Knowledge Management for Injection Molding Defects by a Knowledge Graph

Abstract

1. Introduction

2. Materials and Methods

2.1. Knowledge Graph

2.2. Neo4j

2.3. MongoDB

2.4. BERT

2.5. Graph Construction

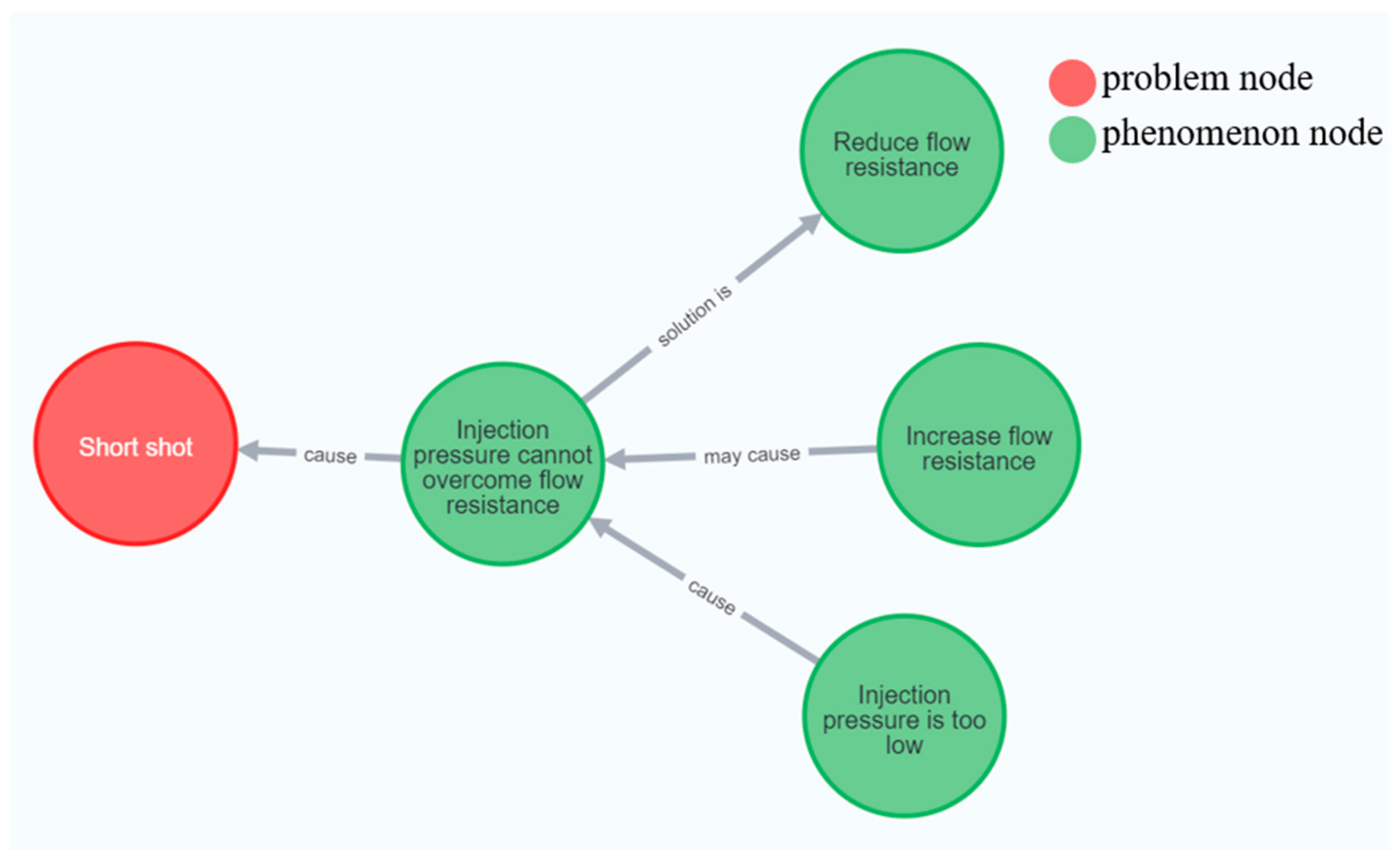

2.5.1. Problem Nodes

2.5.2. Phenomenon Nodes

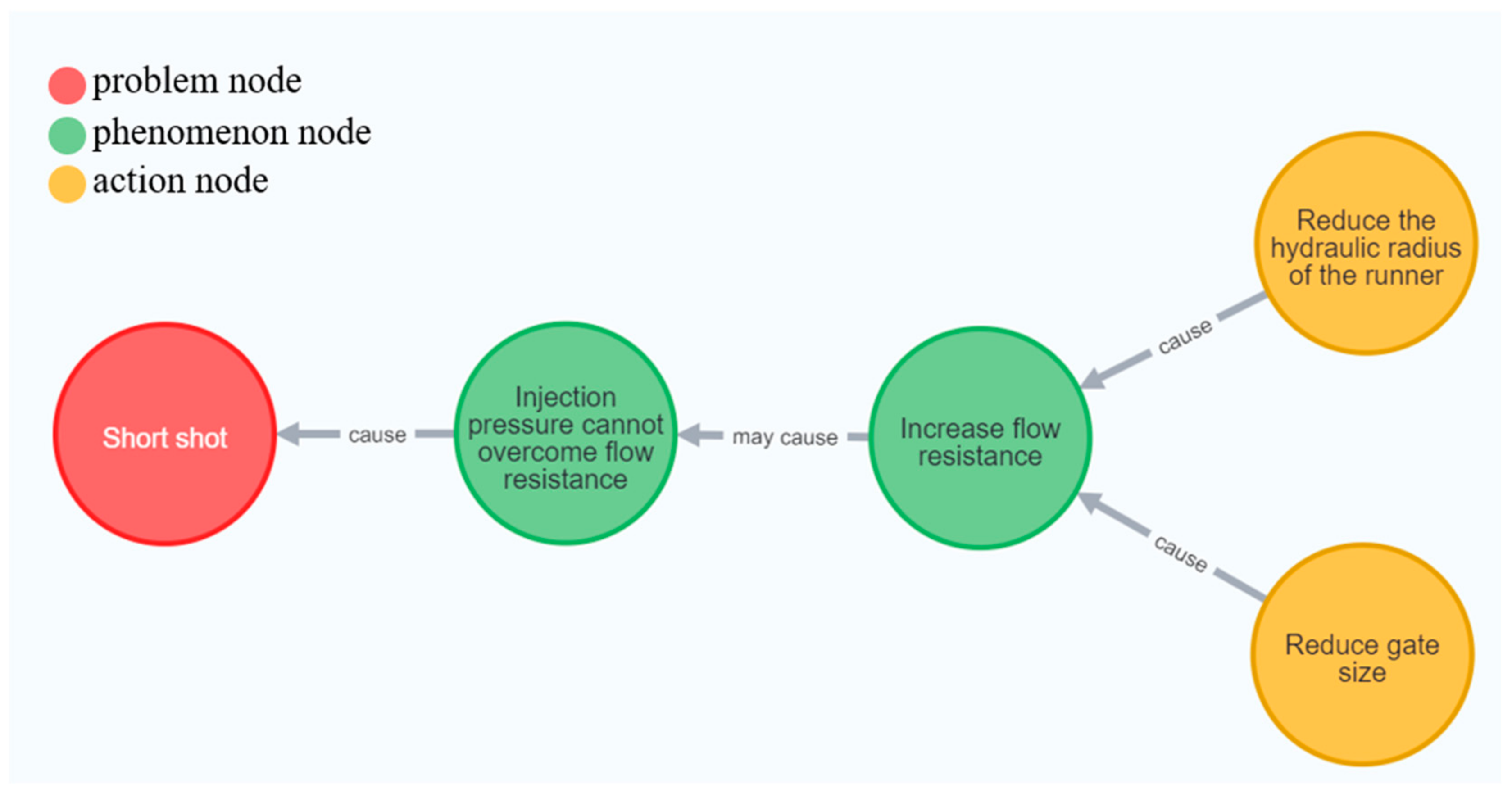

2.5.3. Action Nodes

- Cause

- 2.

- May cause

- 3.

