Abstract

In line with the decarbonization of the domestic sector to meet the 2050 climate neutrality targets, this paper describes the energy, economic, and environmental analysis of a set of different novel configurations of polygeneration installations to provide electricity, air conditioning, domestic hot water, and desalinated water for a building of 80 dwellings. All arrangements were designed to cover 100% of the five demands required in the building with renewable energy only, from photovoltaic (PV) and photovoltaic-thermal (PVT) panels and biomass backup boilers (BB). Electricity can be sold to or purchased from the grid without electrical storage with batteries. Additional electricity generation with thermoelectric generators (TEG) coupled to the PVTs, and the BB was explicitly analyzed. The choice of electrically or thermally activated technologies (heat pump, HP/single-effect absorption chiller, SEAC for cooling and multi-effect distillation, MED/reverse osmosis, RO for desalination) created four configurations from the basic structure based on solar and biomass sources. Thus, the paper has studied four designs in detail and applied them to three case studies corresponding to different locations in Spain. They were modeled with TRNSYS and included specific models for desalination technologies. Both structures provide important energy and CO2 savings concerning the conventional supply of the building demands. The novel life-cycle analysis approach further increases the lifetime CO2 savings for all configurations as well. The electric option (the combination of HP and RO for cooling and desalting) was, by far, the most attractive solution in terms of liability and lower investment required in the three case studies.

1. Introduction

In Europe, buildings are responsible for 40% of energy consumption and 36% of CO2 emissions, and similar figures are reported in the United States [1]. The decarbonization of the building sector by 2050 is an ambitious objective requiring the implementation of energy transition strategies. To do so, the actions needed to perform that plan must be helped by regulatory changes and the support for investments in energy efficiency, especially for existing buildings, in which improvements are easier to reach since present references are relatively high in terms of energy consumption.

Since 2002, three progressive Directives on Energy Performance of Buildings have been approved (Directive 2002/91/CE [2], Directive 2010/31/EU [3], and Directive (EU) 2018/844 [4]). This has led to a gradual improvement in enclosures to reduce losses, which has been transposed into national regulations. Consequently, from 2020, all new residential, office, and service buildings are expected to be nearly zero-energy buildings. In the next few years, new rules will try to account for many new and existing decarbonized buildings by the year 2050. A new directive is currently being drafted, which would limit the use of fossil fuels for community heating and promote high-efficiency heat pumps. A new energy rating for buildings is to be upgraded in quality in each country depending on the age of the building.

To reduce final energy consumption, it is evident that improving the thermal envelope could lead to significant cuts in demand. It could also lead to better thermal comfort [5]. Note that around 50% of the primary energy demands in buildings are linked to heating, ventilation, and air conditioning. Building energy codes (BECs) have been one of the keys in reducing buildings’ energy consumption. Unfortunately, their effectiveness is based on their mandatory and enforced nature [6]. This can be shown in comparative studies of BECs in neighboring countries with similar climate conditions [7,8].

On the other hand, energy demands have to be served more sustainably. A sustainable and safe solution for a building is a polygeneration scheme that simultaneously produces electricity, heating, cooling, and freshwater (partly converted into domestic hot water) from a single or several primary resources. Polygeneration schemes have been used in industry, in many cases with products other than those described above, and not always using only renewable energy sources [9,10]. Several studies on providing electricity, freshwater, and heating and cooling for diverse uses have recently presented sustainable solutions in isolated and/or rural areas [11,12,13,14,15,16,17,18], coming from solar and biomass resources. In the case of these four basic demands for a building, the number of scientific references is already somewhat smaller according to our state-of-the-art review [19,20,21,22,23,24]. In all cases, simulations are carried out, including the optimization of their design, their energy, environmental, and economic analysis, and their sensitivity to the externalities of the proposed plant. Still, there are no experimental studies analyzing the feasibility of this integrated approach, given its complexity and the significant investment required.

A polygeneration scheme mainly based on RES heat-producing technologies, such as PVTs and biomass boilers, is a natural solution since these are the only available renewable sources in a water-scarce area near the coast. Anyway, at the tail of the scheme, different options to produce cooling and desalinated water should be checked to find the best integration. In other words, consuming heat or electricity will lead to different designs for the same purpose. In most of the previously analyzed papers, only a configuration has been performed for a case study. Therefore, the main novelty of this paper is the analysis of different structures of a polygeneration scheme based on renewable energies, essentially thermal, to cover the five typical demands of a building of 80 dwellings. The building already has a good energy standard in its envelope, so the integrated production scheme generates the minimum energy demand for its occupants. The additional electricity contribution of the TEGs to the system has also been analyzed as a novelty in the proposed schemes.

Three case studies in Spain have been conducted to compare four configurations for the same building type. Every combination will differ, using HP or SEAC for cooling and RO or MED for desalination. In all, 100% coverage of electricity (in annual net balance), heating, cooling, cold, cold water, and domestic hot water are pursued. Energy analysis is based on primary energy saving (PESR). Environmental benefits were estimated by comparing the CO2 emitted by the integrated scheme proposed along its life cycle following an LCA approach, that is, also including the impact on the materials, transport, and end-life of the analyzed installation, apart from the operational phase. This approach also constitutes a novelty since, to our knowledge, it is the first time that it has been applied to a polygeneration scheme. Economic analysis uses the simple payback period (SPB), net present value (NPV), and internal rate of return (IRR) of the investment required, as well as the levelised costs of any of the five covered demands (LCOx).

2. Materials and Methods

This research combines different software to carry out the study. Design Builder was used to estimate the building demands. EES was taken to model some devices that were not available in TRNSYS. The former was the core for simulations of the proposed four polygeneration arrangements. Excel has been used to analyze the performance of each design based on the monthly results obtained from TRNSYS. Finally, SimaPro was required to perform the environmental assessment of the four schemes along their life cycle. A sequential process has been followed to find the results; thus, any modification must be carefully attended.

2.1. Building Demands

The building type was located in Spain, a country characterized by its mild climate and water scarcity. The choice of the typical residential building in Spain has been based on data collected from the Population and Housing Census [25]. It corresponds to the average surface of new real estate developments in the expansion areas of medium and large cities. Their main geometric characteristics are detailed in Table 1.

Table 1.

Geometric characteristics of the building type considered.

