Calibration and Testing of Discrete Element Modeling Parameters for Fresh Goji Berries

Abstract

1. Introduction

2. Materials and Methods

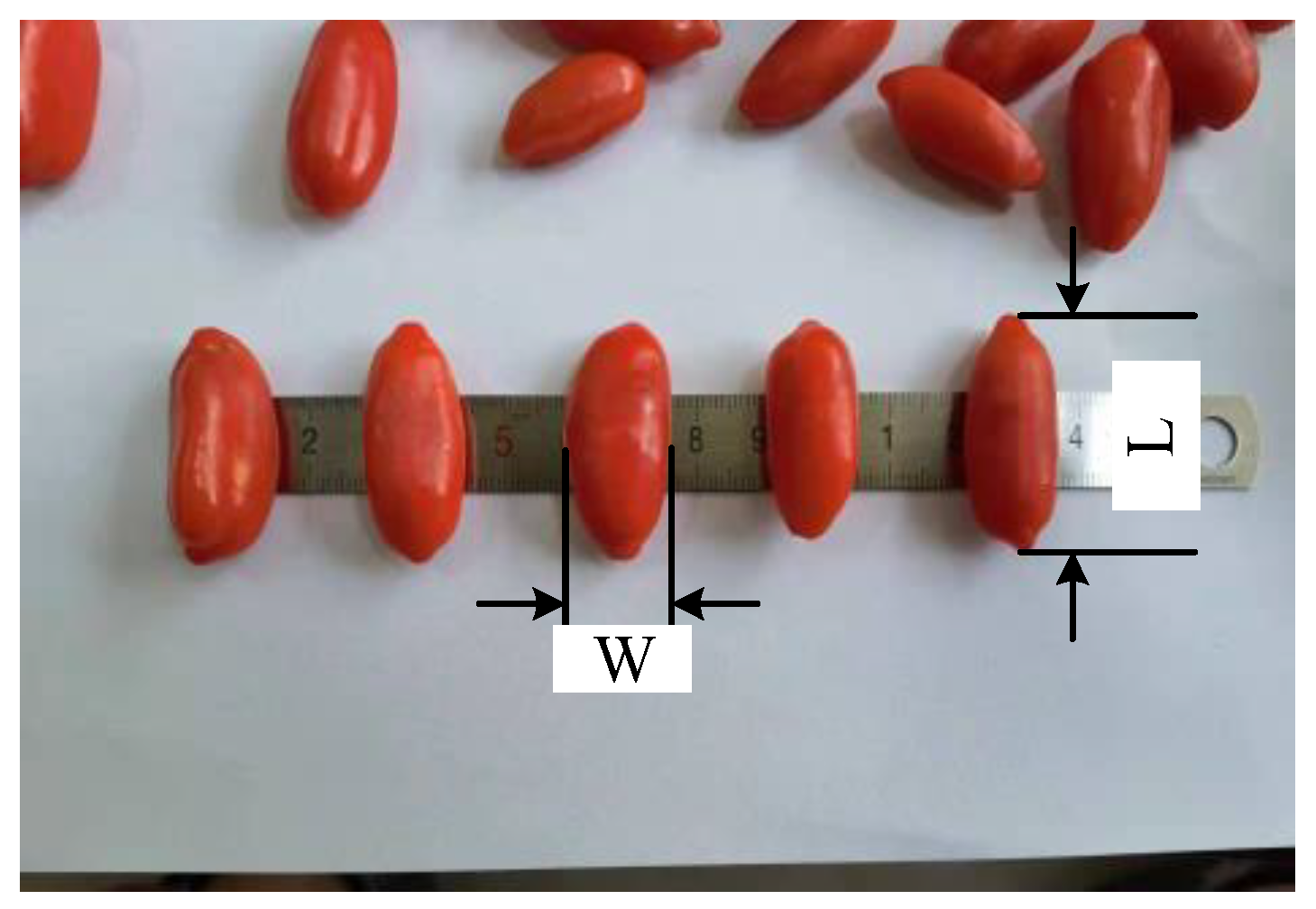

2.1. Fresh Goji Berry Material Characteristics

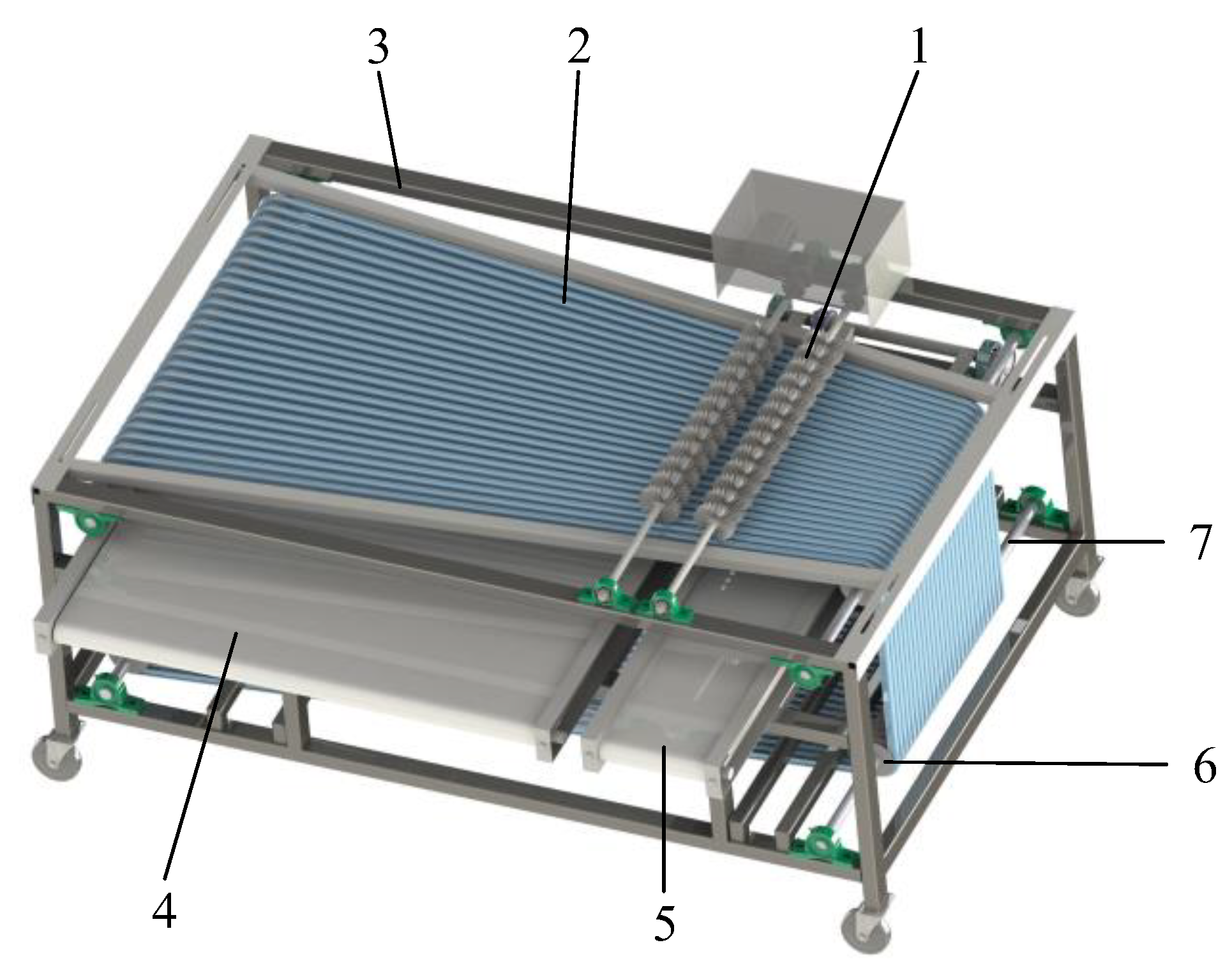

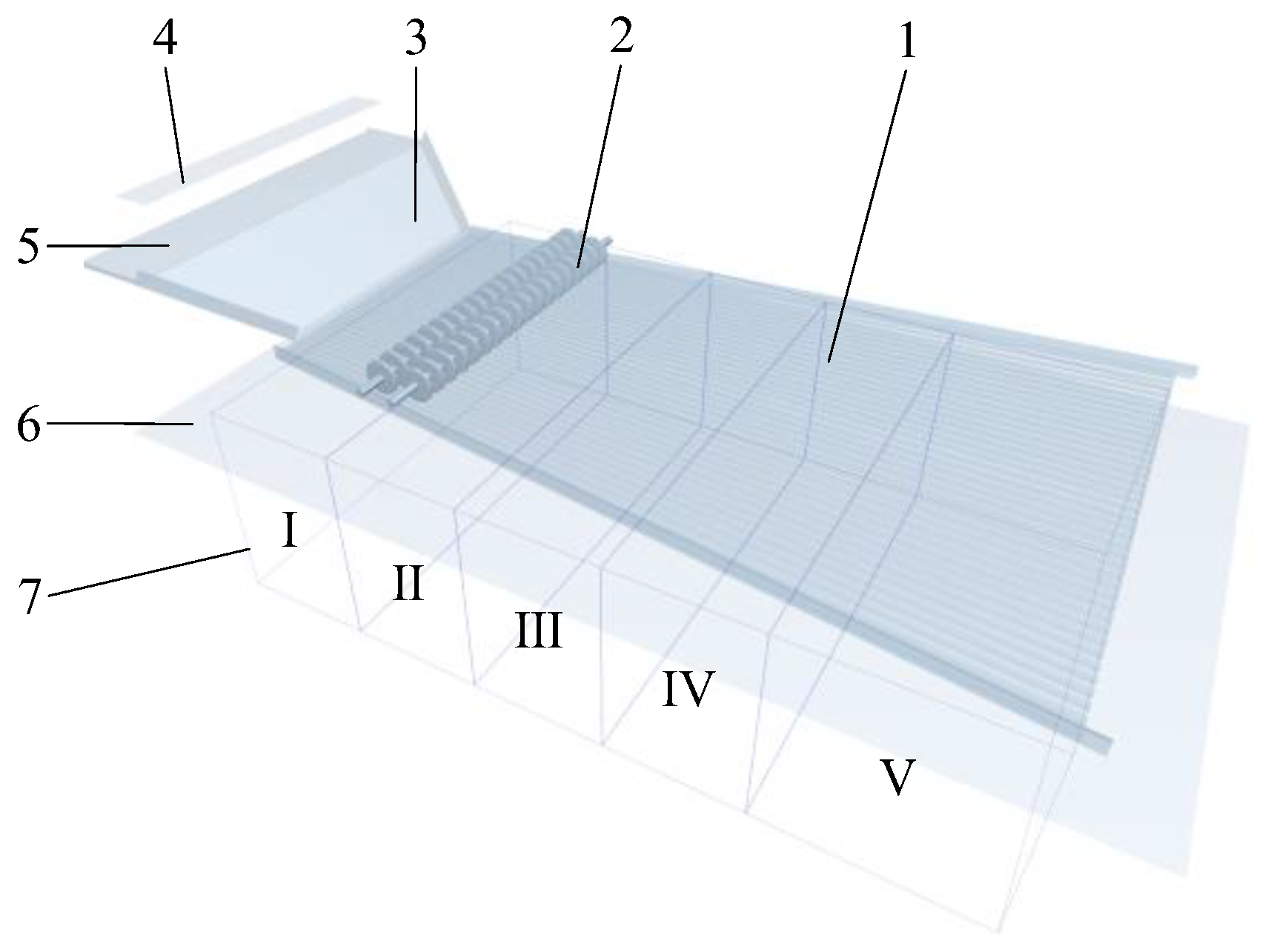

2.2. Design of Variable Gap-Type Fresh Goji Berry Grading Machine

2.2.1. Overall Structure and Working Principle of the Machine

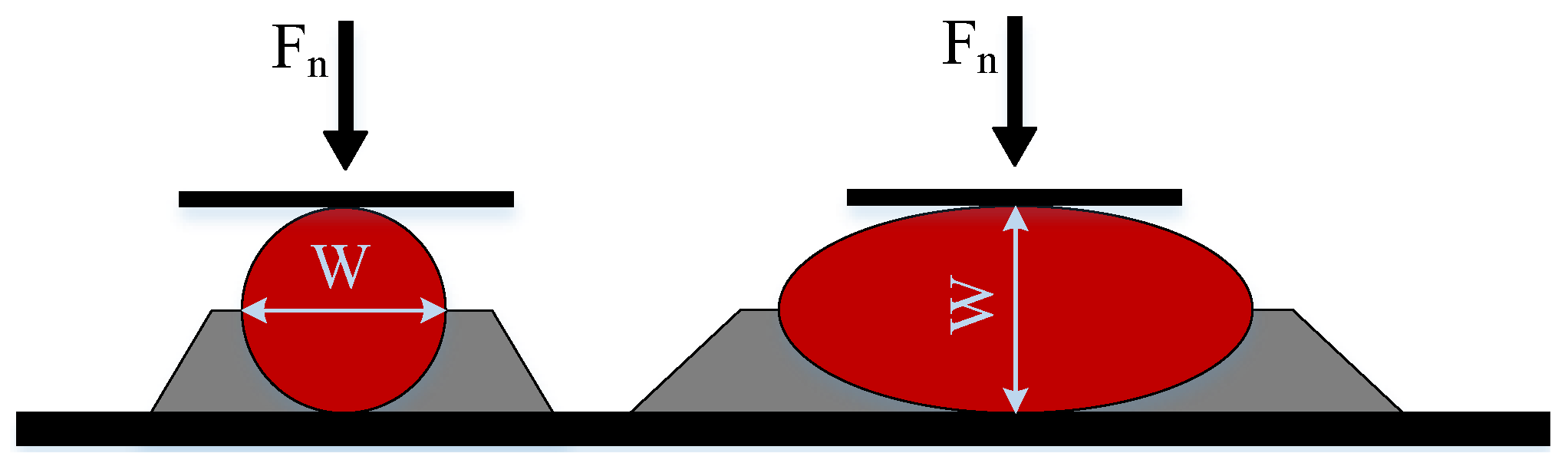

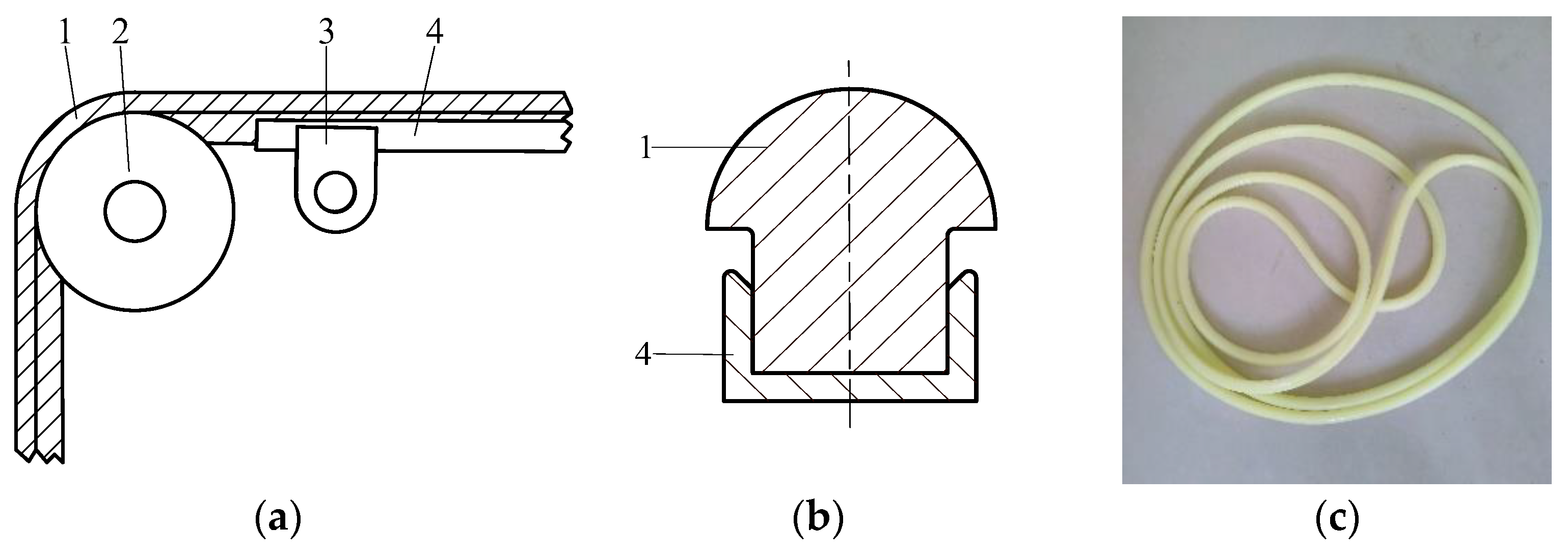

2.2.2. Design of Grading Belt

2.3. Physical Experiments for the Calibration of Contact Parameters

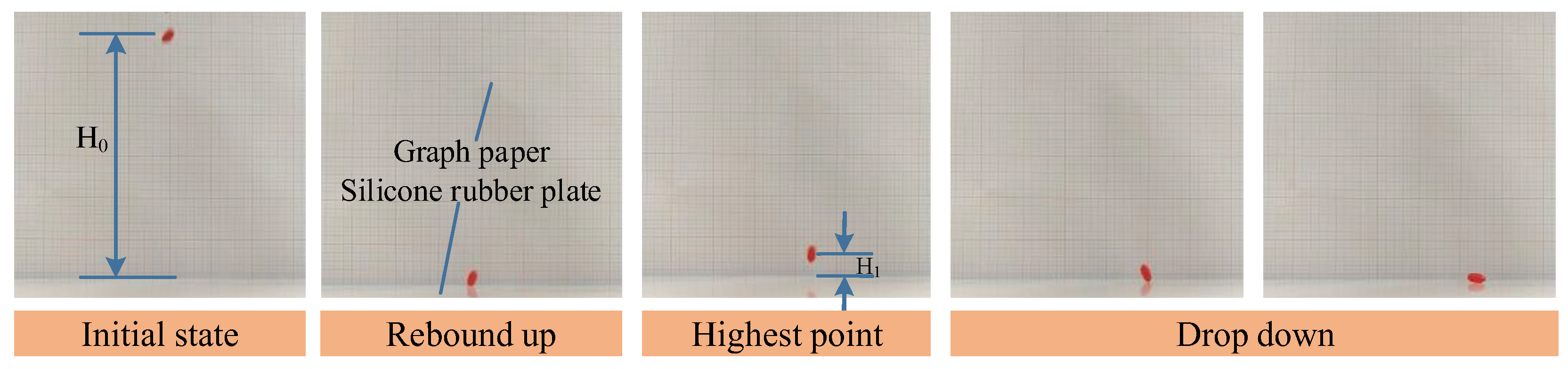

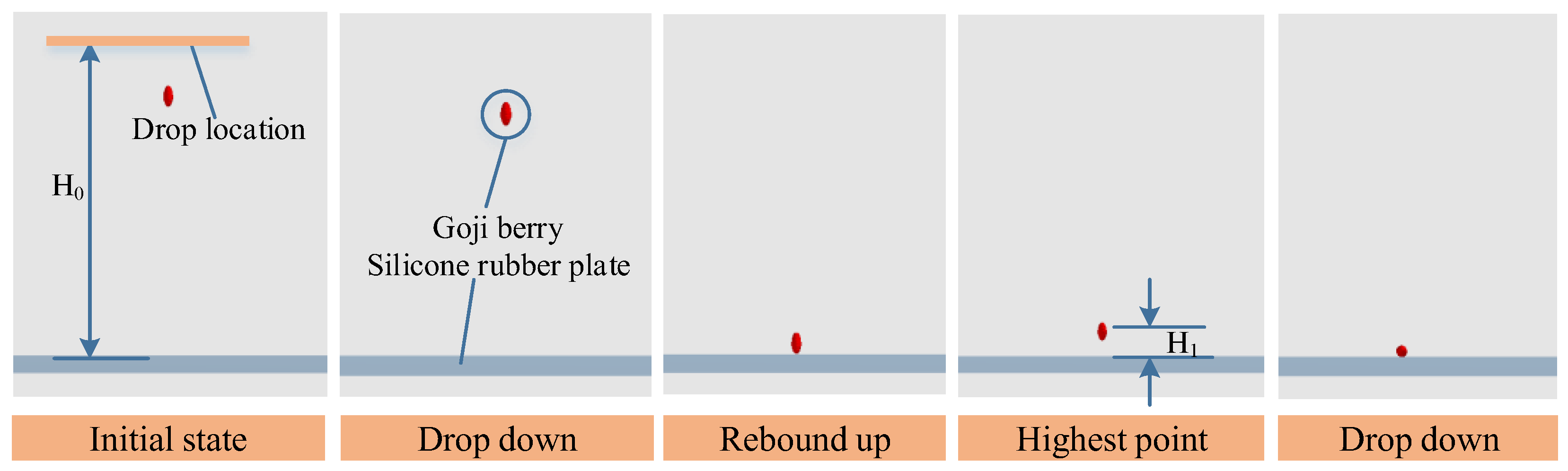

2.3.1. Collision Restitution Coefficient of Fresh Goji Berry–Silicone Rubber Material

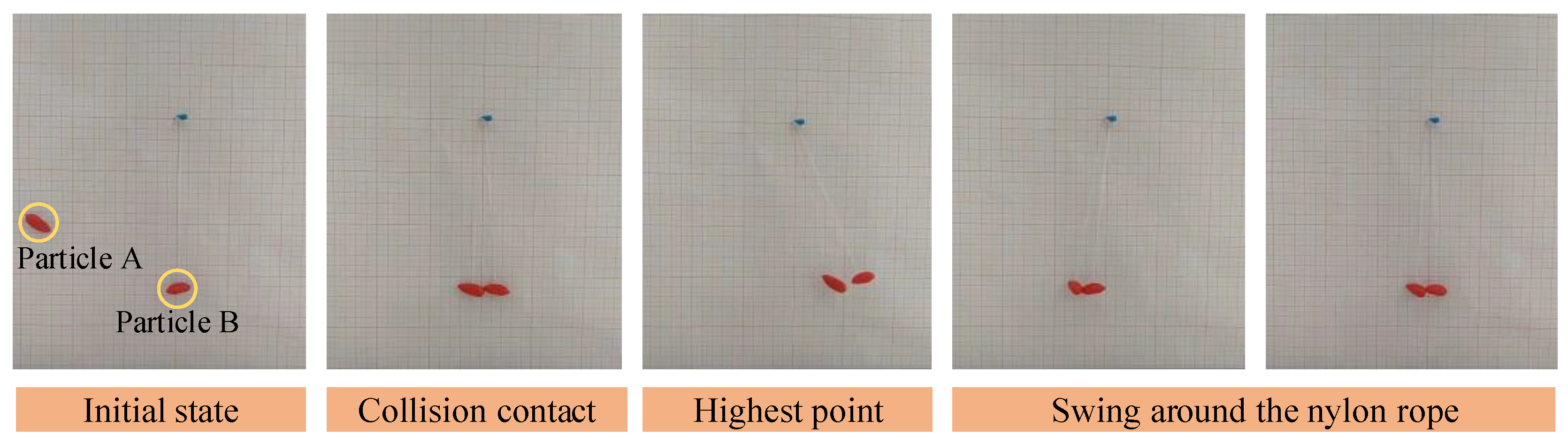

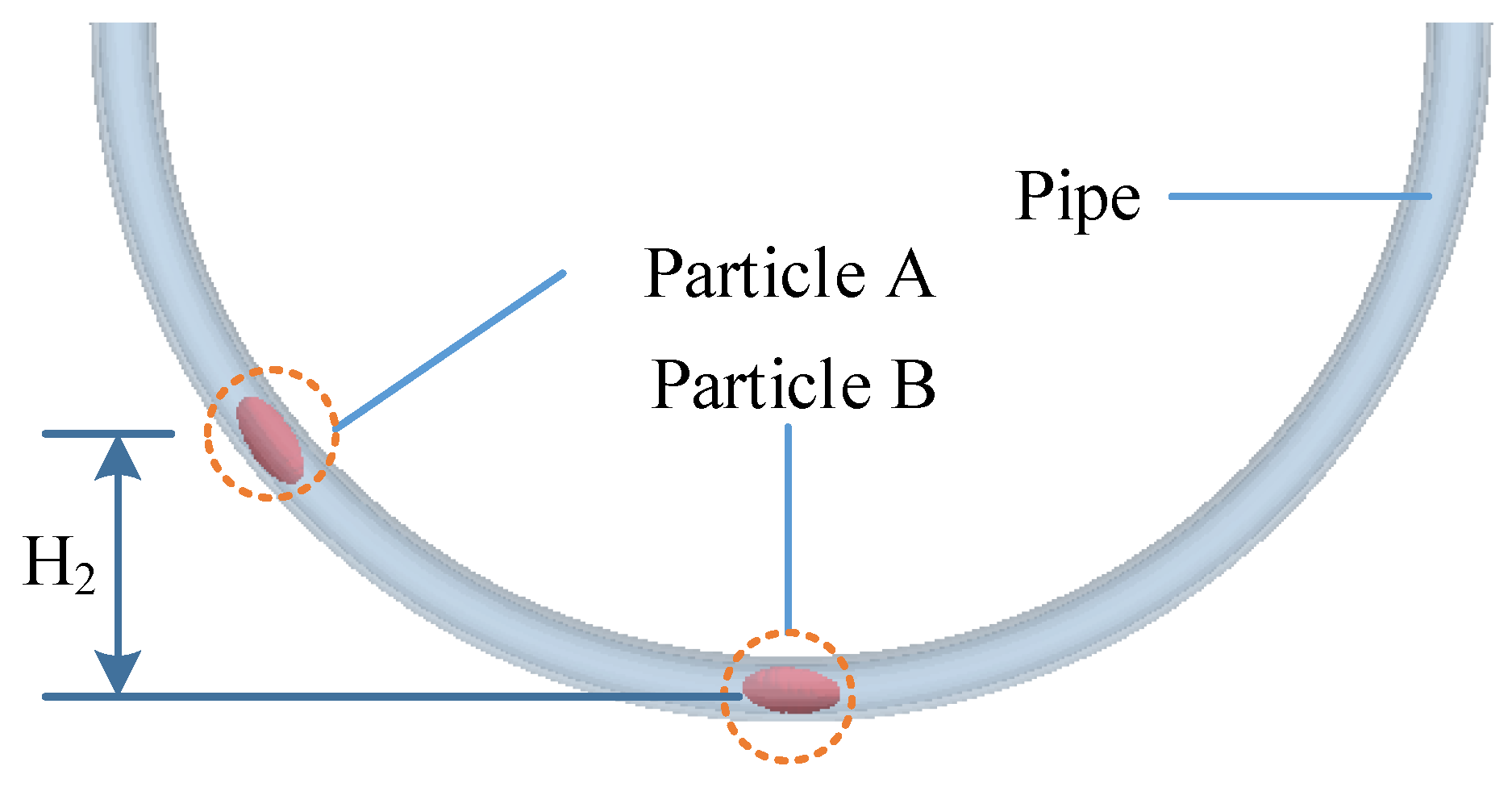

2.3.2. Collision Restitution Coefficient of Fresh Goji Berry-Fresh Goji Berry

2.3.3. Static Friction Coefficient of Fresh Goji Berry–Silicone Rubber Material

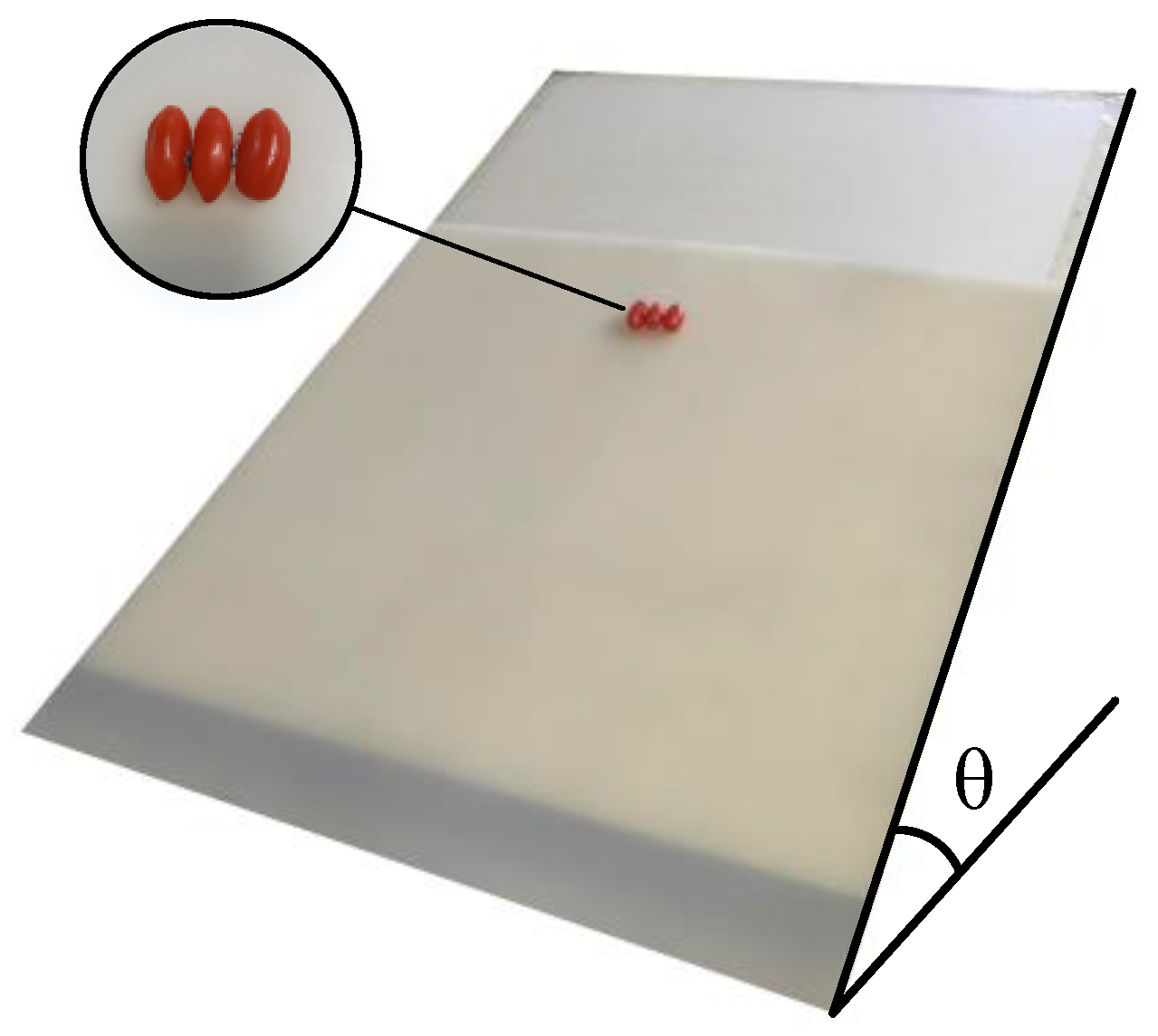

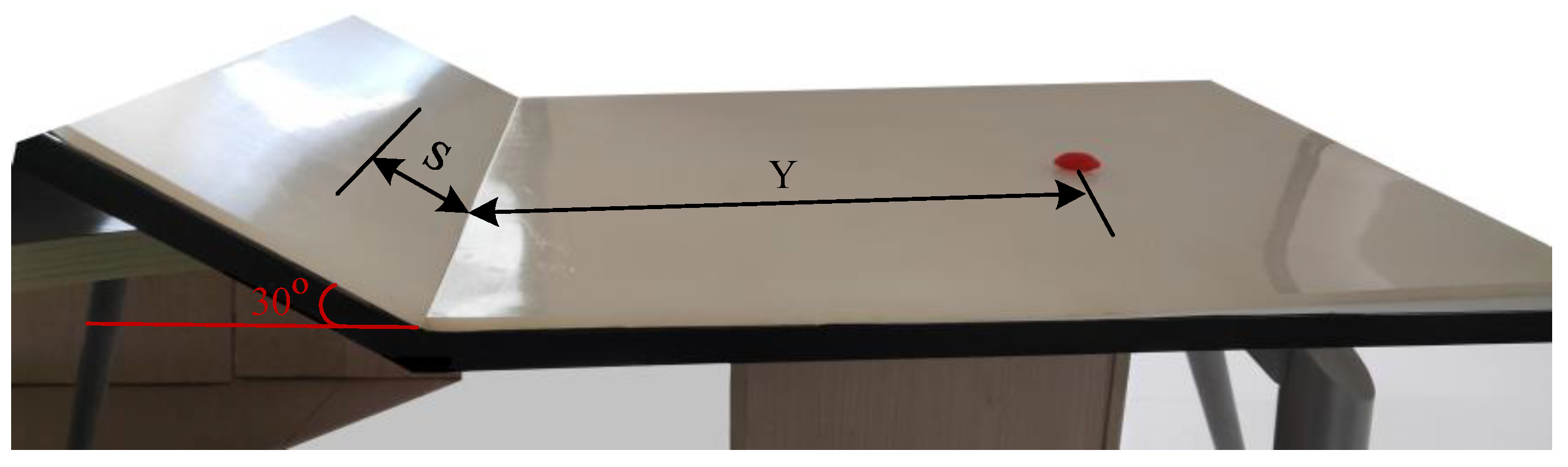

2.3.4. Rolling Friction Coefficient of Fresh Goji Berry–Silicone Rubber Material

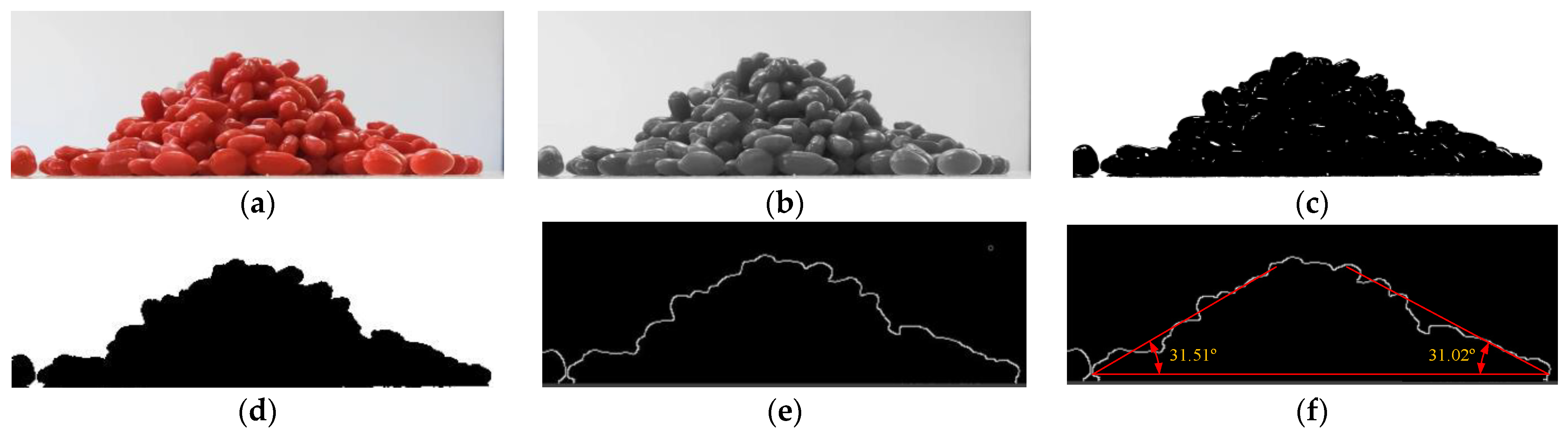

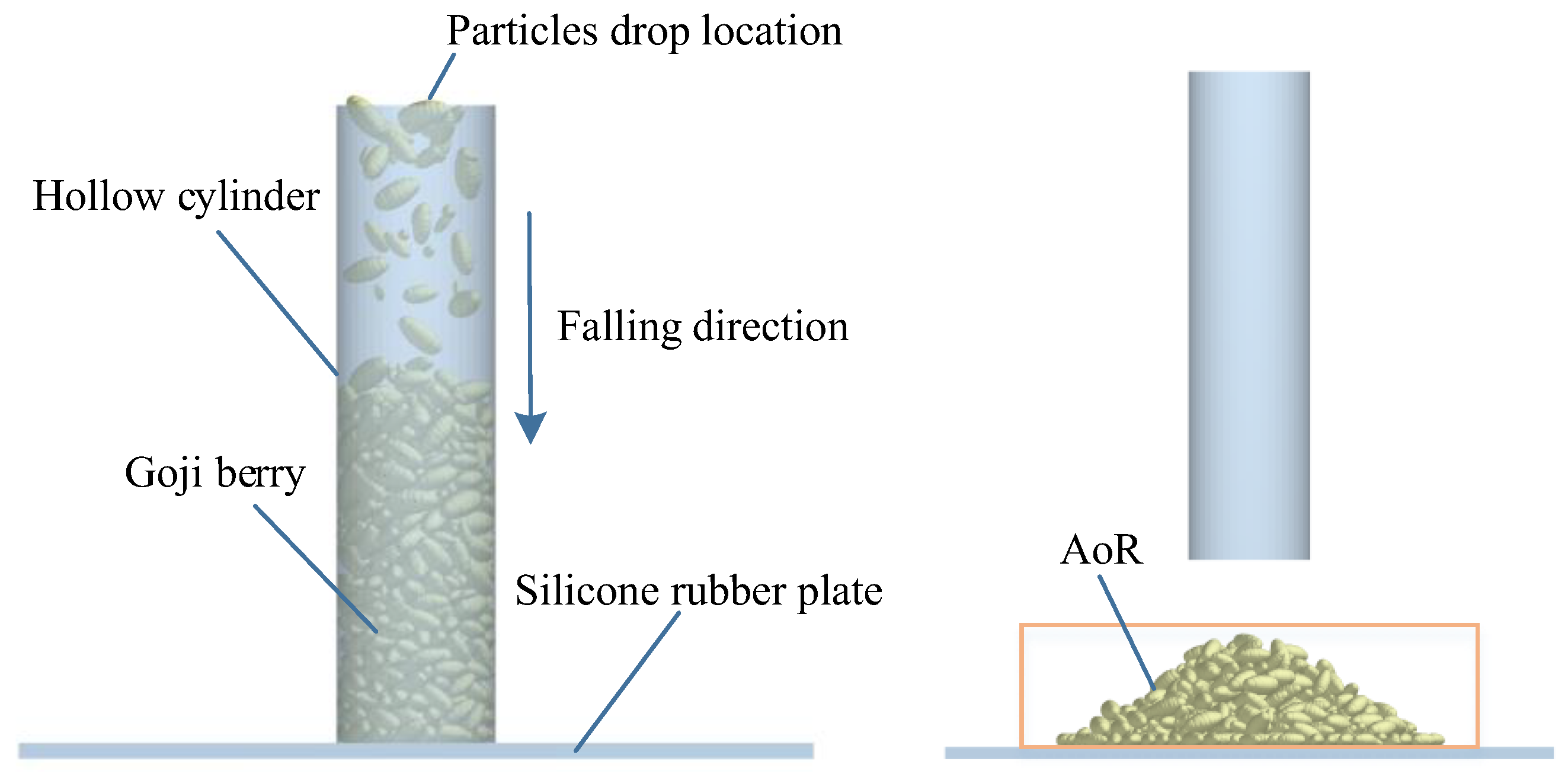

