Analysis of Truck Tractor Tire Damage in the Context of the Study of Road Accident Causes

Abstract

1. Introduction

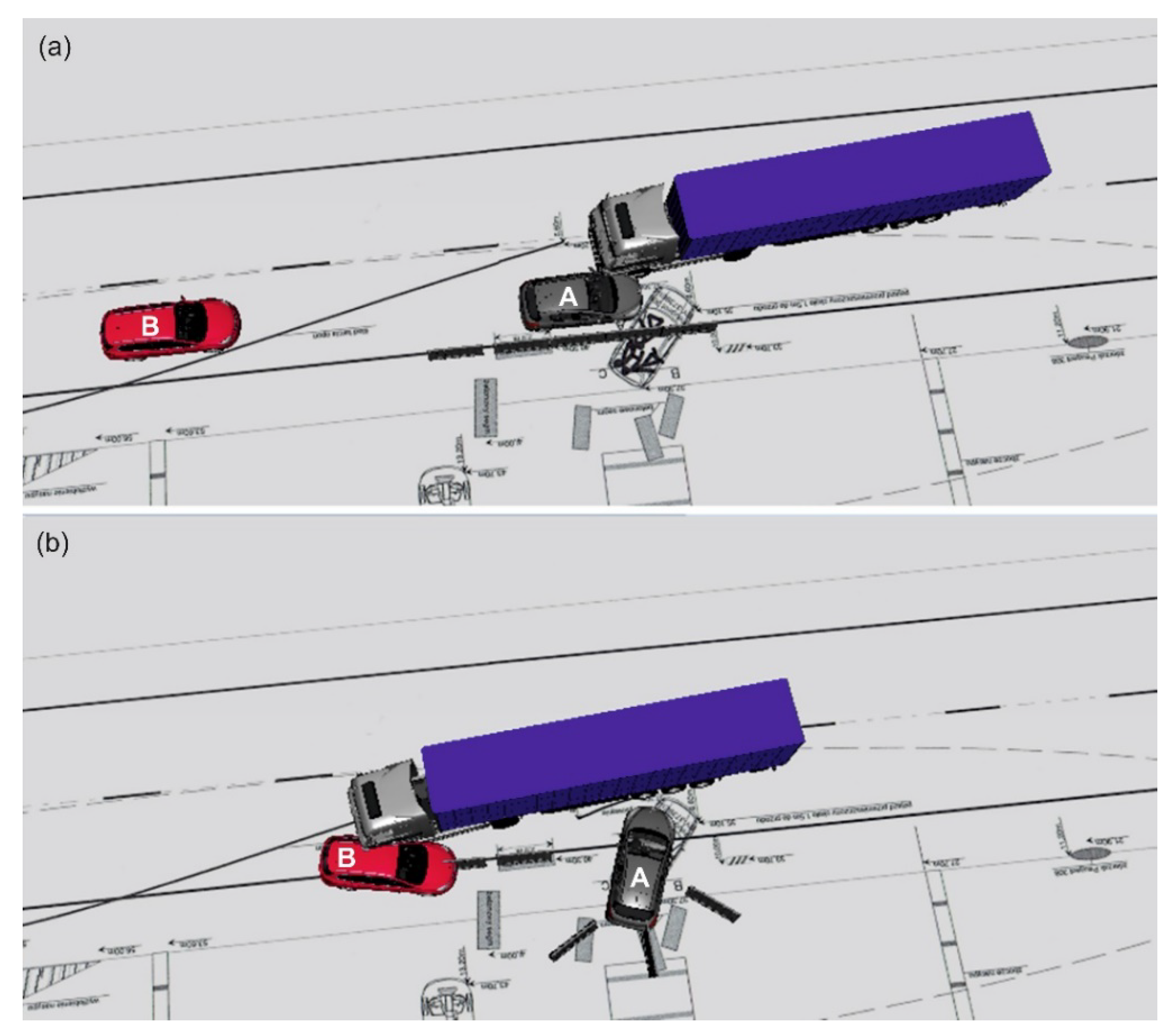

