Effect of Different Surface Treatments on the Surface Roughness and Gloss of Resin-Modified CAD/CAM Ceramics

Abstract

1. Introduction

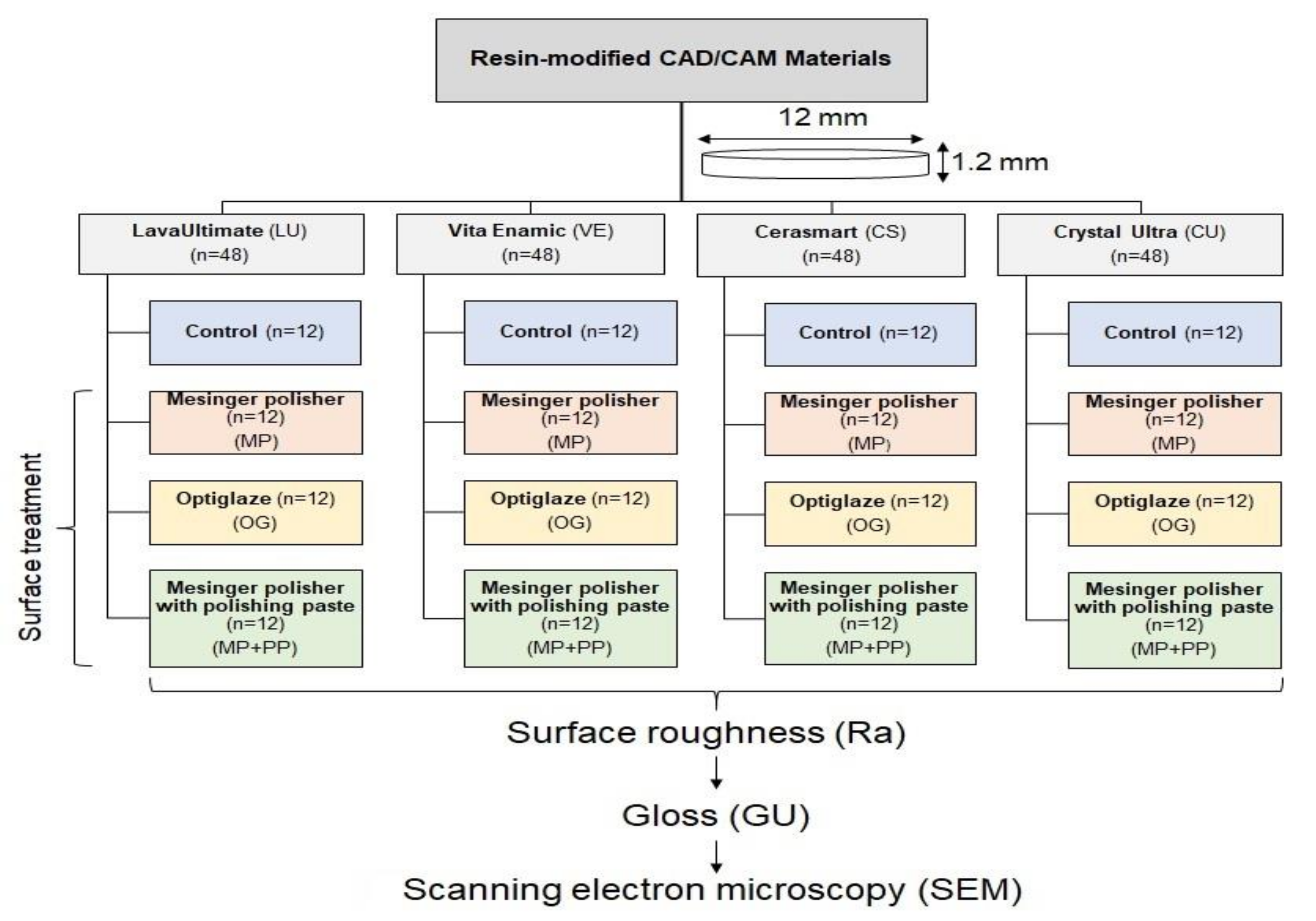

2. Materials and Methods

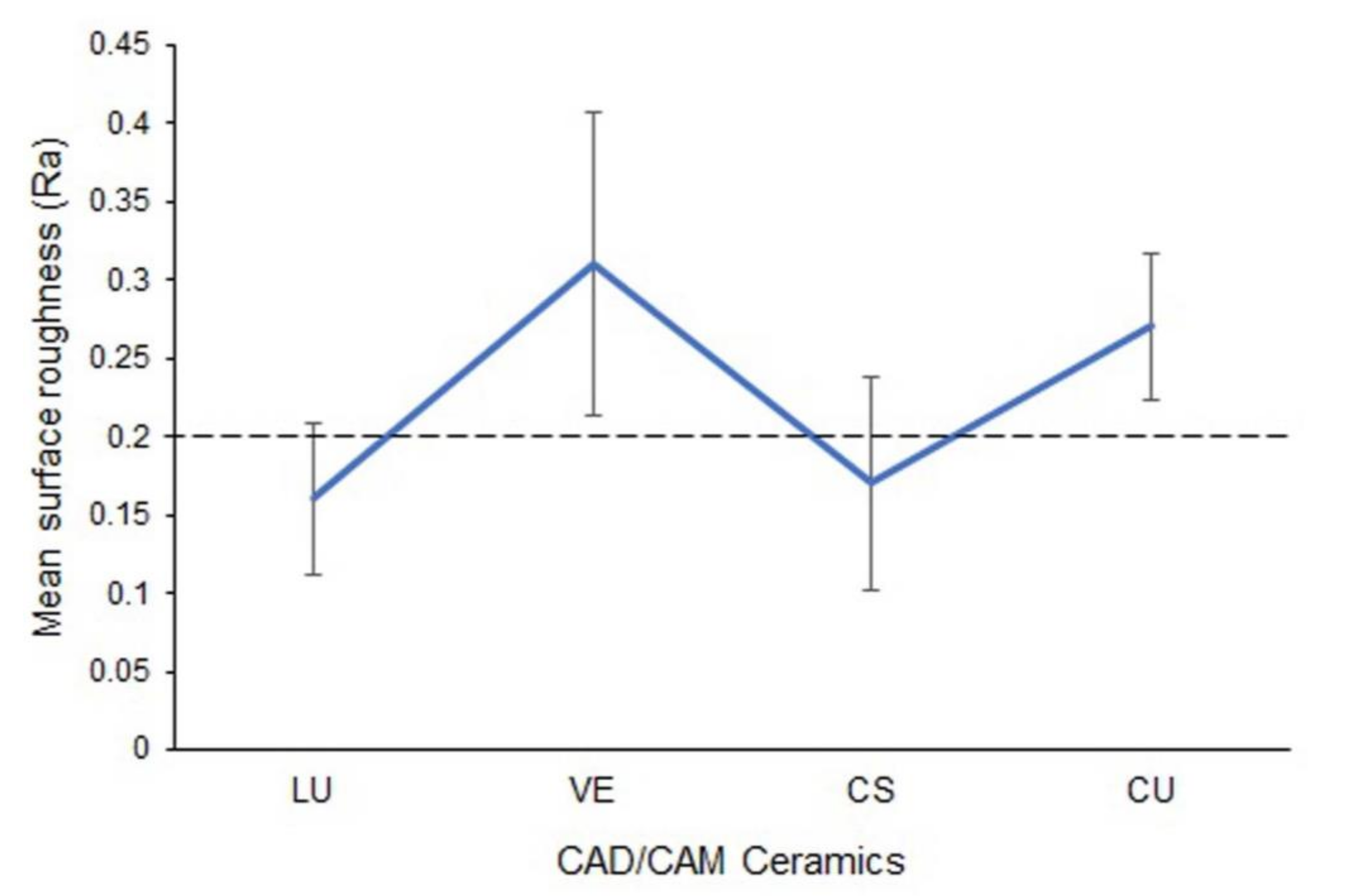

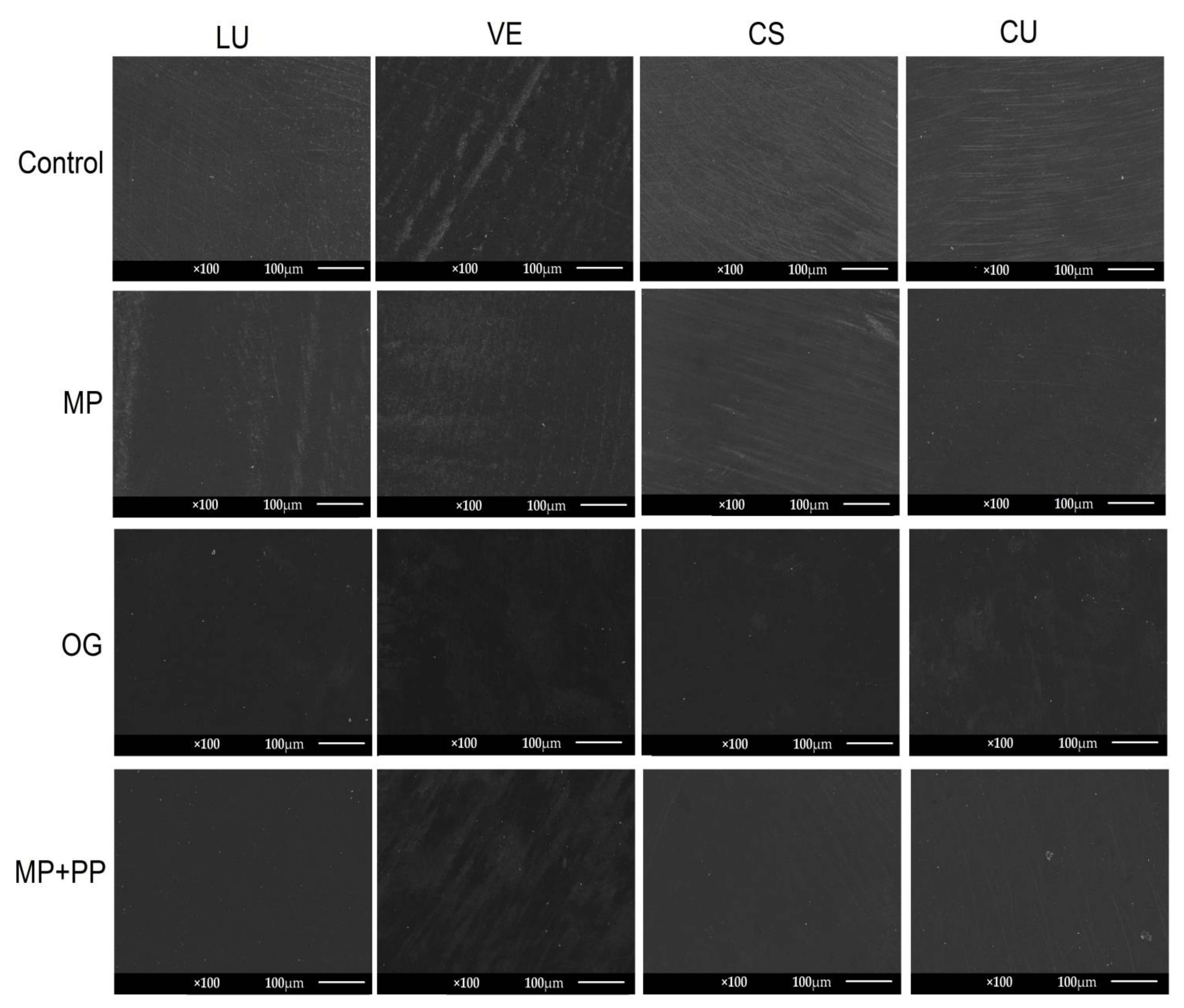

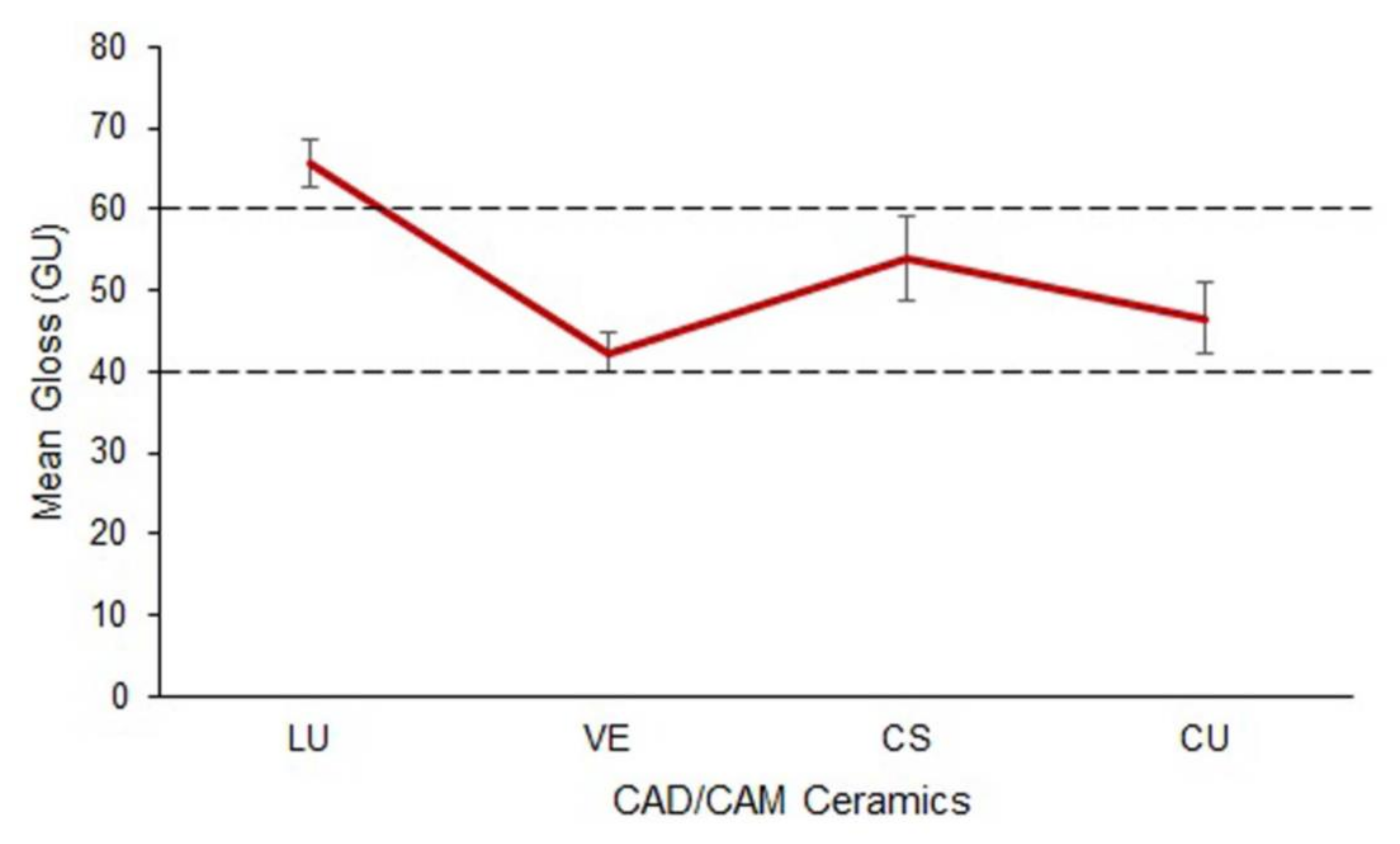

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blatz, M.B.; Conejo, J. The Current State of Chairside Digital Dentistry and Materials. Dent. Clin. N. Am. 2019, 63, 175–197. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lim, S.-W.; Lee, M.-K.; Ju, S.W.; Park, S.-H.; Ahn, J.-S.; Hwang, K.-G. Which Three-Dimensional Printing Technology Can Replace Conventional Manual Method of Manufacturing Oral Appliance? A Preliminary Comparative Study of Physical and Mechanical Properties. Appl. Sci. 2022, 12, 130. [Google Scholar] [CrossRef]