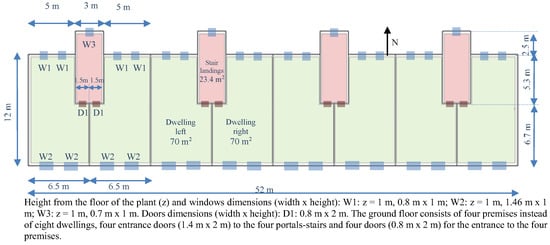

The following figures include a 3D view (Figure 1) and floor plans (Figure 2) of the building type considered. The floor plan of the building corresponds to a simple layout with landings every two floors and carpentry oriented to the north and south for all the dwellings.

Figure 1.

3D view of the building type’s south façade (left) and north façade (right).

Figure 2.

Typical floor plan of the building type. Source: [26].

As this article focuses on an integrated energy and water supply solution for the demands, it is assumed that the building meets the best energy efficiency standards. The amendments introduced with Directive 2010/31/EU [3] led to an update of the Basic Document HE on Energy Saving of the Technical Building Code in 2013 [27], which has to be applied to the buildings in the period 2014–2019. Finally, this document was updated again in 2019 [28] to include the new requirements of Directive (EU) 2018/844 [4].

The Spanish regulation included in the Basic Document HE on Energy Saving of the Technical Building Code [27] establishes 15 climate zones classified according to their winter (5, from A to E) and summer (4, from 1 to 4) climate severities. They are ranked from each zone’s degree days and solar radiation. Three cities were selected for the analysis. Two correspond to a specific location in the Mediterranean area, with different heating and cooling demands and water scarcity. The third one is an inland location with a higher climate severity but not a freshwater shortage, despite being an arid area. They were then coded as A4 (Almeria), B3 (Valencia), and D3 (Zaragoza). Table 2 shows a description of the leading climate conditions of these localities.

Table 2.

Description of the main climate conditions of the selected cities. Source: [28,29,30].

Detailed calculations on the building demands are shown in Appendix A. Table 3 presents the annual demands based on the hourly estimates following the methodology presented in Annex A. Unitary consumptions per dwelling and year are also included in the table.

Table 3.

Annual energy and water consumption for the same building in the three selected cities.

2.2. System Layouts

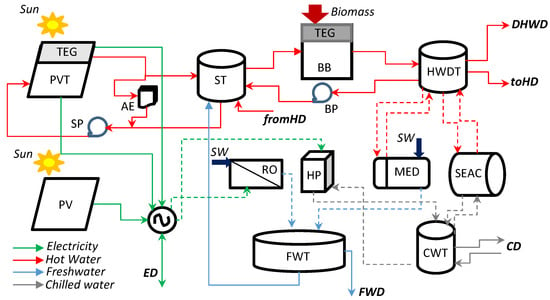

The main integrated scheme starts with a solar loop consisting of PVTs, a storage tank (ST), and a heat sink to avoid overheating (AE). Additional electricity generation to cover the demands of the building is provided by a PV field and supported by the installation of TEGs on 50% of the solar aperture of the resulting PVT field. The facility will have the corresponding inverter according to the absolute power, buying and selling energy to the grid depending on the demand (ED) and instantaneous production.

The DHW demand is covered by a mixture of the secondary tank (HWDT) and cold freshwater to serve the required flow rate at 45 °C. The heating demand (HD) is covered in the same way as DHW, but in this case, it is done at 35 °C and returned at 25 °C, considering there is underfloor heating in the building.

The fundamental difference between the configurations analyzed for the three sites with the same base building is the production of cooling and desalinated water. They may require either heat, which will come from the secondary tank, or electricity. For cooling (CD), a single-effect lithium bromide absorption cycle (SEAC) or a high-efficiency heat pump (HP) connected to an aquifer with a stable temperature (15 °C) can be chosen. A membrane technique (RO) or distillation (MED) is proposed for seawater desalination. The biomass boiler (BB) allows the secondary tank to maintain a setpoint temperature according to the cooling and desalinated water demands since they operate at the highest temperatures. TEGs were also incorporated at its top to produce more electricity for the system.

Finally, a 50 m3 tank (FWT) has been foreseen to regulate desalinated water production concerning consumption (FWD). The selected cooling technology has a third storage tank to avoid system start-ups and shutdowns while meeting demand.

Thus, the four combinations analyzed for the polygeneration system differ in selecting technology for cooling and desalination (whose flows are marked as dashed lines in Figure 3 depending on the chosen technology), as shown in the attached Table 4. In any case, the final design of each option will be different in terms of the number of PV/PVTs, biomass boiler power, HP/SEAC capacity, and size of the hot and cold water storage tanks. Moreover, the setpoints of the boiler and start-up of the thermally activated technologies (MED, SEAC) may differ slightly depending on the overall integration scheme.

Figure 3.

The general layout of the polygeneration schemes to serve the building demands.

Table 4.

Configurations analyzed in the polygeneration scheme.

2.3. System Model

The configurations have been modeled in TRNSYSv18, using its types whenever possible. There are two unusual situations in this regard: The first is that the regression models available for the HP and SEAC types have been used to adapt the capacities required in the installation with variable load performances. The second is that there is no specific type for this technology in the case of desalination. Consequently, complex models were first developed in the EES software for RO and MED. However, given the slowness of calculation observed when integrating both software, a simplified version of each technology has been incorporated into the TRNSYS scheme through a new DHW demand and its return or additional electricity consumption but with fixed performance parameters (see the next table). In the case of TEGs, a simple EES model was carried out and then immersed in the PVTs and the BB types as other equations to estimate the power generation.

The following Table 5 summarizes the essential information of the components included in the analyzed configurations. If no parameter number is given, it will depend on the end design of each composition (Var.). Auxiliary types for integrating variables and graphical representation have not been included for simplicity.

Table 5.

Summary of main components of the TRNSYS installation.

The simulation was performed for the entire annual period in the four configurations and three locations, with a time step of 5 min. Several key performance indicators (KPI) have been used from the annual results with TRNSYS to evaluate the best alternative comprehensively. They will be presented next.

2.4. Energy Analysis

The energy KPI selected is the primary energy saving ratio (PESR). It compares the energy performance of the proposed system (PS) through a comparison with a suitable reference system (RS). The PS solely considers the demand unattended by electricity from the grid, because, in all cases, the demand for air conditioning and water is served at 100%. The RS supposes all demands are produced by conventional technologies based on fossil fuels and appropriate conversion efficiencies (see Table 6 for details). The PES and its ratio (PESR) are calculated as shown in Equations (1) and (2):

where PES is the primary energy saving, and PERS and PEPS are, respectively, the energy consumption in the reference and proposed system. ED is the electricity demand of the building, QSH, QDHW, and QCL are the building’s space heating, domestic hot water, and cooling demands, and WD is its freshwater demand. Regarding the technical parameters, ηE is the electric efficiency of the Spanish grid system, and ηQ is the thermal efficiency of the auxiliary boiler. For the reference system, COPR is the coefficient of performance of the cooling system, and SECR is the specific energy consumption of the desalting system. EFG is the electricity demand of the building taken from the grid.

