Application of a Selected Pseudorandom Number Generator for the Reliability of Farm Tractors

Abstract

1. Introduction

2. Materials and Methods

- The theoretical distributions are divided into N intervals of equal probability.

- The value of the cumulative distribution function is randomized from each interval.

- The cumulative distribution function is inverted to obtain the value of the variable for the randomized value of the cumulative distribution function.

- The values of individual variables are randomly combined to obtain a multivariate random variable. In this procedure, the relationships between variables are ignored.

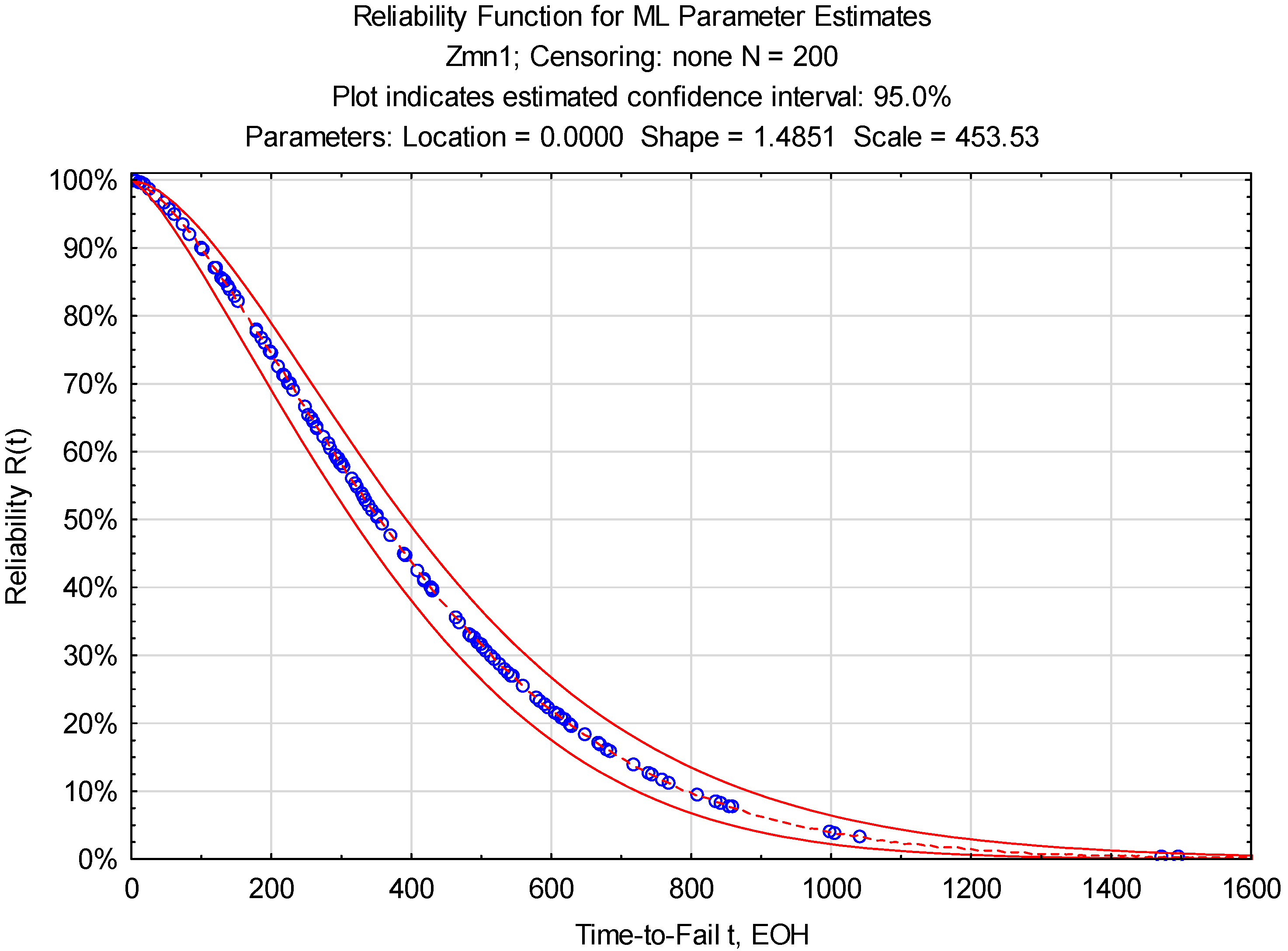

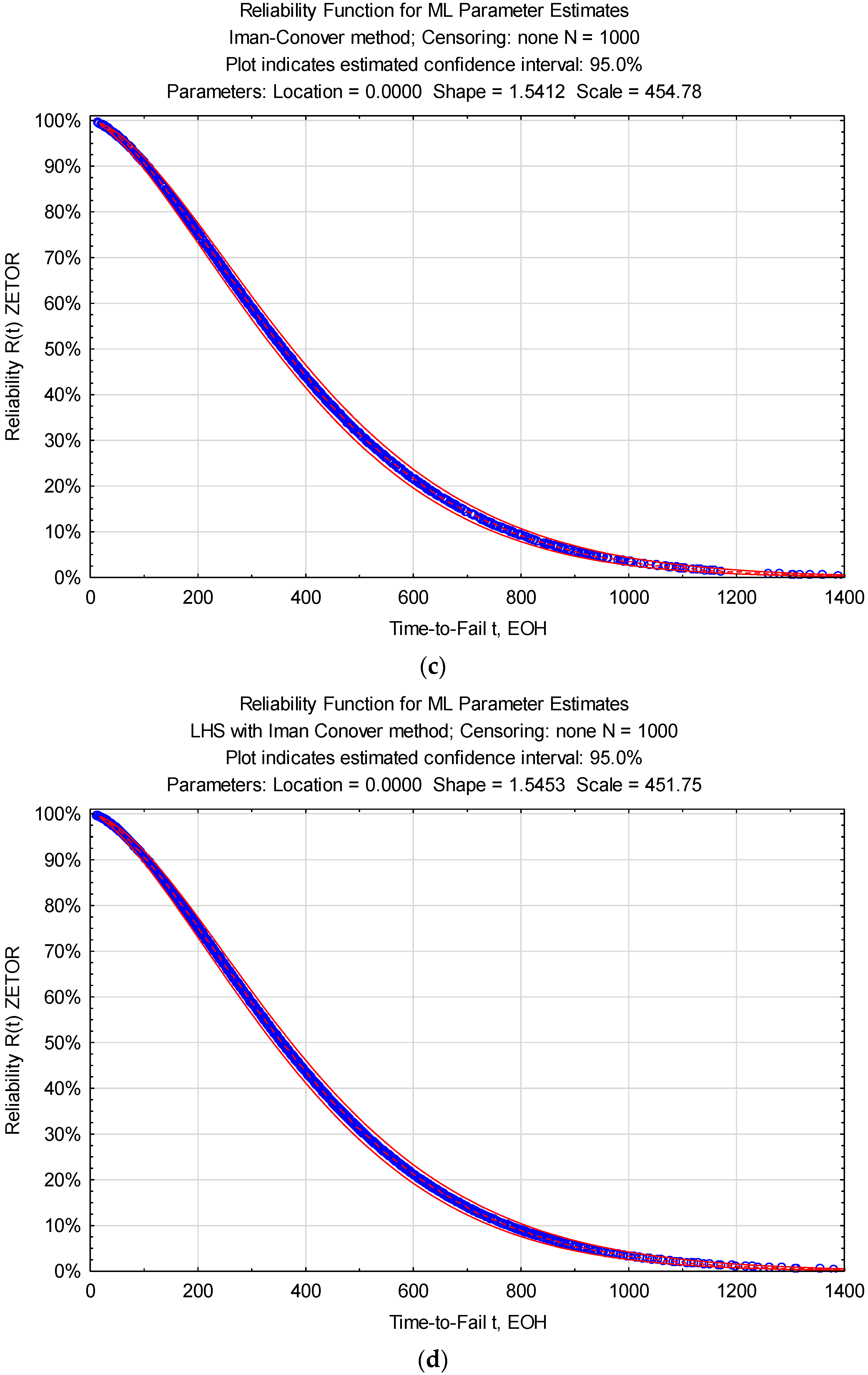

3. Results

4. Discussion

5. Conclusions

- Empirical (sampling) data which allow for historical events give reliable results of the assessment of the reliability of technological devices such as farm tractors. However, it is difficult to obtain such data from reliable sources such as manufacturers and service technicians of agricultural equipment. Therefore, it is helpful to identify alternative ways of obtaining these data, e.g., available statistical methods such as random/pseudorandom number generators.