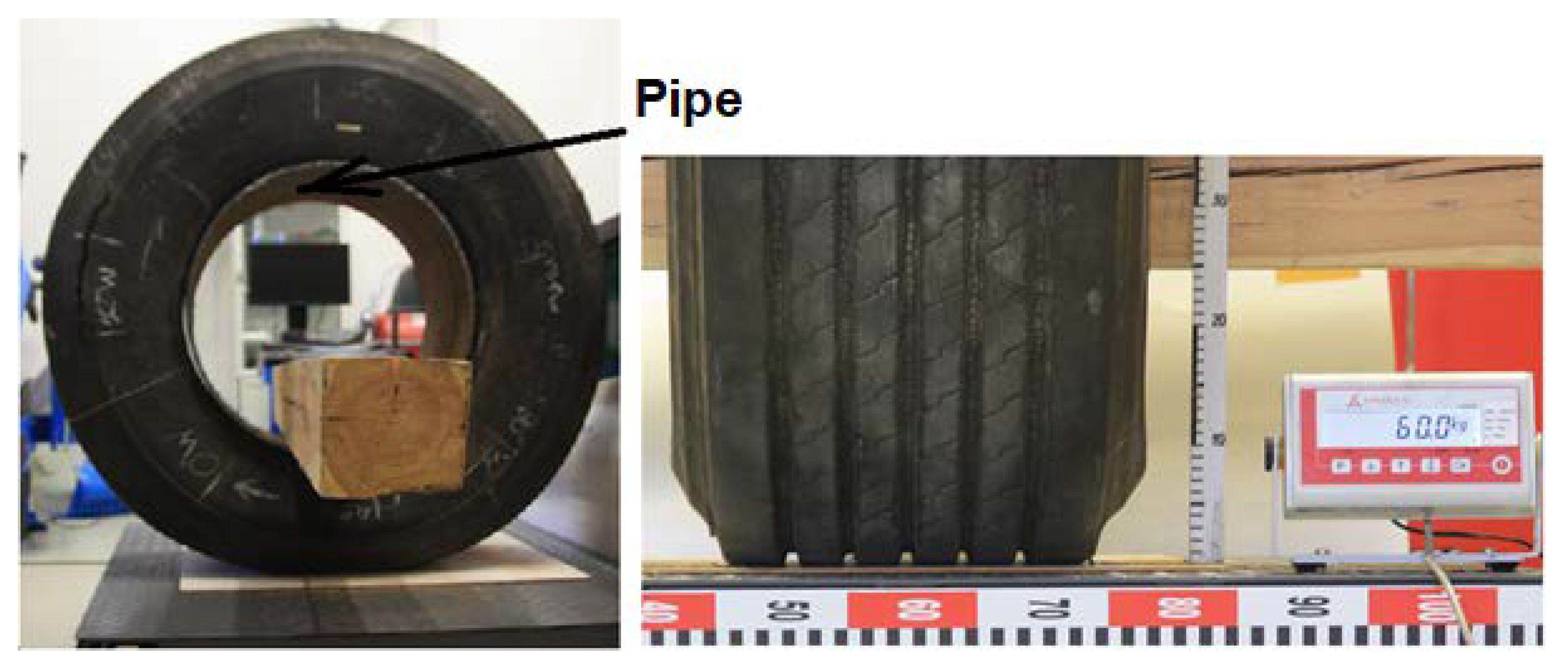

2. Analyzed Road Incident

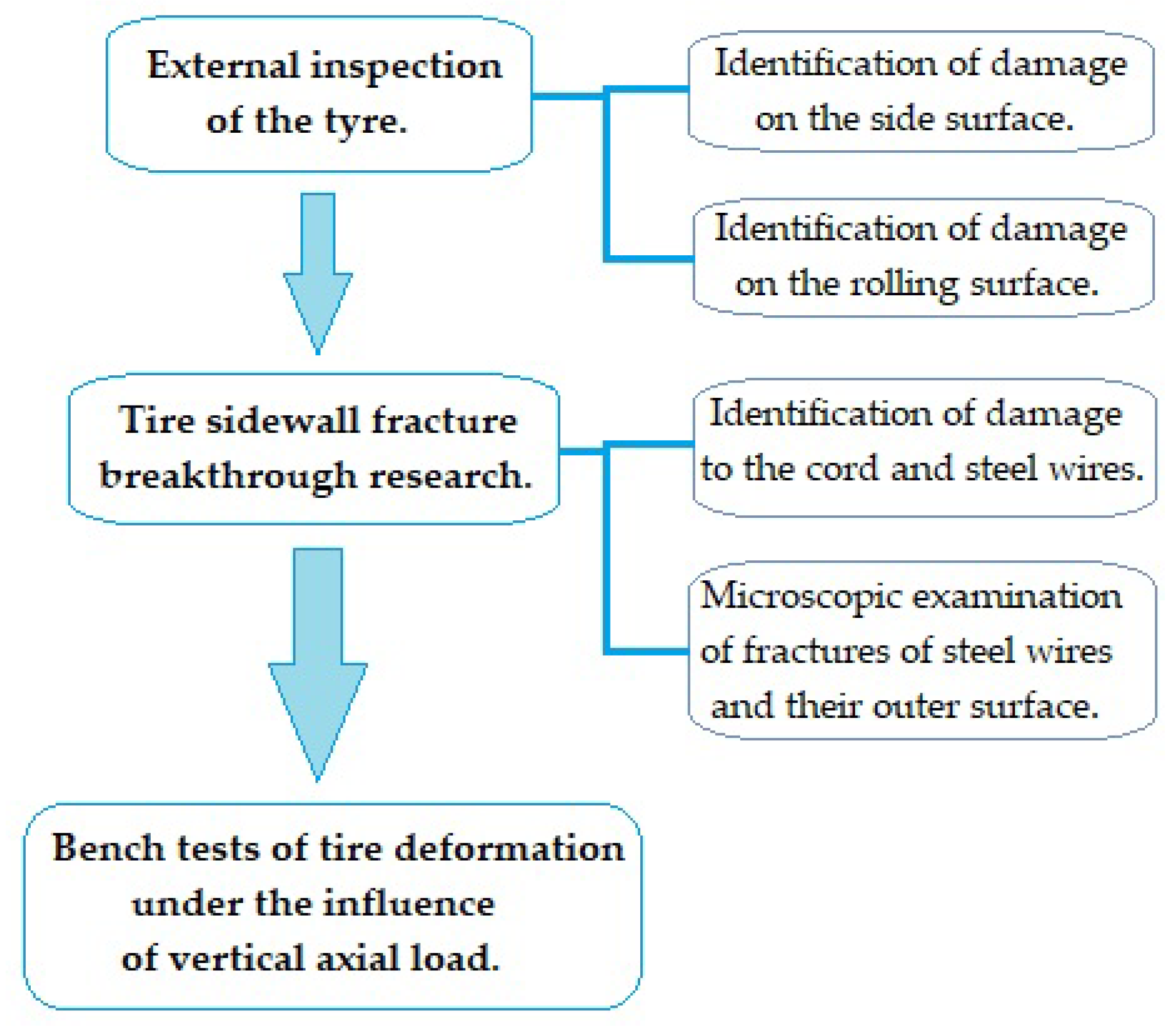

3. Characterization of Damaged Tire and Methods of its Testing

- Primewell PTL711 tire;

