A Combined Safety Monitoring Model for High Concrete Dams

Abstract

1. Introduction

2. Method

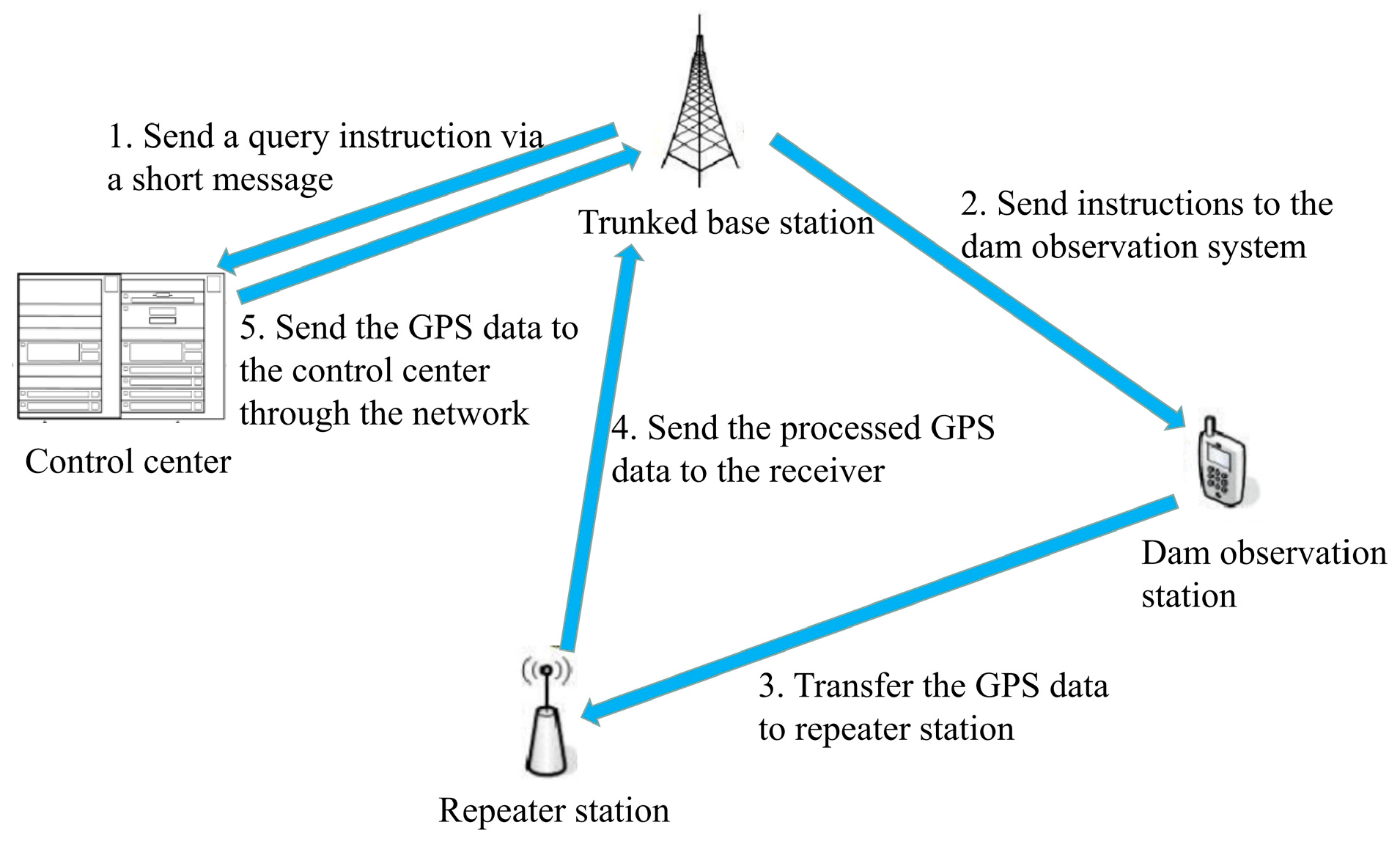

2.1. Method of Acquiring the Data with the GPS Technique

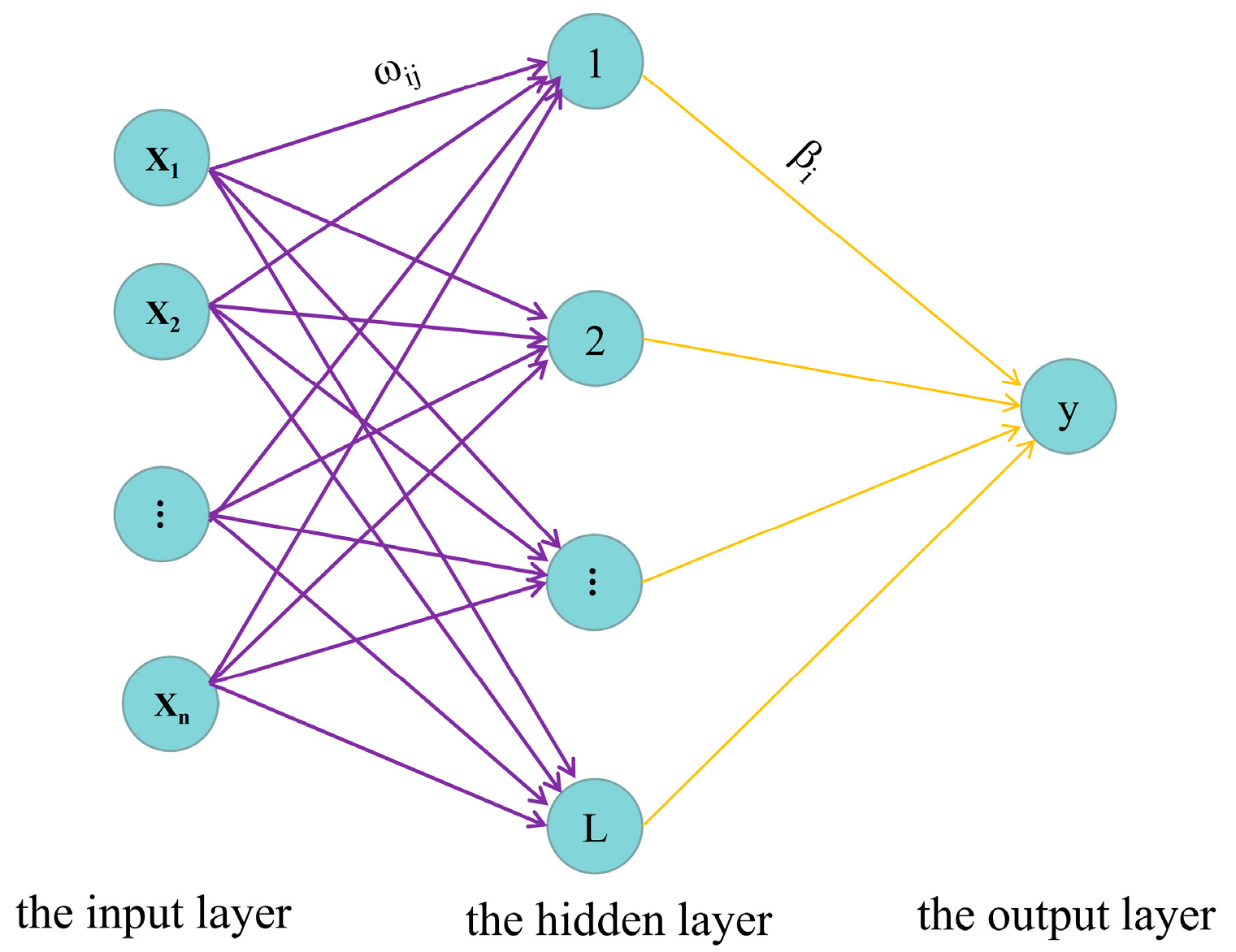

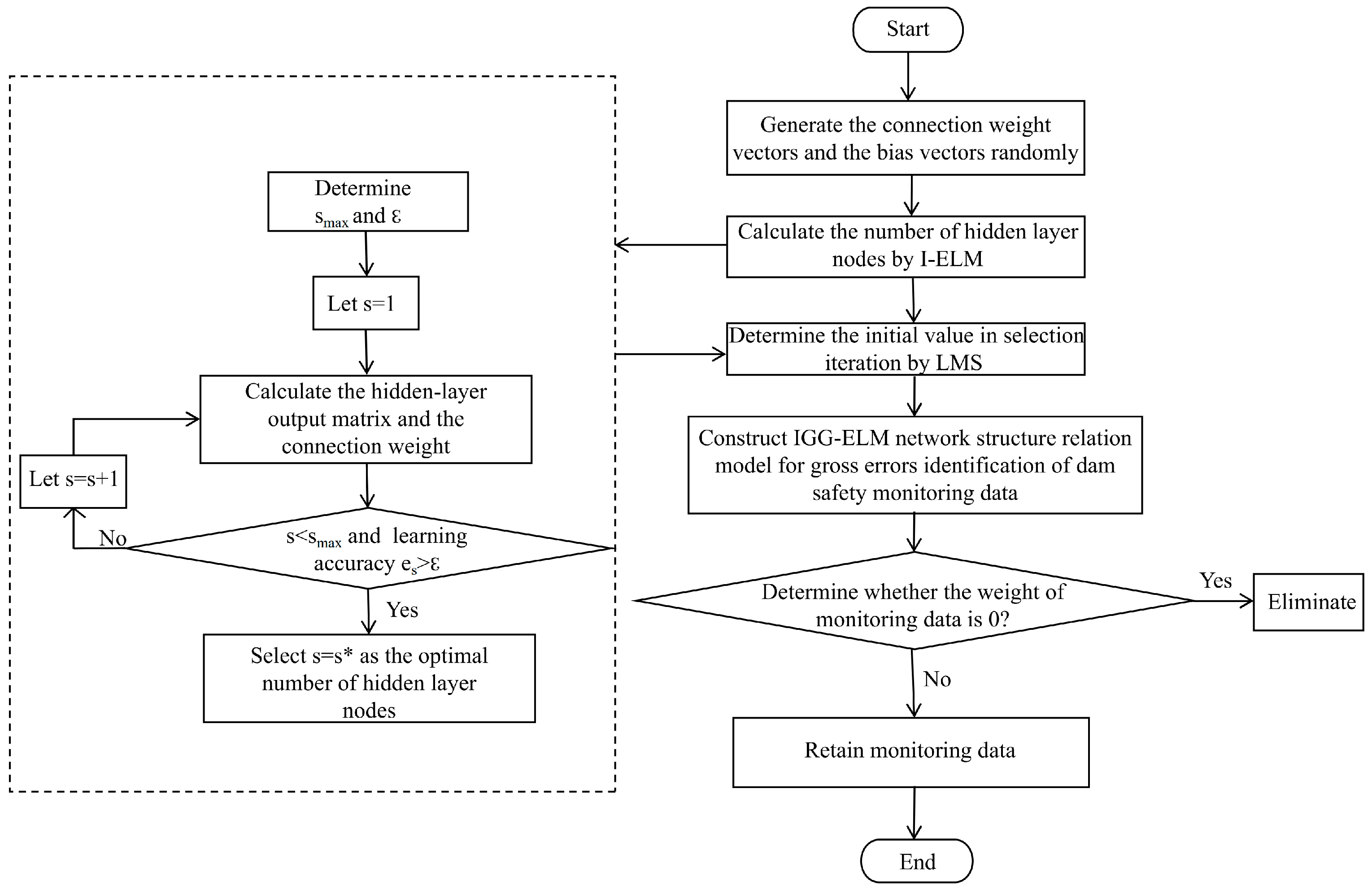

2.2. The Gross Errors Detection Method of Concrete Dam Deformation Monitoring Data Based on IGG-ELM

2.3. Determine the Principle of Initial Value in Selection Iteration Based on the LMS Method

2.4. Determine the Number of Hidden Layer Nodes through the Incremental Extreme Learning Machine Method (I-ELM)