- Solution

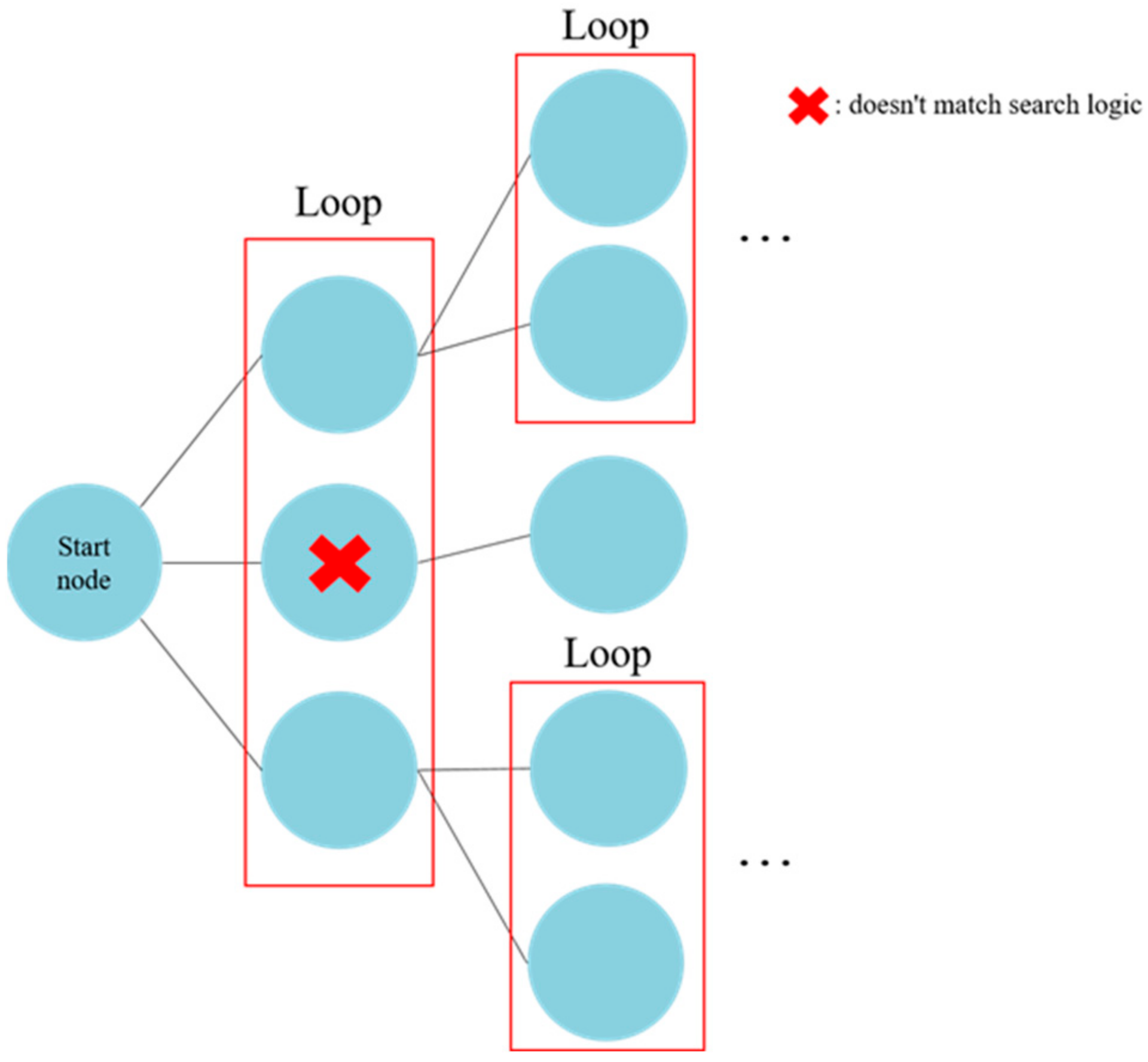

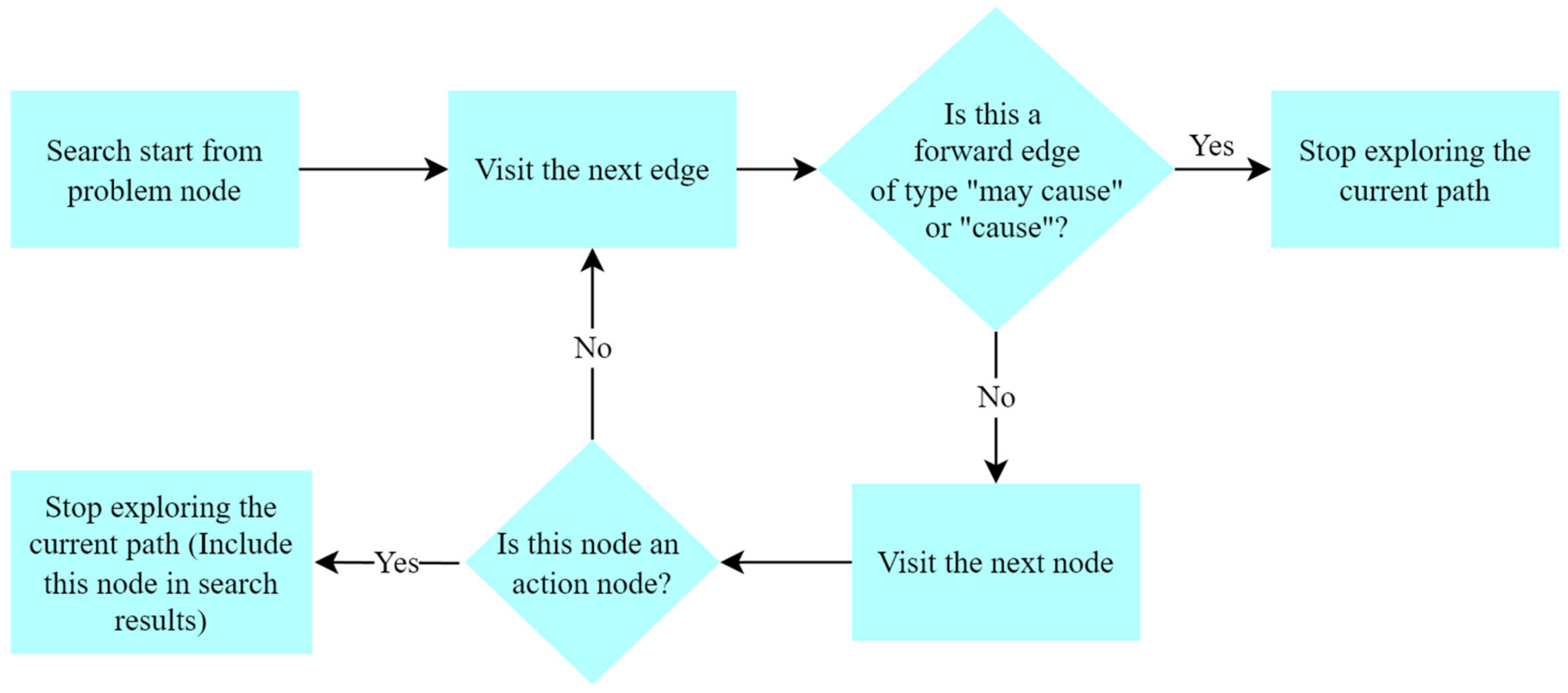

2.6. Search Engine

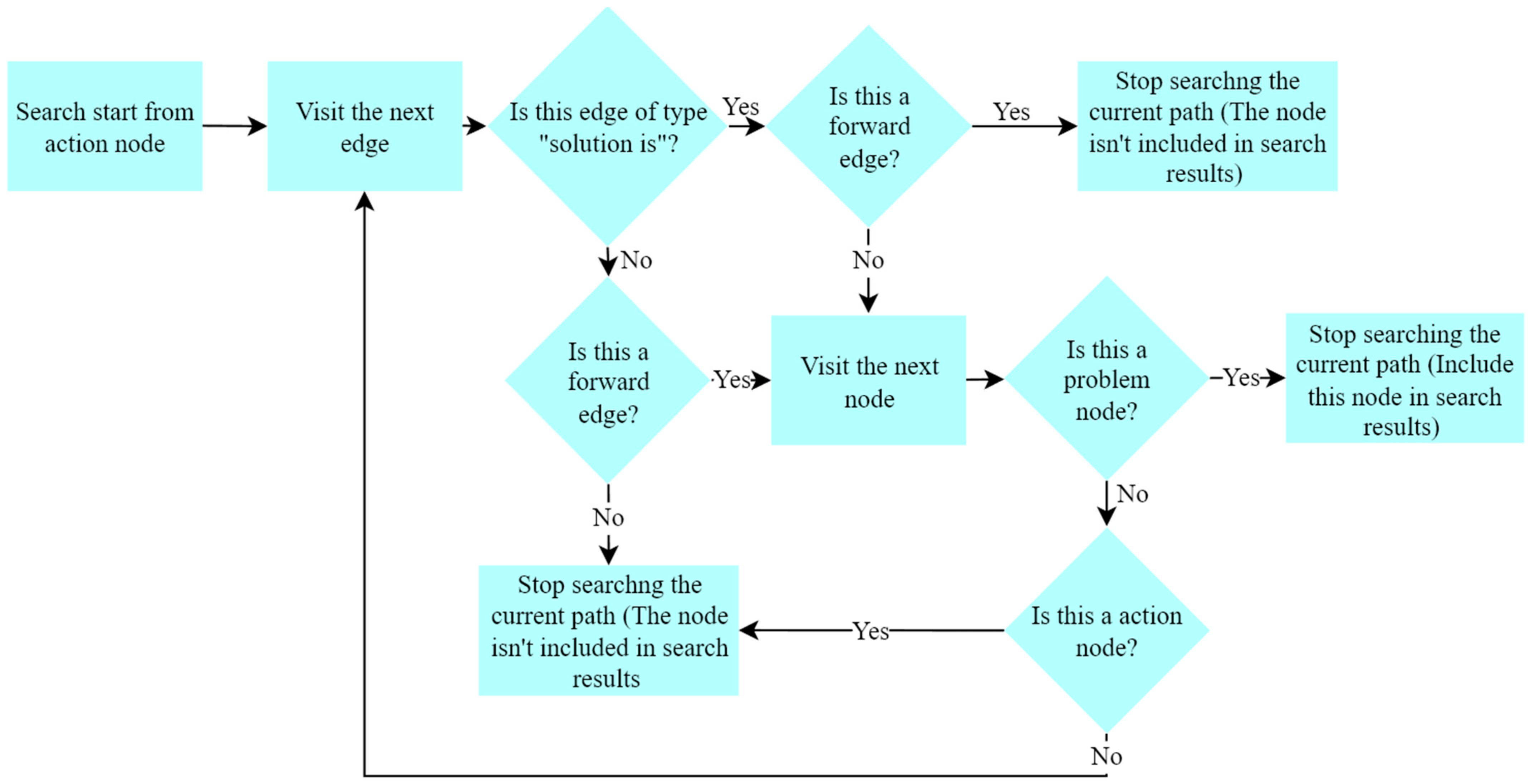

2.7. Search Logic

2.7.1. Problem Search Logic