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.; Bonfante, E.A. A new classification system for all-ceramic and ceramic-like restorative materials. Int. J. Prosthodont. 2015, 28, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Al Amri, M.D.; Labban, N.; Alhijji, S.; Alamri, H.; Iskandar, M.; Platt, J.A. In Vitro Evaluation of Translucency and Color Stability of CAD/CAM Polymer-Infiltrated Ceramic Materials after Accelerated Aging. J. Prosthodont. 2021, 30, 318–328. [Google Scholar] [CrossRef]

- Johnston, W.M. Review of translucency determinations and applications to dental materials. J. Esthet. Restor. Dent. 2014, 26, 217–223. [Google Scholar] [CrossRef]

- Miyazaki, T.; Hotta, Y.; Kunii, J.; Kuriyama, S.; Tamaki, Y. A review of dental CAD/CAM: Current status and future perspectives from 20 years of experience. Dent. Mater. J. 2009, 28, 44–56. [Google Scholar] [CrossRef]

- Sadowsky, S.J. An overview of treatment considerations for esthetic restorations: A review of the literature. J. Prosthet. Dent. 2006, 96, 433–442. [Google Scholar] [CrossRef] [PubMed]

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef] [PubMed]

- He, L.H.; Swain, M. A novel polymer infiltrated ceramic dental material. Dent. Mater. 2011, 27, 527–534. [Google Scholar] [CrossRef] [PubMed]

- Alfouzan, A.F.; Al-Otaibi, H.N.; Labban, N.; Taweel, S.M.A.; Al-Tuwaijri, S.; AlGazlan, A.S.; Tashkandi, E.A. Influence of thickness and background on the color changes of CAD/CAM dental ceramic restorative materials. Mater. Res. Exp. 2020, 7, 055402. [Google Scholar] [CrossRef]

- Lawson, N.C.; Bansal, R.; Burgess, J.O. Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent. Mater. 2016, 32, e275–e283. [Google Scholar] [CrossRef]

- Alnafaiy, S.; Labban, N.; Maawadh, A.; Alshehri, H.; Albaijan, R. Repair Bond Strength of Composite Resin to Aged Resin and Glass-Matrix CAD/CAM Ceramic Materials Using Two Different Repair Systems. Coatings 2021, 11, 1331. [Google Scholar] [CrossRef]

- Alnafaiy, S.M.; Labban, N.; Maawadh, A.; Alshehri, H.; Aljamhan, A.S.; Alghamdi, W. Biaxial flexural strength and hardness of resin-matrix ceramic CAD/CAM materials. Ceramics–Silikáty 2021, 65, 285–294. [Google Scholar] [CrossRef]