2.3.5. Angle of Repose Experiment

2.4. Simulation Experiments for the Calibration of Contact Parameters

2.4.1. Three-Dimensional Reconstruction of the Fresh Goji Berry Model

2.4.2. Simulation Experiment for Collision Restitution Coefficient of Fresh Goji Berry–Silicone Rubber Material

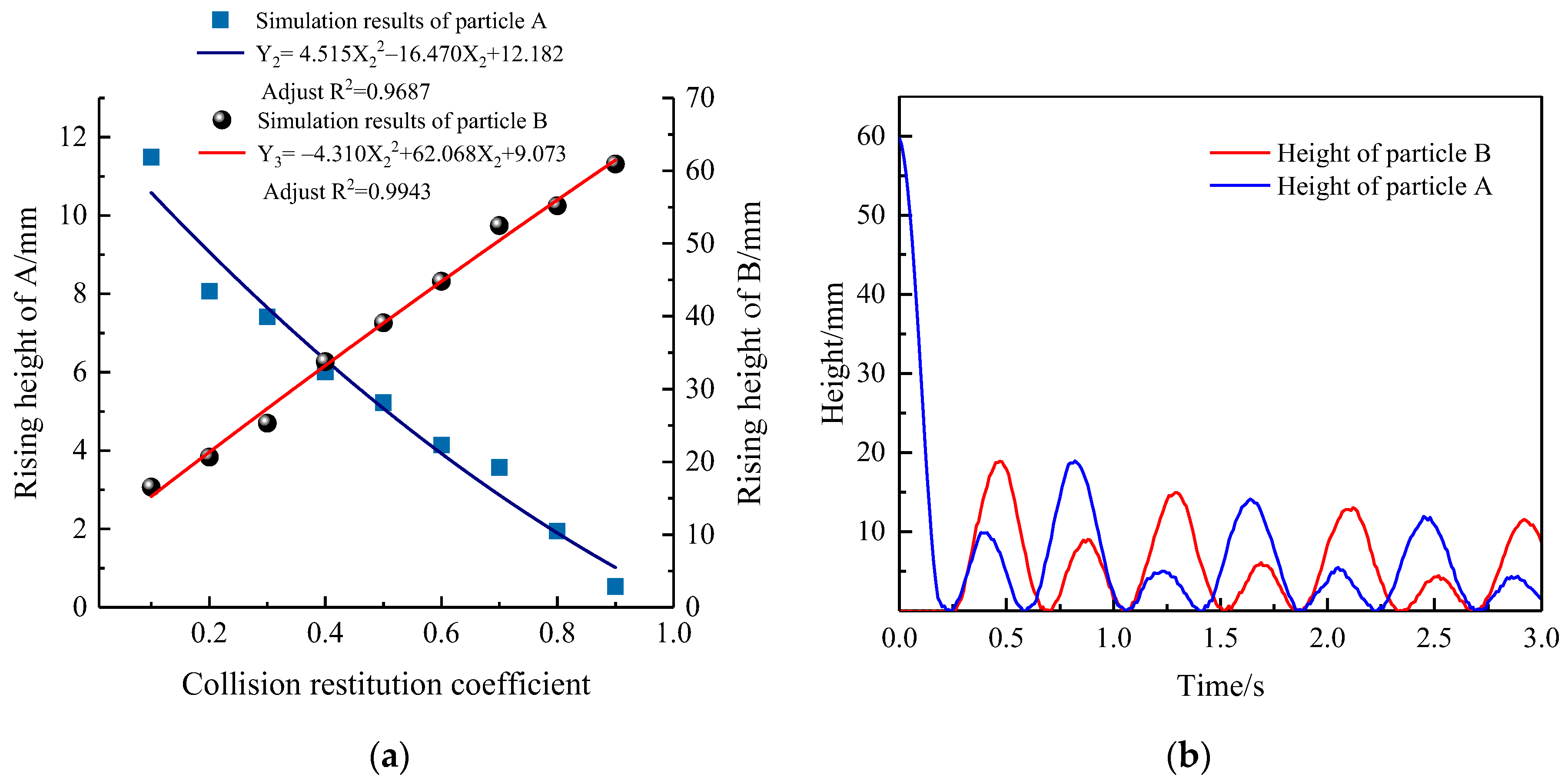

2.4.3. Simulation Experiment for Collision Restitution Coefficient of Fresh Goji Berry–Fresh Goji Berry

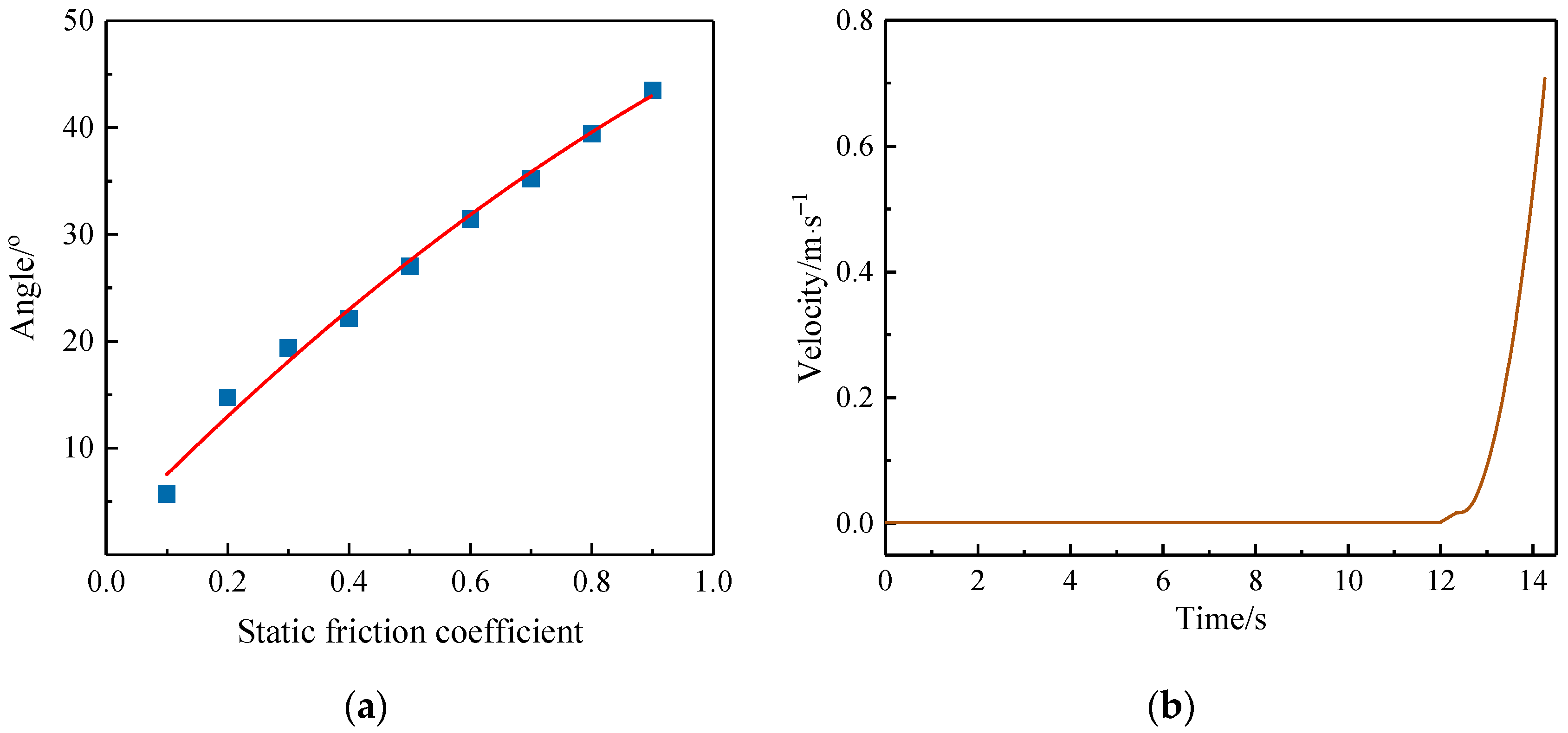

2.4.4. Simulation Experiment for Static Friction Coefficient of Fresh Goji Berry–Silicone Rubber Material

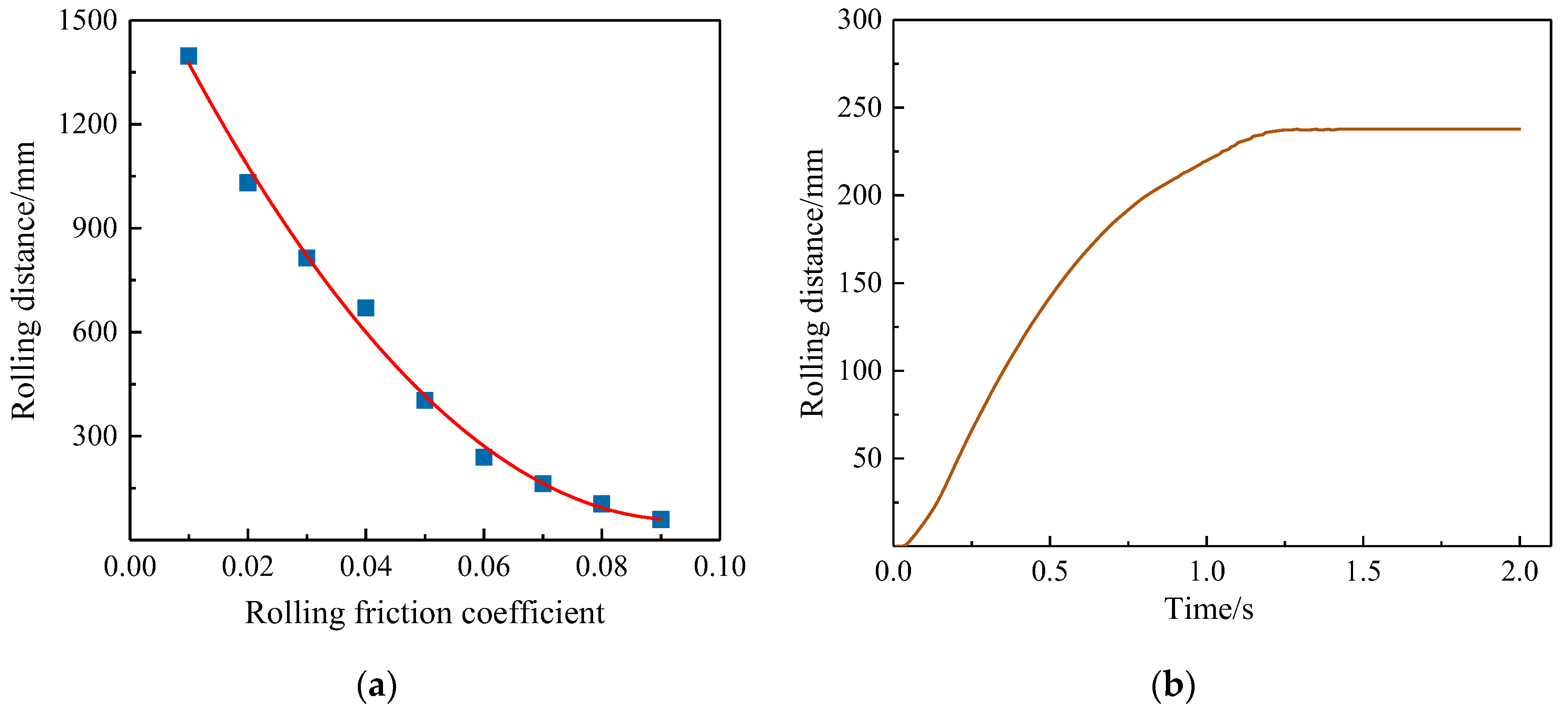

2.4.5. Simulation Experiment for Rolling Friction Coefficient of Fresh Goji Berry–Silicone Rubber Material

2.5. Calibration of Static and Friction Rolling Friction Coefficients of Fresh Goji Berry–Fresh Goji Berry

2.5.1. Simulation of the Angle of Repose

2.5.2. Central Composite Design Experiment

2.6. Validation Tests

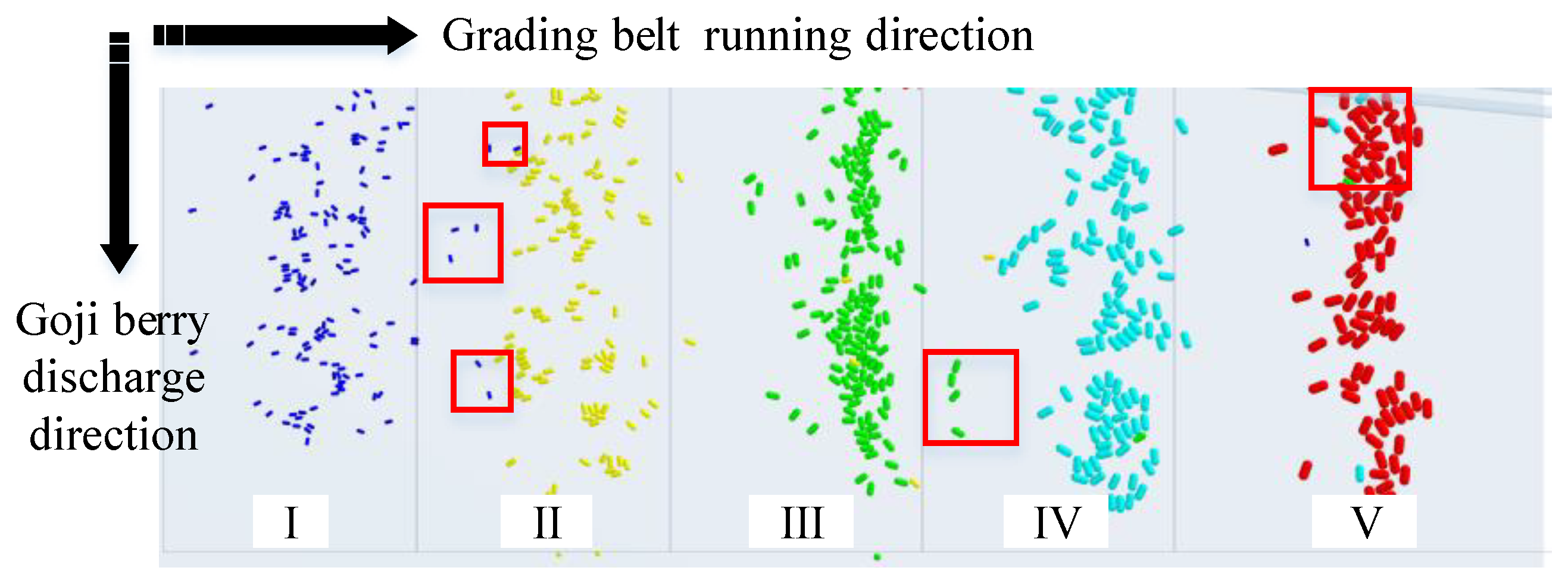

2.6.1. Discrete Element Simulation of the Grading Process

2.6.2. Prototype Experiment

2.6.3. Evaluation Index

3. Results and Discussion

3.1. Determination of Collision Restitution Coefficient of Fresh Goji Berry–Silicone Rubber Material

3.2. Determination of Collision Restitution Coefficient of Fresh Goji Berry–Fresh Goji Berry