2.5. Specific Steps of Eliminating Gross Errors of the Dam Monitoring Data

3. Case Study

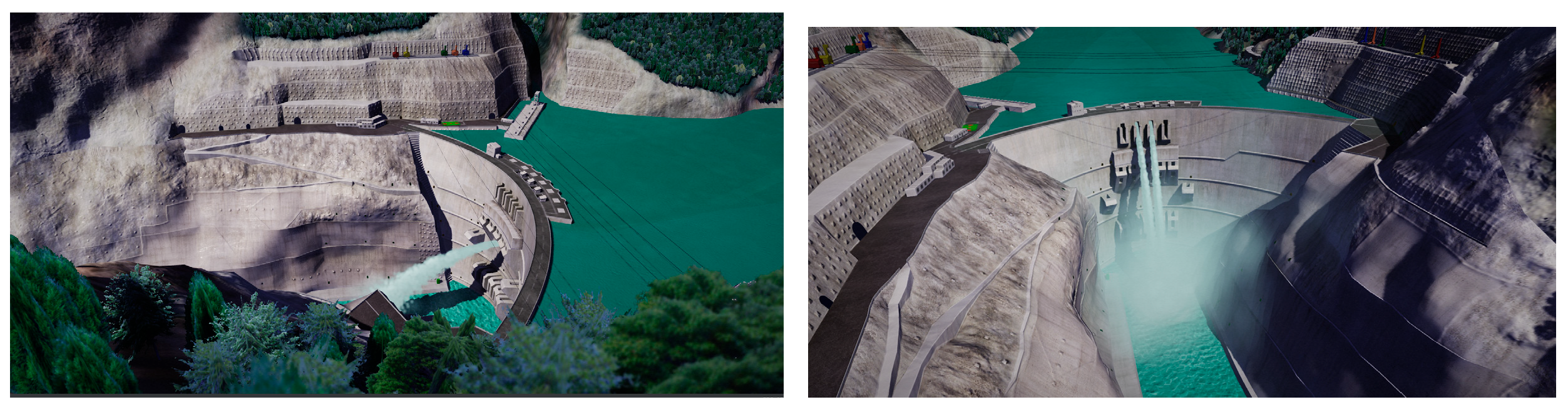

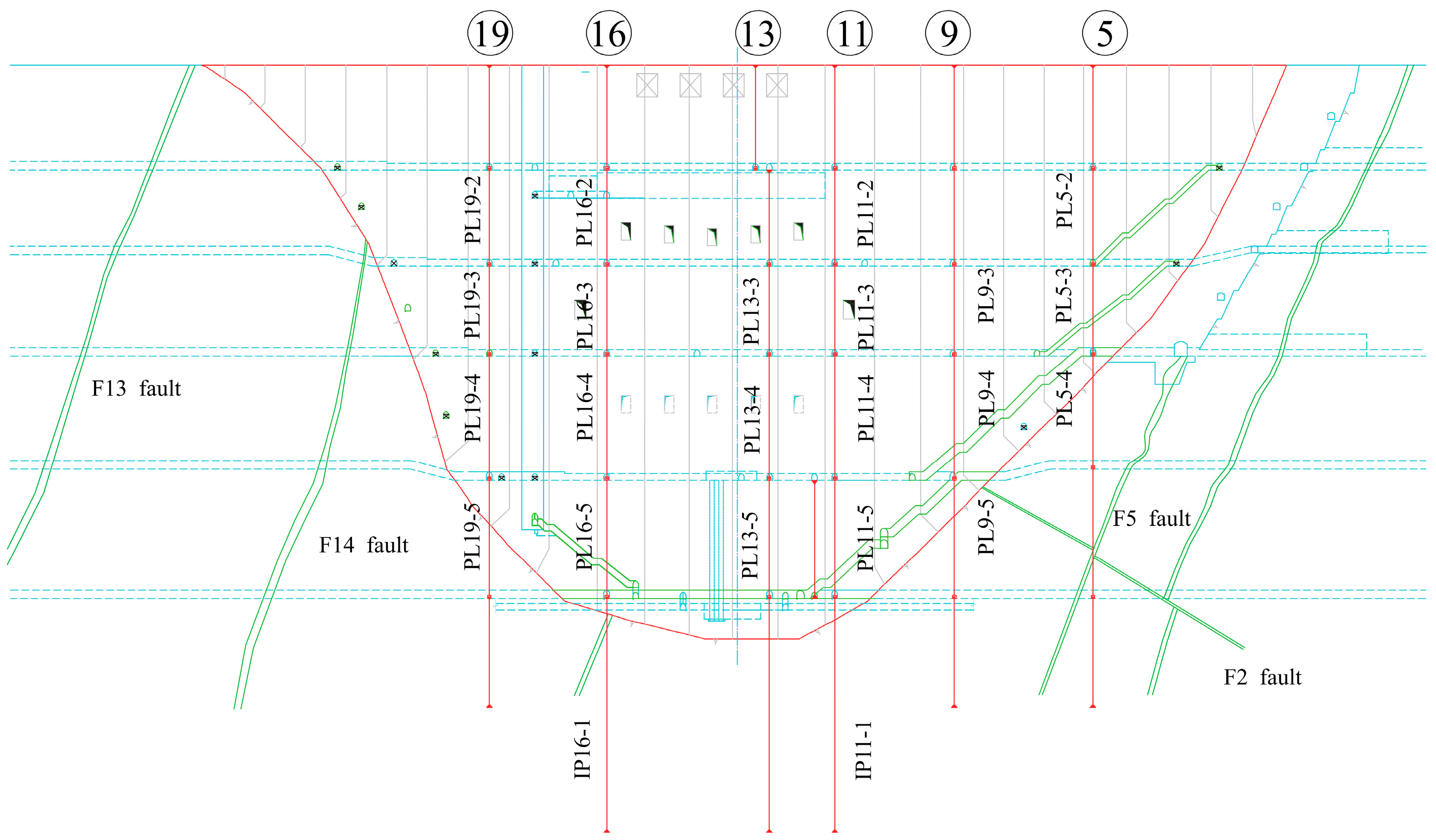

3.1. Project Overview

3.2. Selection of Model Influence Factors and Division of Data Sets

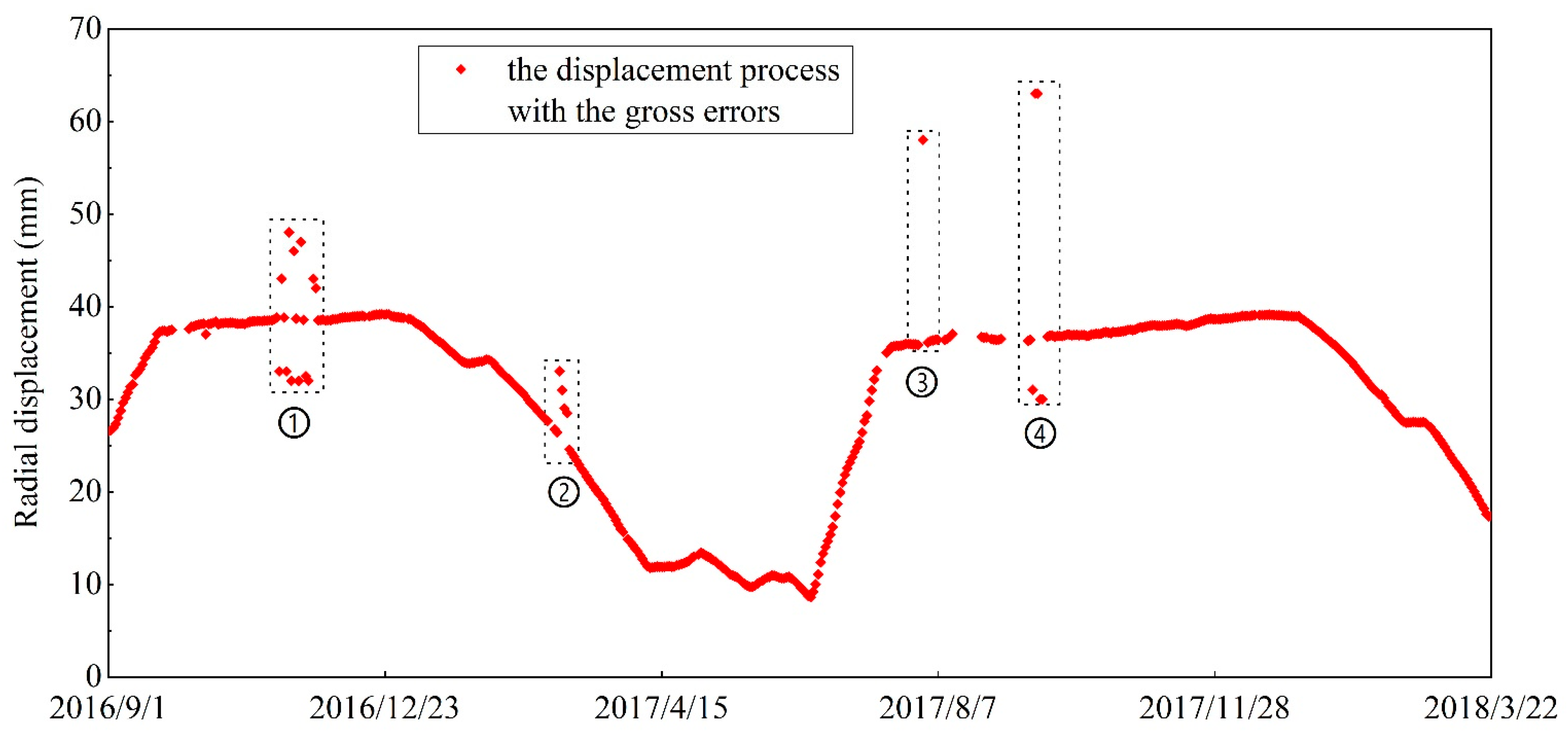

3.3. Comparison and Analysis of the Gross Error Removal Effect

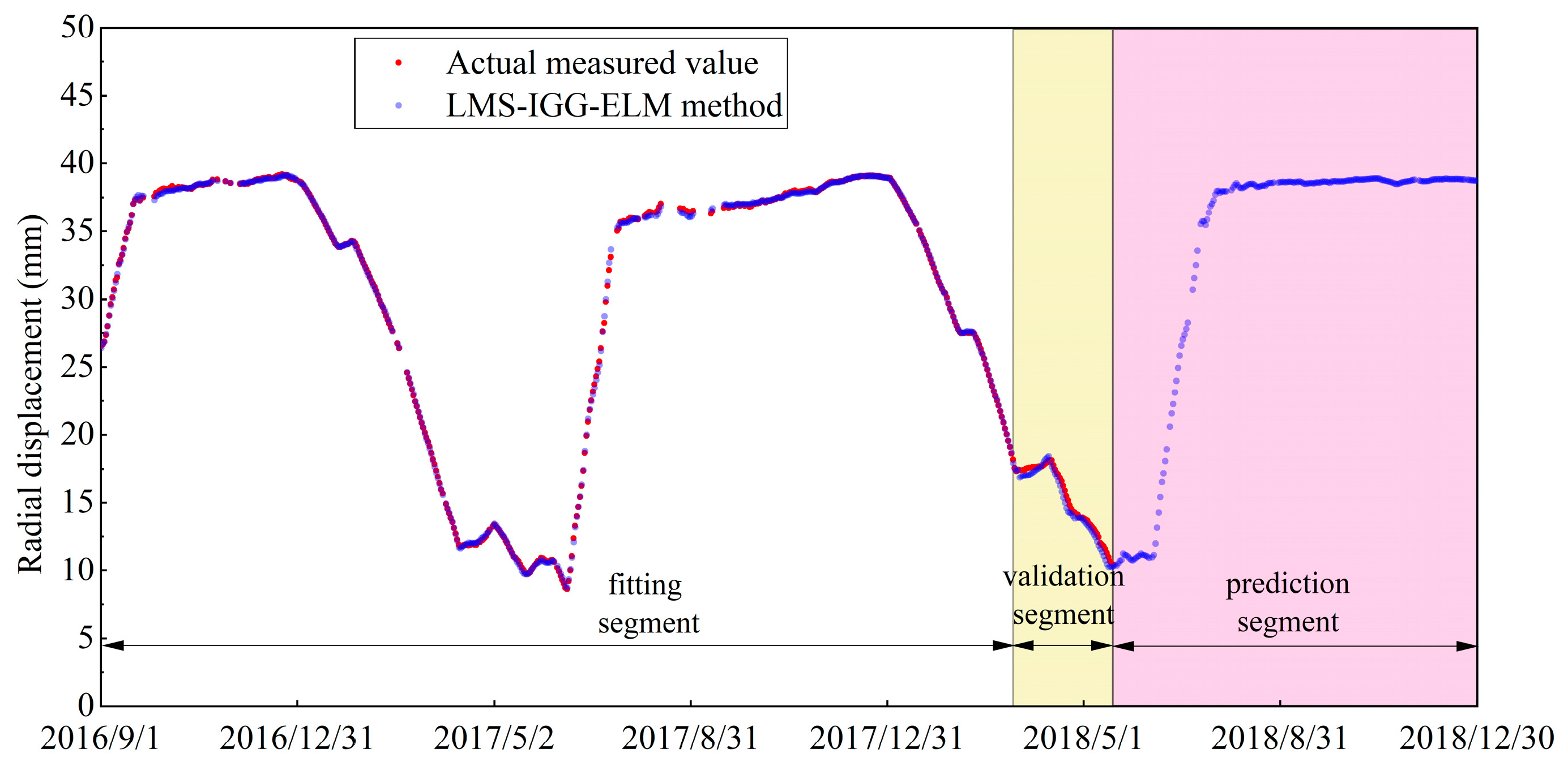

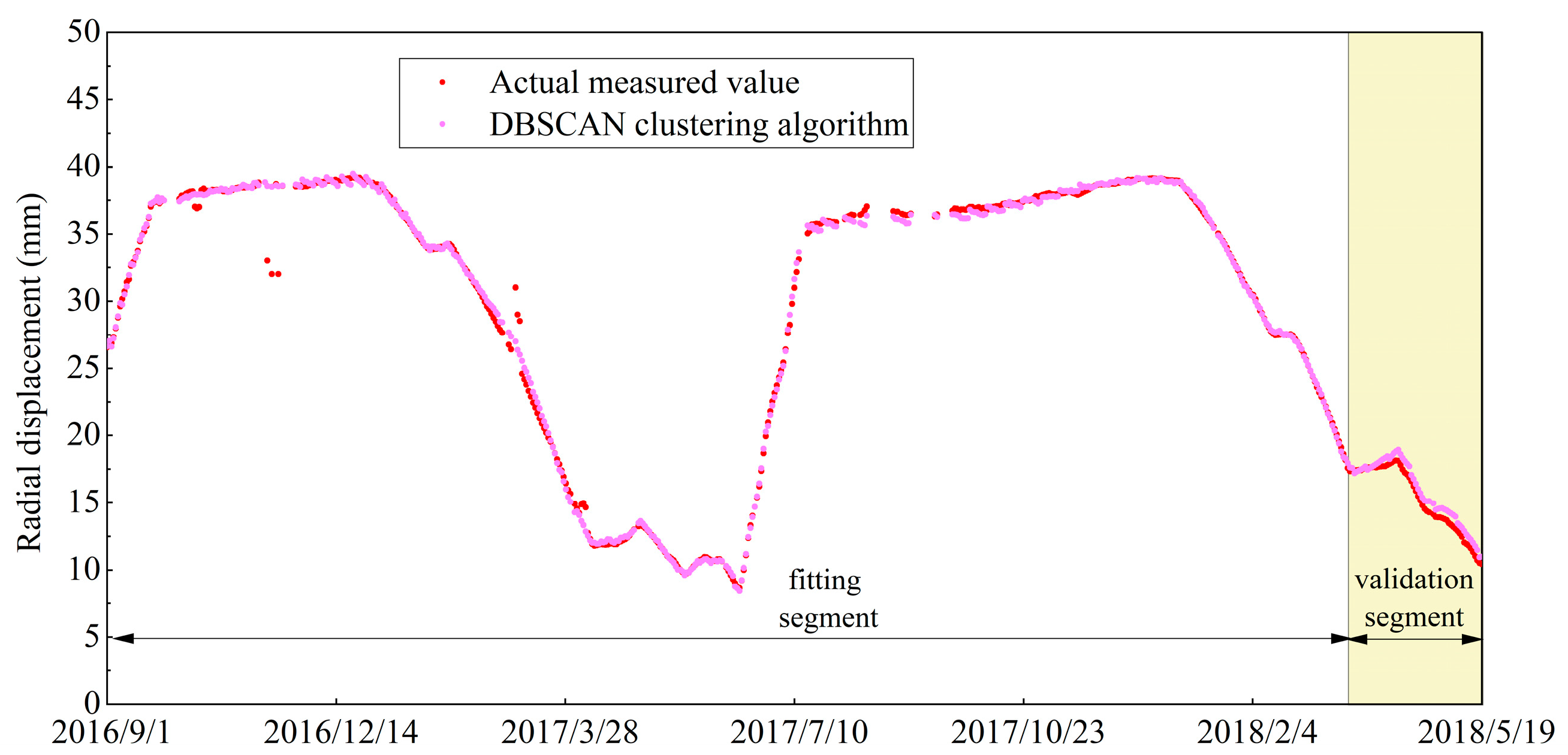

3.4. Validation Effect after Eliminating Gross Errors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, Y. Improvement of Dam Deformation Monitoring System by Remote Sensing Technology. J. Silicon Val. 2013, 5, 217–218. [Google Scholar]

