Repair of Damaged Continuity Joints Using Ultra-High Performance, Fiber Reinforced Self-Consolidating, and Magnesium–Aluminum–Liquid–Phosphate Concretes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Concrete Mix Designs and Mixing Procedures

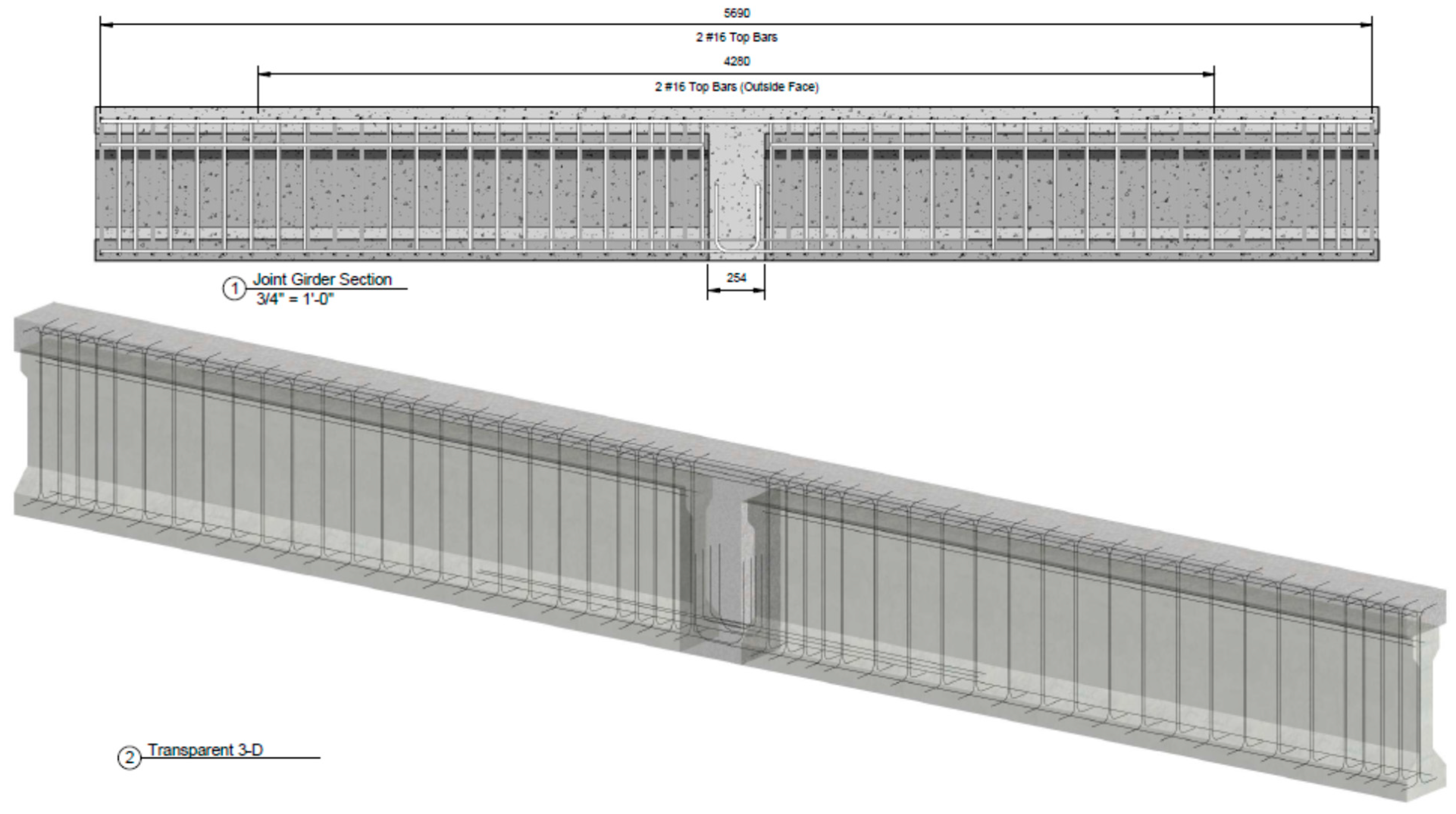

2.2. Continuous Girder Construction

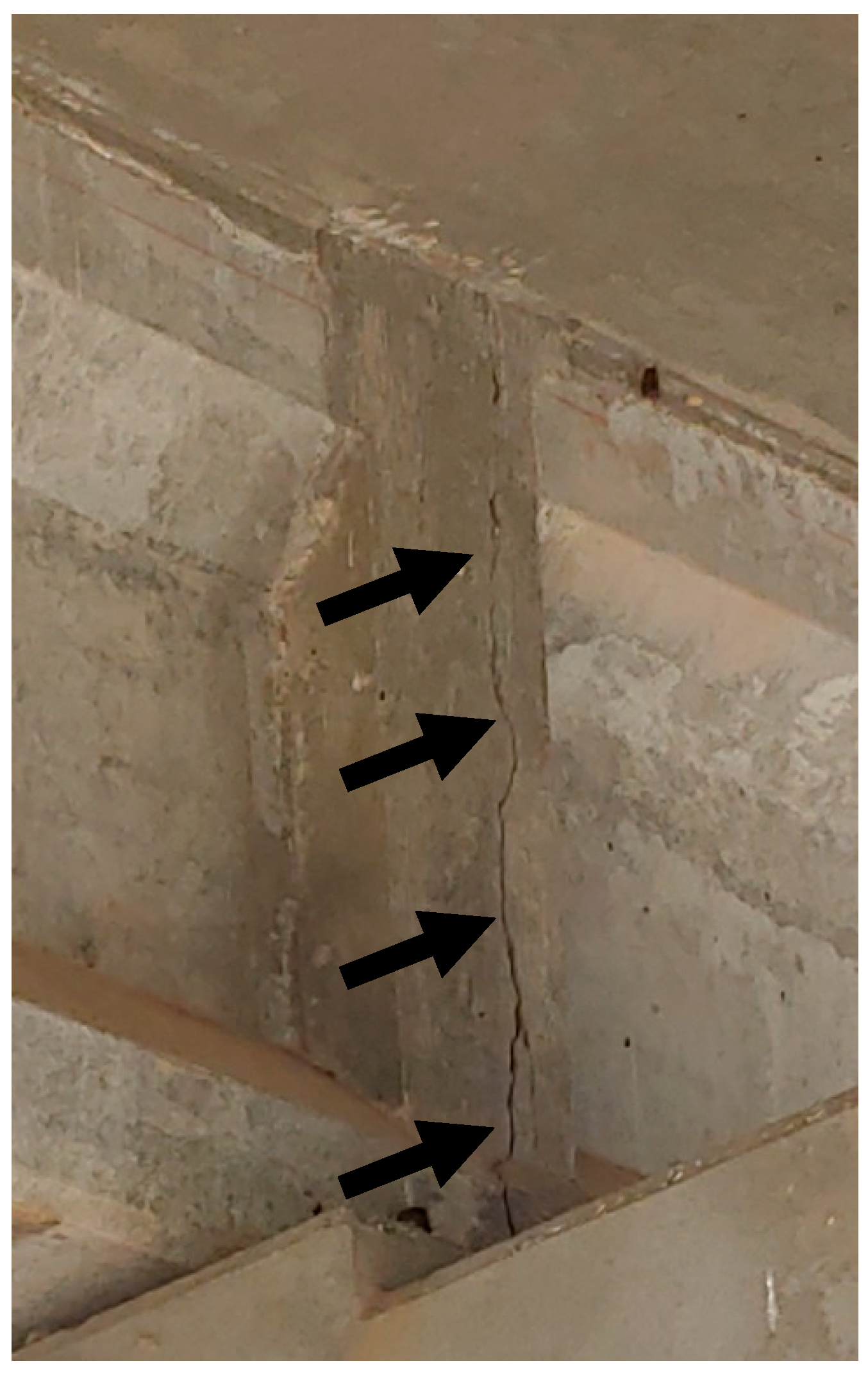

2.3. Positive Bending to Induce Crack Mimicking In Situ Damage

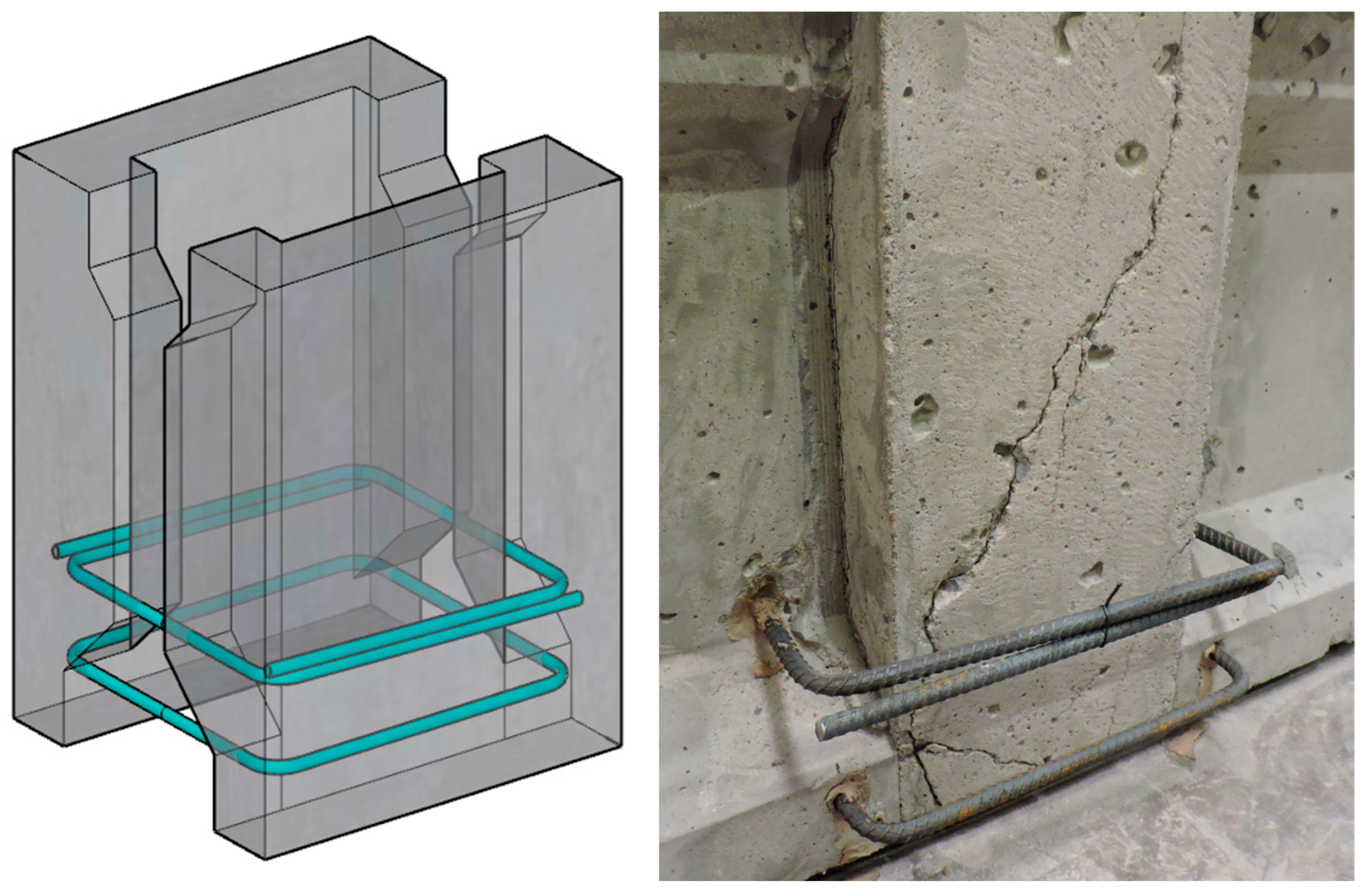

2.4. Continuity Joint Repair

2.5. Post-Repair Testing

3. Discussion of Results

3.1. Compressive Strengths

3.2. Behavior during Pre-Repair Crack Formation

3.3. Positive Bending Behavior Post-Repair

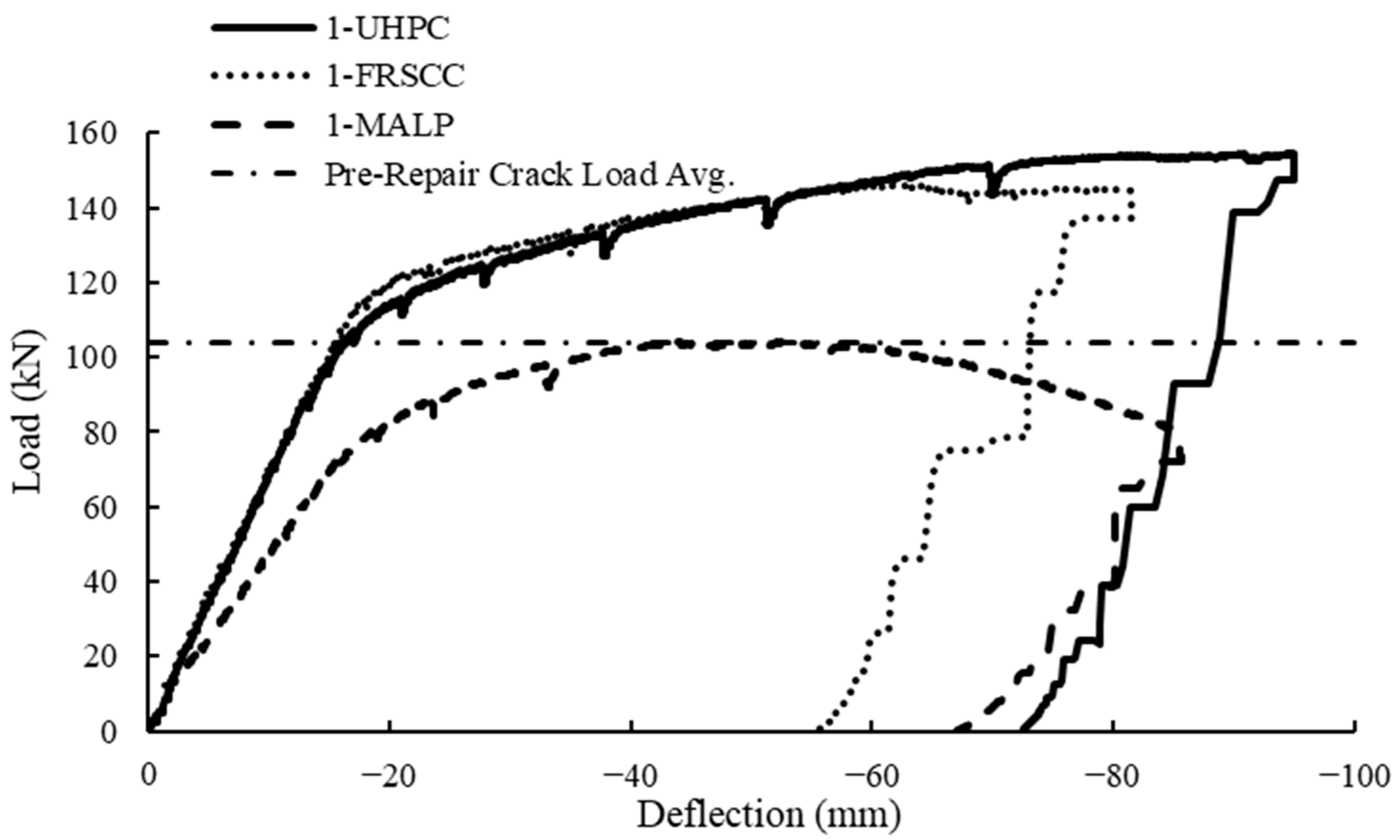

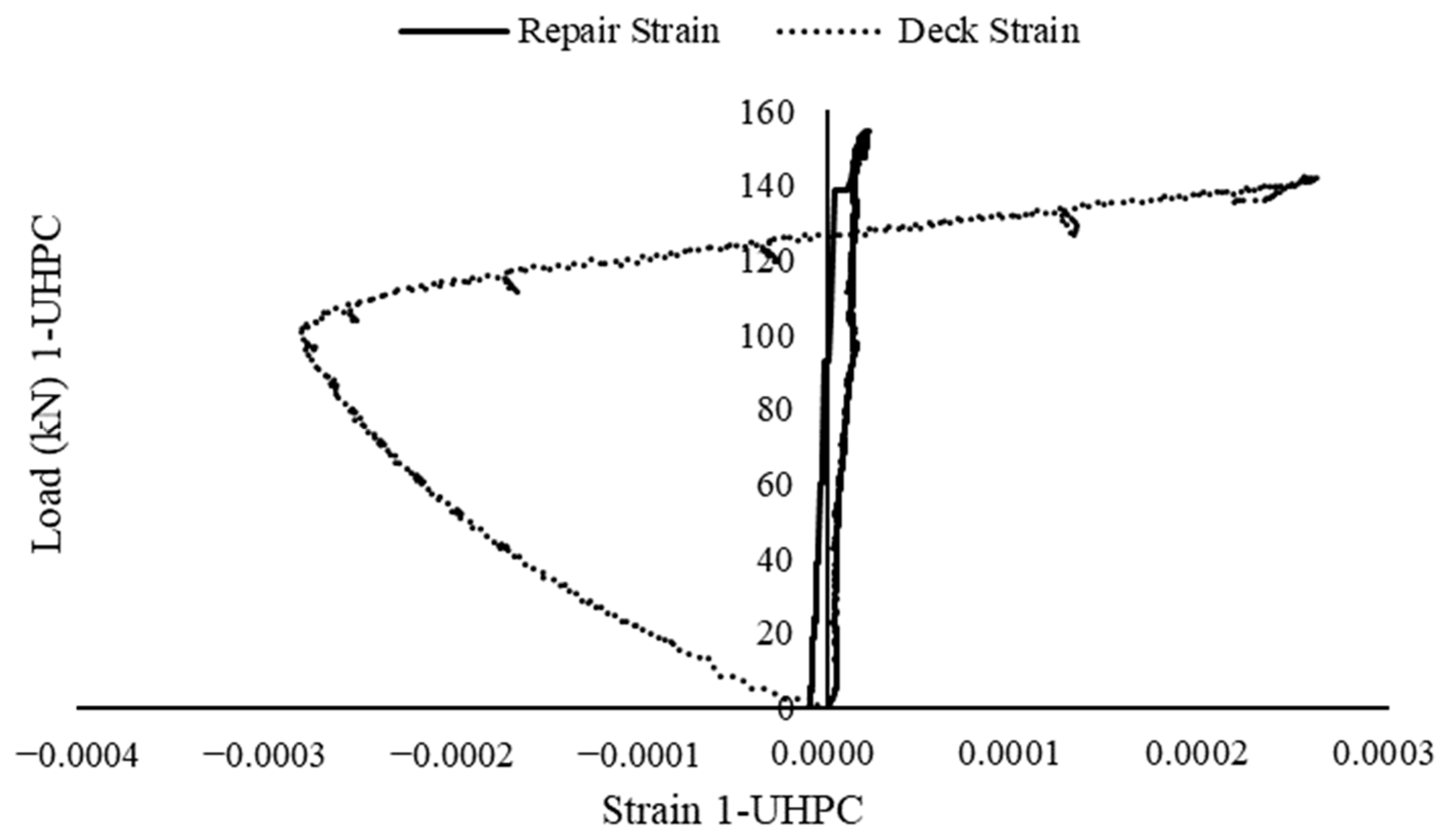