2.7.2. Phenomenon Node Search Logic

2.7.3. Phenomenon Node Search Logic

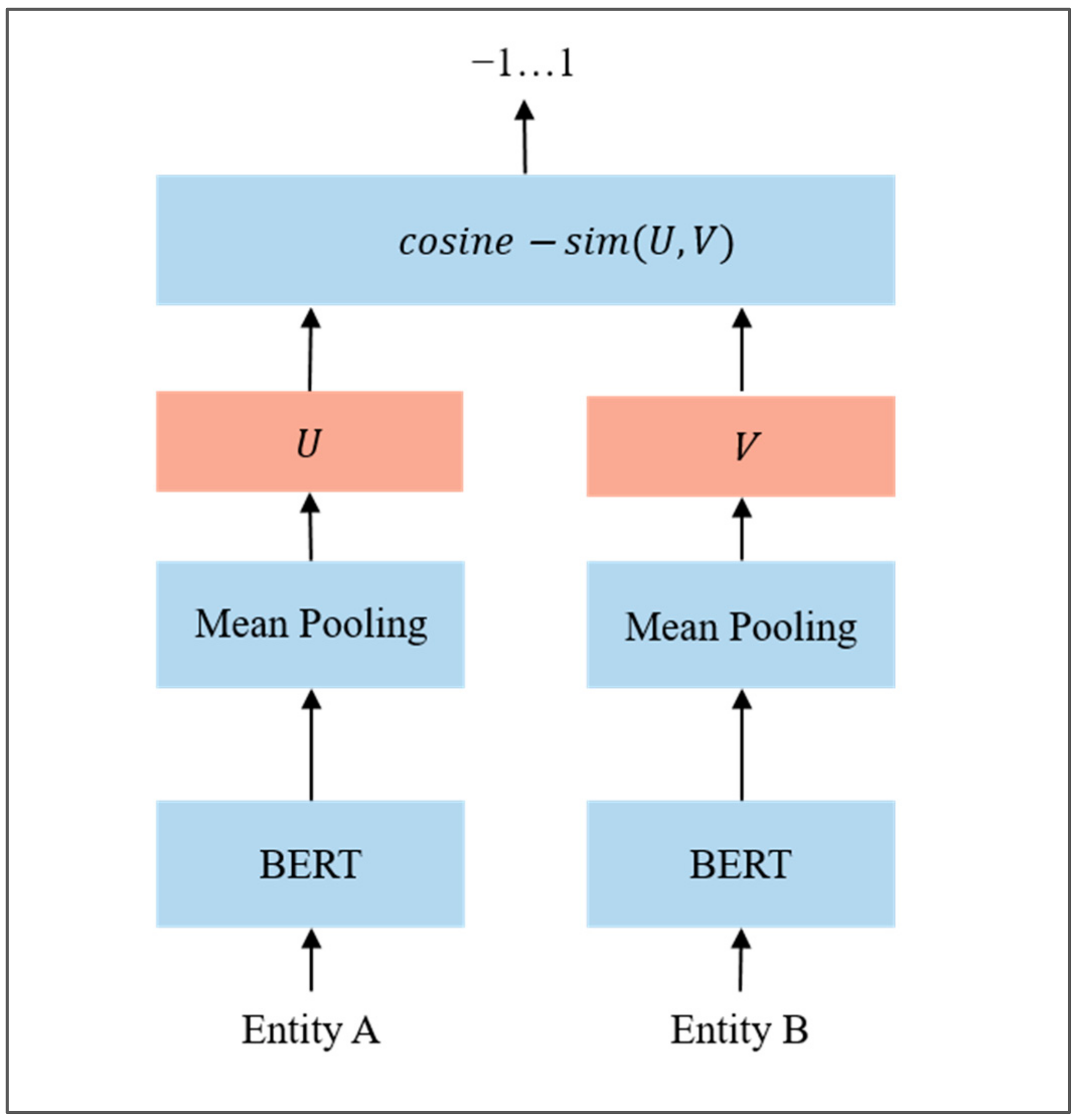

2.8. Semantic Comparison

3. Results and Discussion