- Yang, G. Application of GPS combined with near-view photography in landslide monitoring. J. Tour. Overv. 2011, 12, 66. [Google Scholar]

- Song, W.; Lv, J.; Liu, C.; Yang, L.; Huang, H.; Liu, Y.; Shi, Z.; Yan, S.; Lv, G.; Li, X. The Application of Remote Sensing Technology in the Construction of Digital Twin Watershed. J. China Flood Control. Drought Relief 2022, 32, 15–20. [Google Scholar]

- Luo, W. Application of GPS in Deformation Monitoring of Hydropower Station. J. Value Eng. 2022, 41, 129–131. [Google Scholar]

- Xi, R.; Liang, Y.; Chen, Q.; Jiang, W.; Chen, Y.; Liu, S. Analysis of Annual Deformation Characteristics of Xilongchi Dam Using Historical GPS Observations. Remote Sens. 2022, 14, 4018. [Google Scholar] [CrossRef]

- Galdelli, A. A Novel Remote Visual Inspection System for Bridge Predictive Maintenance. Remote Sens. 2022, 14, 2248. [Google Scholar] [CrossRef]

- Shang, Z.; Shen, Z. Flight Planning for Survey-Grade 3D Reconstruction of Truss Bridges. Remote Sens. 2022, 14, 3200. [Google Scholar] [CrossRef]

- Graves, W.; Aminfar, K.; Lattanzi, D. Full-Scale Highway Bridge Deformation Tracking via Photogrammetry and Remote Sensing. Remote Sens. 2022, 14, 2767. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Chahid, A.; Alam Khan, J.; Adegboro, O.G.; Samson, M.I. CTIMS: Automated Defect Detection Framework Using Computed Tomography. Appl. Sci. 2022, 12, 2175. [Google Scholar] [CrossRef]

- Li, X.; Jiang, M.; Wu, Z.; Chen, J. Comparison and improvement of coarse difference identification methods in dam safety monitoring data. J. Rural Water Resour. Hydropower China 2011, 3, 102–105+112. [Google Scholar]

- Gu, H.; Yang, M.; Gu, C.; Huang, X. AC-IBFGS-Based Inversion Method for Estimating the Quasi-Viscoelastic Parameters of Arch Dams. IEEE Access 2022, 10, 68151–68160. [Google Scholar] [CrossRef]

