Correlation and Regression Analysis of Spraying Process Quality Indicators

Abstract

1. Introduction

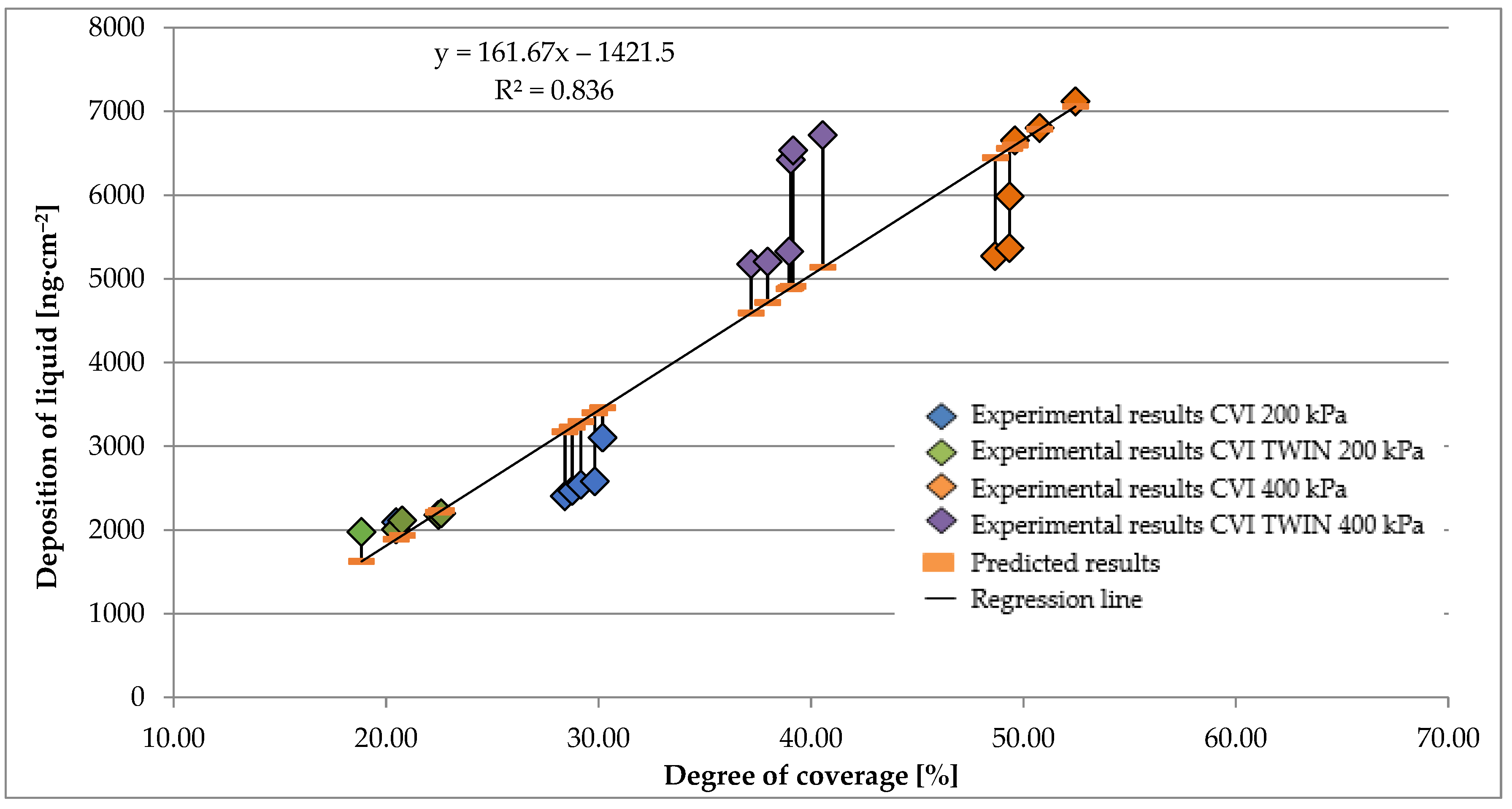

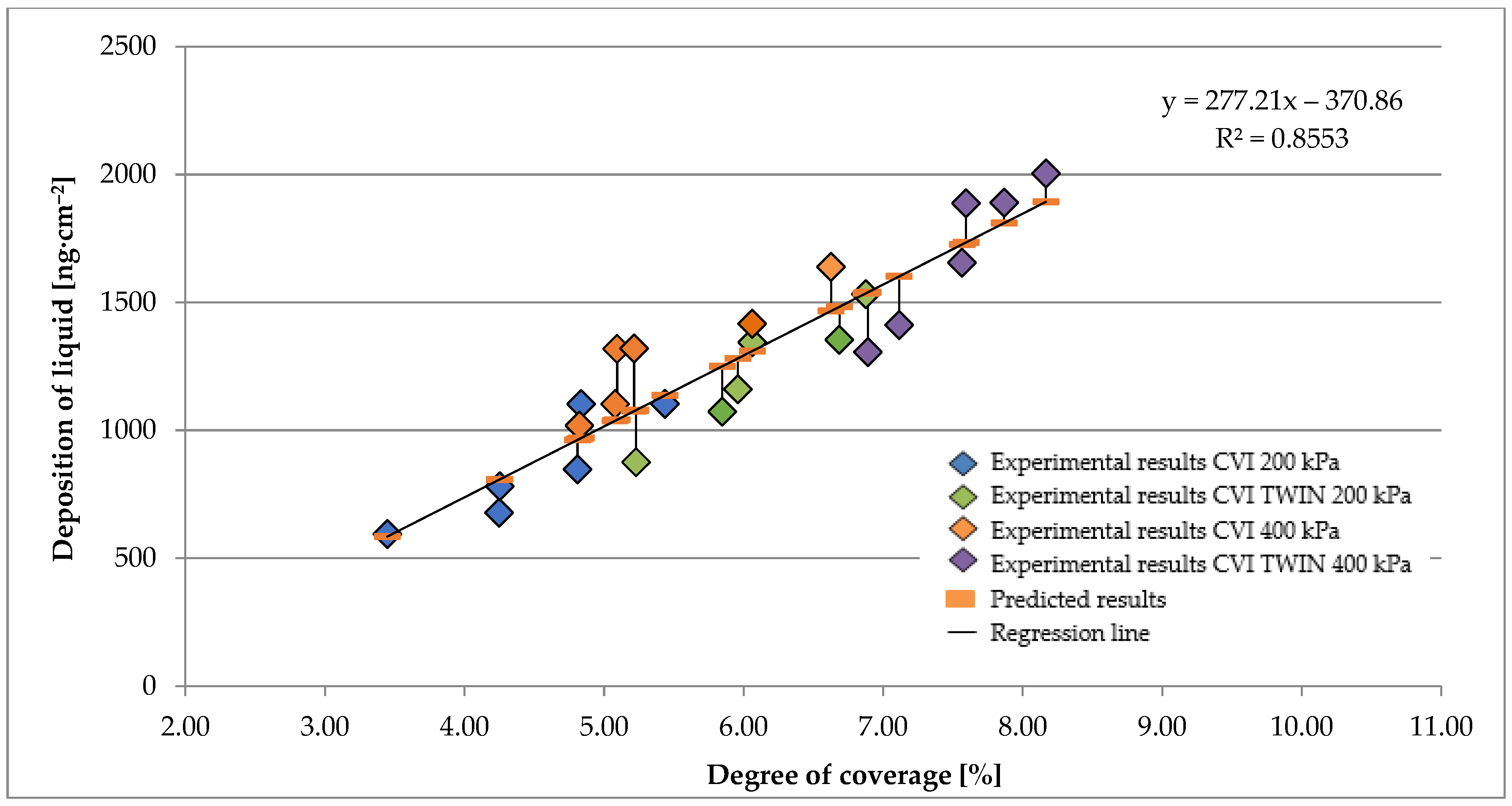