- Size: 385/65R22.5 160K (160-load index: 4500 kg; K-speed index: 110 km/h);

- 18PR-conventional number of canvases (interleaves);

- A radial, tubeless, all-steel cord tire designed for long-distance transport;

- According to the additional load capacity marking on the sidewall, the maximum load is 4500 kg at a pressure of 900 kPa;

- The tire has European approval (E4 0019845 010950-3) and the American safety certificate DOT 9U3W J92;

- The tire is adapted to regeneration by deepening the tread (“regroovable” designation).

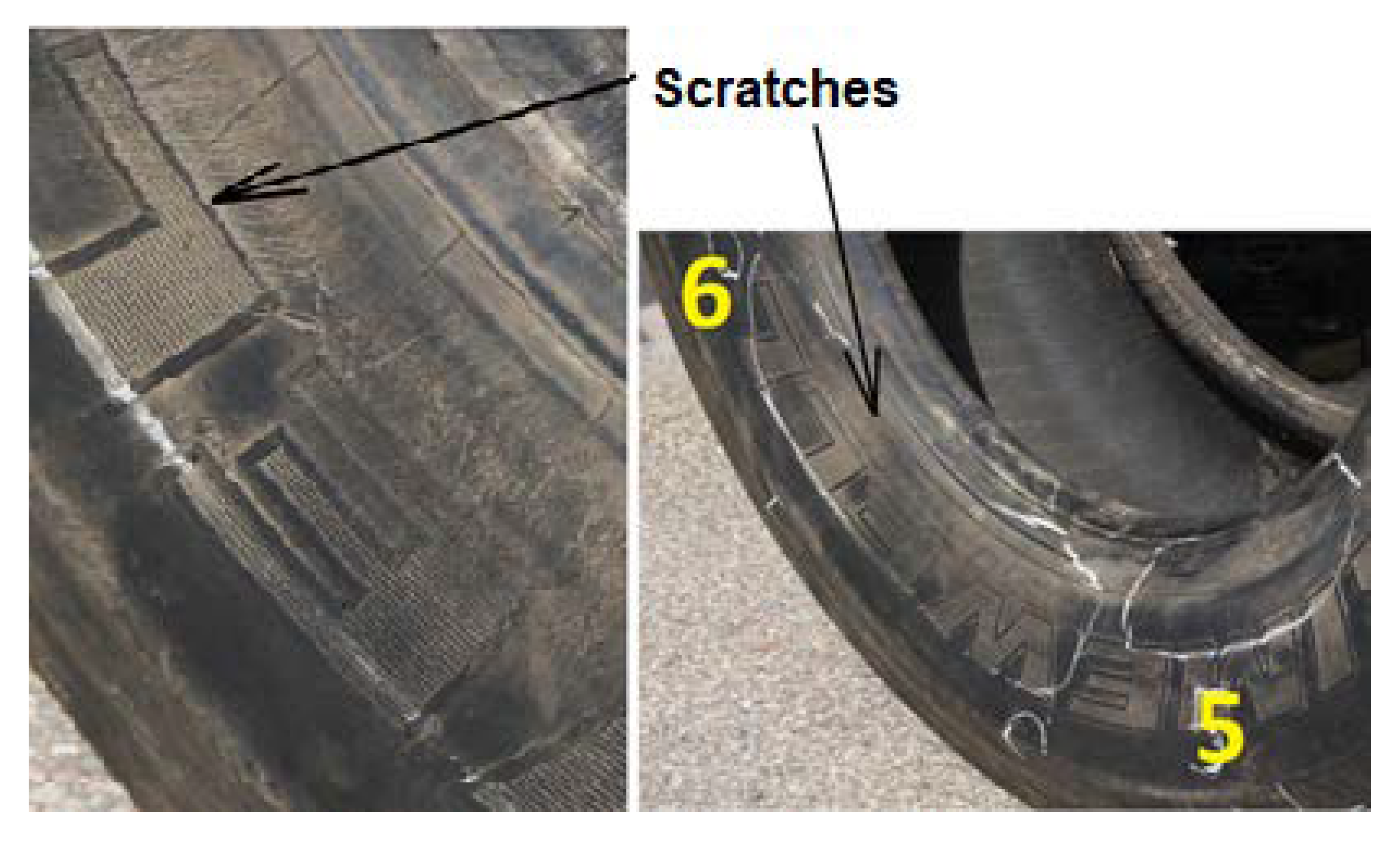

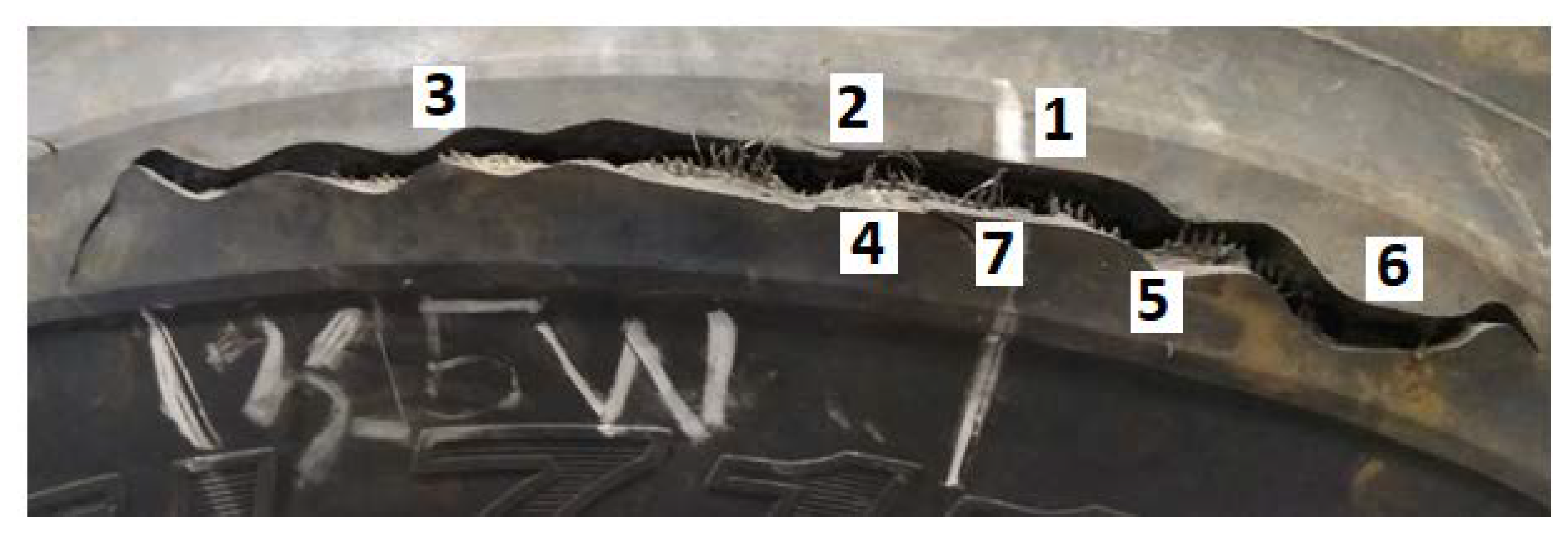

- A crack on the side of the tire, approximately 300 mm long (marked with number 4 in Figure 5), located along the angular length of 270 ÷ 315° W on the part of the tire named “belt”;