Table 6.

Main economic and environmental parameters of the study.

2.5. Economic Analysis

The simple payback (SPB) has been selected first in this section. It is calculated as the ratio of the total capital cost and the savings achieved by PS concerning RS. In particular, 25 years of a lifetime is considered.

In Equations (5) and (6), SPB is the simple payback of the investment, TIPS is the total investment in the proposed system, ASPS is the annual saving in the proposed system, and OCRS and OCPS are the operating cost in the reference system and proposed system, respectively.

The yearly economic saving of the proposed system takes into account the economic gains concerning the reference system. In RS, electricity is provided only by the national grid. On the other hand, in PS, the electric user load is matched by the PV, PVT, and TEG in an overall yearly balance, but sometimes the electricity is supplied by the grid. Moreover, different prices are found when electricity is purchased or sold to the grid. A fee for natural gas, biomass pellets (assuming a fixed low heating value, LHV), and water from the grid is also necessary to establish the annual cost of the reference facility to compare with the proposal (see Table 6). The yearly operating costs (OC) also include a percentage of the investment required for each central technology as a maintenance cost. These investment and installation costs for each technology have been taken from the bibliography of similar studies and are also compiled in Table 6.

The right side of Equation (7) includes the investment costs of all the devices composing the system: PV field, PVT field, inverters, solar, demand hot water and cooling water tanks, solar and boiler pumps, biomass boiler, selected cooling technology (HP or SEAC), and chosen desalination technology (RO or MED). To focus on the comparative analysis of alternative production systems, the cost of the distribution system to the dwellings is not included, nor is the assembly of the central drive system itself. In Equations (8) and (9), to provide the operating costs of the compared alternatives, the terms pE,p, pNG, and pW are the purchase cost of electricity, natural gas, and water from their respective grids. On the other hand, pE,s is the electricity price of surplus electricity, EB is the energy supplied by the biomass boiler, pE,b is the purchase energy cost of biomass pellets, and OMx are the operating and maintenance costs of the x technology.

As an additional economic indicator, the levelized costs of each demand (LCOx) have also been estimated. Taking into account that some driving technologies provide energy for several demands, heat (and even electricity) and distribution factors (fE,x and fQ,x) based on the electrical or thermal energy required for each need concerning the total produced by the system must first be estimated. As an example, the estimation of the LCOW is shown. Note that it is one of the most complex demands to assess at the tail end of the integrated system. The total cost, O&M, and energy required for the desalination plant also consider the upstream equipment’s fractional costs, with the distribution factors described above.

In Equation (10), CW is the total investment cost associated with water, OMW is the total cost for O&M associated with water, r is the rate of return, and EW is the total energy required for water, depending on the seawater desalting facility adopted.

Finally, the internal rate of return (IRR) and the net present value (NPV) of the investment have also been estimated as fundamental economic indicators.

2.6. Environmental Analysis during the Operational Phase

Similarly, the environmental analysis was first checked by using a KPI based on the calculation of the saving in CO2 emissions (ΔCO2) and its ratio (CO2R) as shown in Equation (11) to (12):

In these equations, the values of the CO2 produced in the reference and proposed systems (CO2,RS and CO2,PS) used the CO2 emission factor for electricity generation in Spain (fCO2,E), and the CO2 emission factor for heat provided by natural gas combustion (reference, fCO2,NG). These factors are also presented in Table 6.

2.7. Lifecycle Environmental Performance

The environmental KPI mentioned above does not consider the CO2 emissions along the life cycle of the installations proposed. Furthermore, their values are similar to those found with the PES, especially when CO2 factors for electricity and natural gas combustion are similar (that is the Spanish case).

Therefore, the life cycle assessment (LCA) of the proposed installations and the alternative reference to cover the building demands have been analyzed in detail. In this manner, the environmental impacts of the proposed solution are compared by considering the whole life cycle of the alternatives. That is, they included the impact associated with the construction and transport of the materials used in each technology as the end phase after the installation dismantle. Those impacts are added to the impact generated during its operation, which is usually the easiest to estimate (see the previous section), in order to give a more comprehensive vision of the environmental burdens. Despite its complexity, this method is being progressively introduced in the thorough analysis of experimental solutions based on RES for this purpose [45,46,47], but never for a polygeneration scheme providing five services.

The LCA requires the selection of a life cycle impact assessment method (LCIA) that evaluates, through diverse impact categories (in the mid- or end-point vision), which are grouped into three damage categories (human health, ecosystems, and resources depletion), the environmental impact of the resources supplied or consumed in the life cycle of the product analyzed. Thus, several steps are compulsory to carry out to perform this LCA. First, a functional unit must be defined, and the system limits must be clearly marked. Second, a complete inventory with the list of the materials used and resources consumed in the life-cycle time of the system has to be completed. Third, an LCIA method is usually selected from existing software. Finally, a critical analysis of the results found and further recommendations from the environmental penalties of the study are desirable, this being a non-mandatory phase after the previous ones.

The functional unit here is a rather complex issue. Considering that five demands are produced (heating, cooling, domestic hot water, electricity, and water), the functional unit is the installation itself, which makes 100% of the five demands throughout the year. In any case, it is possible, through the consideration of the equipment involved in the production, to assign an impact for each demand (in % of the total) and per unit of demand (kWh, or m3).

Regarding the life cycle inventory (LCI) of this study, since each option A, B, C, or D incorporates a different number of units of PV, PVT, etc., the inventory of materials and transportation, as well as their final destination, has been carried out for each of these units. In this way, it is easier to build the total inventory for the four alternatives in the LCA software SimaPro v9.0. As a general rule, the Ecoinvent database (EIDB [48]) has been used to compute the emissions generated by the various materials and other databases using European standards (ELCD [49]). The transport required for the equipment depends on the distance to the supplier. This value may vary if there is another data source for similar equipment in terms of performance. Concerning the end-of-life phase, the most conservative option of landfilling the entire facility has been chosen in line with other studies [45]. The following table shows the global inventory of the four alternatives, grouped by the different equipment involved in each configuration. It includes the data source to perform such a list for the various equipment. For each technology, the inventory of similar equipment from published studies or selected from internal databases has been taken as a basis and then extrapolated to its final capacity in each configuration (see Table 7). In the conventional case, only one natural gas boiler is included, and the impacts of electricity (low voltage, LV) and water will be taken from 1 kWh and 1 m3 obtained from the aforementioned databases.