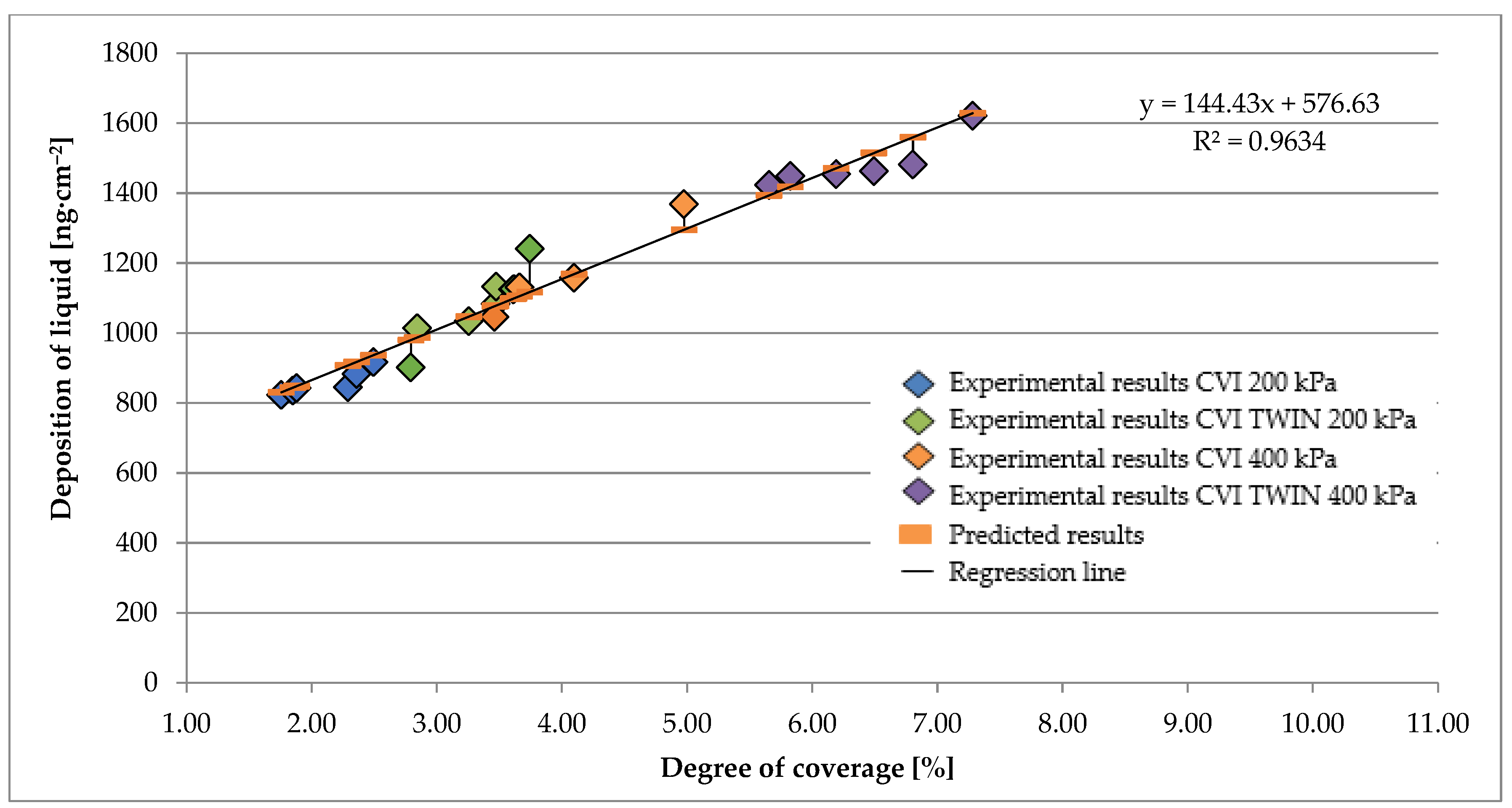

2. Materials and Methods

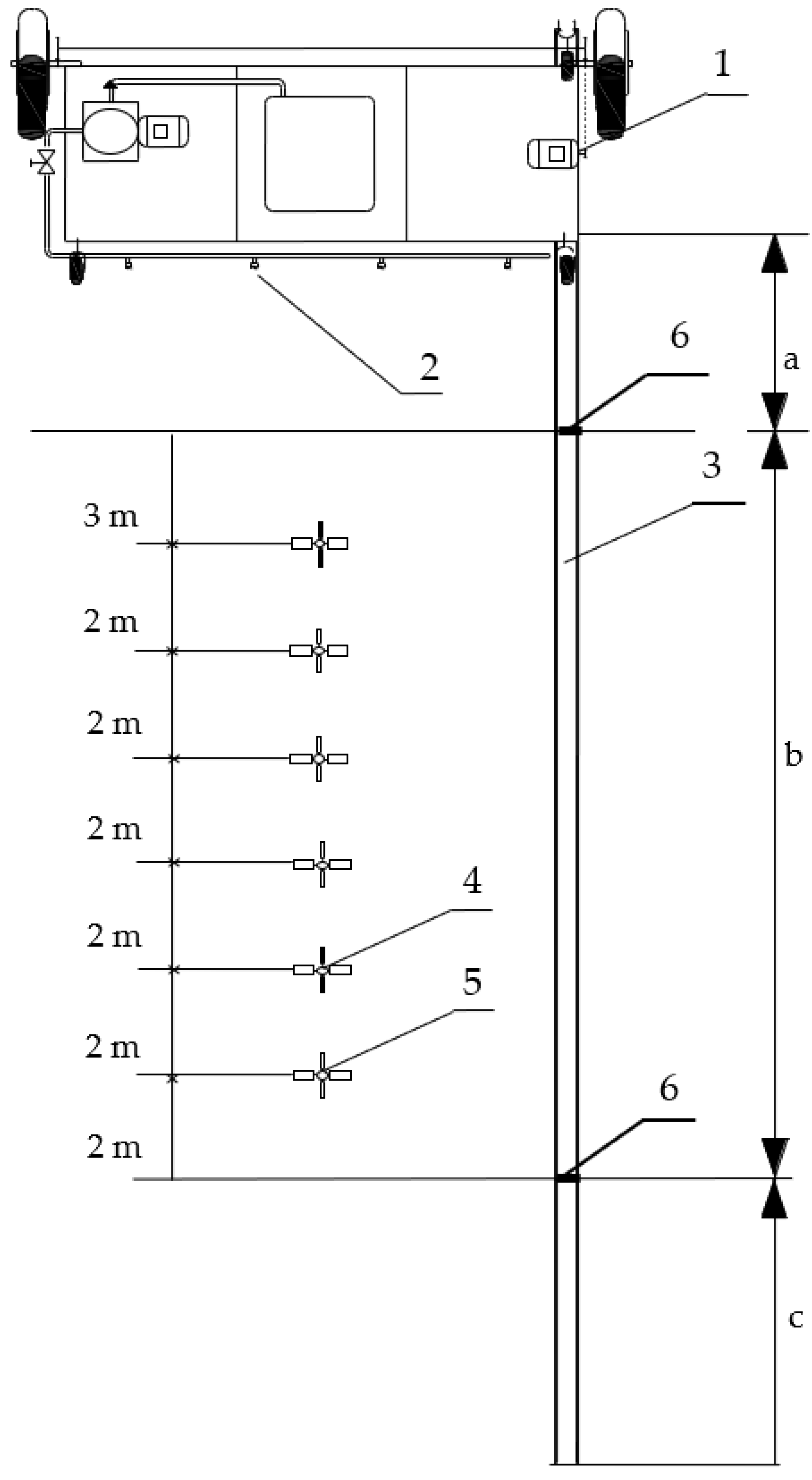

2.1. Experimental Set

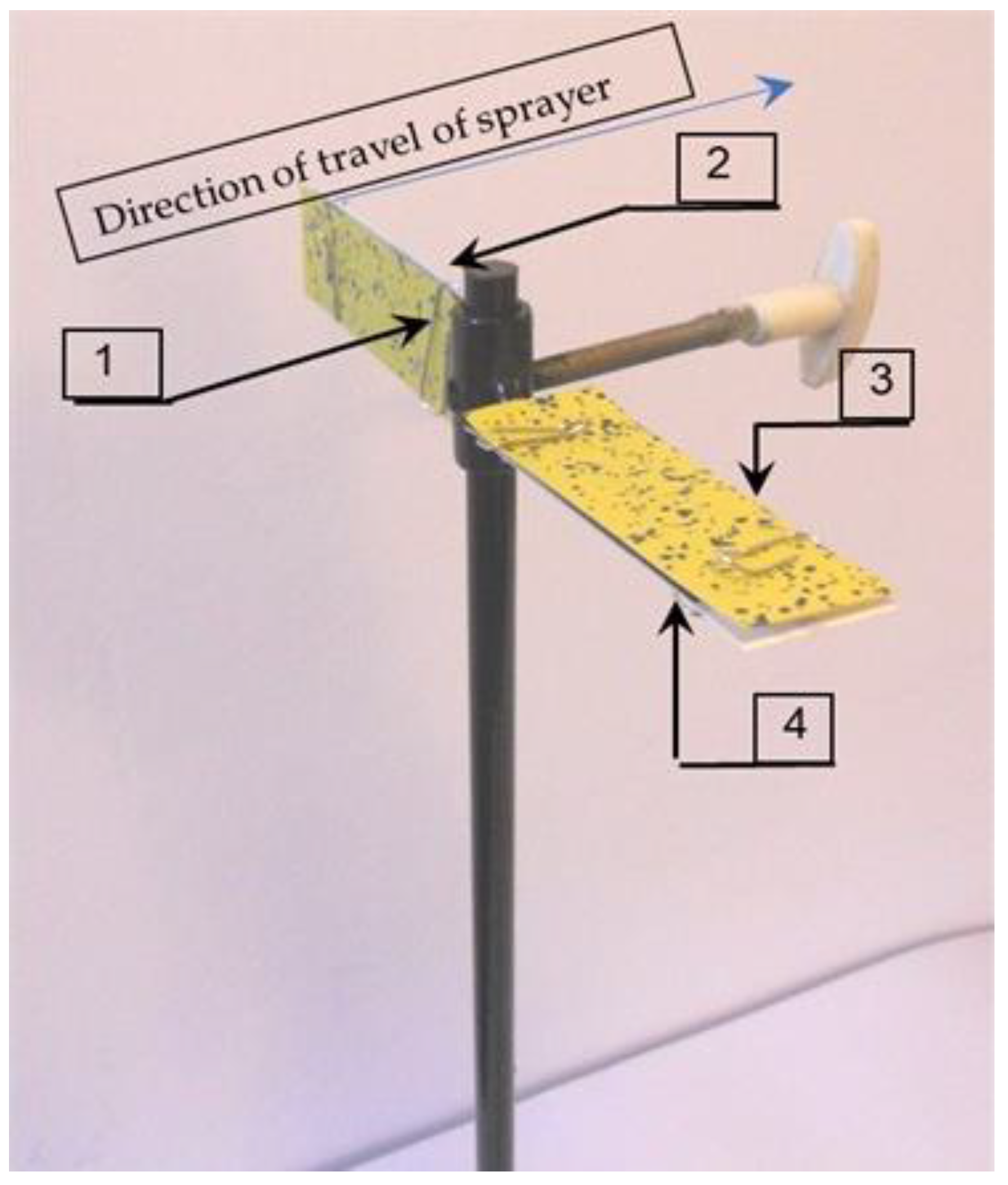