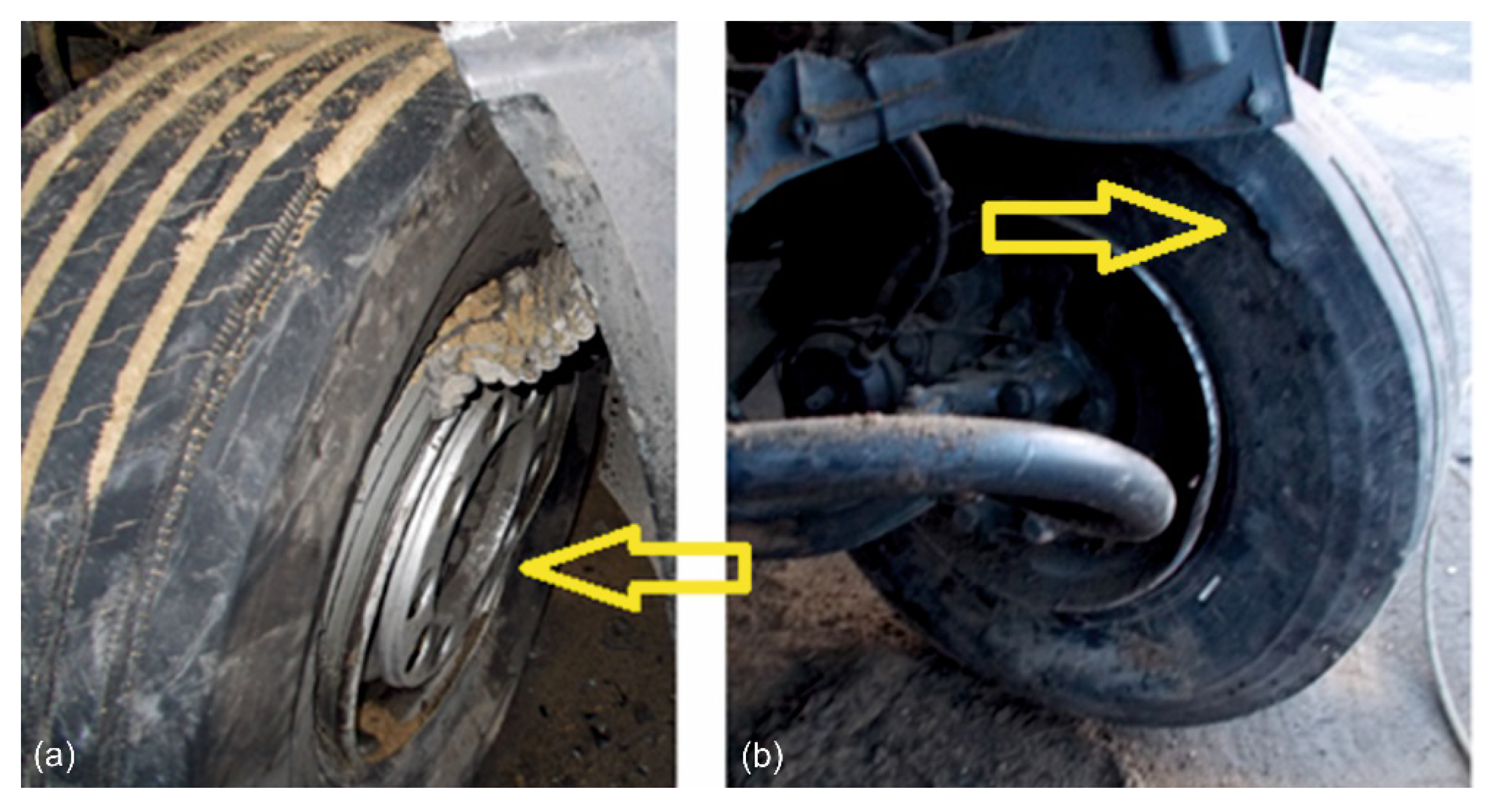

- Irregular sidewall abrasions on the “belt” on both sides of the tire around the entire circumference;

- Local deformation of the side resulted from damage to the cord (Figure 7), which was at the 110° W site.

- Inspection of the tire tread allowed us to identify the following characteristics:

- Local loss of material on the tread face with the exposed cord (marked with the number 1 in Figure 8), which was in the place marked with 90° Z;

- Tearing of the tread face (marked with number 2 in Figure 9), located in the place marked 140° W;

- The structure of the material in the grooves and edges of the tread indicates that the tire tread has not been regrooved.

4. Tire Testing Results and Discussion

5. Conclusions

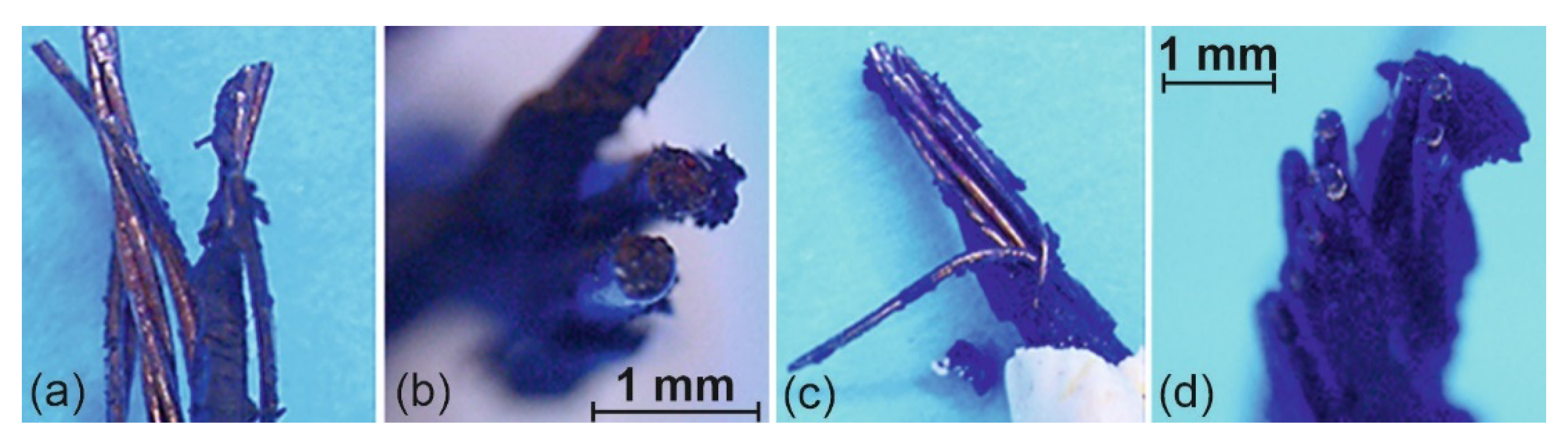

- There were no indications that the tire rupture was caused by external exposure to the metal part.

- Crack analysis (e.g., delamination of material coatings and traces of corrosion on steel wires) shows that the structure of the tire was weakened in the place of the crack. This could be the result of two independent reasons. The first of them could have been caused by much earlier damage to the tire, followed by the ingress of moisture inside, which initiated the corrosion processes of the steel cord wires. The second reason may be related to the tire’s design defect in the use of a cord with traces of corrosion during production.

- As indicated in the literature, in cases where the structure of the tire is weakened, it may become unsealed (cracked) during the operation of the vehicle. Taking into account the authors’ experience, there has not been a case of tire fracture in a situation where the place of weakening of its structure did not coincide with the place of external force. However, such a possibility cannot be categorically ruled out.