3.1. Discussion of the Actual Cases

3.1.1. Problem Search Result

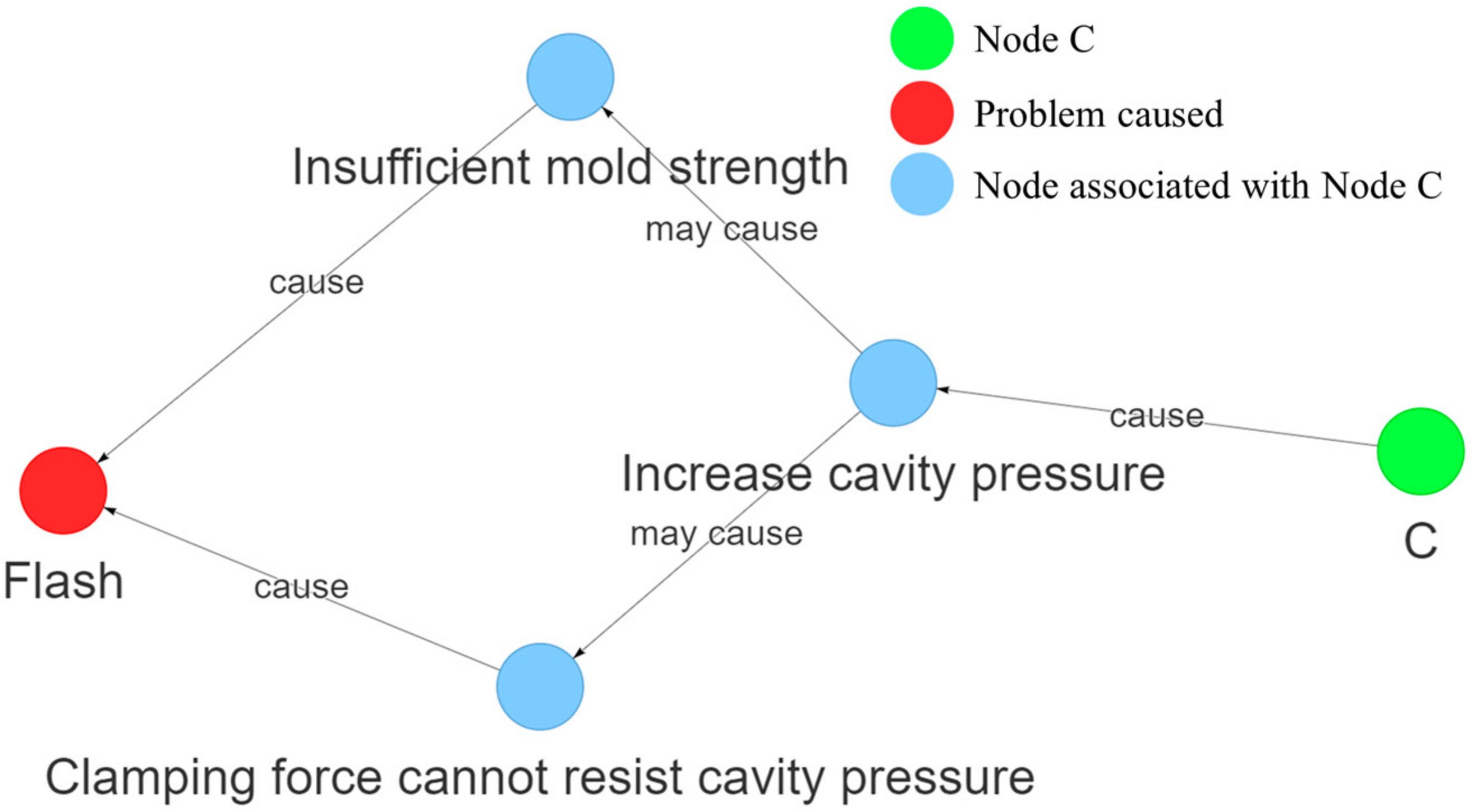

3.1.2. Phenomenon Search Result

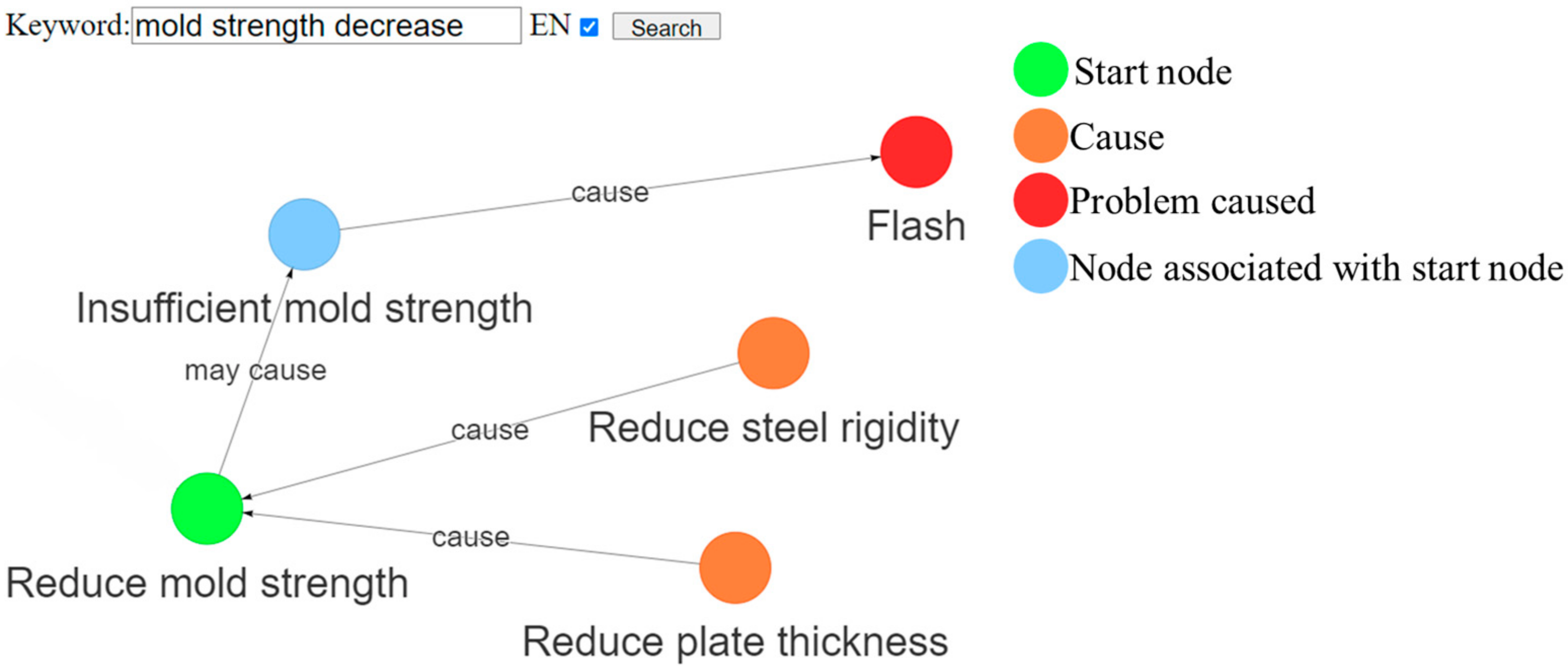

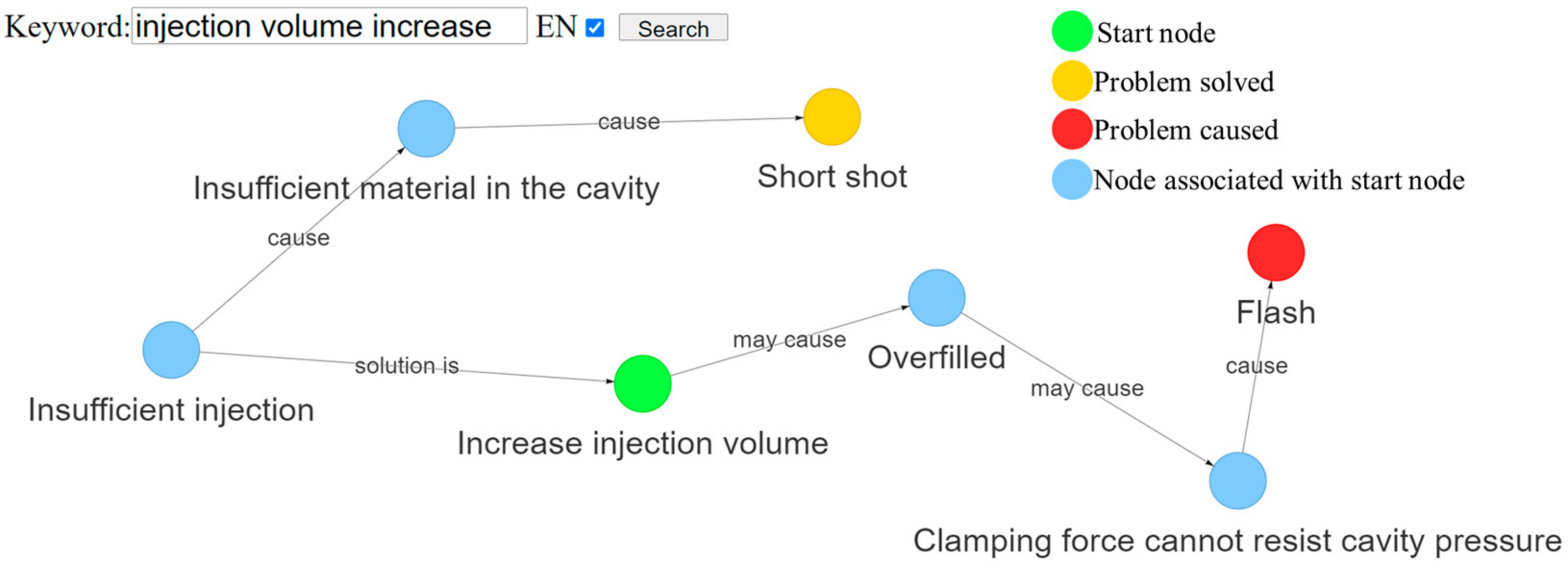