Table 7.

Reference items to perform the LCI of the four options and the conventional supply.

When choosing an environmental impact assessment method and considering the previous KPI analysis with the CO2 savings in operation, we have opted for a simple but well-recognized LCIA method in the more generalist field, such as the IPCC 100-year GWP method that computes in kg of CO2 equivalent. It is a single-indicator method. In any case, the analysis of the installation has been considered for 25 years, after which all its components should be replaced.

3. Results

3.1. End Design for Each Option

Given the complexity of supplying five demands at 100%, the optimal configuration for each site (1–3) and technology selection (A–D) imply a different final design. Most of them correspond to the Var. values included in Table 5, which also contains the technical data of each technology. The following table summarizes the final design required for each case, the objective being to cover all demands at around 100%. However, in the case of electricity, this is done through an approximated annual net balance with the grid. For cooling, the buffer tank also prevents covering precisely 100% of the demand (see Table 8).

Table 8.

The final design for each proposed configuration (A-D) and site (1–3).

The comparative analysis by configuration and location of the results presented in the table above is summarised below.

- The solar field required for Zaragoza (3) is higher than Almería and Valencia (see annex A for details) to cover its higher electricity and DHW demand. Moreover, its heating demand is also higher due to its continental climate.

- A much larger solar field with PVT, a boiler, and hot water tanks is necessary when the desalination technology is the MED, and to a lesser extent, when the cold production comes through the SEAC. That is, options D and A require a higher dimension of the thermal supply side than the others.

- In that case, the share of PV and PVT is reduced for the first technology to complete the electricity demand.

- The PVT required in configuration A (HP and MED) is higher than the theoretical maximum one (configuration D) for each location. This is mainly due to the lower setpoint temperature of the BB, which was adjusted only to activate the MED.

- Rapidly following thermal demand sometimes forces a biomass boiler to upsize. However, the BB is a modulable device, and the equivalent number of operating hours may differ significantly for the same capacity. Especially in the spring and autumn periods where cooling is unnecessary, it is really underutilised.

- The heat demand required by the SEAC matches better with the solar resource in summer. Thus, its choice does not provoke a substantial increase in the final configuration (number of PVT panels) needed to cover the cooling demand.

- Heat-activated technologies provide better control to avoid overheating and, therefore, the use of the dissipative device (AE). When the option only requires low temperatures (case B) to cover the heating and DHW demands, the highest portion of exhausted heat was found when setting up 55 °C in the boiler.

- According to its technical characteristics, the response to cold demand is slower for the SEAC than for the HP. This means that higher capacities and associated CWT are required for the same purpose. Almeria (1) had the highest cooling capacity for both options due to its most demanding summer weather.

Regarding the impact of the electricity supplied by the TEGs, we must say that is almost irrelevant. First, it should be clarified that the capacity finally installed in each configuration (see the third block of Table 8) depends on the size of the PVT field and the boiler. In addition, the production in the boiler also depends on its operation. Experimental tests carried out by the authors [52] measured the low ΔT available in the PVTs, which is not enough to work with appreciable conversion efficiencies in this device. This means that TEG in PVTs is less than 0.5% of the total electricity generated by PV and PVT fields, respectively. In the case of BB, tests integrating TEGs [53] indicate that the hot temperature is maintained at 300 °C in its operation, and the cold side depends on the service temperature. Therefore, it is possible to obtain more electrical generation with better efficiencies (up to the 1% of the total demand, see the fourth block in Table 9). In any case, it is much less than the specific one of photovoltaic technologies. The following table shows the electrical generation fractions of each technology analyzed.

Table 9.

Gross electricity fraction obtained by each power technology.

3.2. Performance Analysis

Once the designs for each site and configuration have been presented, the results from the KPIs and the LCOx of each demand establish the best arrangement, with slight variations in the results according to the three sites analyzed. These results can be seen in the following Table 10.

Table 10.

Performance analysis of the proposed configurations for each site.

The analysis of the above table is detailed below, row by row.

- From the point of view of the PESR, all configurations yield similar data (0.64–0.68), and the remaining is due to the net electricity balance in periods of higher demand than production. Zaragoza has the best PESR due to its higher demands, followed by Valencia and, finally, Almería, with the lowest overall needs (see Table 3).

- A similar pattern was found with CO2 savings. All configurations and alternatives also show similar relative values to PESR. A higher value is found (0.72–0.78) since natural gas emission factors exceed the Spanish grid’s electricity factor (see Table 6).

In the economic analysis, the major findings are:

- The highest investment is found in option C, due to the largest solar field required and the SEAC cost. Option B requires the minimum investment. MED technology is, in general, expensive but used throughout the year.

- However, electrically activated technologies (HP and RO) have better energy performances. The use of thermal energy displacing PV to PVTs is penalized electrically. In addition, a high number of operating hours of the boiler are needed to maintain the required temperature for MED (throughout the year) and SEAC (in summer). This makes the cost of pellet supply the most significant component of expenditure in the polygeneration installation, thereby reducing the annual savings significantly.

- Thus, the highest annual savings was found with the B option (HP + RO), then option C is the second in this term (SEAC + RO), followed by A (HP + MED), and finally, D (SEAC + MED).

- Therefore, by combining investment and annual savings, the order found according to the feasibility of configurations (measured in terms of the SPB) is relatively straightforward: option B is the best option (HP + RO), followed by option C (SEAC + RO), option A (HP + MED), and finally, option D (SEAC + MED).

The analysis of internalized costs requires a particular study:

- Similar and attractive costs were found for electricity production in both configurations (less than 0.04 €/kWh), coming from the PV + PVT field.

- As heating and DHW demands take the heat from the same tank (DHWT), equal costs are found.

- Lower costs for heat are estimated if thermally activated technologies take part in the configuration. This is because heat infrastructure is divided into additional demands (MED and SEAC).

- Cooling provided by HP is cheaper (about one-third) than using the SEAC for the same purpose. This is explained by its respective COPs, despite the higher cost of electricity versus heat.

