Experimental Study on Coal Specimens Subjected to Uniaxial Cyclic Loading and Unloading

Abstract

1. Introduction

2. Experiment Design

2.1. Specimen

2.2. Experimental Devices

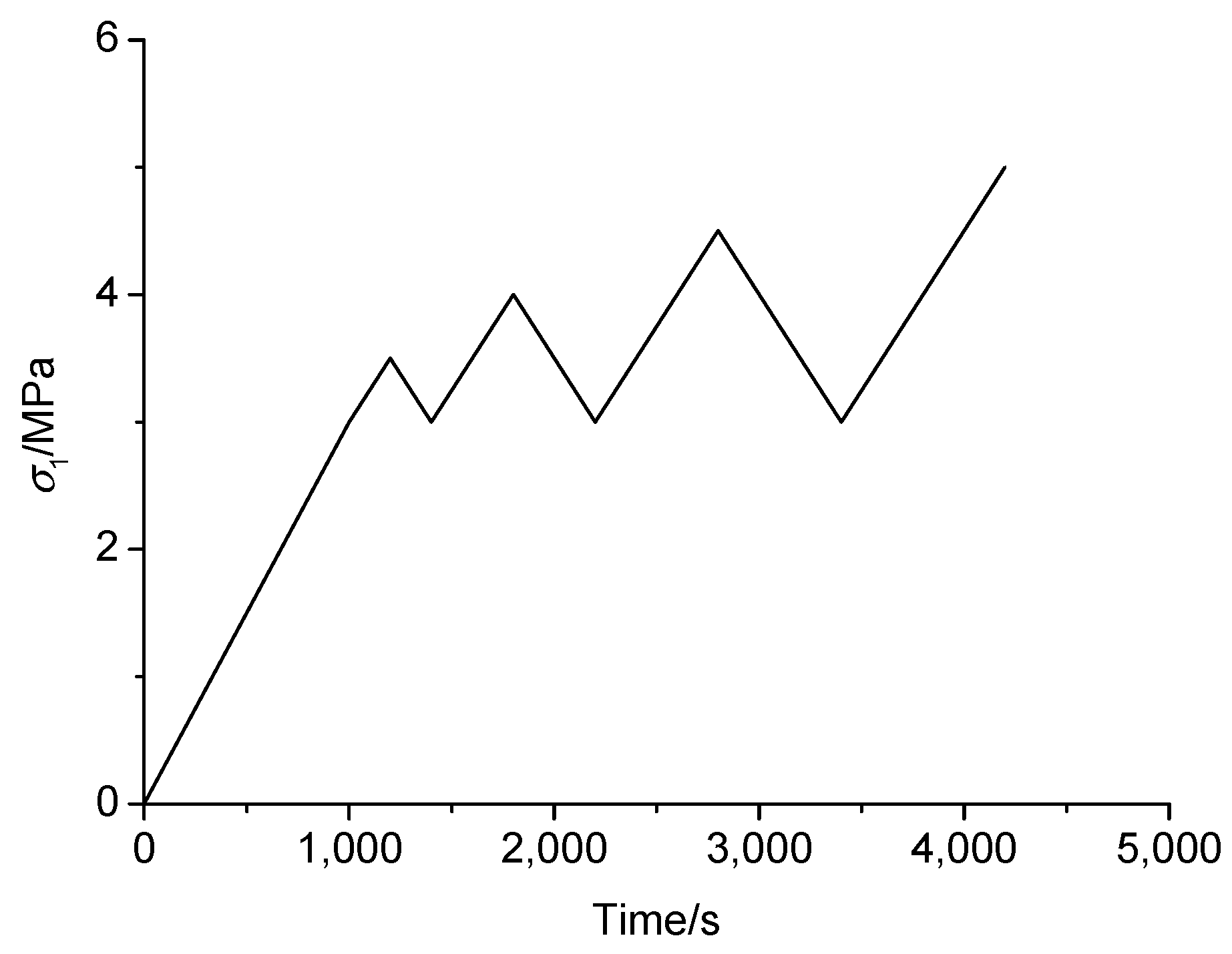

2.3. Test Scheme

3. Testing Results

3.1. Deformation and Elastic Modulus

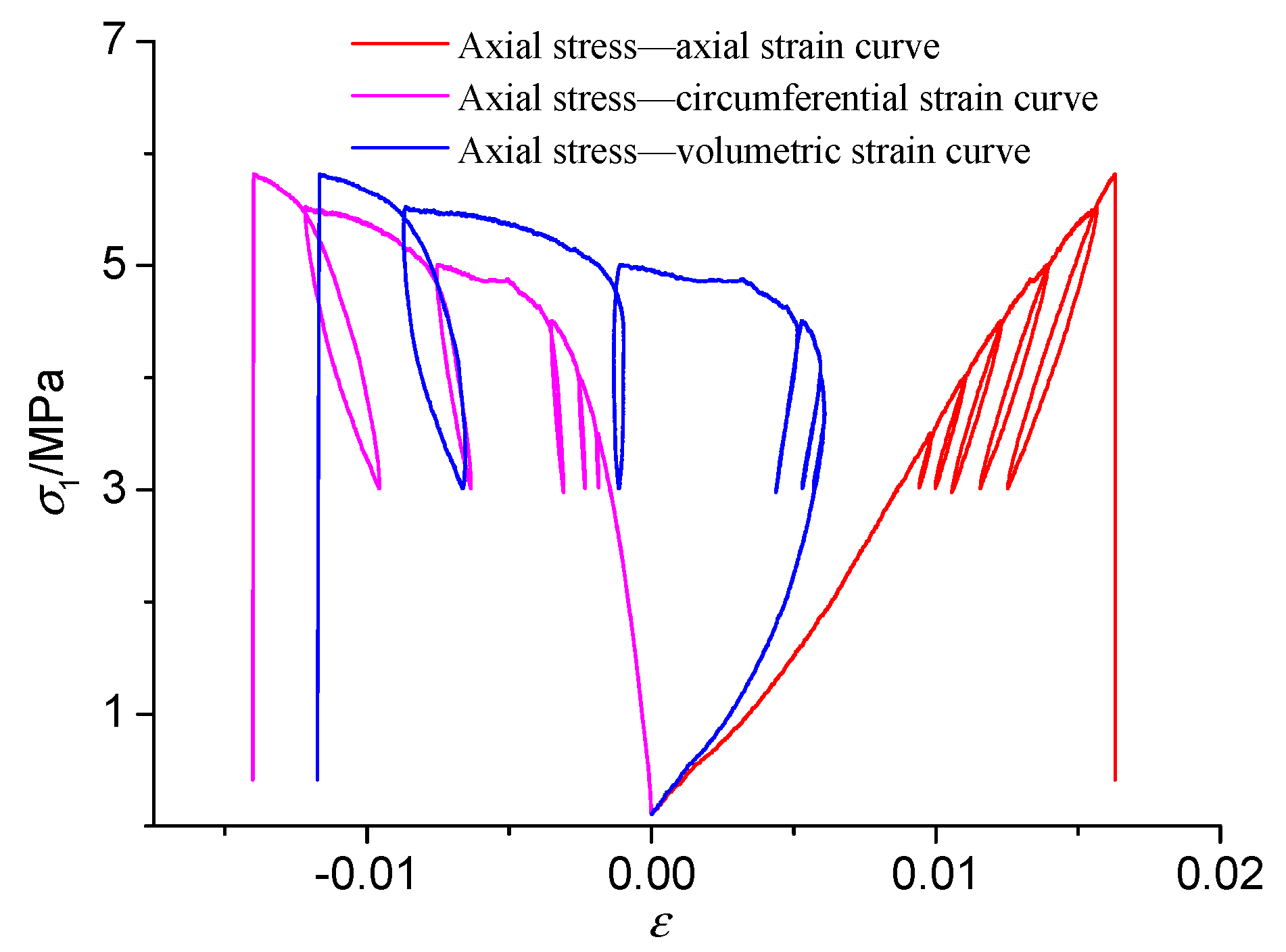

3.1.1. Stress versus Strain Curves

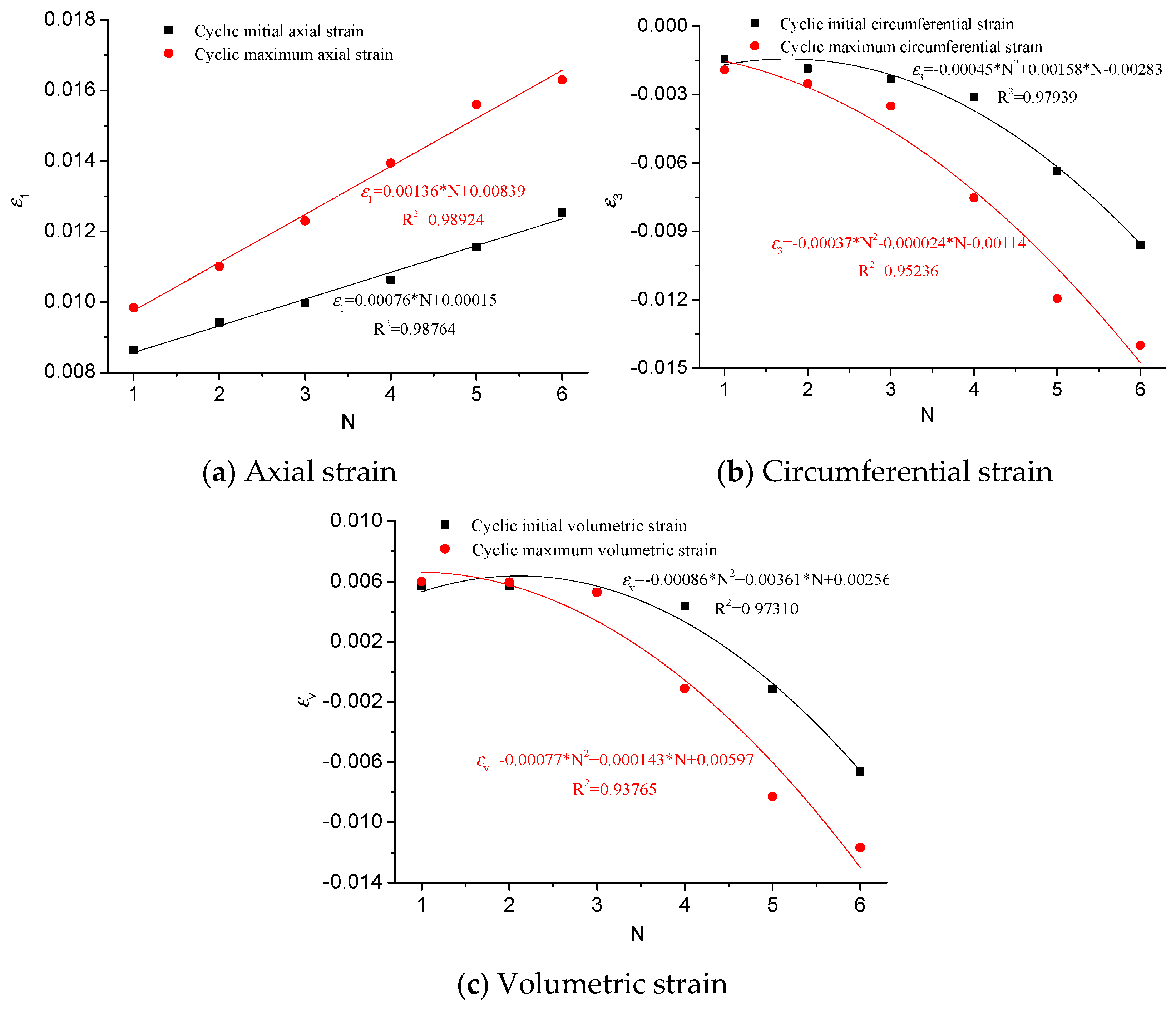

3.1.2. Relation between Strain and Loading–Unloading Cycle Number

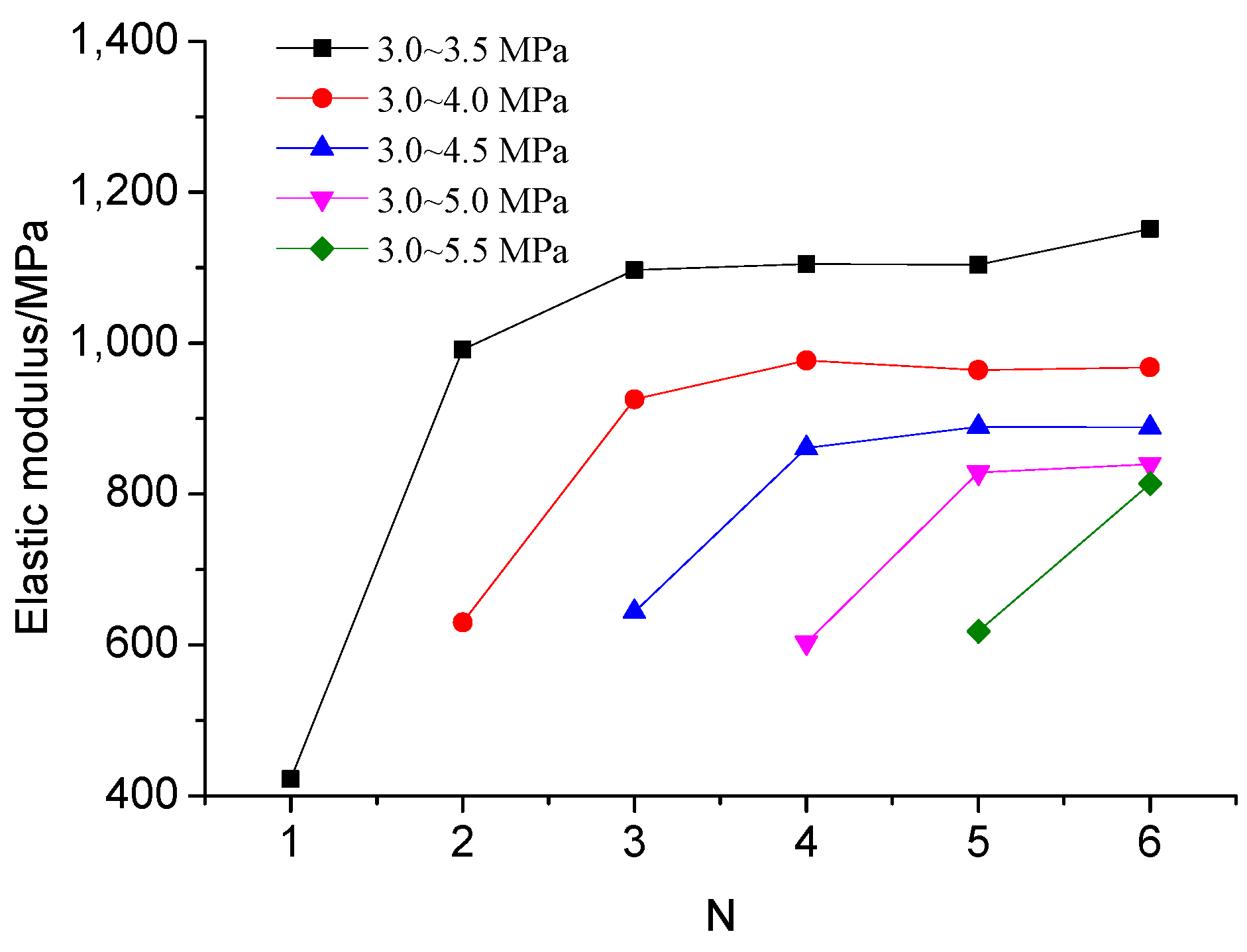

3.1.3. Elastic Modulus

