioanal. Chem. 2011, 399, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Ji, M.; Cai, H.; Deng, L.; Huang, Y.; Huang, Q.; Xia, J.; Li, Z.; Yu, J.; Wang, Y. Enhanced parametric frequency conversion in a compact silicon-graphene microring resonator. Opt. Express 2015, 23, 18679–18685. [Google Scholar] [CrossRef] [PubMed]

- Miarabbas Kiani, K.; Mbonde, H.M.; Frankis, H.C.; Mateman, R.; Leinse, A.; Knights, A.P.; Bradley, J.D.B. Four-wave mixing in high-Q tellurium-oxide-coated silicon nitride microring resonators. OSA Contin. 2020, 3, 3497–3507. [Google Scholar] [CrossRef]

- Grassani, D.; Azzini, S.; Liscidini, M.; Galli, M.; Strain, M.J.; Sorel, M.; Sipe, J.E.; Bajoni, D. Micrometer-scale integrated silicon source of time-energy entangled photons. Optica 2015, 2, 88–94. [Google Scholar] [CrossRef] [Green Version]

- La Notte, M.; Troia, B.; Muciaccia, T.; Campanella, C.E.; De Leonardis, F.; Passaro, V.M. Recent advances in gas and chemical detection by Vernier effect-based photonic sensors. Sensors 2014, 14, 4831–4855. [Google Scholar] [CrossRef] [PubMed]

- Rabus, D.G.; Hamacher, M.; Troppenz, U.; Heidrich, H. Optical filters based on ring resonators with integrated semiconductor optical amplifiers in GaInAsP-InP. IEEE. J. Sel. Top. Quant. 2002, 8, 1405–1411. [Google Scholar] [CrossRef]

- Dubray, O.; Seyedi, M.A.; Chen, C.H.; Charbonnier, B.; Descos, A.; Fiorentino, M.; Beausoleil, R.G.; Menezo, S. 30 Gbit/s PAM-4 transmission by modulating a dual silicon ring resonator modulator. In Proceedings of the Optical Interconnects Conference, San Diego, CA, USA, 9–11 May 2016. [Google Scholar]

- Luo, L.; Wiederhecker, G.S.; Cardenas, J.; Poitras, C.; Lipson, M. High quality factor etchless silicon photonic ring resonators. Opt. Express 2011, 19, 6284–6289. [Google Scholar] [CrossRef] [PubMed]

- Griffith, A.; Cardenas, J.; Poitras, C.B.; Lipson, M. High quality factor and high confinement silicon resonators using etchless process. Opt. Express 2012, 20, 21341–21345. [Google Scholar] [CrossRef] [PubMed]

- Dong, P.; Qian, W.; Liao, S.; Liang, H.; Kung, C.; Feng, N.; Shafiiha, R.; Fong, J.; Feng, D.; Krishnamoorthy, A.V.; et al. Low loss shallow-ridge silicon waveguides. Opt. Express 2010, 18, 14474–14479. [Google Scholar] [CrossRef] [PubMed]

- Guill, M.A.; Caverley, M.; Cretu, E.; Jaeger, N.A.F.; Chrostowski, L. Large-Area, High- Q SOI Ring Resonators. IEEE Photon. Conf. IPC 2014, 4, 336–337. [Google Scholar]

- Burla, M.; Crockett, B.; Chrostowski, L.; Azaña, J. Ultra-high Q multimode waveguide ring resonators for microwave photonics signal processing. In Proceedings of the International Topical Meeting on Microwave Photonics, Paphos, Cyprus, 26–29 October 2015. [Google Scholar]

- Zhang, Y.; Hu, X.; Chen, D.; Wang, L.; Li, M.; Feng, P.; Xiao, X.; Yu, S. Design and demonstration of ultra-high-Q silicon microring resonator based on a multi-mode ridge waveguide. Opt. Lett. 2018, 43, 1586–1589. [Google Scholar]

- Zhang, L.; Jie, L.; Zhang, M.; Wang, Y.; Xie, Y.; Shi, Y.; Dai, D. Ultrahigh-Q silicon racetrack resonators. Photon. Res. 2020, 8, 684–689. [Google Scholar] [CrossRef]

- Biberman, A.; Shaw, M.J.; Timurdogan, E.; Wright, J.B.; Watts, M.R. Ultralow-loss silicon ring resonators. Opt. Lett. 2012, 37, 4236–4238. [Google Scholar] [CrossRef] [PubMed]

- Nezhad, M.P.; Bondarenko, O.; Khajavikhan, M.; Simic, A.; Fainman, Y. Etch-free low loss silicon waveguides using hydrogen silsesquioxane oxidation masks. Opt. Express 2011, 19, 18827–18832. [Google Scholar] [CrossRef] [PubMed]

- Bellegarde, C.; Pargon, E.; Sciancalepore, C.; Petit-Etienne, C.; Hugues, V.; Robin-Brosse, D.; Hartmann, J.; Lyan, P. Improvement of Sidewall Roughness of Submicron SOI Waveguides by Hydrogen Plasma and Annealing. IEEE Photon. Technol. Lett. 2018, 30, 591–594. [Google Scholar] [CrossRef]

- Horikawa, T.; Shimura, D.; Mogami, T. Low-loss silicon wire waveguides for optical integrated circuits. MRS Commun. 2016, 6, 9–15. [Google Scholar] [CrossRef]