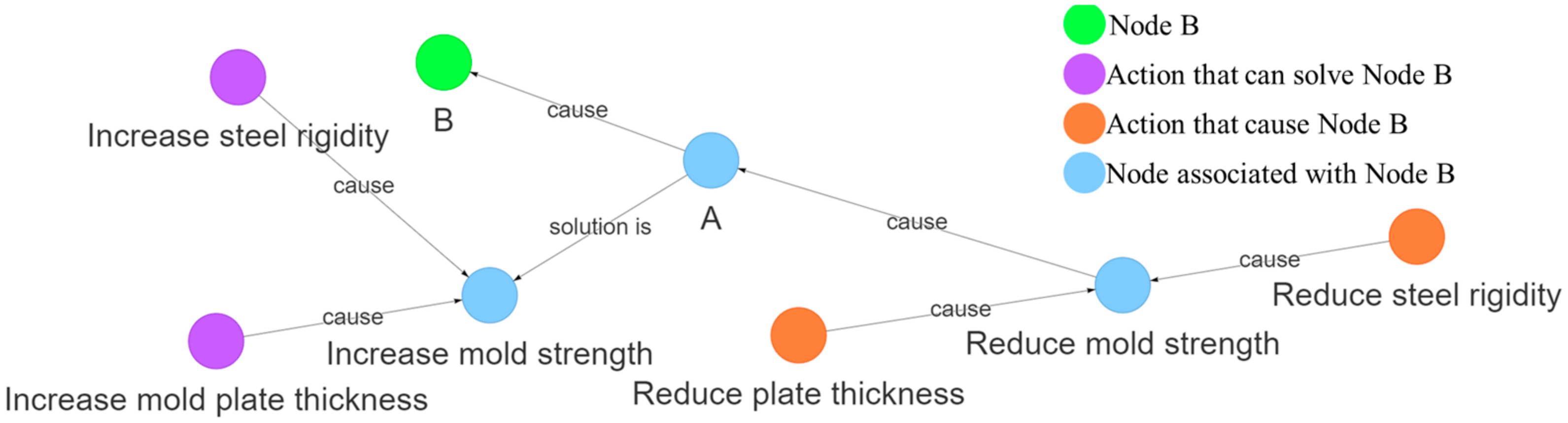

3.1.3. Action Search Result

3.2. Search Efficiency

3.3. Graph Expansion

3.3.1. Case 1

3.3.2. Case 2

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Jong, W.R.; Wu, C.H.; Li, M.Y. Web-based navigating system for conceptual mould design with knowledge management. Int. J. Prod. Res. 2010, 49, 553–567. [Google Scholar] [CrossRef]