2.2. Analysis of the Coverage Degree of Sprayed Surfaces

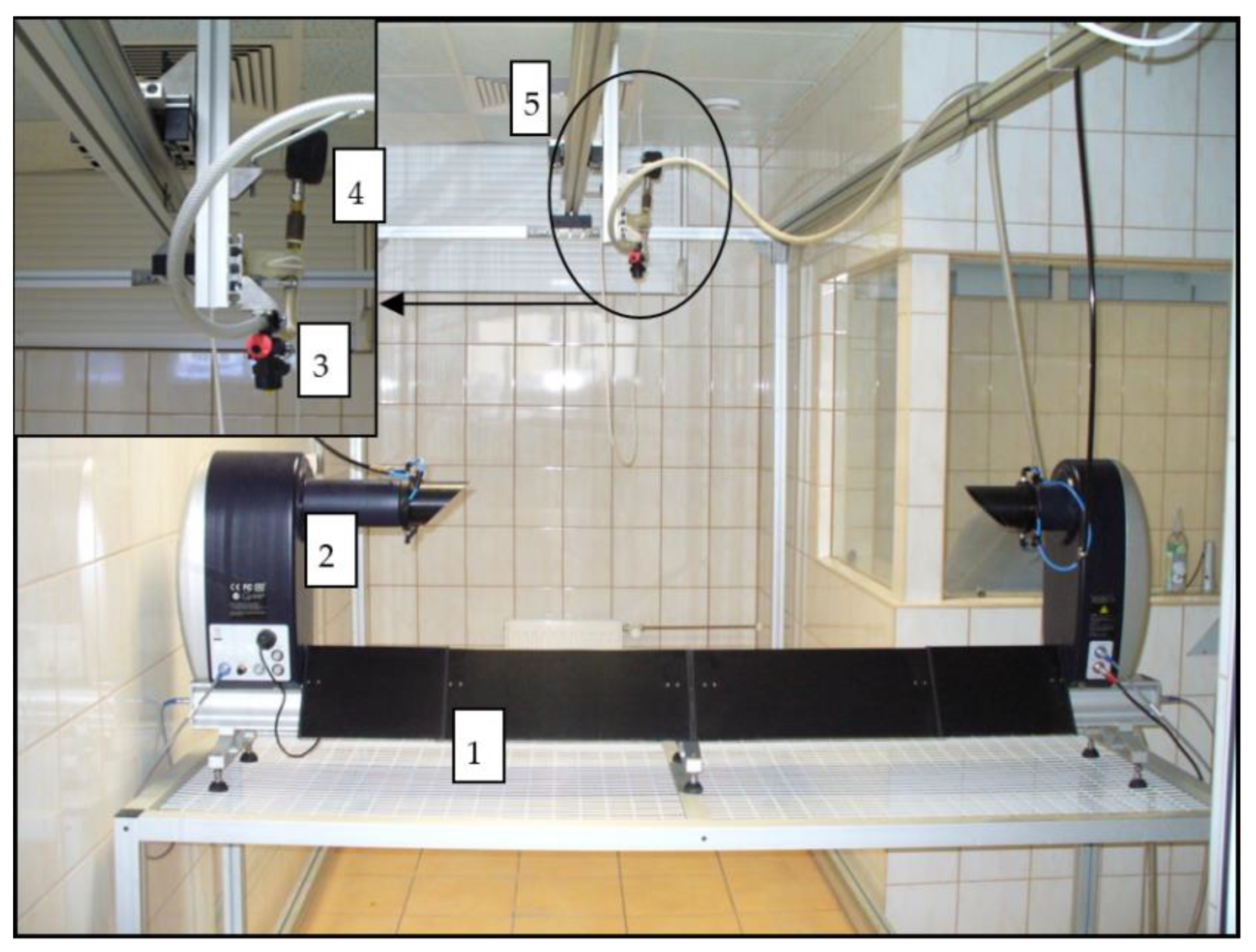

2.3. Analysis of the Deposition of Spray Liquid

2.4. Nozzle Type and Droplet Size Classification

2.5. Research Conditions

- Speed of the sprayer—2.2 m·s−1;

- Pressure of liquid—200 and 400 kPa (the highest and lowest value of the liquid pressure due to the nozzles used);

- Height of the sprayer boom—0.5 m.