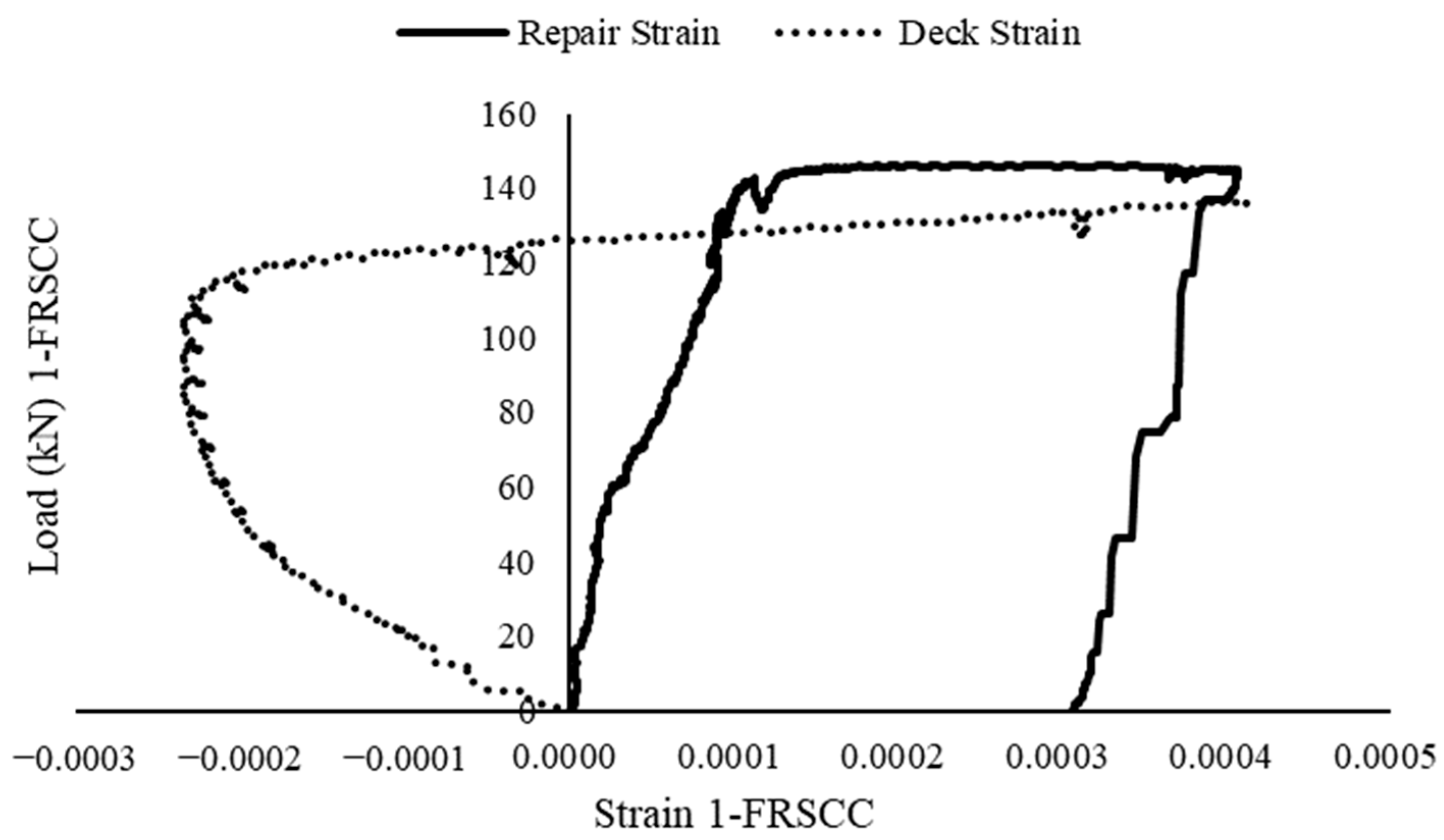

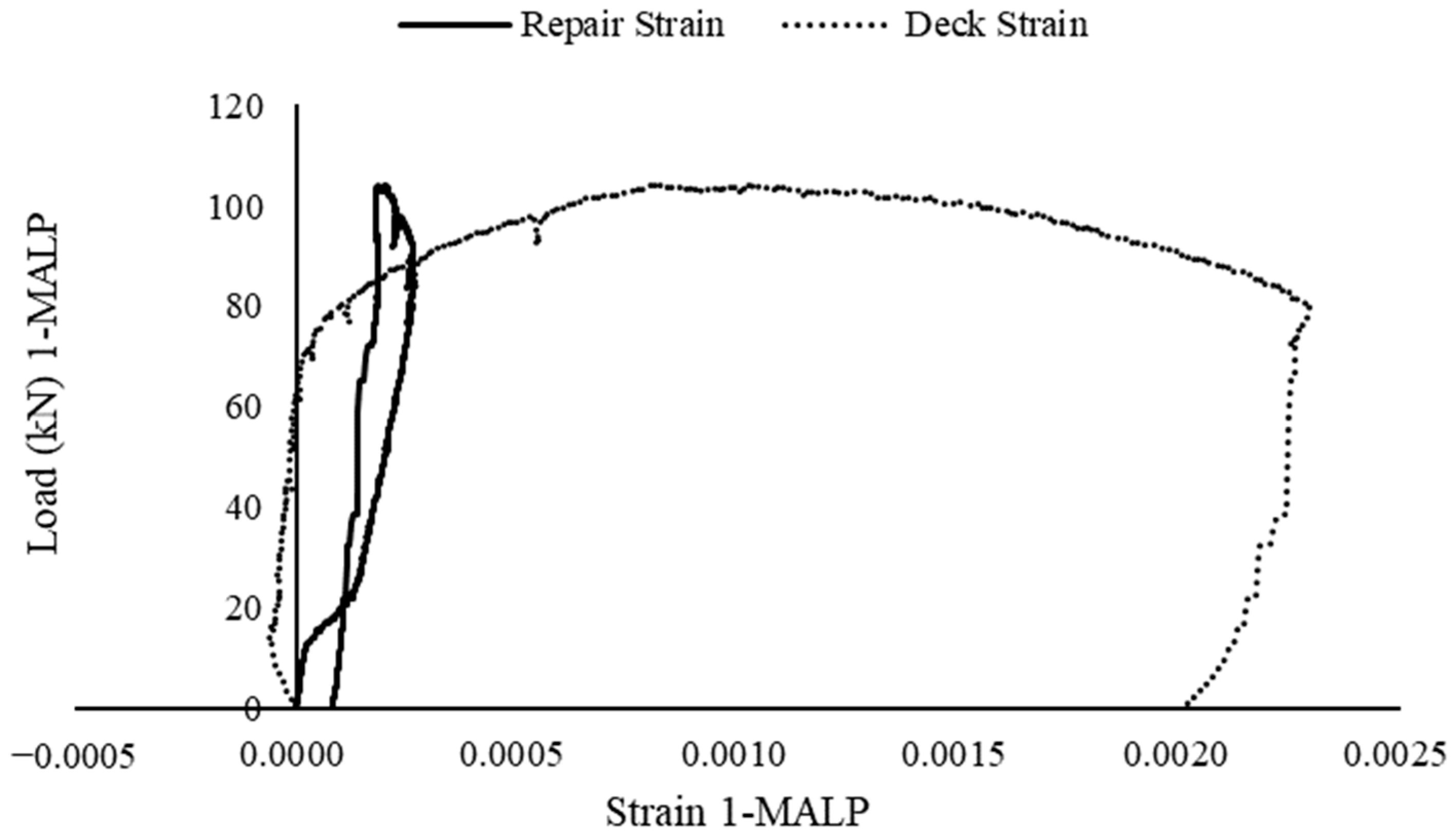

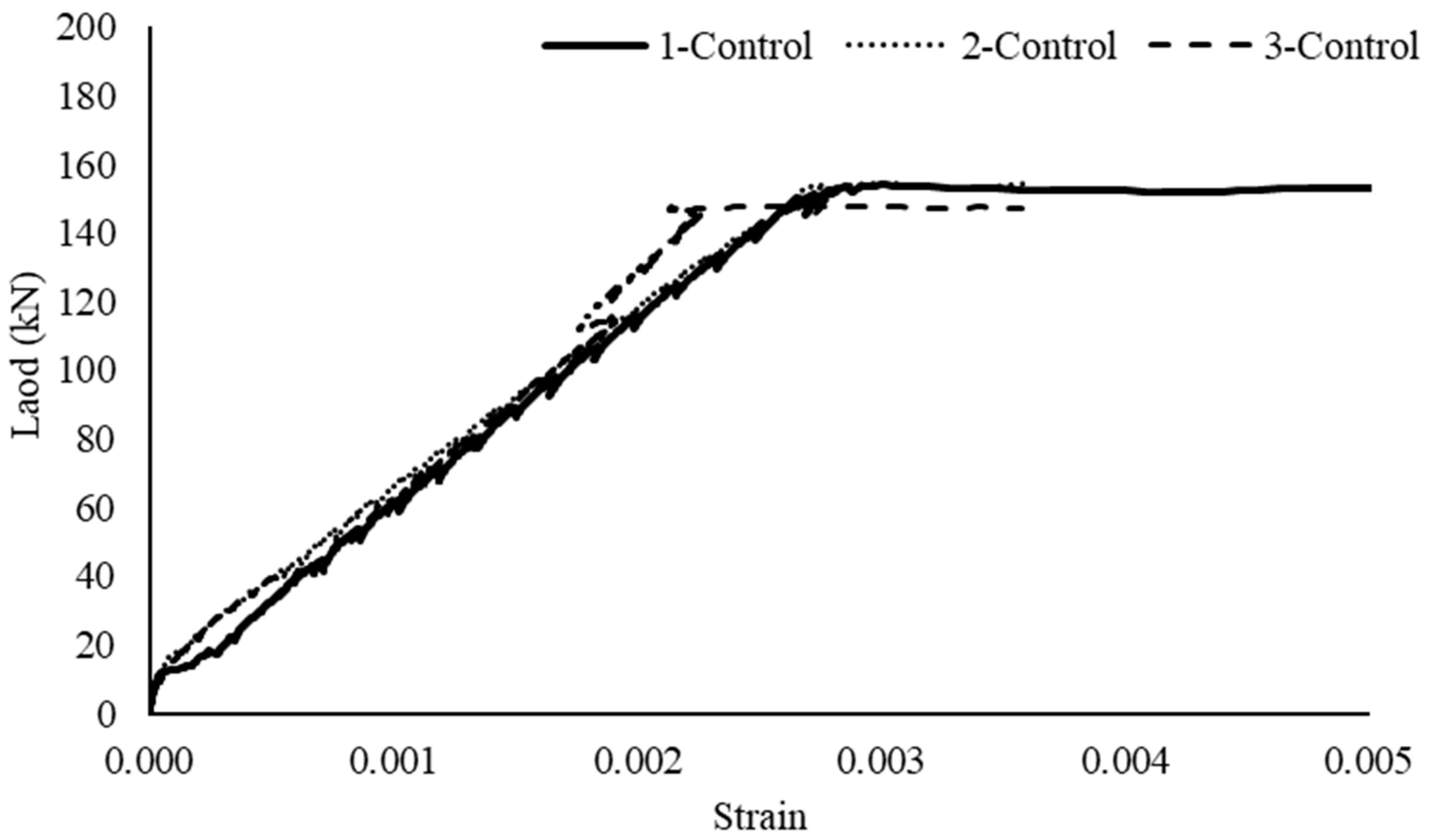

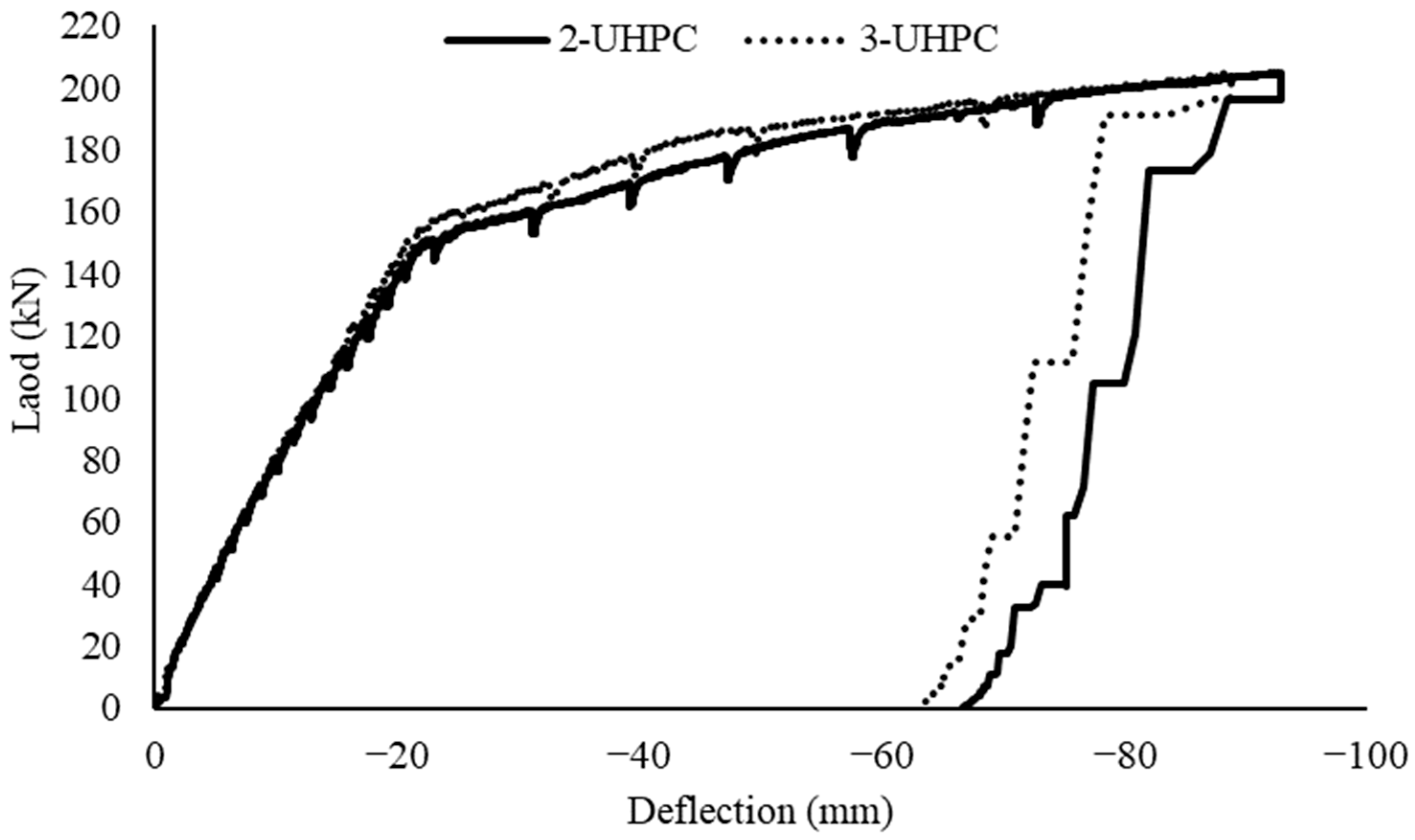

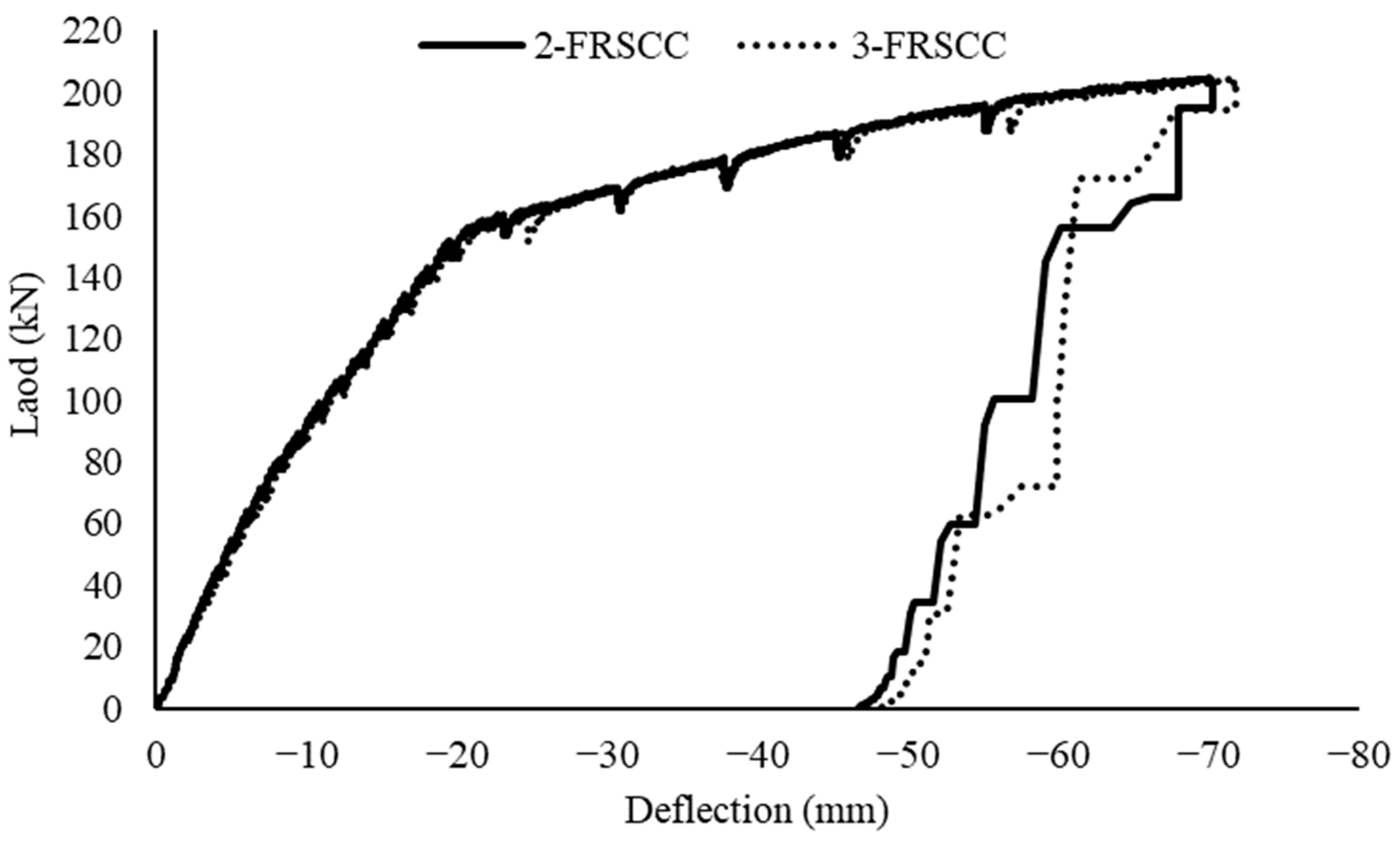

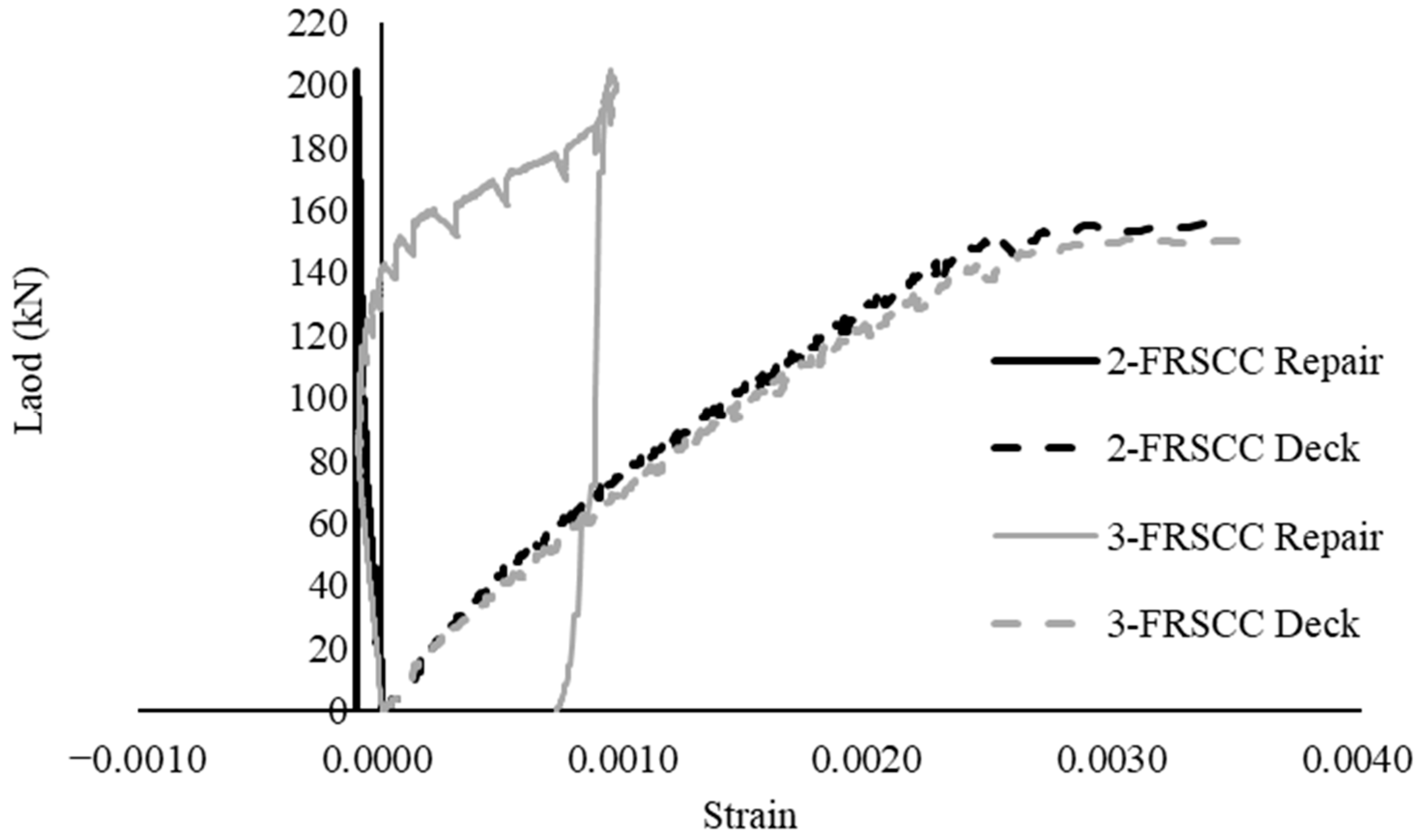

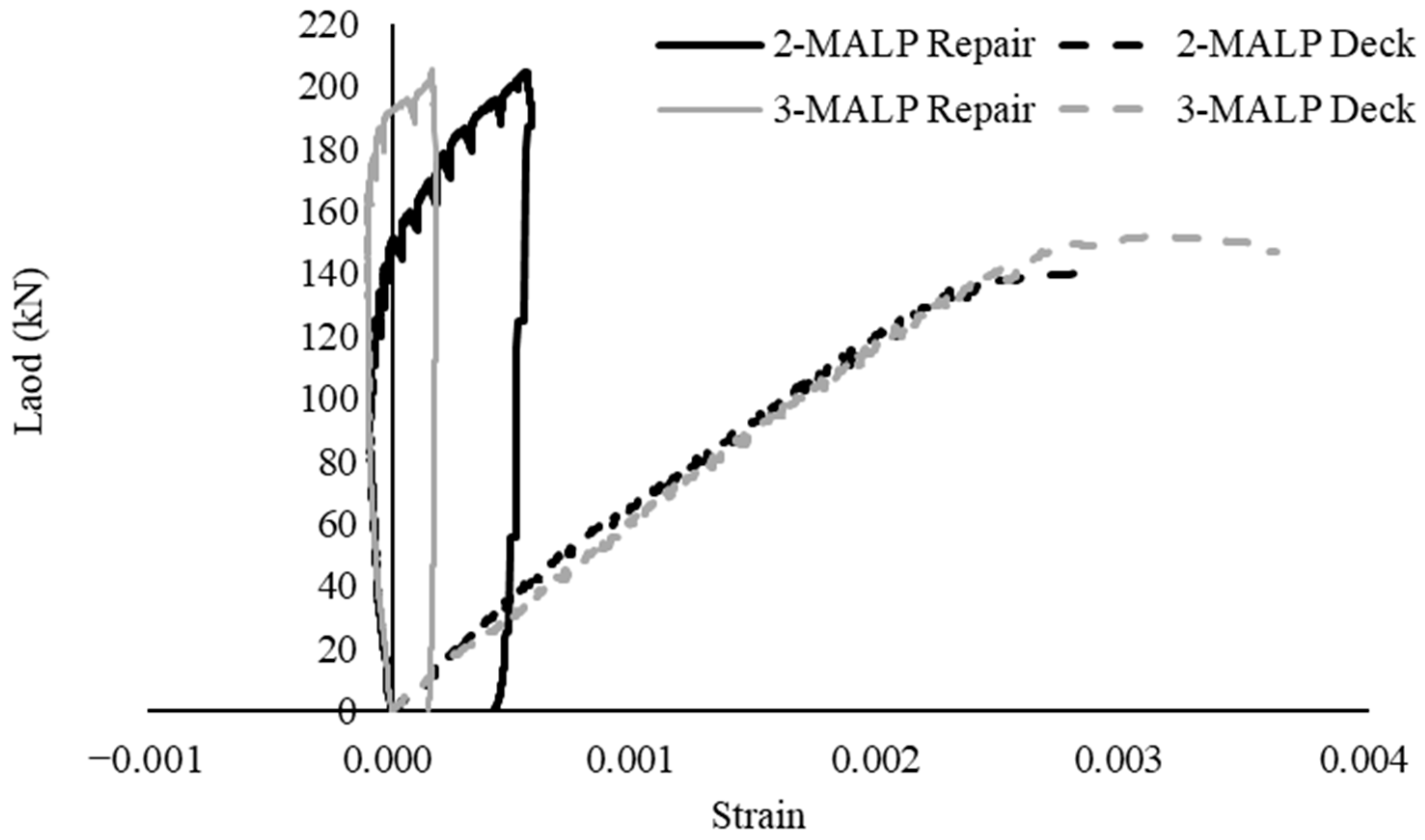

3.4. Negative Bending Behavior of Undamaged and Post-Repair Girders

4. Conclusions

- The UHPC and FRSCC repairs were able to increase the positive moment capacity of the connected girder specimens beyond the initial cracking load and the MALP repairs did not. Overall, the UHPC and FRSCC specimens appeared to exhibit better load transfer between the original joint material and the repair material.