- Simulation methods are a separate group of methods of analysis of the reliability of technological devices, which is important for practice. The unquestionable advantages of simulation methods are ease of implementation, the possibility of obtaining results with any accuracy, and insensitivity to nondifferentiability of the limit function or the existence of multiple design points.

- The verification and validation of failure times of the working units obtained from four dedicated random number generators in the Statistica program showed that they could be successfully used in agricultural practice to estimate the failure probability value. It is impossible to indicate the best adaptive method due to the small dataset of only 200 elements, i.e., the failure times of Zetor tractors which were repaired at an authorized service station in Poland.

- Each of the random number generators tested in our study can be regarded as dedicated because it enables the estimation of failure times of technological devices in various units of durability, i.e., CTU (conventional time units). For farm tractors, it is an hour of engine operation, which depends on the engine load, i.e., an engine-operating hour. For agricultural machinery, these may also be a clock hour (e.g., for seed drills, combine harvesters or potato harvesting machines), hectare (e.g., for ploughs and sprayers) or year (e.g., for slurry tankers). Other conventional time units are kilometers travelled (e.g., for transport sets) and tones or kilograms of capacity (e.g., for forage harvesters and collecting presses). The durability of relays and contactors in mechatronic systems can be measured with the number of their correct operations. However, as such data are not publicly available, there are no rankings of machinery and vehicle reliability relevant to farmers.

- There are only two states describing the condition of a technological device in the classical theory of reliability. Proven random number generators are also based only on this assumption. All identified failures (their recorded times) are treated as equally important, which does not reflect reality. Therefore, further improvement of the quality of random number generators is necessary.

- The future is likely to be quantum generators of pseudorandom numbers. Such generators are already finding applications in encryption devices to enhance the security of distributed systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rzeźnik, C.; Durczak, K.; Rybacki, P. Serwis Techniczny Maszyn; Wydawnictwo Uniwersytetu Przyrodniczego w Poznaniu: Poznań, Poland, 2015; ISBN 978-83-7160-788-2. [Google Scholar]

- Mishra, D.; Satapathy, S. Reliability and maintenance of agricultural machinery by MCDM approach. Int. J. Syst. Assur. Eng. Manag. 2021, 1–12. [Google Scholar] [CrossRef]

- Durczak, K.; Selech, J.; Ekielski, A.; Żelaziński, T.; Waleński, M.; Witaszek, K. Using the Kaplan–Meier Estimator to Assess the Reliability of Agricultural Machinery. Agronomy 2022, 12, 1364. [Google Scholar] [CrossRef]

- Shao, X.; Zheng, B.; Luo, Z.; Song, Z. Establishment and Validation of a Structural Dynamics Model with Power Take-Off Driveline for Agricultural Tractors. Agriculture 2022, 12, 1297. [Google Scholar] [CrossRef]

- Zhuravel, D.; Samoichuk, K.; Petrychenko, S.; Bondar, A.; Hutsol, T.; Kuboń, M.; Niemiec, M.; Mykhailova, L.; Gródek-Szostak, Z.; Sorokin, D. Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels. Energies 2022, 15, 1795. [Google Scholar] [CrossRef]

- Fu, X.; Wu, M.; Zhang, L. Probabilistic Life Prediction of Tunnel Boring Machine under Wearing Conditions with Incomplete Information. Buildings 2022, 12, 1959. [Google Scholar] [CrossRef]

- Oszczypała, M.; Ziółkowski, J.; Małachowski, J. Reliability Analysis of Military Vehicles Based on Censored Failures Data. Appl. Sci. 2022, 12, 2622. [Google Scholar] [CrossRef]

- Odeyar, P.; Apel, D.B.; Hall, R.; Zon, B.; Skrzypkowski, K. A Review of Reliability and Fault Analysis Methods for Heavy Equipment and Their Components Used in Mining. Energies 2022, 15, 6263. [Google Scholar] [CrossRef]