- Griggs, J.A.; Thompson, J.Y.; Anusavice, K.J. Effects of flaw size and auto-glaze treatment on porcelain strength. J. Dent. Res. 1996, 75, 1414–1417. [Google Scholar] [CrossRef] [PubMed]

- Wright, M.D.; Masri, R.; Driscoll, C.F.; Romberg, E.; Thompson, G.A.; Runyan, D.A. Comparison of three systems for the polishing of an ultra-low fusing dental porcelain. J. Prosthet. Dent. 2004, 92, 486–490. [Google Scholar] [CrossRef] [PubMed]

- Herion, D.T.; Ferracane, J.L.; Covell, D.A., Jr. Porcelain surface alterations and refinishing after use of two orthodontic bonding methods. Angle Orthod. 2010, 80, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Maciel, L.C.; Silva, C.F.B.; de Jesus, R.H.; Concílio, L.R.D.S.; Kano, S.C.; Xible, A.A. Influence of polishing systems on roughness and color change of two dental ceramics. J. Adv. Prosthodont. 2019, 11, 215–222. [Google Scholar] [CrossRef]

- Carlén, A.; Nikdel, K.; Wennerberg, A.; Holmberg, K.; Olsson, J. Surface characteristics and in vitro biofilm formation on glass ionomer and composite resin. Biomaterials 2001, 22, 481–487. [Google Scholar] [CrossRef] [PubMed]

- Sasahara, R.M.; Ribeiro Fda, C.; Cesar, P.F.; Yoshimura, H.N. Influence of the finishing technique on surface roughness of dental porcelains with different microstructures. Oper. Dent. 2006, 31, 577–583. [Google Scholar] [CrossRef]

- Tholt de Vasconcellos, B.; Miranda-Júnior, W.G.; Prioli, R.; Thompson, J.; Oda, M. Surface roughness in ceramics with different finishing techniques using atomic force microscope and profilometer. Oper. Dent. 2006, 31, 442–449. [Google Scholar] [CrossRef] [PubMed]

- Carrabba, M.; Vichi, A.; Vultaggio, G.; Pallari, S.; Paravina, R.; Ferrari, M. Effect of Finishing and Polishing on the Surface Roughness and Gloss of Feldspathic Ceramic for Chairside CAD/CAM Systems. Oper. Dent. 2017, 42, 175–184. [Google Scholar] [CrossRef] [PubMed]

- Kawai, K.; Urano, M.; Ebisu, S. Effect of surface roughness of porcelain on adhesion of bacteria and their synthesizing glucans. J. Prosthet. Dent. 2000, 83, 664–667. [Google Scholar] [CrossRef] [PubMed]

- Aykent, F.; Yondem, I.; Ozyesil, A.G.; Gunal, S.K.; Avunduk, M.C.; Ozkan, S. Effect of different finishing techniques for restorative materials on surface roughness and bacterial adhesion. J. Prosthet. Dent. 2010, 103, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Coşkun, E.; Aslan, Y.U.; Özkan, Y.K. Evaluation of two different CAD-CAM inlay-onlays in a split-mouth study: 2-year clinical follow-up. J. Esthet. Restor. Dent. 2020, 32, 244–250. [Google Scholar] [CrossRef] [PubMed]

- Bollen, C.M.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef] [PubMed]

- Haywood, V.B.; Heymann, H.O.; Scurria, M.S. Effects of water, speed, and experimental instrumentation on finishing and polishing porcelain intra-orally. Dent. Mater. 1989, 5, 185–188. [Google Scholar] [CrossRef] [PubMed]

- Whitehead, S.A.; Shearer, A.C.; Watts, D.C.; Wilson, N.H. Comparison of methods for measuring surface roughness of ceramic. J. Oral Rehabil. 1995, 22, 421–427. [Google Scholar] [CrossRef] [PubMed]

- Ward, M.T.; Tate, W.H.; Powers, J.M. Surface roughness of opalescent porcelains after polishing. Oper. Dent. 1995, 20, 106–110. [Google Scholar] [PubMed]

- Heintze, S.D.; Forjanic, M.; Ohmiti, K.; Rousson, V. Surface deterioration of dental materials after simulated toothbrushing in relation to brushing time and load. Dent. Mater. 2010, 26, 306–319. [Google Scholar] [CrossRef]

- Mörmann, W.H.; Stawarczyk, B.; Ender, A.; Sener, B.; Attin, T.; Mehl, A. Wear characteristics of current aesthetic dental restorative CAD/CAM materials: Two-body wear, gloss retention, roughness and Martens hardness. J. Mech. Behav. Biomed. Mater. 2013, 20, 113–125. [Google Scholar] [CrossRef]