- The same was found for freshwater provided by RO against MED, taking into account the SEC values of both alternatives.

Anyway, the lower costs found in HD and DHW do not compensate for the remaining services, and B is globally the more profitable solution for the three buildings.

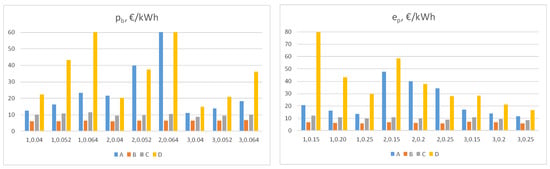

3.3. Sensitivity to Externalities

The above results for the base scenario take economic data on the prices of the demands served and the performance and costs of the equipment set by the (Spanish) regulations or taken from the scientific literature. But as expected, the effect of externalities on the polygeneration plant liability is significant, such as the purchase and sale prices of electricity, natural gas, and biomass. However, the interest rate was not found as a crucial parameter for the SPB. The following Figure 4 shows a sensitivity analysis of two selected parameters, which demonstrates the above. In any case, it must be remembered that in the annual savings section, the possible avoidance of CO2 has not been considered as income; therefore, in the current context of decarbonization, some details not considered in the study (O&M of some equipment piping, etc.) can be compensated in the applied economic balance.

Figure 4.

Sensitivity analysis of the proposed configurations for each site: SPB (years) as a function of the biomass pb (0.04, 0.052, 0.064) and electricity purchase ep prices (0.15, 0.20, 0.25) in €/kWh for the three locations (1–3) and four configurations (A–D).

3.4. Environmental Life-Cycle Analysis

The life-cycle analysis of the polygeneration facility has only been carried out due to the extensive complexity and as a comparative example to the results previously obtained in Table 10 with the main energy, economic, and environmental KPIs on site 2 (Valencia). Table 11 shows the more interesting results from the applied LCA, especially the associated emissions in the life cycle of the installation for each one of the five demands covered in the study.

Table 11.

Total emissions (in kgCO2eq) of the polygeneration scheme.

The results are overwhelming in terms of the minimal impact (1 to 10 approximately) of the four polygeneration schemes using renewable energies, even though by using a net electricity balance, it is necessary to take a significant amount of electricity from the grid, which computes the environmental impact in the same way as the conventional solution that uses the external supply of the demands. It is also worth noting the low contribution of the transport of the equipment and its dismantling after 25 years of operation.

With respect to the unit emissions obtained for each demand, it can be observed that it presents similar patterns to those obtained for the LCOx, in the sense that the MED technology has a more significant environmental impact within the integration, and the use of SEAC for the production of cold also concerning the use of HP. It is important to note that for the four schemes, the unit impact of kWh electricity is very similar and that producing heat has a lower impact than the rest of the demands, as it is the first source of secondary energy produced from the sun. In any case, the unit values are generally an order of magnitude lower than the emissions of the conventional alternative.

4. Discussion

The first consequence of this configurational analysis is the appropriate selection of the number of PVs or PVTs in the solar field to meet downstream demands. Although PVT technology has a higher overall performance than PV since it also produces heat simultaneously, it could not be the best solution. Suppose such heat serves a demand that can be generated with an electrical technology of lower equivalent consumption and lower investment cost. In that case, it does not justify the purely thermal integration for a polygeneration scheme, including desalinated water. This case is clearly shown in our comparative analysis A-D, when HP and RO are used to produce cooling and water with an electrical rather than thermal technology. This is especially the case when using MED to cover water demand, as it overstretches the required solar field too much compared with having RO as an alternative. The subject of SEAC is more compatible with the higher solar input in summer, and its effect concerning an HP is lower than in the case of desalination.

In any case, it is important to note that this four-option analysis arises from the selection of desalination and cooling technologies. Therefore, this optional analysis is meaningless outside the scope of an area with water scarcity and similar building cooling and heating demands.

At this point, it is worth remembering that this analysis focused on polygeneration with equipment that produces thermal energy, particularly those equipped with the possibility of integrating TEG devices within them to provide free electricity generation. Finally, it should be remarked that the TEG devices integrated with the PVTs and the BB do not represent a substantial additional advantage in electricity generation. They only contribute a mere 1.5% to the generation obtained with the PVs and PVTs, and they are a dispensable option in any proposed configuration.

This analysis covers three locations within Spain, which essentially influence the required air conditioning demands and the appropriate building standards to meet a similar energy efficiency (see annex). In any case, the values obtained for the KPIs are pretty similar for all three, with the choice of cooling and water technologies leaving the best integrations in terms of liability. The 100% RES solution (that is, not using an energy balance with the grid and using (or not using) energy storage systems, ESS) has not been included here for economic reasons. Still, the authors have also studied it for an isolated domestic dwelling [54,55]. In these analyses, the polygeneration configuration only includes PVT panels, the RO being the desalination technique but including the desiccant wheel (SDW) as the cooling system. In addition, the economy of scale criterion is met; the required configuration and its feasibility were worse than those obtained here, giving a more extensive installation and worse SPB.

The economic analysis started from an energy price scenario (the end of 2021 in Spain) that has changed significantly from then. With the current trend in the energy sector, it is true that it predicts an increase in biomass costs, which reduces the viability of this basic configuration (see Section 3.2). However, the rest of the parameters favor the schemes’ viability with respect to the values initially estimated in Table 6. These include the price of natural gas, the price of buying and selling electricity, as well as the unit investment costs of solar panels and biomass boilers. Suppose we also include as income the CO2 avoided (with data from the CO2 emissions trading market) with their alternative operation with respect to the supply from conventional grids. In that case, the results obtained can be considered clearly conservative. Therefore, this trend dramatically encourages the liability of those integrated schemes based on RES and efficient energy management. In short, the promising environmental and energy KPIs found in this preliminary assessment will undoubtedly be improved with the corresponding economic ones in the following years.

As for the reliability of the results, unfortunately, it is impossible for the authors to make any reasonable comparison with other references, given that the configurations analyzed do not coincide with the rest of the proposals. Moreover, as previously mentioned, the external input parameters significantly affect these values. Even in defining some parameters, the criteria applied are not precisely the same. Despite this limitation, we consider that given the complexity of the simulations performed, their reduced time step, and the verification of the internal temperature profiles of the scheme allow us to ensure that the results obtained have very reasonable reliability.