- Ahmadi, S.; Hajihassani, M.; Moosazadeh, S.; Moomivand, H. An Overview of the Reliability Analysis Methods of Tunneling Equipment. Open Constr. Build. Technol. J. 2020, 14, 218–219. [Google Scholar] [CrossRef]

- Rao, K.R.; Prasad, P.V. Graphical methods for reliability of repairable equipment and maintenance planning. In Proceedings of the Annual Symposium on Reliability and Maintainability (RAMS), Philadelphia, PA, USA, 22–25 January 2001; pp. 123–128. [Google Scholar]

- Kumar, R.; Vardhan, A.; Kishorilal, D.B.; Kumar, A. Reliability analysis of a hydraulic shovel used in open pit coal mines. J. Mines Met. Fuels 2018, 66, 472–477. [Google Scholar]

- Sinha, R.S.; Mukhopadhyay, A.K. Reliability centered maintenance of cone crusher: A case study. Int. J. Syst. Assur. Eng. Manag. 2015, 6, 32–35. [Google Scholar] [CrossRef]

- Ruijters, E.; Stoelinga, M. Fault Tree Analysis: A survey of the state-of-the-art in modeling, analysis and tools. Comput. Sci. Rev. 2015, 15–16, 29–62. [Google Scholar] [CrossRef]

- Kang, J.; Sun, L.; Soares, C.G. Fault Tree Analysis of floating offshore wind turbines. Renew. Energy 2019, 133, 1455–1467. [Google Scholar]

- Relkar, A.S. Risk Analysis of Equipment Failure through Failure Mode and Effect Analysis and Fault Tree Analysis. J. Fail. Anal. Prev. 2021, 21, 793–805. [Google Scholar] [CrossRef]

- Li, S.; Yang, Z.; Tian, H.; Chen, C.; Zhu, Y.; Deng, F.; Lu, S. Failure Analysis for Hydraulic System of Heavy-Duty Machine. Appl. Sci. 2021, 11, 1249. [Google Scholar] [CrossRef]

- Jiang, G.-J.; Li, Z.-Y.; Qiao, G.; Chen, H.-X.; Li, H.-B.; Sun, H.-H. Reliability Analysis of Dynamic Fault Tree Based on Binary Decision Diagrams for Explosive Vehicle. Math. Probl. Eng. 2021, 2021, 5559475. [Google Scholar] [CrossRef]

- Coolen, F. Parametric probability distributions in reliability. In Quantitative Risk Analysis and Assessment; Melnick, E.L., Everitt, B.S., Eds.; Wiley: West Sussex, UK, 2008. [Google Scholar]

- Durczak, K.; Jurek, P.; Beba, J.; Ekielski, A.; Żelaziński, T. A Multistate Model of Reliability of Farming Machinery. BIO Web Conf. 2018, 10, 02005. [Google Scholar] [CrossRef][Green Version]

- Koohsari, A.; Kalatehjari, R.; Moosazadeh, S.; Hajihassani, M.; Van, B. A Critical Investigation on the Reliability, Availability, and Maintainability of EPB Machines: A Case Study. Appl. Sci. 2022, 12, 11245. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, B.; Shi, H.; Kang, S.; Feng, Y. Reliability Evaluation and Optimization of a System with Mixed Run Shock. Axioms 2022, 11, 366. [Google Scholar] [CrossRef]

- Durczak, K.; Selech, J. The Quantification of Operational Reliability of Agricultural Tractors with the Competing Risks Method. Teh. Vjesn. 2022, 29, 628–633. [Google Scholar] [CrossRef]

- Muzalewski, A.; Pawlak, J.; Domasiewicz, T.; Mróz, M. Sposoby Oceny Racjonalności Zakupu Maszyn, Urządzeń i Ciągników Rolniczych; IBMER: Warszawa, Poland, 2007. [Google Scholar]

- Gazzarin, C. Maschinenkosten 2021: Gültig bis September 2022. Agroscope Transf. 2021, 408, 1–52. [Google Scholar] [CrossRef]