3.3. Determination of Static Friction Coefficient of Fresh Goji Berry–Silicone Rubber Material

3.4. Determination of Rolling Friction Coefficient of Fresh Goji Berry–Silicone Rubber Material

3.5. Determination of Static and Rolling Friction Coefficients of Fresh Goji Berry–Fresh Goji Berry

3.6. Validation Tests

3.7. Discussion

4. Conclusions

- (1)

- For the accurate and non-destructive grading of fresh goji berries, we designed a variable gap-type fresh goji berry grading machine. The key component of the machine, the grading belt, was made of silicone rubber material.

- (2)

- Intrinsic parameters such as the triaxial size, density, Poisson’s ratio, elastic modulus, and shear modulus of fresh goji berries were determined by physical experiments. By free-fall, suspension collision, slope slip, and slope rolling experiments, the collision restitution, static friction, and rolling friction coefficients of fresh goji berry–silicone rubber material were determined to be 0.196, 0.340, and 0.057, respectively. The collision restitution coefficient of fresh goji berry–fresh goji berry was 0.150.

- (3)

- We used the SFM-CMVS technique to extract the outline of the goji berry, and we obtained the dense point cloud and fitted model of the goji berry. The model was meshed to obtain a 3D model of the fresh goji berry, which was used in EDEM. A discrete element simulation particle model of fresh goji berry was established by using the multi-sphere particle aggregation method.

- (4)

- By simulation, the collision restitution, static friction, and rolling friction coefficients of fresh goji berry–silicone rubber material were calibrated to 0.195, 0.377, and 0.063, respectively; the collision restitution coefficient of fresh goji berry–fresh goji berry was calibrated to 0.158. We designed the steepest ascent search and central composite design experiments to calibrate the static friction and rolling friction coefficients of fresh goji berry–fresh goji berry to 0.454 and 0.037.

- (5)

- Validation tests were conducted on the calibrated discrete element parameters, and the results showed that the grading accuracy obtained from the simulation model matched that under real test conditions.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Editorial Commission of History of Goji. History of Goji; Yellow River Publishing Group: Yinchuan, China, 2019. [Google Scholar]

- Zhou, Y.J.; Lai, Y.K.; Chen, Z.S.Z.; Qu, H.X.; Ma, S.M.; Wang, Y.; Jiang, Y.M. Evolution of physiological characteristics and nutritional quality in fresh goji berry (Lycium barbarum) stored under different temperatures. J. Food Process. Preserv. 2020, 44, 14835. [Google Scholar] [CrossRef]