- Kim, H.S.; Chung, C.K.; Kim, H.K. Geo-spatial data integration for subsurface stratification of dam site with outlier analyses. Environ. Earth Sci. 2016, 75, 1–10. [Google Scholar] [CrossRef]

- Rasheed, F.; Peng, P.; Alhajj, R.; Rokne, J. Fourier Transform Based Spatial Outlier Mining. Lect. Notes Comput. Sci. 2009, 5788, 317–324. [Google Scholar]

- Lach, S. The application of selected statistical tests in the detection and removal of outliers in water engineering data based on the example of piezometric measurements at the Dobczyce dam over the period 2012–2016. E3S Web Conf. 2018, 45, 4500045. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J.; Kou, P. Abnormal Diagnosis of Dam Safety Monitoring Data Based on Ensemble Learning. J. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 062027. [Google Scholar]

- Song, J.; Zhang, S.; Tong, F.; Yang, J.; Zeng, Z.; Yuan, S. Outlier Detection Based on Multivariable Panel Data and K-Means Clustering for Dam Deformation Monitoring Data. J. Adv. Civ. Eng. 2021, 2021, 3739551. [Google Scholar] [CrossRef]

- Shao, C.; Zheng, S.; Gu, C.; Hu, Y.; Qin, X. A novel outlier detection method for monitoring data in dam engineering. J. Expert Syst. Appl. 2022, 193, 116476. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Zhang, H.; Li, Y.; Wu, Z. Crude difference identification method for dam monitoring data based on robust estimation. J. Hydropower Energy Sci. 2018, 36, 68–71. [Google Scholar]

- Li, X.; Li, Y.; Lu, X.; Wang, Y.; Zhang, H.; Zhang, P. An online anomaly recognition and early warning model for dam safety monitoring data. J. Struct. Health Monit. Int. J. 2020, 19, 796–809. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zhang, P.; Yang, Z. Research and application of an improved Pauta criterion based on M estimation in coarse difference identification of monitoring data. J. China’s Rural Water Resour. Hydropower 2019, 8, 133–136. [Google Scholar]

- Hu, D.; Qu, X.; Yang, J.; Cheng, L.; Chang, M. The Dam Deformation Safety Monitoring Model Based on M-ELM. J. Prog. Water Conserv. Hydropower Technol. 2019, 39, 75–80. [Google Scholar]

- Tonini, D. Observed behavior of several leakier arch dams. J. Power Div. 1956, 82, 135–139. [Google Scholar] [CrossRef]

- Bonaldi, P.; Faelli, M.; Giusepptti, G. Displacement forecasting for concrete dams via deterministic mathematical models. J. Int. Water Power Dam Constr. 1977, 29, 42–50. [Google Scholar]

- Yang, J.; Wu, Z. Research status and development of dam safety monitoring at home and abroad. J. Xi’an Univ. Technol. 2002, 1, 26–30. [Google Scholar]

- WU, Z. Research on the deterministic model and hybrid model of concrete dam safety monitoring. J. Hydraul. Eng. 1989, 5, 64–70. [Google Scholar]

- Wu, Z. Safety Monitoring Theory & Its Application of Hydraulic Structures; Higher Education Press: Beijing, China, 2003. [Google Scholar]

- Zhao, E.; Gu, C. Research on health diagnosis of long-term service performance of concrete dam. J. Hydropower Gener. 2021, 40, 22–34. [Google Scholar]

- Huang, H.; Chen, B.; Liu, C. Safety monitoring of a super-high dam using optimal kernel partial least squares. J. Math. Probl. Eng. 2015, 12, 1–13. [Google Scholar] [CrossRef]

- Guang, H. Application of RBF Neural Network in Dam Deformation Prediction. J. Appl. Mech. Mater. 2014, 3547, 261–264. [Google Scholar]

- Gu, H. A factor mining model with optimized random forest for concrete dam deformation monitoring. J. Water Sci. Eng. 2021, 14, 330–336. [Google Scholar] [CrossRef]

- Gabriella, M. Multi-target support vector regression via correlation regressor chains. J. Inf. Sci. 2017, 415, 53–69. [Google Scholar]

- Alocen, P.; Fernandez-Centeno, M.A.; Toledo, M.A. Prediction of Concrete Dam Deformation through the Combination of Machine Learning Models. J. Water 2022, 14, w14071133. [Google Scholar]

- Liu, W.; Tang, S. Robust estimation of the two coarse-error detection methods. J. Liaoning Univ. Eng. Technol. 2016, 35, 54–58. [Google Scholar]

- Massart, D.L.; Kaufman, L.; Rousseeuw, P.J.; Leroy, A. Least median of squares: A robust method for outlier and model error detection in regression and calibration. Anal. Chim. Acta 1986, 187, 171–179. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, P.; Jiang, J. Study on Dam Deformation Prediction Based on EMD-PSO-ELM algorithm. J. Software Guide 2020, 19, 1–5. [Google Scholar]

- Su, L.; Yao, M. Extreme Learning Machine with Multiple Kernels. Proceeidings of the 2013 10th IEEE International Conference on Control and Automation, Hangzhou, China, 12–14 June 2013. [Google Scholar]

- Andrews, D.F.; Bickel, P.J.; Hampel, F.R.; Huber, P.J.; Rogers, W.H.; Tukey, J.W. Robust Estimates of Location: Survey and Advances; Princeton University Press: Princeton, NJ, USA, 1972. [Google Scholar]

- Zhou, J. Classical error theory and differential resistance estimation. J. Surv. Mapp. 1989, 2, 115–120. [Google Scholar]

