Effect of Robot Motion Accuracy on Surface Form during Computer-Controlled Optical Surfacing Process

Abstract

1. Introduction

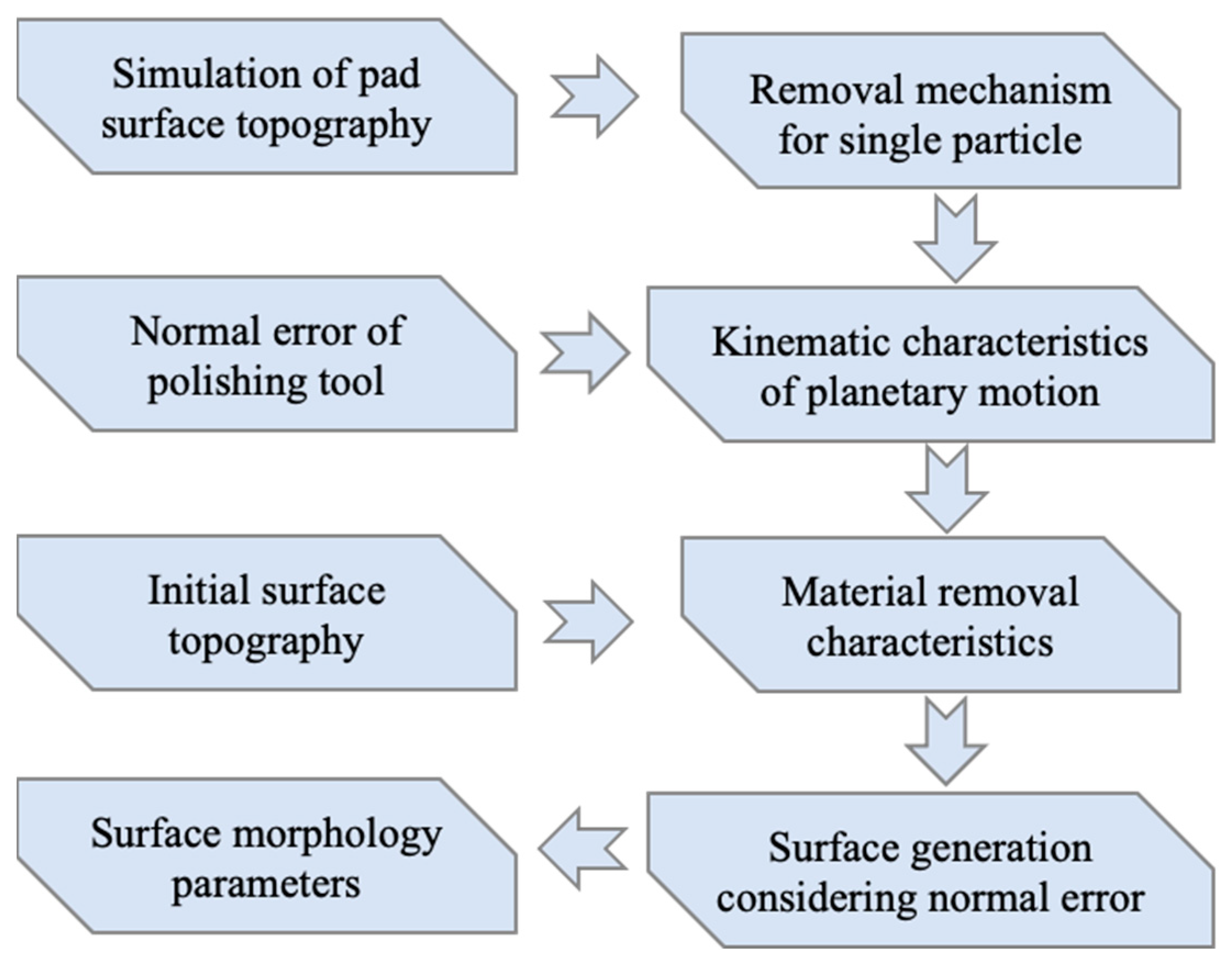

2. Model Development

2.1. Modeling of Pad Surface Topography

- i.