- Li, M.Z.; Chen, H.Q.; Liu, Y.; Zhang, G.F.; Sun, Y.Q. Optimization design and experiments of specification identification and counting device for scallop seedlings. Trans. Chin. Soc. Agric. Eng. 2021, 37, 37–46. [Google Scholar]

- Li, M.Z.; Zhang, G.F.; Yu, G.Z.; Zhao, X.W.; Zhang, H.; Hu, P.; Sun, D.X. Design and experiment of grading and counting device for scallop seedling. Trans. Chin. Soc. Agric. Eng. 2015, 31, 93–101. [Google Scholar]

- Dai, F.; Fu, Q.F.; Zhao, W.Y.; Shi, R.J.; Song, X.F.; Zhang, S.L. Design and test of double duct system of air-screen separating and cleaning machine for flax threshing material. Trans. Chin. Soc. Agric. Mach. 2021, 52, 117–125+247. [Google Scholar]

- Lü, J.Q.; Wen, X.Y.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design and experiment of the grading device for a potato seed cutting machine. Trans. Chin. Soc. Agric. Mach. 2020, 36, 76–83. [Google Scholar]

- Lü, J.Q.; Yu, J.Y.; Feng, X.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design and experiment of roller potato grading machine. Trans. Chin. Soc. Agric. Mach. 2019, 50, 323–332. [Google Scholar]