- Wang, F.; Zhou, S.; Zhou, Q.; Lu, P. Selection robust iteration method with LMS. J. Surv. Mapp. Eng. 2015, 24, 33–35+47. [Google Scholar]

| Observation Points | Satellite Cut-Off Height Angle (°) | The Number of Effectively Observed Satellites | Observation Period | Data Acquisition Interval (s) | ||

|---|---|---|---|---|---|---|

| Simultaneous Observation | Total | Quantity | Observation Time Duration (h) | |||

| The reference points | ≥15 | ≥4 | ≥9 | 2 | / | 30 |

| Work basis points | ≥15 | ≥4 | ≥9 | 2 | ≥5 | 30 |

| Deformation observation points | ≥15 | ≥4 | ≥4 | 2 | ≥5 | 30 |

| Judgment Condition | Monitoring Value | Measure | Weight |

|---|---|---|---|

| normal | reservation weight | 1 | |

| available | reduce the weight | less than 1 | |

| abnormal | eliminate | 0 |

| Data | First Iteration Weights ( = 2.15) | Final Iteration Weights ( = 0.45) | Data | First Iteration Weights ( = 2.15) | Final Iteration Weights ( = 0.45) |

|---|---|---|---|---|---|

| 10 November 2016 | 0 | 0 | 25 November 2016 | 0.9261 | 0 |

| 11 November 2016 | 0.8415 | 0 | 5 March 2017 | 0 | 0 |

| 13 November 2016 | 0 | 0 | 6 March 2017 | 0.6772 | 0 |

| 14 November 2016 | 0 | 0 | 7 March 2017 | 1 | 0 |

| 15 November 2016 | 0 | 0 | 8 March 2017 | 1 | 0 |

| 16 November 2016 | 0 | 0 | 1 August 2017 | 0 | 0 |

| 18 November 2016 | 0 | 0 | 15 September 2017 | 0 | 0 |

| 19 November 2016 | 0 | 0 | 16 September 2017 | 0 | 0 |

| 21 November 2016 | 0 | 0 | 17 September 2017 | 0 | 0 |

| 22 November 2016 | 0 | 0 | 18 September 2017 | 0 | 0 |

| 24 November 2016 | 0.6967 | 0 | 19 September 2017 | 0 | 0 |

| Data | Raw Data/mm | a*/mm | b*/mm | The Identified Situation of Gross Errors | |||

|---|---|---|---|---|---|---|---|

| LMS-IGG-ELM Method | DBSCAN Clustering Algorithm | Romanovsky Criterion | 3σ Method | ||||