- The Academy of Prosthodontics. The Glossary of Prosthodontic Terms: Ninth Edition. J. Prosthet. Dent. 2017, 117, e1–e105. [Google Scholar] [CrossRef] [PubMed]

- Lawson, N.C.; Burgess, J.O. Gloss and Stain Resistance of Ceramic-Polymer CAD/CAM Restorative Blocks. J. Esthet. Restor. Dent. 2016, 28 (Suppl. 1), S40–S45. [Google Scholar] [CrossRef] [PubMed]

- Heintze, S.D.; Forjanic, M.; Rousson, V. Surface roughness and gloss of dental materials as a function of force and polishing time In Vitro. Dent. Mater. 2006, 22, 146–165. [Google Scholar] [CrossRef]

- Monaco, C.; Arena, A.; Scheda, L.; Di Fiore, A.; Zucchelli, G. In vitro 2D and 3D roughness and spectrophotometric and gloss analyses of ceramic materials after polishing with different prophylactic pastes. J. Prosthet. Dent. 2020, 124, 787.e1–787.e8. [Google Scholar] [CrossRef] [PubMed]

- Tosco, V.; Monterubbianesi, R.; Orilisi, G.; Procaccini, M.; Grandini, S.; Putignano, A.; Orsini, G. Effect of four different finishing and polishing systems on resin composites: Roughness surface and gloss retention evaluations. Minerva Stomatol. 2020, 69, 207–214. [Google Scholar] [CrossRef]

- Powers, J.M.; Wataha, J.C. Dental Materials: Properties and Manipulation, 10th ed.; Elsevier Health Sciences: London, UK, 2014. [Google Scholar]

- Barucci-Pfister, N.; Göhring, T.N. Subjective and objective perceptions of specular gloss and surface roughness of esthetic resin composites before and after artificial aging. Am. J. Dent. 2009, 22, 102–110. [Google Scholar]

- Da Costa, J.B.; Ferracane, J.L.; Amaya-Pajares, S.; Pfefferkorn, F. Visually acceptable gloss threshold for resin composite and polishing systems. J. Am. Dent. Assoc. 2021, 152, 385–392. [Google Scholar] [CrossRef]

- Kilinc, H.; Turgut, S. Optical behaviors of esthetic CAD-CAM restorations after different surface finishing and polishing procedures and UV aging: An in vitro study. J. Prosthet. Dent. 2018, 120, 107–113. [Google Scholar] [CrossRef]

- Şen, N.; Tuncelli, B.; Göller, G. Surface deterioration of monolithic CAD/CAM restorative materials after artificial abrasive toothbrushing. J. Adv. Prosthodont. 2018, 10, 271–278. [Google Scholar] [CrossRef]

- Incesu, E.; Yanikoglu, N. Evaluation of the effect of different polishing systems on the surface roughness of dental ceramics. J. Prosthet. Dent. 2020, 124, 100–109. [Google Scholar] [CrossRef]

- Vichi, A.; Fabian Fonzar, R.; Goracci, C.; Carrabba, M.; Ferrari, M. Effect of Finishing and Polishing on Roughness and Gloss of Lithium Disilicate and Lithium Silicate Zirconia Reinforced Glass Ceramic for CAD/CAM Systems. Oper. Dent. 2018, 43, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Baysan, A.; Sleibi, A.; Ozel, B.; Anderson, P. The quantification of surface roughness on root caries using Noncontact Optical Profilometry—An In Vitro study. Lasers Dent. Sci. 2018, 2, 229–237. [Google Scholar] [CrossRef]

- Daud, A.; Gray, G.; Lynch, C.D.; Wilson, N.H.F.; Blum, I.R. A randomised controlled study on the use of finishing and polishing systems on different resin composites using 3D contact optical profilometry and scanning electron microscopy. J. Dent. 2018, 71, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Flury, S.; Diebold, E.; Peutzfeldt, A.; Lussi, A. Effect of artificial toothbrushing and water storage on the surface roughness and micromechanical properties of tooth-colored CAD-CAM materials. J. Prosthet. Dent. 2017, 117, 767–774. [Google Scholar] [CrossRef] [PubMed]

- Ergücü, Z.; Türkün, L.S. Surface roughness of novel resin composites polished with one-step systems. Oper. Dent. 2007, 32, 185–192. [Google Scholar] [CrossRef]

- Kara, D.; Tekçe, N.; Fidan, S.; Demirci, M.; Tuncer, S.; Balcı, S. The Effects of Various Polishing Procedures on Surface Topography of CAD/CAM Resin Restoratives. J. Prosthodont. 2021, 30, 481–489. [Google Scholar] [CrossRef]