- Disclosed traces of abrasions on the tire sidewall, on both sides (on the “belt”), are a significant premise for accepting with a very high probability that before the collision with Car A, the left front wheel of the truck tractor made at least one full turn during which the tire vibrated, indicating a leakage occurred prior to the crash.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hlatka, M.; Kampf, R.; Korec, K.; Kalinova, E.; Gross, P. Failure analysis and identification of causes of SRC system malfunctions—Case study. Eng. Fail. Anal. 2021, 127, 105574. [Google Scholar] [CrossRef]

- Krmela, J.; Krmelova, V. Tire casings and their material characteristics for computational modelling of tires. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 24–26 May 2017; pp. 230–235. [Google Scholar]

- Noor, A.K.; Tanner, J.A. Tire modelling and contact problems: Advances and trends in the development of computational models for tires. Comput. Struct. 1985, 20, 517–533. [Google Scholar] [CrossRef]

- Tashiro, H.; Tarui, T. State of the Art for High Tensile Strength Steel Cord. Nippon Steel Technical Report 2003, 88, 87–91. [Google Scholar]

- Kruzel, R.; Ulewicz, M. The fatigue strength of bidirectionally bent steel cord used in tyres. Eng. Fail. Anal. 2019, 105, 176–181. [Google Scholar] [CrossRef]

- Berisha, B.; Raemy, C.; Becker, C.; Gorji, M.; Hora, P. Multiscale modelling of failure initiation in a ferritic–pearlitic steel. Acta Mater. 2015, 100, 191–201. [Google Scholar] [CrossRef]

- Czarski, A.; Skowronek, T.; Matusiewicz, P. Stability of a lamellar structure—Effect of the true interlamellar spacing on the durability of a pearlite colony. Arch. Metall. Mater. 2015, 60, 2499–2504. [Google Scholar] [CrossRef][Green Version]

- Grygier, D.; Rutkowska-Gorczyca, M.; Jasiński, R.; Dudziński, W. The structural and strength changes resulting from modification of heat treatment of high carbon steel. Arch. Metall. Mater. 2016, 61, 971–976. [Google Scholar] [CrossRef]

- EN 10323:2004; Steel Wire and Wire Products—Bead Wire. Comite Europeen de Normalisation: Brussels, Belgium, 2004.

- Kirihara, K. Production technology of wire rod for high tensile strength steel cord. Kobelco Technol. Rev. 2011, 30, 62–65. [Google Scholar]

- Vedeneev, A.V. Steel cord with a complete penetration of compound into the structure. CIS Iron Steel Rev. 2012, 1, 30–33. [Google Scholar]

- Dižo, J.; Blatnický, M. Investigation of ride properties of a three-wheeled electric vehicle in terms of driving safety. Transp. Res. Proc. 2019, 40, 663–670. [Google Scholar] [CrossRef]

- Droździel, P.; Wrona, R. Legal and utility problems of accidents on express roads and motorways. In Proceedings of the 11th International Science and Technical Conference Automotive Safety, Automotive Safety 2018, Casta, Slovakia, 18–20 April 2018. [Google Scholar]

- Jilek, P.; Krmela, J.; Berg, J. Modification of the adhesive force by changing the radial reaction on vehicle wheels. Transp. Probl. 2021, 16, 179–186. [Google Scholar] [CrossRef]

- Jurecki, R.S.; Jaskiewicz, M. Analysis of road accidents in Poland over the last ten years. Zesz. Nauk./Akad. Morska W Szczec. 2012, 32, 65–70. [Google Scholar]

- Matuszak, Z.; Jaskiewicz, M.; Więckowski, D.; Stokłosa, J. Remarks to the reliability assessment and to human actions-especially car driver. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 134, p. 00036. [Google Scholar]

- Šarkan, B.; Jaśkiewicz, M.; Kiktova, M. The impact of the truck loads on the braking efficiency assessment. Open Eng. 2020, 10, 105–112. [Google Scholar] [CrossRef]

- Zhang, Z.; Dhanasekar, M.; Ling, L.; Thambiratnam, D.P. Effectiveness of a raised road: Rail crossing for the safety of road vehicle occupants. Eng. Fail. Anal. 2019, 97, 258–273. [Google Scholar] [CrossRef]

- Orynycz, O.; Tucki, K.; Wasiak, A.; Sobótka, R.; Gola, A. Evaluation of the brake’s performance dependence upon technical condition of car tires as a factor of road safety management. Energies 2019, 13, 9. [Google Scholar] [CrossRef]

- Sejkorova, M.; Verner, J.; Sejkora, F.; Hurtova, I.; Senkyr, J. Analysis of Operation Wear of Brake Fluid Used in a Volvo Car. In Proceedings of the 22nd International Scientific Conference on Transport Means (Transport Means), Trakai, Lithuania, 3–5 October 2018; pp. 592–596. [Google Scholar]

- Caban, J.; Turski, A.; Nieoczym, A.; Tarkowski, S.; Jereb, B. Impact of specific factors on the state of the tire pressure value. Arch. Automot. Eng. 2019, 85, 137–148. [Google Scholar] [CrossRef]

- Szczucka-Lasota, B.; Węgrzyn, T.; Łazarz, B.; Kamińska, J.A. Tire pressure remote monitoring system reducing the rubber waste. Transp. Res. D Transp. Environ. 2021, 98, 102987. [Google Scholar] [CrossRef]

- Reiter, M.; Wagner, J. Automated automotive tire inflation system—Effect of tire pressure on vehicle handling. IFAC Proc. Vol. 2010, 43, 638–643. [Google Scholar] [CrossRef]

- Toma, M.; Andreescu, M.C.; Stan, C. Influence of tire inflation pressure on the results of diagnosing brakes and suspension. Procedia Manuf. 2018, 22, 121–128. [Google Scholar] [CrossRef]