- We estimated the average spacing between the micropores on the pad surface by observing the total number of micropores on the pad surface and the total surface area of the polishing pad , as shown in Equation (1).The value was taken as the average spacing of uniformly distributed micropores, and the position of the center point of the micropores was expressed as . Since the distribution of micropores mostly presented a disordered random position distribution, the position of the center point of the micropores was randomly shifted in the , , and directions of the spatial coordinates, as follows:where , , and represent the random offset of the initial center point position of the micropore in the three directions of , , and , respectively.

- ii.

- After the random displacement of the center position of the micropore was determined, the hemispherical “micropore” was simulated at the new position, with the diameter of the micropore obeying an exponential distribution with an average value of 85 μm, so as to simulate the pore distribution characteristics of the pad surface.

- iii.

- The statistical analysis of the distribution characteristics of the micropore diameter on the pad surface and the porosity of the pad surface was conducted. Compared with the measured data, if the error of the simulation result was less than 5%, the simulation met the requirements. Otherwise, we re-sampled and simulated the position of the central hole of the micropore until the micropore distribution characteristics met the requirements.

- iv.

- According to the distribution characteristics of the diversion grooves and the central hole on the pad surface, the height of the slurry supply hole and the position of the groove in the theoretical model was set to −1.5 mm; then, the theoretical simulation morphology of the polishing pad surface was generated.