3.2. AE Characteristics

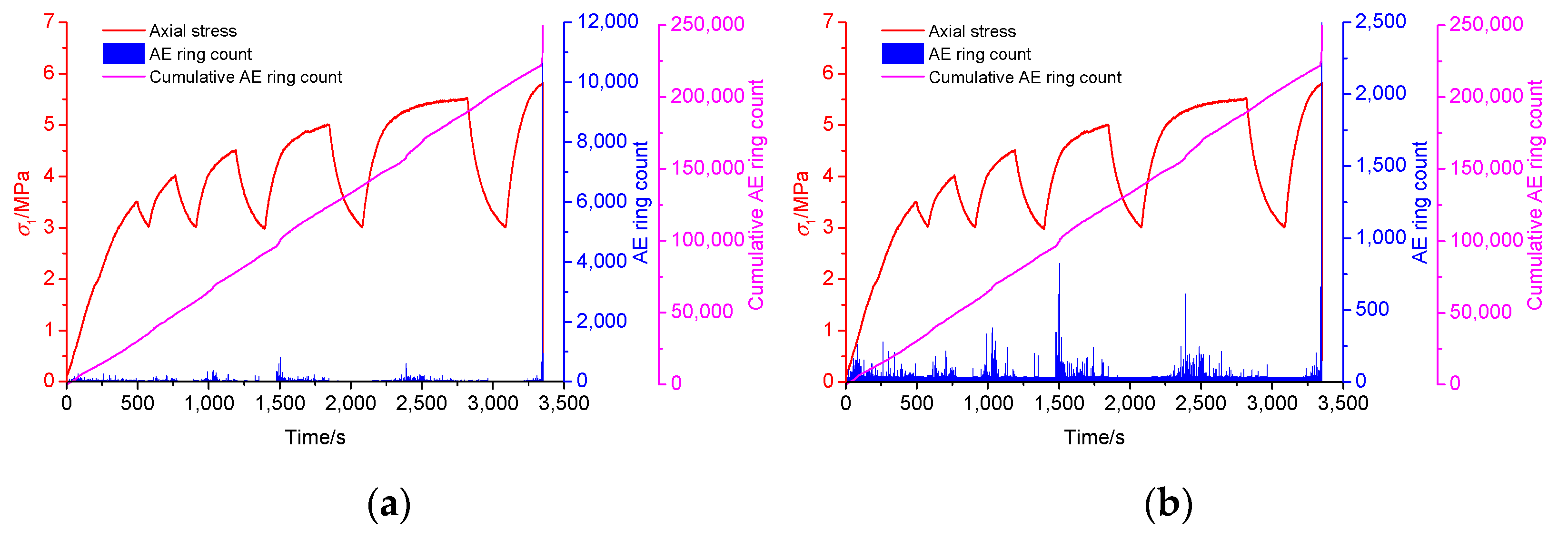

3.2.1. AE Ring Count

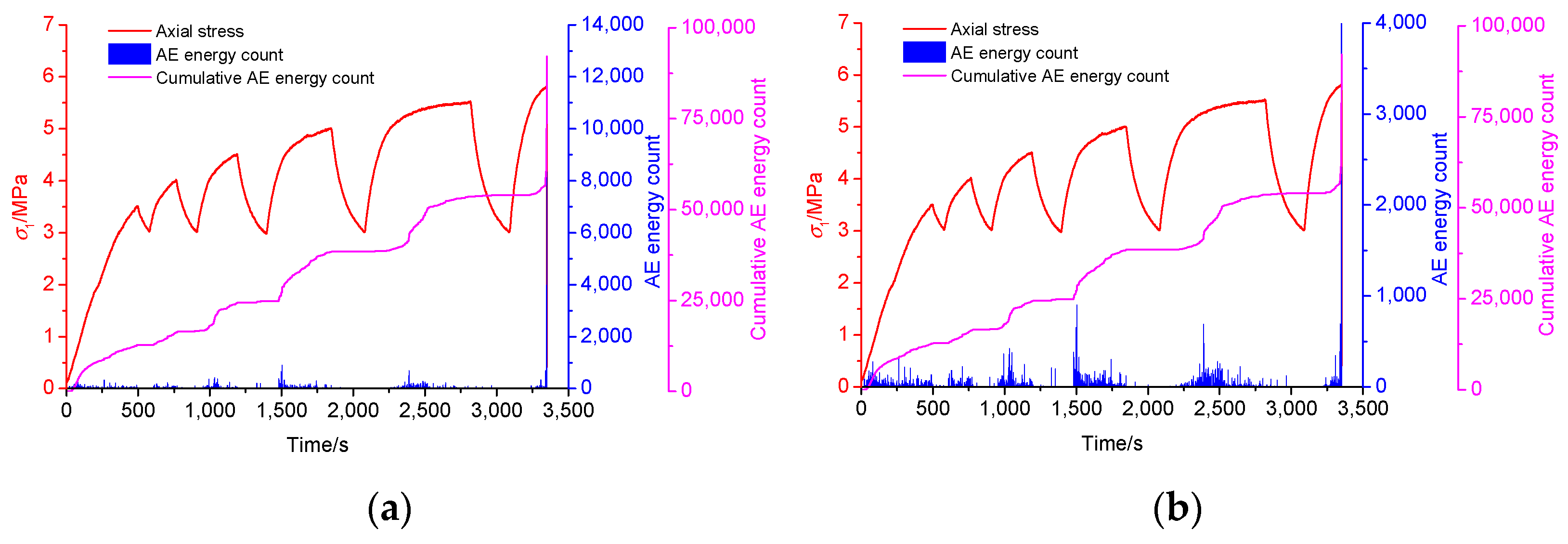

3.2.2. AE Energy Count

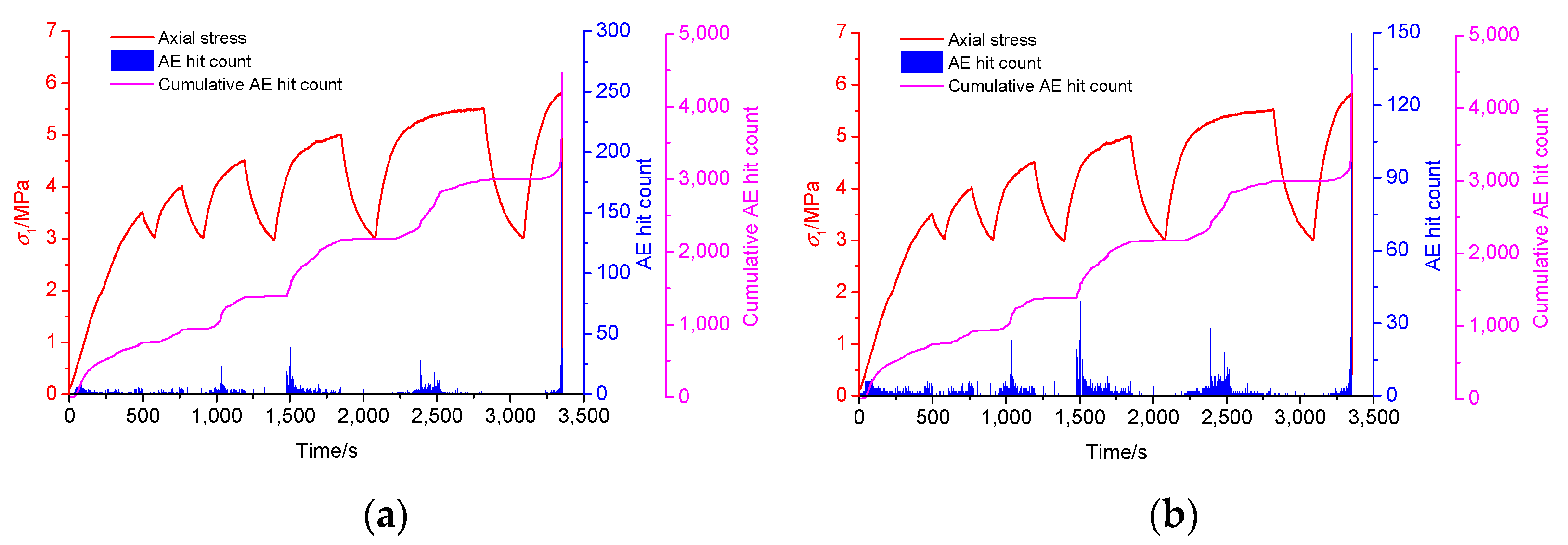

3.2.3. AE Hit Count

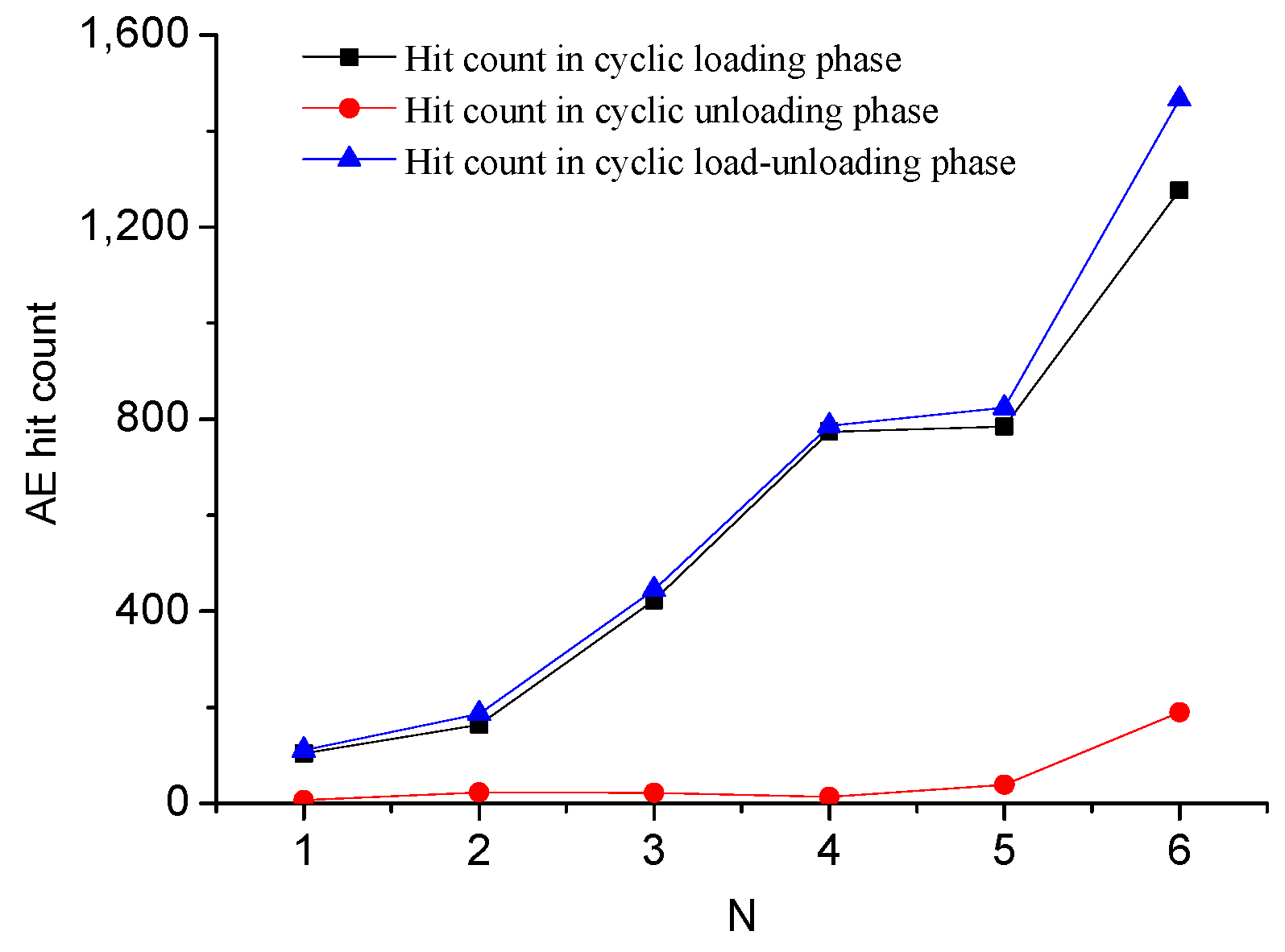

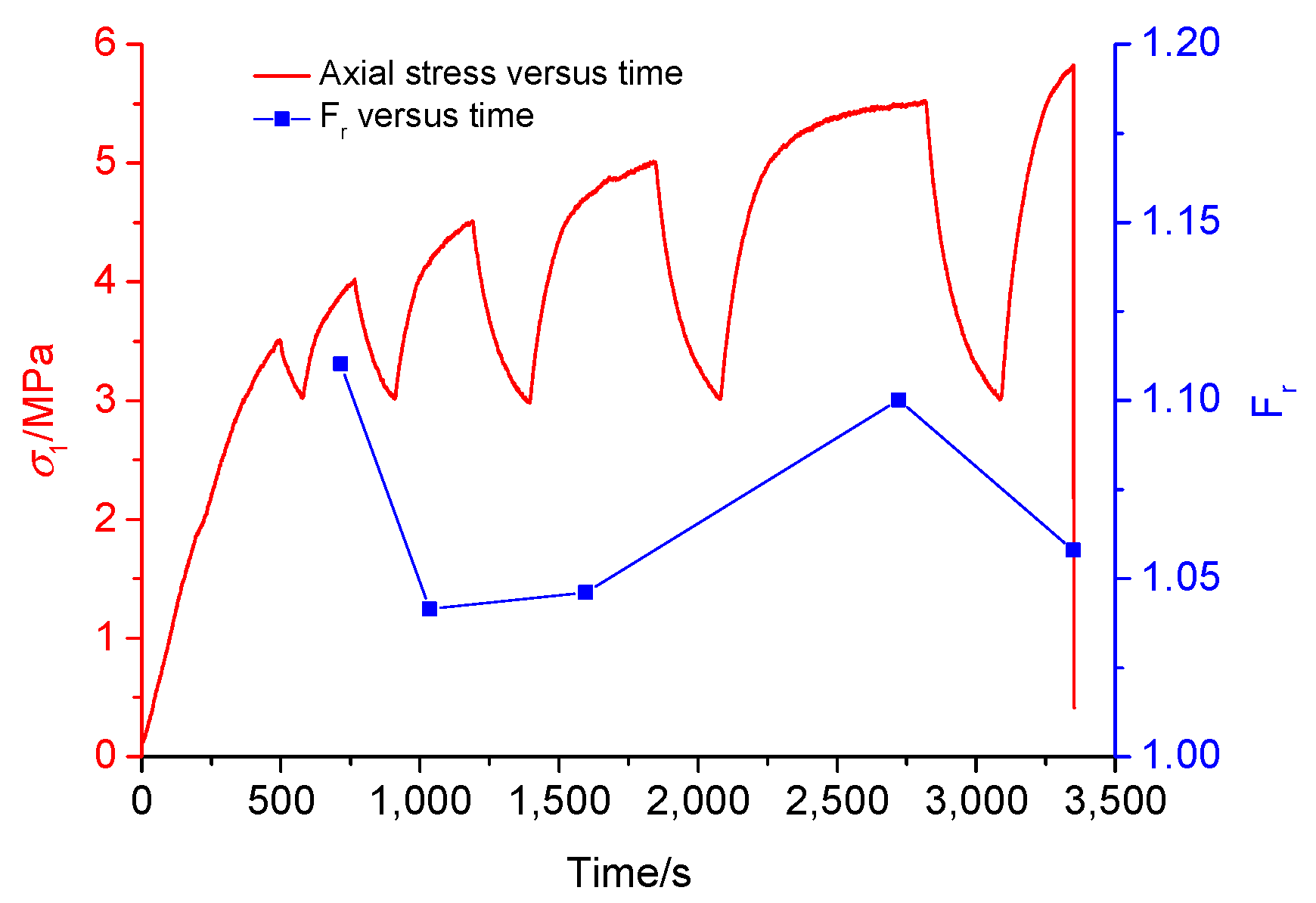

3.2.4. AE Kaiser Effect

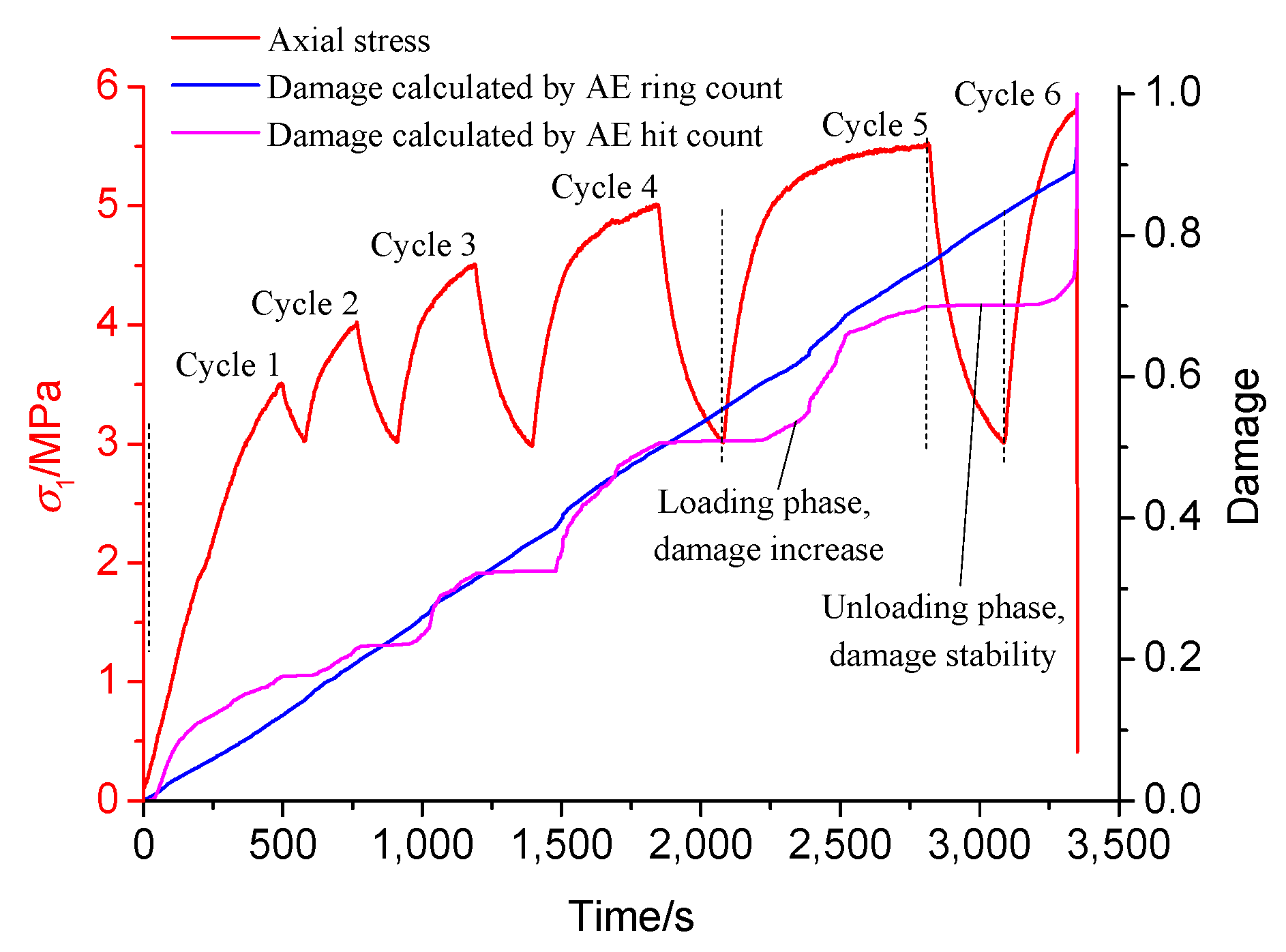

3.3. Damage Evolution Characteristics

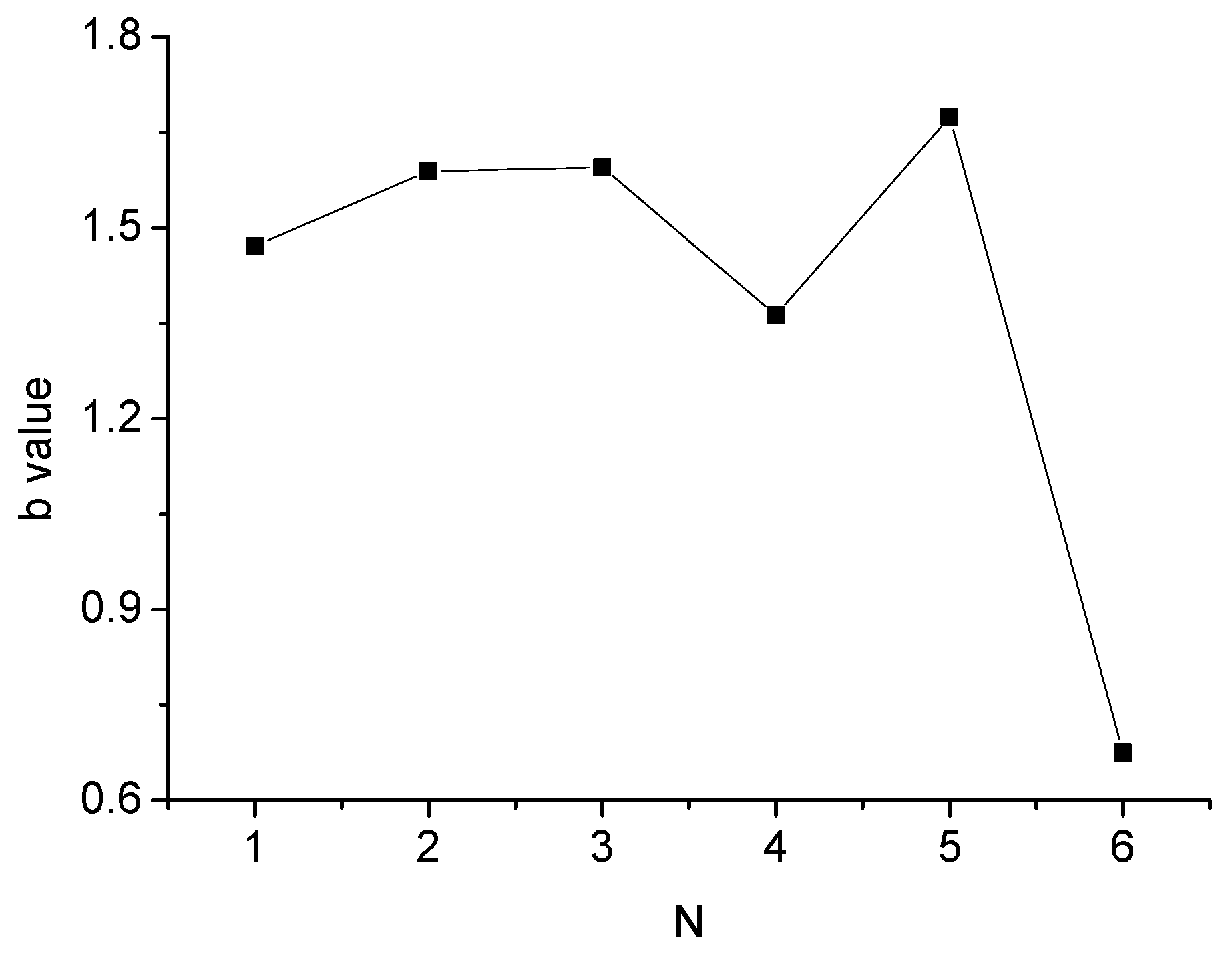

3.4. AE b Value

3.4.1. Calculation of AE b Value

3.4.2. Evolution of AE b Value

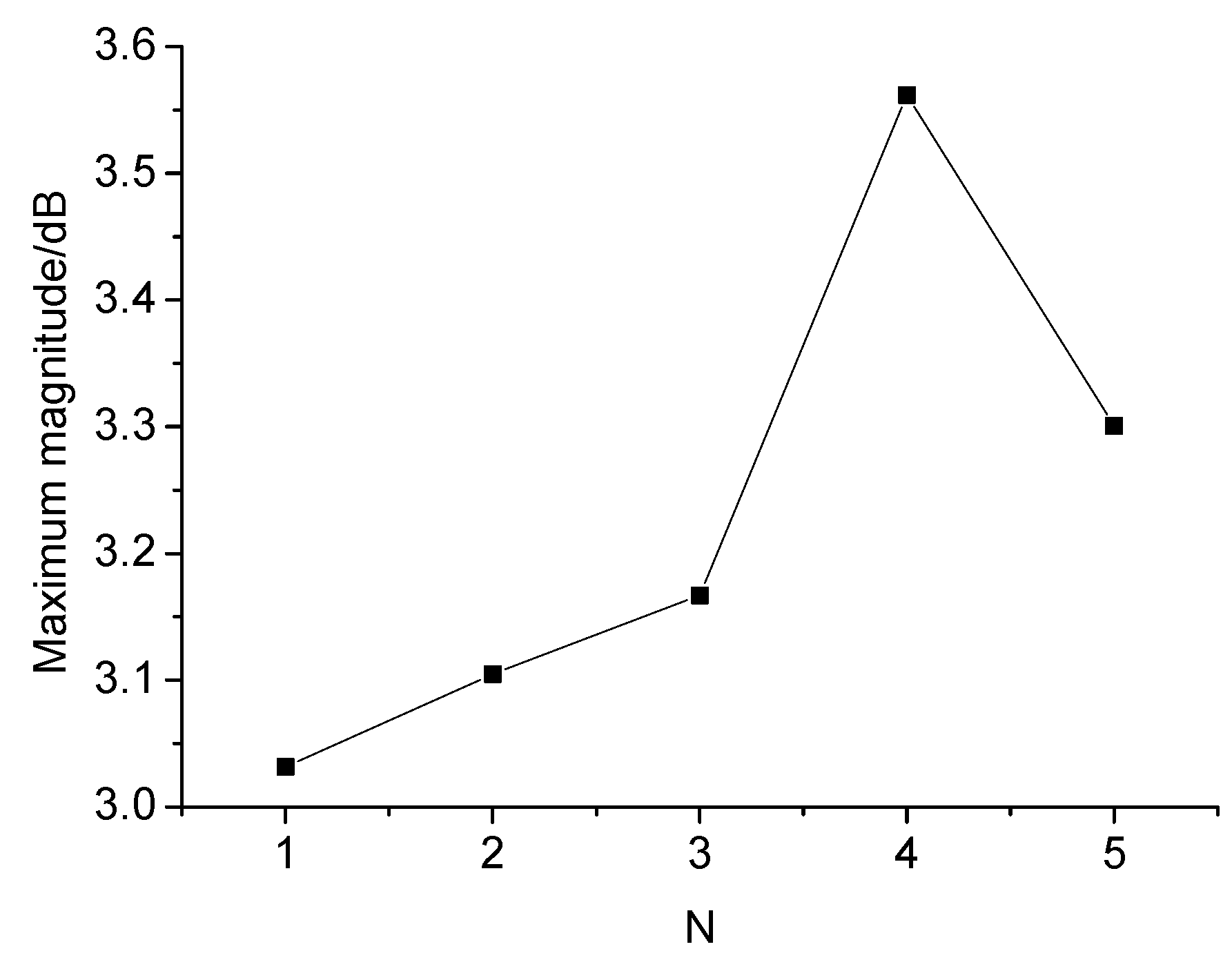