- Oduro, S.D.; Alhassan, T.; Owusu-Ansah, P.; Andoh, P.Y. A mathematical model for predicting the effects of tyre pressure on fuel consumption. Res. J. Appl. Sci. 2013, 6, 123–129. [Google Scholar] [CrossRef]

- Trnka, L.; Gogola, M. Analysis of the tire contact area pressure on the road. Perner’s Contacts 2019, 14, 49–59. [Google Scholar]

- Vrabel, J.; Skrucany, T.; Bartuska, L.; Koprna, J. Movement analysis of the semitrailer with the tank-container at hard braking-the case study. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 710, p. 012025. [Google Scholar]

- Kasprzak, E.; Lewis, K.; Milliken, D. Inflation pressure effects in the nondimensional tire model. SAE Tech. Pap. 2006, 115, 1781–1792. [Google Scholar]

- Li, Y.; Zuo, S.; Lei, L.; Yang, X.; Wu, X. Analysis of impact factors of tire wear. J. Vib. Control 2011, 18, 833–840. [Google Scholar] [CrossRef]

- Gnap, J.; Konečný, V.; Varjan, P. Research on relationship between freight transport performance and GDP in Slovakia and EU countries. Naše More 2018, 65, 32–39. [Google Scholar] [CrossRef]

- Bakowski, H.; Czech, P. Wear estimation of the wheel tyre in different service conditions. Transp. Probl. 2014, 9, 119–127. [Google Scholar]

- Burdzik, R.; Konieczny, Ł.; Czech, P.; Warczek, J.; Wojnar, G. Influence of tire stiffness on acceleration of wheel in forced vibration test method. Vibroeng. Procedia 2014, 3, 219–223. [Google Scholar]

- Dižo, J.; Blatnický, M.; Sága, M.; Harušinec, J.; Gerlici, J.; Legutko, S. Development of a new system for attaching the wheels of the front axle in the cross-country vehicle. Symmetry 2020, 12, 1156. [Google Scholar] [CrossRef]

- Konieczny, Ł.; Burdzik, R.; Łazarz, B. The influence of changing vehicle tire stiffness on phase angle. In Proceedings of the 19th International Congress on Sound and Vibration 2012, ICSV, Vilnius, Lithuania, 8–12 July 2012; Volume 4, pp. 2844–2851. [Google Scholar]

- Lukac, M.; Brumercik, F.; Krzywonos, L. Driveability simulation of vehicle with variant tire properties. Commun.-Sci. Lett. Univ. Zilina 2016, 18, 34–37. [Google Scholar] [CrossRef]

- Rievaj, V.; Vrabel, J.; Synak, F.; Bartuska, L. The effects of vehicle load on driving characteristics. Adv. Sci. Technol. Res. J. 2018, 12, 142–149. [Google Scholar] [CrossRef]

- Koch, S.; Köppen, E.; Gräbner, N.; von Wagner, U. On the influence of multiple equilibrium positions on brake noise. FU Mech. Eng. 2021, 19, 613–632. [Google Scholar] [CrossRef]

- Godlewska, J. Recovery and recycling of waste tires in Poland. Procedia Eng. 2017, 182, 229–234. [Google Scholar] [CrossRef]

- Jacyna, M.; Wasiak, M.; Lewczuk, K.; Karoń, G. Noise and environmental pollution from transport: Decisive problems in developing ecologically efficient transport systems. J. Vibroeng. 2017, 19, 5639–5655. [Google Scholar] [CrossRef]

- Piasecka, I.; Tomporowski, A.; Piotrowska, K. Environmental analysis of post-use management of car tires. Przem. Chem. 2018, 97, 1649–1653. [Google Scholar]

- Katarzyna, P.; Izabela, P.; Patrycja, B.-W.; Weronika, K.; Andrzej, T. LCA as a tool for the environmental management of car tire manufacturing. Appl. Sci. 2017, 10, 7015. [Google Scholar] [CrossRef]

- Čulík, K.; Kalašová, A.; Štefancová, V. Evaluation of Driver’s Reaction Time Measured in Driving Simulator. Sensors 2022, 22, 3542. [Google Scholar] [CrossRef]

- Dirnbach, I.; Kubjatko, T.; Kolla, E.; Ondruš, J.; Šarić, Ž. Methodology designed to evaluate accidents at intersection crossings with respect to forensic purposes and transport sustainability. Sustainability 2020, 12, 1972. [Google Scholar] [CrossRef]

- Rella Riccardi, M.; Mauriello, F.; Scarano, A.; Montella, A. Analysis of contributory factors of fatal pedestrian crashes by mixed logit model and association rules. Int. J. Inj. Control. Saf. Promot. 2022; Online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Vlkovsky, M.; Veselik, P. Cargo securing-comparison of the selected trucks. Transp. Probl. 2020, 15, 265–274, Part 2. [Google Scholar] [CrossRef]

- Kováč, I.; Krmela, J.; Bakošová, D. Parametrizing of material input for modal analyses of FEA tire models. Metall. J. 2011, LXIV, 73–78. [Google Scholar]

- Sadjiep Tchuigwa, B.S.; Krmela, J.; Pokorny, J. A literature review on tire component requirements. Perner’s Contacts 2021, 16, 2. [Google Scholar] [CrossRef]

- Vavroa, J.; Vavro, J.jr.; Kováčiková, P.; Bezdedová, R. The optimization of the materials properties for the passenger cars in dependence on defect distribution at the dynamic loading. Procedia Eng. 2016, 136, 114–119. [Google Scholar] [CrossRef]