Finally, it is worth highlighting the contribution made by the novel life-cycle analysis applied to these polygeneration facilities, in the sense that its results further improve those obtained with the study of the operation in terms of CO2 avoided. It, therefore, reinforces the idea that distributed generation of services close to consumers is a more sustainable solution in the long term.

5. Conclusions

A 3E (energy, environmental, and economic) analysis was performed for a set of novel polygeneration configurations based on thermal technology (PVT, TEG, and biomass boiler, BB). Each arrangement could produce cold and desalinated water from heat or electricity, thus having four different polygeneration schemes based on solar and biomass energy. This analysis was tested for two similar sites on the Mediterranean coast in Spain and the same building site in a more continental climate. An LCA approach was also added to include the environmental penalties associated with the installation’s construction and end phase, apart from the CO2 saved in the operation phase with respect to a conventional supply based on external grids. The results found from the three analyzed case studies are presented next:

- The four schemes present good values for PESR and CO2R (around 0.65 and 0.75, respectively). These values are penalized by the constraint imposed here, which balances the generation and demand of electricity throughout the year, according to a better installation liability.

- The “electric” alternative (B) was the more economical option, i.e., the combination of PV + PVT + TEG + BB with HP and RO as the best integration. In this case, SPB of about six years was found to be much worse in the rest of the configurations.

- The levelised costs of the five demands provided by the polygeneration schemes are lower than the regular supply of commodities. The financial results are strongly dependent on the current prices of electricity and fuels; future trends will surely improve the economic KPIs of these schemes.

- The LCA approach gives even better results if the scheme is compared with the infrastructure required for the conventional supply based on external grids.

Further research centered on including new technologies or the benefits supplied by a well-designed ESS in these polygeneration RES-based schemes are pending issues that could contribute to the sustainable management of the urban sector.

Author Contributions

Conceptualization, methodology, J.U.; software, J.U., I.Z. and L.G.G.; validation, J.U., L.G.G. and A.M.-G.; formal analysis and data curation, I.Z. and A.M.-G.; writing—original draft preparation, J.U.; writing—review and editing, L.G.G.; visualization, S.U.; supervision, S.U.; project administration, S.U. and A.M.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Regional Development Funds (FEDER, UE) / Spanish Ministry of Science, Innovation and Universities (MCIU)–Spanish State Research Agency (AEI), grant number RTI2018-09886-A-100.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1 shows the different U-values for the elements of the thermal envelope based on the standard and three chosen climate zones.

Table A1.

Characteristic U-values (W/m2K) of the thermal envelope of buildings in each climate zone and the selected building standard. Source: own elaboration based on [27].

Table A1.

Characteristic U-values (W/m2K) of the thermal envelope of buildings in each climate zone and the selected building standard. Source: own elaboration based on [27].

| Element | U-Value |

|---|---|

| External wall | 1:0.50 2:0.38 3:0.27 |

| Roof | 1:0.47 2:0.33 3:0.22 |

| Party walls and horizontal/vertical internal partitions between zones with different uses | 1:1.25 2:1.10 3:0.85 |

| Horizontal internal partitions between zones with the same use | 1:1.80 2:1.55 3:1.20 |

| Vertical internal partitions between zones with the same use | 1:1.40 2:1.20 3:1.20 |

| Ground floor | 1:0.50 2:0.38 3:0.27 |

| South-facing windows without obstacles (high solar gain) considering the window-to-wall ratio of 15% | 1:2.60 2:2.10 3:1.80 |

| North-facing windows without obstacles (low solar gain) considering the window-to-wall ratio of 10% | 1:2.60 2:2.00 3:1.40 |

More information regarding infiltration, thermal bridges, and ventilation can be supplied to the readers upon request as supplementary information. The heating and cooling demands were estimated using a user profile. Here it follows the Spanish regulation [23] and consists of the following aspects:

Table A2.

Air-conditioning timetables and set points.

Table A2.

Air-conditioning timetables and set points.

| Period | Setpoint | Time | |

|---|---|---|---|

| Heating service | October to May | 20 °C 17 °C | 8:00–23:59 0:00–7:59 |

| Cooling service | June to September | 25 °C 27 °C None | 16:00–23:59 0:00–7:59 8:00–15:59 |

Design Builder was used as the energy simulation tool, considering the abovementioned characteristics and typical internal loads. Regarding the climate data, the SWEC (Spanish Weather for Energy Calculations) was considered according to the reference adopted in the technical code. This software also estimates electricity demand following recommendations [28] in the case of Valencia and Almería:

Table A3.

Internal loads to estimate the building demands.

Table A3.

Internal loads to estimate the building demands.

| Internal Load | Characteristics | Occupancy Rate (%) | Time |

|---|---|---|---|

| Metabolic rate | 117.21 W/person 0.03 people/m2 3.51 W/m2 61% sensitive, 39% latent | 100 25 50 100 | 0:00–7:59 8:00–15:59 16:00–23:59 Weekend and holidays |

| Equipment and lighting | Both 4.40 W/m2 90% sensitive*, 10% latent** *70% by convection, 30% by radiation **50% by convection, 30% Long-Wave Radiation (thermal), 20% Short-Wave Radiation (visible) | 10 30 50 100 | 1:00–7:59 8:00–18:59 19:00–19:59 20:00–23.59 |

In the case of Zaragoza, an alternative pattern based on existing Spanish regulation [56] for on-grid PV domestic installations was used to estimate the hourly electricity demand for every day of the year, also accounting for statistical data of the sector in Spain [57].

Freshwater and DHW hourly demands were calculated using a statistical study with measurements on domestic consumption carried out by the public water management company in Madrid [58]. Additionally, the average monthly temperature of tap water has been compiled from the Spanish regulation [28] to estimate the DHW demand.

References

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; Report; United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- European Union. Directive 2002/91/EC of the European Parliament and of the Council of 16 December 2002 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/ (accessed on 22 March 2022).

- European Union. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/ (accessed on 22 March 2022).

- European Union. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/ (accessed on 22 March 2022).