2.2. Removal Mechanism for Single Particle

2.3. Material Removal Model under Planetary Motion

2.4. Material Removal Considering the Normal Error of the Polishing Tool

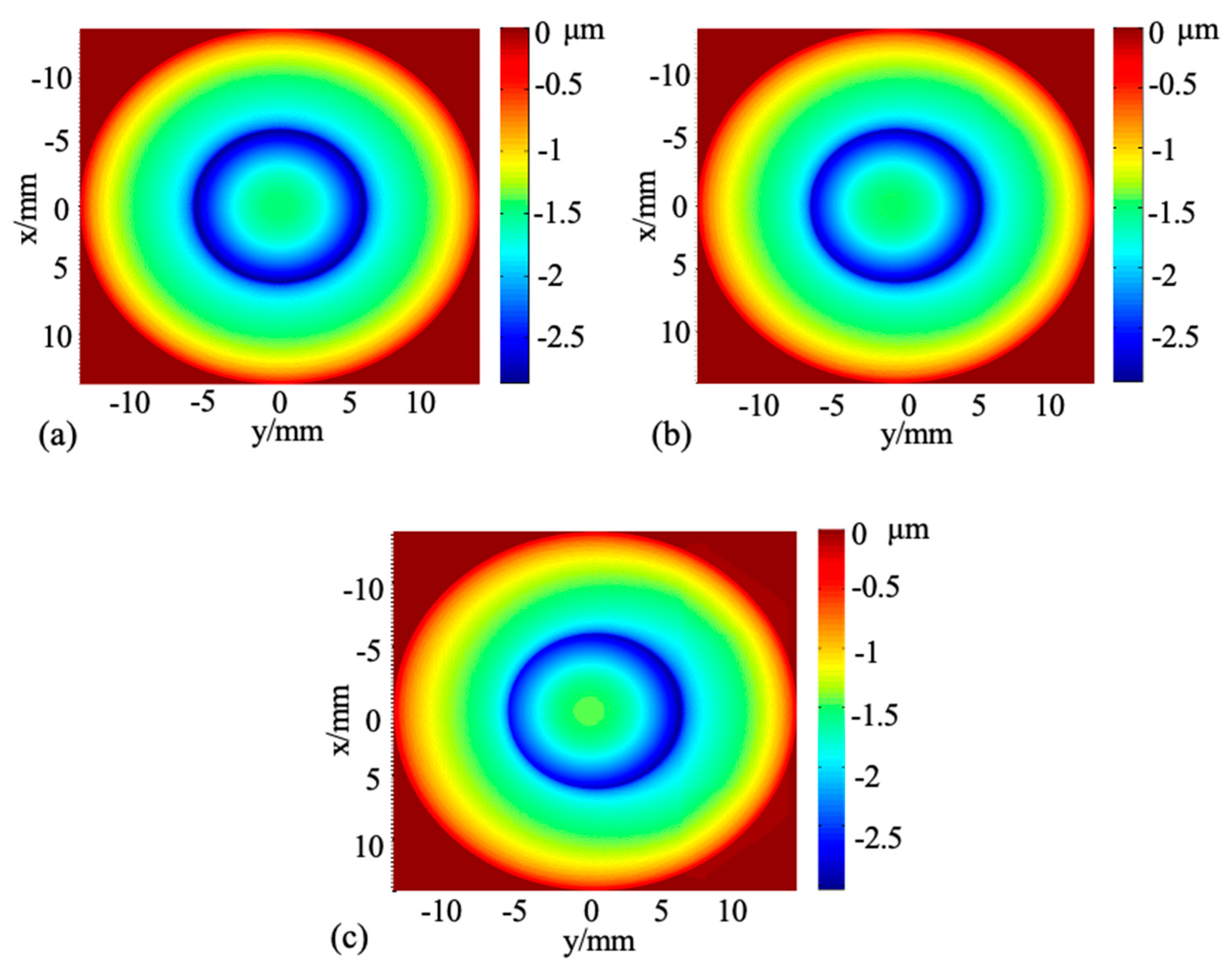

2.5. Surface Generation Considering Normal Error of Polishing Tool

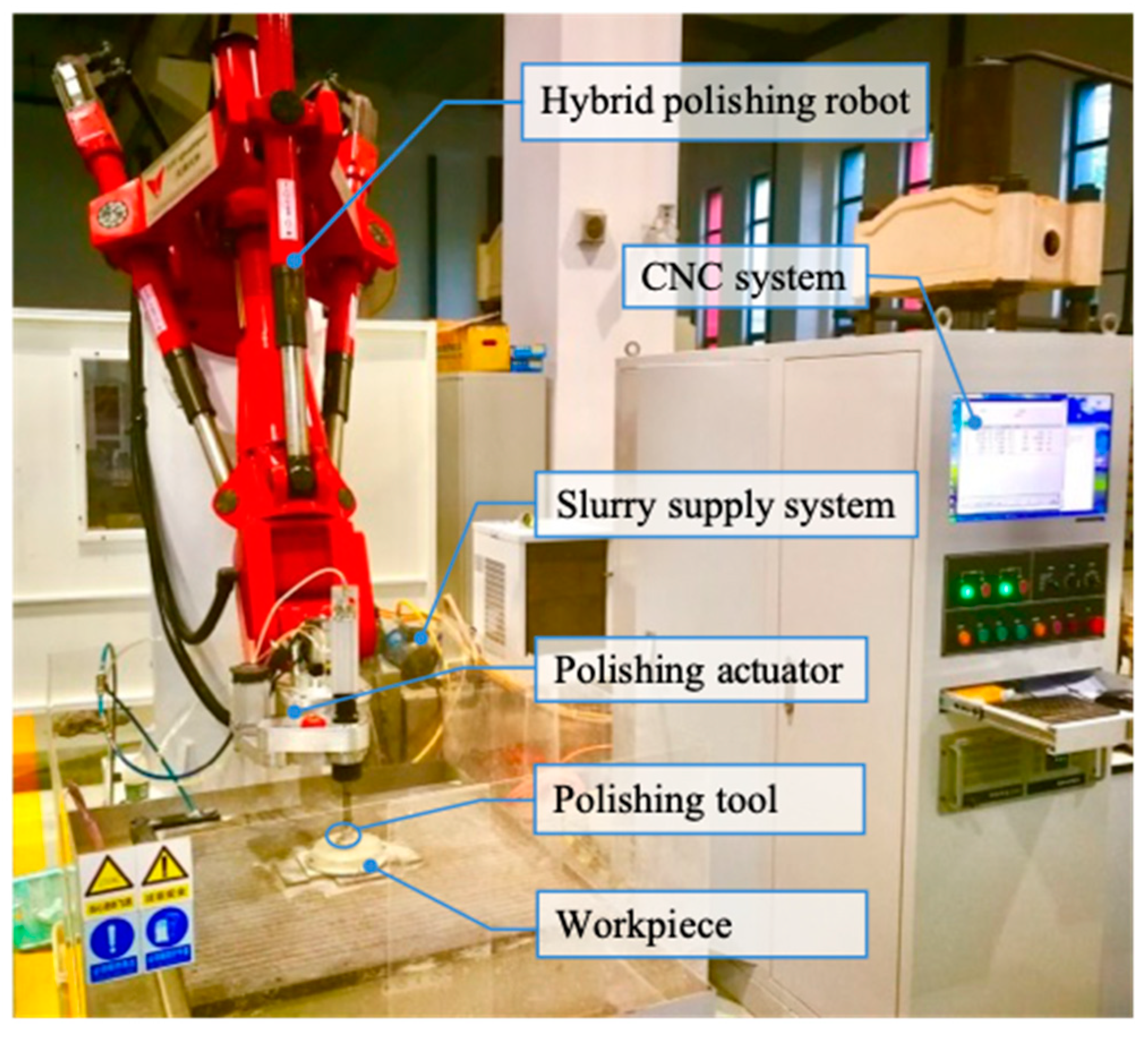

3. Experimental Design

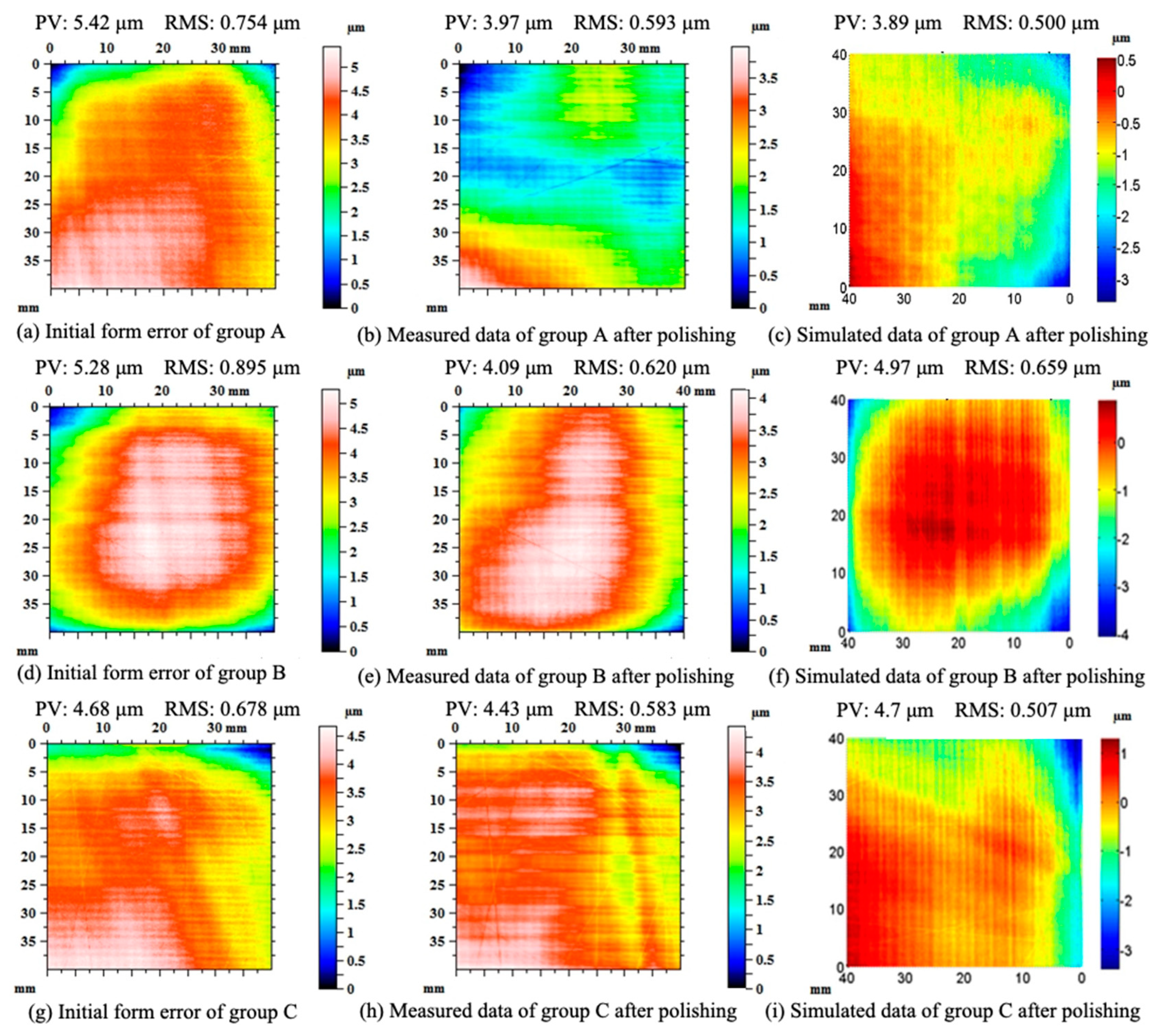

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, S.; Tong, Z.; Jiang, X. Advances in the design and manufacturing of novel freeform optics. Int. J. Extrem. Manuf. 2022, 4, 032004. [Google Scholar] [CrossRef]