- Each of the repair materials increased the negative moment capacity of the repaired connected girder specimens beyond that of the control specimens and each failed at approximately the same load. While the pre-yielding stiffness was nearly identical for specimens with each of the repair materials, the UHPC specimens exhibited a softer response and the MALP and FRSCC specimens exhibited a stiffer response post-yield. Due to the similar failure loads, the repair materials most likely acted as a confinement material to increase the capacity of the girders.

- These results appear to indicate that using each of the tested materials as an encapsulation repair for damaged continuity joints is viable to re-establish continuity. However, the UHPC repairs’ resistance to cracking could indicate the best performance by further protecting the continuity joint reinforcing steel from water ingress. Such repairs should be designed to be thick enough to provide the minimum clear distance required, and reinforcement designed based on effects of a temperature gradient on the bridge as defined in AASHTO LRFD Bridge Design Specifications [3] on existing damaged continuity joints. Thicker repair sections could provide additional capacity and protection from moisture ingress to damaged concrete. Future testing would be necessary to verify the behavior of such a repair.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, R.A.; Castrodale, R.; Mirmiran, A.; Hastak, M. Connection of Simple-Span Precast Concrete Girders for Continuity; National Cooperative Highway Research Program Report 519; The National Academies Press: Washington, DC, USA, 2004. [Google Scholar] [CrossRef]