- Pourdarbani, R.; Ghassemzadeh, H.R.; Seyedarabi, H.; Nahandi, F.Z.; Vahed, M.M. Study on an automatic sorting system for Date fruits. J. Saudi Soc. Agric. Sci. 2015, 14, 83–90. [Google Scholar] [CrossRef]

- Arun Kumar, R.; Rajpurohit, V.S. Wavelet features for pomegranate sorting using machine vision. In Proceedings of the Innovations in Computer Science and Engineering, Singapore, 22–24 February 2019; pp. 179–186. [Google Scholar]

- Zhao, H.B.; Huang, Y.X.; Liu, Z.D.; Liu, W.Z.; Zheng, Z.Q. Applications of discrete element method in the research of agricultural machinery: A review. Agriculture 2021, 11, 425. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Liang, Z.W.; Li, J.; Liang, J.M.; Shao, Y.F.; Zhou, T.F.; Si, Z.Y.; Li, Y.M. Investigation into experimental and DEM simulation of guide blade optimum arrangement in multi-rotor combine harvesters. Agriculture 2022, 12, 435. [Google Scholar] [CrossRef]

- Li, H.; Zeng, S.; Luo, X.W.; Fang, L.Y.; Liang, Z.H.; Yang, W.W. Design, DEM simulation, and field experiments of a novel precision seeder for dry direct-seeded rice with film mulching. Agriculture 2021, 11, 378. [Google Scholar] [CrossRef]

- Chen, Z.; Wassgren, C.; Veikle, E. Determination of material and interaction properties of maize and wheat kernels for DEM simulation. Biosyst. Eng. 2020, 195, 208–226. [Google Scholar] [CrossRef]