- Frankis, H.C.; Miarabbas Kiani, K.; Bonneville, D.B.; Zhang, C.; Norris, S.; Mateman, R.; Leinse, A.; Bassim, N.D.; Knights, A.P.; Bradley, J.D.B. Low-loss TeO2-coated Si3N4 waveguides for application in photonic integrated circuits. Opt. Express 2019, 27, 12529–12540. [Google Scholar] [CrossRef]

- Miarabbas Kiani, K.; Frankis, H.C.; Mbonde, H.M.; Mateman, R.; Leinse, A.; Knights, A.P.; Bradley, J.D.B. Thulium-doped tellurium oxide waveguide amplifier with 7.6 dB net gain on a silicon nitride chip. Opt. Lett. 2019, 44, 5788–5791. [Google Scholar] [CrossRef]

- Miarabbas Kiani, K.; Frankis, H.C.; Mateman, R.; Leinse, A.; Knights, A.P.; Bradley, J.D.B. Thulium-doped tellurium oxide microring lasers integrated on a low-loss silicon nitride platform. Opt. Mater. Express 2021, 11, 3656–3665. [Google Scholar] [CrossRef]

- Jha, A.; Richards, B.; Jose, G.; Teddy-Fernandez, T.; Joshi, P.; Jiang, X.; Lousteau, J. Rare-earth ion doped TeO2 and GeO2 glasses as laser materials. Prog. Mater. Sci. 2012, 57, 1426–1491. [Google Scholar] [CrossRef]

- Miarabbas Kiani, K.; Frankis, H.C.; Naraine, C.M.; Bonneville, D.B.; Knights, A.P.; Bradley, J.D.B. Lasing in a hybrid rare-earth silicon microdisk. Laser Photon. Rev. 2022, 16, 210034. [Google Scholar] [CrossRef]

- Preston, K.; Schmidt, B.; Lipson, M. Polysilicon photonic resonators for large-scale 3D integration of optical networks. Opt. Express 2013, 15, 17283–17290. [Google Scholar] [CrossRef]

- Payne, F.P.; Lacey, J.P.R. A theoretical analysis of scattering loss from planar optical waveguides. Opt. Quantum Electron. 1994, 26, 977–986. [Google Scholar] [CrossRef]

- Hagan, D.E.; Knights, A.P. Mechanisms for optical loss in SOI waveguides for mid-infrared wavelengths around 2 μm. J. Opt. 2017, 19, 025801. [Google Scholar] [CrossRef]

- Yap, K.P.; Delâge, A.; Lapointe, J.; Lamontagne, B.; Schmid, J.H.; Waldron, P.; Syrett, B.A.; Janz, S. Correlation of Scattering Loss, Sidewall Roughness and Waveguide Width in SiO2/Si Silicon-on-Insulator (SOI) Ridge Waveguides. J. Lightwave Technol. 2009, 27, 3999–4008. [Google Scholar]

- Shang, H.; Sun, D.; Yu, P.; Wang, B.; Yu, T.; Li, T.; Jiang, H. Investigation for Sidewall Roughness Caused Optical Scattering Loss of Silicon-on-Insulator Waveguides with Confocal Laser Scanning Microscopy. Coatings 2020, 10, 236. [Google Scholar] [CrossRef] [Green Version]

- Miller, J.W.; Chesaux, M.; Deligiannis, D.; Mascher, P.; Bradley, J.D.B. Low-loss GeO2 thin films deposited by ion-assisted alternating current reactive sputtering for waveguide applications. Thin Solid Films 2020, 709, 13816. [Google Scholar] [CrossRef]

| Cladding Material | Cladding Thickness (nm) | Film Loss @ 638 nm (dB/cm) | Film Loss @ 1550 nm (dB/cm) | Extinction Ratio (dB) | External Q Factor | Internal Q Factor | Propagation Loss (dB/cm) |

|---|---|---|---|---|---|---|---|

| Uncladded | ---- | ---- | ---- | 1.2 | 2.8 × 106 | 2.0 × 105 | 3.4 |

| SiO2 | 2000 | ---- | ---- | 2.8 | 4.2 × 106 | 6.7 × 105 | 0.97 |

| TeO2 | 270 | 0.5 ± 0.2 | 0.1 ± 0.1 | 2.8 | 9.0 × 106 | 1.5 × 106 | 0.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miarabbas Kiani, K.; Bonneville, D.B.; Knights, A.P.; Bradley, J.D.B. High-Q TeO2–Si Hybrid Microring Resonators. Appl. Sci. 2022, 12, 1363. https://doi.org/10.3390/app12031363

Miarabbas Kiani K, Bonneville DB, Knights AP, Bradley JDB. High-Q TeO2–Si Hybrid Microring Resonators. Applied Sciences. 2022; 12(3):1363. https://doi.org/10.3390/app12031363

Chicago/Turabian StyleMiarabbas Kiani, Khadijeh, Dawson B. Bonneville, Andrew P. Knights, and Jonathan D. B. Bradley. 2022. "High-Q TeO2–Si Hybrid Microring Resonators" Applied Sciences 12, no. 3: 1363. https://doi.org/10.3390/app12031363

APA StyleMiarabbas Kiani, K., Bonneville, D. B., Knights, A. P., & Bradley, J. D. B. (2022). High-Q TeO2–Si Hybrid Microring Resonators. Applied Sciences, 12(3), 1363. https://doi.org/10.3390/app12031363