- Vavro, J.; Kopecký, M.; Koštial, P.; Hajská, H.; Fandáková, M. The experimental measurement of the tyre impurities circulation by the dynamic loading and application of the experiment evaluation by the method of the active factor experiment. Mach. Dyn. Probl. 2004, 28, 171–176. [Google Scholar]

- Subramonian, S.; Umesh, K.S.; Salleh, M.S.; Sivakumar, D.; Izamshah, R.; Ali, M.A. Mathematical modelling and conceptual design of novel automatic tyre inflating system. J. Teknol. 2018, 80. [Google Scholar] [CrossRef][Green Version]

- Tarkowski, S.; Nieoczym, A.; Caban, J.; Jilek, P.; Sejkorová, M. The Analysis of Pneumatic Wheel Rim Deformation while Hitting an Obstacle. Appl. Sci. 2022, 12, 6371. [Google Scholar] [CrossRef]

- Motrycz, G.; Helnarska, K.J.; Stryjek, P. Continuing a vehicle fitted with run flat tyres. Sci. J. Sil. Univ. Technol. Series Transp. 2021, 112, 157–169. [Google Scholar] [CrossRef]

- Jilek, P.; Nemec, J. Changing adhesion force for testing road vehicles at safe speed. In Proceedings of the 19th International Scientific Conference Engineering for Rural Development, Jeglava, Latvia, 20–22 May 2020; pp. 1411–1417. [Google Scholar]

- Pardeshi, S.S.; Patange, A.D.; Jegadeeshwaran, R.; Bhosale, M.R. Tyre Pressure Supervision of Two Wheeler Using Machine Learning. Struct. Durab. Health Monit. 2022, 16, 271–290. [Google Scholar] [CrossRef]

- Islam, M.B.; Hernandez, S. Modeling Injury Outcomes of Crashes Involving Heavy Vehicles on Texas Highways. Transp. Res. Rec. J. Transp. Res. Board 2013, 2388, 28–36. [Google Scholar] [CrossRef]

- Mazur, T.; Rucki, M.; Gutsalenko, Y. Accuracy analysis of the curved profile measurement with CMM: A case study. FU Mech. Eng. 2022. first online. [Google Scholar] [CrossRef]

- Ryba, T.; Rucki, M.; Siemiatkowski, Z.; Bzinkowski, D.; Solecki, M. Design and calibration of the system supervising belt tension and wear in an industrial feeder. FU Mech. Eng. 2022, 20, 166–176. [Google Scholar] [CrossRef]

- Chocholac, J.; Hruska, R.; Machalik, S.; Sommerauerova, D.; Sohajek, P. Framework for Greenhouse Gas Emissions Calculations in the Context of Road Freight Transport for the Automotive Industry. Sustainability 2021, 13, 4068. [Google Scholar] [CrossRef]

- Droździel, P.; Komsta, H.; Krzywonos, L. Repair costs and the intensity of vehicle use. Transp. Probl. 2013, 8, 131–138. [Google Scholar]

- Guzek, M.; Lozia, Z. Are EDR Devices Undoubtedly Helpful in the Reconstruction of a Road Traffic Accident? Energies 2021, 14, 6940. [Google Scholar] [CrossRef]

- Jurecki, R.; Jaskiewicz, M.; Wdowski, T. Testing the influence of car load and pressure in tyres on the value of damping of shock absorbers specified with the use of the Eusama method. Diagnostyka 2014, 15, 45–50. [Google Scholar]

- Vaiana, R.; Perri, G.; Iuele, T.; Gallelli, V. A Comprehensive Approach Combining Regulatory Procedures and Accident Data Analysis for Road Safety Management Based on the European Directive 2019/1936/EC. Safety 2021, 7, 6. [Google Scholar] [CrossRef]

- Zaranka, J.; Pečeliūnas, R.; Žuraulis, V. A Road Safety-Based Selection Methodology for Professional Drivers: Behaviour and Accident Rate Analysis. Int. J. Environ. Res. Public Health 2021, 18, 12487. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drozd, K.; Tarkowski, S.; Caban, J.; Nieoczym, A.; Vrábel, J.; Krzysiak, Z. Analysis of Truck Tractor Tire Damage in the Context of the Study of Road Accident Causes. Appl. Sci. 2022, 12, 12333. https://doi.org/10.3390/app122312333

Drozd K, Tarkowski S, Caban J, Nieoczym A, Vrábel J, Krzysiak Z. Analysis of Truck Tractor Tire Damage in the Context of the Study of Road Accident Causes. Applied Sciences. 2022; 12(23):12333. https://doi.org/10.3390/app122312333

Chicago/Turabian StyleDrozd, Kazimierz, Sławomir Tarkowski, Jacek Caban, Aleksander Nieoczym, Jan Vrábel, and Zbigniew Krzysiak. 2022. "Analysis of Truck Tractor Tire Damage in the Context of the Study of Road Accident Causes" Applied Sciences 12, no. 23: 12333. https://doi.org/10.3390/app122312333

APA StyleDrozd, K., Tarkowski, S., Caban, J., Nieoczym, A., Vrábel, J., & Krzysiak, Z. (2022). Analysis of Truck Tractor Tire Damage in the Context of the Study of Road Accident Causes. Applied Sciences, 12(23), 12333. https://doi.org/10.3390/app122312333