- Freyermuth, C.L. Design of Continuous Highway Bridges with Precast, Prestressed Concrete Girders. PCI J. 1969, 14, 14–39. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications, 8th ed.; AASHTO: Washington, DC, USA, 2017. [Google Scholar]

- Looney, T.; Volz, J.; Floyd, R. Behavior of a 3-Span Continuous Bridge Before and After Continuity Joint Replacement Using Ultra-High Performance Concrete. J. Perform. Constr. Facil. 2021, 35, 04021087. [Google Scholar] [CrossRef]

- Looney, T.; McDaniel, A.; Volz, J.; Floyd, R. Development and Characterization of Ultra-High Performance Concrete with Slag Cement for Use as Bridge Joint Material. Br. J. Civ. Archit. Eng. 2019, 1, 1–14. [Google Scholar]

- Graybeal, B. Material Property Characterization of Ultra-High Performance Concrete; FHWA-HRT-06-103; Federal Highway Administration: McLean, VA, USA, 2006.

- Graybeal, B. Compression Response of a Rapid-Strengthening Ultra-High Performance Concrete Formulation; FHWA-HRT-12-64; Federal Highway Administration: McLean, VA, USA, 2012.

- Graybeal, B.A.; Baby, F. Development of Direct Tension Test Method for Ultra-High Performance Fiber-Reinforced Concrete. ACI Mater. J. 2013, 110, 177–186. [Google Scholar] [CrossRef]

- Haber, Z.B.; De la Varga, I.; Graybeal, B.A.; Nakashoji, B.; El-Helou, R. Properties and Behavior of UHPC-Class Materials; FHWA-HRT-18-036; Federal Highway Administration: McLean, VA, USA, 2018.

- Carbonell Muñoz, M.A.C.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond Performance Between Ultrahigh-Performance Concrete and Normal Strength Concrete. J. Mater. Civ. Eng. 2014, 26, 04014031. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Baker, B.H.; Megat Johari, M.A.; Ranam, M.M. The Relationship Between Substrate Roughness Parameters and Bond Strength of Ultra Higher-Performance Fiber Concrete. J. Adhes. Sci. Technol. 2013, 27, 1790–1810. [Google Scholar] [CrossRef]

- Looney, T.; Coleman, R.; Funderburg, C.; Volz, J.; Floyd, R. Concrete Bond and Behavior of Nonproprietary Utlrahigh-Performance Concrete Bridge Slab Joints. J. Bridge Eng. 2021, 26, 04020128. [Google Scholar] [CrossRef]

- Haber, Z.B.; Munoz, J.F.; Graybeal, B.A. Field Testing of an Ultra-High Performance Concrete Overlay; FHWA-HRT-17-096; Federal Highway Administration: McLean, VA, USA, 2017.