- Durczak, K.; Ekielski, A.; Kozłowski, R.; Żelaziński, T.; Pilarski, K. A computer system supporting agricultural machinery and farm tractor purchase decisions. Heliyon 2020, 6, e05039. [Google Scholar] [CrossRef]

- Durczak, K. Reliability of Agricultural Tractors According to Polish Farmers. Teh. Vjesn. 2020, 27, 1761–1766. [Google Scholar] [CrossRef]

- Gentle, J.E. Random Number Generation and Monte Carlo Methods; Springer: New York, NY, USA, 2004; ISBN 9780387001784. [Google Scholar]

- Giunta, A.; Wojtkiewicz, S.; Eldred, M. Overview of modern design of experiments methods for computational simulations. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003. [Google Scholar] [CrossRef]

- Kroese, D.P.; Taimre, T.; Botev, Z.I. Handbook of Monte Carlo Methods; Wiley Series in Probability and Statistics; John Wiley and Sons: New York, NY, USA, 2011; ISBN 9780470177938. [Google Scholar]

- Vesely, F.J. Computational Physics an Introduction; Springer: New York, NY, USA, 1994; ISBN 978-1-4757-2309-0. [Google Scholar] [CrossRef]

- Betz, W.; Papaioannou, I.; Straub, D. Bayesian post-processing of Monte Carlo simulation in reliability analysis. Reliab. Eng. Syst. Saf. 2022, 227, 108731. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Z.; Broccardo, M.; Song, J. Riemannian Manifold Hamiltonian Monte Carlo based subset simulation for reliability analysis in non-Gaussian space. Struct. Saf. 2022, 94, 102134. [Google Scholar] [CrossRef]

- Jermakow, S.M. Metoda Monte Carlo i Zagadnienia Pokrewne; Państwowe Wydawnictwo Naukowe: Warszawa, Poland, 1976. [Google Scholar]

- Liu, C.; Kramer, A.; Neumann, S. Reliability assessment of repairable phased-mission system by Monte Carlo simulation based on modular sequence-enforcing fault tree model. Eksploat. I Niezawodn.-Maint. Reliab. 2020, 22, 272–281. [Google Scholar] [CrossRef]

- Marek, P.; Guštar, M.; Anagnos, T. Simulation-Based Reliability Assessment for Structural Engineers; CRC Press, Inc.: Boca Raton, FL, USA, 1995. [Google Scholar]

- Ozkan, O.; Kilic, S. A Monte Carlo Simulation for Reliability Estimation of Logistics and Supply Chain Networks. IFAC-PapersOnLine 2019, 52, 2080–2085. [Google Scholar] [CrossRef]

- Kopociński, B. Zarys Teorii Odnowy i Niezawodności; Państwowe Wydawnictwo Naukowe: Warszawa, Poland, 1977. [Google Scholar]

- Stocki, R. Analiza Niezawodności i Optymalizacja Odpornościowa Złożonych Konstrukcji i Procesów Technologicznych; Instytut Podstawowych Problemów Techniki Polskiej Akademii Nauk: Warszawa, Poland, 2010; ISBN 978-83-89687-58-6. Available online: https://rcin.org.pl/dlibra/publication/9320/edition/6731 (accessed on 9 October 2022).

- Okulski, W.; Sujak, A.; Gruszecki, W. Dipalmitoylphosphatidylcholine membranes modified with carotenoid pigment lutein: Experiment versus Monte Carlo simulation study of the membrane. Biochim. Biophys. Acta (BBA)—Biomembr. 2008, 1778, 2105–2118. [Google Scholar] [CrossRef]

- McKay, M.D.; Beckman, R.J.; Conover, W.J. Comparison of Three Methods for Selecting Values of Input Variables in the Analysis of Output from a Computer Code. Technometrics 1979, 21, 239–245. [Google Scholar]

- Kordus, T. The Causes of Damage to Modern Farm Tractors. Master’s Thesis, Institute of Biosystems Engineering, Poznań University of Life Sciences, Poznan, Poland, 2013. [Google Scholar]

- Wang, P.; Fan, J.; Li, Z. Study on Mean Time Between Failures Prediction Algorithms Based on Weibull Distribution. IOP Conf. Ser. Earth Environ. Sci. 2020, 440, 22083. [Google Scholar] [CrossRef]