- Tekçe, N.; Fidan, S.; Tuncer, S.; Kara, D.; Demirci, M. The effect of glazing and aging on the surface properties of CAD/CAM resin blocks. J. Adv. Prosthodont. 2018, 10, 50–57. [Google Scholar] [CrossRef]

- Halis, G.; Şahin, O.; Köroğlu, A.; Cömert, F.; Yilmaz, B. Effect of simulated tootbrushing on surface roughness of sealant agent coupled nanohybrid composite resins. BMC Oral Health 2022, 34, 907–914. [Google Scholar] [CrossRef]

- Eslemez Topcu, E.; Şahin, O.; Köroğlu, A.; Cömert, F.; Yilmaz, B. Surface roughness and Streptococcus mutans adhesion on surface sealant agent coupled interim crown materials after dynamic loading. BMC Oral Health 2022, 22, 299. [Google Scholar] [CrossRef]

- Mitra, S.B.; Wu, D.; Holmes, B.N. An application of nanotechnology in advanced dental materials. J. Am. Dent. Assoc. 2003, 134, 1382–1390. [Google Scholar] [CrossRef]

- Odatsu, T.; Jimbo, R.; Wennerberg, A.; Watanabe, I.; Sawase, T. Effect of polishing and finishing procedures on the surface integrity of restorative ceramics. Am. J. Dent. 2013, 26, 51–55. [Google Scholar] [PubMed]

- Jain, V.; Platt, J.A.; Moore, K.; Spohr, A.M.; Borges, G.A. Color stability, gloss, and surface roughness of indirect composite resins. J. Oral Sci. 2013, 55, 9–15. [Google Scholar] [CrossRef] [PubMed]

- ISO 2813:2014; Paints and Varnishes—Determination of Gloss Value at 20°, 60° and 85°. ISO—International Organization for Standardization: Geneva, Switzerland, 2014.

- Kaizer, M.R.; de Oliveira-Ogliari, A.; Cenci, M.S.; Opdam, N.J.; Moraes, R.R. Do nanofill or submicron composites show improved smoothness and gloss? A systematic review of in vitro studies. Dent. Mater. 2014, 30, e41–e78. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.K.; Lu, H.; Oguri, M.; Powers, J.M. Changes in gloss after simulated generalized wear of composite resins. J. Prosthet. Dent. 2005, 94, 370–376. [Google Scholar] [CrossRef]

- Coldea, A.; Fischer, J.; Swain, M.V.; Thiel, N. Damage tolerance of indirect restorative materials (including PICN) after simulated bur adjustments. Dent. Mater. 2015, 31, 684–694. [Google Scholar] [CrossRef]

| Material | Shade/Code | Manufacturer | Composition |

|---|---|---|---|

| Lava Ultimate Restorative | A2-HT/LU | 3M ESPE, St. Paul, MN, USA | Matrix: BisGMA, BisEMA, TEGDMA, and UDMA (20 wt.%) Fillers: zirconia nanoparticles, silica, and silica/zirconia nanoclusters (80 wt.%) |

| Vita Enamic | 2M2-HT/EN | Vita Zahnfabrik, H. Rauter GmbH & Co, Bad Säckingen, Germany | Feldspathic ceramic containing aluminum oxide (86 wt.%) infiltrated by cross-linked polymers of BisGMA and UDMA (14 wt.%) |

| Cerasmart | A2-HT/CS | GC America, Alsip, IL, USA | Matrix: BisMEPP, UDMA, and DMA (29 wt.%) Fillers: barium and silica glass nanoparticles (71 wt.%) |

| Crystal Ultra | A2-C block/CU | Digital Dental, Scottsdale, AZ, USA | Ceramic-like inorganic silicate glass fillers (70 wt.%) infiltrated by cross-linked polymers of BisGMA, UDMA, and BUDMA) (30 wt.%) |

| Source | Sum of Squares | df | Mean Square | F | Sig * |

|---|---|---|---|---|---|

| CAD/CAM materials | 0.759 | 3 | 0.253 | 31.589 | 0.000 |

| Surface treatment | 5.061 | 3 | 1.687 | 210.516 | 0.000 |

| CAD/CAM materials × Surface treatment | 0.397 | 9 | 0.044 | 5.499 | 0.000 |

| Surface Treatment | LU | VE | CS | CU | Total |

|---|---|---|---|---|---|

| Control | 0.34 ± 0.11 | 0.63 ± 0.23 | 0.34 ± 0.12 | 0.54 ± 0.05 | 0.46 ± 0.13 |