- Lin, B.; Li, K.L.; Cao, Z.-C.; Huang, T. Modeling of pad surface topography and material removal characteristics for computer-controlled optical surfacing process. J. Mater. Process. Technol. 2019, 265, 210–218. [Google Scholar] [CrossRef]

- Li, S.; Dai, Y. CCOS Technology Based on Small Polishing Pad; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Ke, X.L.; Wang, T.Y.; Zhang, Z.L.; Huang, L.; Wang, C.J.; Negi, V.S.; Pullen, W.C.; Choi, H.; Kim, D.; Idir, M. Multi-tool optimization for computer controlled optical surfacing. Opt. Express 2022, 30, 16957–16972. [Google Scholar] [CrossRef]

- Cao, Z.-C.; Cheung, C.F.; Ho, L.T.; Liu, M.Y. Theoretical and experimental investigation of surface generation in swing precess bonnet polishing of complex three-dimensional structured surfaces. Precis. Eng. 2017, 50, 361–371. [Google Scholar] [CrossRef]

- Wan, S.; Wei, C.; Hu, C.; Situ, G.; Shao, Y.; Shao, J. Novel magic angle-step state and mechanism for restraining the path ripple of magnetorheological finishing. Int. J. Mach. Tools Manuf. 2021, 161, 103673. [Google Scholar] [CrossRef]

- West, S. Development and Results for Stressed-lap Polishing of Large Telescope Mirrors. In Optical Fabrication and Testing; Optica Publishing Group: Washington, DC, USA, 2014; p. OTh2B-4. [Google Scholar]

- Wang, Y.B.; Dai, Y.F.; Hu, H.; Du, C.Y.; Bao, J.H. Study on rapid convergence strategy of nano-precision optical surface by ion beam figuring. Opt. Commun. 2022, 507, 127614. [Google Scholar] [CrossRef]