2.6. Data Processing

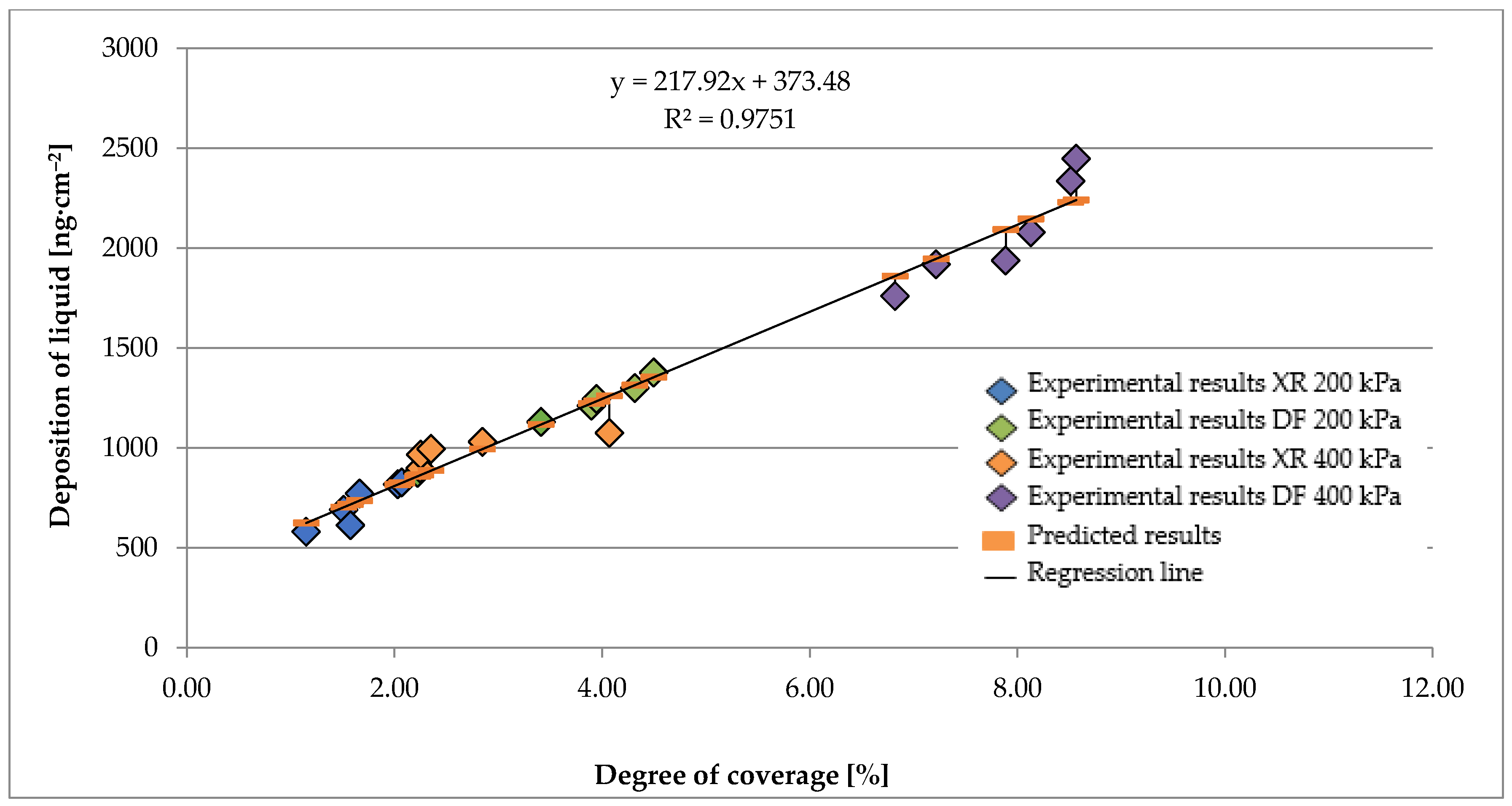

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cooper, J.; Dobson, H. The Benefits of Pesticides to Mankind and the Environment. Crop Prot. 2007, 26, 1337–1348. [Google Scholar] [CrossRef]

- Bonmatin, J.M.; Giorio, C.; Girolami, V.; Goulson, D.; Kreutzweiser, D.P.; Krupke, C.; Liess, M.; Long, E.; Marzaro, M.; Mitchell, E.A.; et al. Environmental Fate and Exposure; Neonicotinoids and Fipronil. Environ. Sci. Pollut. Res. 2015, 22, 35–67. [Google Scholar] [CrossRef] [PubMed]

- Brain, R.; Goodwin, G.; Abi-Akar, F.; Lee, B.; Rodgers, C.; Flatt, B.; Lynn, A.; Kruger, G.; Perkins, D. Winds of Change, Developing a Non-Target Plant Bioassay Employing Field-Based Pesticide Drift Exposure: A Case Study with Atrazine. Sci. Total Environ. 2019, 678, 239–252. [Google Scholar] [CrossRef]

- Wang, J.; Lan, Y.; Wen, S.; Hewitt, A.J.; Yao, W.; Chen, P. Meteorological and Flight Altitude Effects on Deposition, Penetration, and Drift in Pineapple Aerial Spraying. Asia-Pacific J. Chem. Eng. 2020, 15, e2382. [Google Scholar] [CrossRef]

- Carvalho, F.K.; Chechetto, R.G.; Mota, A.A.B.; Antuniassi, U.R. Characteristics and Challenges of Pesticide Spray Applications in Mato Grosso, Brazil. Outlooks Pest Manag. 2017, 28, 4–6. [Google Scholar] [CrossRef]

- Butts, T.R.; Barber, L.T.; Norsworthy, J.K.; Davis, J. Survey of Ground and Aerial Herbicide Application Practices in Arkansas Agronomic Crops. Weed Technol. 2021, 35, 1–11. [Google Scholar] [CrossRef]

- Penney, A.J.; Kandel, Y.R.; Viggers, J.N.; Robertson, A.E.; Mueller, D.S. Comparison of Aerial and Ground Sprayer Fungicide Application Technologies on Canopy Coverage, Disease Severity, Lodging, and Yield of Corn. Crop Prot. 2021, 139, 105393. [Google Scholar] [CrossRef]

- Goebel, K.M.; Davros, N.M.; Andersen, D.E.; Rice, P.J. Tallgrass Prairie Wildlife Exposure to Spray Drift from Commonly Used Soybean Insecticides in Midwestern USA. Sci. Total Environ. 2022, 818, 151745. [Google Scholar] [CrossRef]