- Reis, I.F.G.; Figueiredo, A.; Samagaio, A. Modelling the evolution of construction solutions in residential buildings’ thermal comfort. Appl. Sci. 2021, 11, 2427. [Google Scholar] [CrossRef]

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Allard, I.; Nair, G.; Olofsson, T. Energy performance criteria for residential buildings: A comparison of Finnish, Norwegian, Swedish, and Russian building codes. Energy Build. 2021, 250, 111276. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Oliveira, M.; Rubio-Bellido, C.; Marín, D. A comparative analysis of the international regulation of thermal properties in building envelope. Sustainability 2019, 11, 5574. [Google Scholar] [CrossRef]

- Jana, K.; Ray, A.; Majoumerd, M.M.; Assadi, M.; De, S. Polygeneration as a future sustainable energy solution—A comprehensive review. Appl. Energy 2017, 202, 88–111. [Google Scholar] [CrossRef]

- Calise, F.; Notaristefani di Vastogirardi, G.; Dentice d’Accadia, M.; Vicidomini, M. Simulation of polygeneration systems. Energy 2018, 163, 290–337. [Google Scholar] [CrossRef]

- Luqman, M.; Al-Ansari, T. Thermodynamic analysis of an Energy-Water-Food (Ewf) nexus driven polygeneration system applied to coastal communities. Energy Convers. Manag. 2020, 205, 112432. [Google Scholar] [CrossRef]

- Kumar, P.; Rajagopal, S.; Coronas, A. Integrated polygeneration system for coastal áreas. Therm. Sci. Eng. Prog. 2020, 20, 100739. [Google Scholar]

- Ahmadi, P.; Dincer, I.; Rosen, M.A. Thermoeconomic multi-objective optimization of a novel biomass-based integrated energy system. Energy 2014, 68, 958–970. [Google Scholar] [CrossRef]

- Hogerwaard, J.; Dincer, I.; Naterer, G.F. Solar energy based integrated system for power generation, refrigeration and desalination. Appl. Therm. Eng. 2017, 121, 1059–1069. [Google Scholar] [CrossRef]

- Xi, Z.; Eshaghi, S.; Sardari, F. Energy, exergy, and exergoeconomic analysis of a polygeneration system driven by solar energy with a thermal energy storage tank for power, heating, and freshwater production. J. Energy Storage 2021, 36, 102429. [Google Scholar] [CrossRef]

- Jana, K.; De, S. Polygeneration for power, utility heat, desalination and refrigeration: Comparative performance evaluation for different biomass inputs. Mater. Today Proc. 2018, 5, 22908–22915. [Google Scholar] [CrossRef]

- Thomas, S.; Sahoo, S.S.; Ajithkumar, G.; Thomas, S.; Rout, A.; Mahapatra, S.K. Socio-economic and environmental analysis on solar thermal energy-based polygeneration system for rural livelihoods applications on an Island through interventions in the energy-water-food nexus. Energy Convers. Manag. 2022, 270, 116235. [Google Scholar] [CrossRef]

- Kumar, G.P.; Ayou, D.S.; Narendran, C.; Saravanan, R.; Maiya, M.P.; Coronas, A. Renewable heat powered polygeneration system based on an advanced absorption cycle for rural communities. Energy 2023, 262, 125300. [Google Scholar] [CrossRef]

- Rong, A.; Su, Y. Polygeneration systems in buildings: A survey on optimization approaches. Energy Build. 2017, 151, 439–454. [Google Scholar] [CrossRef]

- Calise, F.; Cipollina, A.; Dentice d’Accadia, M.; Piacentino, A. A novel renewable polygeneration system for a small Mediterranean volcanic island for the combined production of energy and water: Dynamic simulation and economic assessment. Appl. Energy 2014, 135, 675–693. [Google Scholar] [CrossRef]

- Calise, F.; Dentice d’Accadia, M.; Piacentino, A. Exergetic and exergoeconomic analysis of a renewable polygeneration system and viability study for small isolated communities. Energy 2015, 92, 290–307. [Google Scholar] [CrossRef]

- Calise, F.; Macaluso, A.; Piacentino, A.; Vanoli, L. A novel hybrid polygeneration system supplying energy and desalinated water by renewable sources in Pantelleria Island. Energy 2017, 137, 1086–1106. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Vicidomini, M.; Petrakopoulou-Robinson, F. Water-energy nexus: A thermoeconomic analysis of polygeneration systems for small Mediterranean islands. Energy Convers. Manag. 2020, 220, 113043. [Google Scholar] [CrossRef]

- Mouaky, A.; Rachek, A. Thermodynamic and thermo-economic assessment of a hybrid solar/biomass polygeneration system under the semi-arid climate conditions. Renew. Energy 2020, 156, 14–30. [Google Scholar] [CrossRef]

- Spanish National Institute of Statistics. Population and Housing Census. Available online: www.ine.es/censos2011_datos/cen11_datos_inicio.htm (accessed on 11 November 2021).

- Zabalza, I.; Gesteira, L.G.; Uche, J. The impact of building energy codes evolution on the residential thermal demand. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 588. [Google Scholar] [CrossRef]

- Spanish Ministry of Development. Order FOM/1635/2013, of September 10th, Which Updates the Basic Document DB-HE of Energy Saving of the Technical Building Code, Approved by Royal Decree 314/2006, of March 17th. BOE no. 219, 12/09/2013. Available online: https://www.boe.es/eli/es/ (accessed on 22 March 2022).

- Spanish Ministry of Development. Royal Decree 732/2019, of December 20th, Which Modifies the Technical Building Code, Approved by Royal Decree 314/2006, of March 17th. BOE no. 311, 27/12/2019. Available online: https://www.boe.es/diario_boe/ (accessed on 15 May 2022).

- State Meteorological Agency of Spain. Municipal Climate Data. Available online: http://www.aemet.es (accessed on 11 November 2021).

- Meteotest AG. Meteonorm 8. Handbook Part I: Software. Available online: https://meteonorm.com/assets/downloads/mn81_software.pdf (accessed on 11 November 2021).

- Calise, F.; Cappiello, F.L.; Dentice d’Accadia, M.; Petrakopoulou, F.; Vicidomini, M. A solar-driven 5th generation district heating and cooling network with ground-source heat pumps: A thermo-economic analysis. Sustain. Cities Soc. 2022, 76, 103438. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Dentice d’Accadia, M.; Vicidomini, M. Dynamic simulation, energy and economic comparison between BIPV and BIPVT collectors coupled with micro-wind turbines. Energy 2020, 191, 116439. [Google Scholar] [CrossRef]

- Calise, F.; d’Accadia, M.D.; Figaj, R.D.; Vanoli, L. A novel solar-assisted heat pump driven by photovoltaic/thermal collectors: Dynamic simulation and thermoeconomic optimization. Energy 2016, 95, 346–366. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; d’Accadia, M.D.; Vicidomini, M. A hybrid renewable system based on wind and solar energy coupled with an electrical storage: Dynamic simulation and economic assessment. Energy 2018, 155, 174–189. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Ferruzzi, G.; Vanoli, L. A novel renewable polygeneration system for hospital buildings: Design, simulation and thermo-economic optimization. Appl. Therm. Eng. 2014, 67, 43–60. [Google Scholar] [CrossRef]

- Instituto para la Diversificación y Ahorro de la Energía (IDAE). Renewable Energy Plan in Spain 2005–2010 (2005). Available online: https://www.idae.es (accessed on 31 March 2022).