- Jong, W.R.; Ting, Y.H.; Li, T.C.; Chen, K.Y. An integrated application for historical knowledge management with mould design navigating process. Int. J. Prod. Res. 2012, 51, 3191–3205. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Nasiri, S.; Weinberg, K. Application of case-based reasoning in a fault detection system on production of drippers. Appl. Soft Comput. 2018, 75, 227–232. [Google Scholar] [CrossRef]

- Mikos, W.L.; Ferreira, J.C.E.; Gomes, F.G.C. A distributed system for rapid determination of nonconformance causes and solutions for the thermoplastic injection molding process: A Case-Based Reasoning Agents approach. In Proceedings of the 2011 IEEE International Conference on Automation Science and Engineering, Trieste, Italy, 24–27 August 2011; pp. 755–760. [Google Scholar]

- Khosravani, M.R.; Nasiri, S.; Reinicke, T. Intelligent knowledge-based system to improve injection molding process. J. Ind. Inf. Integr. 2022, 25, 100275. [Google Scholar] [CrossRef]

- Mathivanan, D.; Nouby, M.; Vidhya, R. Minimization of sink mark defects in injection molding process—Taguchi approach. Int. J. Eng. Sci. Technol. 2010, 2, 13–22. [Google Scholar] [CrossRef]

- Altan, M. Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods. Mater. Des. 2010, 31, 599–604. [Google Scholar] [CrossRef]

- Utomo, A.P.; Bintara, R.D.; Suprayitno. Optimization Injection Molding Parameters of Polypropylene Materials to Minimize Product Not Complete Defects Using the Taguchi Method. Proc. Int. Conf. Relig. Sci. Educ. 2022, 1, 605–611. [Google Scholar]

- Yin, F.; Mao, H.; Hua, L.; Guo, W.; Shu, M. Back Propagation neural network modeling for warpage prediction and optimization of plastic products during injection molding. Mater. Des. 2011, 32, 1844–1850. [Google Scholar] [CrossRef]

- Kurtaran, H.; Ozcelik, B.; Erzurumlu, T. Warpage optimization of a bus ceiling lamp base using neural network model and genetic algorithm. J. Mater. Process. Technol. 2005, 169, 314–319. [Google Scholar] [CrossRef]

- Zhang, Y.; Sheng, M.; Zhou, R.; Wang, Y.; Han, G.; Zhang, H.; Xing, C.; Dong, J. HKGB: An Inclusive, Extensible, Intelligent, Semi-auto-constructed Knowledge Graph Framework for Healthcare with Clinicians’ Expertise Incorporated. Inf. Process. Manag. 2020, 57, 102324. [Google Scholar] [CrossRef]

- Kim, H. Chapter 5—A knowledge graph of medical institutions in Korea. In Web Semantic; Jain, S., Jain, V., Balas, V.E., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 55–68. [Google Scholar]

- Jiang, Y.; Gao, X.; Su, W.; Li, J. Systematic Knowledge Management of Construction Safety Standards Based on Knowledge Graphs: A Case Study in China. Environ. Res. Public Health 2021, 18, 10692. [Google Scholar] [CrossRef]

- Shi, Y.-X.; Zhang, B.-K.; Wang, Y.-X.; Luo, H.-Q.; Li, X. Constructing Crop Portraits Based on Graph Databases Is Essential to Agricultural Data Mining. Information 2021, 12, 227. [Google Scholar] [CrossRef]

- Lee, J.W.; Park, J. An Approach to Constructing a Knowledge Graph Based on Korean Open-Government Data. Appl. Sci. 2019, 9, 4095. [Google Scholar] [CrossRef]

- Yan, J.; Lv, T.; Yu, Y. Construction and Recommendation of a Water Affair Knowledge Graph. Sustainability 2018, 10, 3429. [Google Scholar] [CrossRef]

- Chi, Y.; Yu, C.; Qi, X.; Xu, H. Knowledge Management in Healthcare Sustainability: A Smart Healthy Diet Assistant in Traditional Chinese Medicine Culture. Sustainability 2018, 10, 4197. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G.; Lu, Q.; Chang, F. Graph-based knowledge reuse for supporting knowledge-driven decision-making in new product development. Int. J. Prod. Res. 2017, 55, 7187–7203. [Google Scholar] [CrossRef]

- Park, S.; Lee, W.; Choe, B.; Lee, S.G. A Survey on Personalized PageRank Computation Algorithms. IEEE Access 2019, 7, 163049–163062. [Google Scholar] [CrossRef]

- Gao, H.; Miao, L.; Liu, J.; Dong, K.; Lin, X. Construction and Application of Knowledge Graph for Power System Dispatching. In Proceedings of the 7th International Forum on Electrical Engineering and Automation (IFEEA), Hefei, China, 25–27 September 2020. [Google Scholar]

- Su, X.; He, J.; Ren, J.; Peng, J. Personalized Chinese Tourism Recommendation Algorithm Based on Knowledge Graph. Appl. Sci. 2022, 12, 10226. [Google Scholar] [CrossRef]

- Zhang, J.; Song, Z. Research on knowledge graph for quantification of relationship between enterprises and recognition of potential risks. In Proceedings of the 2019 4th IEEE International Conference on Cybernetics, Tokyo, Japan, 27–30 September 2019. [Google Scholar]