- Hunter, J.E.; Gannon, T.W.; Richardson, R.J.; Yelverton, F.H.; Leon, R.G. Coverage and Drift Potential Associated with Nozzle and Speed Selection for Herbicide Applications Using an Unmanned Aerial Sprayer. Weed Technol. 2020, 34, 235–240. [Google Scholar] [CrossRef]

- Samples, C.A.; Butts, T.R.; Vieira, B.C.; Irby, J.T.; Reynolds, D.B.; Catchot, A.; Kruger, G.R.; Dodds, D.M. Effect of Deposition Aids Tank-Mixed with Herbicides on Cotton and Soybean Canopy Deposition and Spray Droplet Parameters. Agronomy 2021, 11, 278. [Google Scholar] [CrossRef]

- Song, R.; Shen, G.; Liu, Y.; Tang, F.; Chen, Q.; Sun, P. Preparation and Characterization of an Oil-in-Water Microemulsion of Thiamethoxam and Acetamiprid without Organic Solvent for Unmanned Aerial Vehicle Spraying. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 607, 125485. [Google Scholar] [CrossRef]

- Szwedziak, K.; Niedbała, G.; Grzywacz, Ż.; Winiarski, P.; Doležal, P. The Use of Air Induction Nozzles for Application of Fertilizing Preparations Containing Beneficial Microorganisms. Agriculture 2020, 10, 303. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, H.; Zheng, J.; Liao, J.; Hewitt, A.J. Adjuvant’s Influence to Droplet Size Based on Forestry Pests’ Prevention with Ground and Air Chemical Application. Linye Kexue/Scientia Silvae Sin. 2020, 56, 118–129. [Google Scholar] [CrossRef]

- Zwertvaegher, I.; Lamare, A.; Douzals, J.P.; Balsari, P.; Marucco, P.; Grella, M.; Caffini, A.; Mylonas, N.; Dekeyser, D.; Foqué, D.; et al. Boom Sprayer Optimizations for Bed-Grown Carrots at Different Growth Stages Based on Spray Distribution and Droplet Characteristics. Pest Manag. Sci. 2022, 78, 1729–1739. [Google Scholar] [CrossRef]

- Alves, G.S.; Kruger, G.R.; da Cunha, J.P.A.R. Spray Drift and Droplet Spectrum from Dicamba Sprayed Alone or Mixed with Adjuvants Using Air-Induction Nozzles. Pesqui. Agropecu. Bras. 2018, 53, 1729–1739. [Google Scholar] [CrossRef]

- Hołownicki, R.; Doruchowski, G.; Świechowski, W.; Konopacki, P.; Godyń, A. Effect of Nozzle Type and Adjuvants on Spray Coverage on Apple Leaves. Agronomy 2021, 11, 1790. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Ma, Y.; Cui, H.; Yang, Z.; Lu, H. Effects of Leaf Response Velocity on Spray Deposition with an Air-Assisted Orchard Sprayer. Int. J. Agric. Biol. Eng. 2021, 14, 123–132. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.R.; Humburg, D.D. Using Variable Spray Angle Fan Nozzle on Long Spray Booms. Agric. Eng. Int. CIGR J. 2016, 18, 82–90. [Google Scholar]

- Biocca, M.; Cutini, M.; Romano, E.; Pallottino, F.; Gallo, P. Evaluation of Drift-Reducing Nozzles for Pesticide Application in Hazelnut (Corylus avellana L.). AgriEngineering 2021, 3, 15. [Google Scholar] [CrossRef]

- Milanowski, M.; Subr, A.; Combrzyński, M.; Różańska-Boczula, M.; Parafiniuk, S. Effect of Adjuvant, Concentration and Water Type on the Droplet Size Characteristics in Agricultural Nozzles. Appl. Sci. 2022, 12, 5821. [Google Scholar] [CrossRef]

- Moraes, J.G.; Butts, T.R.; Anunciato, V.M.; Luck, J.D.; Hoffmann, W.C.; Antuniassi, U.R.; Kruger, G.R. Nozzle Selection and Adjuvant Impact on the Efficacy of Glyphosate and PPO-Inhibiting Herbicide Tank-Mixtures. Agronomy 2021, 11, 754. [Google Scholar] [CrossRef]

- Ranta, O.; Marian, O.; Muntean, M.V.; Molnar, A.; Ghețe, A.B.; Crișan, V.; Stănilă, S.; Rittner, T. Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution. Sustainability 2021, 13, 7780. [Google Scholar] [CrossRef]

- Cieniawska, B.; Pentos, K. Average Degree of Coverage and Coverage Unevenness Coefficient as Parameters for Spraying Quality Assessment. Agriculture 2021, 11, 151. [Google Scholar] [CrossRef]

- Cieniawska, B.; Pentos, K.; Luczycka, D. Neural modeling and optimization of the coverage of the sprayed surface. Bull. Pol. Acad. Sci.-Tech. Sci. 2020, 68, 601–608. [Google Scholar] [CrossRef]

- Witton, J.T.; Pickering, M.D.; Alvarez, T.; Reed, M.; Weyman, G.; Hodson, M.E.; Ashauer, R. Quantifying Pesticide Deposits and Spray Patterns at Micro-Scales on Apple (Malus domesticus) Leaves with a View to Arthropod Exposure. Pest Manag. Sci. 2018, 74, 2884–2893. [Google Scholar] [CrossRef] [PubMed]

- Bueno, M.R.; da Cunha, J.P.A.R.; de Santana, D.G. Assessment of Spray Drift from Pesticide Applications in Soybean Crops. Biosyst. Eng. 2017, 154, 35–45. [Google Scholar] [CrossRef]

- Pergher, G.; Zucchiatti, N. Influence of Canopy Development in the Vineyard on Spray Deposition from a Tunnel Sprayer. J. Agric. Eng. 2018, 49, 164–173. [Google Scholar] [CrossRef]

- Kluza, P.A.; Kuna-Broniowska, I.; Parafiniuk, S. Modeling and Prediction of the Uniformity of Spray Liquid Coverage from Flat Fan Spray Nozzles. Sustainability 2019, 11, 6716. [Google Scholar] [CrossRef]

- Lodwik, D.; Pietrzyk, J.; Malesa, W. Analysis of Volume Distribution and Evaluation of the Spraying Spectrum in Terms of Spraying Quality. Appl. Sci. 2020, 10, 2395. [Google Scholar] [CrossRef]