- Wibowo, H.; Sritharan, S. Use of Ultra-High-Performance Concrete for Bridge Deck Overlays; IHRB Project TR-683; Bridge Engineering Center: Ames, IA, USA, 2018. [Google Scholar]

- Khayat, K.H.; Valipour, M. Design and Performance of Cost-Effective Ultra High Performance Concrete for Bridge Deck Overlays; CMR 18-006; Missouri. Dept. of Transportation. Construction and Materials Division: Jefferson City, MO, USA, 2018.

- Zmetra, K.M.; McMullen, K.F.; Zaghi, A.E.; Wille, K. Experimental Study of UHPC Repair for Corrosion-Damaged Steel Girder Ends. J. Bridge Eng. 2017, 22, 04017037. [Google Scholar] [CrossRef]

- Fan, Z.F.; Huang, W.; Negoita, A. Repairing Steel Girder End Corrosion Using Ultra-High Performance Concrete. J. Bridge Eng. 2022, 27, 05021015. [Google Scholar] [CrossRef]

- Shafei, B.; Phares, B.; Shi, W. Beam End Repair for Prestressed Concrete Beams; IHRB Project TR-715; Bridge Engineering Center: Ames, IA, USA, 2020. [Google Scholar]

- Wirkman, C. Performance of Fiber-Reinforced Self-Consolidating Concrete for Repair of Bridge Sub-Structures. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 2016. [Google Scholar]

- Kassimi, F.; El-Sayed, A.K.; Khayat, K.H. Performance of Fiber-Reinforced Self-Consolidating Concrete for Repair of Reinforced Concrete Beams. ACI Struct. J. 2014, 111, 1277–1286. [Google Scholar] [CrossRef]

- Khayat, K.H.; Abdelrazik, A. Performance of Fiber-Reinforced Self-Consolidating Concrete for Repair of Bridge Sub-Structures and Fiber-Reinforced Super-Workable Concrete for Infrastructure Construction; CMR 17-012; Missouri. Dept. of Transportation. Construction and Materials Division: Jefferson City, MO, USA, 2017.

- Choate, J.G. Implementing Fiber-Reinforced, Self-Consolidating Concrete as a Repair Material for AASHTO Prestressed Concrete Girders. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 2018. [Google Scholar]

- Fournier, P. Bridge Maintenance Experts Evaluate MALP Concrete Repair Technology Applied to Route 26 Span. Constructioneer 2014, 4–6. [Google Scholar]

- Ding, Z.; Li, Z. High-Early-Strength Magnesium Phosphate Cement with Fly Ash. ACI Mater. J. 2005, 102, 375–381. [Google Scholar] [CrossRef]

- Yue, L.; Bing, C. Factors That Affect the Properties of Magnesium Phosphate Cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar] [CrossRef]

- Concrete Repair Products—See Our Data Guides. Available online: https://www.phoscrete.com/data-guides/ (accessed on 12 November 2022).

- Expansion Joint Headers. Available online: https://www.phoscrete.com/expansion-joint-repairs/ (accessed on 12 November 2022).

- Concrete Spall Patches. Available online: https://www.phoscrete.com/horizontal-spall-patches/ (accessed on 12 November 2022).

- Oklahoma Department of Transportation (ODOT). Standard Specifications for Highway Construction; ODOT: Oklahoma City, OK, USA, 2019.

- Mayhorn, D. Investigations of the Effects of End Region Deterioration in Precast, Prestressed Concrete Bridge Girders. Master’s Thesis, University of Oklahoma, Norman, OK, USA.

- Murray, C.D. Understanding Ultimate Shear Behavior of Prestressed Concrete Girder Bridges as a System Through Experimental Testing and Analytical Methods. Ph.D. Thesis, University of Oklahoma, Norman, OK, USA, 2017. [Google Scholar]

- Casey, C.W. Ultra-High Performance Concrete for Connections of Precast, Prestressed Girders Made Continuous for Live Load. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 2019. [Google Scholar]

| Class AA | UHPC | FRSCC | |

|---|---|---|---|

| Type I/II Cement (kg/m3) | 267 | 535 | 187 |

| #57 Crushed Limestone (kg/m3) | 835 | 0 | 0 |

| 9.5 mm River Rock (kg/m3) | 0 | 0 | 575 |

| Concrete Sand (kg/m3) | 581 | 0 | 648 |

| Fine Masonry Sand (kg/m3) | 0 | 892 | 0 |

| Type K additive (kg/m3) | 0 | 0 | 51 |

| Class C Fly Ash (kg/m3) | 0 | 0 | 102 |

| Slag Cement (kg/m3) | 0 | 268 | 0 |

| Silica Fume (kg/m3) | 0 | 89 | 0 |

| High Range Water Reducer (oz./cwt) | 3 | 19.5 | 61.9 |

| Air Entrainer (oz./cwt) | 0.7 | 0 | 8.2 |

| Steel Fibers (kg/m3) | 0 | 120 | 0 |

| MasterFiber MAC Matrix Fibers (kg/m3) | 0 | 0 | 3 |

| Water (kg/m3) | 105 | 178 | 0 |

| Compressive Strength (MPa) | Coefficient of Variation | |

|---|---|---|

| Class AA | 34.9 | 3.3% |

| UHPC | 139.5 | 3.3% |

| FRSCC | 48.7 | 15.0% |

| MALP | 30.6 | 1.7% |

| Repair Material | Specimen # | Failure Load (kN) | Average Failure Load (kN) | Coefficient of Variation |

|---|---|---|---|---|

| Control | 1 | 198.38 | 193.9 | 3.33% |

| 2 | 198.47 | |||

| 3 | 184.73 | |||

| UHPC | 2 | 204.70 | 204.7 | 0.02% |

| 3 | 204.61 | |||

| FRSCC | 2 | 204.65 | 204.7 | 0.00% |

| 3 | 204.65 | |||

| MALP | 2 | 204.79 | 205.0 | 0.10% |

| 3 | 205.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Looney, T.; Mesigh, M.; Volz, J.; Floyd, R. Repair of Damaged Continuity Joints Using Ultra-High Performance, Fiber Reinforced Self-Consolidating, and Magnesium–Aluminum–Liquid–Phosphate Concretes. Appl. Sci. 2022, 12, 12775. https://doi.org/10.3390/app122412775

Looney T, Mesigh M, Volz J, Floyd R. Repair of Damaged Continuity Joints Using Ultra-High Performance, Fiber Reinforced Self-Consolidating, and Magnesium–Aluminum–Liquid–Phosphate Concretes. Applied Sciences. 2022; 12(24):12775. https://doi.org/10.3390/app122412775

Chicago/Turabian StyleLooney, Trevor, Michael Mesigh, Jeffery Volz, and Royce Floyd. 2022. "Repair of Damaged Continuity Joints Using Ultra-High Performance, Fiber Reinforced Self-Consolidating, and Magnesium–Aluminum–Liquid–Phosphate Concretes" Applied Sciences 12, no. 24: 12775. https://doi.org/10.3390/app122412775

APA StyleLooney, T., Mesigh, M., Volz, J., & Floyd, R. (2022). Repair of Damaged Continuity Joints Using Ultra-High Performance, Fiber Reinforced Self-Consolidating, and Magnesium–Aluminum–Liquid–Phosphate Concretes. Applied Sciences, 12(24), 12775. https://doi.org/10.3390/app122412775