- Beaucamp, A.; Namba, Y. Super-smooth finishing of diamond turned hard X-ray molding dies by combined fluid jet and bonnet polishing. CIRP Ann.—Manuf. Technol. 2013, 62, 315–318. [Google Scholar] [CrossRef]

- Kim, D.W.; Burge, J.H.; Davis, J.M.; Martin, H.M.; Tuell, M.T.; Graves, L.R.; West, S.C. New and Improved Technology for Manufacture of GMT Primary Mirror Segments. In Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II; Navarro, R., Burge, J.H., Eds.; Proceedings of SPIE; SPIE: Bellingham, WA, USA, 2016; Volume 9912. [Google Scholar]

- Kim, D.W.; Burge, J.H. Rigid conformal polishing tool using non-linear visco-elastic effect. Opt. Express 2010, 18, 2242–2257. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, H. Generic model of time-variant tool influence function and dwell-time algorithm for deterministic polishing. Int. J. Mech. Sci. 2021, 211, 106795. [Google Scholar] [CrossRef]

- Liao, D.; Yuan, Z.; Tang, C.; Xie, R.; Chen, X. Mid-Spatial Frequency Error (PSD-2) of optics induced during CCOS and full-aperture polishing. J. Eur. Opt. Soc.-Rapid 2013, 8, Artn 13031. [Google Scholar] [CrossRef]

- Jones, R.A.; Plante, R.L. Rapid fabrication of large aspheric optics. Precis. Eng. 1987, 9, 65–70. [Google Scholar] [CrossRef]

- Lin, B.; Jiang, X.-M.; Cao, Z.-C.; Huang, T. Development and theoretical analysis of novel center-inlet computer-controlled polishing process for high-efficiency polishing of optical surfaces. Robot. Comput.-Integr. Manuf. 2019, 59, 1–12. [Google Scholar] [CrossRef]

- Wan, S.; Zhang, X.; Wang, W.; Xu, M.; Jiang, X. Edge control in precision robotic polishing based on space-variant deconvolution. Precis. Eng. 2019, 55, 110–118. [Google Scholar] [CrossRef]

- Kang, H.; Wang, T.Y.; Choi, H.; Kim, D. Genetic algorithm-powered non-sequential dwell time optimization for large optics fabrication. Opt. Express 2022, 30, 16442–16458. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.H.; Yang, J.X.; Huang, W.L.; Li, J. A tool-path planning method used in computer controlled optical surfacing based on improved prim algorithm. Int. J. Adv. Manuf. Technol. 2022, 119, 5917–5927. [Google Scholar] [CrossRef]

- Lin, B.; Jiang, X.M.; Cao, Z.C.; Huang, T.; Li, K.L. Theoretical and experimental analysis of material removal and surface generation in novel fixed abrasive lapping of optical surface. J. Mater. Process. Technol. 2019, 279, 116570. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-T.; Liu, M.; Cao, Z.-C. Effect of Robot Motion Accuracy on Surface Form during Computer-Controlled Optical Surfacing Process. Appl. Sci. 2022, 12, 12301. https://doi.org/10.3390/app122312301

Chen Y-T, Liu M, Cao Z-C. Effect of Robot Motion Accuracy on Surface Form during Computer-Controlled Optical Surfacing Process. Applied Sciences. 2022; 12(23):12301. https://doi.org/10.3390/app122312301

Chicago/Turabian StyleChen, Yong-Tong, Mingyu Liu, and Zhong-Chen Cao. 2022. "Effect of Robot Motion Accuracy on Surface Form during Computer-Controlled Optical Surfacing Process" Applied Sciences 12, no. 23: 12301. https://doi.org/10.3390/app122312301

APA StyleChen, Y.-T., Liu, M., & Cao, Z.-C. (2022). Effect of Robot Motion Accuracy on Surface Form during Computer-Controlled Optical Surfacing Process. Applied Sciences, 12(23), 12301. https://doi.org/10.3390/app122312301