- Iman, R.L.; Conover, W.J. A Distribution-Free Approach to Inducing Rank Correlation Among Input Variables. Commun. Stat. 1982, 1, 311–334. [Google Scholar] [CrossRef]

- Ulbrich, D.; Selech, J.; Kowalczyk, J.; Jóźwiak, J.; Durczak, K.; Gil, L.; Pieniak, D.; Paczkowska, M.; Przystupa, K. Reliability Analysis for Unrepairable Automotive Components. Materials 2021, 14, 7014. [Google Scholar] [CrossRef]

| No. | Model | VIN * | EOH ** | Symptoms of Failure | Broken Part | Cause of Failure |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1. | Forterra 95 | 1337 | 330 | air escapes | quick coupler | damaged sealing flange |

| 2. | Forterra 115 | 6708 | 323 | wrong sensor indication | air pressure sensor | short circuit |

| 3. | Forterra 125 | 2534 | 221 | worn out mounts | wheel disc | inaccurate processing |

| 4. | Forterra 105 | 1286 | 130 | no light | headlight | short circuit |

| 5. | Forterra 125 | 2408 | 220 | worn out mounts | wheels | wheel disc |

| … | … | … | … | … | … | … |

| 196. | Proxima 85 | 2657 | 610 | shock absorption failure | cabin | gas spring |

| 197. | Proxima 85 | 3028 | 487 | shock absorption failure | cabin | gas spring |

| 198. | Proxima 85 | 3028 | 487 | engine hour meter failure | panel | short circuit |

| 199. | Proxima Plus 85 | 1690 | 4 | voltage drop | battery | faulty battery cell |

| 200. | Forterra 125 | 2743 | 304 | shock absorption failure | gas spring | damaged surface of sealing flange |

| No. | Empirical DataEOH | New Random Data (EOH) Generated with Method | |||

|---|---|---|---|---|---|

| MC | LHS | IC | LHS + IC | ||

| 1 | 2 | 3 | 4 | 5 | 6 |

| 1. | 2 | 15 | 13 | 16 | 13 |

| 2. | 3 | 15 | 15 | 17 | 15 |

| 3. | 3 | 15 | 17 | 20 | 17 |

| 4. | 4 | 15 | 19 | 22 | 19 |

| 5. | 4 | 15 | 20 | 24 | 19 |

| … | … | … | … | … | … |

| 196. | 1041 | 164 | 164 | 166 | 164 |

| 197. | 1474 | 165 | 165 | 166 | 165 |

| 198. | 1474 | 167 | 165 | 167 | 166 |

| 199. | 1474 | 168 | 166 | 169 | 166 |

| 200. | 1498 | 168 | 167 | 169 | 166 |

| … | … | … | … | … | … |

| 996. | - | 1197 | 1281 | 1305 | 1284 |

| 997. | - | 1209 | 1304 | 1318 | 1309 |

| 998. | - | 1291 | 1319 | 1337 | 1313 |

| 999. | - | 1317 | 1349 | 1361 | 1356 |

| 1000. | - | 1357 | 1383 | 1389 | 1381 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durczak, K.; Rybacki, P.; Sujak, A. Application of a Selected Pseudorandom Number Generator for the Reliability of Farm Tractors. Appl. Sci. 2022, 12, 12452. https://doi.org/10.3390/app122312452

Durczak K, Rybacki P, Sujak A. Application of a Selected Pseudorandom Number Generator for the Reliability of Farm Tractors. Applied Sciences. 2022; 12(23):12452. https://doi.org/10.3390/app122312452

Chicago/Turabian StyleDurczak, Karol, Piotr Rybacki, and Agnieszka Sujak. 2022. "Application of a Selected Pseudorandom Number Generator for the Reliability of Farm Tractors" Applied Sciences 12, no. 23: 12452. https://doi.org/10.3390/app122312452

APA StyleDurczak, K., Rybacki, P., & Sujak, A. (2022). Application of a Selected Pseudorandom Number Generator for the Reliability of Farm Tractors. Applied Sciences, 12(23), 12452. https://doi.org/10.3390/app122312452