- Huang, H.; Chen, Y.; Lou, B.; Hongzhou, Z.; Wu, J.; Yan, K. Constructing Knowledge Graph from Big Data of Smart Grids. In Proceedings of the 2019 10th International Conference on Information Technology in Medicine and Education (ITME), Qingdao, China, 23–25 August 2019. [Google Scholar]

- Haussmann, S.; Seneviratne, O.; Chen, Y.; Ne’eman, Y.; Codella, J.; Chen, C.H.; McGuinness, D.L.; Zaki, M.J. FoodKG: A Semantics-Driven Knowledge Graph for Food Recommendation. In International Semantic Web Conference: The Semantic Web—ISWC 2019; Springer: Cham, Switzerland, 2019; pp. 146–162. [Google Scholar]

- Liu, J.; Schmid, F.; Li, K.; Zheng, W. A knowledge graph-based approach for exploring railway operational accidents. Reliab. Eng. Syst. Saf. 2021, 207, 107352. [Google Scholar] [CrossRef]

- Zehra, S.; Mohsin, S.F.M.; Wasi, S.; Jami, S.I.; Siddiqui, M.S.; Syed, M.K.R. Financial Knowledge Graph Based Financial Report Query System. IEEE Access 2021, 9, 69766–69782. [Google Scholar] [CrossRef]

- Acikalin, U.U.; Bardak, B.; Kutlu, M. Turkish Sentiment Analysis Using BERT. In Proceedings of the 28th Signal Processing and Communications Applications Conference, Gaziantep, Turkey, 5–7 October 2020; pp. 1–4. [Google Scholar]

- Mozafari, M.R.; Farahbakhsh, R.; Crespi, N. A BERT-Based Transfer Learning Approach for Hate Speech Detection in Online Social Media. In Proceedings of the 8th International Conference on Complex Networks and Their Applications COMPLEX NETWORKS, Lisbon, Portugal, 10–12 December 2019; Volume 1, pp. 928–940. [Google Scholar]

- Dang, J.; Wei, H.; Yan, Y.; Jia, R.; Li, Y. Construction of Knowledge Graph of Electrical Equipment Based on Sentence—BERT. In Proceedings of the 2021 International Conference on Advanced Electrical Equipment and Reliable Operation, Beijing, China, 15–17 October 2021; pp. 1–5. [Google Scholar]

- Casillas, R.; Gómez-Adorno, H.; Lomas-Barrie, V.; Ramos-Flores, O. Automatic Fact Checking Using an Interpretable Bert-Based Architecture on COVID-19 Claims. Appl. Sci. 2022, 12, 10644. [Google Scholar] [CrossRef]

- Introducing the Knowledge Graph: Things, Not Strings. Available online: https://blog.google/products/search/introducing-knowledge-graph-things-not/ (accessed on 21 December 2021).

- Guia, J.; Soares, V.G.; Bernardino, J. Graph Databases: Neo4j Analysis. Int. Conf. Enterp. Inf. Syst. 2017, 1, 351–356. [Google Scholar]

- Devlin, J.; Chang, M.W.; Lee, K.; Toutanova, K. Bert: Pre-training of deep bidirectional transformers for language understanding. In Proceedings of the 2019 Conference of the North American Chapter of the Association for Computational Linguistics: Human Language Technologies, Minneapolis, MN, USA, 2–7 June 2019. [Google Scholar]

| Node Type | Node Name | Total Number of Associated Nodes | Comparison | ||

|---|---|---|---|---|---|

| F1_Score of the Rule Based Search Engine | F1_Score of the Neo4j Cypher (Search Depth = 3) | F1_Score of the Neo4j Cypher (Search Depth = 5) | |||

| Problem | Flash | 26 | 1.000 | 0.721 | 0.366 |

| Problem | Splay | 51 | 1.000 | 0.649 | 0.415 |

| Problem | Short shot | 87 | 1.000 | 0.492 | 0.697 |

| Phenomenon | Reduce the flow resistance | 30 | 1.000 | 0.565 | 0.282 |

| Phenomenon | Reduce the plastic temperature | 36 | 1.000 | 0.458 | 0.310 |

| Phenomenon | Increase the venting capacity of the mold | 17 | 1.000 | 0.415 | 0.159 |

| Action | Decrease the mold temperature | 30 | 1.000 | 0.456 | 0.282 |

| Action | Increase the coolant flow rate | 21 | 1.000 | 0.426 | 0.237 |

| Action | Increase the nozzle temperature | 30 | 1.000 | 0.542 | 0.339 |

| Node Type | Node Name | Total Number of Associated Nodes | Searching Time of The Rule Based Search Engine (s) | Searching Time of the Neo4j Cypher + Manual Filtering (s) |

|---|---|---|---|---|

| Problem | Flash | 26 | 0.225 | 100 |

| Phenomenon | Reduce the plastic temperature | 36 | 0.50 | 150 |

| Action | Increase the coolant flow rate | 21 | 0.349 | 97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.-W.; Ting, Y.-H.; Jong, W.-R.; Chiu, M.-C. Knowledge Management for Injection Molding Defects by a Knowledge Graph. Appl. Sci. 2022, 12, 11888. https://doi.org/10.3390/app122311888

Zhou Z-W, Ting Y-H, Jong W-R, Chiu M-C. Knowledge Management for Injection Molding Defects by a Knowledge Graph. Applied Sciences. 2022; 12(23):11888. https://doi.org/10.3390/app122311888

Chicago/Turabian StyleZhou, Zhe-Wei, Yu-Hung Ting, Wen-Ren Jong, and Ming-Chien Chiu. 2022. "Knowledge Management for Injection Molding Defects by a Knowledge Graph" Applied Sciences 12, no. 23: 11888. https://doi.org/10.3390/app122311888

APA StyleZhou, Z.-W., Ting, Y.-H., Jong, W.-R., & Chiu, M.-C. (2022). Knowledge Management for Injection Molding Defects by a Knowledge Graph. Applied Sciences, 12(23), 11888. https://doi.org/10.3390/app122311888