- Coetzee, C.J. Review: Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Zhang, S.W.; Zhang, R.Y.; Chen, T.Y.; Fu, J.; Yuan, H.F. Calibration of simulation parameters of mung bean seeds using discrete element method and verification of seed-metering test. Trans. Chin. Soc. Agric. Mach. 2022, 53, 71–79. [Google Scholar]

- Liu, R.; Li, Y.; Liu, Z.; Liu, L.; LÜ, H. Analysis and calibration of discrete element parameters of coated maize seed. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–8+18. [Google Scholar]

- Li, H.; Zeng, R.; Niu, Z.; Zhang, J. A calibration method for contact parameters of maize kernels based on the discrete element method. Agriculture 2022, 12, 664. [Google Scholar] [CrossRef]

- Zhang, R.F.; Jiao, W.; Zhou, J.L.; Qi, B.; Liu, H.; Xia, Q.Q. Parameter calibration and experiment of rice seeds discrete element model with different filling particle radius. Trans. Chin. Soc. Agric. Mach. 2020, 51, 227–235. [Google Scholar]

- Liu, F.Y.; Zhang, J.; Li, B.; Chen, J. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Trans. Chin. Soc. Agric. Eng. 2016, 32, 247–253. [Google Scholar]

- Yan, J.W.; Wei, S.; Hu, D.J.; Liu, Q.H.; Zhang, F.G. Parameter calibration of radish seeds with different filling particle radius by DEM. J. Agric. Sci. Technol. 2022, 24, 119–128. [Google Scholar]