- Cavassan, N.R.V.; Camargo, C.C.; de Pontes, L.G.; Barraviera, B.; Ferreira, R.S.; Miot, H.A.; Abbade, L.P.F.; dos Santos, L.D. Correlation between Chronic Venous Ulcer Exudate Proteins and Clinical Profile: A Cross-Sectional Study. J. Proteomics 2019, 192, 280–290. [Google Scholar] [CrossRef]

- Malchiodi, L.; Giacomazzi, E.; Cucchi, A.; Ricciotti, G.; Caricasulo, R.; Bertossi, D.; Gherlone, E. Relationship between Crestal Bone Levels and Crown-to-Implant Ratio of Ultra-Short Implants with a Microrough Surface: A Prospective Study with 48 Months of Follow-Up. J. Oral Implantol. 2019, 45, 18–28. [Google Scholar] [CrossRef] [PubMed]

- Arunrat, N.; Sansupa, C.; Kongsurakan, P.; Sereenonchai, S.; Hatano, R. Soil Microbial Diversity and Community Composition in Rice–Fish Co-Culture and Rice Monoculture Farming System. Biology 2022, 11, 1242. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Shen, F.; Yang, L.; Xing, W.; Clothier, B. Limited Acclimation in Leaf Morphology and Anatomy to Experimental Drought in Temperate Forest Species. Biology 2022, 11, 1186. [Google Scholar] [CrossRef] [PubMed]

- Locatelli, D.A.; Nazareno, M.A.; Fusari, C.M.; Camargo, A.B. Cooked Garlic and Antioxidant Activity: Correlation with Organosulfur Compound Composition. Food Chem. 2017, 220, 219–224. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Pan, D.; Du, H.; Ma, J.; Kong, B.; Diao, J. Flavor Differences of Edible Parts of Grass Carp between Jingpo Lake and Commercial Market. Foods 2022, 11, 2594. [Google Scholar] [CrossRef]

- Bayissa, Y.; Maskey, S.; Tadesse, T.; Van Andel, S.J.; Moges, S.; Van Griensven, A.; Solomatine, D. Comparison of the Performance of Six Drought Indices in Characterizing Historical Drought for the Upper Blue Nile Basin, Ethiopia. Geosciences 2018, 8, 81. [Google Scholar] [CrossRef]

- Sanou, A.-G.; Saeidi, A.; Heidarzadeh, S.; Chavali, R.V.P.; Samti, H.E.; Rouleau, A. Geotechnical Parameters of Landslide-Prone Laflamme Sea Deposits, Canada: Uncertainties and Correlations. Geosciences 2022, 12, 297. [Google Scholar] [CrossRef]

- Ferreira, P.; Silva, M.F.d.; Santana, I.S.d. Detrended Correlation Coefficients between Exchange Rate (in Dollars) and Stock Markets in the World’s Largest Economies. Economies 2019, 7, 9. [Google Scholar] [CrossRef]

- Wielechowski, M.; Czech, K.; Grzęda, Ł. Decline in Mobility: Public Transport in Poland in the time of the COVID-19 Pandemic. Economies 2020, 8, 78. [Google Scholar] [CrossRef]

- Ayiti, O.E.; Ayangbenro, A.S.; Babalola, O.O. 16S Amplicon Sequencing of Nitrifying Bacteria and Archaea Inhabiting Maize Rhizosphere and the Influencing Environmental Factors. Agriculture 2022, 12, 1328. [Google Scholar] [CrossRef]

- Kaushalya Madhavi, B.G.; Bhujel, A.; Kim, N.E.; Kim, H.T. Measurement of Overlapping Leaf Area of Ice Plants Using Digital Image Processing Technique. Agriculture 2022, 12, 1321. [Google Scholar] [CrossRef]

- Gorzelany, J.; Belcar, J.; Kuźniar, P.; Niedbala, G.; Pentoś, K. Modelling of Mechanical Properties of Fresh and Stored Fruit of Large Cranberry Using Multiple Linear Regression and Machine Learning. Agriculture 2022, 12, 200. [Google Scholar] [CrossRef]

- Pentoś, K.; Mbah, J.T.; Pieczarka, K.; Niedbała, G.; Wojciechowski, T. Evaluation of Multiple Linear Regression and Machine Learning Approaches to Predict Soil Compaction and Shear Stress Based on Electrical Parameters. Appl. Sci. 2022, 12, 8791. [Google Scholar] [CrossRef]

- Rokhafrouz, M.; Latifi, H.; Abkar, A.A.; Wojciechowski, T.; Czechlowski, M.; Naieni, A.S.; Maghsoudi, Y.; Niedbała, G. Simplified and Hybrid Remote Sensing-Based Delineation of Management Zones for Nitrogen Variable Rate Application in Wheat. Agriculture 2021, 11, 1104. [Google Scholar] [CrossRef]

- Cerruto, E.; Aglieco, C.; Failla, S.; Manetto, G. Parameters Influencing Deposit Estimation When Using Water Sensitive Papers. J. Agric. Eng. 2013, 44, e9. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Longo, D.; Failla, S.; Papa, R. A Model to Estimate the Spray Deposit by Simulated Water Sensitive Papers. Crop Prot. 2019, 124, 104861. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, R.; Chen, L.; Huang, Y.; Yi, T.; Xu, G.; Li, L.; Hewitt, A.J. A New Spray Deposition Pattern Measurement System Based on Spectral Analysis of a Fluorescent Tracer. Comput. Electron. Agric. 2019, 160, 14–22. [Google Scholar] [CrossRef]

- ASABE S572.1; Spray Nozzle Classification by Droplet Spectra. ASABE: St. Joseph, MI, USA, 2020.