3.4.3. Prediction of AE Maximum Magnitude

4. Conclusions

- (1)

- The axial strain is very well linear with the loading–unloading cycle number, and the circumferential and volumetric strains are approximately quadratic functions with the loading–unloading cycle number;

- (2)

- Under the same loading stress interval, the elastic modulus firstly increases and then keeps basically stable with the loading–unloading cycle number. In addition, the higher the maximum stress of a loading–unloading cycle, the more significant the plastic strengthening effect produced by this cycle;

- (3)

- The damage calculated by the cumulative AE hit count can better reflect the fact that the damage has been increasing in the loading phase and keeps basically unchanged in the unloading phase. So, the AE hit count as a damage variable can better describe the damage development of coal specimens;

- (4)

- The significant fluctuation of the AE b value can be used as the precursor of coal specimen failure. In addition, it decreases rapidly at coal specimen failure;

- (5)

- The closer to the loading–unloading cycle of coal specimen failure, the more accurate the predicted “maximum magnitude” at coal specimen failure.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, S.J.; Guo, W.J.; Zhou, H.; Shen, B.; Liu, J.B. Field investigation of long-term bearing capacity of strip coal pillars. Int. J. Rock Mech. Min. Sci. 2014, 70, 109–114. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, L.S.; Jiang, J.Q.; Zheng., P.Q.; Li., W. Strata behaviors and rock burst-inducing mechanism under the coupling effect of a hard, thick stratum and a normal fault. Int. J. Geomech. 2018, 18, 04017135. [Google Scholar] [CrossRef]