- Wu, M.C.; Cong, J.L.; Yan, Q.; Zhu, T.; Peng, X.Y.; Wang, Y.S. Calibration and experiments for discrete element simulation parameters of peanut seed particles. Chin. Soc. Agric. Eng. 2020, 36, 30–38. [Google Scholar]

- Mi, G.P.; Liu, Y.; Wang, T.; Dong, J.X.; Zhang, S.L.; Li, Q.W.; Chen, K.Z.; Huang, Y.X. Measurement of physical properties of sorghum seeds and calibration of discrete element modeling parameters. Agriculture 2022, 12, 681. [Google Scholar] [CrossRef]

- Wang, R.; Jiao, Q.Y.; Wei, D.Q. Determination of macromechanic parameters of grapes and tomatoes. Trans. Chin. Soc. Agric. Eng. 2004, 20, 54–57. [Google Scholar]

- Wang, L.L.; Wang, Y.X.; Li, Y.S.; Liu, B.B.; Chen, W.Y. On the material parameters determination of 110 methyl silicone rubber. J. Exp. Mech. 2013, 28, 761–769. [Google Scholar]

- Xie, Z.L.; Ma, X.; Wu, S.H. Expansion of high performance elastomers(part 3)—Silicone rubber. China Rubber Ind. 2021, 68, 864–875. [Google Scholar]

- Liao, Y.Y.; You, Y.; Wang, D.C.; Zhang, X.N.; Zhang, H.F.; Ma, W.P. Parameter calibration and experiment of discrete element model for mixed seeds of oat and arrow pea. Trans. Chin. Soc. Agric. Mach. 2022, 53, 14–22. [Google Scholar]

- Liu, W.Z.; He, J.; Li, H.W.; Li, X.Q.; Zheng, K.; Wei, Z.C. Calibration of simulation parameters for potato minituber based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135. [Google Scholar]

- Wang, Y.; Liang, Z.; Zhang, D.; Cui, T.; Shi, S.; Li, K.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar]

- Li, J.R.; Xie, S.S.; Liu, F.; Guo, Y.P.; Liu, C.L.; Shang, Z.Y.; Zhao, X. Calibration and testing of discrete element simulation parameters for sandy soils in potato growing areas. Appl. Sci. 2022, 12, 10125. [Google Scholar] [CrossRef]

- Yang, G.Y. Research on Jujube Tree Model Construction and Vibration Simulation Experiment Based on Multi-View. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2021. [Google Scholar]

- Zhang, L.W. 3D Reconstruction Technology of Blueberry Fruit and Its Discrete Element Parameter Calibration. Master’s. Thesis, Northeast Forestry University, Harbin, China, 2021. [Google Scholar]

- Han, L.J.; Yuan, W.; Yu, J.J.; Jin, J.J.; Xie, D.S.; Xi, X.B.; Zhang, Y.F.; Zhang, R.H. Simulation and experiment of spiral soil separation mechanism of compound planter based on discrete element method (DEM). Agriculture 2022, 12, 511. [Google Scholar] [CrossRef]

| Material Properties | Values |

|---|---|

| Shore A hardness/HA | 55 |

| Elongation/% | 200~600 |

| Tensile strength/Pa | 5 × 106~10 × 106 |

| Density/kg·m−3 | 1150 |

| Poisson’s ratio | 0.480 |

| Elastic modulus/Pa | 1.30 × 106 |

| Group No. | Ex1 | H1/mm |

|---|---|---|

| 1 | 0.1 | 2.214 |

| 2 | 0.2 | 14.220 |

| 3 | 0.3 | 30.659 |

| 4 | 0.4 | 43.573 |

| 5 | 0.5 | 74.025 |

| 6 | 0.6 | 110.760 |

| 7 | 0.7 | 151.756 |

| 8 | 0.8 | 198.919 |

| 9 | 0.9 | 256.737 |

| Group No. | Ex2 | Ha/mm | Hb/mm |

|---|---|---|---|

| 1 | 0.1 | 11.488 | 16.523 |

| 2 | 0.2 | 8.066 | 20.650 |

| 3 | 0.3 | 7.417 | 25.301 |

| 4 | 0.4 | 6.003 | 33.752 |

| 5 | 0.5 | 5.223 | 39.096 |

| 6 | 0.6 | 4.143 | 44.803 |

| 7 | 0.7 | 3.575 | 52.447 |

| 8 | 0.8 | 1.947 | 55.170 |

| 9 | 0.9 | 0.530 | 60.933 |

| Group No. | μs1 | θ/° |

|---|---|---|

| 1 | 0.1 | 5.696 |

| 2 | 0.2 | 14.745 |

| 3 | 0.3 | 19.388 |

| 4 | 0.4 | 22.130 |

| 5 | 0.5 | 27.012 |

| 6 | 0.6 | 31.447 |

| 7 | 0.7 | 35.240 |

| 8 | 0.8 | 39.457 |

| 9 | 0.9 | 43.503 |

| Group No. | μr1 | Y/mm |

|---|---|---|

| 1 | 0.01 | 1396.870 |

| 2 | 0.02 | 1031.026 |

| 3 | 0.03 | 813.731 |

| 4 | 0.04 | 670.109 |

| 5 | 0.05 | 403.698 |

| 6 | 0.06 | 238.752 |

| 7 | 0.07 | 163.066 |

| 8 | 0.08 | 104.283 |

| 9 | 0.09 | 59.407 |

| Group No. | μs2 | μr2 | ε/% |

|---|---|---|---|

| 1 | 0.5 | 0.0279289 | 7.04 |

| 2 | 0.5 | 0.035 | 2.33 |

| 3 | 0.5 | 0.035 | 2.50 |

| 4 | 0.570711 | 0.035 | 5.81 |

| 5 | 0.5 | 0.035 | 1.98 |

| 6 | 0.5 | 0.035 | 2.07 |

| 7 | 0.45 | 0.04 | 0.62 |

| 8 | 0.429289 | 0.035 | 0.95 |

| 9 | 0.5 | 0.0420711 | 1.77 |

| 10 | 0.55 | 0.04 | 4.82 |

| 11 | 0.5 | 0.035 | 2.29 |

| 12 | 0.55 | 0.03 | 6.92 |

| 13 | 0.45 | 0.03 | 3.71 |

| Material Properties | Fresh Goji Berry | Silicone Rubber Material |

|---|---|---|

| Poisson’s ratio | 0.420 | 0.480 |

| Elastic modulus/Pa | 2.217 × 106 | 1.30 × 106 |

| Density/kg·m−3 | 689.550 | 1150 |

| Contact Parameters | Fresh Goji Berry– Fresh Goji Berry | Fresh Goji Berry– Silicone Rubber Material |

| Collision restitution coefficient | 0.158 | 0.195 |

| Static friction coefficient | 0.454 | 0.377 |

| Rolling friction coefficient | 0.037 | 0.063 |

| Error Source | Sum of Squares | Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 55.89 | 5 | 11.18 | 88.72 | <0.0001 ** |

| A-A | 25.50 | 1 | 25.50 | 202.41 | <0.0001 ** |

| B-B | 19.98 | 1 | 19.98 | 158.59 | <0.0001 ** |

| AB | 0.2450 | 1 | 0.2450 | 1.94 | 0.2058 |

| A2 | 2.54 | 1 | 2.54 | 20.16 | 0.0028 ** |

| B2 | 8.68 | 1 | 8.68 | 68.86 | <0.0001 ** |

| Residual | 0.8819 | 7 | 0.1260 | ||

| Lack of fit | 0.7074 | 3 | 0.2358 | 5.40 | 0.0684 |

| Pure error | 0.1745 | 4 | 0.0436 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Ren, S.; Li, J.; Chang, J.; Yu, S.; Sun, C.; Chen, T. Calibration and Testing of Discrete Element Modeling Parameters for Fresh Goji Berries. Appl. Sci. 2022, 12, 11629. https://doi.org/10.3390/app122211629

Yu Y, Ren S, Li J, Chang J, Yu S, Sun C, Chen T. Calibration and Testing of Discrete Element Modeling Parameters for Fresh Goji Berries. Applied Sciences. 2022; 12(22):11629. https://doi.org/10.3390/app122211629

Chicago/Turabian StyleYu, Yang, Simin Ren, Jie Li, Jiaqian Chang, Song Yu, Chao Sun, and Tingmin Chen. 2022. "Calibration and Testing of Discrete Element Modeling Parameters for Fresh Goji Berries" Applied Sciences 12, no. 22: 11629. https://doi.org/10.3390/app122211629

APA StyleYu, Y., Ren, S., Li, J., Chang, J., Yu, S., Sun, C., & Chen, T. (2022). Calibration and Testing of Discrete Element Modeling Parameters for Fresh Goji Berries. Applied Sciences, 12(22), 11629. https://doi.org/10.3390/app122211629