| MP | 0.20 ± 0.05 | 0.39 ± 0.11 | 0.22 ± 0.13 | 0.34 ± 0.05 | 0.29 ± 0.09 |

| OG | 0.04 ± 0.01 | 0.07 ± 0.01 | 0.05 ± 0.01 | 0.06 ± 0.02 | 0.05± 0.01 |

| MP+PP | 0.06 ± 0.01 | 0.13 ± 0.02 | 0.07 ± 0.00 | 0.13 ± 0.05 | 0.10 ± 0.02 |

| Material | Surface Treatment | Dunnett’s Multiple Comparison | |||

|---|---|---|---|---|---|

| Control | MP | OG | MP+PP | ||

| LU | Control | 1 | |||

| MP | 0.009 * | 1 | |||

| OG | 0.00 * | 0.00 * | 1 | ||

| MP+PP | 0.00 * | 0.00 * | 0.001 * | 1 | |

| VE | Control | 1 | |||

| MP | 0.00 * | 1 | |||

| OG | 0.00 * | 0.00 * | 1 | ||

| MP+PP | 0.00 * | 0.00 * | 0.006 * | 1 | |

| CS | Control | 1 | |||

| MP | 0.188 | 1 | |||

| OG | 0.00 * | 0.005 * | 1 | ||

| MP+PP | 0.00 * | 0.014 * | 0.00 * | 1 | |

| CU | Control | 1 | |||

| MP | 0.00 * | 1 | |||

| OG | 0.00 * | 0.00 * | 1 | ||

| MP+PP | 0.00 * | 0.00 * | 0.006 * | 1 | |

| Source | Sum of Squares | df | Mean Square | F | Sig * |

|---|---|---|---|---|---|

| CAD/CAM materials | 14,859.47 | 3 | 4953.16 | 306.87 | 0.000 |

| Surface treatment | 50,368.31 | 3 | 16,789.43 | 1040.19 | 0.000 |

| CAD/CAM materials × Surface treatment | 2006.13 | 9 | 222.90 | 13.81 | 0.000 |

| Surface Treatment | LU | VE | CS | CU | Total |

|---|---|---|---|---|---|

| Control | 35.87 ± 1.95 | 23.32 ± 2.41 | 31.05 ± 5.60 | 26.92 ± 3.95 | 29.29 ± 3.48 |

| MP | 57.19 ± 1.95 | 38.34 ± 2.76 | 49.24 ± 5.91 | 41.79 ± 4.30 | 46.64 ± 3.73 |

| OG | 90.48 ± 4.69 | 59.54 ± 2.80 | 76.92 ± 5.11 | 65.69 ± 6.05 | 73.16 ± 4.6 |

| MP+PP | 78.88 ± 3.02 | 48.52 ± 2.41 | 58.82 ± 4.16 | 52.06 ± 3.40 | 59.57 ± 3.25 |

| Material | Surface Treatment | Dunnett’s Multiple Comparison | |||

|---|---|---|---|---|---|

| Control | MP | OG | MP+PP | ||

| LU | Control | 1 | |||

| MP | 0.000 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 0.000 * | 1 | |

| VE | Control | 1 | |||

| MP | 0.000 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 0.000 * | 1 | |

| CS | Control | 1 | |||

| MP | 0.000 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.001 * | 0.000 * | 1 | |

| CU | Control | 1 | |||

| MP | 0.000 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 0.000 * | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhassan, M.; Maawadh, A.; Labban, N.; Alnafaiy, S.M.; Alotaibi, H.N.; BinMahfooz, A.M. Effect of Different Surface Treatments on the Surface Roughness and Gloss of Resin-Modified CAD/CAM Ceramics. Appl. Sci. 2022, 12, 11972. https://doi.org/10.3390/app122311972

Alhassan M, Maawadh A, Labban N, Alnafaiy SM, Alotaibi HN, BinMahfooz AM. Effect of Different Surface Treatments on the Surface Roughness and Gloss of Resin-Modified CAD/CAM Ceramics. Applied Sciences. 2022; 12(23):11972. https://doi.org/10.3390/app122311972

Chicago/Turabian StyleAlhassan, Mona, Ahmed Maawadh, Nawaf Labban, Sarah M. Alnafaiy, Hanan N. Alotaibi, and Abdulelah M. BinMahfooz. 2022. "Effect of Different Surface Treatments on the Surface Roughness and Gloss of Resin-Modified CAD/CAM Ceramics" Applied Sciences 12, no. 23: 11972. https://doi.org/10.3390/app122311972

APA StyleAlhassan, M., Maawadh, A., Labban, N., Alnafaiy, S. M., Alotaibi, H. N., & BinMahfooz, A. M. (2022). Effect of Different Surface Treatments on the Surface Roughness and Gloss of Resin-Modified CAD/CAM Ceramics. Applied Sciences, 12(23), 11972. https://doi.org/10.3390/app122311972