- Pina, E.A.; Lozano, M.A.; Serra, L.M. Allocation of economic costs in trigeneration systems at variable load conditions including renewable energy sources and thermal energy storage. Energy 2018, 151, 633–646. [Google Scholar] [CrossRef]

- Mata-Torres, C.; Escobar, R.A.; Cardemil, J.M.; Simsek, Y.; Matute, J.A. Solar polygeneration for electricity production and desalination: Case studies in Venezuela and northern Chile. Renew. Energy 2017, 101, 387–398. [Google Scholar] [CrossRef]

- Esrafilian, M.; Ahmadi, R. Energy, environmental and economic assessment of a polygeneration system of local desalination and CCHP. Desalination 2019, 454, 20–37. [Google Scholar] [CrossRef]

- Uche, J.; Acevedo, L.; Círez, F.; Usón, S.; Martínez-Gracia, A.; Bayod-Rújula, Á.A. Analysis of a domestic trigeneration scheme with hybrid renewable energy sources and desalting techniques. J. Clean. Prod. 2019, 212, 1409–1422. [Google Scholar] [CrossRef]

- Red Eléctrica Española (REE). CO2 Emissions of Electricity Generation in Spain. 2021. Available online: https://api.esios.ree.es/documents/580/download?locale=es (accessed on 15 February 2022).

- Pinto, E.S.; Serra, L.M.; Lázaro, A. Optimization of the design of polygeneration systems for the residential sector under different self-consumption regulations. Int. J. Energy Res. 2020, 44, 11248–11273. [Google Scholar] [CrossRef]

- Spanish Ministry of Development. Updating of the Energy Saving Document DB-HE of the Technical Building Code. 2019. Available online: https://www.codigotecnico.org/pdf/Documentos/HE/DBHE.pdf (accessed on 1 October 2021).

- Instituto para la Diversificación y Ahorro de la Energía (IDAE). CO2 Emission Factors and Primary Energy Coefficients for Different Final Energy Sources Consumed in the Building Sector in Spain. 2014. Available online: https://energia.gob.es/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otros%20documentos/Factores_emision_CO2.pdf (accessed on 15 February 2022).

- Herrando, M.; Elduque, D.; Javierre, C.; Fueyo, N. Life cycle assessment of solar energy systems for the provision of heating, cooling and electricity in buildings: A comparative analysis. Energy Convers. Manag. 2022, 257, 115402. [Google Scholar] [CrossRef]

- Solano-Olivares, K.; Romero, R.J.; Santoyo, E.; Herrera, L.; Galindo-Luna, Y.R.; Rodríguez-Martínez, A.; Santoyo-Castelazo, E.; Cerezo, J. Life cycle assessment of solar absorption air-conditioning system. J. Clean. Prod. 2019, 240, 118206. [Google Scholar] [CrossRef]

- Lozano, J.A.; López, R.; Palomar, J.M.; Rey, F.J. Comparative study of heat pump system of biomass boiler system to a tertiary building using the Life Cycle Assessment (LCA). Renew. Energy 2020, 152, 1439–1450. [Google Scholar] [CrossRef]

- Ecoinvent Data Base, Version 3.4.; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2018.

- ELCD Data Base, Database of LCI Data Sets with European Market or Production Scope, Version 3.2; The European Platform on LCA: Bruxelles, Belgium, 2013.

- Beccali, M.; Cellura, M.; Longo, S. IEA Solar Heating and Cooling Program (Task 48). Final Deliverable; Report on Life Cycle Analysis; IEA: Paris, France, 2014. [Google Scholar]

- Raluy, G.; Serra, L.; Uche, J. Life cycle assessment of MSF, MED and RO desalination technologies. Energy 2006, 31, 2361–2372. [Google Scholar] [CrossRef]

- Pintanel, M.T.; Martínez-Gracia, A.; Galindo, M.P.; Bayod-Rújula, A.A.; Uche, J.; Tejero, J.A.; Del Amo, A. Analysis of the Experimental Integration of Thermoelectric Generators in Photovoltaic–Thermal Hybrid Panels. Appl. Sci. 2021, 11, 2915. [Google Scholar] [CrossRef]

- Usón, S.; Royo, J.; Canalís, P. Experimental tests of the integration of thermoelectric generators in a biomass boiler. In Proceedings of the 7th International Conference on Contemporary Problems of Thermal Engineering (CPOTE22), Warsaw, Poland, 20–23 October 2022. [Google Scholar]

- Gesteira, L.G.; Uche, J. A Novel Polygeneration System Based on Solar-Assisted Desiccant Cooling System for Residential Buildings: An Energy and Environmental Analysis. Sustainability 2022, 14, 3449. [Google Scholar] [CrossRef]

- Gesteira, L.G.; Uche, J.; Dejo, N. A Polygeneration System Based on Desiccant Air Conditioning Coupled with an Electrical Storage. Sustainability 2022, 14, 15784. [Google Scholar] [CrossRef]

- Boletín Oficial del Estado (BOE-A-2020-17282). Resolution of 18 December 2020, of the Directorate General for Energy Policy and Mines, which approves the consumption profile and the calculation method for the purposes of energy settlement, applicable to type 4 and type 5 consumers who do not have an hourly consumption register, in accordance with Royal Decree 1110/2007, of 24 August, which approves the Unified Regulation of Measuring Points of the Electricity System, for the year 2021. Available online: https://www.boe.es/eli/es/ (accessed on 15 May 2022). (In Spanish).

- Instituto de Diversificación y Ahorro de Enegía (IDAE). Informe Anual de Indicadores Energéticos. Sector Doméstico. 2018. Available online: https://www.idae.es (accessed on 18 October 2020).

- Canal de Isabel II. Cuadernos de I+D+i. No. 28. Las Claves del Consumo Doméstico en la Comunidad de Madrid. 2018. Available online: https://www.canaldeisabelsegunda.es/documents/ (accessed on 18 June 2022). (In Spanish).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).