- Gao, M.T.; Song, Z.Q.; Duan, H.Q.; Xin, H.Q.; Tang, J.Q. Mechanical Properties and Control Rockburst Mechanism of Coal and Rock Mass with Bursting Liability in Deep Mining. Shock Vib. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Zhu, S.T.; Jiang, F.X.; Liu, J.H.; Ma, Y.Z.; Meng, X.J.; Zhang, X.F.; Jiang, Y.W.; Qu, X.C.; Wang, B.Q. Types, occurcenec mecha-nism and prevention of overall istability induced rockbursts in China coal mines. J. China Coal Soc. 2020, 45, 3667–3677. [Google Scholar]

- Yang, Y.J.; Zhao, N.N.; Ma, D.P.; Zhang, F.J. Study on stability of strip coal pillar with different moisture content. J. Min. Saf. Eng. 2016, 33, 42–48. [Google Scholar]

- Van der Merwe, J.N. South African Coal Pillar Database. J. S. Afr. Inst. Min. Metall. 2006, 106, 115–128. [Google Scholar]

- Yang, R.; Zhou, Y.; Ma, D.P. Failure mechanism and acoustic emission precursors of coal samples considering bedding effect under triaxial unloading condition. Geofluids 2022, 2022, 8083443. [Google Scholar] [CrossRef]