- Ratner, B. The Correlation Coefficient: Its Values Range between +1/−1, or do they? J. Target. Meas. Anal. Mark. 2009, 17, 139–142. [Google Scholar] [CrossRef]

- Creech, C.F.; Henry, R.S.; Hewitt, A.J.; Kruger, G.R. Herbicide Spray Penetration into Corn and Soybean Canopies Using Air-Induction Nozzles and a Drift Control Adjuvant. Weed Technol. 2018, 32, 72–79. [Google Scholar] [CrossRef]

- Zhu, H.; Dorner, J.W.; Rowland, D.L.; Derksen, R.C.; Ozkan, H.E. Spray Penetration into Peanut Canopies with Hydraulic Nozzle Tips. Biosyst. Eng. 2004, 87, 275–283. [Google Scholar] [CrossRef]

- Penido, É.d.C.C.; Teixeira, M.M.; Fernandes, H.C.; Monteiro, P.B.; Cecon, P.R. Development and Evaluation of a Remotely Controlled and Monitored Self-Propelled Sprayer in Tomato Crops. Rev. Cienc. Agron. 2019, 50, 8–17. [Google Scholar] [CrossRef]

- Li, S.; Chen, C.; Wang, Y.; Kang, F.; Li, W. Study on the Atomization Characteristics of Flat Fan Nozzles for Pesticide Application at Low Pressures. Agriculture 2021, 11, 309. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Papa, R.; Longo, D. Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles. Appl. Sci. 2021, 11, 9283. [Google Scholar] [CrossRef]

- Simão, L.M.; Easterly, A.C.; Kruger, G.R.; Creech, C.F. Herbicide Spray Deposition in Wheat Stubble as Affected by Nozzle Type and Application Direction. Agronomy 2020, 10, 1507. [Google Scholar] [CrossRef]

- Badules, J.; Vidal, M.; Boné, A.; Gil, E.; García-Ramos, F.J. CFD Models as a Tool to Analyze the Performance of the Hydraulic Agitation System of an Air-Assisted Sprayer. Agronomy 2019, 9, 769. [Google Scholar] [CrossRef]

- Javier García-Ramos, F.; Vidal, M.; Boné, A.; Malón, H.; Aguirre, J. Analysis of the Air Flow Generated by an Air-Assisted Sprayer Equipped with Two Axial Fans Using a 3D Sonic Anemometer. Sensors 2012, 12, 7598. [Google Scholar] [CrossRef] [PubMed]

- García-Ramos, F.J.; Malón, H.; Aguirre, A.J.; Boné, A.; Puyuelo, J.; Vidal, M. Validation of a CFD Model by Using 3D Sonic Anemometers to Analyse the Air Velocity Generated by an Air-Assisted Sprayer Equipped with Two Axial Fans. Sensors 2015, 15, 2399–2418. [Google Scholar] [CrossRef] [PubMed]

| Nozzle | Pressure (kPa) | Flow Rate (dm3·min−1) | Droplet Size (μm) | Drop Size Class | ||

|---|---|---|---|---|---|---|

| DV0.1 | DV0.5 | DV0.9 | ||||

| DF 12002 | 200 | 0.65 | 127 | 221.1 | 332.8 | fine |

| DF 12002 | 400 | 0.91 | 110.5 | 191.6 | 275.7 | fine |

| XR 11002 | 200 | 0.65 | 105.7 | 206 | 350.1 | fine |

| XR 11002 | 400 | 0.91 | 88.8 | 178.2 | 295.3 | fine |

| CVI 11002 | 200 | 0.65 | 180.2 | 385.6 | 699 | coarse |

| CVI 11002 | 400 | 0.92 | 143 | 296.7 | 510.2 | medium |

| CVI TWIN 11002 | 200 | 0.65 | 205.1 | 468.9 | 822.7 | very coarse |

| CVI TWIN 11002 | 400 | 0.92 | 164.9 | 336.9 | 557.7 | coarse |

| Correlation Coefficient | Interpretation |

|---|---|

| 0 | no linear relationship |

| (0; 0.40)/(−0.40; 0) | weak positive linear relationship/ weak negative linear relationship |

| <0.40; 0.70)/(−0.70; −0.40> | moderate positive linear relationship/ moderate negative linear relationship |

| <0.70; 0.90)/(−0.90; −0.70> | strong positive linear relationship/ strong negative linear relationship |

| <0.9; 1)/(−1; −0.9> | very strong positive linear relationship/ very strong negative linear relationship |

| +1/−1 | perfect positive linear relationship/ perfect negative linear relationship |

| Nozzles | Surface | F | Se | S(a) | S(b) | Ve [%] | R |

|---|---|---|---|---|---|---|---|

| XR and DF—standard nozzles | horizontal upper | 166.4558 | 711.7962 | 12.5976 | 622.7839 | 14.7221 | 0.9398 |

| vertical approach | 359.9703 | 113.7631 | 11.6734 | 75.0449 | 8.3603 | 0.9708 | |

| vertical leaving | 860.9794 | 87.5600 | 7.4268 | 35.1296 | 6.9483 | 0.9875 | |

| CVI and CVI TWIN—air-induction nozzles | horizontal upper | 112.1109 | 817.1803 | 15.2684 | 555.8545 | 19.4904 | 0.9143 |

| vertical approach | 130.0897 | 147.1545 | 24.3045 | 146.7021 | 11.6151 | 0.9249 | |

| vertical leaving | 578.5757 | 47.7444 | 6.0044 | 25.4283 | 4.1824 | 0.9815 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cieniawska, B.; Pentoś, K.; Szulc, T. Correlation and Regression Analysis of Spraying Process Quality Indicators. Appl. Sci. 2022, 12, 12034. https://doi.org/10.3390/app122312034

Cieniawska B, Pentoś K, Szulc T. Correlation and Regression Analysis of Spraying Process Quality Indicators. Applied Sciences. 2022; 12(23):12034. https://doi.org/10.3390/app122312034

Chicago/Turabian StyleCieniawska, Beata, Katarzyna Pentoś, and Tomasz Szulc. 2022. "Correlation and Regression Analysis of Spraying Process Quality Indicators" Applied Sciences 12, no. 23: 12034. https://doi.org/10.3390/app122312034

APA StyleCieniawska, B., Pentoś, K., & Szulc, T. (2022). Correlation and Regression Analysis of Spraying Process Quality Indicators. Applied Sciences, 12(23), 12034. https://doi.org/10.3390/app122312034