| 10 November 2016 | 38.85 | −5.85 | 33.00 | √ | √ | ||

| 11 November 2016 | 38.75 | 4.25 | 43.00 | √ | √ | ||

| 13 November 2016 | 38.82 | −5.82 | 33.00 | √ | |||

| 14 November 2016 | 38.81 | 9.19 | 48.00 | √ | √ | ||

| 15 November 2016 | 38.78 | −6.78 | 32.00 | √ | |||

| 16 November 2016 | 38.70 | 7.30 | 46.00 | √ | √ | ||

| 18 November 2016 | 38.67 | −6.67 | 32.00 | √ | |||

| 19 November 2016 | 38.60 | 8.40 | 47.00 | √ | √ | ||

| 21 November 2016 | 38.52 | −6.02 | 32.50 | √ | √ | ||

| 22 November 2016 | 38.48 | −6.48 | 32.00 | √ | √ | ||

| 24 November 2016 | 38.47 | 4.53 | 43.00 | √ | √ | ||

| 25 November 2016 | 38.48 | 3.52 | 42.00 | √ | √ | ||

| 5 March 2017 | 26.05 | 6.95 | 33.00 | √ | √ | ||

| 6 March 2017 | 25.72 | −12.22 | 13.50 | √ | |||

| 7 March 2017 | 25.36 | 3.64 | 29.00 | √ | |||

| 8 March 2017 | 25.00 | 3.50 | 28.50 | √ | |||

| 1 August 2017 | 28.24 | 29.76 | 58.00 | √ | √ | √ | |

| 15 September 2017 | 36.56 | −5.56 | 31.00 | √ | √ | ||

| 16 September 2017 | 36.48 | 26.52 | 63.00 | √ | √ | √ | √ |

| 17 September 2017 | 36.73 | 26.27 | 63.00 | √ | √ | √ | √ |

| 18 September 2017 | 36.74 | −6.74 | 30.00 | √ | √ | ||

| 19 September 2017 | 36.63 | −6.63 | 30.00 | √ | √ | ||

| Gross Errors Identification Method | Nd | rd(%) |

|---|---|---|

| LMS-IGG-ELM method | 22 | 100 |

| DBSCAN clustering algorithm | 16 | 72.73 |

| Romanovsky criterion | 3 | 13.64 |

| 3σ method | 2 | 9.1 |

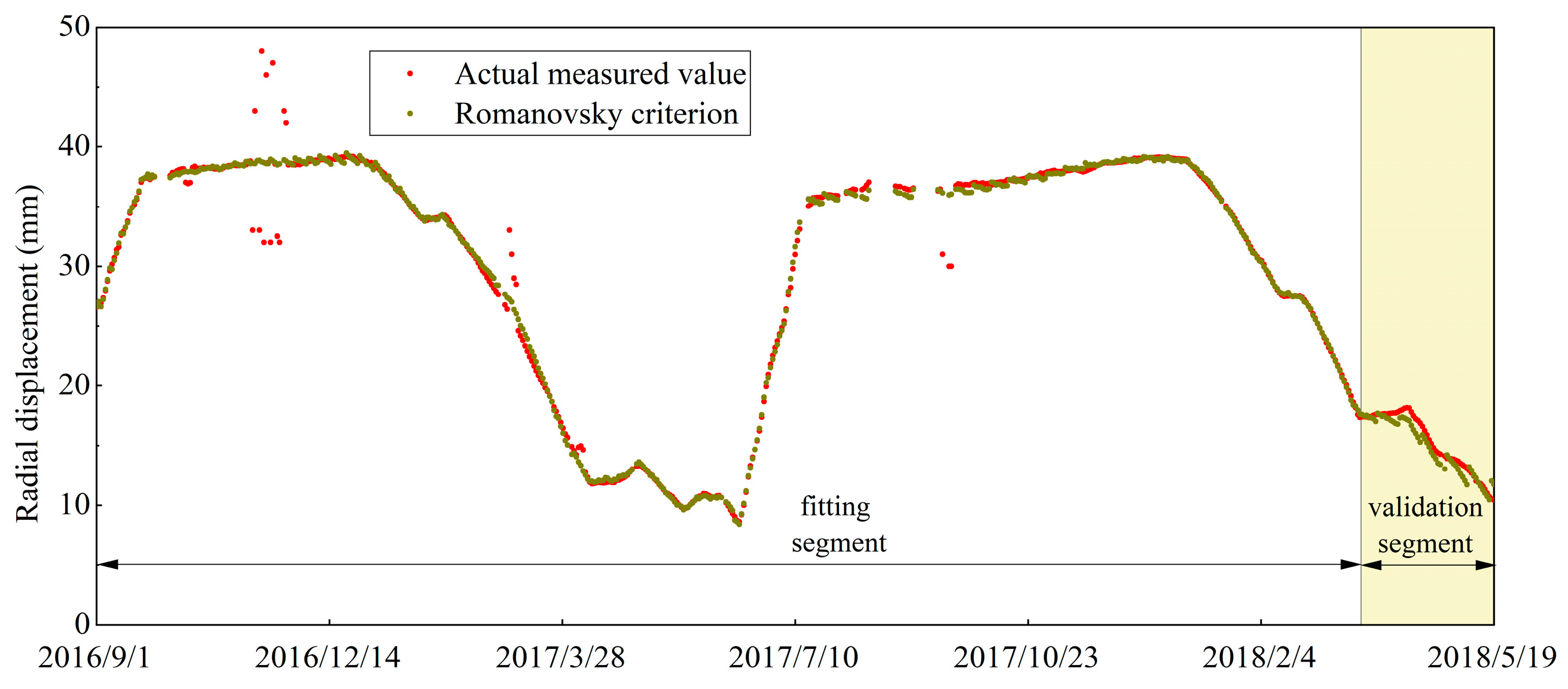

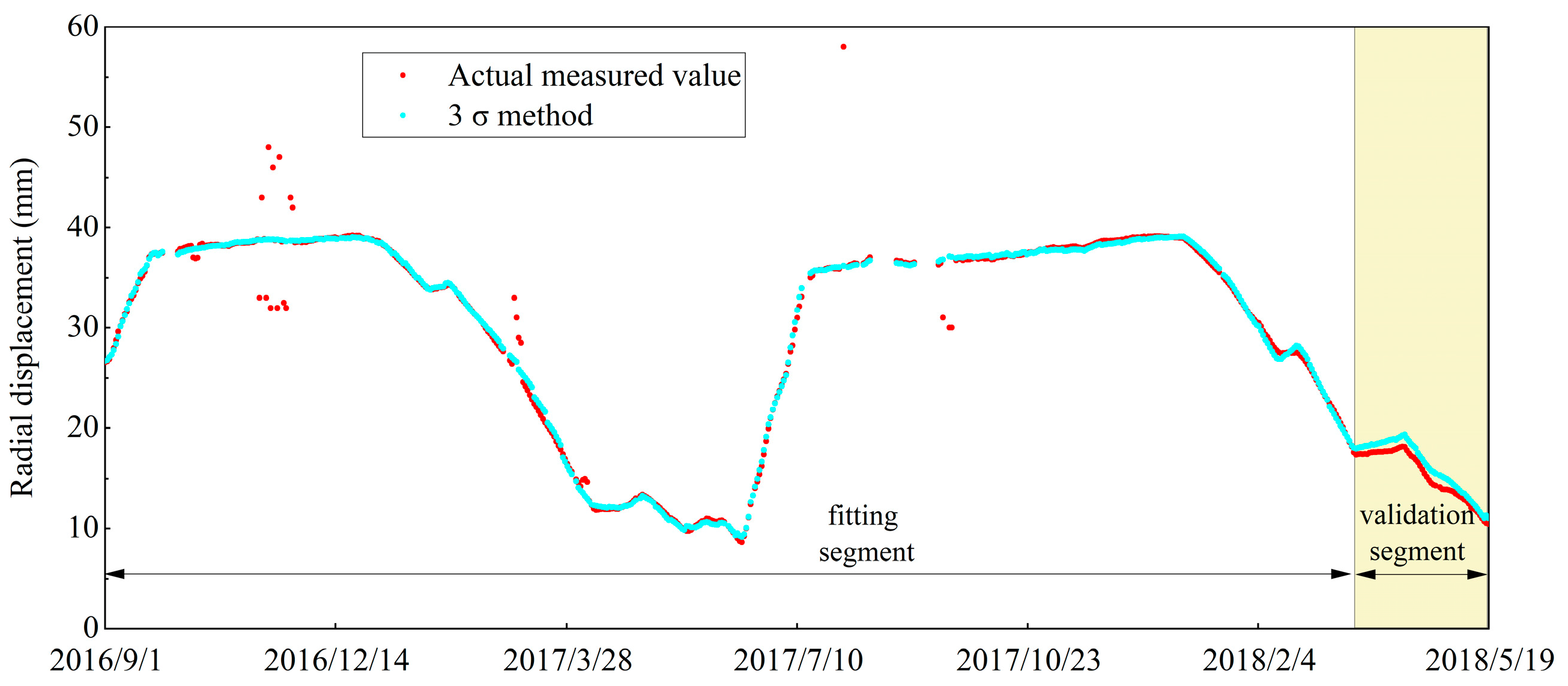

| Gross Errors Identification Method | Fitting Segment | Validation Segment | ||||

|---|---|---|---|---|---|---|

| MAE | RMSE | R2 | MAE | RMSE | R2 | |

| LMS-IGG-ELM method | 0.0890 | 0.1261 | 0.9998 | 0.3284 | 0.4101 | 0.9720 |

| DBSCAN clustering algorithm | 0.3764 | 0.9526 | 0.9706 | 0.5572 | 0.6127 | 0.9375 |

| 3σ method | 0.4104 | 1.1582 | 0.9863 | 0.5947 | 0.7316 | 0.9106 |

| Romanovsky criterion | 0.4684 | 1.5355 | 0.9762 | 0.8668 | 0.9107 | 0.8614 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, C.; Wang, Y.; Gu, H.; Hu, Y.; Yang, M.; Cao, W.; Fang, Z. A Combined Safety Monitoring Model for High Concrete Dams. Appl. Sci. 2022, 12, 12103. https://doi.org/10.3390/app122312103

Gu C, Wang Y, Gu H, Hu Y, Yang M, Cao W, Fang Z. A Combined Safety Monitoring Model for High Concrete Dams. Applied Sciences. 2022; 12(23):12103. https://doi.org/10.3390/app122312103

Chicago/Turabian StyleGu, Chongshi, Yanbo Wang, Hao Gu, Yating Hu, Meng Yang, Wenhan Cao, and Zheng Fang. 2022. "A Combined Safety Monitoring Model for High Concrete Dams" Applied Sciences 12, no. 23: 12103. https://doi.org/10.3390/app122312103

APA StyleGu, C., Wang, Y., Gu, H., Hu, Y., Yang, M., Cao, W., & Fang, Z. (2022). A Combined Safety Monitoring Model for High Concrete Dams. Applied Sciences, 12(23), 12103. https://doi.org/10.3390/app122312103