- Meng, Q.B.; Zhang, M.W.; Han, L.J.; Pu, H.; Nie, T.Y. Effects of Acoustic Emission and Energy Evolution of Rock Specimens Under the Uniaxial Cyclic Loading and Unloading Compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Kong, X.G.; Wang, E.Y.; Hu, S.B.; Shen, R.X.; Li, X.L.; Zhan, T.Q. Fractal characteristics and acoustic emission of coal containing methane in triaxial compression failure. J. Appl. Geophys. 2016, 124, 139–147. [Google Scholar] [CrossRef]

- Wang, X.; Wen, Z.J.; Jiang, Y.J.; Huang, H. Experimental Study on Mechanical and Acoustic Emission Characteristics of Rock-Like Material Under Non-uniformly Distributed Loads. Rock Mech. Rock Eng. 2018, 51, 729–745. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.L.; Yu, R.G.; Hu, L.Q.; Irfan, M. Effect of Loading Rate on the Felicity Effect of Three Rock Types. Rock Mech. Rock Eng. 2017, 50, 1673–1681. [Google Scholar] [CrossRef]

- Chen, Y.L.; Irfan, M.; Song, C.P. Verification of the Kaiser Effect in Rocks under Tensile Stress: Experiment Using the Brazilian Test. Int. J. Geéomeéch. 2018, 18, 04018059. [Google Scholar] [CrossRef]

- Zhang, M.W.; Meng, Q.B.; Liu, S.D.; Qian, D.Y.; Zhang, N. Impacts of Cyclic Loading and Unloading Rates on Acoustic Emission Evolution and Felicity Effect of Instable Rock Mass. Adv. Mater. Sci. Eng. 2018, 2018, 8365396. [Google Scholar] [CrossRef]

- Li, H.R.; Yang, C.H.; Liu, Y.G.; Chen, F.; Ma, H.L.; Wang, B.W. Experimental research on ultrasonic velocity and acoustic emission properties of granite under failure process. Chin. J. Geotech. Eng. 2014, 36, 1915–1923. [Google Scholar]

- Yang, Y.J.; Ma, D.P.; Zhou, Y. Experimental research on spectrum signature eigen of acoustic emission of coal and sandstone damage under triaxial unloading confining pressure. J. Min. Saf. Eng. 2019, 36, 1002–1008. [Google Scholar]

- Fu, B.; Zhou, Z.H.; Wang, H.Q.; Wang, Y.X. Precursor information study on acoustic emission characteristics of marble under uniaxial cyclic loading-unloading. J. China Coal Soc. 2016, 41, 1946–1953. [Google Scholar]

- Zhang, J.; Yu, Z.H.; Tang, Y.X.; Shen, J.; Chen, H.N. Fracture properties of concrete under cyclic loading. Constr. Build. Mater. 2021, 281, 122610. [Google Scholar] [CrossRef]

- Zhou, Y.Q.; Sheng, Q.; Li, N.N.; Fu, X.D. The relationship between dynamic strength and strain rate and damage to rock materials subjected to dynamic cyclic loading. Geéomeéch. Geophys. Geo-Energy Geo-Resour. 2021, 7, 88. [Google Scholar] [CrossRef]

- Pu, S.Y.; Zhu, Z.D.; Song, L.; Song, W.L.; Peng, Y.Y. Fractional-order visco-elastoplastic constitutive model for rock under cyclic loading. Arab. J. Geosci. 2020, 13, 326. [Google Scholar] [CrossRef]

- Wang, J.B.; Zhang, Q.; Song, Z.P.; Zhang, Y.W. Experimental study on creep properties of salt rock under long-period cyclic loading. Int. J. Fatigue 2021, 143, 106009. [Google Scholar] [CrossRef]

- Yang, F.J.; Hu, D.W.; Zhou, H.; Lu, J.J. Physico-mechanical Behaviors of Granite Under Coupled Static and Dynamic Cyclic Loadings. Rock Mech. Rock Eng. 2020, 53, 2157–2173. [Google Scholar] [CrossRef]

- Zhang, M.X. Study on Fatigue Characteristics and Damage Behavior of Cemented-Stabilized Soil under Cyclic Loading. Master’s Thesis, Fuzhou University, Fuzhou, China, 2004. [Google Scholar]

| Specimen Number | Diameter/mm | Height/mm | Density/g·cm−3 | Mass/g |

|---|---|---|---|---|

| 1 | 50.3 | 101.2 | 1.157 | 232.6 |

| 2 | 49.5 | 99.1 | 1.158 | 220.8 |

| 3 | 49.4 | 98.2 | 1.161 | 218.4 |

| 4 | 49.5 | 99.6 | 1.158 | 221.8 |

| Cycle Number | Cumulative AE Hit Count in Several Key Stress Points | |||||

|---|---|---|---|---|---|---|

| 3.5 MPa | 4.0 MPa | 4.5 MPa | 5.0 MPa | 5.5 MPa | 5.826 MPa | |

| 1 | 104 | — | — | — | — | — |

| 2 | 9 | 164 | — | — | — | — |

| 3 | 2 | 49 | 423 | — | — | — |

| 4 | 0 | 0 | 267 | 774 | — | — |

| 5 | 0 | 0 | 1 | 35 | 785 | — |

| 6 | 0 | 0 | 0 | 2 | 27 | 1277 |

| Cycle Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Cyclic loading maximum stress/MPa | 3.5 | 4 | 4.5 | 5 | 5.5 | 5.826 |

| Kaiser point/MPa | — | 3.886 | 4.166 | 4.708 | 5.501 | 5.819 |

| Fr | — | 1.110 | 1.042 | 1.046 | 1.100 | 1.058 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, M.; Yan, H.; Duan, H.; Xiong, S. Experimental Study on Coal Specimens Subjected to Uniaxial Cyclic Loading and Unloading. Appl. Sci. 2022, 12, 11810. https://doi.org/10.3390/app122211810

Gao M, Yan H, Duan H, Xiong S. Experimental Study on Coal Specimens Subjected to Uniaxial Cyclic Loading and Unloading. Applied Sciences. 2022; 12(22):11810. https://doi.org/10.3390/app122211810

Chicago/Turabian StyleGao, Mingtao, Hongyu Yan, Huiqiang Duan, and Si Xiong. 2022. "Experimental Study on Coal Specimens Subjected to Uniaxial Cyclic Loading and Unloading" Applied Sciences 12, no. 22: 11810. https://doi.org/10.3390/app122211810

APA StyleGao, M., Yan, H., Duan, H., & Xiong, S. (2022). Experimental Study on Coal Specimens Subjected to Uniaxial Cyclic Loading and Unloading. Applied Sciences, 12(22), 11810. https://doi.org/10.3390/app122211810